1. Introduction

The rising interest in natural fibers in the composites field is undeniable, mainly due to sustainability, but also because of their good mechanical properties and low cost. The differences observed among different natural fibers are due to their chemical composition, origin, climate conditions,

etc. On average, vegetable fibers are made of 60%–70% of cellulose, 10%–20% of hemicellulose, 5%–15% of lignin and up to 2% of pectin and waxes [

1].

Banana fiber is obtained from the superimposed leaves forming the pseudostem of the plant, which currently has no use, apart from a low percentage dedicated to cattle feed. It belongs to Musa genre, as a monocot. Banana is the most important crop in Canary Islands, which are the most important producers of bananas in Europe. It is important to highlight that fibers are obtained from the pseudostems of the plant once the fruit has been harvested, and that each plant only bears fruit once; this is one of the main benefits of banana fibers in comparison with other natural fibers, as this one is obtained from an agricultural residue.

The use of natural fibers as reinforcement of polymeric parts has been widely studied, specially focusing on injection molding technology. In fact, around 21,000 tons of natural fibers were used in 2003 in the European industry; the most relevant fibers for the industrial production of plastic composites are flax, sisal and hemp. Natural fibers are less harmful to humans, machinery and the environment, thus being realistic alternatives to glass fiber [

2].

Some studies have also been carried out for the compression molding technology, some with long fibers [

3,

4] and others with woven fibers [

5,

6,

7], both for thermoset and thermoplastic polymers. These studies show that specific mechanical properties of natural fibers composites are similar to those reinforced with glass fiber, although mechanical properties under humid conditions show an important decrease for the natural fiber composites, due to their moisture absorption. These studies mainly focus on the production of non-structural parts for the automotive sector [

7].

It is known that mechanical properties of composites strongly depend on the orientation of the fibers, getting better properties when the fiber is woven and placed in the composite in an appropriate orientation. The BANTEX project (MAT2013-47393-C2-1-R) is aimed at obtaining a composite material made of woven banana fibers. Woven fabrics have the advantage of enabling the orientation of the fibers, allowing control of the density of the fabric and its mechanical properties. Nonwovens provide multiaxial orientation but lower and non-predictable mechanical properties. There is wide bibliography about the production of composite materials with natural fibers (flax, hemp, jute) in woven and non-woven fabrics [

8,

9,

10,

11]; however, no references have been found in the use of banana fibers to produce them. Furthermore, the use of banana fibers to produce yarns for technical textile products has not been reported.

Banana fibers are made of cellulose (43.6%), hemicellulose (14%), lignin (11%) and other substances (such as pectin, wax, 31.4%) [

12]. Chemical methods for fiber extraction are usually performed with NaOH, although other chemicals are also used (KMnO

4, benzoyl chloride, stearic acid, among others); these processes may cause environmental problems due to the need for treating the residues produced. Mechanical means are not able to remove the non-cellulosic constituents (lignin). An alternative is the use of biological processes, such as the immersed [

13] or solid state [

14] fermentations. Enzymatic means are considered more environmentally friendly, and also avoid the fibers breakage, while altering the properties of the cellulosic fibers [

15]. There are different parameters which affect the enzyme choice, such as the type of substrate, composition, size, lignin content,

etc. [

15]. Previous studies show Pectinase [

16] and Xylanase [

17] as the most suitable ones for fiber extraction. Enzymatic treatments have been applied to hemp, flax or pineapple for fiber refining. Celullases are used to remove fibrils from the surface and increase the smoothness of the fiber, although this treatment can also damage the fibers and reduce their mechanical properties. Pectinases are used in the textile industry for retting and degumming fiber crops, as they are capable of breaking down complex molecules of plant tissues into simpler ones, such as galacturonic acid [

18]; on the other hand, endoglucanases only act on amorphous celluloses.

Hemicellulases are able to reduce water absorption by pentosan hydrolysis; xylanase and mannanase are used to dissolve hemicellulose (mainly xylan and glucomannan, respectively) [

19].

Tests have been performed using a cocktail of two different enzymes made of pectinase and hemicellulase. In this research, different formulations of the enzymatic treatment have been applied to the banana fibers in order to determine the optimal conditions (time, temperature, enzymes content, bath renewal, fiber/enzymes ratio, etc.) for the refining process, in order to obtain a banana textile grade fiber. Fibers have been characterized prior to and after the enzymatic treatment, in terms of length, diameter and thermal stability. The spinning process at the lab scale has taken place, resulting in the production of a yarn with enough quality to be woven and produce a technical textile suitable for composite reinforcement.

