Deposition of Ultrathin Nano-Hydroxyapatite Films on Laser Micro-Textured Titanium Surfaces to Prepare a Multiscale Surface Topography for Improved Surface Wettability/Energy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Coating Deposition

2.3. Atomic Force Microscopy (AFM) Measurements

2.4. X-ray Diffraction (XRD)

2.5. Contact Angle and Surface Free Energy Measurements

3. Results and Discussion

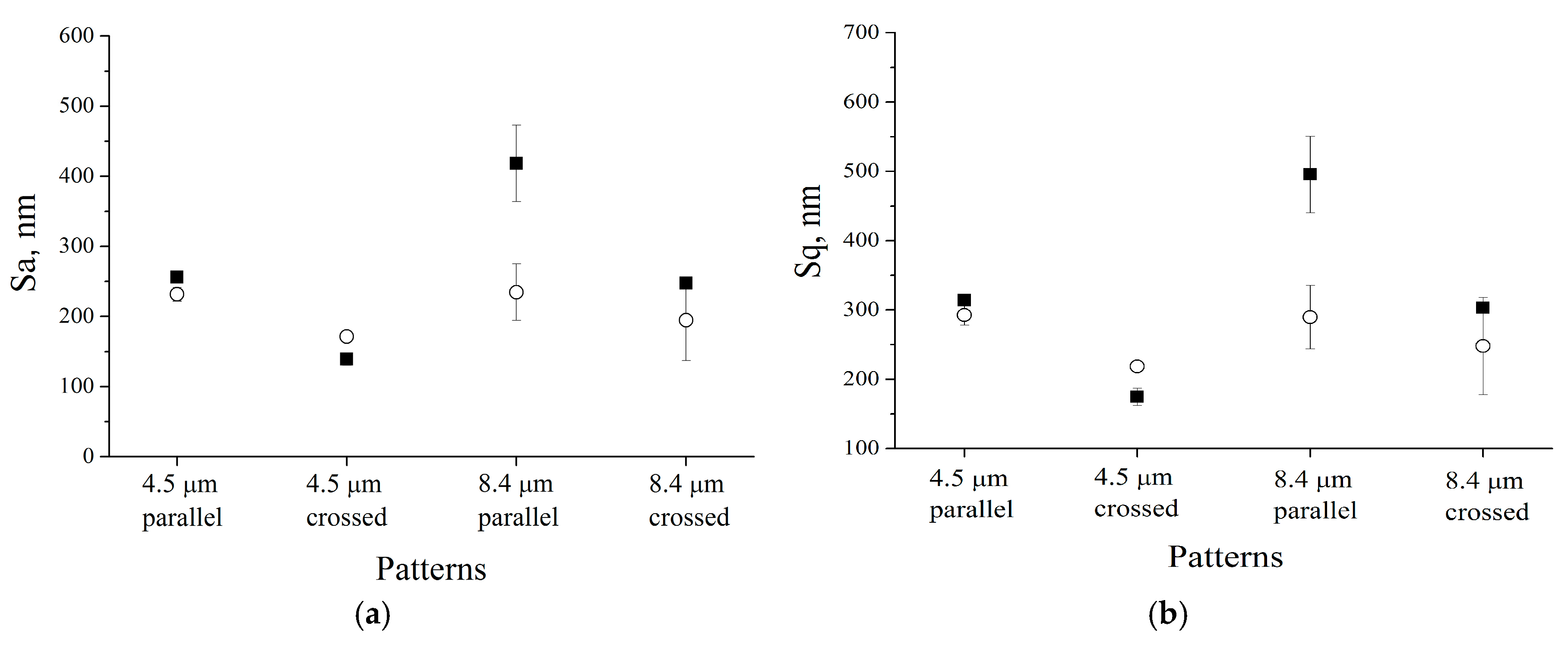

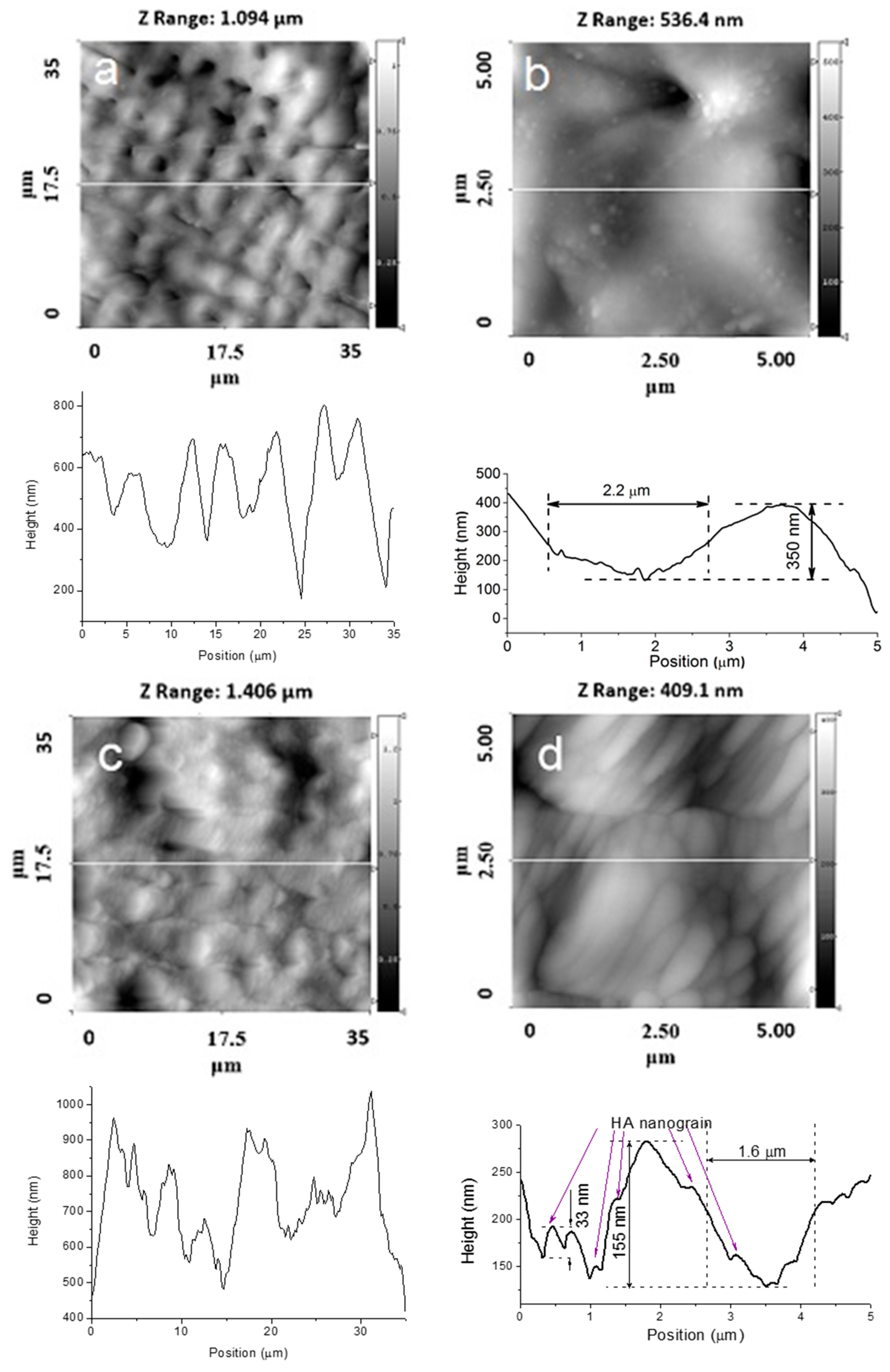

3.1. Surface Roughness and Morphology

3.2. Phase and Structure Characterization

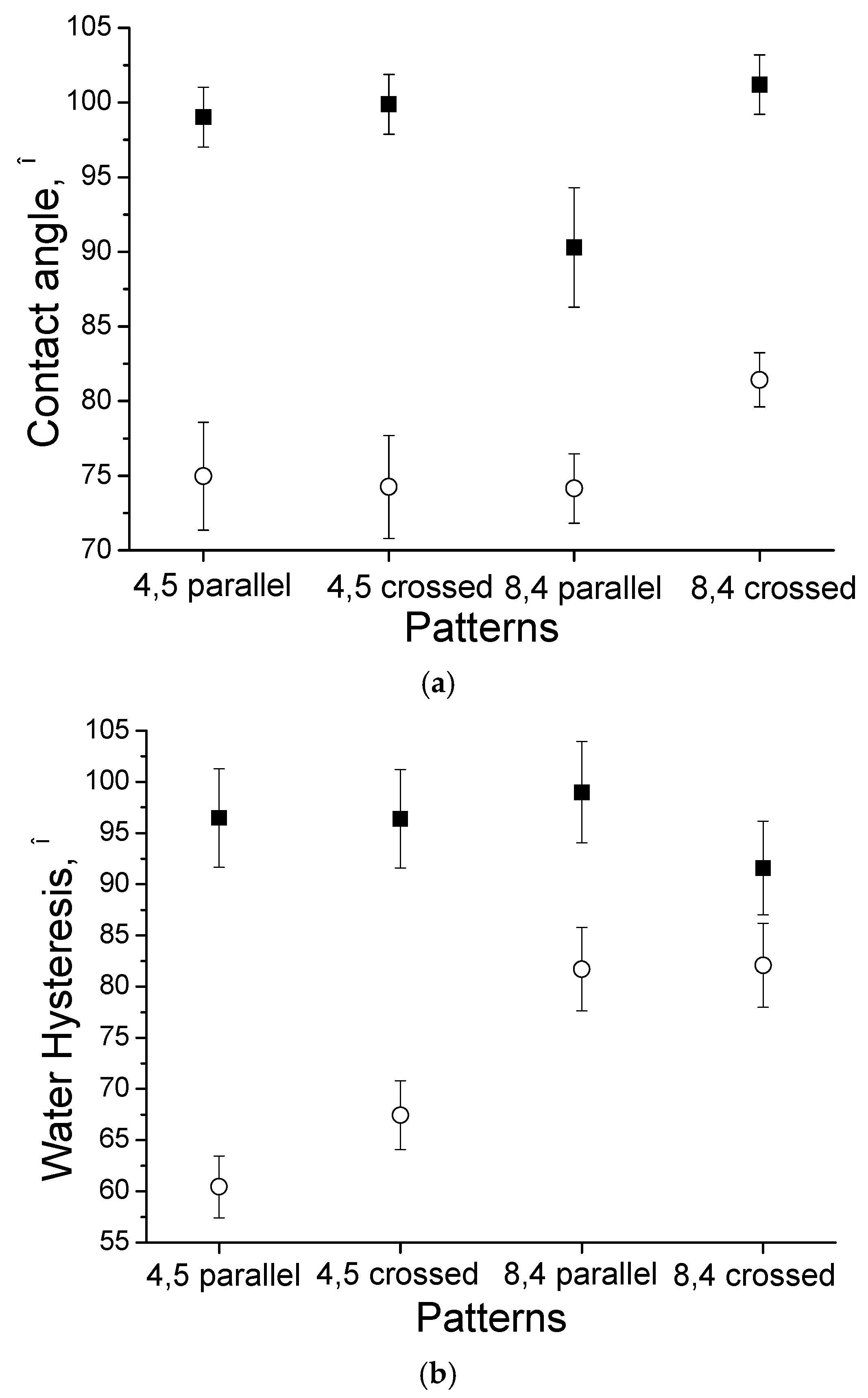

3.3. Wettability and Surface Free Energy

3.4. Antibacterial Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Holzapfel, B.M.; Reichert, J.C.; Schantz, J.T.; Gbureck, U.; Rackwitz, L.; Nöth, U.; Jakob, F.; Rudert, M.; Groll, J.; Hutmacher, D.W. How smart do biomaterials need to be? A translational science and clinical point of view. Adv. Drug Deliv. Rev. 2013, 65, 581–603. [Google Scholar] [CrossRef] [PubMed]

