1. Introduction

Electron tomography is a technique to visualize three-dimensional (3D) structures inside materials in a transmission electron microscope (TEM) with the aid of computational reconstruction processes. This technique has been applied for various fields of materials science so far [

1]. One of the recent challenges in 3D tomography is the visualization of dislocations in metals and other materials. 3D tomographic observation of dislocations was firstly reported for a GaN single crystal specimen using the weak-beam dark-field (DF) transmission electron microscopy (TEM) imaging method [

2,

3]. Because of the invisible criterion (

g•

b = 0;

g and

b are, respectively, the excited reciprocal lattice vector and Burgers vector in concern) [

4], excitation of a selected

ghkl throughout the tilt-series acquisition is mandatory for dislocation tomography. After the pioneering work by Sharp

et al. 3D visualization of lattice defects including dislocations has been demonstrated by several researchers for materials including Si [

5], stainless steel [

6,

7], Al [

8], and nanoparticles [

9,

10]. These works have mainly focused on the development and verification of novel techniques; therefore, materials for 3D observation have been mostly limited in specimens with a single-crystal or large grains. Our attempt here is to visualize dislocations in a rather narrow area in two-phase alloys. For this purpose, we selected a quenched Ti–35mass%Nb alloy composed of a so-called α'' martensite with an orthorhombic structure and a small amount of the β phase with a body centered cubic (bcc) structure [

11]. The alloy system has been attracted for biomedical applications due to their excellent biocompatibility, high corrosion resistance, low Young’s modulus, high strength, toughness, and so on [

12]. In general, the β phase contributes primarily to ductility and workability of the two-phase alloy, because it is softer than the α'' martensite. It is also noted that there is few report on the dislocation tomography of bcc crystals. Therefore, a proper characterization of dislocations in the β phase is necessary for better understanding mechanical properties of two-phase Ti-alloys.

In this study, we have examined 3D visualization of dislocations in β phase of a Ti–Nb alloy using single-axis tilt tomography. We employed bright-field scanning transmission electron microscopy (BF-STEM) for imaging dislocations by exciting hh0 systematic reflections parallel to the tilt axis. Effects of lowness in contrasts and the maximum tilt angle on the shapes and width of reconstructed dislocations are discussed.

