High Density Polyethylene Composites Reinforced with Hybrid Inorganic Fillers: Morphology, Mechanical and Thermal Expansion Performance

Abstract

:1. Introduction

2. Results and Discussion

2.1. Composites with Individual Glass Fibers

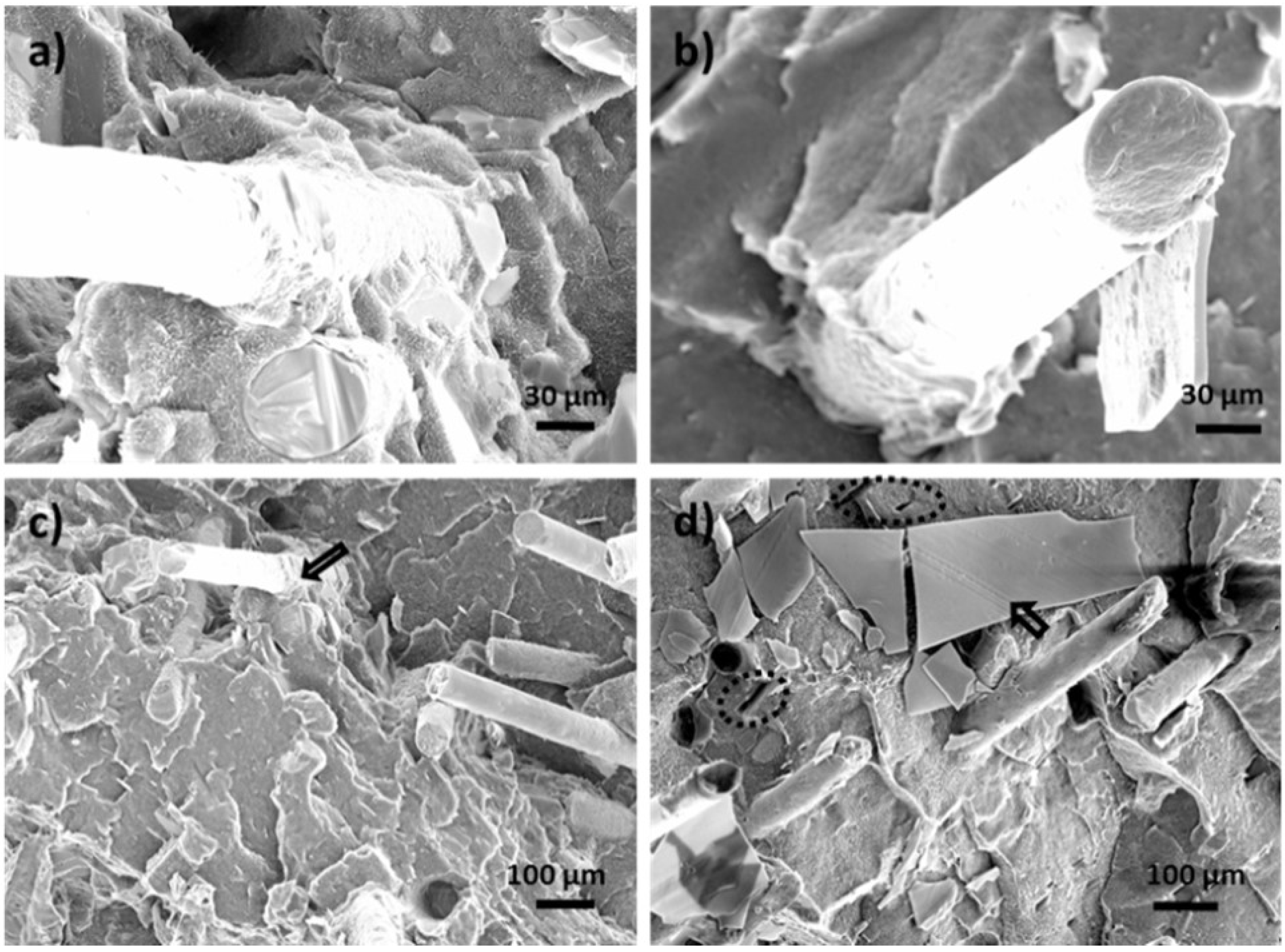

2.1.1. Morphology

2.1.2. Tensile Properties

| System | Filler Content (wt %) a | Strength | Modulus | |||

|---|---|---|---|---|---|---|

| Tensile (MPa) b,c | Flexural (MPa) | Impact (kJ/m2) | Tensile (GPa) | Flexural (GPa) | ||

