Effects of WC-17Co Coating Combined with Shot Peening Treatment on Fatigue Behaviors of TC21 Titanium Alloy

Abstract

:1. Introduction

2. Materials and Methods

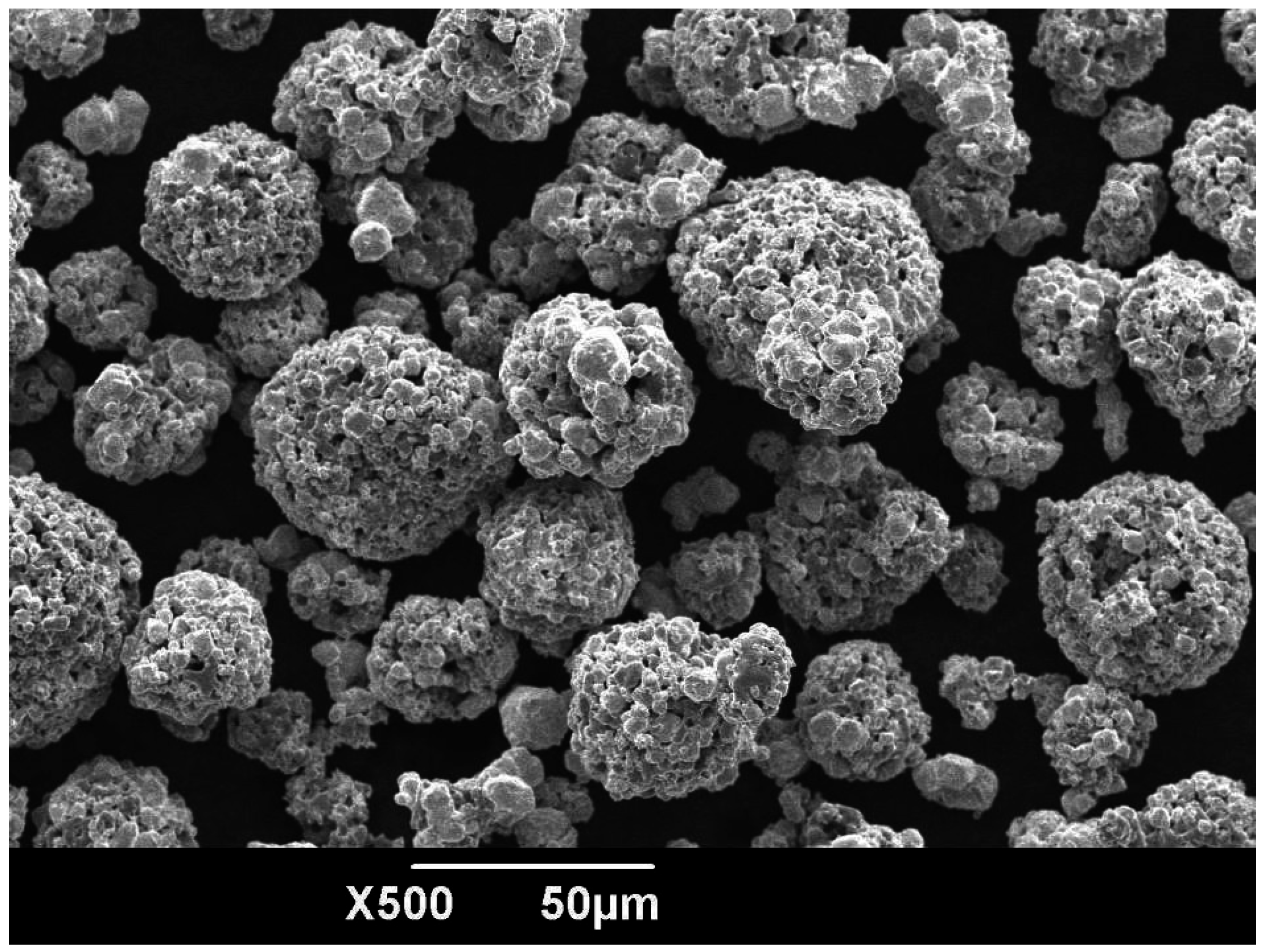

2.1. Materials and Spraying Powder

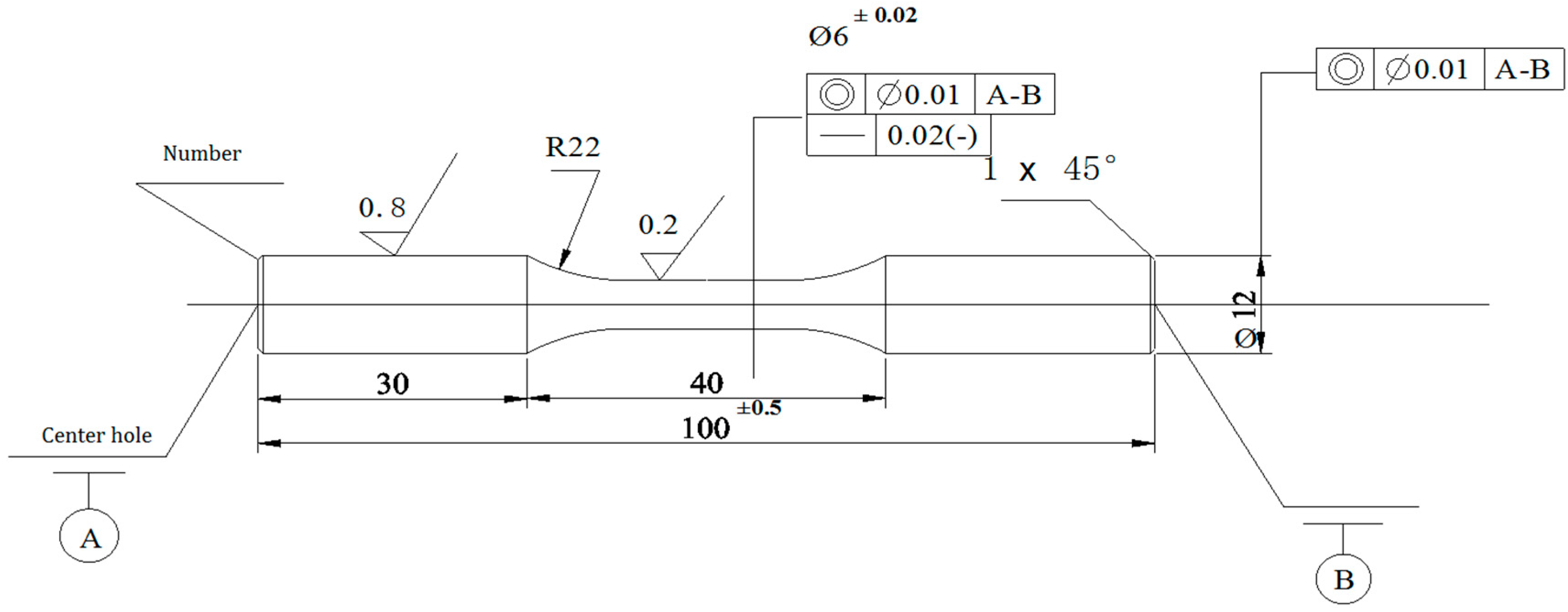

2.2. Research Methods

3. Results

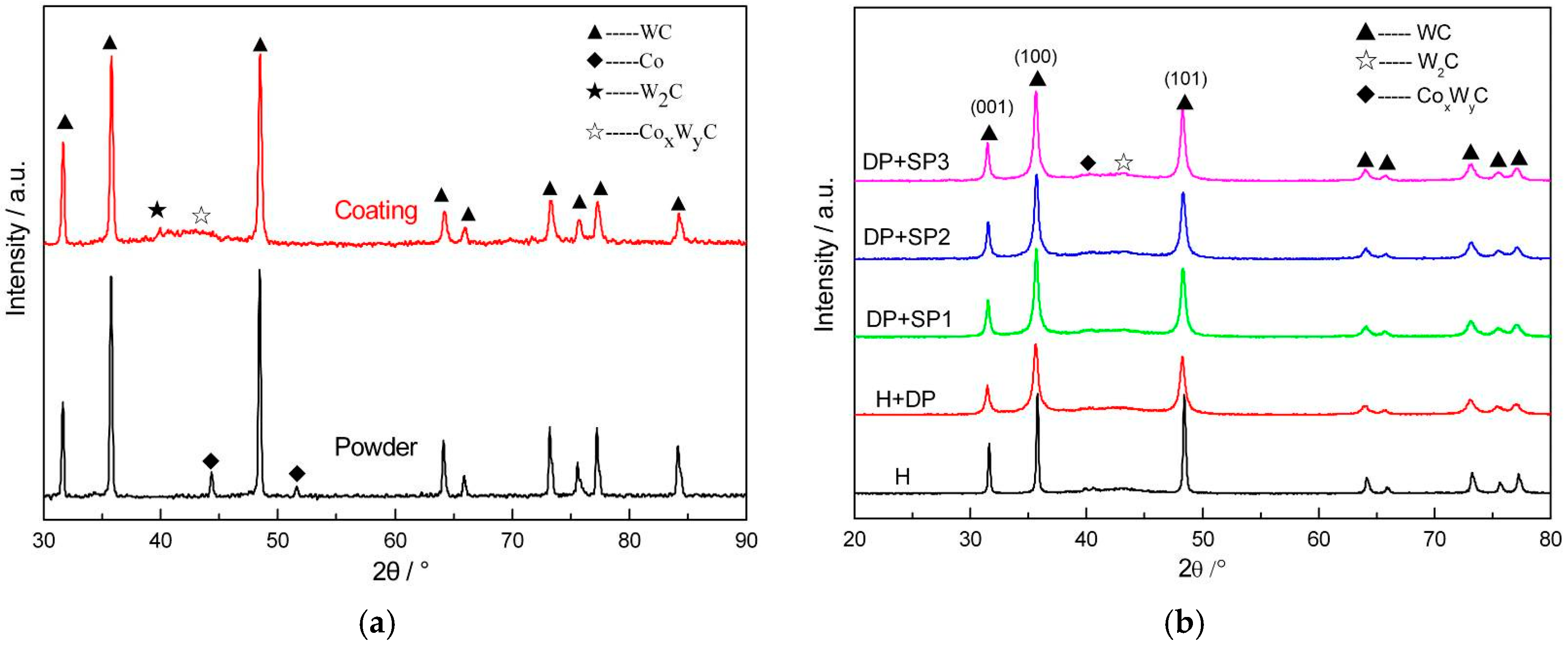

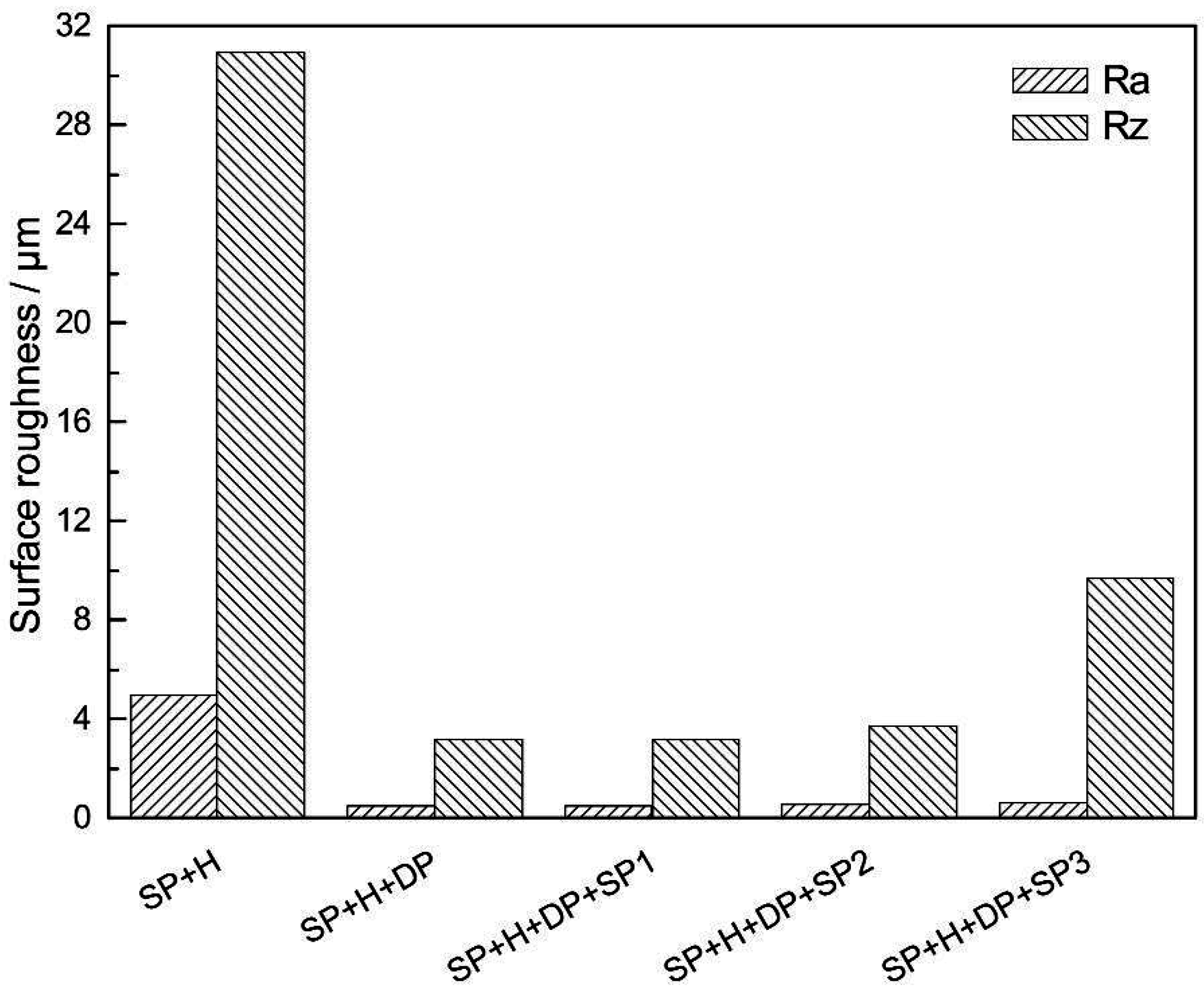

