Dissolution and Precipitation Behaviour during Continuous Heating of Al–Mg–Si Alloys in a Wide Range of Heating Rates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Analysed Aluminium Alloys and Investigated Initial Conditions

| Aluminium Alloy | Mass fraction in % | |||||||

|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | |

| EN AW-6005A | 0.67 | 0.23 | 0.03 | 0.41 | 0.59 | 0.01 | 0.02 | 0.02 |

| DIN EN 573-3 | 0.5–0.9 | ≤0.35 | ≤0.3 | ≤0.5 | 0.4–0.7 | ≤0.3 | ≤0.2 | ≤0.1 |

| EN AW-6082 | 0.73 | 0.22 | 0.05 | 0.48 | 0.61 | 0.003 | 0.01 | 0.02 |

| DIN EN 573-3 | 0.7–1.3 | ≤0.5 | ≤0.1 | 0.4–1.0 | 0.6–1.2 | ≤0.25 | ≤0.2 | ≤0.1 |

| EN AW-6016 | 1.15 | 0.24 | 0.07 | 0.07 | 0.40 | 0.022 | 0.007 | 0.04 |

| DIN EN 573-3 | 1.0–1.5 | ≤0.5 | ≤0.2 | ≤0.2 | 0.25–0.6 | ≤0.1 | ≤0.2 | ≤0.15 |