3. Results

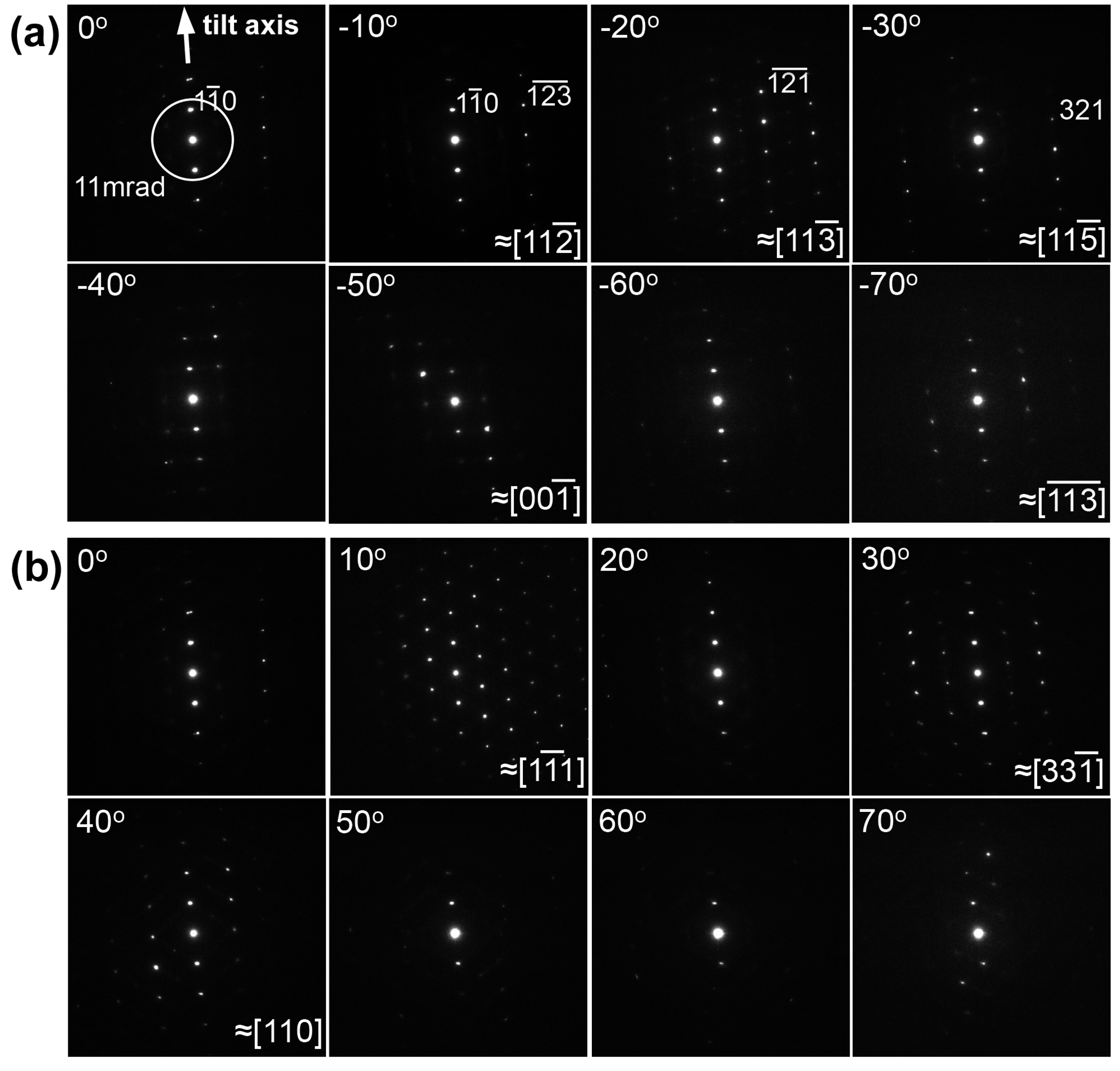

Figure 1 shows a series of selected area electron diffraction (SAED) patterns obtained from the β phase region. All these patterns were obtained using parallel beam illumination. Tilt angles are shown in the upper left corner of each pattern. As seen,

hh0 systematic reflections are excited along the tilt axis of the triple-axes holder. The circle indicates the outer collection angle of 11 mrad of the BF-detector used for STEM imaging; hence only three beams, 000, 1

0 and

10 are contributed to the image formation.

Figure 1.

Tilt-series of selected area electron diffraction (SAED) patterns obtained from the β phase region in a Ti–35mass%Nb alloy. The hh0 systematic reflections are excited parallel to the tilt axis. (a) SAED patterns obtained at tilt angles from 0° to −70°, and (b) those from 0° to 70°.

Figure 1.

Tilt-series of selected area electron diffraction (SAED) patterns obtained from the β phase region in a Ti–35mass%Nb alloy. The hh0 systematic reflections are excited parallel to the tilt axis. (a) SAED patterns obtained at tilt angles from 0° to −70°, and (b) those from 0° to 70°.

As can be seen, zone axis patterns, such as [11

], [11

], [11

], or [001], appear during the specimen tilting of up to ±70°. It should be noted that

ghkl = 1

0 is satisfied even at a tilt angle as high as 70°. Thus, the invisible criterion (

g•

b = 0) is maintained throughout the tilt-series acquisition. It can also be noted that zone axes of [11

] and [

] are apart from each other by 50.5° in a cubic crystal, and accordingly that these two patterns were obtained at the stage tilt angle of −20° and −70°, respectively, further demonstrating that the tilting axis is parallel to the