- Majeed, A.; He, J.; Jiao, L.; Zhong, X.; Sheng, Z. Surface properties and biocompatibility of nanostructured TiO2 film deposited by RF magnetron sputtering. Nanoscale Res. Lett. 2015, 10, 56. [Google Scholar] [CrossRef] [PubMed]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Franz, S.; Rammelt, S.; Scharnweber, D.; Simon, J.C. Immune responses to implants—A review of the implications for the design of immunomodulatory biomaterials. Biomaterials 2011, 32, 6692–6709. [Google Scholar] [CrossRef] [PubMed]

- Williams, D.F. On the mechanisms of biocompatibility. Biomaterials 2008, 29, 2941–2953. [Google Scholar] [CrossRef] [PubMed]

- Hans, M.; Müller, F.; Grandthyll, S.; Hüfner, S.; Mücklich, F. Anisotropic wetting of copper alloys induced by one-step laser micro-patterning. Appl. Surf. Sci. 2012, 263, 416–422. [Google Scholar] [CrossRef]

- Hans, M.; Gachot, C.; Müller, F.; Mücklich, F. Direct laser interference structuring as a tool to gradually tune the wetting response of titanium and polyimide surfaces. Adv. Eng. Mater. 2009, 11, 795–800. [Google Scholar] [CrossRef]

- Mücklich, F.; Lasagni, A.; Daniel, C. Laser interference metallurgy: Using interference as a tool for micro/nano structuring. Int. J. Mater. Res. 2006, 97, 1337–1344. [Google Scholar] [CrossRef]

- Dorozhkin, S.V.; Epple, M. Biological and medical significance of calcium phosphates. Angew. Chem. Int. Ed. 2002, 41, 3130–3146. [Google Scholar] [CrossRef]

- Surmeneva, M.A.; Surmenev, R.A.; Pichugin, V.F.; Koval, N.N.; Teresov, A.D.; Ivanova, A.A.; Grubova, I.Yu.; Ignatov, V.P.; Prymak, O.; Epple, M. Adhesion properties of a silicon-containing calcium phosphate coating deposited by RF magnetron sputtering on a heated substrate. J. Surf. Investig. X-ray Synchrotron Neutron Tech. 2013, 7, 944–951. [Google Scholar] [CrossRef]

- Surmeneva, M.A.; Mukhametkaliyev, T.M.; Tyurin, A.I.; Teresov, A.D.; Koval, N.N.; Pirozhkova, T.S.; Shuvarin, I.A.; Shuklinov, A.V.; Zhigachev, A.O.; Oehr, C.; et al. Effect of silicate doping on the structure and mechanical properties of thin nanostructured RF magnetron sputter-deposited hydroxyapatite films. Surf. Coat. Technol. 2015, 275, 176–184. [Google Scholar] [CrossRef]

- Ivanova, A.A.; Surmeneva, M.A.; Surmenev, R.A.; Depla, D. Influence of deposition conditions on the composition, texture and microstructure of RF-magnetron sputter-deposited hydroxyapatite thin films. Thin Solid Films 2015, 591, 368–374. [Google Scholar] [CrossRef]

- Ivanova, A.A.; Surmeneva, M.A.; Tyurin, A.I.; Pirozhkova, T.S.; Shuvarin, I.A.; Prymak, O.; Epple, M.; Chaikina, M.V.; Surmenev, R.A. Fabrication and physico-mechanical properties of thin magnetron sputter deposited silver-containing hydroxyapatite films. Appl. Surf. Sci. 2016, 360, 929–935. [Google Scholar] [CrossRef]

- Shadanbaz, S.; Dias, G.J. Calcium phosphate coatings on magnesium alloys for biomedical applications: A review. Acta Biomater. 2012, 8, 20–30. [Google Scholar] [CrossRef] [PubMed]

- Surmeneva, M.A.; Kluger, P.J.; Schönhaar, V.; Müller, M.; Hein, S.B.; Wittmar, A.; Ulbricht, M.; Prymak, O.; Oehr, C.; Surmenev, R.A. Nano-hydroxyapatite-coated metal-ceramic composite of iron-tricalcium phosphate: Improving the surface wettability, adhesion and proliferation of mesenchymal stem cells in vitro. Colloids Surf. B Biointerfaces 2015, 135, 386–393. [Google Scholar] [CrossRef] [PubMed]