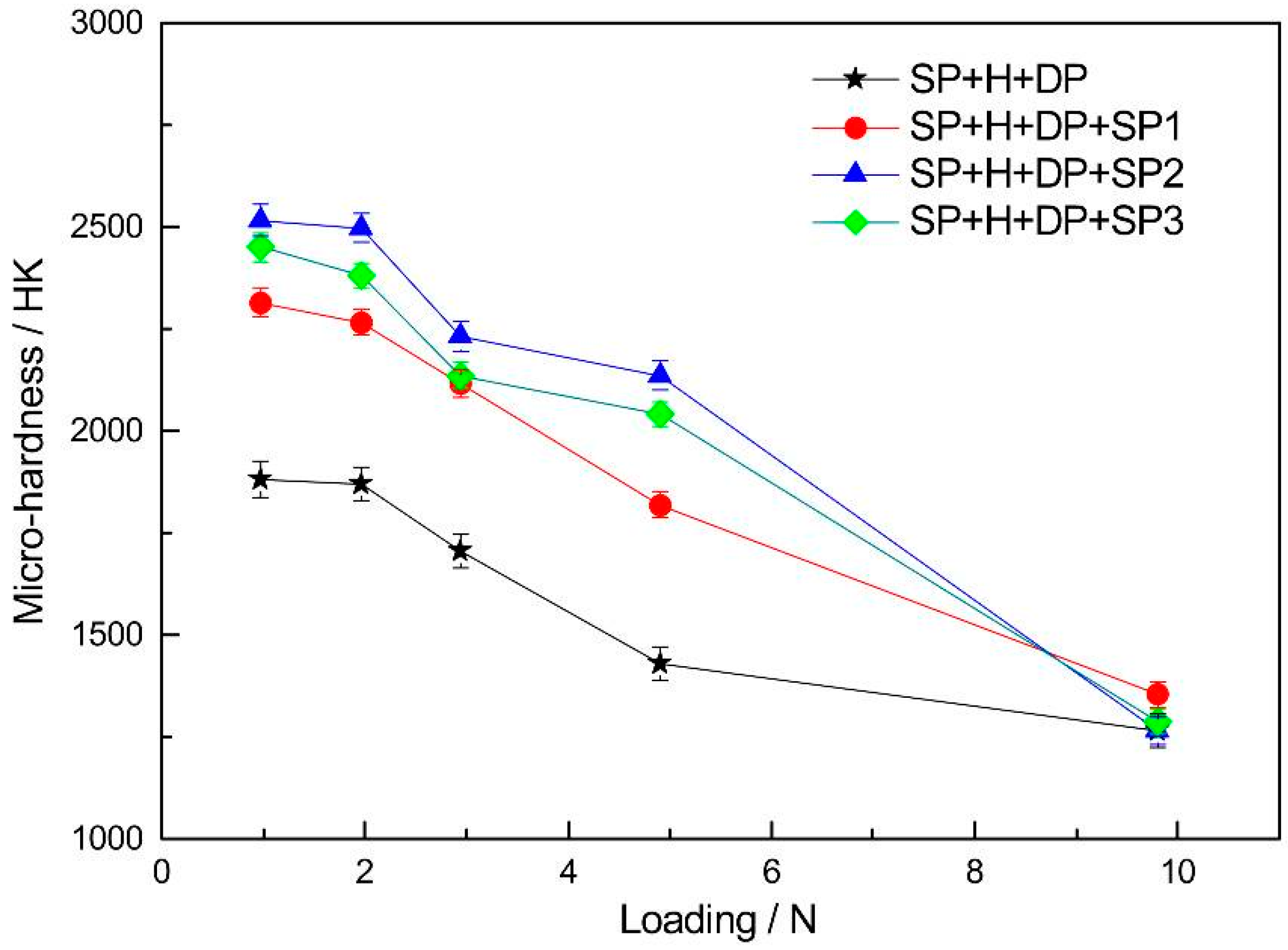

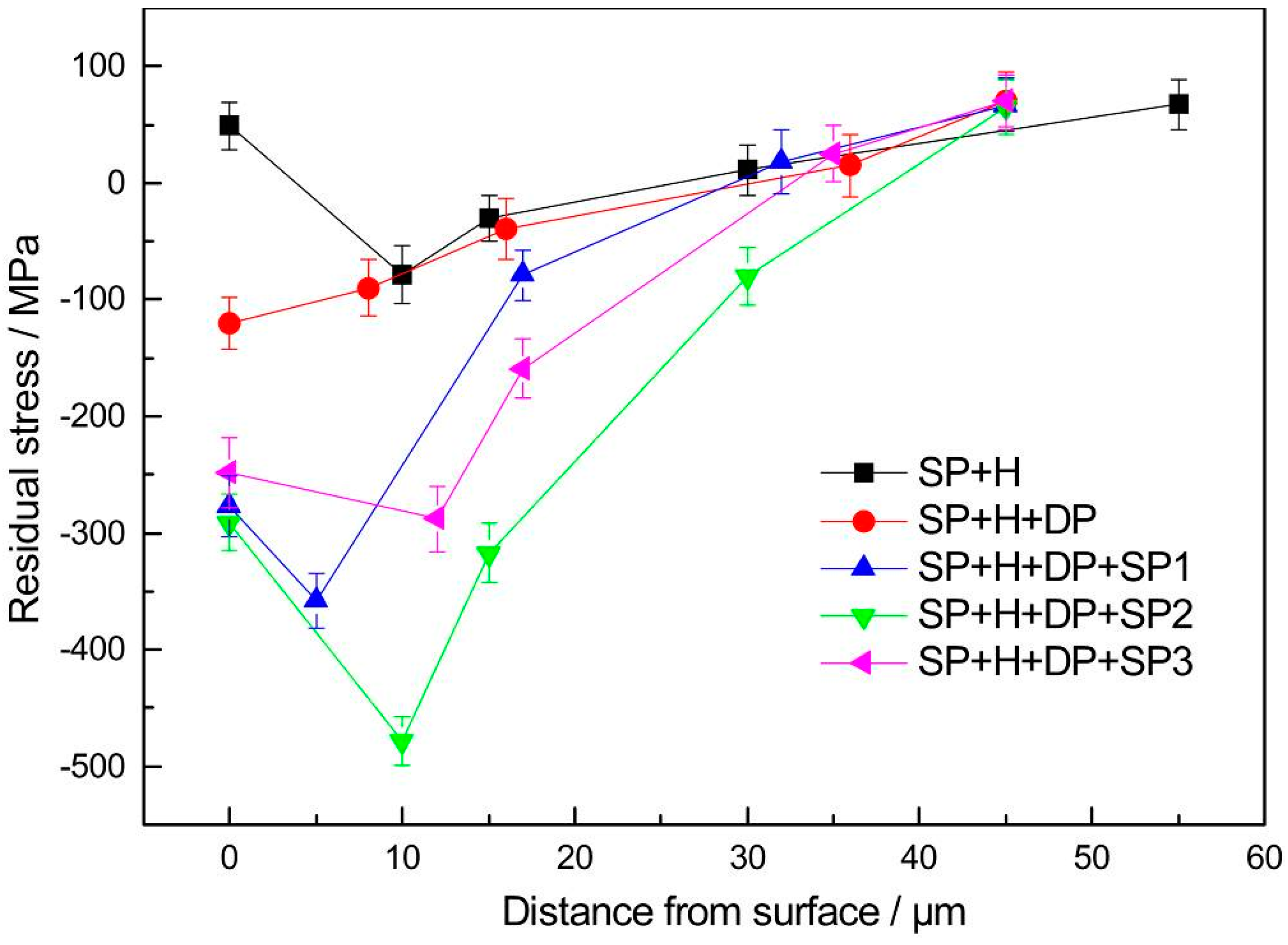

3.1. Characteristics

3.2. Toughness

3.3. Fatigue Life

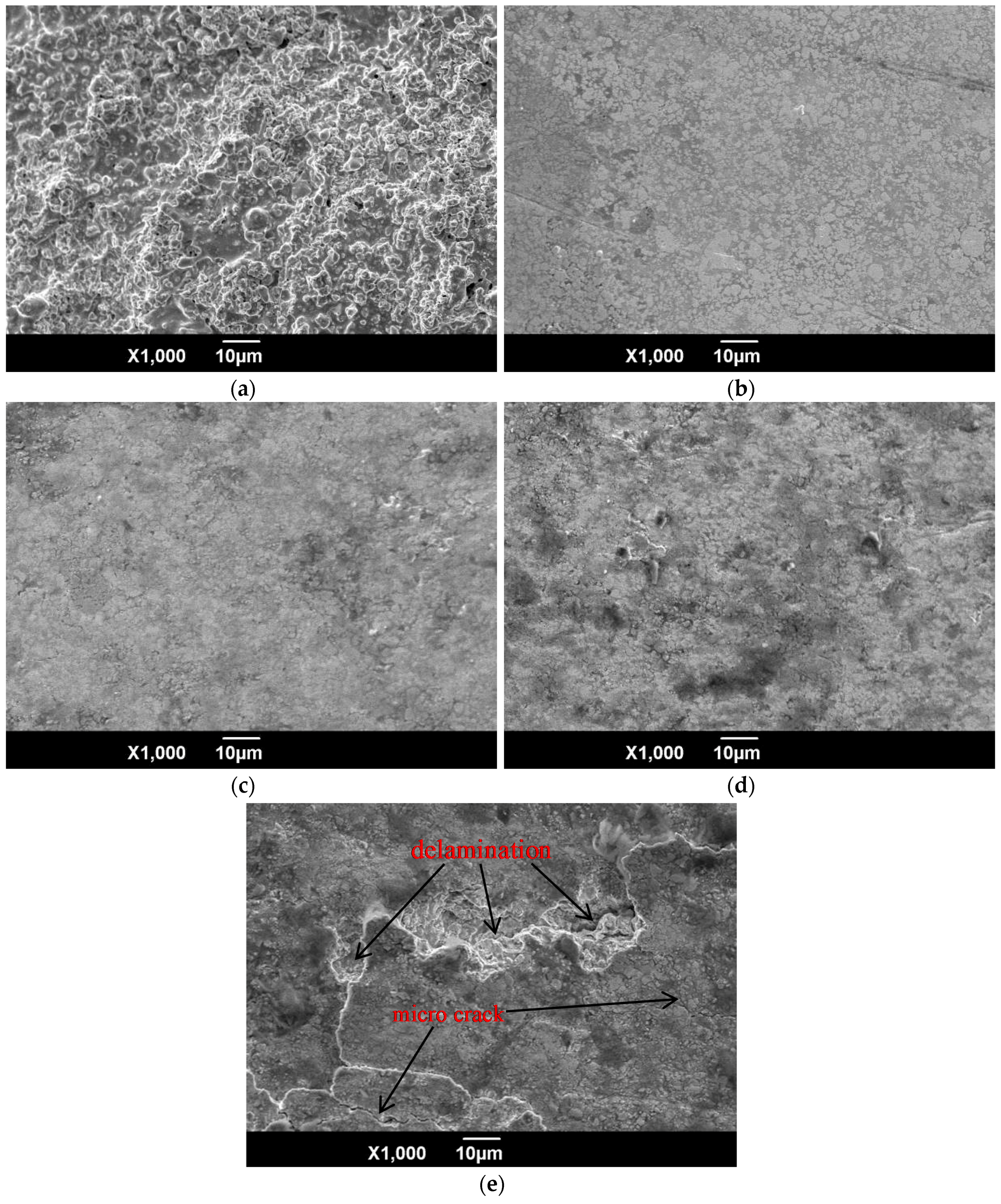

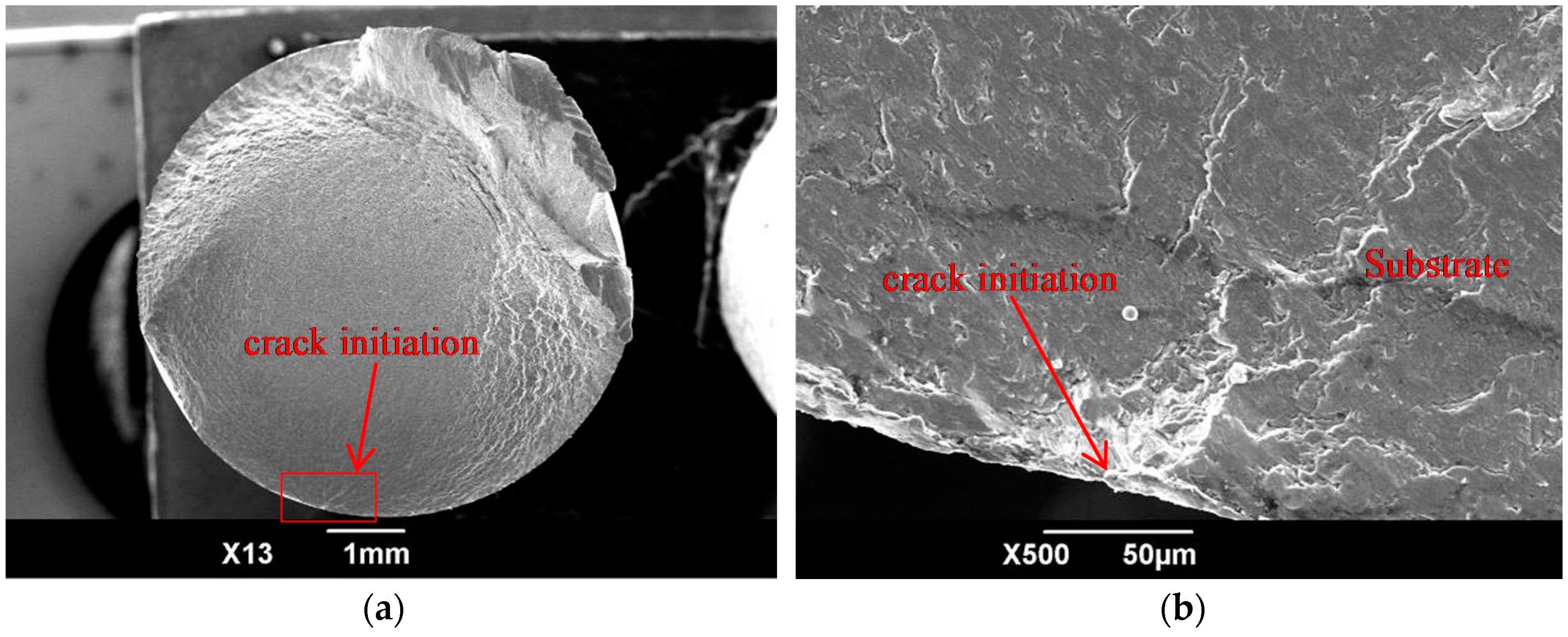

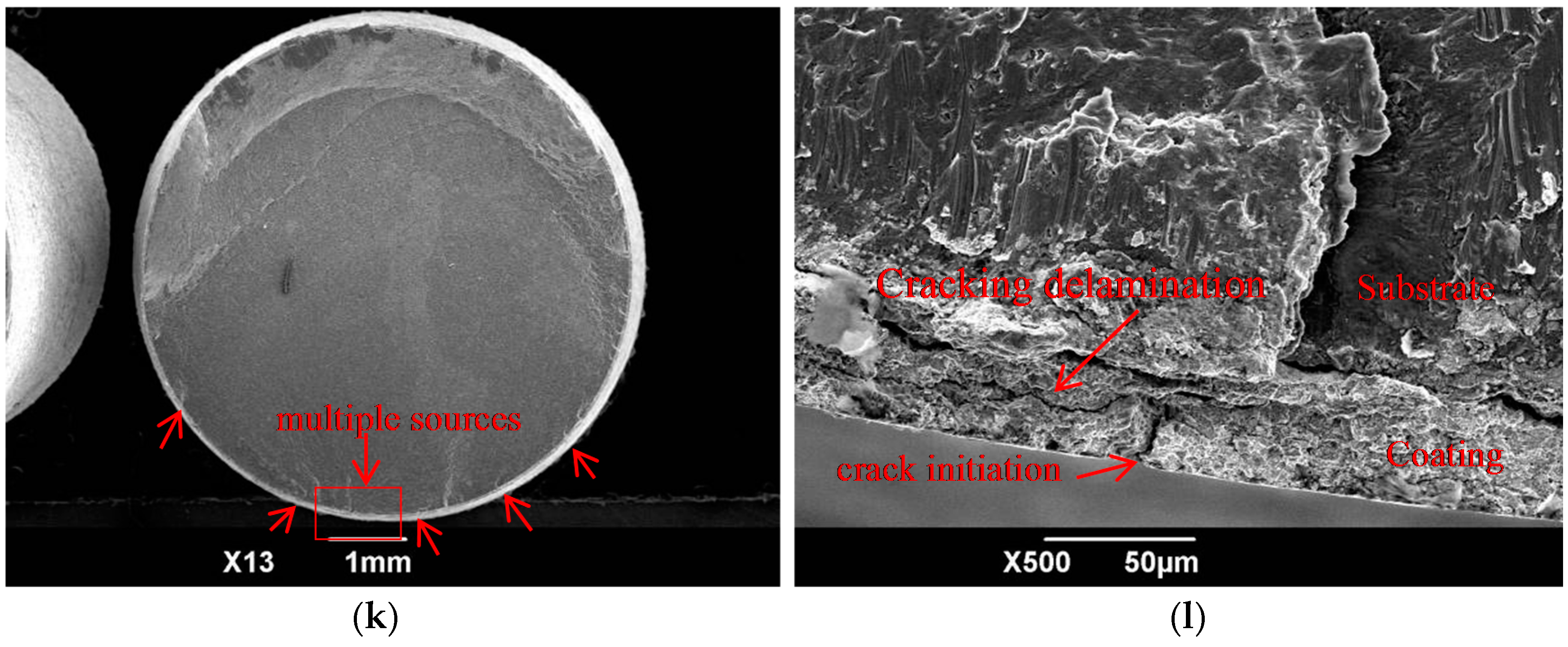

3.4. Fatigue Fracture Morphology

4. Discussion

5. Conclusions

- (1)