2. Results

2.1. Fiber Treatments

A design of experiments (DoE) was made for the enzymatic treatment of the fibers, taking into account the composition and characteristics of banana fibers. Two enzymatic formulations were applied to the fibers: Biopectinase M01 (made of pectinase and hemicellulase) and Biopectinase K (made of poligalacturonase). The chosen factors are treatment time and concentration of enzymes related to fiber weight (r.f.w.). Fiber to bath volume ratio was set to 1:40 for scalability purposes, while temperature and pH were fixed according to datasheets for the selected enzymes: pH = 4.5 and T = 45 °C. The design of experiments was done using Design Expert 9.0® (Stat-Ease, Inc., Minneapolis, MN, USA), varying the treatment time from 1 to 8 h and the enzyme concentration from 1% to 5% r.f.w.

The DoE was applied using each enzyme formulation with varying the treatment time and the concentration of enzymes (r.f.w.), at the same pH and temperature. As Biopectinase M01 is less active, the amount of enzymes used is 44% higher than for Biopectinase K.

The DoE is a Box–Hunter Central composite, with rotation factor of 1,41. The design is (

X,Y)–(time, concentration).

Scheme 1 shows the DoE, while

Table 1 lists all performed experiments.

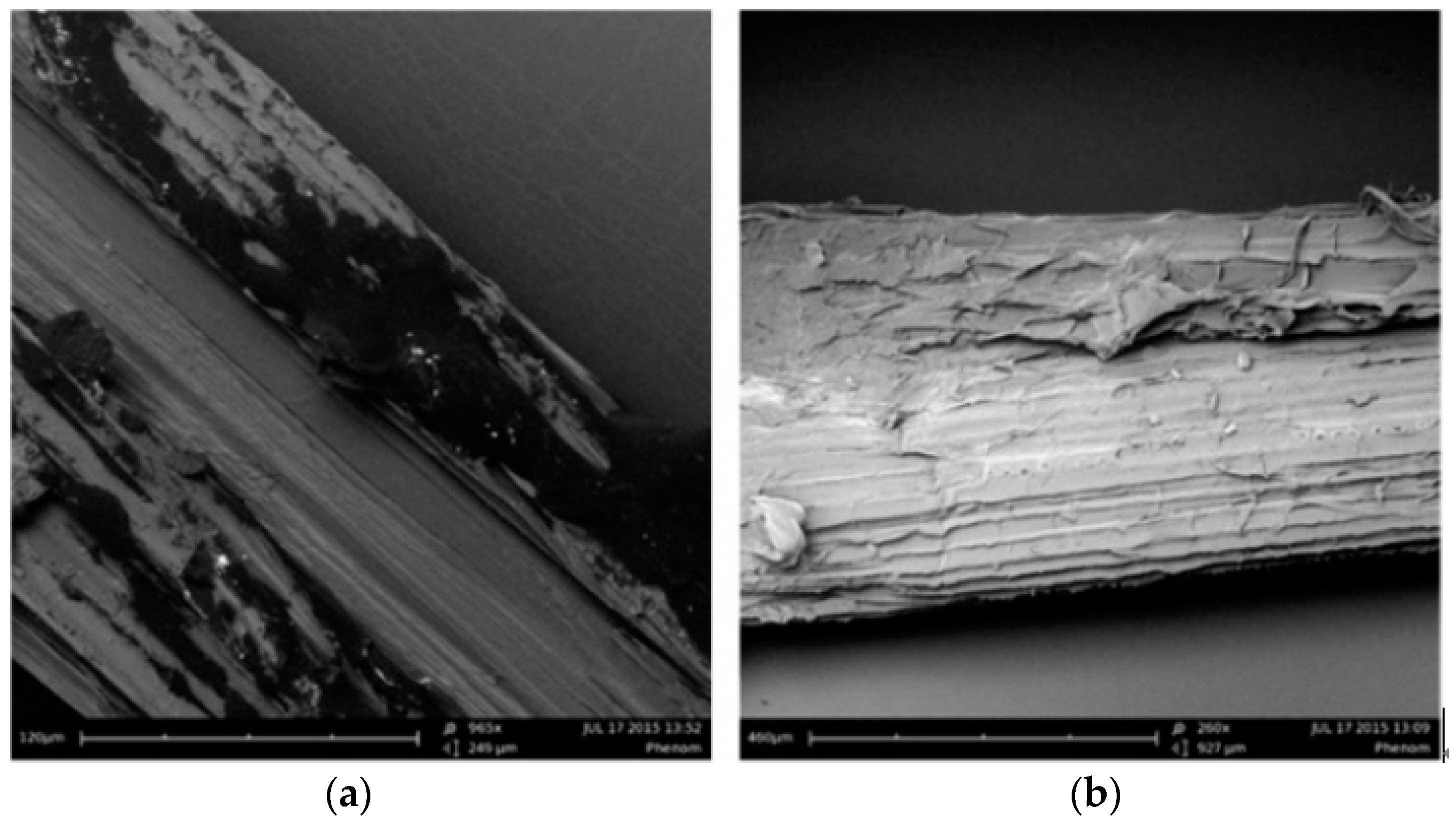

Microscopic observations were carried out to determine the extent of the removal of undesired compounds (hemicellulose, pectin) from the fibers and their surface structure. Biopectinase K tests showed better results, even though not enough cleanliness was achieved (

Figure 1).

The following step was the preparation of a new DoE, consisting of 6 experiments performed varying the time, enzyme (Biopectinase K) concentration, contact surface and fiber to bath ratio, in order to determine the limit conditions (summarized in

Table 2). Temperature was kept at 45 °C, pH at 4.5 and stirring at 200 rpm.

Stability of the Biopectinase K enzyme in the operating conditions was used to determine the maximum reaction time, determining the optimum point for the bath renewal. Enzymatic activity was determined through the concentration of galacturonic acid in the bath. The poligalacturonase activity was measured in samples of 5 cm long banana fiber treated for 24 h, with a Biopectinase K concentration of 50%, at the conditions indicated above. Enzyme activity was measured each 30 min, for the first 4 h, every hour for the following 4 h and finally at the end of the test (24 h).