| HDPE-6706/GF | 0 | 18.9(0.2)A | 19.76(0.39)A | 8.12(0.21)A | 0.26(0.02)A | 0.73(0.05)A |

| 10 | 27.1(0.38)C | 25.3(1.0)C | 7.37(0.21)A | 1.86(0.21)C | 1.2(0.06)BC | |

| 20 | 35.42(0.15)E | 37.7(0.3)E | 9.72(0.82)B | 3.43(0.41)E | 1.6(0.8)DE | |

| 30 | 46.74(0.88)G | 56.3(0.7)G | 11.81(0.88)C | 5.37(0.24)G | 3.4(0.1)G | |

| HDPE-AD60/GF | 0 | 23.8(1.4)B | 21.8(1.0)B | 28.57(2.0)E | 0.86(0.09)B | 0.85(0.06)AB |

| 10 | 31.54(0.57)D | 29.2(0.2)D | 9.62(0.37)B | 2.46(0.22)D | 1.3(0.02)CD | |

| 20 | 39.34(0.93)F | 40.9(0.6)F | 10.37(0.37)B | 5.17(0.94)F | 2.3(0.3)F | |

| 30 | 48.80(0.50)H | 57.8(0.7)H | 11.94(0.16)C | 6.22(0.97)G | 3.6(0.08)G | |

| 40 d | 64.92(0.34)I | 85.9(1.6)I | 14.55(0.34)D | 8.87(0.51)H | 5.8(0.2)H | |

2.1.3. Flexural Properties

2.1.4. Impact Strength

2.1.5. Dynamic Mechanical Properties

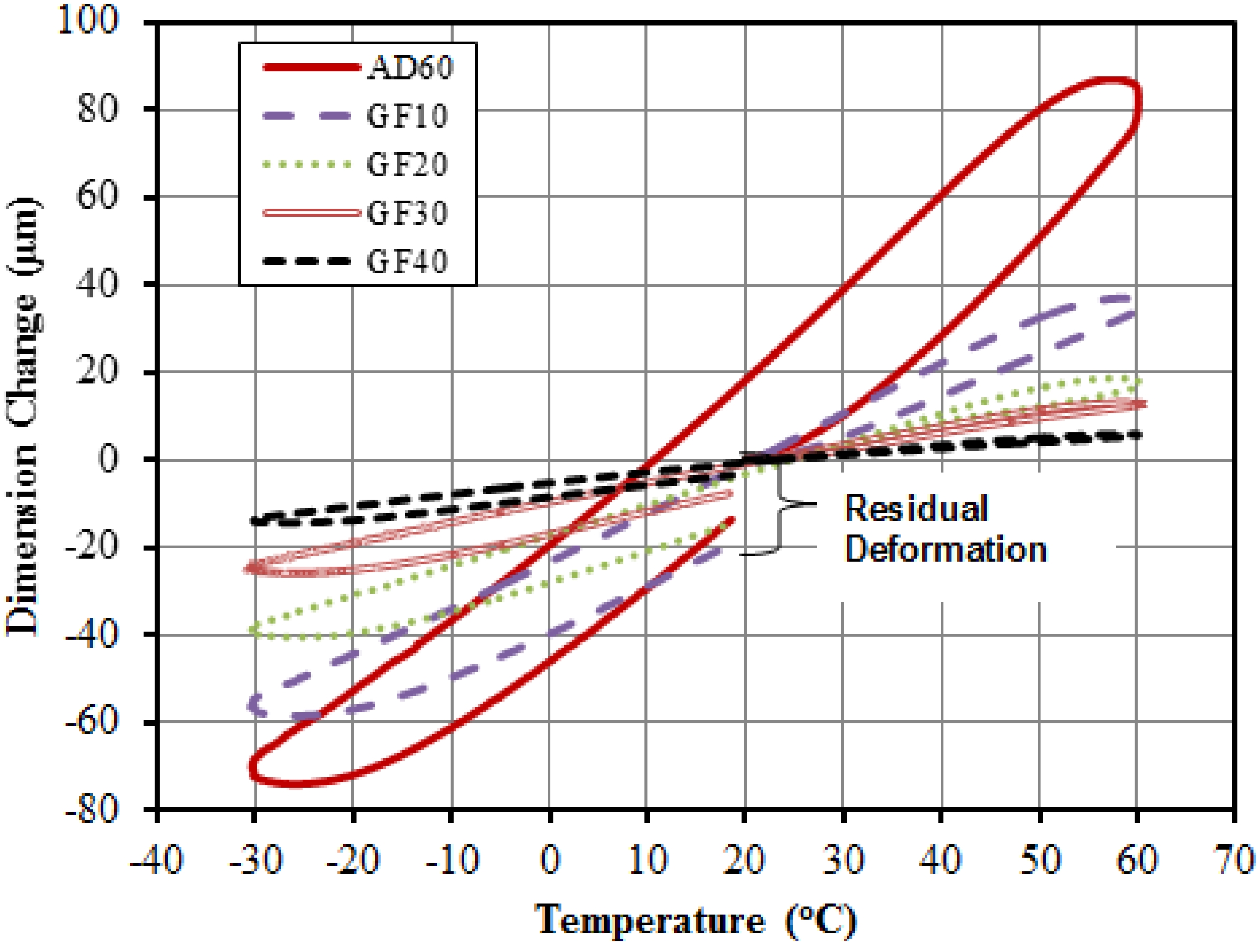

2.1.6. Thermal Expansion Properties

| System | Filler content (wt %) | Linear Coefficient of Thermal Expansion (LCTE) (10−6/°C) a,b,c | ||

