1. Introduction

Concrete and cementitious materials are vulnerable to tension developing in individual components and structures. Reinforcing materials such as steel fibers [

1,

2,

3,

4,

5,

6] are commonly used in concrete structures to control cracks [

7,

8,

9,

10,

11,

12]. The application of steel fiber reinforced shotcrete (SFRS) in tunneling construction has been part of tunneling practice since the 1970s, especially in Europe and the United States [

13,

14,

15,

16]. SFRS is characterized by ductile behavior, namely better post-cracking strength and energy absorption, where the latter is referred to as the “toughness” of a material. More specifically, toughness is the amount of energy that is absorbed before and after fracture [

16].

Polyamide fiber reinforced shotcrete (PAFRS) was developed to improve mechanical properties and workability. The detailed manufacturing process has been described in other documents [

17,

18]. A comparison of 0.47 m diameter and 30 mm long polyamide (PA) fiber to 1.0 mm × 0.5 mm rectangular and 42 mm long polypropylene (PP) fiber [

19] shows that 650 MPa tensile strength of PA fiber is higher than 550 MPa of PP fiber, though PA fiber (3 GPa) has less elastic modulus than PP fiber (8.2 GPa). Note also that a higher density of PA fiber (1.14 g/cm

3) compared to PP fiber (0.9–0.92 g/cm

3) is advantageous because higher density of PA fiber prevents the fiber from floating in the cement matrix.

Compared to steel fibers, PA fiber has lower weight density, which prevents the fiber from sinking down in the cement matrix and improves the durability without corrosion. Steel fibers may sometimes induce a mixing problem that prevents a uniform distribution of fibers in concrete [

20]. The improved mechanical and mixing properties and adhesion characteristics of PA fiber lead to improved workability and less rebounding during spouting of shotcrete.

The objective of this study is to establish PAFRS mechanical properties in terms of compressive and flexural strengths, in accordance with ASTM C1609/C1609M-12 [

21]. The mechanical properties reveal the influence of PA fiber content on the PAFRS strength. This study evaluated the toughness of PAFRS using the Morgan level [

14] and proposed additional toughness level criteria to better represent organic fiber performance. In addition, based on PAFRS application in Korea, the rebounding rate and performance in a tunneling application were evaluated. PA fibers in tunneling shotcrete significantly improved flexural ductility, toughness, and ultimate load capacity.

