Fabrication of Bendable Circuits on a Polydimethylsiloxane (PDMS) Surface by Inkjet Printing Semi-Wrapped Structures

Abstract

:1. Introduction

2. Results and Discussion

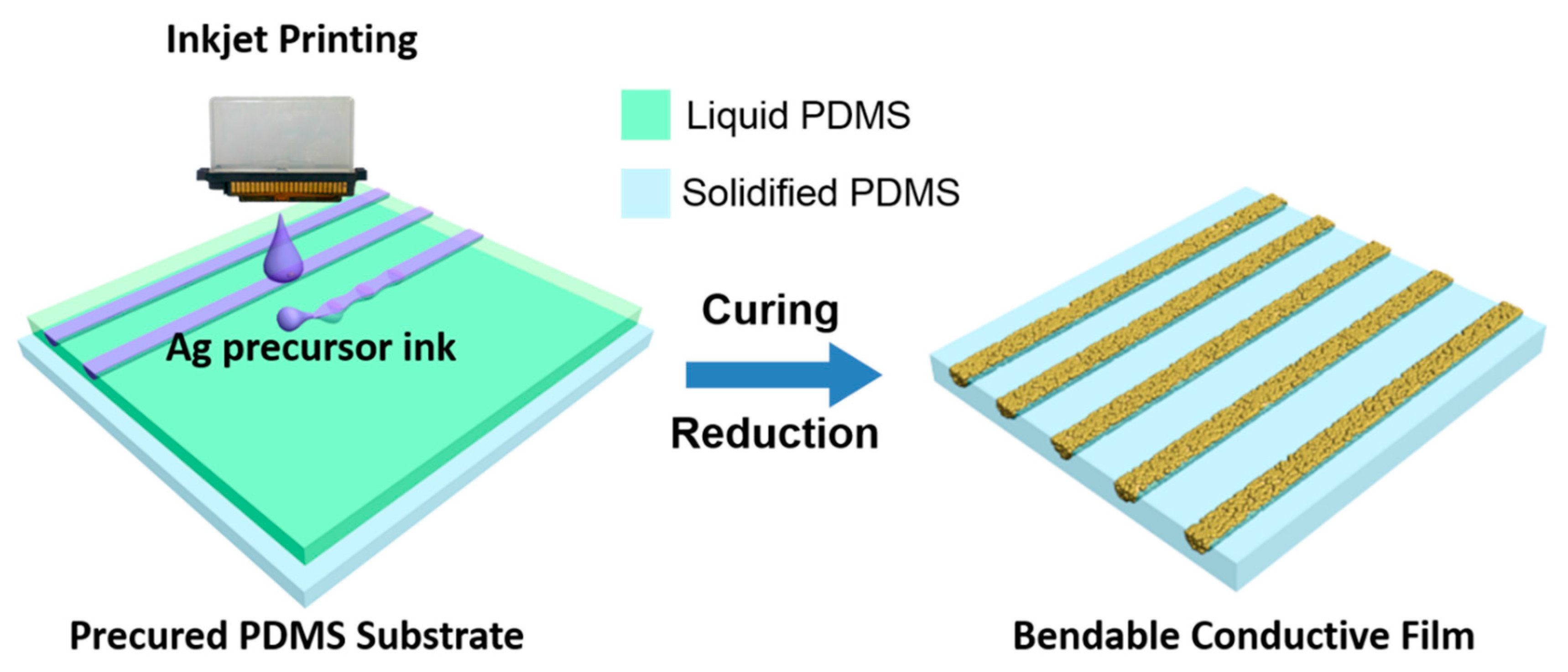

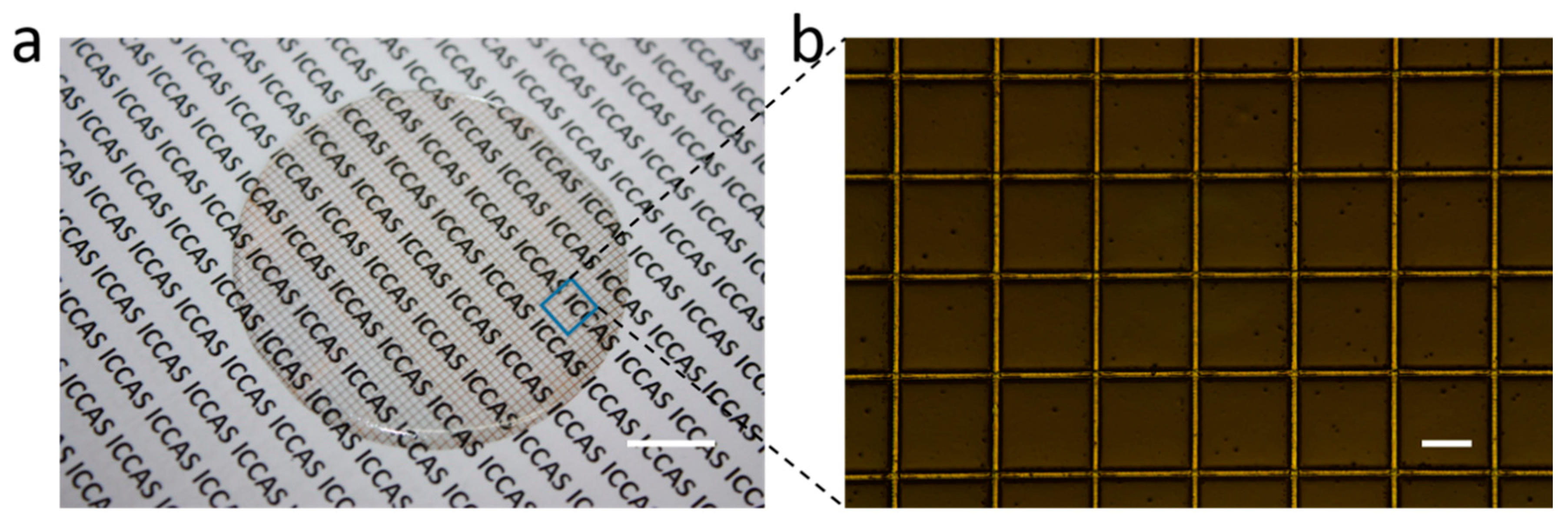

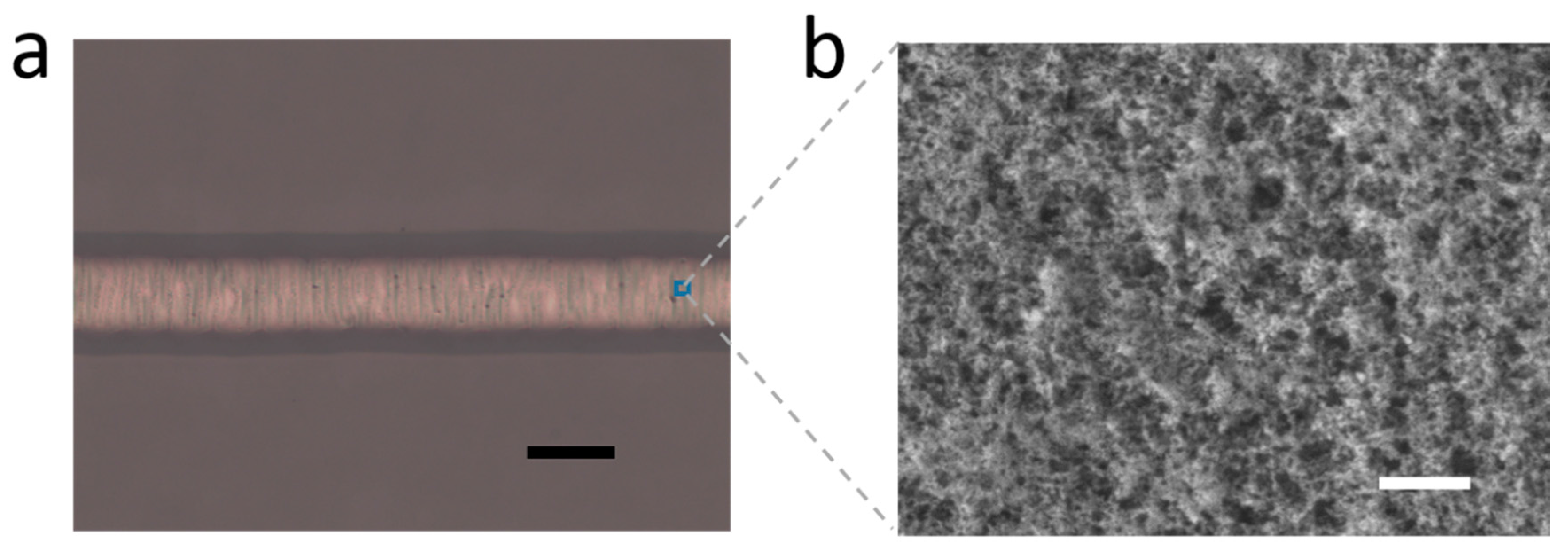

2.1. Fabrication and Characterization of the Inkjet Printed Circuit on PDMS Surface

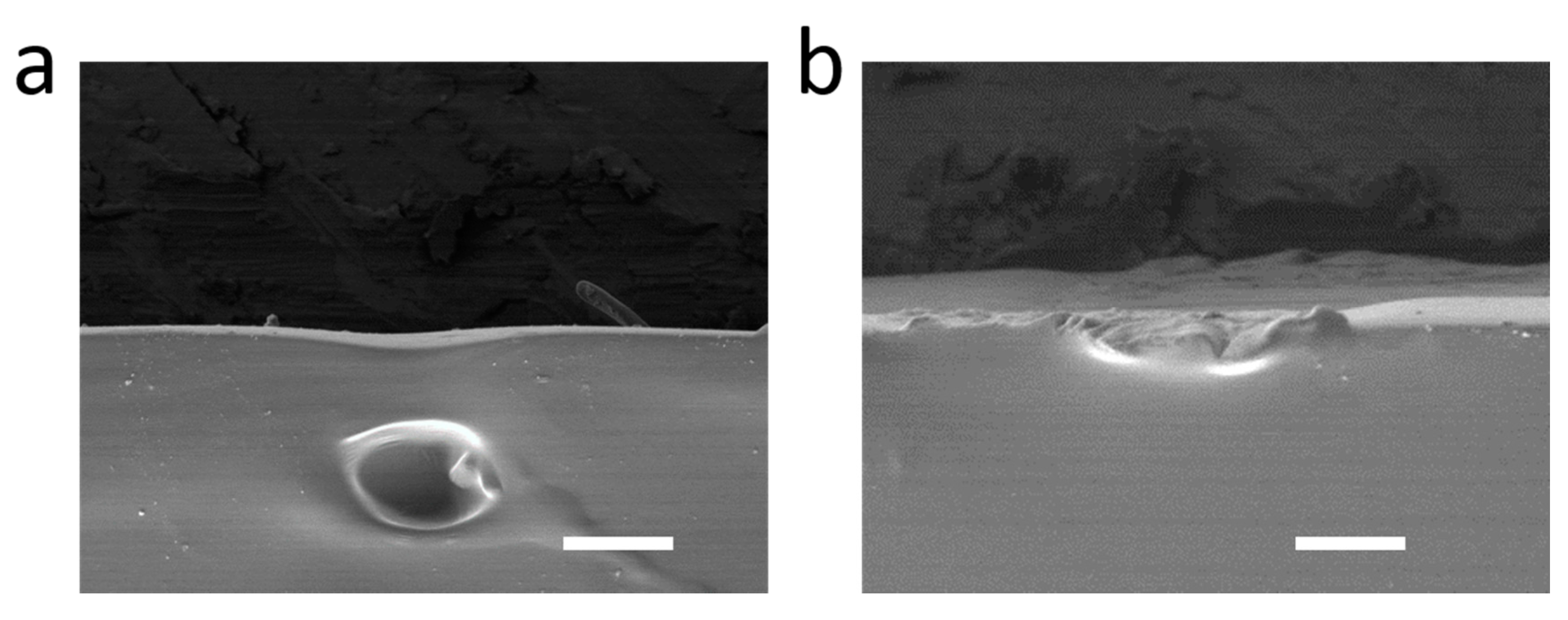

2.2. Depositing Morphologies of Coalesced Inkjet Droplets on the Precured PDMS Liquid Film

2.3. In Situ Hydrazine Reduction of Ag with Vapor Phase Method

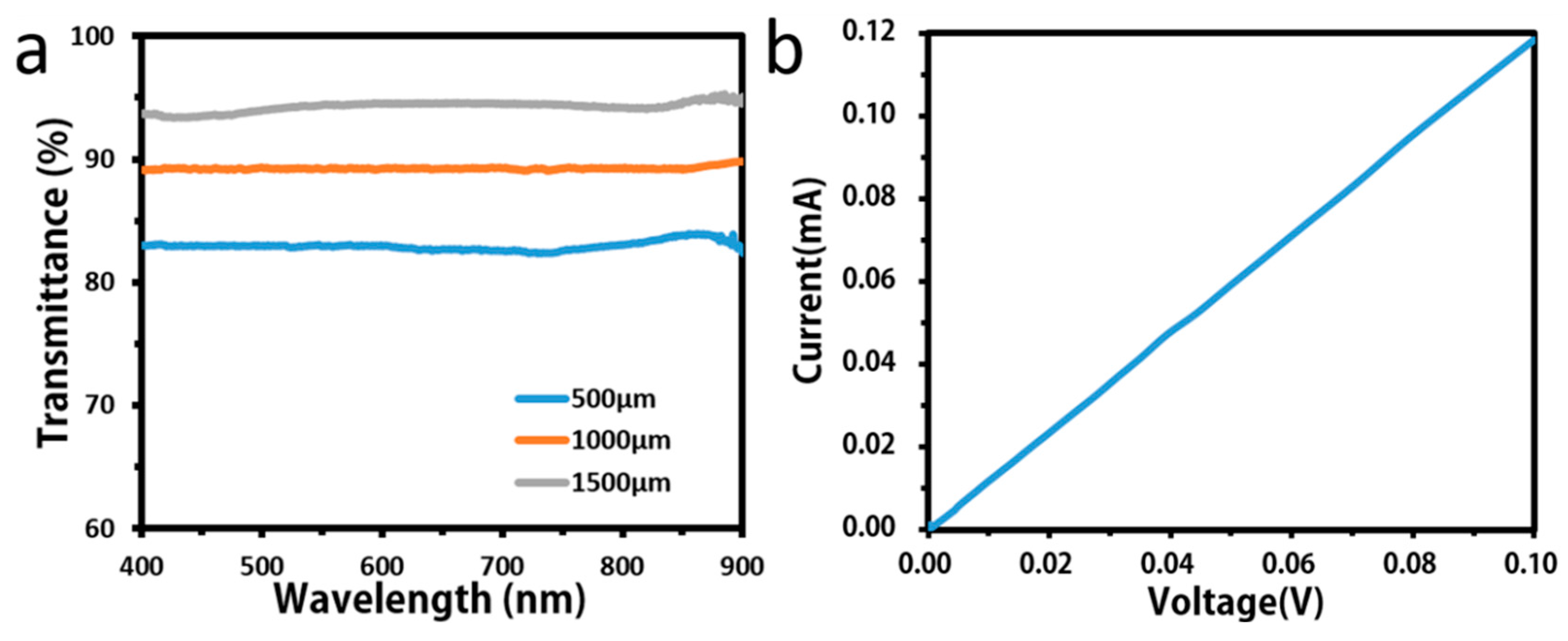

2.4. Measurement of Transparency and Conductivity

2.5. Conductive Test of the Bent Semi-Wrapped Circuit

3. Experimental Section

3.1. Preparation of Printing Ink

3.2. Preparation of the Precured PDMS Substrates