|---|---|---|---|---|

| 20→60 °C | 60→−30 °C | −30→20 °C | ||

| HDPE 6706/GF | 0 | 203.9(3.0)G | 164.8(6.3)G | 143.8(4.8)I |

| 10 | 71.1(0.4)E | 79.7(1.4)E | 82.5(1.1)F | |

| 20 | 32.0(1.1)C | 41.6(3.8)C | 50.9(0.8)D | |

| 30 | 19.8(0.7)B | 28.6(1.5)B | 34.1(1.1)C | |

| HDPE AD60/GF | 0 | 199.1(2.8)G | 162.7(2.5)G | 137.8(1.0)H |

| 10 | 75.1(0.5)F | 87.6(3.1)F | 87.8(0.7)G | |

| 20 | 39.6(2.2)D | 55.1(0.1)D | 57.8(0.7)E | |

| 30 | 22.4(0.3)B | 33.1(1.8)B | 33.9(0.3)B | |

| 40 | 11.1(0.2)A | 17.1(0.2)A | 19.7(0.2)A | |

2.2. Composites with Combined Talc and Glass Fiber Fillers

2.2.1. Morphology

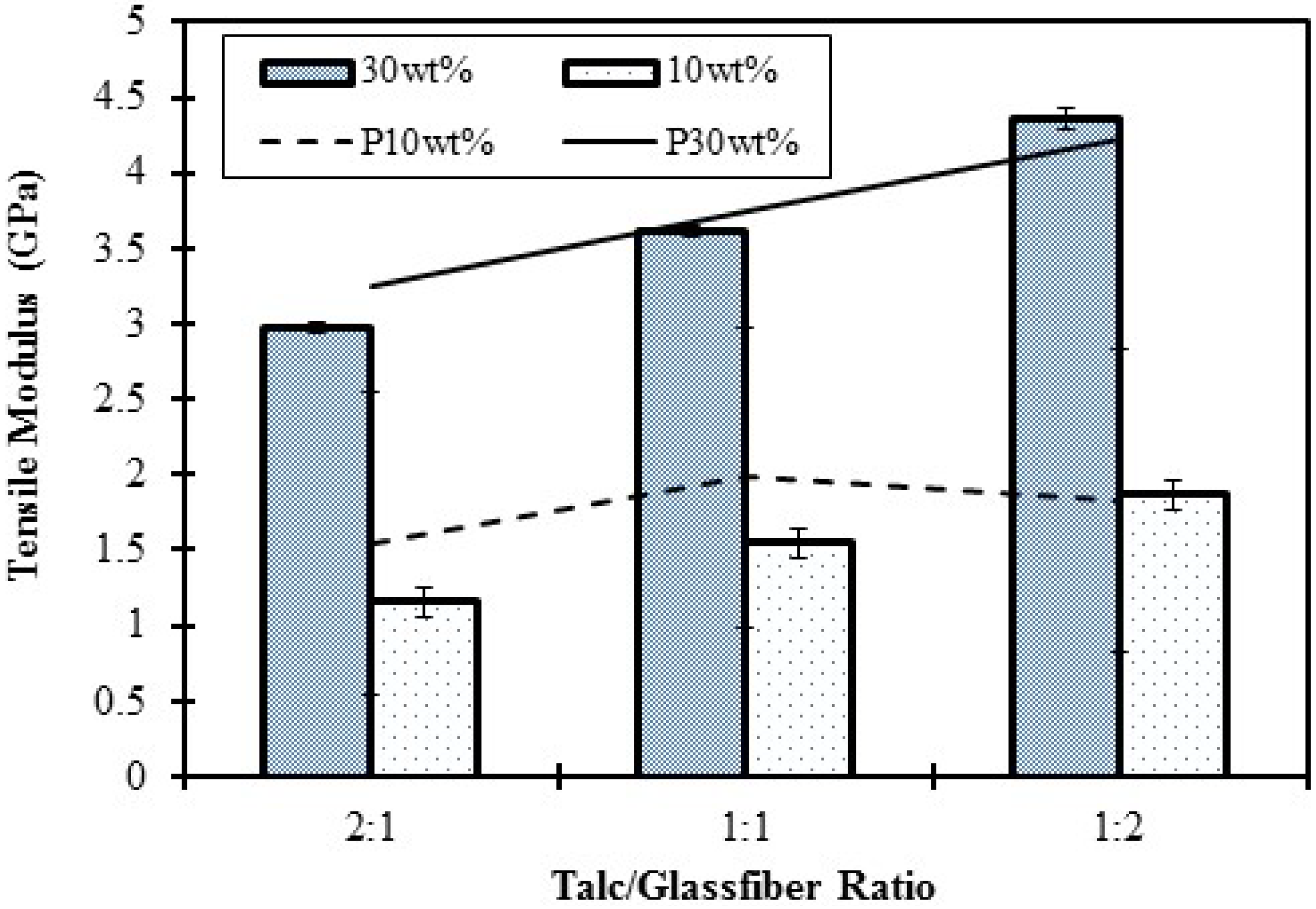

2.2.2. Mechanical Properties

| System | Filler content (wt%) a | Talc/GF Ratio | Strength | Modulus | |||

|---|---|---|---|---|---|---|---|

| Tensile (MPa) b,c | Flexural (MPa) | Impact (kJ/m2) | Tensile (GPa) | Flexural (GPa) | |||