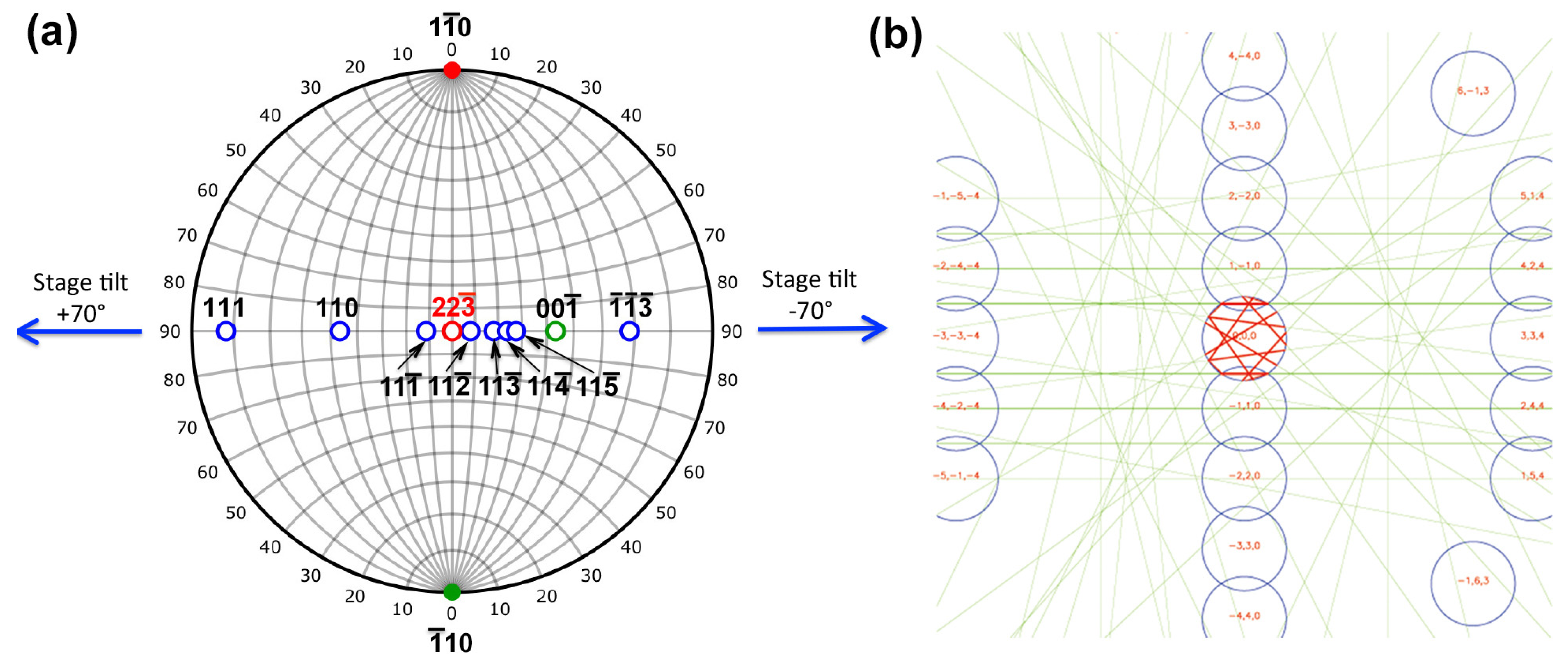

hh0 systematic reflections. Changes of zone axes as a function of stage tilt angle can be summarized on a stereographic projection shown in

Figure 2a. As seen, the initial beam incidence is close to [22

]

β, and both 1

0 and

10 reflections are always excited during the specimen tilt. A simulated CBED pattern with the [22

]

β zone, which corresponds to the BF-STEM imaging condition, is shown in

Figure 2b. As seen, the

hh0 systematic reflections are excited and the non-systematic reflections are far from the systematic row.

Figure 2.

(a) Stereographic projection indicating changes of zone axes as a function of stage tilt angle. The initial beam incidence is close to [22]β, and both 10 and 10 reflections are always excited during the tilt series acquisition; (b) A simulated convergent-beam electron diffraction (CBED) pattern with the [22]β zone.

Figure 2.

(a) Stereographic projection indicating changes of zone axes as a function of stage tilt angle. The initial beam incidence is close to [22]β, and both 10 and 10 reflections are always excited during the tilt series acquisition; (b) A simulated convergent-beam electron diffraction (CBED) pattern with the [22]β zone.