- The fatigue resistance of the TC21 titanium alloy with HVOF WC-17Co coatings that underwent a shot peening pre-treatment, was lower than that of the titanium alloy (i.e., the base material). This resulted from the high hardness, low toughness, rough surface, and the surface residual stress of the coatings. The samples with polished coatings exhibited almost the same anti-fatigue performance as that of the TC21 titanium alloy substrate. This is attributed to the polishing-induced residual compressive stress on the surface and a weakening of the notch stress-concentration effect.

- (2)

- Moderate-intensity shot peening can effectively improve the fatigue resistance of the polished HVOF WC-17Co coatings. This is attributed to the deep distribution, high residual compressive stress field, and hardening effect of the coatings.

- (3)

- The HVOF WC-17Co coatings subjected to excessively high intensities of shot peening crack and separate from the substrate, and the residual compressive stress (induced by shot peening) is relaxed. These occurrences are all detrimental to the fatigue resistance.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Du, D.; Liu, D.; Meng, B. Effects of pretreatment and HVOF sprayed cermet coating on fatigue properties of TC21 titanium alloy. Sci. China Technol. Sci. 2013, 56, 1029–1037. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, B.; Zhu, Z. The high temperature deformation behavior and microstructure of TC21 titanium alloy. Mater. Sci. Eng. A 2010, 527, 5360–5367. [Google Scholar] [CrossRef]

- Amiriyan, M.; Blais, C.; Savoie, S. Tribo-Mechanical Properties of HVOF Deposited Fe3Al Coatings Reinforced with TiB2 Particles for Wear-Resistant Applications. Materials 2016, 9, 117. [Google Scholar] [CrossRef]

- Cabrera, E.; Berrios-Ortiz, J.A.; Da-Silva, J. Fatigue behavior of a 4140 steel coated with a Colmonoy 88 alloy applied by HVOF. Surf. Coat. Technol. 2003, 172, 128–138. [Google Scholar] [CrossRef]