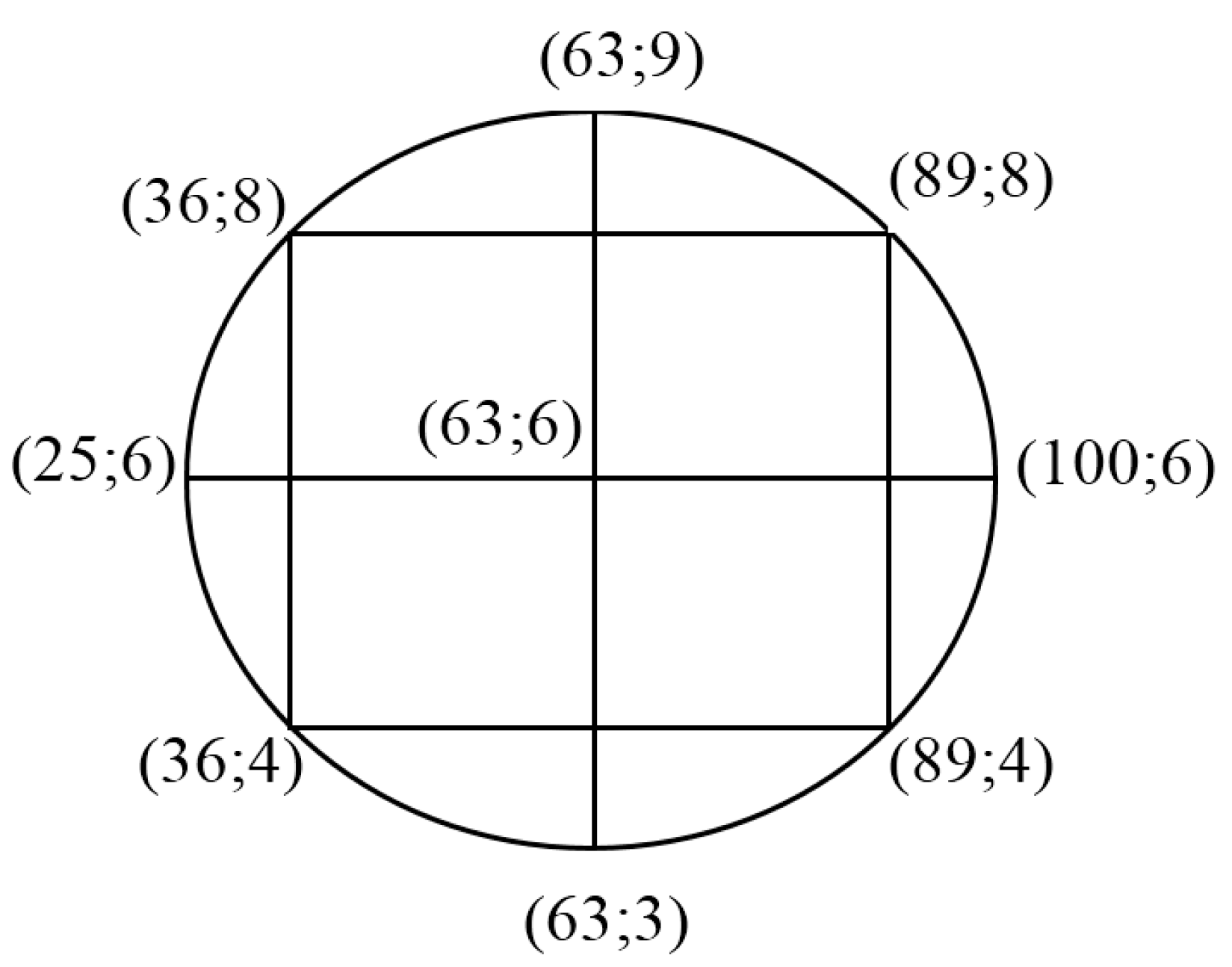

Taking into account results obtained from the activity test, a final DoE was performed, adapting the treatment time and enzyme concentration. Treatment was performed using Biopectinase K at 45 °C and pH 4.5, varying the treatment time from 3 to 9 h and the enzyme concentration, related to fiber weight, from 25% to 100%. From previous experiments, it was determined that an enzymatic bath should be renewed every 3 h.

The design is a Box–Hunter Central composite type with a rotation factor of 1.41. The design is (

X,Y)–(time, concentration).

