Ethylene Formation by Catalytic Dehydration of Ethanol with Industrial Considerations

Abstract

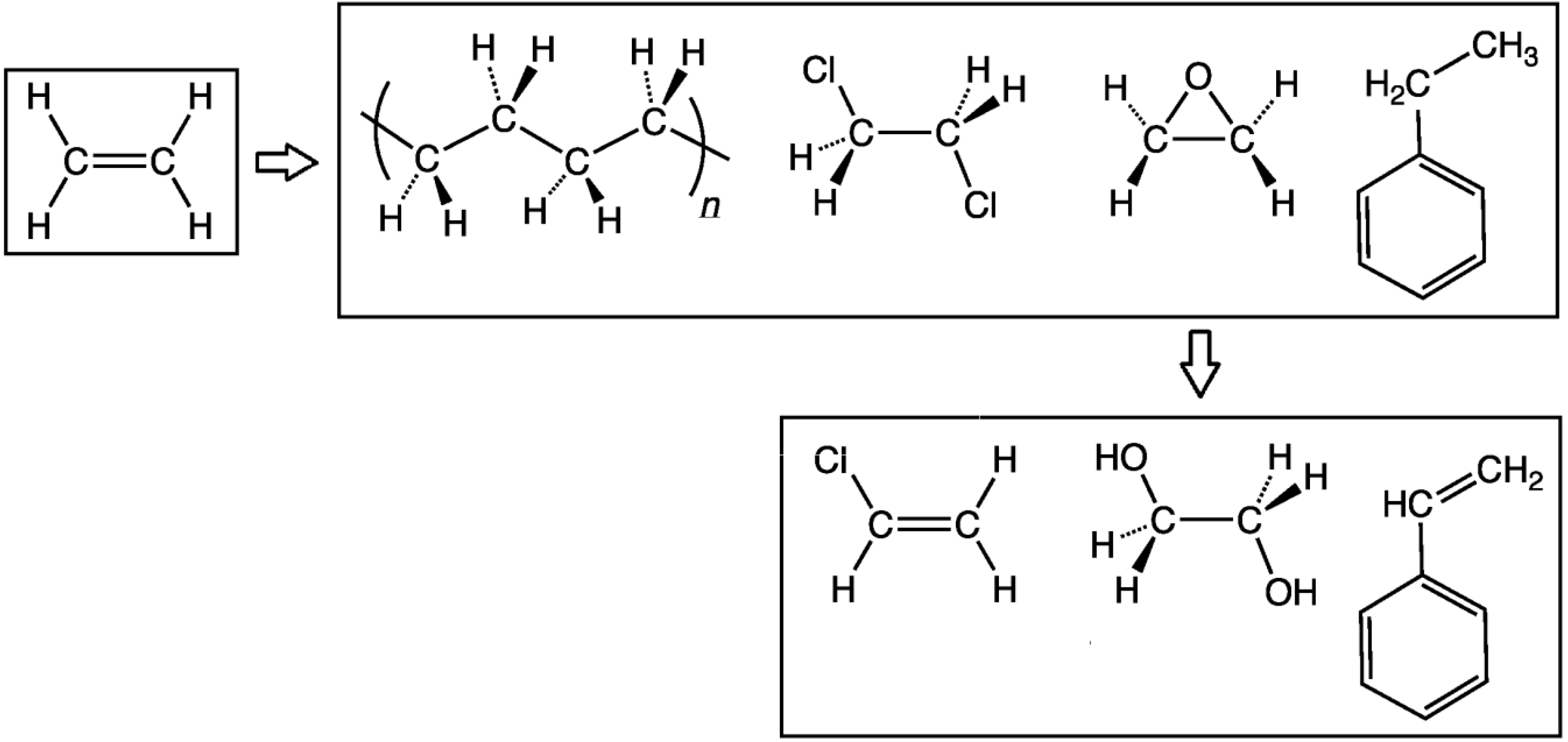

:1. Introduction

| Company | Location | Ton/year |

|---|---|---|

| Steam-cracking plants | – | – |

| Formosa Petrochemical Corporation | Mailiao, Taiwan, | 2,935,000 |

| Nova Chemicals Corporation | Joffre, Alberta, Canada | 2,811,792 |

| Arabian Petrochemical Company | Jubail, Saudi Arabia | 2,250,000 |

| ExxonMobil Chemical Company | Baytown, TX, USA | 2,197,000 |

| ChevronPhillips Chemical Company | Sweeny, TX, USA | 1,865,000 |

| Dow Chemical Company | Terneuzen, Netherlands | 1,800,000 |

| Ineos Olefins & Polymers | Chocolate Bayou, TX, USA | 1,752,000 |

| Equistar Chemicals LP | Channelview, TX, USA | 1,750,000 |

| Yanbu Petrochemical Company | Yanbu, Saudi Arabia | 1,705,000 |

| Equate Petrochemical Company | Shuaiba, Kuwait | 1,650,000 |

| Ethanol to ethylene plants | – | – |

| Braskem | Triunfo, Brazil | 200,000 |

| Dow Chemical Company | Santa Vitoria, Brazil (under construction) | 190,000 |

| Solvay Indupa | Santo Andre, Brazil | 60,000 |

2. Catalysis

2.1. Modification of γ-Al2O3

2.2. Modification of HZSM-5

2.3. Heteropolyacids

| Catalyst | Max ethylene selectivity | Ethanol conversion | Reaction Temperature | LHSV a/ WHSV b/ GHSV c | Lifespan, Stability | Comments | Reference |