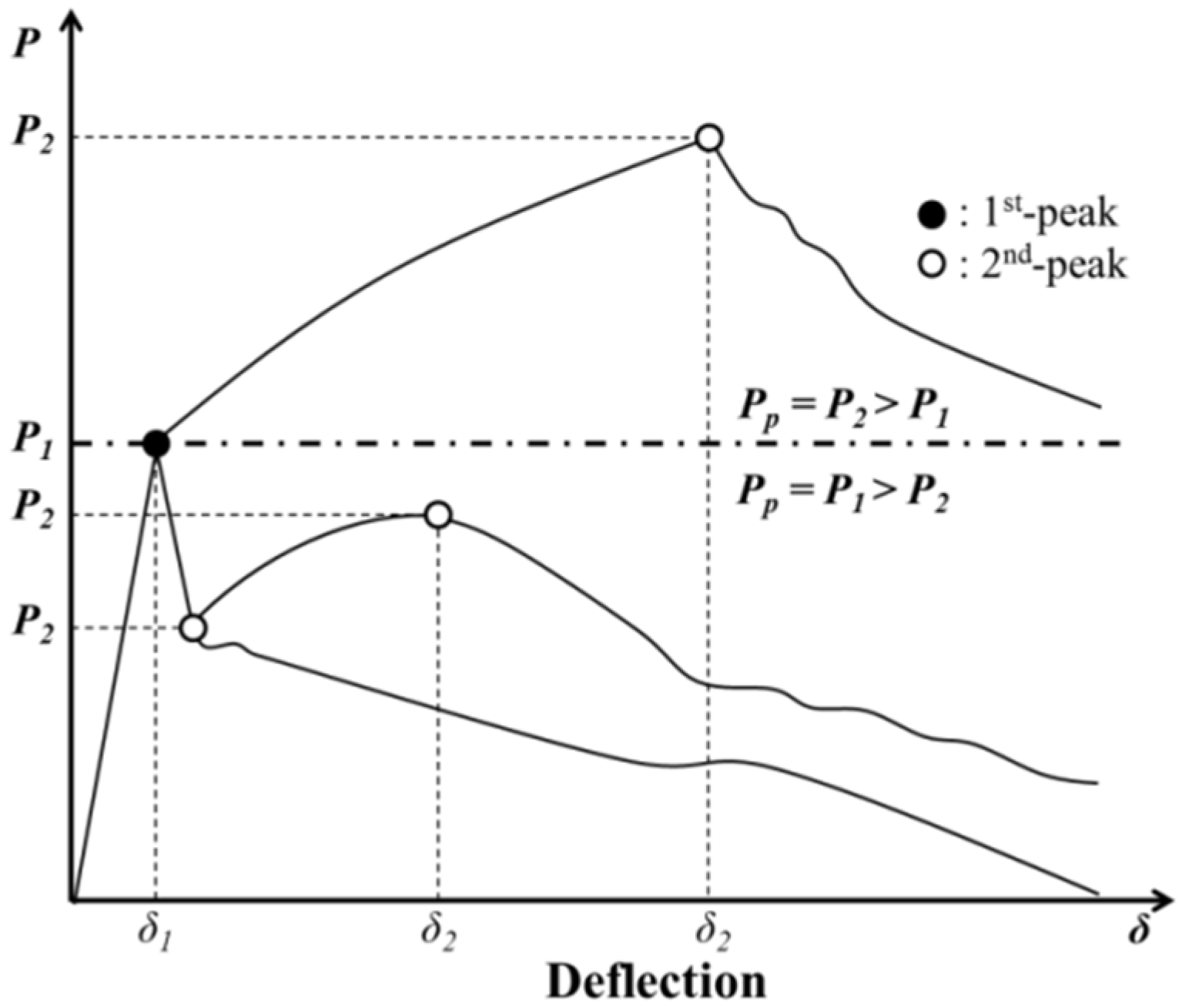

2. Characterization of PAFRS Flexural Strength

Flexural strength of PAFRSs can be tested in accordance with ASTM C1609/C1609M-12 [

21]. As in

Figure 1, this study identified two peak loads: (1) the first-peak load (

) on the load-deflection curve, which was caused by crack initiation of the specimen; and (2) the second-peak load (

) on the load-deflection curve when the PA fibers reached the ultimate strength. Corresponding strengths and deflections are denoted as

and

for

and

and

for

, respectively. Residual loads (

and

) and strength (

and

) at a net deflection of

L/600 and

L/150 (

L = clear span) were measured for a beam with a depth of

d (=100 mm in

Figure 2a). Toughness (

) and equivalent flexural strength ratio (

) at a net deflection of

L/150 (=300 mm in

Figure 2a) were also identified. Flexural strength of

and

, equivalent bending strength of

and equivalent flexural strength ratio of

were computed as follows:

where

=

ith peak load at

;

L = clear span length (=300 mm);

b and

d = beam cross-section width and depth at the fracture surface, respectively;

= area under the load-deflection curves up to

(N·mm); and

= deflection of

L/150 (=2.0 mm).

Based on the deflection (

) at the first-peak load, three additional points were investigated at 3

, 5.5

, and 10.5

as per ASTM C1018-97 [

22]. The current ASTM standard [

21] specifies

,

(deflection at the peak load regardless of the first-peak or second-peak), L/600 and L/150. However, PAFRS occasionally exhibits a larger second peak than the first peak depending on the PA fiber volume content. Thus, this study clearly stipulated pre-(1st peak) and post(2nd peak)-cracking strengths. Also, PAFRS displays yielding after cracking before the PA fiber reaches its ultimate strength, similar to hyper-elastic materials. Thus, additional points at 3

, 5.5

, and 10.5

were used in this study.