- Surmenev, R.A.; Surmeneva, M.A.; Evdokimov, K.E.; Pichugin, V.F.; Peitsch, T.; Epple, M. The influence of the deposition parameters on the properties of an rf-magnetron-deposited nanostructured calcium phosphate coating and a possible growth mechanism. Surf. Coat. Technol. 2011, 205, 3600–3606. [Google Scholar] [CrossRef]

- Surmeneva, M.A.; Chaikina, M.V.; Zaikovskiy, V.I.; Pichugin, V.F.; Buck, V.; Prymak, O.; Epple, M.; Surmenev, R.A. The structure of an RF-magnetron sputter-deposited silicate-containing hydroxyapatite-based coating investigated by high-resolution techniques. Surf. Coat. Technol. 2013, 218, 39–46. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Levänen, E. Superhydrophobic surfaces for the reduction of bacterial adhesion. RSC Adv. 2013, 3, 12003–12020. [Google Scholar] [CrossRef]

- Extrand, C.W.; Kumagai, Y. An experimental study of contact angle hysteresis. J. Colloid Interface Sci. 1997, 191, 378–383. [Google Scholar] [CrossRef] [PubMed]

- Surmeneva, M.A.; Surmenev, R.A. Microstructure characterization and corrosion behaviour of a nano-hydroxyapatite coating deposited on AZ31 magnesium alloy using radio frequency magnetron sputtering. Vacuum 2015, 117, 60–62. [Google Scholar] [CrossRef]

- Grubova, I.Y.; Surmeneva, M.A.; Ivanova, A.A.; Kravchuk, K.; Prymak, O.; Epple, M.; Buck, V.; Surmenev, R.A. The effect of patterned titanium substrates on the properties of silver-doped hydroxyapatite coatings. Surf. Coat. Technol. 2015, 276, 595–601. [Google Scholar] [CrossRef]

- Padial-Molina, M.; Galindo-Moreno, P.; Fernández-Barbero, J.E.; O’Valle, F.; Jódar-Reyes, A.B.; Ortega-Vinuesa, J.L.; Ramón-Torregrosa, P.J. Role of wettability and nanoroughness on interactions between osteoblast and modified silicon surfaces. Acta Biomater. 2011, 7, 771–778. [Google Scholar] [CrossRef] [PubMed]

- Wennerberg, A.; Albrektsson, T. Effects of titanium surface topography on bone integration: A systematic review. Clin. Oral Implants Res. 2009, 20, 172–184. [Google Scholar] [CrossRef] [PubMed]

- Le Guehennec, L.; Lopez-Heredia, M.A.; Enkel, B.; Weiss, P.; Amouriq, Y.; Layrolle, P. Osteoblastic cell behaviour on different titanium implant surfaces. Acta Biomater. 2008, 4, 535–543. [Google Scholar] [CrossRef] [PubMed]

- Ulerich, J.P.; Ionescu, L.C.; Chen, J.; Soboyejo, W.O.; Arnold, C.B. Modifications of Ti-6Al-4V surfaces by direct-write laser machining of linear grooves. Photon Processing in Microelectronics and Photonics VI. Proc. SPIE 2007, 6458, 645819. [Google Scholar]

- Brown, M.S.; Arnold, C.B. Fundamentals of laser-material interaction and application to multiscale surface modification. In Laser Precision Microfabrication; Springer: Berlin, Germany, 2010; Volume 135, p. 91. [Google Scholar]

- Surmeneva, M.A.; Surmenev, R.A.; Nikonova, Y.A.; Selezneva, I.I.; Ivanova, A.A.; Putlyaev, V.I.; Prymak, O.; Epple, M. Fabrication, ultra-structure characterization and in vitro studies of RF magnetron sputter deposited nano-hydroxyapatite thin films for biomedical applications. Appl. Surf. Sci. 2014, 317, 172–180. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Hans, M.; Gachot, C.; Thome, A.; Bonk, S.; Mücklich, F. Direct laser interference patterning: Tailoring of contact area for frictional and antibacterial properties. Lubricants 2016, 4, 2. [Google Scholar] [CrossRef]

