Effect of Solids-To-Liquids, Na2SiO3-To-NaOH and Curing Temperature on the Palm Oil Boiler Ash (Si + Ca) Geopolymerisation System

Abstract

:1. Introduction

2. Results and Discussion

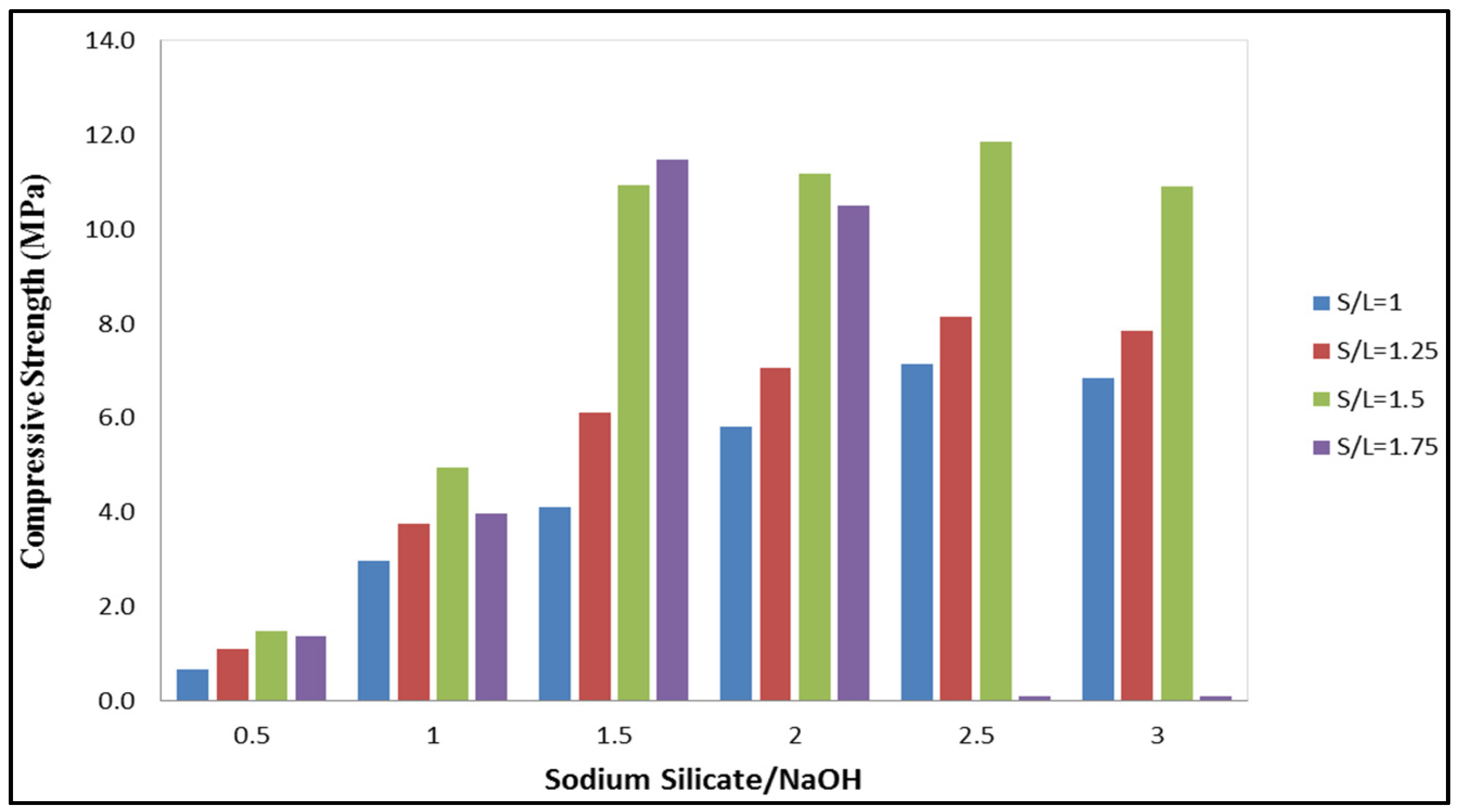

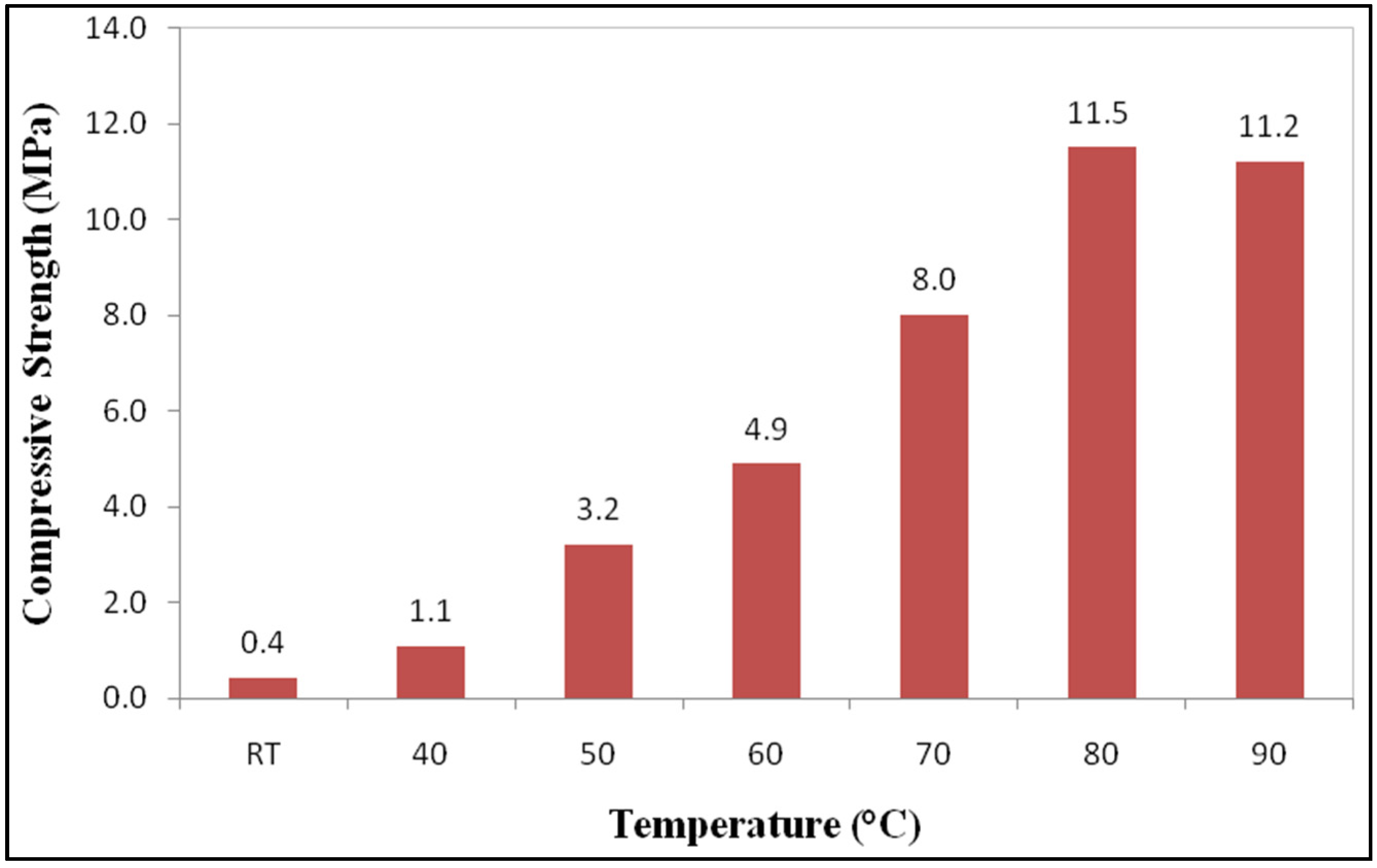

2.1. Compressive Strength

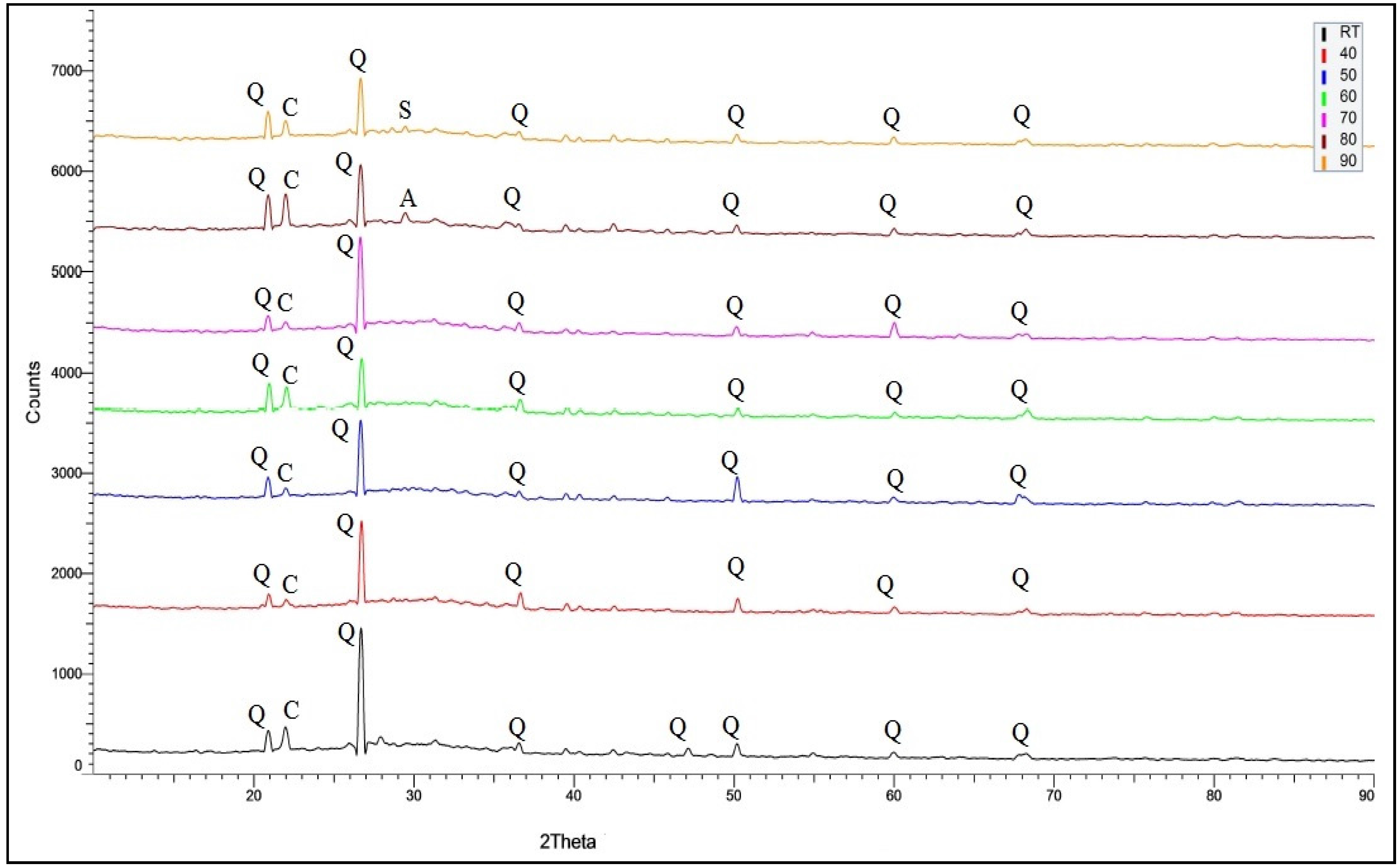

2.2. X-Ray Diffraction (XRD) Analysis

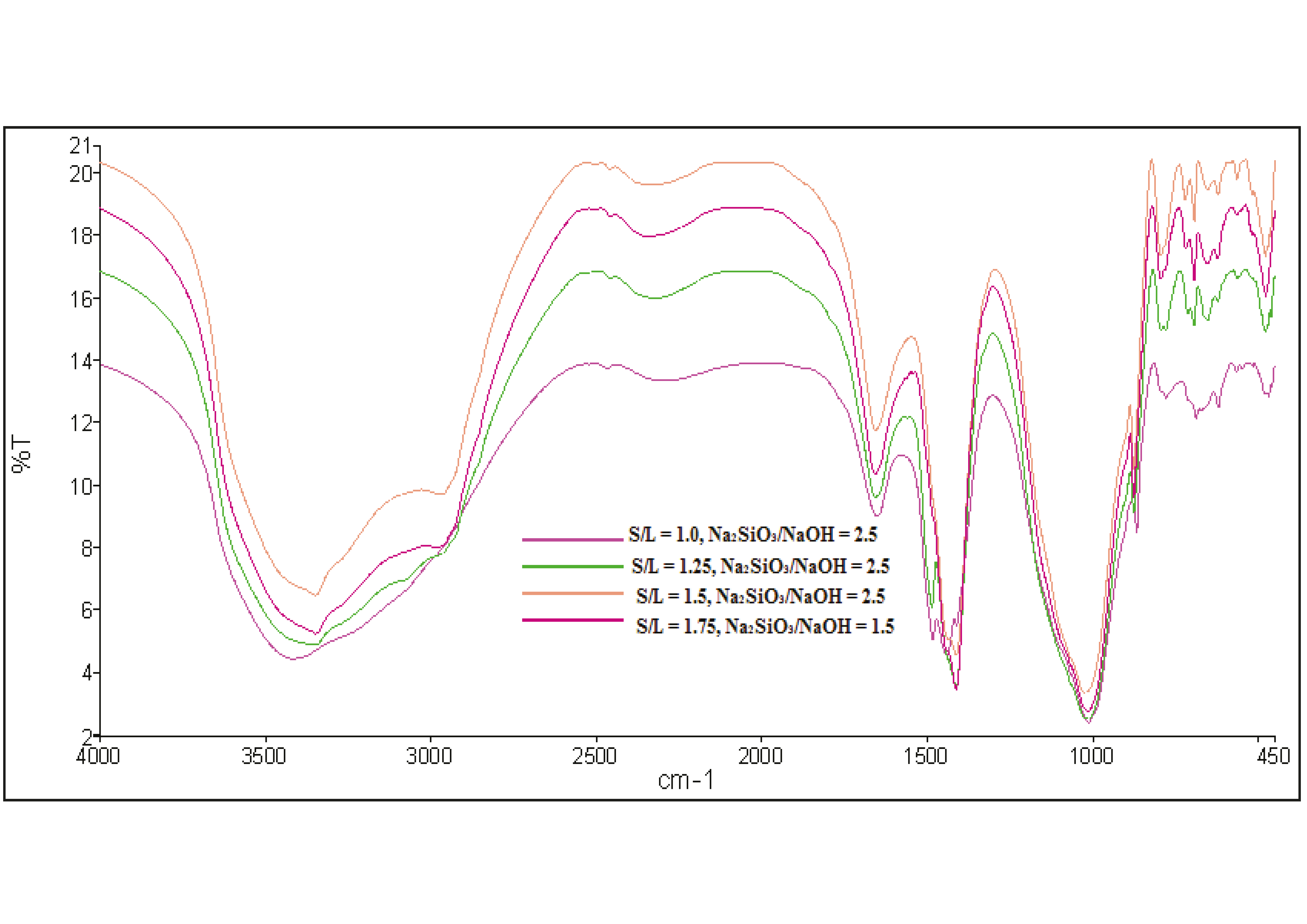