- Padilla, K.; Velasquez, A.; Berrios, J.A. Fatigue behavior of a 4140 steel coated with a NiMoAl deposit applied by HVOF thermal spray. Surf. Coat. Technol. 2002, 150, 151–162. [Google Scholar] [CrossRef]

- Oliveira, F.; Hernandez, L.; Berrios, J.A. Corrosion-fatigue properties of a 4340 steel coated with Colmonoy 88 alloy, applied by HVOF thermal spray. Surf. Coat. Technol. 2001, 140, 128–135. [Google Scholar] [CrossRef]

- Savarimuthu, A.C.; Taber, H.F.; Megat, I. Sliding wear behavior of tungsten carbide thermal spray coatings for replacement of chromium electroplate in aircraft applications. J. Therm. Spray Technol. 2001, 10, 502–510. [Google Scholar] [CrossRef]

- Costa, M.Y.P.; Venditti, M.L.R.; Voorwald, H.J.C. Effect of WC-10%Co-4%Cr coating on the Ti-6Al-4V alloy fatigue strength. Mater. Sci. Eng. A 2009, 507, 29–36. [Google Scholar] [CrossRef]

- Wielage, B.; Wank, A.; Pokhmurska, H. Development and trends in HVOF spraying technology. Surf. Coat. Technol. 2006, 201, 2032–2037. [Google Scholar] [CrossRef]

- Nascimento, M.P.; Souza, R.C.; Miguel, I.M. Effects of tungsten carbide thermal spray coating by HP/HVOF and hard chromium electroplating on AISI 4340 high strength steel. Surf. Coat. Technol. 2001, 138, 113–124. [Google Scholar] [CrossRef]

- Nascimento, M.P.; Souza, R.C.; Pigatin, W.L. Effects of surface treatments on the fatigue strength of AISI 4340 aeronautical steel. Int. J. Fatigue 2001, 23, 607–618. [Google Scholar] [CrossRef]

- Liu, D.; Tang, B.; Zhu, X. Improvement of the fretting fatigue and fretting wear of Ti6Al4V by duplex surface modification. Surf. Coat. Technol. 1999, 116, 234–238. [Google Scholar] [CrossRef]

- Kubiak, K.; Fouvry, S.; Marechal, A.M. Behaviour of shot peening combined with WC–Co HVOF coating under complex fretting wear and fretting fatigue loading conditions. Surf. Coat. Technol. 2006, 201, 4323–4328. [Google Scholar] [CrossRef]

- Du, D.; Liu, D.; Ye, Z. Fretting wear and fretting fatigue behaviors of diamond-like carbon and graphite-like carbon films deposited on Ti-6Al-4V alloy. Appl. Surf. Sci. 2014, 313, 462–469. [Google Scholar] [CrossRef]

- Arola, D.; Williams, C.L. Estimating the fatigue stress concentration factor of machined surfaces. Int. J. Fatigue 2002, 24, 923–930. [Google Scholar] [CrossRef]

- Lindemann, J.; Buque, C.; Appel, F. Effect of shot peening on fatigue performance of a lamellar titanium aluminide alloy. Acta Mater. 2006, 54, 1155–1164. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, D.; Tan, H. Effect of TiN/Ti composite coating and shot peening on fretting fatigue behavior of TC17 alloy at 350 °C. Surface Coat. Technol. 2009, 203, 2315–2321. [Google Scholar] [CrossRef]

- Tang, J.; Liu, D.; Zhang, X. Effects of Plasma ZrN Metallurgy and Shot Peening Duplex Treatment on Fretting Wear and Fretting Fatigue Behavior of Ti6Al4V Alloy. Materials 2016, 9, 217. [Google Scholar] [CrossRef]

| Powder Feed Rate (kg/h) | Carrier Gas Pressure (Mpa) | Oxygen Pressure (Mpa) | Combustion Gas | Combustion Gas Pressure (Mpa) | Spray Distance (mm) | Gun Traverse Speed (mm/s) | Specimen Rotation (r/min) | Temperature of Substrate (°C) |

|---|---|---|---|---|---|---|---|---|

| 4 | 1.4 | 1.5 | Propane | 1.4 | 300 | 200 | 3000 | <150 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, D.; Liu, D.; Zhang, X.; Tang, J.; Meng, B. Effects of WC-17Co Coating Combined with Shot Peening Treatment on Fatigue Behaviors of TC21 Titanium Alloy. Materials 2016, 9, 865. https://doi.org/10.3390/ma9110865

Du D, Liu D, Zhang X, Tang J, Meng B. Effects of WC-17Co Coating Combined with Shot Peening Treatment on Fatigue Behaviors of TC21 Titanium Alloy. Materials. 2016; 9(11):865. https://doi.org/10.3390/ma9110865

Chicago/Turabian StyleDu, Dongxing, Daoxin Liu, Xiaohua Zhang, Jingang Tang, and Baoli Meng. 2016. "Effects of WC-17Co Coating Combined with Shot Peening Treatment on Fatigue Behaviors of TC21 Titanium Alloy" Materials 9, no. 11: 865. https://doi.org/10.3390/ma9110865