| EN AW-6181 | 0.85 | 0.33 | 0.18 | 0.06 | 0.77 | 0.009 | 0.021 | 0.01 |

| DIN EN 573-3 | 0.8–1.2 | ≤0.45 | ≤0.1 | ≤0.15 | 0.6–1.0 | ≤0.1 | ≤0.2 | ≤0.1 |

| Step I | Step II |

|---|---|

| Solution annealing 540 °C 20 min. | Water quenching |

| 98 h furnace cooling |

2.2. Thermal Analysis through DSC

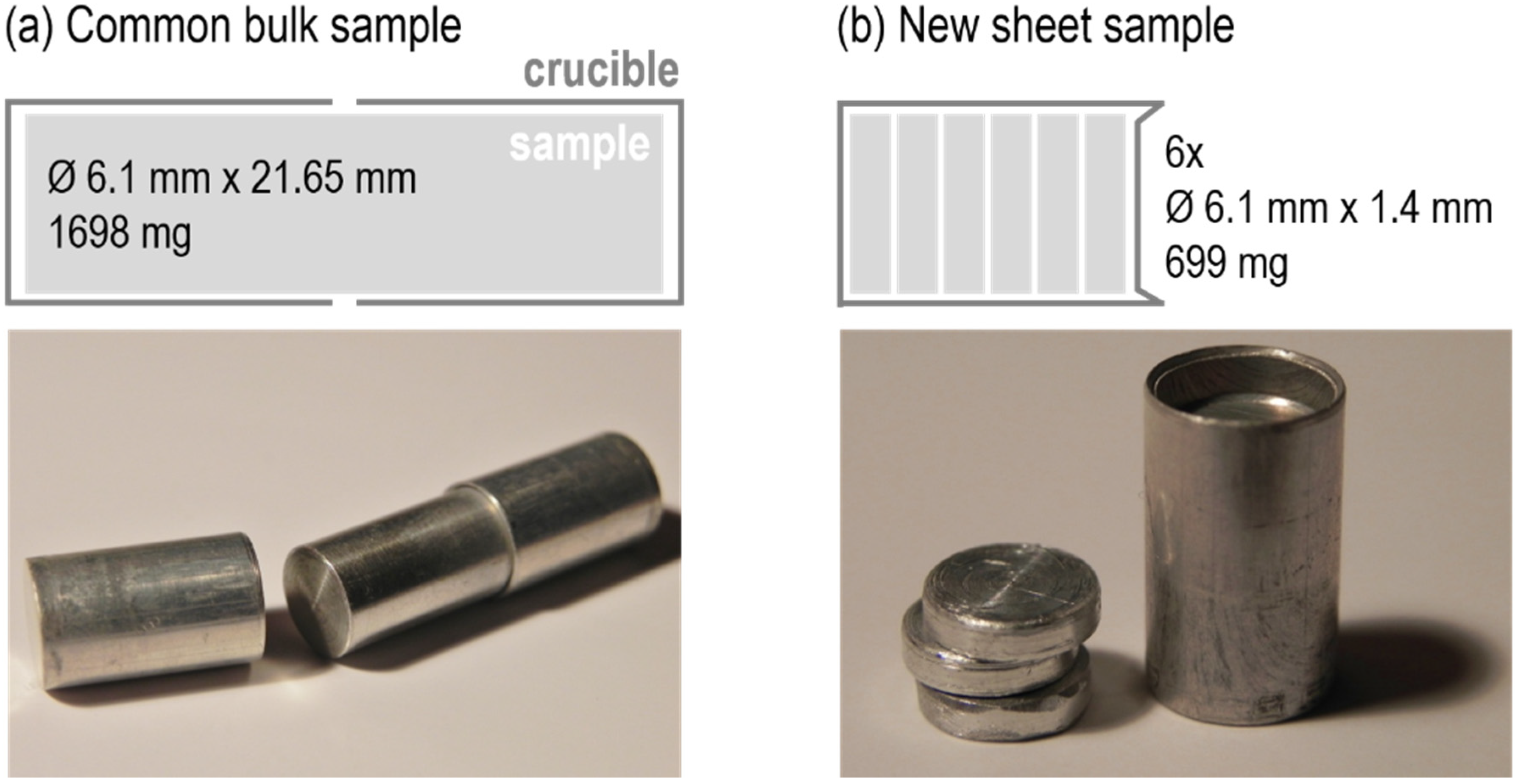

2.3. Specifics for Using Modified Sample Geometries during DSC Measurements