Scheme 2 shows the DoE and

Table 3 lists all performed experiments.

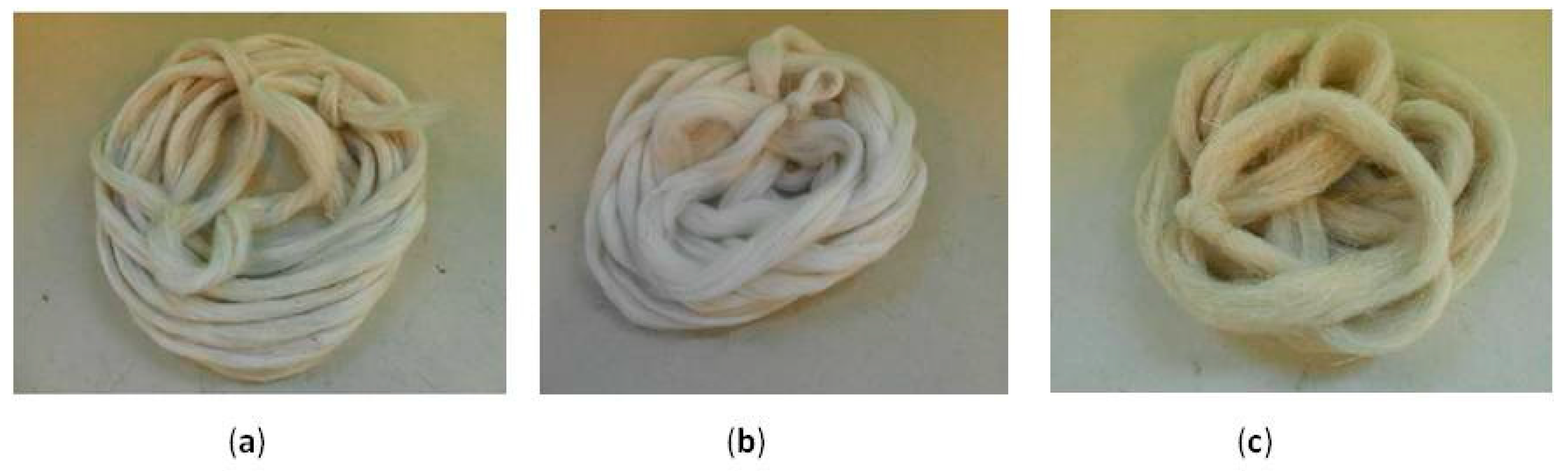

Results of mechanical testing for the above mentioned fiber together with microscopic observations have led to the reduction of experiments in two enzymatic treatments: Biopectinase K enzyme at 25%, and 100% concentration r.f.w. for 6 h, with bath renewal after 3 h of treatment. These treatments will be referred to as Treatment 1 and Treatment 2, respectively. Fibers after Treatment 2 were carried to a pilot scale yarn production plant for spinning tests.