- Gemelli, E.; Camargo, N.H.A. Oxidation kinetics of commercially pure titanium. Matér. (Rio Jan.) 2007, 12, 525–531. [Google Scholar] [CrossRef]

- Tamada, Y.; Ikada, Y. Effect of preadsorbed proteins on cell adhesion to polymer surfaces. J. Colloid Interface Sci. 1993, 155, 334–339. [Google Scholar] [CrossRef]

- Meirelles, L.; Albrektsson, T.; Kjellin, P.; Arvidsson, A.; Franke-Stenport, V.; Andersson, M.; Currie, F.; Wennerberg, A. Bone reaction to nano hydroxyapatite modified titanium implants placed in a gap-healing model. J. Biomed. Mater. Res. A 2008, 87, 624–631. [Google Scholar] [CrossRef] [PubMed]

- Eliaz, N.; Shmueli, S.; Shur, I.; Benayahu, D.; Aronov, D.; Rosenman, G. The effect of surface treatment on the surface texture and contact angle of electrochemically deposited hydroxyapatite coating and on its interaction with bone-forming cells. Acta Biomater. 2009, 5, 3178–3191. [Google Scholar] [CrossRef] [PubMed]

- Pešáková, V.; Kubies, D.; Hulejová, H.; Himmlová, L. The influence of implant surface properties on cell adhesion and proliferation. J. Mater. Sci. Mater. Med. 2007, 18, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Lai, Y.-H.; Yang, J.-T.; Shieh, D.-B. A microchip fabricated with a vapor-diffusion self-assembled-monolayer method to transport droplets across superhydrophobic to hydrophilic surfaces. Lab Chip 2010, 10, 499–504. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.G.; Black, R.A.; Curran, J.M.; Hunt, J.A.; Rhodes, N.P.; Williams, D.F. Surface properties and biocompatibility of solvent-cast poly [ε-caprolactone] films. Biomaterials 2004, 25, 4741–4748. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Liu, Y.; Zhang, H.; Wang, Y.; Qiang, X. Superhydrophobic alumina surface with high adhesive force and long-term stability. Colloids Surfaces A Physicochem. Eng. Asp. 2012, 410, 66–71. [Google Scholar] [CrossRef]

- Oliveira, S.M.; Song, W.; Alves, N.M.; Mano, J.F. Chemical modification of bioinspired superhydrophobic polystyrene surfaces to control cell attachment/proliferation. Soft Matter 2011, 7, 8932–8941. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Koc, Y.; Mello, A.J.; McHale, G.; Newton, M.I.; Roach, P.; Shirtcliffe, N.J. Nano-scale superhydrophobicity: Suppression of protein adsorption and promotion of flow-induced detachment. Lab Chip 2008, 8, 582–586. [Google Scholar] [CrossRef] [PubMed]

- Hsu, S.H.; Tang, C.M.; Chiu, J.J.; Liao, T.C.; Lin, C.C.; Iwata, H. Cell migration rate on poly(ε-caprolactone)/poly(ethylene glycol) diblock copolymers and correlation with the material sliding angle. Macromol. Biosci. 2007, 7, 482–490. [Google Scholar] [CrossRef] [PubMed]

- Surmenev, R.A.; Surmeneva, M.A.; Ivanova, A.A. Significance of calcium phosphate coatings for the enhancement of new bone osteogenesis—A review. Acta Biomater. 2014, 10, 557–579. [Google Scholar] [CrossRef] [PubMed]

- Marmur, A.; Bittoun, E. When Wenzel and Cassie are right: Reconciling local and global considerations. Langmuir 2009, 25, 1277–1281. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, L.; Sanchez, M.; Carmona, F.J.; Palacio, L.; Calvo, J.I.; Hernandez, A.; Pradanos, P. Analysis of the grafting process of PVP on a silicon surface by AFM and contact angle. Langmuir 2011, 27, 11636–11649. [Google Scholar] [CrossRef] [PubMed]