3.3. Inkjet Printing Silver Precursor Ink

3.4. Reducing the Printed Patterns

3.5. Electrical Measurement

3.6. Characterization

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Layani, M.; Kamyshny, A.; Magdassi, S. Transparent conductors composed of nanomaterials. Nanoscale 2014, 6, 5581–5591. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.W.; Mao, L.; Gao, Y.L.; Zhang, P.; Li, C.; Ma, C.Q.; Tu, Y.F.; Cui, Z.; Chen, L.W. ITO-free photovoltaic cell utilizing a high-resolution silver grid current collecting layer. Sol. Energy Mat. Sol. C 2013, 113, 85–89. [Google Scholar] [CrossRef]

- Kim, J.; Park, C.J.; Yi, G.; Choi, M.S.; Park, S.K. Low-temperature solution-processed gate dielectrics for high-performance organic thin film transistors. Materials 2015, 8, 6926–6934. [Google Scholar] [CrossRef]

- Hsu, P.; Wang, S.; Wu, H.; Narasimhan, V.K.; Kong, D.S.; Lee, H.R.; Cui, Y. Performance enhancement of metal nanowire transparent conducting electrodes by mesoscale metal wires. Nat. Commun. 2013, 4, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.Y.; Zhao, J.W.; Qian, L.; Han, X.Y.; Wu, L.Z.; Wu, W.C.; Song, M.S.; Zhou, L.; Su, W.M.; Wang, C.; et al. Sorting of large-diameter semiconducting carbon nanotube and printed flexible driving circuit for organic light emitting diode (OLED). Nanoscale 2014, 6, 1589–1595. [Google Scholar] [CrossRef] [PubMed]

- Bao, C.X.; Yang, J.; Gao, H.; Li, F.M.; Yao, Y.F.; Yang, B.; Fu, G.; Zhou, X.X.; Yu, T.; Qin, Y.Q.; et al. In situ fabrication of highly conductive metal nanowire networks with high transmittance from deep-ultraviolet to near-infrared. ACS Nano 2015, 9, 2502–2509. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.M.; You, I.; Cho, W.K.; Shon, H.K.; Lee, T.G.; Choi, I.S.; Karp, J.M.; Lee, H. One-step modification of superhydrophobic surfaces by a mussel-inspired polymer coating. Angew. Chem. Int. Ed. 2010, 49, 9401–9404. [Google Scholar] [CrossRef] [PubMed]

- Domachuk, P.; Tsioris, K.; Omenetto, F.G.; Kaplan, D.L. Bio-microfluidics: Biomaterials and biomimetic designs. Adv. Mater. 2010, 22, 249–260. [Google Scholar] [CrossRef] [PubMed]

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2007, 442, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Moon, J.H.; Kim, J.H.; Jeong, S.M.; Lee, S.H. Flexible, stretchable and implantable PDMS encapsulated cable for implantable medical device. Biomed. Eng. Lett. 2011, 1, 199–203. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, H.C.; Yang, Q.; Li, M.Z.; Song, Y.L.; Jiang, L. Bio-inspired photonic-crystal microchip for fluorescent ultratrace detection. Angew. Chem. Int. Ed. 2014, 53, 5791–5795. [Google Scholar] [CrossRef] [PubMed]

- Larmagnac, A.; Eggenberger, S.; Janossy, H.; Vosro, J. Stretchable electronics based on Ag-PDMS composites. Sci. Rep. 2014, 4, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Cheng, T.; Zhang, Y.; Lai, W.Y.; Huang, W. Stretchable thin-film electrodes for flexible electronics with high deformability and stretchability. Adv. Mater. 2015, 27, 3349–3376. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Zhang, C.; Han, C.B.; Fan, F.R.; Tang, W.; Wang, Z.L. Woven structured triboelectric nanogenerator for wearable devices. ACS Appl. Mater. Interfaces 2014, 6, 14695–14701. [Google Scholar] [CrossRef] [PubMed]