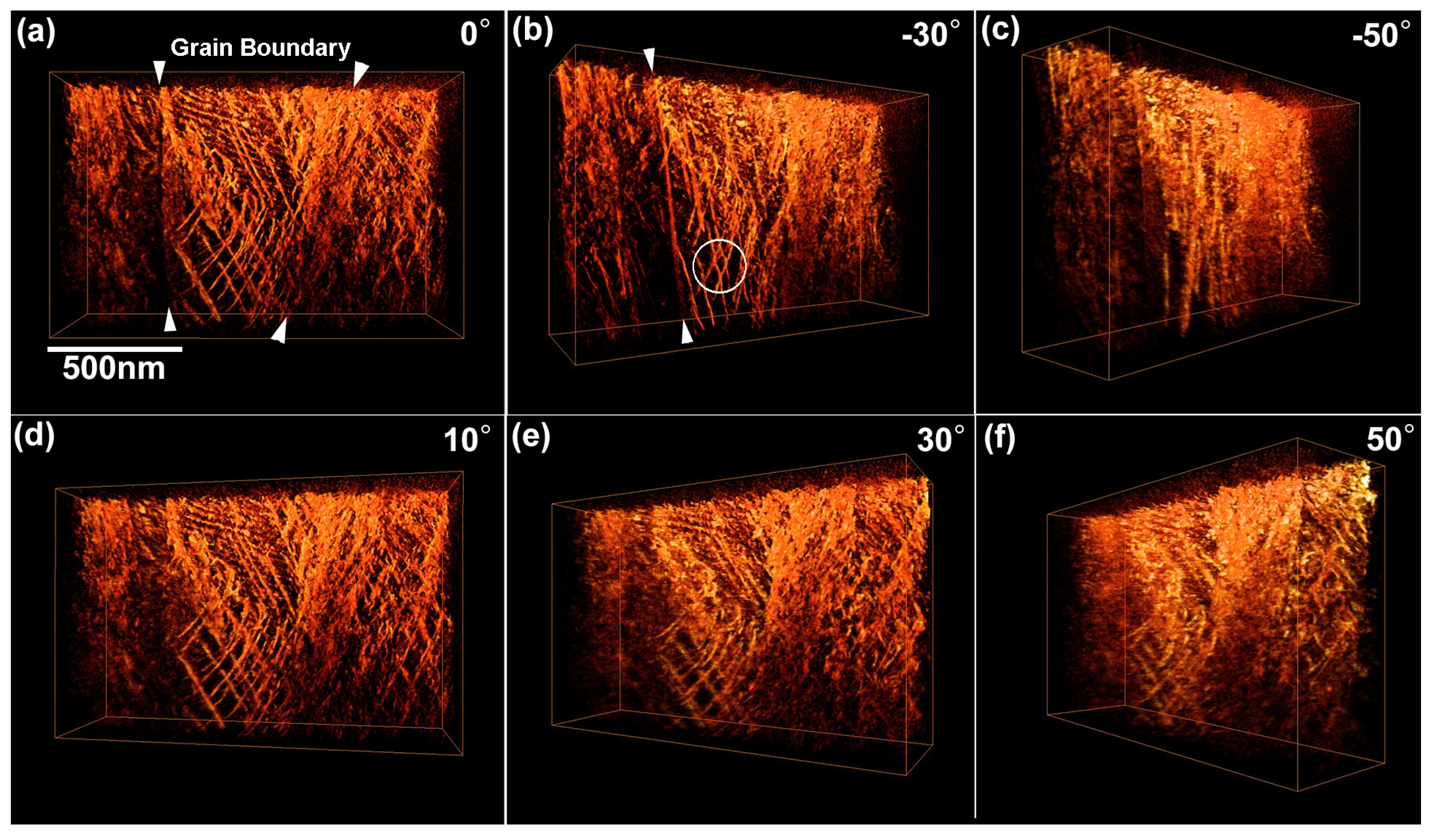

Figure 3 shows snapshots of BF-STEM images of the as-quenched Ti–35mass%Nb alloy acquired during a tilt-series observation. They are shown after the alignment of tilt axis, which is set vertical here. The tilt angles are (a) 0°, (b) −30°, (c) −50°, (d) 10°, (e) 30°, and (f) 50°. This tilt-series was obtained sequentially from 0 to −70° and then 0 to +70° with an angular increment of 2°. The SAED patterns shown in

Figure 1 were obtained from an area indicated by the circle in

Figure 3a (~750 nm in diameter) near the specimen edge. Arrowheads in the image shown in

Figure 3a indicate dark contrast arising from acicular α'' martensite, which can be typically observed in a quenched Ti–Nb alloy [

11]. Thus, it can be stated that the encircled area composed of the β phase exists in between the α'' martensite plates. Dotted lines indicate α''/β grain boundaries. Note that α'' martensite is the primary phase of this quenched alloy. Morphology and distribution of acicular α'' martensite can be found in the literature [

11].