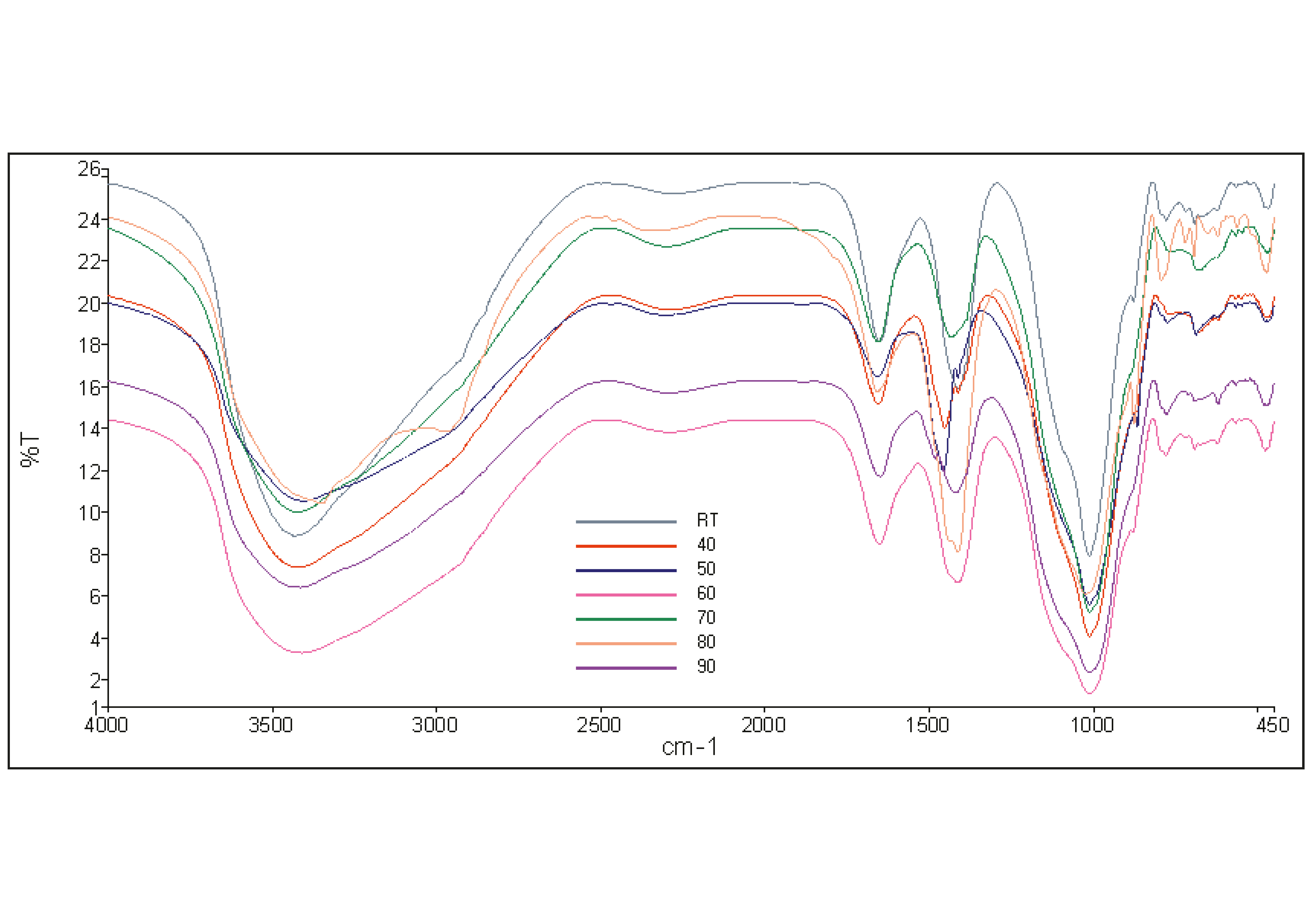

2.3. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

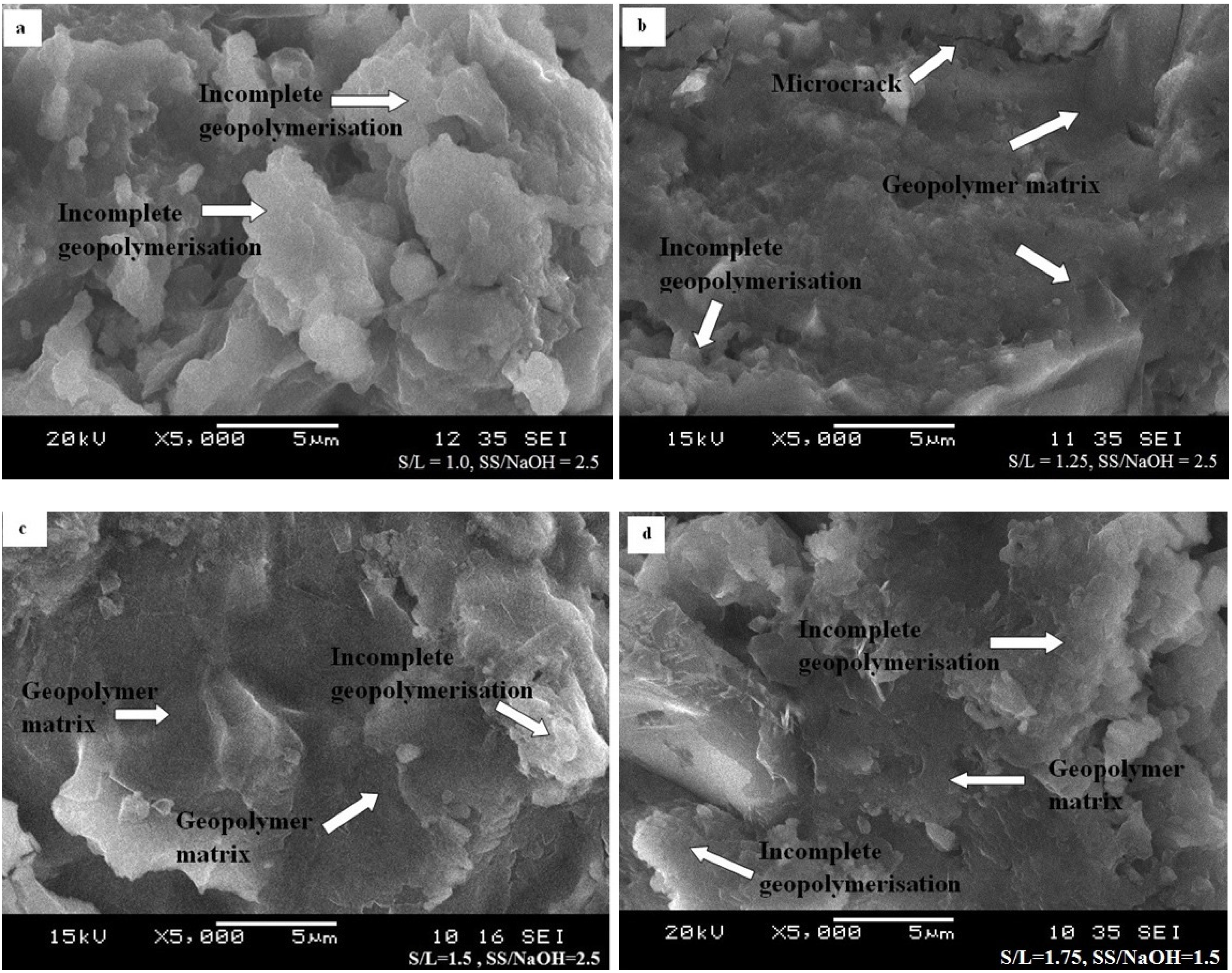

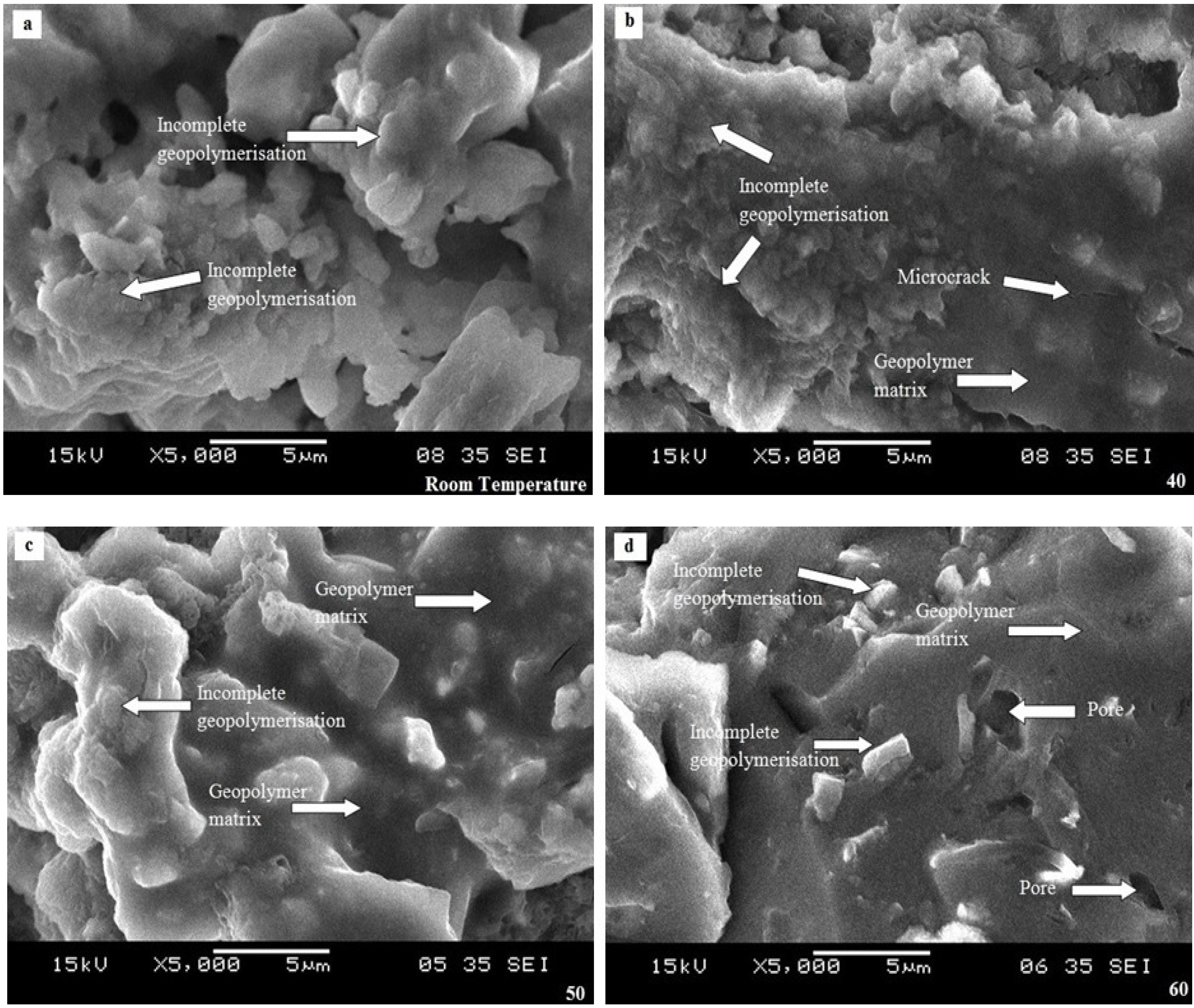