- Yi, P.; Awang, R.A.; Rowe, W.S.T.; Kalantar-zadeh, K.; Khoshmanesh, K. PDMS nanocomposites for heat transfer enhancement in microfluidic platforms. Lab Chip 2014, 14, 3419–3426. [Google Scholar] [CrossRef] [PubMed]

- Hammock, M.L.; Chortos, A.; Tee, B.C.; Tok, J.B.; Bao, Z.N. The Evolution of Electronic Skin (E-Skin): A brief history, design considerations, and recent progress. Adv. Mater. 2013, 25, 5997–6038. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.T.; Zhang, L.; Duan, S.S.; Jing, S.L.; Jiang, H.; Li, C.Z. Highly stretchable conductors integrated with a conductive carbon nanotube/graphene network and 3D porous poly(dimethylsiloxane). Adv. Funct. Mater. 2014, 24, 7548–7556. [Google Scholar] [CrossRef]

- Cong, H.L.; Pan, T.R. Photopatternable conductive PDMS materials for microfabrication. Adv. Funct. Mater. 2008, 18, 1912–1921. [Google Scholar] [CrossRef]

- Liu, C.X.; Choi, J.W. Patterning conductive PDMS nanocomposite in an elastomer using microcontact printing. J. Micromech. Microeng. 2009, 19, 1–8. [Google Scholar] [CrossRef]

- Niu, X.Z.; Peng, S.L.; Liu, L.Y.; Wen, W.J.; Sheng, P. Characterizing and patterning of PDMS-based conducting composites. Adv. Mater. 2007, 19, 2682–2686. [Google Scholar] [CrossRef]

- Li, H.; Luo, C.X.; Ji, H.; Ouyang, Q.; Chen, Y. Micro-pressure sensor made of conductive PDMS for microfluidic applications. Microelectron. Eng. 2010, 87, 1266–1269. [Google Scholar] [CrossRef]

- Ito, T.; Okazaki, S. Pushing the limits of lithography. Nature 2000, 406, 1027–1031. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.Q.; Kong, X.Y.; Gao, L.J.; Tian, Y.; Wen, L.P.; Jiang, L. Fabrication of nanochannels. Materials 2015, 8, 6277–6308. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. High-speed roll-to-roll nanoimprint lithography on flexible plastic substrates. Adv. Mater. 2008, 20, 2044–2049. [Google Scholar] [CrossRef]

- Guo, L.J. Nanoimprint lithography: Methods and material requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef]

- Yan, X.; Yao, J.M.; Lu, G.A.; Chen, X.; Zhang, K.; Yang, B. Microcontact printing of colloidal crystals. J. Am. Chem. Soc. 2004, 126, 10510–10511. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.K.; Chang, C.J. Fabrications and applications of stimulus-responsive polymer films and patterns on surfaces: A review. Materials 2014, 7, 805–875. [Google Scholar] [CrossRef]

- Tian, D.L.; Song, Y.L.; Jiang, L. Patterning of controllable surface wettability for printing techniques. Chem. Soc. Rev. 2013, 42, 5184–5209. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet printing-process and its applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef] [PubMed]

- Shimoni, A.; Azoubel, S.; Magdassi, S. Inkjet printing of flexible high-performance carbon nanotube transparent conductive films by “coffee ring effect”. Nanoscale 2014, 6, 11084–11089. [Google Scholar] [CrossRef] [PubMed]

- Abulikemu, M.; Da’as, E.H.; Haverinen, H.; Cha, D.; Malik, M.A.; Jabbour, G.E. In situ synthesis of self-assembled gold nanoparticles on glass or silicon substrates through reactive inkjet printing. Angew. Chem. Int. Ed. 2014, 53, 420–423. [Google Scholar] [CrossRef] [PubMed]

