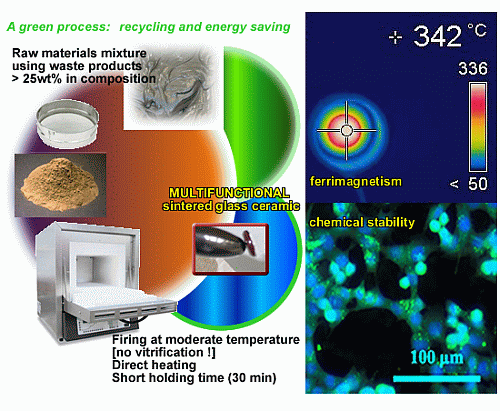

Magnetic Glass Ceramics by Sintering of Borosilicate Glass and Inorganic Waste

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Processing Methods

| Component | S1 | S2 | BS |

|---|---|---|---|

| Chemical composition (wt%) | |||

| SiO2 | 29 | 24 | 72 |

| FeO | 52 | 32 | – |

| Al2O3 | 4 | 6 | 7 |

| CaO | 2 | 21 | 1 |

| MgO | 1 | 1 | – |

| Na2O | <1 | <1 | 6 |

| K2O | <1 | <1 | 2 |

| ZnO | 7 | 7 | – |

2.2. Microstructural Characterization and Mechanical Properties

2.3. Chemical Durability Tests

2.4. Cytotoxicity Investigation

2.5. Induction Heating Tests

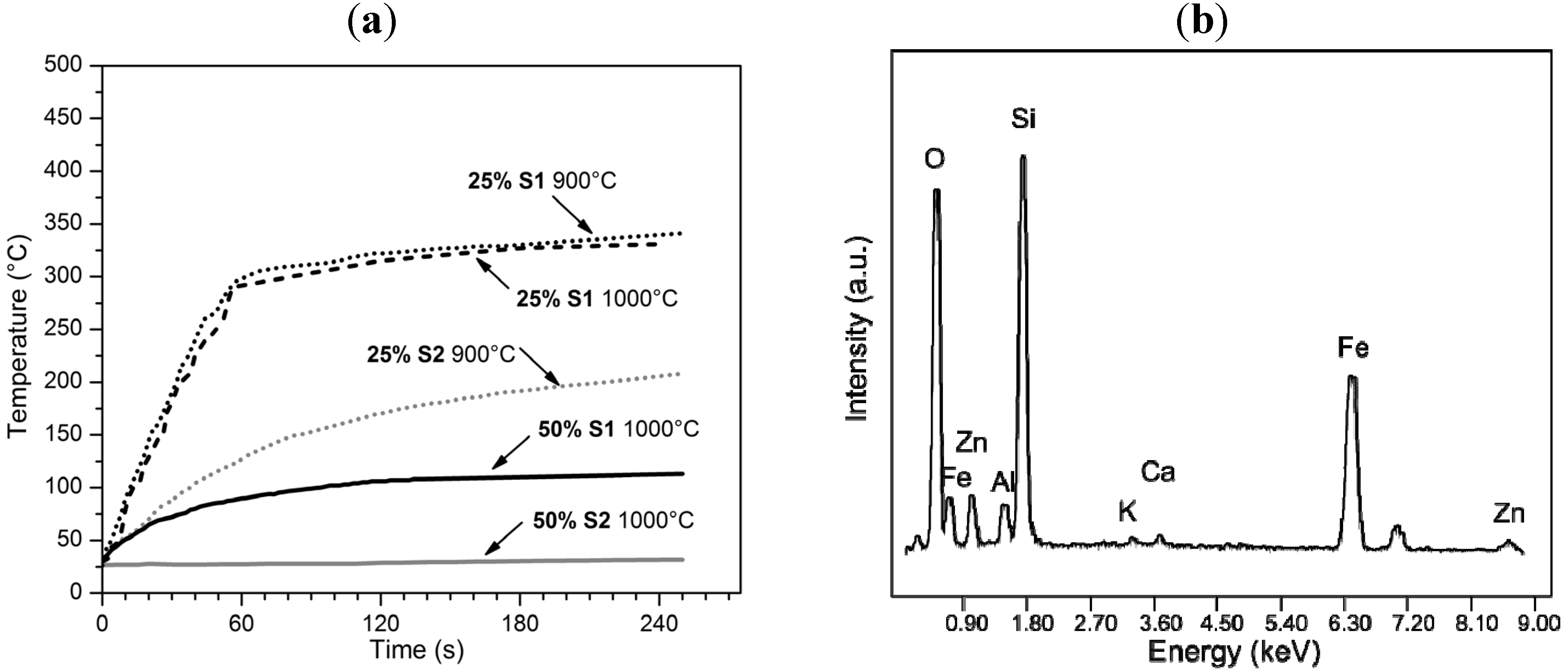

3. Results and Discussion

3.1. Microstructural Evolution

3.2. Mechanical and Functional Characterization

| Sample | Sintering Temperature (°C) | Apparent density (g/cm3) | Porosity (%) | Elastic modulus (GPa) | Bending strength (MPa) | Vickers Hardness (GPa) |