2.4. Scanning Electron Microscope (SEM) Analysis

3. Experimental Section

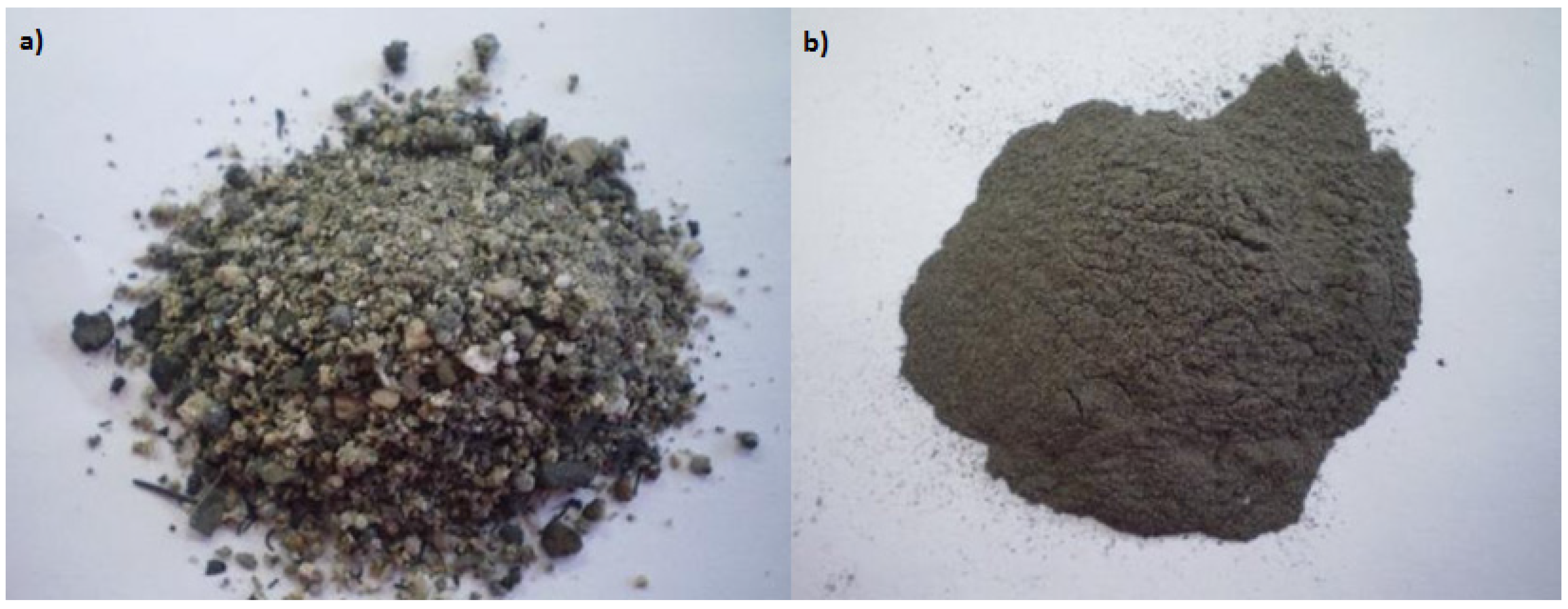

3.1. Material

| No. | Compositions | POBA (wt%) |

|---|---|---|

| 1 | SiO2 | 40.60 |

| 2 | Al2O3 | 3.71 |

| 3 | Fe2O3 | 15.74 |

| 4 | CaO | 19.60 |

| 5 | MgO | 1.30 |

| 6 | P2O5 | 2.73 |

| 7 | K2O | 13.80 |

| 8 | SO3 | 0.44 |

| 9 | TiO2 | 0.35 |

| 10 | MnO | 0.28 |

3.2. Mix Design

3.2.1. Solids-to-Liquids (S/L) and Na2SiO3/NaOH

3.2.2. Various Curing Temperatures

| S/L Ratio | Na2SiO3/NaOH Ratio | Mass of Solid (g) | Na2SiO3 Solution (g) | NaOH Solution (g) |