| HDPE6706 | 0 | 0 | 18.9(0.2)A | 19.8(0.4)A | 8.12(0.21)E | 0.26(0.02)A | 0.73(0.05)A |

| HDPEAD60 | 0 | 0 | 23.8(1.4)C | 21.8(1.0)B | 28.57(2.0)F | 0.86(0.09)B | 0.85(0.06)B |

| HDPEAD60/ HDPE6706/ Talc/GF | 30 | 2:1 | 27.7(0.48)D | 33.7(1.4)D | 5.77(0.59)A | 2.9(0.13)D | 2.0(0.20)E |

| 1:1 | 31.9(0.41)E | 38.8(0.3)E | 6.35(0.22)AB | 3.6(0.39)E | 2.4(0.06)F | ||

| 1:2 | 36.8(0.63)F | 44.7(0.6)F | 7.80(0.36)DE | 4.4(0.33)F | 2.8(0.07)G | ||

| 10 | 2:1 | 21.8(0.22)B | 26.4(0.3)C | 5.43(0.35)A | 1.2(0.15)B | 1.2(0.01)C | |

| 1:1 | 22.6(0.36)B | 26.8(0.8)C | 6.12(0.30)AB | 1.6(0.23)C | 1.3(0.05)C | ||

| 1:2 | 24.6(0.23)C | 27.1(0.6)C | 7.03(0.11)CD | 1.9(0.15)C | 1.6(0.03)D | ||

| System | Filler content (wt %) a | Talc/GF ratio | LCTE (10−6/°C) a,b,c | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 20→60 °C | 60→30 °C | −30→20 °C | |||||||