3. PA Fiber Volume Content Influence on PAFRS Mechanical Properties

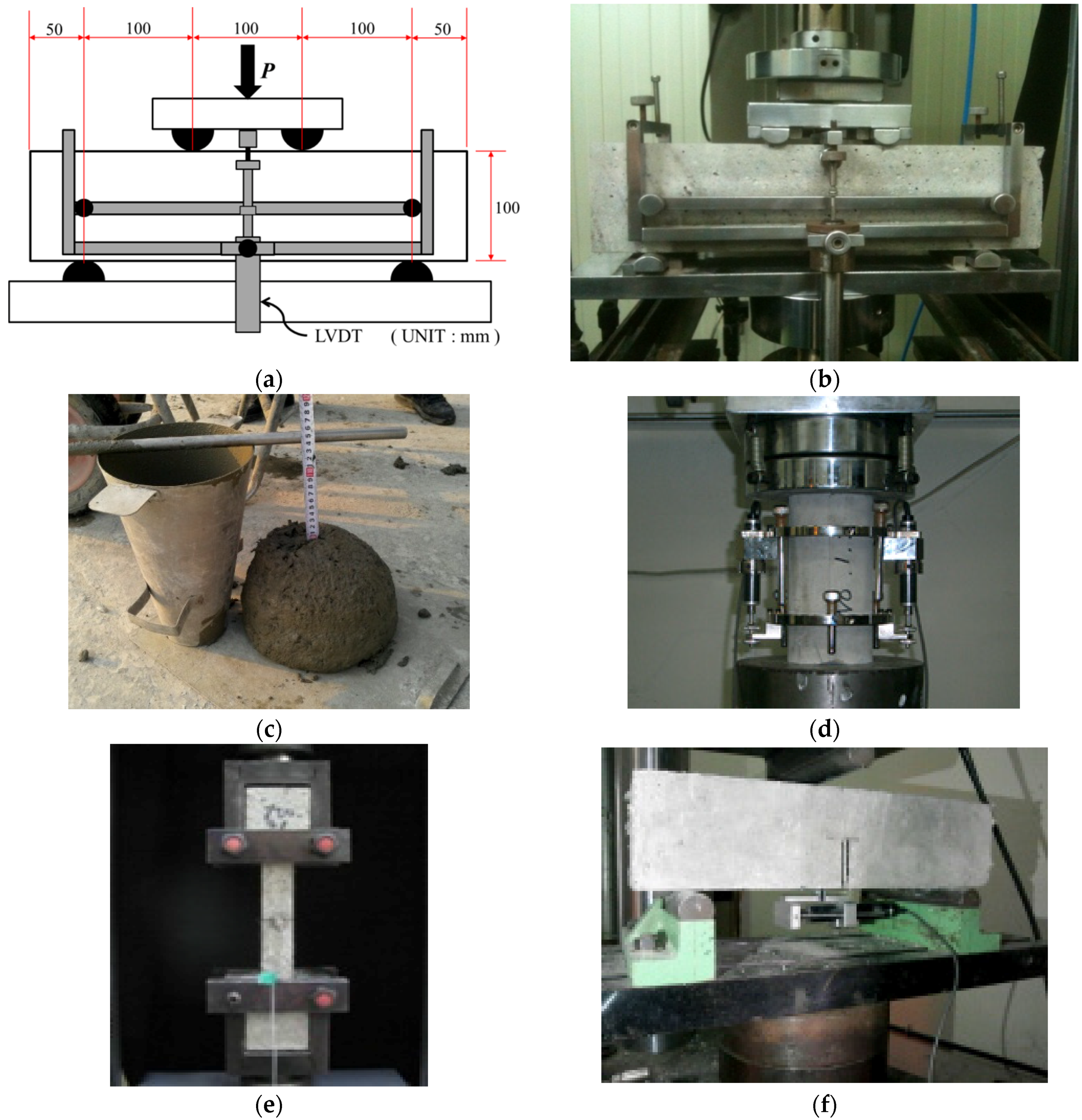

The PAFRS specimens were prepared with varying PA fiber content ratios from 0.0% to 1.5%. Detailed shotcrete mix design of water to cement ratio (W/C), sand to aggregate ratio (S/a), water (W), cement (C), fly ash (FA), sand (S), gravel (G), and water-reducing admixture (AD) is presented in

Table 1. The PAFRS was tested for slump, bending strength, direct tensile strength, and fracture energy, as shown in

Figure 2. A bending test was performed in accordance with ASTM C1609/C1609M-12 [

21]. A rectangular beam was saw-cut to dimensions of 100 mm × 100 mm × 400 mm. To carry out compressive tests, a

100 mm × 200 mm cylindrical specimen was used. A direct tensile test was conducted used a dog-bone shaped specimen. For a fracture energy test, a rectangular specimen of 100 mm × 100 mm × 400 mm, which is the same as to the specimen employed in the bending strength test, was used and the test procedure followed RILEM TCS [

23]. The obtained test results with respect to varying PA fiber contents are tabulated in

Table 2.

3.1. Compressive Strength and Elastic Modulus

As presented in

Figure 3, compressive strength tests were performed for PAFRS specimens with varying PA fiber content from 0.0% to 1.5%. It was clearly observed that the slope or elastic modulus of PAFRS decreased as the PA fiber content increased. Obtained maximum compressive strengths with respect to PA fiber content from 0.0% to 1.5% are shown in

Table 2. However, the maximum compressive strengths of PA-0.5 and PA-0.75 (42.86 and 43.69 MPa) were less than that of Plain (44.94 MPa), but those of PA-1.00, PA-1.25 and PA-1.50 (47.44, 49.82 and 50.35 MPa) were larger than that of Plain. This phenomenon is commonly encountered in fiber-reinforced concrete.

The elastic moduli of the PAFRS specimens slightly decreased compared to those of the plain specimen. The elastic modulus of the plain shotcrete mix was larger than those of PAFRSs. The elastic moduli of PAFRSs were not proportional to the PA fiber content. The order of magnitude of the PAFRS elastic modulus was 0.5% > 1.0% > 0.75% >1.5% > 1.25% in terms of PA fiber content.