|---|---|---|---|---|

| 1.0 | 0.5 | 480 | 160.0 | 320.0 |

| 1.0 | 240.0 | 240.0 | ||

| 1.5 | 288.0 | 192.0 | ||

| 2.0 | 320.0 | 160.0 | ||

| 2.5 | 342.9 | 137.1 | ||

| 3.0 | 360.0 | 120.0 | ||

| 1.25 | 0.5 | 480 | 128.0 | 256.0 |

| 1.0 | 192.0 | 192.0 | ||

| 1.5 | 230.4 | 153.6 | ||

| 2.0 | 256.0 | 128.0 | ||

| 2.5 | 274.3 | 109.7 | ||

| 3.0 | 288.0 | 96.0 | ||

| 1.5 | 0.5 | 480 | 106.7 | 213.3 |

| 1.0 | 160.0 | 160.0 | ||

| 1.5 | 192.0 | 128.0 | ||

| 2.0 | 213.3 | 106.7 | ||

| 2.5 | 228.6 | 91.4 | ||

| 3.0 | 240.0 | 80.0 | ||

| 1.75 | 0.5 | 480 | 91.4 | 182.9 |

| 1.0 | 137.1 | 137.1 | ||

| 1.5 | 164.6 | 109.7 | ||

| 2.0 | 182.9 | 91.4 | ||

| 2.5 | 195.9 | 78.4 | ||

| 3.0 | 205.7 | 68.6 |

3.3. Mixing Process

3.4. Testing

3.4.1. Compressive Strength

3.4.2. X-Ray Diffraction (XRD)

3.4.3. Fourier Transform Infrared Spectroscopy (FTIR)

3.4.4. Microstructure Analysis

4. Conclusions

- (a)

- The optimum mix design for geopolymer paste using POBA is S/L = 1.5 and Na2SiO3/NaOH = 2.5 with maximum compressive strength 11.9 MPa. During XRD analysis, the existence of albite which is due to the formation of an aluminosilicate gel was detected in the optimum mix design. The ratio of Na2SiO3/NaOH also plays an important role in the mix design of the geopolymer paste. When the ratio of Na2SiO3/NaOH is more than 2.5, the compressive strength for S/L (1.0, 1.25, and 1.5) tends to decrease due to excessive alkali content that retards the geopolymerisation process.

- (b)

- The optimum curing temperature for POBA in this study was 80 °C which led to maximum compressive strength (11.5 MPa) at 24 h curing period. Thus, heat curing for geopolymer is needed in order to obtain sufficient strength and with heat curing, the geopolymerisation becomes more rapid. The presence of albite during XRD analysis was also detected in the geopolymer sample cured at 80 °C. The morphology of the geopolymer samples showed changes in the matrix when the curing temperature was increased.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Alkali-activated binders: A review. Part 1. Historical background, terminology, reaction mechanism and hydration products. Constr. Build. Mater. 2008, 22, 1305–1314. [Google Scholar] [CrossRef] [Green Version]

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A review and prospect for the mineral industry. Miner. Eng. 2007, 20, 1261–1277. [Google Scholar] [CrossRef]

- Davidovits, J. Soft mineralurgy and geopolymer. In Proceedings of the 1st International Conference on Geopolymer '88, Compiegne, France, 1–3 June 1988; Davidovits, J., Orlinski, J., Eds.; Volume 1, pp. 19–23.

- Hermann, E.; Kunze, C.; Gatzweiler, R.; Davidovits, J. Solidification of various radioactive residues by geopolymer with special emphasis on long term stability. In Proceedings of the Geopolymers Conference, Saint-Quentin, France, 30 June 1999.

- Rafiza, A.R.; Mustafa Al Bakri, M.A.; Kamarudin, H.; Khairul Nizar, I.; Ioan, G.S.; Hardjito, D.; Zarina, Y.; Andrei, V.S. Assessment on the potential of volcano ash as artificial lightweight aggregates using geopolymerisation method. Revista de Chimie 2014, 65, 828–834. [Google Scholar]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes, a cement for the future. Cement Concrete Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Xu, H.; van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- Van jaarsveld, J.G.S.; van Deventer, J.S.J.; Lukey, G.C. The effect of composition and temperature on the properties of fly ash and kaolinite-based geopolymers. Chem. Eng. J. 2002, 89, 63–73. [Google Scholar]

- Yao, X.; Zhang, Z.; Zhu, H.; Chen, Y. Geopolymerization Process of alkali-metakaolinite characterized by isothermal calorimetry. Thermochim. Acta 2009, 493, 49–54. [Google Scholar] [CrossRef]

- Zuhua, Z.; Xiao, Y.; Yue, C. Role of water in the synthesis of calcined kaolin-based geopolymer. Appl. Clay Sci. 2009, 43, 218–223. [Google Scholar] [CrossRef]

- Provis, J.L.; Yong, C.Z.; Duxson, P.; van Deventer, J.S.J. Correlating mechanical and thermal properties of sodium silicate-fly ash geopolymers. Colloids Surf. A: Physicochem. Eng. Asp. 2009, 336, 57–63. [Google Scholar] [CrossRef]

- Villa, C.; Pecina, E.T.; Torres, R.; Gomez, L. Geopolymer synthesis using alkaline activation of natural zeolite. Constr. Build. Mater. 2010, 24, 2084–2090. [Google Scholar] [CrossRef]

- Lee, W.K.W.; van Deventer, J.S.J. The effects of inorganic salt contamination on the strength and durability of geopolymers. Colloids Surf. A: Physicochem. Eng. Asp. 2002, 211, 115–126. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cement Concrete Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. Development fly ash-based geopolymer concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. Fly ash-based geopolymer concrete. Austr. J. Struct. Eng. 2005, 6, 1–9. [Google Scholar]

- Hardjito, D.; Cheak, C.C.; Ing, C.H.L. Strength and setting times of low calcium fly ash-based geopolymer mortar. Mod. Appl. Sci. 2008, 2, 3–11. [Google Scholar] [CrossRef]