Figure 3.

Snapshots of bright-field scanning transmission electron microscopy (BF-STEM) images of the as-quenched Ti–35mass%Nb alloy acquired during a tilt-series observation. SAED patterns were observed from a circular area indicated in (a). Arrowheads indicate acicular α'' martensite plates. Dotted lines indicate α''/β grain boundaries. Tilt angles for each image is as follows: (a) 0°, (b) −30°, (c) −50°, (d) 10°, (e) 30°, (f) 50°.

Figure 3.

Snapshots of bright-field scanning transmission electron microscopy (BF-STEM) images of the as-quenched Ti–35mass%Nb alloy acquired during a tilt-series observation. SAED patterns were observed from a circular area indicated in (a). Arrowheads indicate acicular α'' martensite plates. Dotted lines indicate α''/β grain boundaries. Tilt angles for each image is as follows: (a) 0°, (b) −30°, (c) −50°, (d) 10°, (e) 30°, (f) 50°.

Figure 4 shows a magnified BF-STEM image and a corresponding SAED pattern of the Ti–35mass%Nb alloy observed at a stage tilt of 0°. The image contrast shown here is reversed in order to clearly show fine dislocation arrangement. The beam incidence is close to the [22

]

β. As seen, there are dense dislocations in the β phase region. The rectangular area indicated by dashed lines was selected for subsequent 3D reconstruction.

Figure 4.

Magnified BF-STEM image and corresponding SAED pattern of the Ti–35mass%Nb alloy observed at a stage tilt of 0°. The image contrast is reversed in order to clearly show fine dislocations. The beam incidence is close to the [22]β. The rectangular area indicated by dashed lines was selected for subsequent 3D reconstruction.

Figure 4.

Magnified BF-STEM image and corresponding SAED pattern of the Ti–35mass%Nb alloy observed at a stage tilt of 0°. The image contrast is reversed in order to clearly show fine dislocations. The beam incidence is close to the [22]β. The rectangular area indicated by dashed lines was selected for subsequent 3D reconstruction.

Figure 5 shows reconstructed 3D images of dislocations in the β phase region. Tilt angles indicated for each image correspond to those shown in

Figure 3. The reconstructed volume size is 1003 nm × 1532 nm × 489 nm (377 × 576 × 183 pixels,

i.e., 2.66 nm/pixel). The reconstruction have revealed that the reconstructed region of the specimen had a wedge shape with thickness increasing from approximately 100 to 200 nm (top to bottom in the image). It should be mentioned that at the tilt angle of 70° the specimen thickness reaches approximately 290 to 580 nm; the thickness is within the maximum observable limit for electrons accelerated at 300 kV (~1 μm for Fe) [

14]. The arrowheads shown in

Figure 5a indicates grain boundary between α'' and β phases, which can be seen in the original image shown in

Figure 4. Dislocations with different directions overlap and some of them are bent. Rather wavy shape implies that they are mostly mixed dislocations. The dislocation density estimated was rather high value of ~10

14 m

−2. According to the literature, dislocation densities of 10

12 m

−2 and 10

15 m

−2 were reported for the β phase in Ti–10V–2Fe–3Al alloys before and after deformation, respectively [

15]. This implies that the dislocations in the β phase observed in this study are introduced by compressive stress arising from the volume changes of adjacent crystals due to the martensitic transformation during quenching.

Figure 5.

Three-dimensional views of the dislocations reconstructed from a BF-STEM tilt-series dataset using a weighted back-projection (WBP) technique. Arrowheads indicate the α''/β grain boundary. A kink on a (01) slip plane is seen in the encircled area. Tilt angles for each image is as follows: (a) 0°, (b) −30°, (c) −50°, (d) 10°, (e) 30°, (f) 50°.

Figure 5.