- Li, L.H.; Guo, Y.Z.; Zhang, X.Y.; Song, Y.L. Inkjet-printed highly conductive transparent patterns with water based Ag-doped graphene. J. Mater. Chem. A 2014, 2, 19095–19101. [Google Scholar] [CrossRef]

- Chen, S.P.; Chiu, H.L.; Wang, P.H.; Liao, Y.C. Inkjet printed conductive tracks for printed electronics. ECS J. Solid State Sci. Technol. 2015, 4, 3026–3033. [Google Scholar] [CrossRef]

- Sun, J.Z.; Kuang, M.X.; Song, Y.L. Control and application of “coffee ring” effect in inkjet printing. Prog. Chem. 2015, 27, 929–985. [Google Scholar]

- Sun, J.Z.; Bao, B.; He, M.; Zhou, H.H.; Song, Y.L. Recent advances in controlling the depositing morphologies of inkjet droplets. ACS Appl. Mater. Interfaces 2015, 7, 28086–28099. [Google Scholar] [CrossRef] [PubMed]

- Wong, T.S.; Kang, S.H.; Tang, S.K.Y.; Smythe, E.J.; Hatton, B.D.; Grinthal, A.; Aizenberg, J. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 2011, 477, 443–447. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Hu, Y.H.; Grinthal, A.; Wong, T.S.; Mahadevan, L.; Aizenberg, J. Adaptive fluid-infused porous films with tunable transparency and wettability. Nat. Mater. 2013, 12, 529–534. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.B.; Li, F.Y.; Kuang, M.X.; Gao, M.; Wang, J.X.; Huang, Y.; Jiang, L.; Song, Y.L. Interface manipulation for printing three-dimensional microstructures under magnetic guiding. Small 2015, 11, 1900–1904. [Google Scholar] [CrossRef] [PubMed]

- Kuang, M.X.; Wang, L.B.; Song, Y.L. Controllable printing droplets for high-resolution patterns. Adv. Mater. 2014, 26, 6950–6958. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Zhang, Q.L.; Zeng, X.P.; Cui, D.P.; Chen, J.; Li, H.L.; Wang, J.J.; Song, Y.L. Hierarchical porous surface for efficiently controlling microdroplets’ self-removal. Adv. Mater. 2013, 25, 2291–2295. [Google Scholar] [CrossRef] [PubMed]

- Van Osch, T.H.J.; Perelaer, J.; de Laat, A.W.M.; Schubert, U.S. Inkjet printing of narrow conductive tracks on untreated polymeric substrates. Adv. Mater. 2008, 20, 343–345. [Google Scholar] [CrossRef]

- Liu, M.J.; Wang, J.X.; He, M.; Wang, L.B.; Li, F.Y.; Jiang, L.; Song, Y.L. Inkjet printing controllable footprint lines by regulating the dynamic wettability of coalescing ink droplets. ACS Appl. Mater. Interfaces 2014, 6, 13344–13348. [Google Scholar] [CrossRef] [PubMed]

- Chiolerio, A.; Rivolo, P.; Porro, S.; Stassi, S.; Ricciardi, S.; Mandracci, P.; Canavese, G.; Bejtka, K.; Pirri, C.F. Inkjet-printed PEDOT: PSS electrodes on plasma-modified PDMS nanocomposites: Quantifying plasma treatment hardness. RSC Adv. 2014, 4, 51477–51485. [Google Scholar] [CrossRef]

- Wu, J.W.; Wang, R.D.; Yu, H.X.; Li, G.J.; Xu, K.X.; Tien, N.C.; Roberts, R.C.; Li, D.C. Inkjet-printed microelectrodes on PDMS as biosensors for functionalized microfluidic systems. Lab Chip 2015, 15, 690–695. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, A.; Bahadur, V.; Shang, W.; Zhu, Y.; Buckley, D.; Dhinojwala, A.; Sohal, M. Influence of substrate elasticity on droplet impact dynamics. Langmuir 2013, 29, 4520–4524. [Google Scholar] [CrossRef] [PubMed]