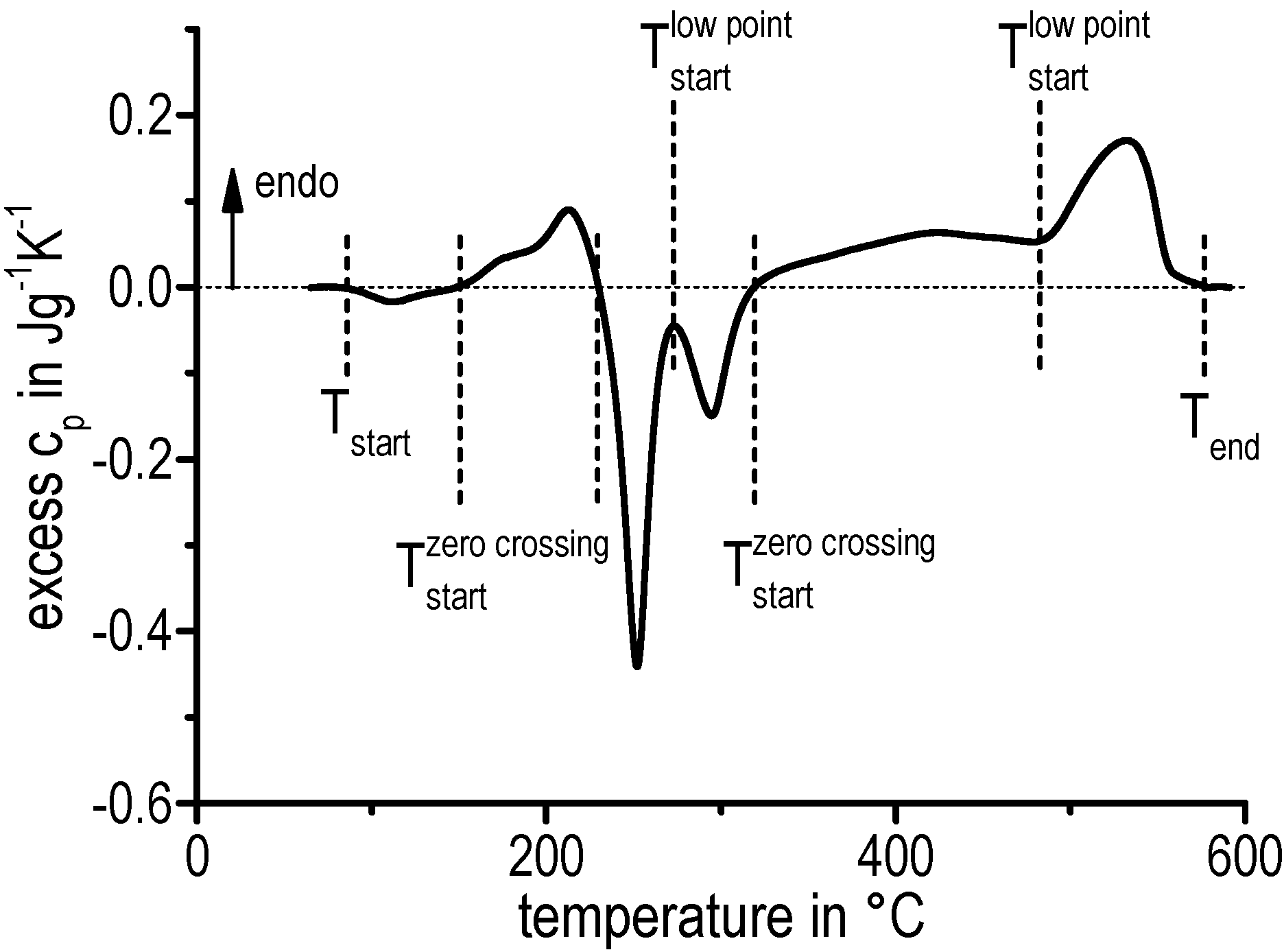

2.4. Evaluation of Heat Flow Curves

3. Results and Discussion

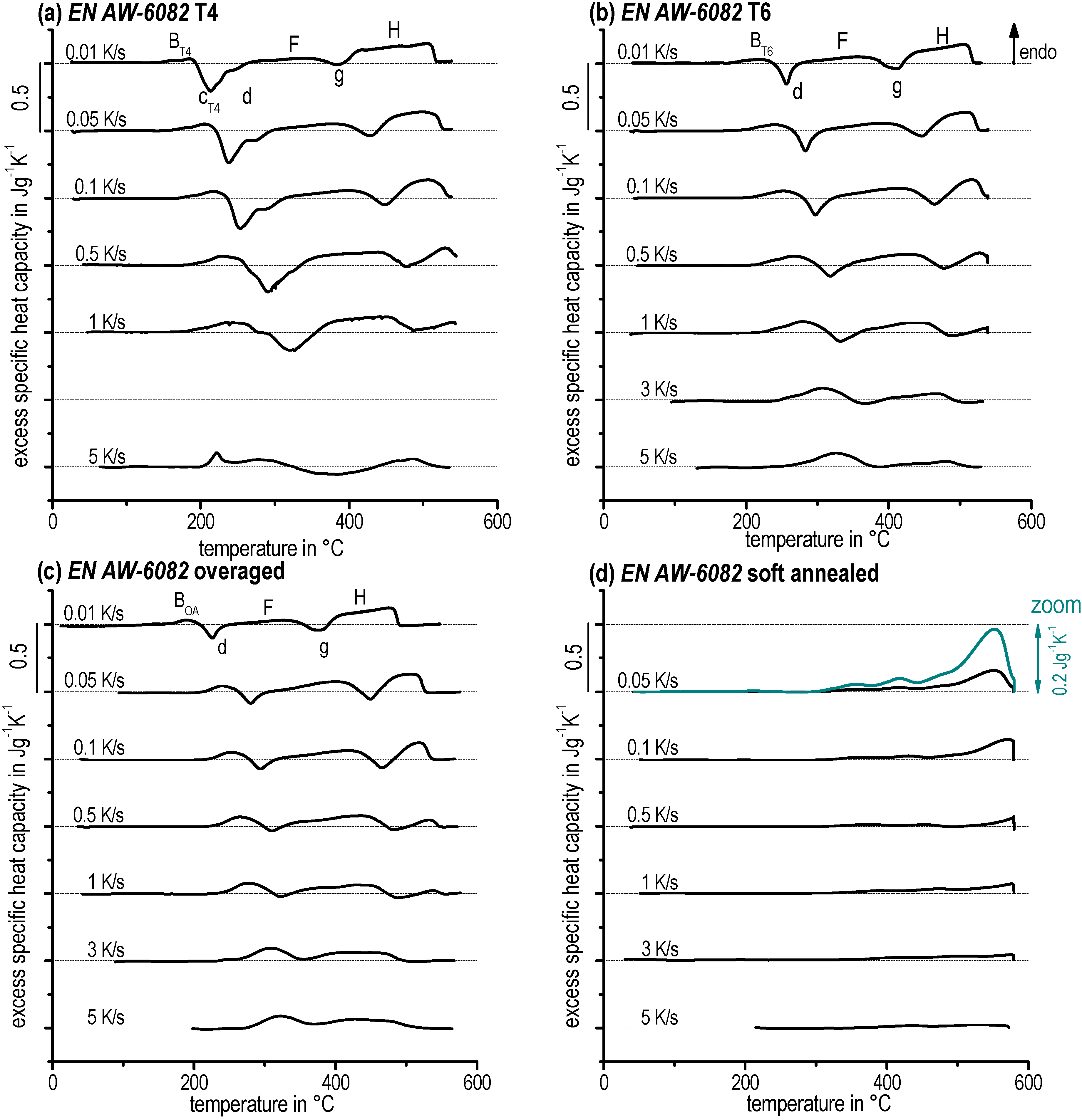

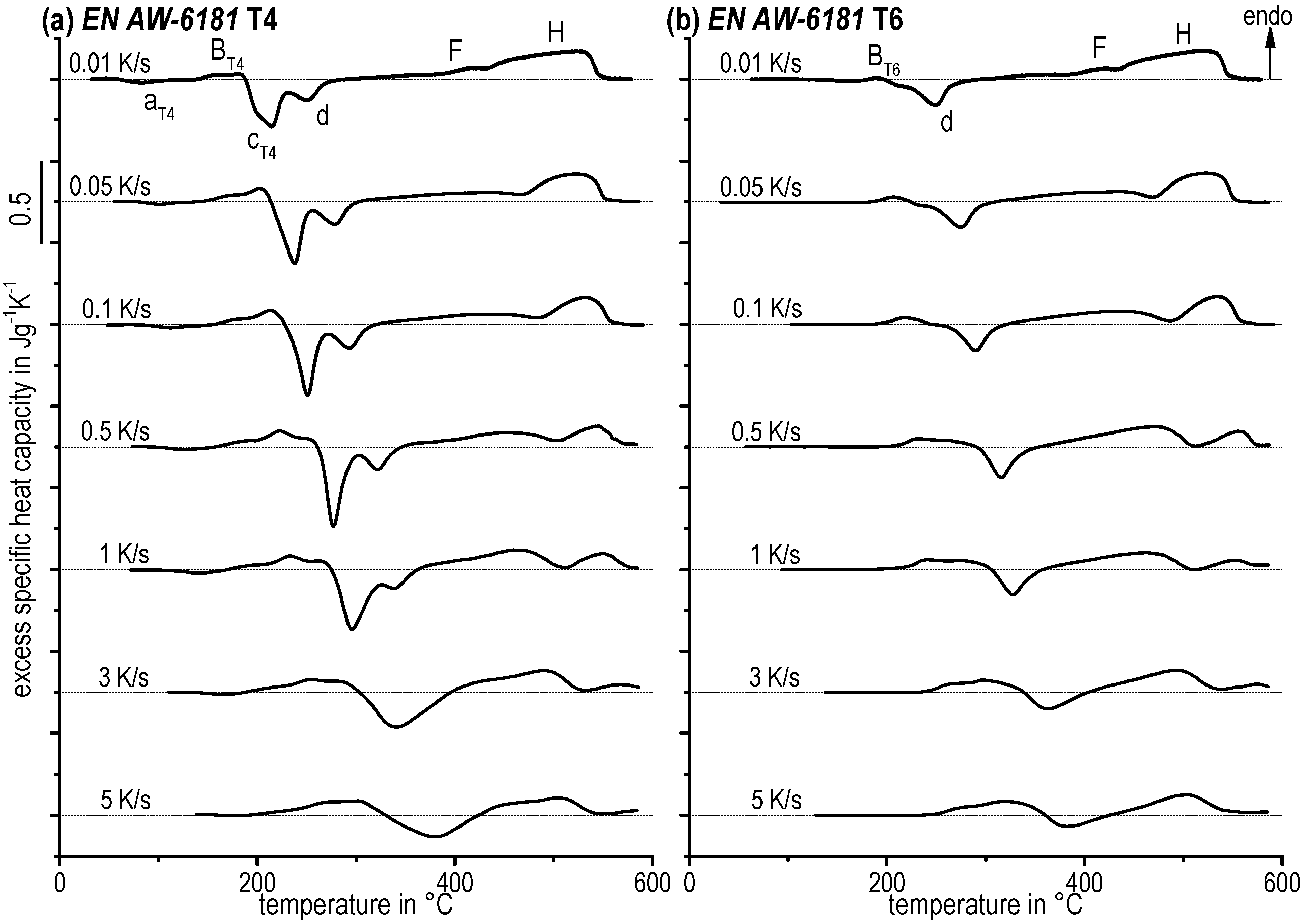

3.1. Excess Specific Heat Capacity Curves

3.2. Dissolution and Precipitation Behaviour in a Wide Range of Heating Rates

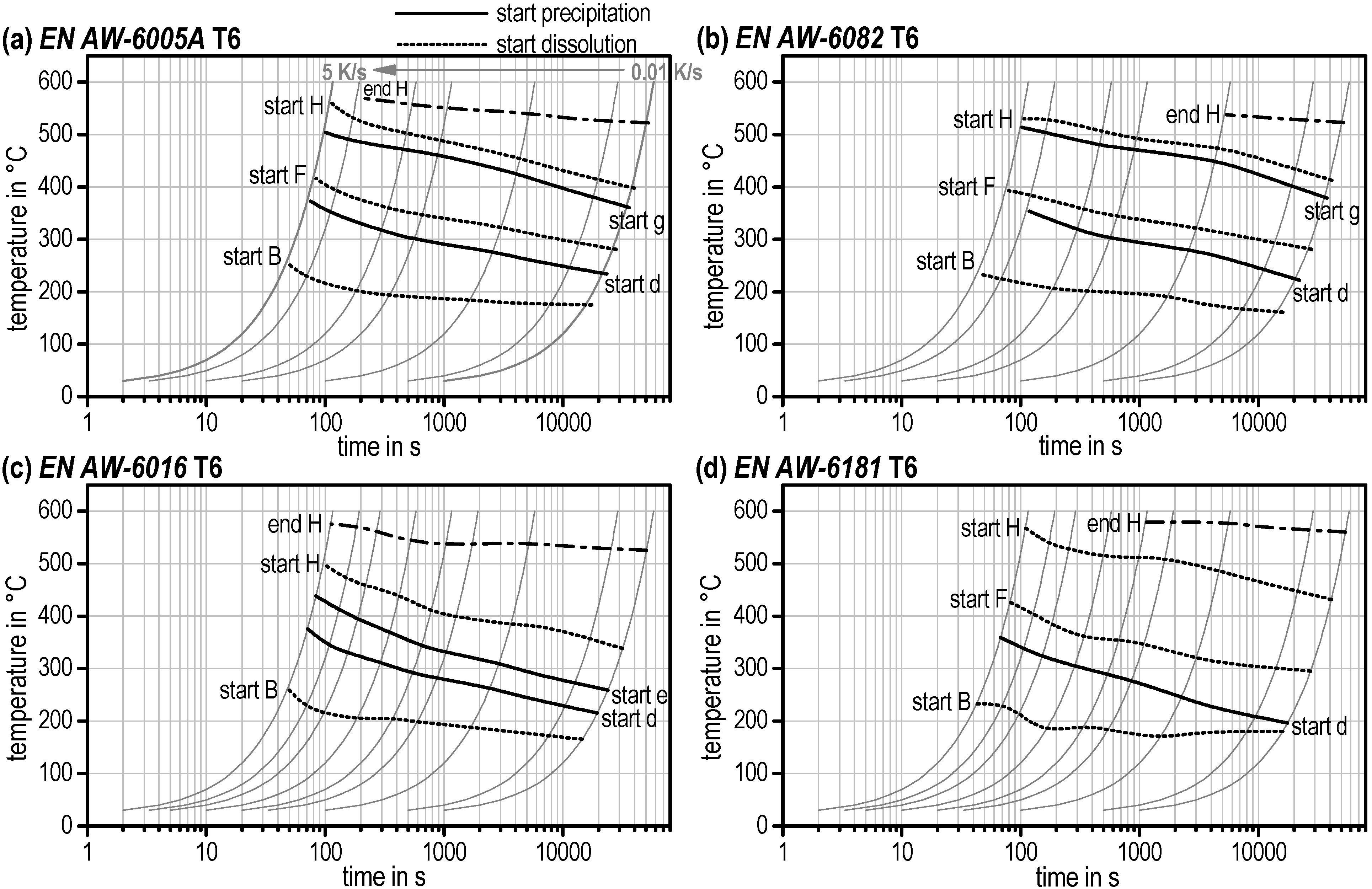

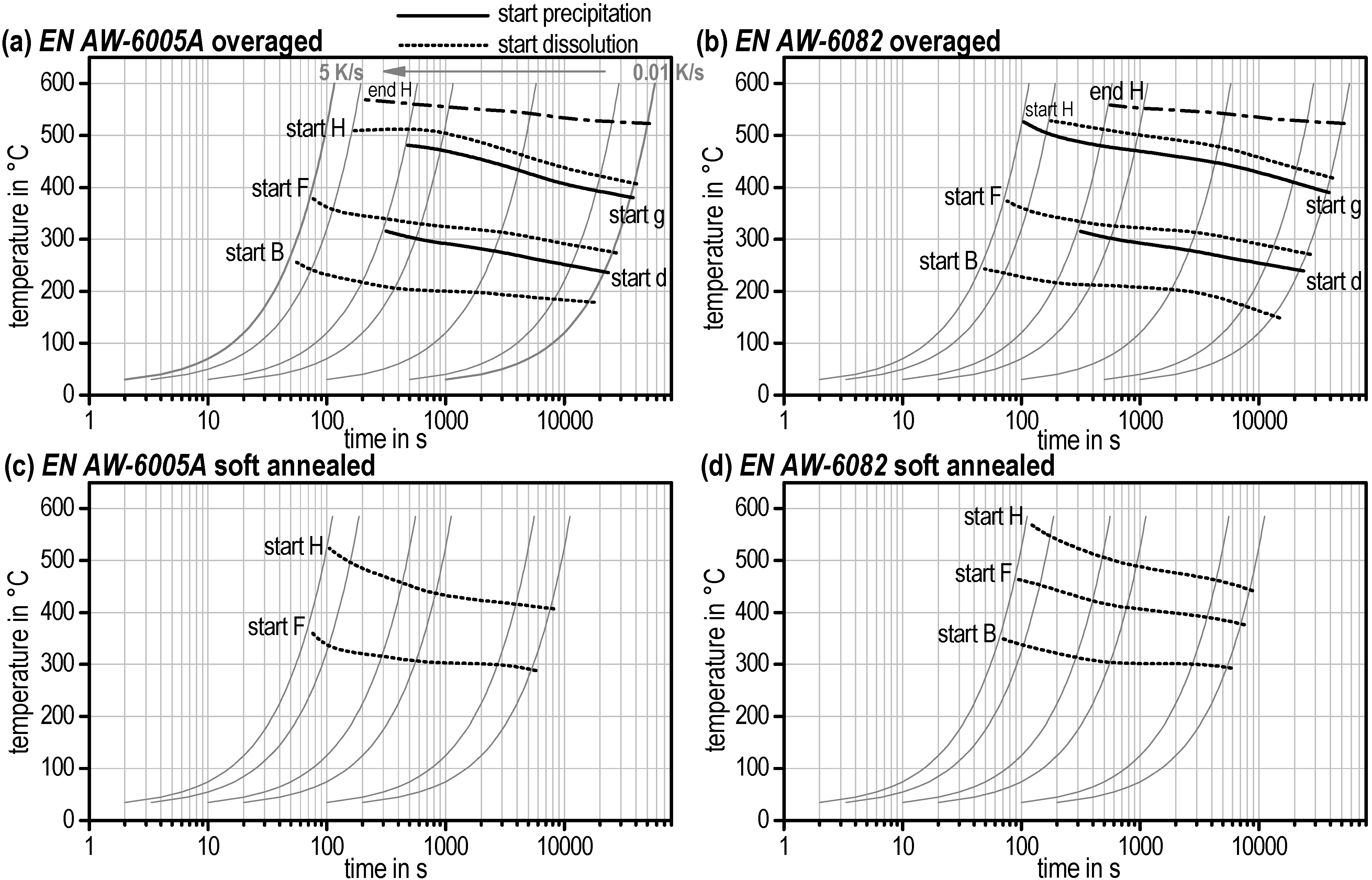

3.3. Continuous Heating Dissolution Diagrams

3.4. Enthalpy Change

| Aluminium Alloy | Enthalpy change in J/g | ||

|---|---|---|---|

| Initial condition | |||

| T4 | T6 | OA | |

| EN AW-6005A | 6 ± 2 | 10 ± 1 | 12 ± 1 |

| EN AW-6082 | 7 ± 3 | 10 ± 1 | 12 ± 1 |

| EN AW-6016 | 3 ± 1 | 7 ± 1 | - |

| EN AW-6181 | 7 ± 1 | 13 ± 1 | - |

4. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Merklein, M.; Johannes, M.; Lechner, M.; Kuppert, A. A review on tailored blanks—Production, applications and evaluation. J. Mater. Process. Technol. 2014, 214, 151–164. [Google Scholar] [CrossRef]

- Osten, J.; Söllig, P.; Reich, M.; Kalich, J.; Füssel, U.; Keßler, O. Softening of high-strength steel for laser assisted clinching. Adv. Mater. Res. 2014, 966–967, 617–627. [Google Scholar] [CrossRef]