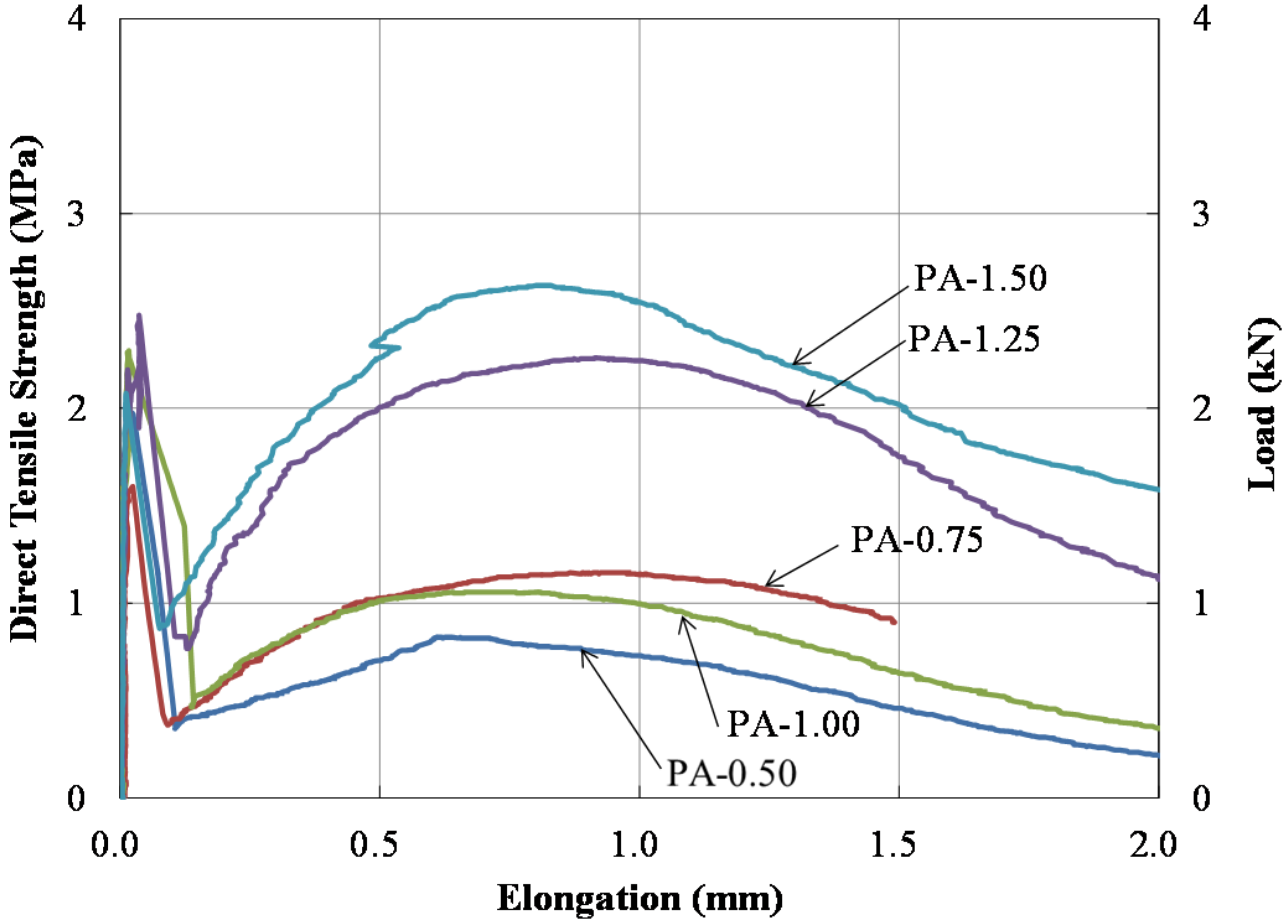

3.2. Direct Tensile Strength Test

Direct tensile strength test results are presented in

Figure 4. It was observed that the shotcrete toughness was significantly improved by inclusion of PA fibers. The tensile strength tended to linearly increase as the PA fiber content increased, except for the PA-0.75 specimen. The maximum tensile strength is shown in

Table 2. In

Figure 4, the 1st peak tensile strengths were 2.00, 1.60, 2.48, 2.30, and 2.08 MPa for PA-0.5, 0.75, 1.25, 1.0, and 1.5. The 2nd peak tensile strengths were 0.82, 1.16, 2.26, 0.73, and 2.63 MPa for PA-0.5, 0.75, 1.25, 1.0, and 1.5. All specimens exhibited larger first peak tensile strengths than the second peak strengths except for the PA-1.5 specimen. The PA-1.5 specimen exhibited a larger second peak tensile strength than the first peak tensile strength. It was expected that the PA fiber content generally increased the second peak strength.