| HDPE6706 | 0 | 0 | 203.9(3.0)G | 164.8(6.3)G | 143.8(4.8)G | ||||

| HDPEAD60 | 0 | 0 | 199.1(2.8)G | 162.7(2.5)F | 137.8(1.0)F | ||||

| HDPE AD60/ HDPE6706/ Talc/GF | 10 | 2:1 | 144.9(3.4)F | 123.2(8.4)E | 113.5(2.3)E | ||||

| 1:1 | 117.7(0.9)D | 111.3(2.1)D | 105.1(0.9)D | ||||||

| 1:2 | 124.0(0.7)E | 114.2(3.2)D | 107.0(0.5)D | ||||||

| 30 | 2:1 | 75.5(2.7)C | 67.1(2.5)C | 66.3(0.7)C | |||||

| 1:1 | 48.2(0.7)A | 47.8(1.3)A | 52.5(0.3)A | ||||||

| 1:2 | 54.6(0.5)B | 53.8(2.2)B | 54.8(0.6)B | ||||||

2.2.3. Thermal Expansion

3. Experimental Section

3.1. Raw Material and Experimental Design

3.2. Sample Preparation

3.3. Characterization and Data Analysis

3.4. Statistical Data Analysis.

4. Conclusions

- (1)

- The use of silane-modified short GFs had a much larger effect in improving mechanical properties and in reducing LCTE values of filled composites compared with the use of talc due to enhanced bonding to the matrix, larger aspect ratio and fiber alignment for GFs.

- (2)

- Mechanical properties and LCTE values of composites with combined talc and GF fillers varied with talc and GF ratio at a given total filler loading level. The use of a larger portion of GFs in the mix can lead to better composite performance, while the use of talc can help lower the composite costs and increase its recyclability. The use of 30 wt % combined filler seems necessary to control LCTE values of filled HDPE in the data value range generally reported for commercial wood plastic composites.

- (3)

- Tensile modulus for talc-filled composite can be predicted with rule of mixture, while a PPA-based model can be used to predict the modulus and strength of GF-filled composites.

- (4)

- The material developed can be used as an effective shell layer in co-extruded NFPCs/WPCs to enhance their performance properties.

Acknowledgments

Conflicts of Interest

References

- Yao, F.; Wu, Q.L. Coextruded polyethylene and wood-flour composite: Effect of shell thickness, wood loading, and core quality. J. Appl. Polym. Sci. 2010, 118, 3594–3601. [Google Scholar] [CrossRef]

- Jin, S.; Matuana, L.M. Wood/plastic composites co-extruded with multi-walled carbon nanotube-filled rigid poly(vinyl chloride) cap layer. Polym. Int. 2010, 59, 648–657. [Google Scholar]

- Kim, B.J.; Yao, F.; Han, G.P.; Wu, Q.L. Performance of bamboo plastic composites with hybrid bamboo and precipitated calcium carbonate fillers. Polym. Compos. 2012, 33, 68–78. [Google Scholar] [CrossRef]

- Karrad, S.; Cuesta, J.M.L.; Crespy, A. Influence of a fine talc on the properties of composites with high density polyethylene and polyethylene/polystyrene blends. J. Mater. Sci. 1998, 33, 453–461. [Google Scholar] [CrossRef]

- Huang, R.; Xiong, W.; Xu, X.; Wu, Q. Effect of hybrid mineral and bamboo fillers on thermal expansion behavior of bamboo fiber and recycled polypropylene-polyethylene composites. BioResources 2012, 7, 4563–4574. [Google Scholar]

- Huang, R.; Kim, B.J.; Lee, S.Y.; Zhang, Y.; Wu, Q. Co-extruded wood plastic composites with talc filled shells: morphology, mechanical and thermal expansion performance. BioResources 2013, 8, 2283–2299. [Google Scholar]

- Singh, S.; Mohanty, A.K. Wood fiber reinforced bacterial bioplastic composites: Fabrication and performance evaluation. Compos. Sci. Technol. 2007, 67, 1753–1763. [Google Scholar] [CrossRef]

- Nielson, L.E.; Landel, R.F. Mechanical Properties of Polymers and Composites; CRC Press: New York, NY, USA, 1993. [Google Scholar]

- Tsai, S.W.; Pagano, N.J. Invariant Properties of Composite Materials; Defense Technical Information: Fort Bellvoir, VA, USA, 1968. [Google Scholar]