2.2. Fiber Characterization

2.2.1. SEM Microscopy

Results of the first DoE (conditions shown in

Table 1) were analyzed by SEM microscopy, as fibers have not shown good enough macroscopic quality to carry out the characterization tests. Images obtained at the same magnification show that fiber depletion does not occur, thus indicating that performed treatments were not enough to reach the target quality for a textile fiber degree. However, it can also be concluded that treatment with Biopectinase K seems to provide better results than Biopectinase M01, as the fibers appear cleaner.

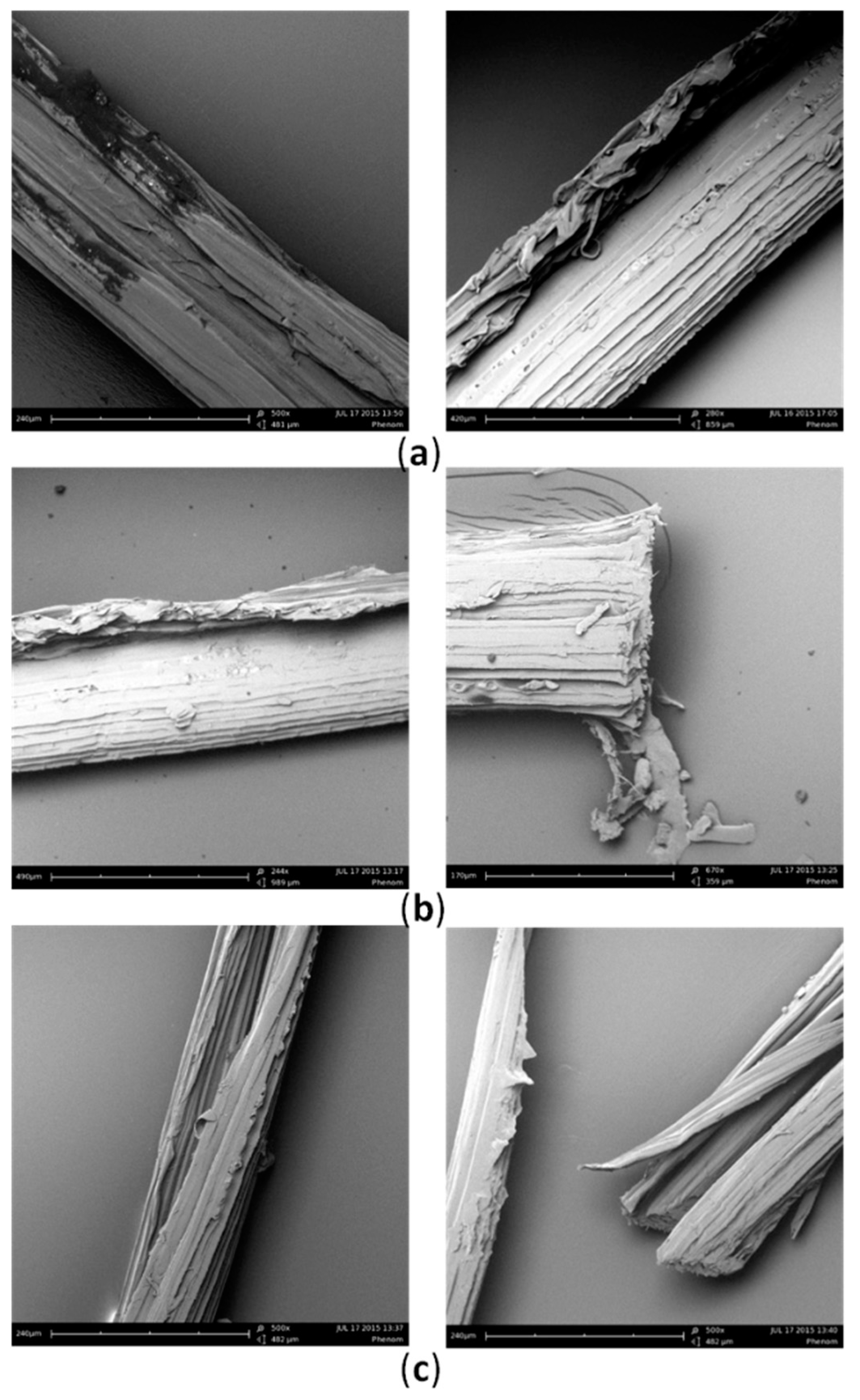

Observations carried out for selected treatments (25% and 100% r.f.w. for 6 h: Treatments 1 and 2) as well as for virgin fibers, show that treated fibers are cleaner than virgin ones. Furthermore, as observed in