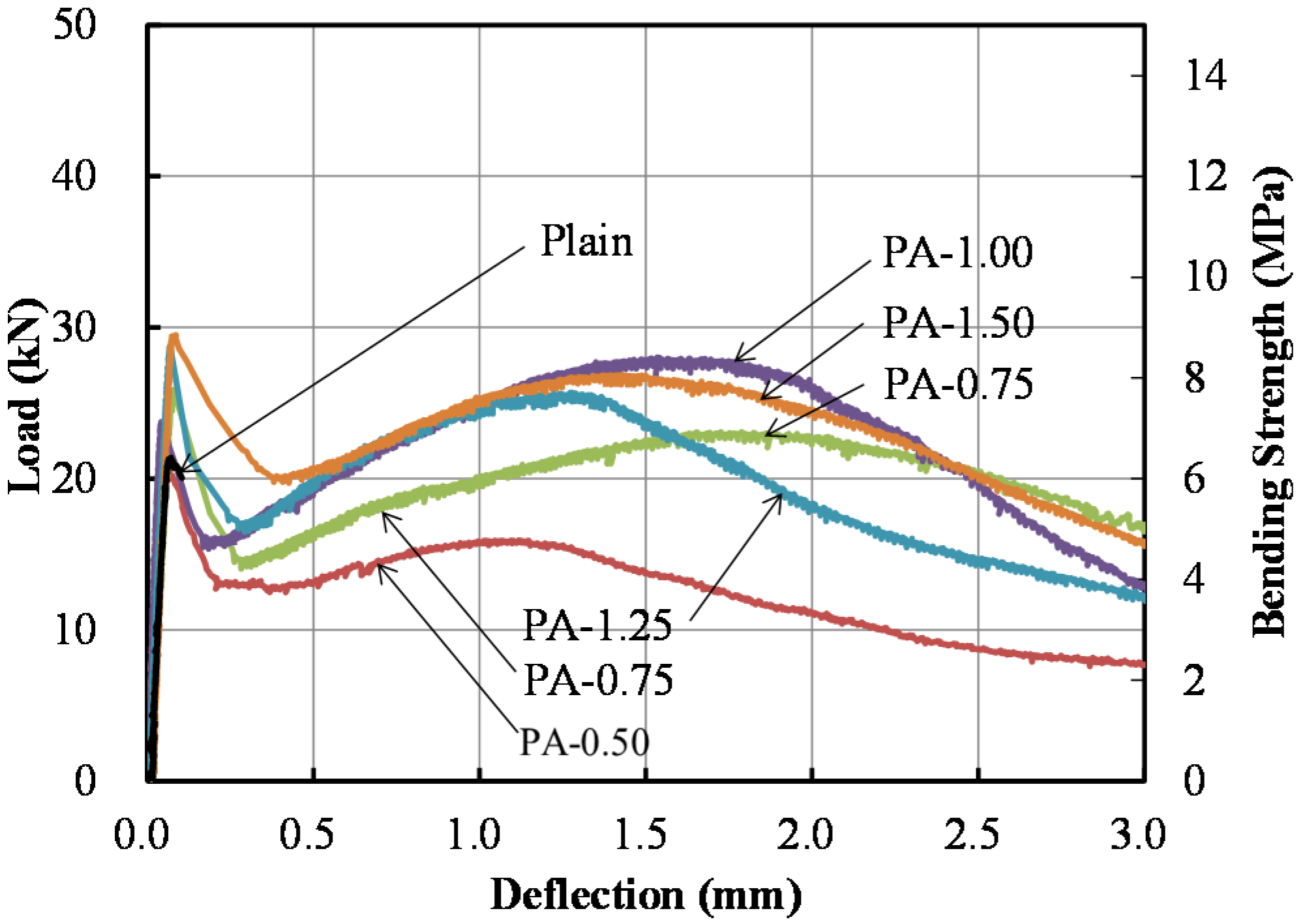

3.3. Flexural Bending Test Results

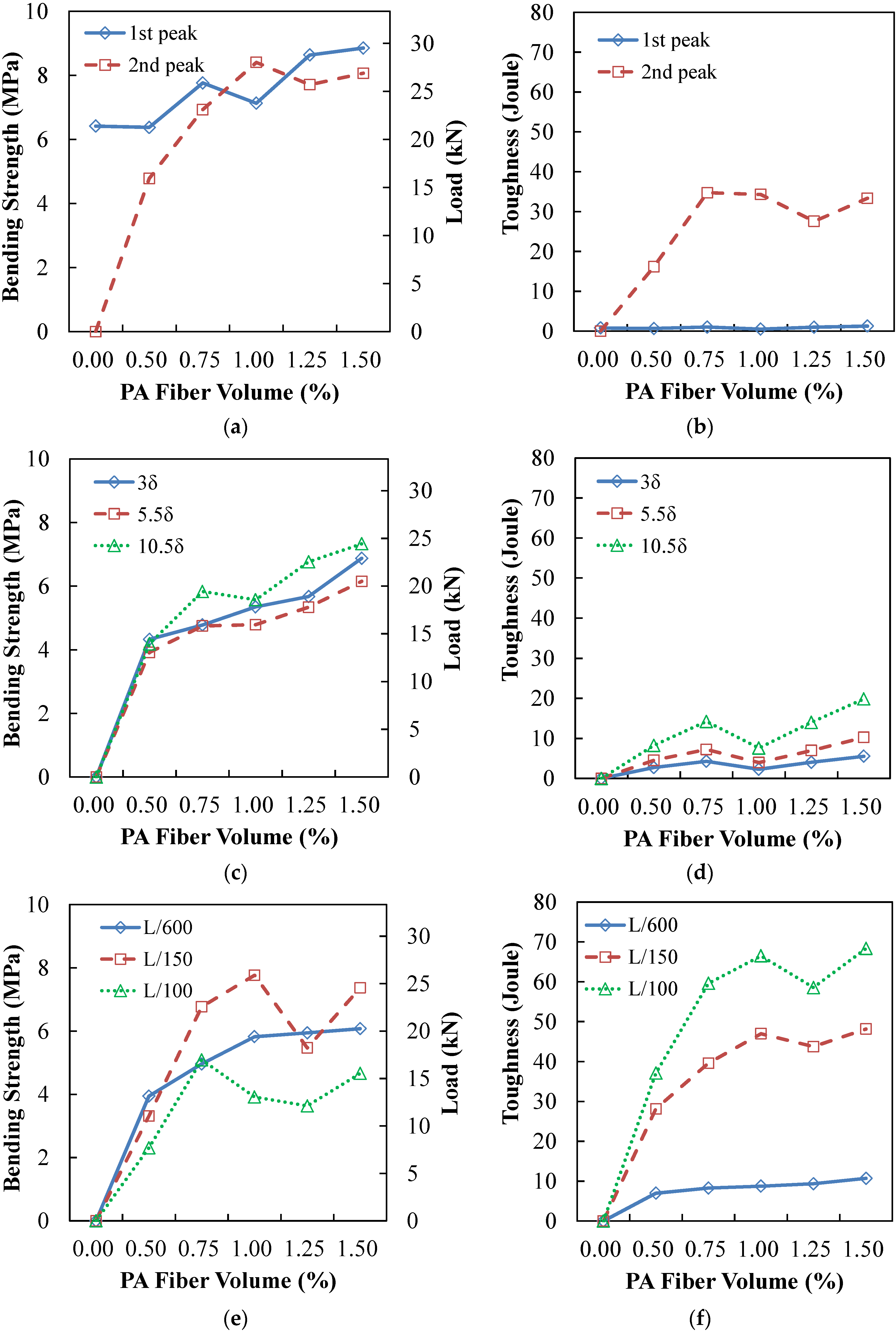

Flexural bending test results are presented in

Figure 5. Similar to the direct tensile test results, the flexural bending strengths were significantly improved by PA fibers. As aforementioned, the PAFRS exhibited two distinct peaks: (1) the first peak was induced by the initiation of the crack; and (2) the second peak was reached as the fiber reached its ultimate strength.