Three-dimensional views of the dislocations reconstructed from a BF-STEM tilt-series dataset using a weighted back-projection (WBP) technique. Arrowheads indicate the α''/β grain boundary. A kink on a (01) slip plane is seen in the encircled area. Tilt angles for each image is as follows: (a) 0°, (b) −30°, (c) −50°, (d) 10°, (e) 30°, (f) 50°.

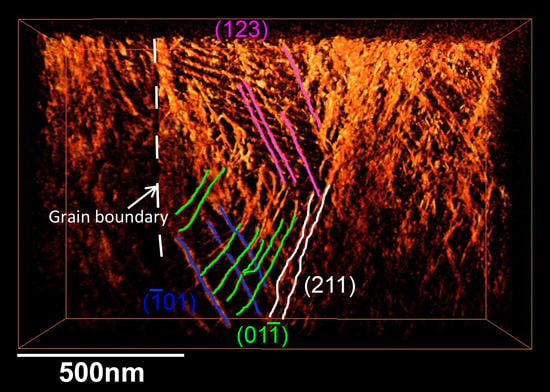

By rotating the reconstructed volume, we can analyze slip planes of these dislocations with the aid of corresponding SAED patterns. When a trace of dislocations viewed from an edge-on direction is orthogonal to a diffraction vector

ghkl, the slip plane can be assigned as (

hkl). For example, the slip plane analysis led us to conclude that the bending of dislocations as seen in

Figure 5b (encircled area) is a kink of dislocations on a (

01) slip plane. The existence of the kink is practically difficult to detect on the original STEM images and this is a benefit of using tomographic reconstruction. The slip planes determined are (

01), (01

), (211), and (123), and dislocations exist on these planes are marked by different colors in

Figure 6. It can be pointed out that these are typical slip planes for metals with the bcc structure.

Figure 6.

A result of slip plane analyses: dislocations on different slip planes are marked by different colors.

Figure 6.

A result of slip plane analyses: dislocations on different slip planes are marked by different colors.