Figure 2, fibers from Treatment 2 are the thinner ones, showing microfibrillation, due to the removal of hemicellulose and pectin, which act as bonding agents between the microfibrils that form a fiber; these bonding substances can be observed in untreated fiber images.

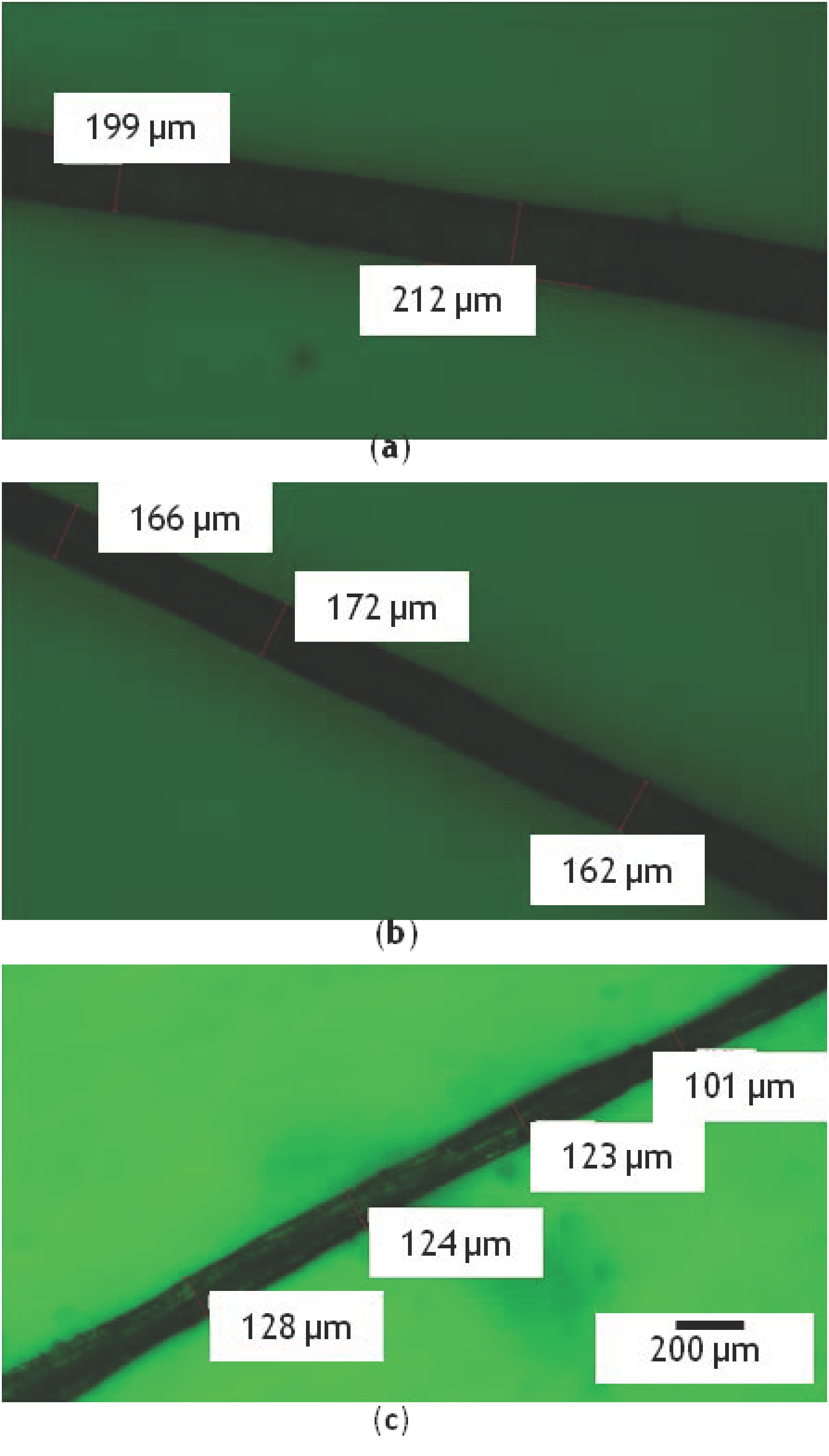

2.2.2. Optical Microscopy

Banana fibers were observed at different magnifications, under normal and polarized light. Ten individual fibers were measured. Virgin banana fiber had an average diameter of about 200 μm, while treated fibers show smaller average diameters: 160 µm for fiber after Treatment 1 and 114 µm for Treatment 2 fibers.