Detailed flexural responses at various points are presented in

Figure 6 and

Table 3. As shown in

Figure 6, it was clearly observed that the bending strength and toughness increased as the PA fiber content increased. Also, the second peak tended to increase as the PA fiber content increased.

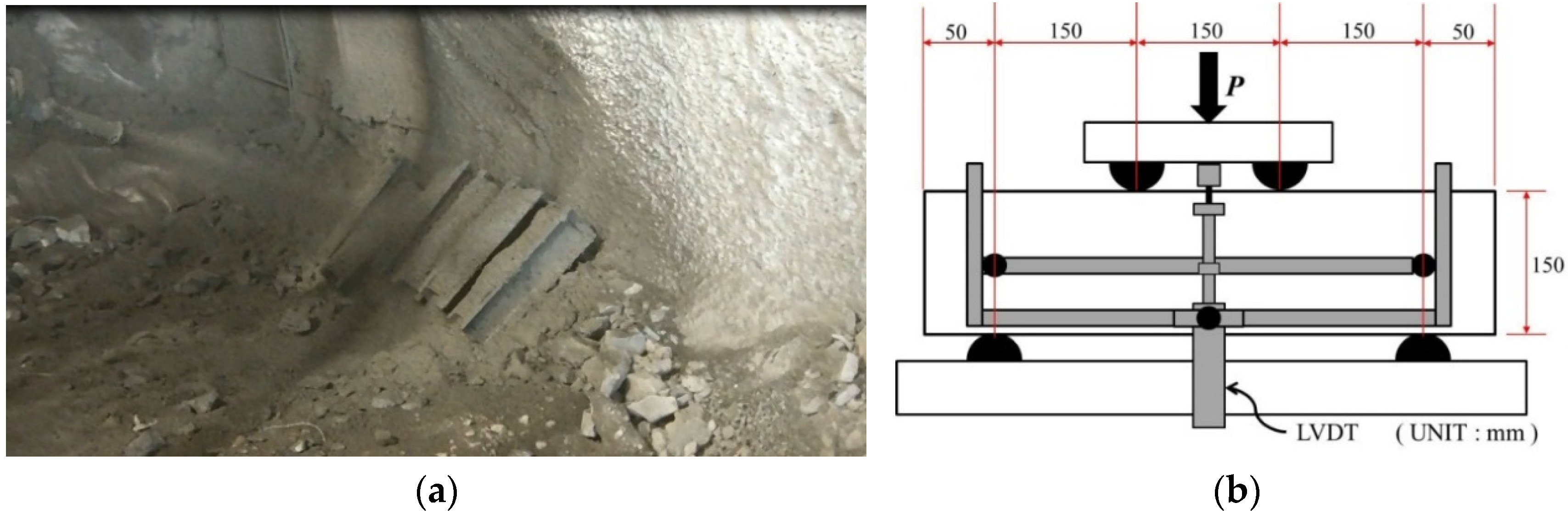

4. Field and Laboratory Fabricated PAFRS

For tunnel application of PAFRS, field and laboratory specimens were fabricated according to the approach discussed earlier, and the flexural performance was evaluated in accordance with ASTM C1609/C1609M-12 [

21] and the Morgan level [

14]. First, appropriate PA fiber content was determined based on the bending strength in Equation (1) and equivalent bending strength in Equation (2), since compressive strengths of PAFRS in

Figure 3 were far higher than the minimum limit in

Table 4. There are four applicable Korean tunnel design guidelines for fiber-reinforced shotcrete, listed in

Table 4. All four design guidelines specify the minimum compressive strength, bending strength, and equivalent bending strength. For this study, 0.6%~0.8% of PA fiber content was determined to be the optimal content based on

Table 3, and both laboratory and field specimens were then prepared. Shotcrete mix design such as the maximum gravel size (G

max), ratio of water to cement (W/C) and sand to aggregate (S/a), unit weight of water (W), cement (C), crushed sand (CS), gravel (G), polyamide fiber (PA). and water-reducing admixture (AD) is presented in

Table 5. The test specimens were fabricated from tunnel lining shotcrete during construction as in

Figure 7a and dimensions of specimens and the test setup were slightly modified to meet the Korean standard and are presented in

Figure 7b. For each shotcrete mix design, three specimens were prepared and tested.