|---|---|---|---|---|---|---|---|

| TiO2/γ-Al2O3 | 99.4% | 100% | 360–500°C | 26–234 h−1 a | 400 h, stable | Lab modified | [15] |

| 0.5% La-2% P-HZSM-5 | 99.9% | 100% | 240–280°C | 2 h−1 b | Very stable | Lab modified | [13] |

| Nano-CAT | 99.7% | 100% | 240°C | 1 h−1 b | 630 h, very stable | Lab modified | [25] |

| Ag3PW12O40 | 99.2% | 100% | 220°C | 6000 h−1 c | Stable in 9% humidity | Lab synthesized | [29] |

| TPA-MCM-41 | 99.9% | 98% | 300°C | 2.9 h−1 b | Very stable | Lab modified | [31] |

| STA-MCM-41 | 99.9% | 99% | 250°C | 2.9 h−1 b | Stable | Lab modified | [33] |

| TRC-92 | 99.0% | 70% | 280°C | 2.9 h−1 b | Very stable | Lab synthesized | [34] |

| SynDol (Halcon) (SD, USA) | 96.8% | 99% | 450 °C | 26–234 h−1 a | Very stable | Commercial catalyst | [15] |

3. Reaction Conditions

| Catalyst | Reaction Condition | Condition Setting | Ethanol Conversion | Ethylene Selectivity | Reference |

|---|---|---|---|---|---|

| TiO2/γ-Al2O3 | Space velocity (LHSV) | 52 h −1 | 100% | 98% | [15] |

| 234 h −1 | 96% | 97% | |||

| SAPO | Space velocity (WHSV) | 2 h −1 | 100% | 100% | [8] |

| 30 h −1 | 65% | 20% | |||

| La-HZSM-5 | Space velocity (LHSV) | 0.5 h −1 | 100% | 97% | [23] |

| 25 h −1 | 39% | 100% |

| Catalyst | Reaction Condition | Condition Setting | Ethanol Conversion | Ethylene Selectivity | GHSV | Reference |