4. Discussion

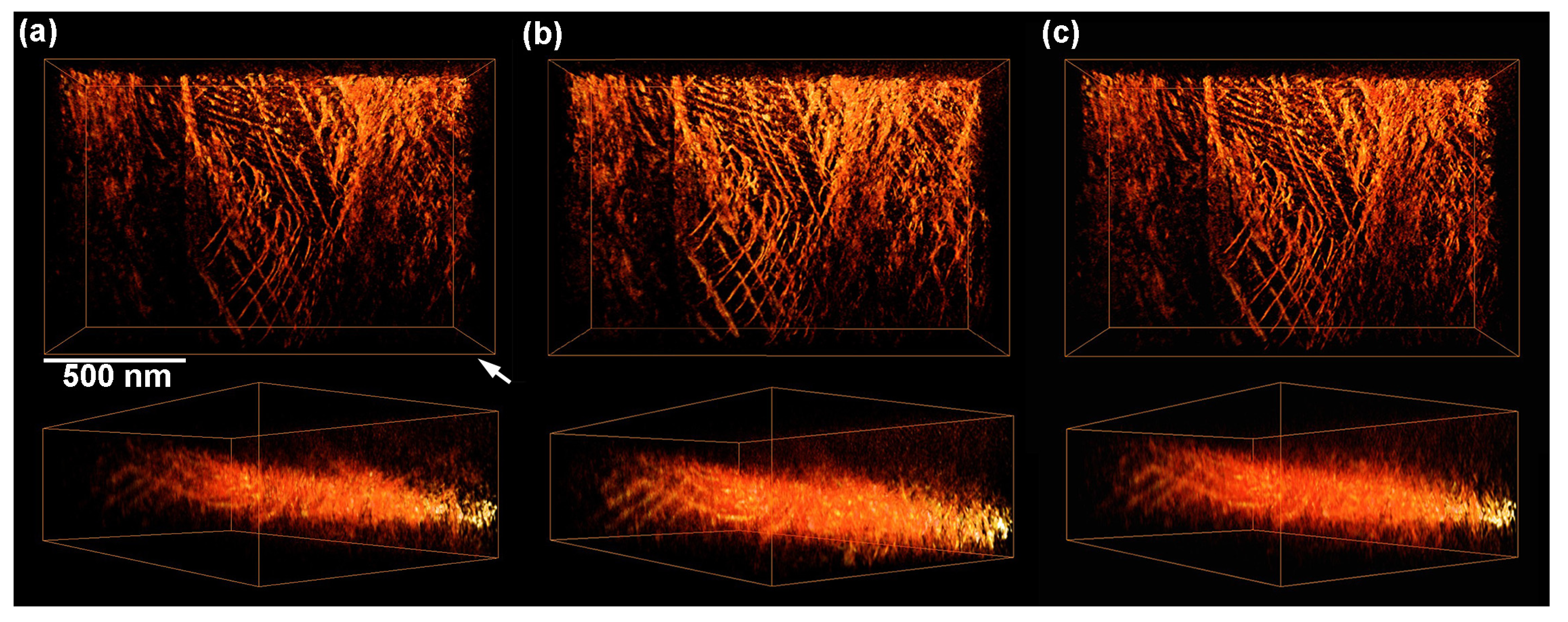

Here, we discuss practical aspects of 3D dislocation imaging from the viewpoints of contrast quality of data set and of the extent of tilting angle. In the tilt-series obtained in this study, SAED patterns with zone axes appeared at −10° ([11

]), −20° ([11

]), −30° ([11

]), −50° ([00

]), −70° ([

]), −10° ([1

1]), 30° ([33

]), and 40° ([110]) as shown in

Figure 1. When the tilt angle reaches an angle satisfying a low-order zone axis (satisfying the Bragg conditions for

hkl reflections other than the

hh0 systematic reflections), background intensity was enhanced in the corresponding STEM images, and hence the contrasts of dislocations were reduced. Such low contrast images can be discarded in the reconstruction process as recently reported by Kacher

et al. [

7]. To check the effect of such Bragg reflections other than the

hh0 systematic reflections on the quality of reconstructed dislocation images, we examined 3D reconstruction removing images obtained under low-order zone axes incidence. The result is shown in

Figure 7a. An arrow indicates the viewing direction of the attached cross section images. For comparison, the result, reconstructed using all the experimental images, is shown in

Figure 7b, which is the same image shown in

Figure 5a. As can be seen, the effects of low contrast images taken at zone axes on shapes and width of dislocations are negligibly small within the resolution of the present study. This is probably due to the nature of the BF-STEM imaging in the present study with the outer collection angle of 11 mrad. This condition excludes most of the Bragg reflections other than 000, 1

0, and

10 throughout the tilt-series (The [1

1] incidence is the only exception; four kinds of 110 reflections are incorporated within the aperture in addition to 000, 1

0, and

10 reflections).

Figure 7.

Effects of low contrast images and the maximum tilt angles on shapes and width of reconstructed dislocations. The maximum tilt angles and the number of images used for the reconstruction are as follows: (a) 70°, 63 images, (b) 70°, 71 images, (c) 40°, 41 images. An arrow indicates the viewing direction of the attached cross section images.

Figure 7.

Effects of low contrast images and the maximum tilt angles on shapes and width of reconstructed dislocations. The maximum tilt angles and the number of images used for the reconstruction are as follows: (a) 70°, 63 images, (b) 70°, 71 images, (c) 40°, 41 images. An arrow indicates the viewing direction of the attached cross section images.

We also examined the effect of maximum tilt angles on the reconstruction. Some of the recent studies on electron tomography of dislocations were carried out to visualize dislocations with tilt angles less than 40° [

7,

16]. In general such a limitation of the maximum tilt angle degrades the resolution of reconstructed images in the

z direction (parallel to the optic axis) due to the effect of missing wedges as reported in the preceding studies using a phantom [

1] or a real 3D object [

17].

Figure 7c shows the results of a trial reconstruction using only 41 images with the maximum tilt angle of 40°. The shapes and width of dislocations have been well reconstructed. As seen, there is no apparent difference in the reconstructed images shown in

Figure 7b (70°) and 7c (40°). In the latter case, dislocation images in the

z-direction parallel to optic axis became blur by at most 30% due to the missing wedge, while the overall features still remain in the reconstructed volume. Thus it can be stated that the maximum tilt angle as low as 40° is practically acceptable to qualitatively visualize 3D configurations of dislocations without losing essential information, such as slip planes; while, ideally speaking, higher tilt angles are required for better resolution.