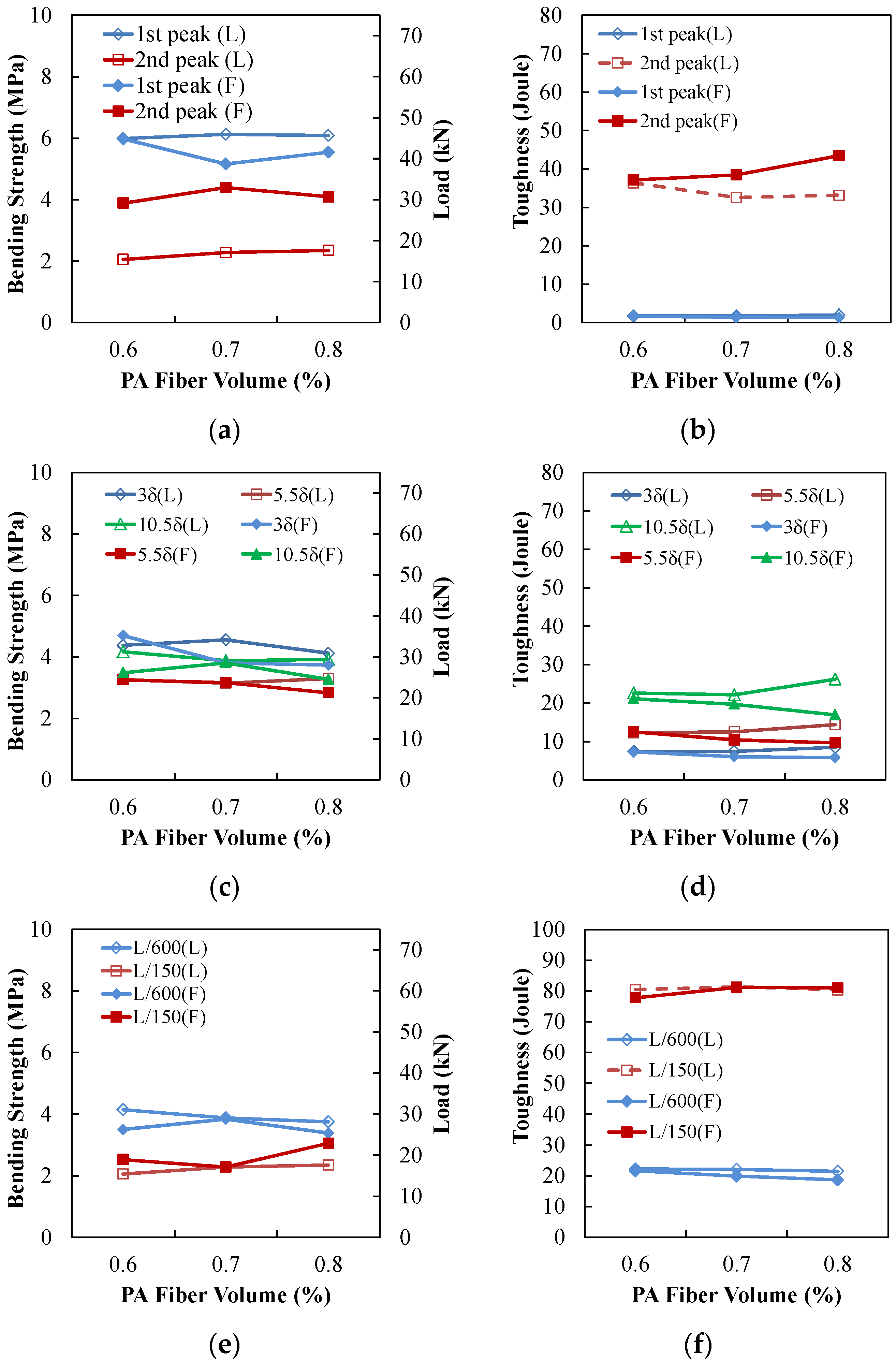

Bending and equivalent bending strength test results from the laboratory and field are presented in

Table 6. All PAFRS specimens fabricated in both laboratory and field exhibited higher bending and equivalent bending strengths (see

Table 7) than the minimum limits in

Table 4. Load-deflection relationship of all specimens was also investigated, as in

Figure 8. The load-deflection curves of PAFRS specimens were similar to each other due to the small variation of PA fiber content. Detailed PAFRS bending strength and toughness with respect to varying fiber content are presented in

Figure 9. The average flexural responses at δ

1, 3δ

1, 5.5δ

1,

L/600, 10.5δ

1, and L/150 are summarized in

Table 7. As shown in the results, the quality and performance of field specimens were similar to those of laboratory specimens.

Based on the load-deflection curves in

Figure 8, Morgan levels [

14] for each specimens were determined to identify the toughness performance level, as presented in

Table 8. The Morgan level evaluates the strength of steel fiber reinforced shotcrete at

L/600 and

L/150. However, PAFRSs exhibit different load-deflection history compared to SFRCs, although the Morgan level was originally suggested for SFRCs. After the first peak in

Figure 8, the load-deflection curve drops until the PA fiber takes the load, then starts to increase up to the second peak or ultimate fiber capacity.

Figure 9a shows that the second peaks of all specimens were larger than or equal to the first peak. As shown in

Figure 8, some of the load-deflection curves of PAFRS specimens at

L/600 after the first peak dropped below the Morgan level IV. However, the load-deflection curves increase again, beyond level IV. Thus, this study evaluated the specimen capacity in terms of toughness. The toughness of each specimen was compared to the toughness specified by Morgan load-deflection curves. The toughness Morgan levels [

14] of all specimens were Level IV while the strength Morgan levels of all specimens were Level III.