Figure 3 shows an image of each type of fiber at the same magnification, where the reduction of the fiber diameter can be clearly observed. Diameters of micro-fibrils measure approx. 23 µm for virgin fibers and 16 μm for treated ones.

2.2.3. Mechanical Properties of Banana Fiber

Up to 10 samples of fiber were tested. Results show a tensile strength of 42.8 ± 6.5 cN/tex for virgin banana fibers. As can be observed in

Table 4, the tensile strength of fibers with Treatment 1 is virtually unchanged, while a reduction of 14% is observed for fiber with Treatment 2.

Table 4 shows the results obtained for mechanical testing of fibers after the selected treatments; however, as explained in

Section 2.1, mechanical tests were also performed for fibers treated according to

Table 3. Results obtained for 6 h treated fibers are summarized in

Table 5.

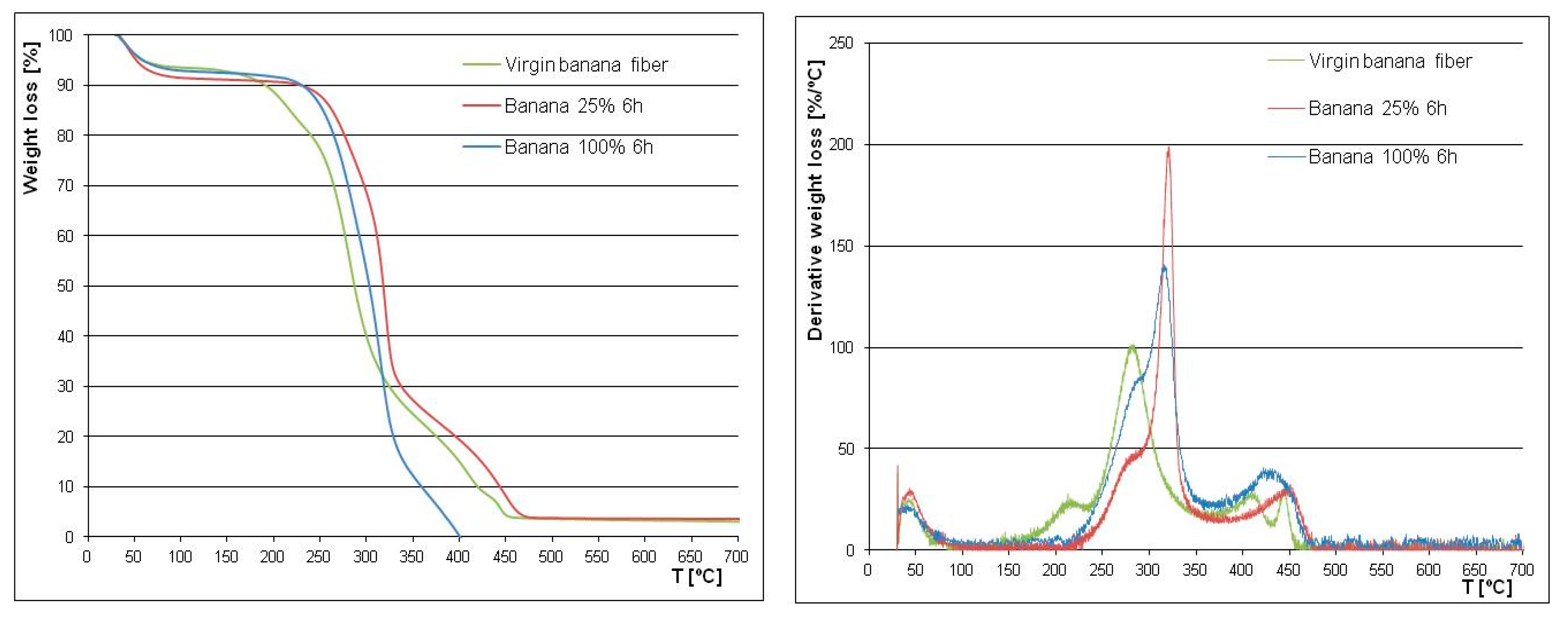

2.2.4. Thermal Stability

Table 6 shows the average values obtained in thermal tests using thermogravimetric analysis (TGA). It is clearly observed how the thermal stability of the fibers is increased significantly due to the enzymatic treatment. The left limit temperature refers to the temperature at which weight loss starts (apart from humidity removal). Onset temperature is obtained from the intersection between the protractions of the flat part of the curve before the left limit temperature and the most important weight loss section of the curve; as it is needed from graphical calculations, it may be an inexact parameter, but it has been calculated for comparison purposes with bibliography data. Peak temperature corresponds to the maximal degradation rate, and it is obtained from the weight loss derivative curve. Results can be more clearly observed in

Figure 4.

Isothermal tests (carried out at 220 °C) show higher weight loss for untreated fiber (39.7%); an important decrease in this parameter was observed for treated fibers: 25.2% and 15.2% for fibers after Treatments 1 and 2, respectively. This parameter confirms the higher thermal stability achieved from the enzymatic treatments due to the removal of less thermally stable substances (mainly hemicelluloses and pectin). This temperature was chosen as it is a usual temperature in thermoplastic parts processing.

2.3. Processability: Spinning Process

2.3.1. Opening

This stage was performed in a lab-scale Shirley opener for short fiber. As banana fiber shows high stiffness (around 360 cN/tex) compared to other fibers such as flax or hemp (150 cN/tex) or cotton (80 cN/tex), higher amounts of fiber are collected on the tray, even when varying the blades and working rates. However, the processed fiber is more open and its processing is improved in the combing flats. Some mechanical adjustments could be done to improve this first step yielding.

2.3.2. Revolving Flat Card

This part of the work was conducted on a Platt card with rigid cards, at high levels of humidity (17 g water per dry air kg). First, results showed broken fibers with low interfibrillar cohesion; fibers are adhered to the drum, the flats ant the comber noils, as shown in