- Surmenev, R.A. A review of plasma-assisted methods for calcium phosphate-based coatings fabrication. Surf. Coat. Technol. 2012, 206, 2035–2056. [Google Scholar] [CrossRef]

- Shimazaki, T.; Miyamoto, H.; Ando, Y.; Noda, I.; Yonekura, Y.; Kawano, S.; Miyazaki, M.; Mawatari, M.; Hotokebuchi, T. In vivo antibacterial and silver-releasing properties of novel thermal sprayed silver-containing hydroxyapatite coating. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 92, 386–389. [Google Scholar] [PubMed]

- Ando, Y.; Miyamoto, H.; Noda, I.; Sakurai, N.; Akiyama, T.; Yonekurac, Y.; Shimazakic, T.; Miyazakic, M.; Mawataric, M.; Hotokebuchic, T. Calcium phosphate coating silver shows high antibacterial activity and low cytotoxicity and inhibit bacterial adhesion. Mater. Sci. Eng. 2010, 30, 175–180. [Google Scholar] [CrossRef]

- Kittler, S.; Greulich, C.; Diendorf, J.; Koeller, M.; Epple, M. Toxicity of silver nanoparticles increases during storage because of slow dissolution under release of silver ions. Chem. Mater. 2010, 22, 4548–4554. [Google Scholar] [CrossRef]

- Greulich, C.; Diendorf, J.; Simon, T.; Eggeler, G.; Epple, M.; Koeller, M. Uptake and intracellular distribution of silver nanoparticles in human mesenchymal stem cells. Acta Biomater. 2011, 7, 347–354. [Google Scholar] [CrossRef] [PubMed]

- Sondi, I.; Salopek-Sondi, B. Silver nanoparticles as antimicrobial agent: A case study on E. coli as a model for Gram-negative bacteria. J. Colloid Interface Sci. 2004, 275, 177–182. [Google Scholar] [CrossRef] [PubMed]

- Li, W.-R.; Xie, X.-B.; Shi, Q.-S.; Zeng, H.-Y.; OU-Yang, Y.-S.; Chen, Y.-B. Antibacterial activity and mechanism of silver nanoparticles on Escherichia coli. Appl. Microbiol. Biotechnol. 2010, 85, 1115–1122. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Wang, S.; Mueller-Steinhagen, H. Tailored surface free energy of membrane diffusers to minimize microbial adhesion. Appl. Surf. Sci. 2004, 230, 371–378. [Google Scholar] [CrossRef]

- Boyd, R.D.; Verran, J.; Jones, M.V.; Bhakoo, M. Use of the atomic force microscope to determine the effect of substratum surface topography on bacterial adhesion. Langmuir 2002, 18, 2343–2346. [Google Scholar] [CrossRef]

- Hsu, L.C.; Fang, J.; Borca-Tasciuc, D.A.; Worobo, R.W.; Morarua, C.I. Effect of micro- and nanoscale topography on the adhesion of bacterial cells to solid surfaces. Appl. Environ. Microbiol. 2013, 79, 2703–2712. [Google Scholar] [CrossRef] [PubMed]

- Whitehead, K.A.; Colligon, J.; Verran, J. Retention of microbial cells in substratum surface features of micrometer and sub-micrometer dimensions. Colloids Surf. B Biointerfaces 2005, 41, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Woodling, S.E.; Moraru, C.I. Influence of surface topography on the effectiveness of pulsed light treatment for the inactivation of Listeria innocua on stainless-steel surfaces. J. Food Sci. 2005, 70, m345–m351. [Google Scholar] [CrossRef]

- Perera-Costa, D.; Morales Bruque, J.; Luisa González-Martín, M.; Cándido Gómez-García, A.; Vadillo-Rodríguez, V. Studying the influence of surface topography on bacterial adhesion using spatially organized microtopographic surface patterns. Langmuir 2014, 30, 4633–4641. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; Chen, A.; Song, X.; Brasch, M.E.; Henderson, J.H.; Ren, D. How Escherichia coli lands and forms cell clusters on a surface: A new role of surface topography. Sci. Rep. 2016, 6, 29516. [Google Scholar] [CrossRef] [PubMed]