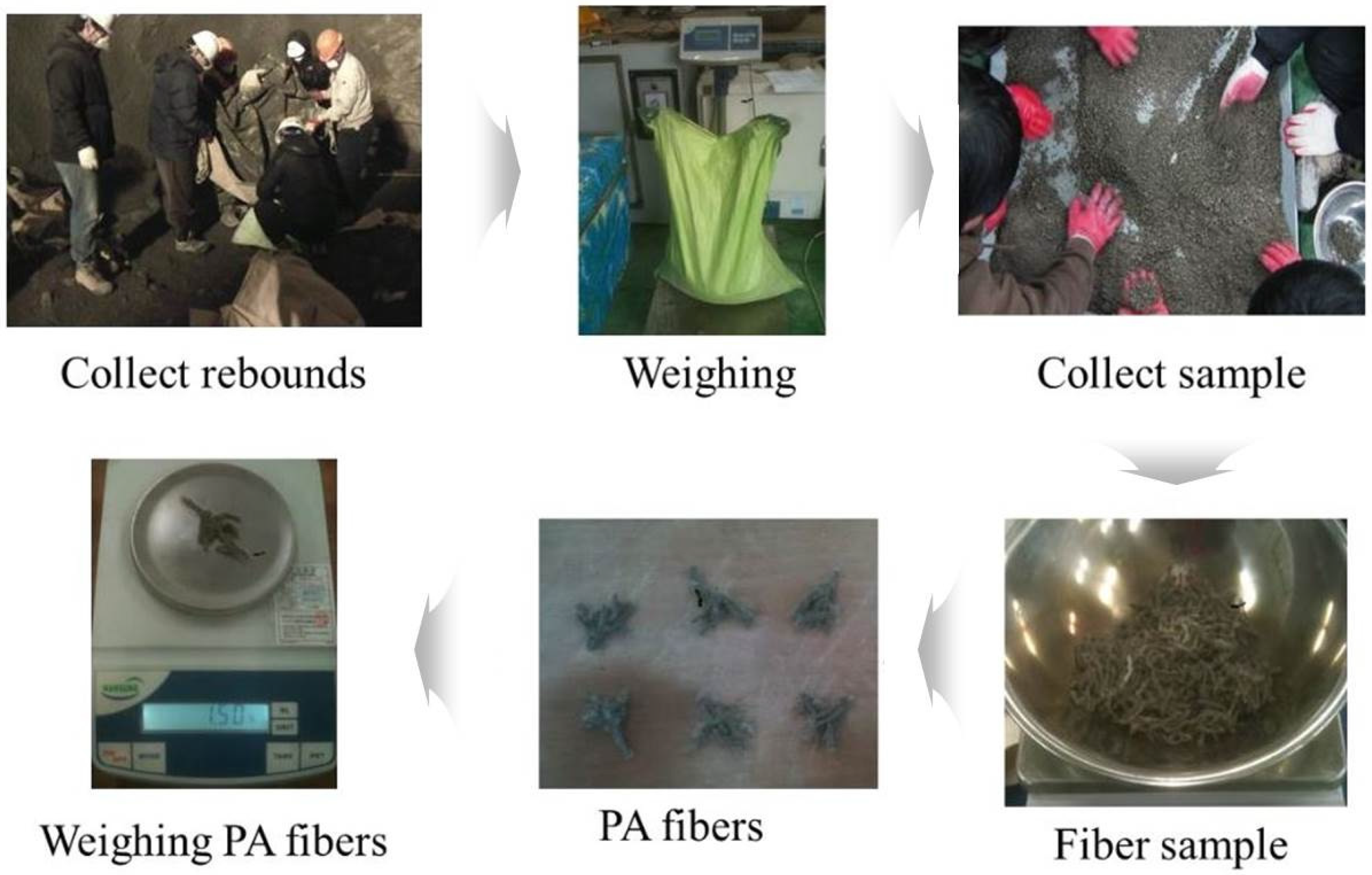

5. PAFRS Shotcrete Application Results

The PAFRS of PA-0.7F in

Table 5,

Table 6 and

Table 7 was conservatively selected and was used in tunnel shotcrete to evaluate shotcrete stresses and rebounding rate for constructability, as presented in

Figure 10. For comparison, steel fiber (0.5 mm diameter, 30 mm long and hooked type) reinforced shotcrete was also applied at the same construction site. Also, four sample cores with an average thickness of 168 mm were collected to confirm the shotcrete thickness and contact to the rock. The flexural strength of the specimen was satisfactory compared to the tunnel codes, as presented in

Table 7.

Also, the flexural stress limits by Korean Tunnel Design Specifications [

27] were checked. The measured shotcrete stresses are presented in

Table 9. Both PA and steel fiber reinforced shotcrete satisfied the allowable limits (allowable flexural compressive stress = 8.4 MPa, allowable flexural tensile stress = 0.60 MPa). The maximum compressive and tensile stresses of PA shotcrete were observed at the crown and the East springline, respectively, but the stress was only 2.5% and 10% with respect to the allowable stresses.

Finally, PA shotcrete rebounding was checked to identify the fiber ratio included and dropped in the final shotcrete. The test procedure is presented in

Figure 11. The rebounding test results are presented in

Table 10. The average rebounding rate was 8.5%, which is less than the limit of 12.5% designated by Korean Tunnel Design Specifications [

27]. The average dropped fiber rate was 63.5%. The average fiber content rate was 103.4%.