|---|---|---|---|---|---|---|

| 25% S1 | 900 | 2.34 ± 0.01 | 7.9 ± 0.5 | 69.0 ± 14.9 | 39.6 ± 11.1 | 5.3 ± 2.1 |

| 50% S1 | 1000 | 2.39 ± 0.01 | 16.4 ± 0.5 | 62.3 ± 13.4 | 33.0 ± 1.3 | 5.9 ± 1.1 |

| 25% S2 | 900 | 2.32 ± 0.01 | 9.6 ± 0.5 | 69.3 ± 4.8 | 37.6 ± 6.2 | 4.6 ± 0.7 |

| 50% S2 | 1000 | 2.39 ± 0.01 | 18.1 ± 0.5 | 56.8 ± 3.0 | 32.4 ± 7.6 | 5.4 ± 1.3 |

3.3. Chemical Stability and Cytotoxicity Studies

| Element | Leachate (ppm) | ||

|---|---|---|---|

| Sample | 25 wt% S1 900 °C | 25 wt% S2 900 °C | EN Limits # |

| As | <0.0049 | <0.0049 | 0.5 |

| Ba | 0.0029 | 0.0538 | 20 |

| Cd | <0.0002 | <0.0002 | 0.04 |

| Cr | <0.0004 | <0.0004 | 0.5 |

| Cu | <0.0001 | <0.0001 | 2 |

| Hg | <0.0004 | <0.0004 | 0.01 |

| Mo | <0.0033 | 0.0048 | 0.5 |

| Ni | 0.0302 | 0.0166 | 0.4 |

| Pb | <0.0047 | 0.0077 | 0.5 |

| Sb * | n.d. | n.d. | 0.06 |

| Se | <0.0122 | <0.0122 | 0.1 |

| Zn | <0.0203 | <0.0203 | 4 |

4. Conclusions

- Metallurgical slags were successfully sintered, mixed with recycled borosilicate glass, at temperatures not exceeding 1000 °C. The developed glass ceramics, owing to the negligible water absorption, could be used as low-cost lightweight tiles;

- Fe-rich phases developed according to slag/glass interactions;

- Owing to the presence of magnetite, the developed glass ceramics (for a slag concentration of 25 wt%), exhibit intensive heating when subjected to an alternating magnetic field, so that they could be applied as novel heating elements;

- The chemical durability of the glass ceramics was assessed by TCLP testing, while the materials biocompatibility was confirmed by cytotoxicity tests.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, W.E. The contribution of ceramics to environmental clean up. Adv. Appl. Ceram. 2006, 105, 1. [Google Scholar] [CrossRef]

- Rawlings, R.D.; Wu, J.P.; Boccaccini, A.R. Glass ceramics: Their production from wastes—A Review. J. Mat. Sci. 2006, 41, 733–761. [Google Scholar] [CrossRef]

- Höland, W.; Beall, G.H. Glass Ceramic Technology, 2nd ed.; The American Ceramics Society: Westerville, OH, USA, 2002. [Google Scholar]

- Colombo, P.; Brusatin, G.; Bernardo, E.; Scarinci, G. Inertization and reuse of waste materials by vitrification and fabrication of glass based products. Curr. Opin. Solid State Mater. Sci. 2003, 7, 225–239. [Google Scholar] [CrossRef]

- Francis, A.A.; Rawlings, R.D.; Sweeney, R.; Boccaccini, A.R. Processing of coal ash into glass ceramic products by powder technology and sintering. Glass Technol. 2002, 43, 58–62. [Google Scholar]

- Dimech, C.; Cheeseman, C.R.; Cook, S.; Simon, J.; Boccaccini, A.R. Production of sintered materials from air pollution control residues from waste incineration. J. Mater. Sci. 2008, 43, 4143–4151. [Google Scholar] [CrossRef]

- Bernardo, E.; Dal Maschio, R. Glass ceramics from vitrified sewage sludge pyrolysis residues and recycled glasses. Waste Manag. 2001, 31, 2245–2252. [Google Scholar] [CrossRef]

- Chinnam, R.K.; Francis, A.A.; Will, J.; Bernardo, E.; Boccaccini, A.R. Review. Functional glasses and glass ceramics derived from iron rich waste and combination of industrial residues. J. Non-Cryst. Sol. 2013, 365, 63–74. [Google Scholar] [CrossRef]