- Hardjito, D.; Rangan, B.V. Development and properties of low-calcium fly ash based geopolymer concrete. In Research Report GC1; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2005. [Google Scholar]

- Matthew, R.; Brian, O.C. Chemical optimisation of the compressive strength of luminosilicate geopolymers synthesised by sodium silicate activation of metakaolinite. J. Mater. Chem. 2003, 13, 1161–1165. [Google Scholar] [CrossRef]

- Wan Mastura, W.I.; Mustafa Al Bakri, A.M.; Andrei, V.S.; Kamarudin, H.; Ioan, G.S.; Khairul Nizar, I.; Aeslina, A.K.; Binhussain, M. Processing and characterization of fly ash-based geopolymer bricks. Revista de Chimie 2014, 65, 1340–1345. [Google Scholar]

- Bakharev, T. Geopolymeric materials prepared using class F fly ash and elevated temperature curing. Cement Concrete Res. 2005, 25, 1224–1232. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Fernandez-Jimenez, A.; Palomo, A.; Macphee, D.E. Effect of Fresh C-S-H gels of the simultaneous addition of alkali and aluminium. Cement Concrete Res. 2010, 40, 27–32. [Google Scholar] [CrossRef]

- Alvarez-Ayuso, E.; Querol, X.; Plana, F.; Alastuey, A.; Moreno, N.; Izquierdo, M.; Font, O.; Moreno, T.; Diez, S.; Vázquez, E.; Barra, M. Environmental, physical and structural characterisation of geopolymer matrixes synthesised from coal (co-) combustion fly ashes. J. Hazard. Mater. 2008, 154, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Panias, D.; Giannopoulou, I.P.; Perraki, T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids Surf. A 2007, 301, 246–254. [Google Scholar] [CrossRef]

- Nath, S.K.; Kumar, S. Influence of iron making slags on strength and microstructure of fly ash geopolymer. Constr. Build. Mater. 2013, 38, 924–930. [Google Scholar] [CrossRef]

- Jaarsveld, J.G.S.; Deventer, J.S.J.; Lukey, G.C. The characterization of source materials in fly ash-based geopolymers. Mater. Lett. 2003, 57, 1272–1280. [Google Scholar] [CrossRef]

- Zarina, Y.; Mustafa Al Bakri, A.M.; Kamarudin, H.; Khairul Nizar, I.; Andrei, V.S.; Petrica, V.; Rafiza, A.R. Chemical and physical characterization of boiler ash from palm oil industry waste for geopolymer composite. Revista de Chimie 2013, 64, 1408–1412. [Google Scholar]

- Chub-uppakarn, T.; Thaenlek, N.; Thaisiam, R. Palm ash-based geopolymer mortar incorporating metakaolin. In Proceedings of the Pure and Applied Chemistry International Conference, Bangkok, Thailand, 5–7 January 2011; pp. 347–350.

- Ariffin, M.A.M.; Hussin, M.; Warid, M.; Rafique Bhutta, M.A. Mix design and compressive strength of geopolymer concrete containing blended ash from agro-industrial wastes. Adv. Mater. Res. 2011, 339, 452–457. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.; Kamarudin, H.; Mohammed, H.; Khairul Nizar, I.; Rafiza, A.R.; Zarina, Y. The relationship of NaOH molarity, Na2SiO3/NaOH ratio, fly ash/alkaline activator ratio and curing temperature to the strength of fly ash-based geopolymer. Adv. Mater. Res. 2011, 328, 1475–1482. [Google Scholar] [CrossRef]

- Mustafa Al Bakri, A.M.; Kamarudin, H.; Binhussain, M.; Rafiza, A.R.; Zarina, Y. Effect of Na2SiO3/NaOH ratios and NaOH molarities on compressive strength of fly-ash-based geopolymer. ACI Mater. J. 2012, 109, 503–508. [Google Scholar]

- </b>Mustafa Al Bakri, A.M.; Kamarudin, H.; BinHussain, M.; Khairul Nizar, I.; Zarina, Y.; Rafiza, A.R. The effect of curing temperature on physical and chemical properties of geopolymers. Phys. Procedia 2011, 22, 286–291. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yahya, Z.; Abdullah, M.M.A.B.; Hussin, K.; Ismail, K.N.; Razak, R.A.; Sandu, A.V. Effect of Solids-To-Liquids, Na2SiO3-To-NaOH and Curing Temperature on the Palm Oil Boiler Ash (Si + Ca) Geopolymerisation System. Materials 2015, 8, 2227-2242. https://doi.org/10.3390/ma8052227

Yahya Z, Abdullah MMAB, Hussin K, Ismail KN, Razak RA, Sandu AV. Effect of Solids-To-Liquids, Na2SiO3-To-NaOH and Curing Temperature on the Palm Oil Boiler Ash (Si + Ca) Geopolymerisation System. Materials. 2015; 8(5):2227-2242. https://doi.org/10.3390/ma8052227

Chicago/Turabian StyleYahya, Zarina, Mohd Mustafa Al Bakri Abdullah, Kamarudin Hussin, Khairul Nizar Ismail, Rafiza Abd Razak, and Andrei Victor Sandu. 2015. "Effect of Solids-To-Liquids, Na2SiO3-To-NaOH and Curing Temperature on the Palm Oil Boiler Ash (Si + Ca) Geopolymerisation System" Materials 8, no. 5: 2227-2242. https://doi.org/10.3390/ma8052227