- Puckett, S.D.; Taylor, E.; Raimondo, T.; Webster, T.J. The relationship between the nanostructure of titanium surfaces and bacterial attachment. Biomaterials 2010, 31, 706–713. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Patterns | |||||||

|---|---|---|---|---|---|---|---|---|

| 4.5 µm Parallel Grooves | 4.5 µm Crossed Grooves | 8.4 µm Parallel Grooves | 8.4 µm Crossed Grooves | |||||

| Uncoated | Coated | Uncoated | Coated | Uncoated | Coated | Uncoated | Coated | |

| , mJ/ | 0.34 ± 0.02 | 6.20 ± 0.12 | 0.12 ± 0.01 | 5.40 ± 0.11 | 1.74 ± 0.03 | 5.94 ± 0.30 | 0.13 ± 0.01 | 3.19 ± 0.16 |

| , mJ/ | 26.84 ± 1.34 | 29.01 ± 0.58 | 30.96 ± 0.62 | 34.04 ± 0.68 | 26.31 ± 0.53 | 34.79 ± 1.74 | 29.27 ± 0.59 | 32.93 ± 1.65 |

| σ, mJ/ | 27.19 ± 1.36 | 35.21 ± 0.7 | 31.8 ± 0.64 | 39.44 ± 0.79 | 28.04 ± 0.56 | 37.73 ± 1.89 | 29.4 ± 0.59 | 36.13 ± 1.81 |

| Surface/Parameter | Sdr, % | Roughness Factor, r | θm, ° | θy, ° |

|---|---|---|---|---|

| Etched Ti (unpatterned) | 3.32 | 1.0332 | 85.2 ± 2 | 85.6 |

| Uncoated patterned Ti surfaces | ||||

| 4.5 μm line | 11.3 ± 1.3 | 1.113 | 98.4 ± 2 | 98.6 |

| 4.5 μm crossed | 2.4 ± 0.2 | 1.024 | 99.3 ± 2 | 99.3 |

| 8.4 μm line | 5.5 ± 0.4 | 1.055 | 90.3 ± 4 | 90.8 |

| 8.4 μm crossed | 5.3 ± 0.7 | 1.053 | 101.2 ± 2 | 101.2 |

| HA coated Ti patterned surfaces | ||||

| 4.5 μm line | 6.7 ± 0.2 | 1.067 | 75.1 ± 2 | 76.6 |

| 4.5 μm crossed | 2.5 ± 0.3 | 1.025 | 74.1 ± 2 | 74.7 |

| 8.4 μm line | 5.2 ± 0.4 | 1.052 | 73.5 ± 2 | 74.9 |

| 8.4 μm crossed | 2.0 ± 0.4 | 1.020 | 81.5 ± 2 | 81.9 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Surmeneva, M.; Nikityuk, P.; Hans, M.; Surmenev, R. Deposition of Ultrathin Nano-Hydroxyapatite Films on Laser Micro-Textured Titanium Surfaces to Prepare a Multiscale Surface Topography for Improved Surface Wettability/Energy. Materials 2016, 9, 862. https://doi.org/10.3390/ma9110862

Surmeneva M, Nikityuk P, Hans M, Surmenev R. Deposition of Ultrathin Nano-Hydroxyapatite Films on Laser Micro-Textured Titanium Surfaces to Prepare a Multiscale Surface Topography for Improved Surface Wettability/Energy. Materials. 2016; 9(11):862. https://doi.org/10.3390/ma9110862

Chicago/Turabian StyleSurmeneva, Maria, Polina Nikityuk, Michael Hans, and Roman Surmenev. 2016. "Deposition of Ultrathin Nano-Hydroxyapatite Films on Laser Micro-Textured Titanium Surfaces to Prepare a Multiscale Surface Topography for Improved Surface Wettability/Energy" Materials 9, no. 11: 862. https://doi.org/10.3390/ma9110862