- Bretcanu, O.; Spriano, S.; Verné, E.; Coïsson, M.; Tibero, P.; Allia, P. The influence of crystallised Fe3O4 on the magnetic properties of coprecipitation-derived ferrimagnetic glass ceramics. Acta Biomater. 2005, 1, 421–429. [Google Scholar] [CrossRef]

- Bretcanu, O.; Verné, E.; Coïsson, M.; Tibero, P.; Allia, P. Magnetic properties of the ferrimagnetic glass ceramics for hyperthermia. J. Magn. Magn. Mater. 2006, 305, 529–533. [Google Scholar] [CrossRef]

- Deatsch, A.E.; Evans, B.A. Heating efficiency in magnetic nanoparticle hyperthermia. J. Magn. Magn. Mater. 2014, 354, 163–172. [Google Scholar] [CrossRef]

- Gorai, B.; Jana, R.K.; Premchand. Characteristics and utilisation of copper slag—A review. Res. Conserv. Recycl. 2003, 39, 299–313. [Google Scholar] [CrossRef]

- Mihailova, I.; Mehandjiev, D. Characterization of fayalite from copper slags. J. Univ. Chem. Technol. Metal. 2010, 45, 317–326. [Google Scholar]

- Alp, I.; Deveci, H.; Süngün, H. Utilization of flotation wastes of copper slag as raw material in cement production. J. Hazard. Mater. 2008, 159, 390–395. [Google Scholar] [CrossRef]

- Francis, A.A. Magnetic characteristics of iron-containing glass originated from the mixture of various wastes. Ceram. Int. 2007, 33, 163–168. [Google Scholar] [CrossRef]

- Coruh, S.; Ergun, O.N.; Cheng, T.-W. Treatment of copper industry waste and production of sintered glass ceramic. Waste Manag. Res. 2006, 24, 234–241. [Google Scholar] [CrossRef]

- Zhihong, Y.; Qiao, L.; Jixiang, X.; Yong, H.; Guangdong, L.; Yi, K. Preparation and crystallization of glass-ceramics derived from iron-rich copper slag. J. Alloys Comp. 2004, 7, 354–360. [Google Scholar]

- Bernardo, E.; Scarinci, G. Sintering behaviour and mechanical properties of Al2O3 platelet-reinforced glass matrix composites obtained by powder technology. Ceram. Int. 2004, 30, 785–791. [Google Scholar] [CrossRef]

- Hoppe, A.; Güldal, N.S.; Boccaccini, A.R. A review of the biological response to ionic dissolution products from bioactive glasses and glass ceramics. Biomaterials 2011, 32, 2757–2774. [Google Scholar] [CrossRef]

- Bernardo, E. Fast sinter-crystallization of a glass from waste materials. J. Non-Cryst. Sol. 2008, 354, 3486–3490. [Google Scholar] [CrossRef]

- Bernardo, E.; Bonomo, E.; Dattoli, A. Optimisation of sintered glass–ceramics from an industrial waste glass. Ceram. Int. 2010, 36, 1675–1680. [Google Scholar] [CrossRef]

- Ettler, V.; Johan, Z.; Touray, J.C.; Jelínek, E. Zinc partitioning between glass and silicate phases in historical and modern lead-zinc metallurgical slags from the Příbram district, Czech Republic. C. R. de l’Acad. des Sci.-Ser. IIA 2000, 331, 245–250. [Google Scholar]

- Raghavan, V. Phase Diagram Evaluations—Fe-O-Si-Zn (Iron-Oxygen-Silicon-Zinc). J. Phase Equilibria Diffus. 2010, 31, 385–386. [Google Scholar] [CrossRef]

- O’Neill, H.St.C. Quartz-fayalite-iron and quartz-fayalite-magnetite equilibria and the free energy of formation of fayalite (Fe2SiO4) and magnetite (Fe3O4). Am. Mineral. 1987, 72, 67–75. [Google Scholar]

- Appendino, P.; Ferraris, M.; Matekovits, I.; Salvo, M. Production of glass-ceramic bodies from the bottom ashes of municipal solid waste incinerators. J. Eur. Ceram. Soc. 2004, 24, 803–810. [Google Scholar] [CrossRef]

- Shelby, J.E. Introduction to Glass Science and Technology, 2nd ed.; The Royal Society of Chemistry: Cambridge, UK, 2005; pp. 51–71. [Google Scholar]

- Thomas, E.S.; Thompson, J.G.; Withers, R.L.; Sterns, M.; Xiao, Y.; Kirkpatrick, R.J. Further Investigation of the Stabilization of β-Cristobalite. J. Am. Ceram. Soc. 1994, 77, 49–56. [Google Scholar] [CrossRef]