Figure 5. Furthermore, an important amount of scrap is produced during the processing, which reflects the difficulty of spinning this fiber.

To try to improve the efficiency of the process, banana fibers were mixed with cotton at different ratios: 50/50 and 70/30 (banana/cotton). Cotton is acting in this yarn as a supporting fiber. Fibers, after passing through the Shirley opener, were blended together manually and then processed in the revolving flat card. It can still be observed that part of the fibers adhere to the drum and the cards although in a smaller proportion, getting a veil with better interfibrillar adhesion (

Figure 6) and less scraps produced.

As expected, when increasing the ratio of banana fiber up to 70%, the behavior in the carding process is more similar to this for 100% banana fiber, with more damaged fibers and increased adherence to the drum and the card flats (relating to the 50/50 blend). An optimization in the machinery could lead to an improvement in the carding stage for banana fibers, achieving better processability.

Further tests were conducted using polyester conventional fibers as support fiber, at a 50/50 ratio. Results were similar to those obtained with the cotton blend. Finally, wool was also used, in order to increase the amount of banana fiber in the mix, taking advantage of the natural curling in wool as a cohesion element; blends were made with 50% and 70% of banana fibers. The procedure was identical to the one followed for cotton. This blend can be processed in a conventional rubin device under industrial conditions, although at a lower production rate than conventional cotton.

Figure 7 shows the result of the carding process for 70% banana/30% wool blends.

Table 7 shows a summary of the conditions followed for the drawing frame process.

Figure 8 shows images of the drawing sliver obtained for different blends. They were spun after to obtain the rovings and then twisted to obtain the yarns and two ply yarns (

Figure 9).

As a result of the experiments performed, it is observed that banana fibers can be spun to get yarn, although the machinery should be adapted to the high stiffness of these fibers. Better results are obtained when blending banana fibers with other softer fibers; at this stage, the most suitable blend to be obtained at industrial scale would be this with wool.

2.4. Yarn Characterization

Table 8 shows average results obtained for banana and banana/PP yarn. This yarn was made with the blends made of 70% banana fibers and 30% wool. The yarn containing PP fiber was made twisting a banana yarn with PP yarn (330 dtex), at 90 laps/m, in an S sense. Tests on a conventional flax/PP yarn were also conducted for comparison. It is observed that banana/PP yarn has higher tenacity than flax/PP yarn and also that elongation at the break is higher for the banana yarn than for flax/PP yarn.