- Dutta, I.; Allen, S.M. A calorimetric study of precipitation in commercial aluminium alloy 6061. J. Mater. Sci. Lett. 1991, 10, 323–326. [Google Scholar] [CrossRef]

- Takeda, M.; Ohkubo, F.; Shirai, T.; Fukui, K. Precipitation behaviour of Al–Mg–Si ternary alloys. Mater. Sci. Forum 1996, 217-222, 815–820. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al–Mg–Si alloys. Acta Materialia 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Gupta, A.K.; Lloyd, D.J.; Court, S.A. Precipitation hardening in Al–Mg–Si alloys with and without excess Si. Mater. Sci. Eng. A 2001, 316, 11–17. [Google Scholar] [CrossRef]

- Bryant, J.D. The effects of preaging treatments on aging kinetics and mechanical properties in AA6111 aluminum autobody sheet. Metall. Mater. Trans. A 1999, 30, 1999–2006. [Google Scholar] [CrossRef]

- Matsuda, K.; Ikeno, S.; Terayama, K.; Matsui, H.; Sato, T.; Uetani, Y. Comparison of precipitates between excess Si-type and balanced-type Al–Mg–Si alloys during continuous heating. Metall. Mater. Trans. A 2005, 36, 2007–2012. [Google Scholar] [CrossRef]

- Afify, N.; Gaber, A.; Mostafa, M.S.; Abbady, G. Influence of Si concentration on the precipitation in Al-1 at.% Mg alloy. J. Alloys Compd. 2008, 462, 80–87. [Google Scholar] [CrossRef]

- Ohmori, Y.; Doan, L.C.; Nakai, K. Ageing processes in Al–Mg–Si alloys during continuous heating. Mater. Trans. 2002, 43, 246–255. [Google Scholar] [CrossRef]

- Gaber, A.; Ali, A.M.; Matsuda, K.; Kawabata, T.; Yamazaki, T.; Ikeno, S. Study of the developed precipitates in Al–0.63Mg–0.37Si–0.5Cu (wt.%) alloy by using DSC and TEM techniques. J. Alloys Compd. 2007, 432, 149–155. [Google Scholar] [CrossRef]

- Chen, S.P.; Mussert, K.M.; van der Zwaag, S. Precipitation kinetics in Al6061 and in an Al6061-alumina particle composite. J. Mater. Sci. 1998, 33, 4477–4483. [Google Scholar] [CrossRef]

- Ghosh, K.S.; Das, K.; Chatterjee, U.K. Kinetics of Solid-State Reactions in Al–Li–Cu–Mg–Zr Alloys from Calorimetric Studies. Metall. Mater. Trans. A 2007, 38, 1965–1975. [Google Scholar] [CrossRef]

- Starink, M.J. The determination of activation energy from linear heating rate experiments: A comparison of the accuracy of isoconversion methods. Thermochim. Acta 2003, 404, 163–176. [Google Scholar] [CrossRef]

- Starink, M.J. Analysis of aluminium based alloys by calorimetry: quantitative analysis of reactions and reaction kinetics. Int. Mater. Rev. 2004, 49, 191–226. [Google Scholar] [CrossRef]

- Höhne, G.W.H.; Glöggler, E. Some peculiarities of the DSC-2/-7 (Perkin-Elmer) and their influence on accuracy and precision of the measurements. Thermochim. Acta 1989, 151, 295–304. [Google Scholar] [CrossRef]

- Milkereit, B.; Kessler, O.; Schick, C. Recording of continuous cooling precipitation diagrams of aluminium alloys. Thermochim. Acta 2009, 492, 73–78. [Google Scholar] [CrossRef]

- Höhne, G.; Hemminger, W.; Flammersheim, H.-J. Differential Scanning Calorimetry: An Introduction for Practitioners, 2nd ed.; Springer: Berlin, Germany, 2003. [Google Scholar]

- Doan, L.C.; Ohmori, Y.; Nakai, K. Precipitation and dissolution reactions in a 6061 aluminum alloy. Mater. Trans. 2000, 41, 300–305. [Google Scholar] [CrossRef]

- Ohmori, Y.; Doan, L.C.; Matsuura, Y.; Kobayashi, S.; Nakai, K. Morphology and crystallography of β-Mg2Si precipitation in Al–Mg–Si alloys. Mater. Trans. 2001, 42, 2576–2583. [Google Scholar] [CrossRef]

- Birol, Y. DSC Analysis of the precipitation reactions in the alloy AA6082. J. Therm. Anal. Calorim. 2006, 83, 219–222. [Google Scholar] [CrossRef]