- Park, S.J.; Weon, B.M.; Lee, J.S.; Lee, J.; Kim, J.; Je, J.H. Visualization of asymmetric wetting ridges on soft solids with X-ray microscopy. Nat. Commun. 2014, 5, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Bao, B.; Jiang, J.K.; Li, F.Y.; Zhang, P.C.; Chen, S.R.; Yang, Q.; Wang, S.T.; Su, B.; Jiang, L.; Song, Y.L. Fabrication of patterned concave microstructures by inkjet imprinting. Adv. Funct. Mater. 2015, 25, 3286–3294. [Google Scholar] [CrossRef]

- Guo, Y.Z.; Li, L.H.; Li, F.Y.; Zhou, H.H.; Song, Y.L. Inkjet print microchannels based on a liquid template. Lab Chip 2015, 15, 1759–1764. [Google Scholar] [CrossRef] [PubMed]

- Cira1, N.J.; Benusiglio, A.; Prakash, M. Vapour-mediated sensing and motility in two-component droplets. Nature 2015, 519, 446–450. [Google Scholar] [CrossRef] [PubMed]

- Kuang, M.X.; Wang, J.X.; Bao, B.; Li, F.Y.; Wang, L.B.; Jiang, L.; Song, Y.L. Inkjet printing patterned photonic crystal domes for wide viewing-angle displays by controlling the sliding three phase contact Line. Adv. Opt. Mater. 2014, 2, 34–38. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Zhang, X.Y.; Xin, Z.Q.; Deng, M.M.; Wen, Y.Q.; Song, Y.L. Synthesis of monodisperse silver nanoparticles for ink-jet printed flexible electronics. Nanotechnology 2011, 22, 425601–425608. [Google Scholar] [CrossRef] [PubMed]

- Gamerith, S.; Klug, A.; Scheiber, H.; Scherf, U.; Moderegger, E.; List, E.J.W. Direct ink-jet printing of Ag-Cu nanoparticle and Ag-precursor based electrodes for OFET applications. Adv. Funct. Mater. 2007, 17, 3111–3118. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive nanomaterials for printed electronics. Small 2014, 15, 3515–3535. [Google Scholar] [CrossRef]

- Hong, S.; Yeo, J.; Kim, G.; Kim, D.; Lee, H.; Kwon, J.; Lee, H.; Lee, P.; Ko, S.H. Nonvacuum, maskless fabrication of a flexible metal grid transparent conductor by low-temperature selective laser sintering of nanoparticle ink. ACS Nano 2013, 7, 5024–5031. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.K.; Bao, B.; Li, M.Z.; Sun, J.Z.; Zhang, C.; Li, Y.; Li, F.Y.; Yao, X.; Song, Y.L. Fabrication of transparent multilayer circuits by inkjet printing. Adv. Mater. 2016, 28, 1420–1426. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Jiang, J.; Bao, B.; Wang, S.; He, M.; Zhang, X.; Song, Y. Fabrication of Bendable Circuits on a Polydimethylsiloxane (PDMS) Surface by Inkjet Printing Semi-Wrapped Structures. Materials 2016, 9, 253. https://doi.org/10.3390/ma9040253

Sun J, Jiang J, Bao B, Wang S, He M, Zhang X, Song Y. Fabrication of Bendable Circuits on a Polydimethylsiloxane (PDMS) Surface by Inkjet Printing Semi-Wrapped Structures. Materials. 2016; 9(4):253. https://doi.org/10.3390/ma9040253

Chicago/Turabian StyleSun, Jiazhen, Jieke Jiang, Bin Bao, Si Wang, Min He, Xingye Zhang, and Yanlin Song. 2016. "Fabrication of Bendable Circuits on a Polydimethylsiloxane (PDMS) Surface by Inkjet Printing Semi-Wrapped Structures" Materials 9, no. 4: 253. https://doi.org/10.3390/ma9040253