- Cheng, T.W.; Huang, M.Z.; Tzeng, C.C.; Cheng, K.B.; Ueng, T.H. Production of coloured glass ceramics from incinerator ash using thermal plasma technology. Chemosphere 2007, 68, 1937–1945. [Google Scholar] [CrossRef]

- Cheng, T.W.; Chen, Y.S. Characterisation of glass ceramics made from incinerator fly ash. Ceram. Int. 2004, 30, 343–349. [Google Scholar] [CrossRef]

- Andreu, I.; Natividad, E. Accuracy of available methods for quantifying the heat power generation of nanoparticles for magnetic hyperthermia. Int. J. Hyperth. 2013, 29, 739–751. [Google Scholar] [CrossRef]

- Jordan, I.; Wust, P.; Fahling, H.; John, W.; Hinz, A.; Felix, R. Inductive heating of ferrimagnetic particles and magnetic fluids: Physical evaluation of their potential for hyperthermia. Int. J. Hyperth. 2009, 25, 499–511. [Google Scholar] [CrossRef]

- Francis, A.A. Crystallization kinetics of magnetic glass–ceramics prepared by the processing of waste materials. Mater. Res. Bull. 2006, 41, 1146–1154. [Google Scholar] [CrossRef]

- Francis, A.A.; Rawlings, R.D.; Sweeney, R.; Boccaccini, A.R. Crystallization kinetic of glass particles prepared from a mixture of coal ash and soda-lime cullet glass. J. Non-Cryst. Sol. 2004, 333, 187–193. [Google Scholar] [CrossRef]

- Rosenweig, R.E. Heating magnetic fluid with alternating magnetic field. J. Magn. Magn. Mater. 2002, 252, 370–374. [Google Scholar] [CrossRef]

- Sandu, V.; Nicolescu, M.S.; Kuncser, V.; Damian, R.; Sandu, E. Magnetic glass ceramics. J. Adv. Ceram. 2012, 1, 138–143. [Google Scholar] [CrossRef]

- Pollard, T.D.; Earnshaw, W.C.; Lippincott-Schwartz, J. Cell Biology, 2nd ed.; Elsevier Inc.: Philadelphia, PA, USA, 2008. [Google Scholar]

- Boccaccini, A.R.; Petitmermet, M.; Wintermantel, E. Glass ceramics from Municipal Incinerator Fly Ash. Ceram. Bull. 1997, 76, 75–78. [Google Scholar]

- Ponsot, I.; Bernardo, E.; Bontempi, E.; Depero, L.; Chinnam, R.K.; Detsch, R.; Boccaccini, A.R. Recycle of pre-stabilized municipal waste incinerator fly ash and soda-lime glass into sintered glass ceramics. J. Clean. Prod. 2014. submitted. [Google Scholar]

- Trevan, J.W. The Error of Determination of Toxicity. In Series B, Containing Papers of a Biological Character, Proceedings of the Royal Society of London, 1927; JSTOR, Ed.; Royal Society Publishing: London, UK,, 1 July 1927; Volume 101, pp. 483–514. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ponsot, I.M.M.M.; Pontikes, Y.; Baldi, G.; Chinnam, R.K.; Detsch, R.; Boccaccini, A.R.; Bernardo, E. Magnetic Glass Ceramics by Sintering of Borosilicate Glass and Inorganic Waste. Materials 2014, 7, 5565-5580. https://doi.org/10.3390/ma7085565

Ponsot IMMM, Pontikes Y, Baldi G, Chinnam RK, Detsch R, Boccaccini AR, Bernardo E. Magnetic Glass Ceramics by Sintering of Borosilicate Glass and Inorganic Waste. Materials. 2014; 7(8):5565-5580. https://doi.org/10.3390/ma7085565

Chicago/Turabian StylePonsot, Inès M. M. M., Yiannis Pontikes, Giovanni Baldi, Rama K. Chinnam, Rainer Detsch, Aldo R. Boccaccini, and Enrico Bernardo. 2014. "Magnetic Glass Ceramics by Sintering of Borosilicate Glass and Inorganic Waste" Materials 7, no. 8: 5565-5580. https://doi.org/10.3390/ma7085565

APA StylePonsot, I. M. M. M., Pontikes, Y., Baldi, G., Chinnam, R. K., Detsch, R., Boccaccini, A. R., & Bernardo, E. (2014). Magnetic Glass Ceramics by Sintering of Borosilicate Glass and Inorganic Waste. Materials, 7(8), 5565-5580. https://doi.org/10.3390/ma7085565