- Birol, Y. DSC analysis of the precipitation reaction in AA6005 alloy. J. Therm. Anal. Calorim. 2008, 93, 977–981. [Google Scholar] [CrossRef]

- Kim, S.N.; Kim, J.H.; Tezuka, H.; Kobayashi, E.; Sato, T. Formation behaviour of nanoclusters in Al–Mg–Si alloys with different Mg and Si concentration. Mater. Trans. 2013, 54, 297–303. [Google Scholar] [CrossRef]

- Murayama, M.; Hono, K. Pre-precipitate clusters and precipitation processes in Al–Mg–Si alloys. Acta Mater. 1999, 47, 1537–1548. [Google Scholar] [CrossRef]

- Polmear, I.J. Light Alloys: From Traditional Alloys to Nanocrystals, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2005. [Google Scholar]

- Marioara, C.D.; Andersen, S.J.; Jansen, J.; Zandbergen, H.W. The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al–Mg–Si alloy. Acta Materialia 2003, 51, 789–796. [Google Scholar] [CrossRef]

- Tsao, C.-S.; Chen, C.-Y.; Jeng, U.-S.; Kuo, T.-Y. Precipitation kinetics and transformation of metastable phases in Al–Mg–Si alloys. Acta Materialia 2006, 54, 4621–4631. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Uggowitzer, P.J. Influence of starting temperature on differential scanning calorimetry measurements of an Al–Mg–Si alloy. Mater. Lett. 2013, 100, 163–165. [Google Scholar] [CrossRef]

- Starink, M.J. Activation energy determination for linear heating experiments: Deviations due to neglecting the low temperature end of the temperature integral. J. Mater. Sci. 2007, 42, 483–489. [Google Scholar] [CrossRef]

- Lang, P.; Povoden-Karadeniz, E.; Falahati, A.; Kozeschnik, E. Simulation of the effect of composition on the precipitation in 6xxx Al alloys during continuous-heating DSC. J. Alloys Compd. 2014, 612, 443–449. [Google Scholar] [CrossRef]

- Falahati, A.; Povoden-Karadeniz, E.; Lang, P.; Warczok, P.; Kozeschnik, E. Thermo-kinetic computer simulation of differential scanning calorimetry curves of AlMgSi alloys. Int. J. Mater. Res. 2010, 101, 1089–1096. [Google Scholar] [CrossRef]

- Falahati, A.; Wu, J.; Lang, P.; Ahmadi, M.R.; Povoden-Karadeniz, E.; Kozeschnik, E. Assessment of parameters for precipitation simulation of heat treatable aluminum alloys using differential scanning calorimetry. Trans. Nonferr. Met. Soc. 2014, 24, 2157–2167. [Google Scholar] [CrossRef]

- Hersent, E.; Driver, J.H.; Piot, D. Modelling differential scanning calorimetry curves of precipitation in Al–Cu–Mg. Scripta Materialia 2010, 62, 455–457. [Google Scholar] [CrossRef]

- Khan, I.N.; Starink, M.J. Microstructure and strength modelling of Al-Cu-Mg alloys during non-isothermal treatments Part 1—Controlled heating and cooling. Mater. Sci. Technol. 2008, 24, 1403–1410. [Google Scholar] [CrossRef]

- Milkereit, B.; Wanderka, N.; Schick, C.; Kessler, O. Continuous cooling precipitation diagrams of Al–Mg–Si alloys. Mater. Sci. Eng. A 2012, 550, 87–96. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osten, J.; Milkereit, B.; Schick, C.; Kessler, O. Dissolution and Precipitation Behaviour during Continuous Heating of Al–Mg–Si Alloys in a Wide Range of Heating Rates. Materials 2015, 8, 2830-2848. https://doi.org/10.3390/ma8052830

Osten J, Milkereit B, Schick C, Kessler O. Dissolution and Precipitation Behaviour during Continuous Heating of Al–Mg–Si Alloys in a Wide Range of Heating Rates. Materials. 2015; 8(5):2830-2848. https://doi.org/10.3390/ma8052830

Chicago/Turabian StyleOsten, Julia, Benjamin Milkereit, Christoph Schick, and Olaf Kessler. 2015. "Dissolution and Precipitation Behaviour during Continuous Heating of Al–Mg–Si Alloys in a Wide Range of Heating Rates" Materials 8, no. 5: 2830-2848. https://doi.org/10.3390/ma8052830