- Pilla, S.; Gong, S.; O’Neill, E.; Rowell, R.M.; Krzysik, A.M. Polylactide-pine wood flour composites. Polym. Eng. Sci. 2008, 48, 578–587. [Google Scholar] [CrossRef]

- Johnson, R.K.; Zink-Sharp, A.; Renneckar, S.H.; Glasser, W.G. Mechanical properties of wetlaid lyocell and hybrid fiber-reinforced composites with polypropylene. Compos. Part. A Appl Sci. Manuf. 2008, 39, 470–477. [Google Scholar] [CrossRef]

- Fornes, T.D.; Paul, D.R. Modeling properties of nylon 6/clay nanocomposites using composite theories. Polymer 2003, 44, 4993–5013. [Google Scholar] [CrossRef]

- Tsai, S.W.; Halpin, J.C.; Pagano, N.J. Composite Materials Workshop; Technomic Publishing Co. Inc.: Stamford, CT, USA, 1968; pp. 233–253. [Google Scholar]

- Fu, S.Y.; Lauke, B. The elastic modulus of misaligned short-fiber-reinforced polymers. Compos. Sci. Technol. 1998, 58, 389–400. [Google Scholar] [CrossRef]

- Jayaraman, K.; Kortschot, M.T. Correction to the Fukuda-Kawata Young’s modulus theory and the Fukuda-Chou strength theory for short fibre-reinforced composite materials. J. Mater. Sci. 1996, 31, 2059–2064. [Google Scholar] [CrossRef]

- Nicodemo, L.; Nicolais, L. Mechanical-properties of metal polymer composites. J. Mater. Sci. Lett. 1983, 2, 201–203. [Google Scholar] [CrossRef]

- Piggott, M.R. Short fibre polymer composites: A fracture-based theory of fibre reinforcement. J. Compos. Mater. 1994, 28, 588–606. [Google Scholar]

- Huda, M.S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Schut, E. “Green” composites from recycled cellulose and poly(lactic acid): Physico-mechanical and morphological properties evaluation. J. Mater. Sci. 2005, 16, 4221–4229. [Google Scholar] [CrossRef]

- Matuana, L.M.; Balatinecz, J.J.; Park, C.B. Effect of surface properties on the adhesion between PVC and wood veneer laminates. Polym. Eng. Sci. 1998, 38, 765–773. [Google Scholar] [CrossRef]

- Danyadi, L.; Renner, K.; Moczo, J.; Pukanszky, B. Wood flour filled polypropylene composites: Interfacial adhesion and micromechanical deformations. Polym. Eng. Sci. 2007, 47, 1246–1255. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Interfacial, dynamic mechanical, and thermal fiber reinforced behavior of MAPE treated sisal fiber reinforced HDPE composites. J. Appl. Polym. Sci. 2006, 102, 3306–3315. [Google Scholar] [CrossRef]

- IBM. IBM SPSS Advanced statistics 20; IBM Corporation: Armonk, NY, USA, 2011. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Huang, R.; Xu, X.; Lee, S.; Zhang, Y.; Kim, B.-J.; Wu, Q. High Density Polyethylene Composites Reinforced with Hybrid Inorganic Fillers: Morphology, Mechanical and Thermal Expansion Performance. Materials 2013, 6, 4122-4138. https://doi.org/10.3390/ma6094122

Huang R, Xu X, Lee S, Zhang Y, Kim B-J, Wu Q. High Density Polyethylene Composites Reinforced with Hybrid Inorganic Fillers: Morphology, Mechanical and Thermal Expansion Performance. Materials. 2013; 6(9):4122-4138. https://doi.org/10.3390/ma6094122

Chicago/Turabian StyleHuang, Runzhou, Xinwu Xu, Sunyoung Lee, Yang Zhang, Birm-June Kim, and Qinglin Wu. 2013. "High Density Polyethylene Composites Reinforced with Hybrid Inorganic Fillers: Morphology, Mechanical and Thermal Expansion Performance" Materials 6, no. 9: 4122-4138. https://doi.org/10.3390/ma6094122

APA StyleHuang, R., Xu, X., Lee, S., Zhang, Y., Kim, B.-J., & Wu, Q. (2013). High Density Polyethylene Composites Reinforced with Hybrid Inorganic Fillers: Morphology, Mechanical and Thermal Expansion Performance. Materials, 6(9), 4122-4138. https://doi.org/10.3390/ma6094122