|---|---|---|---|---|---|---|

| AgPW | Humidity | 2% | 70% (470 K) | 100% (470 K) | 6000 h−1 | [36] |

| 10% | 100% (470 K) | 80% (470 K) | ||||

| AgPW | Humidity | 2% | 75% (493 K) | 100% (493 K) | 6000 h−1 | [29] |

| 9% | 100% (493 K) | 99% (493 K) |

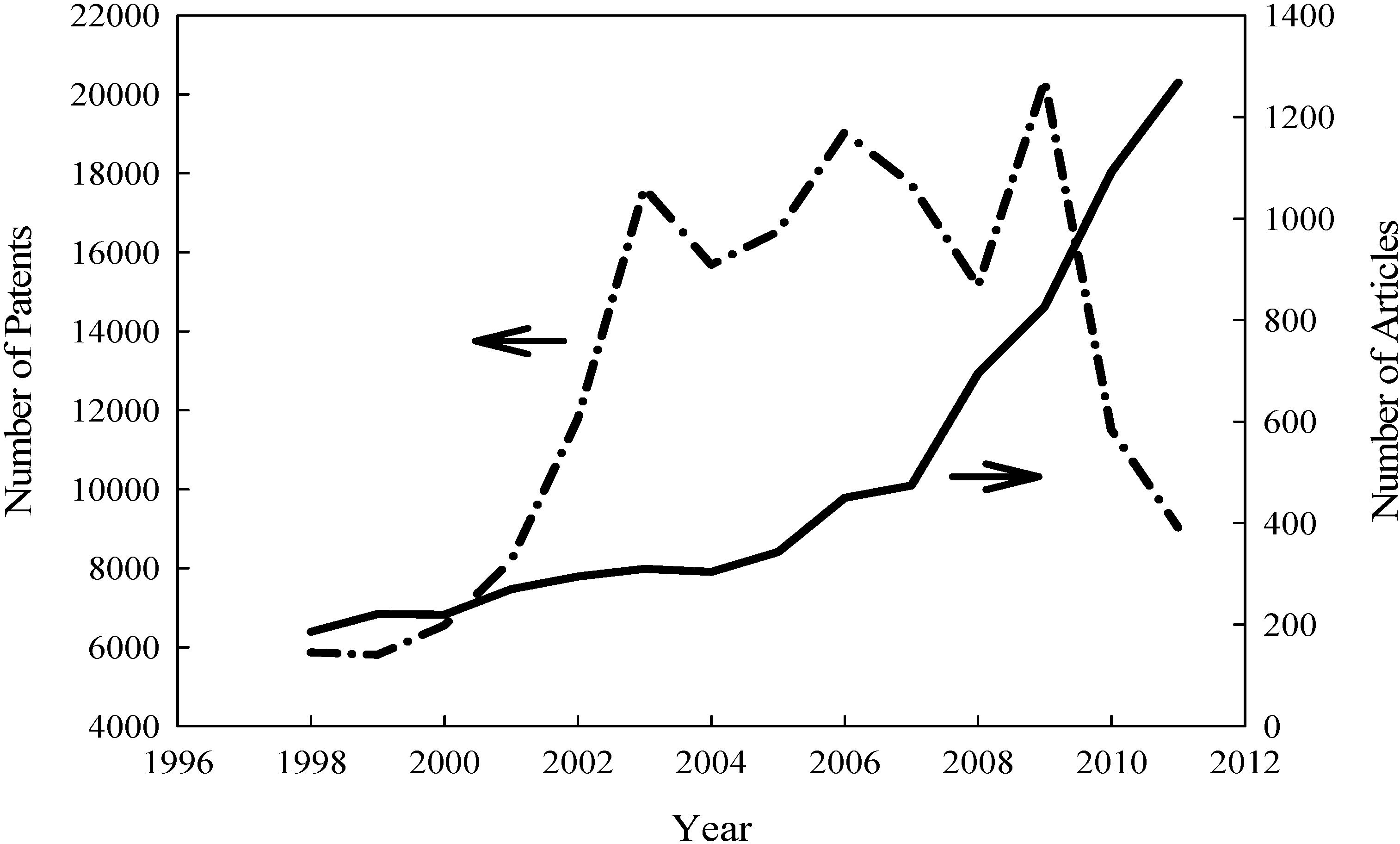

4. Industrial Concerns

| Configuration | Minimum hot utility (MW) | Minimum cold utility (MW) | Net electricity (MW) | Net fuel (MW) |

|---|---|---|---|---|

| Stand-alone EtOH | 112.2 | 147.6 | 24.3 | 0.0 |

| Stand-alone Ethylene | 18.7 | 48.1 | −4.4 | −15.9 |

| Biorefinery | 79.2 | 141.1 | 8.0 | −7.9 |

| Bio-F 1 | 68.0 | 140.4 | 8.5 | 7.5 |

| Bio-MVR 2 | 32.1 | 102.4 | −15.8 | −7.9 |

| Bio-VHP 3 | 76.0 | 137.6 | 17.1 | −7.9 |

5. Conclusions

Acknowledgments

References

- Production: Growth is the Norm. Available online: http://pubs.acs.org/cen/coverstory/84/pdf/8428production.pdf (accessed on 23 July 2012).

- Ethylene. Available online: http://en.wikipedia.org/wiki/Ethylene (accessed on 23 July 2012).

- OECD SIDS Initial Assessment Profile—Ethylene. Available online: http://www.inchem.org/documents/sids/sids/74851.pdf (accessed on 23 July 2012).

- Kniel, L.; Winter, O.; Stork, K. Ethylene, Keystone to the Petrochemical Industry; M. Dekker: New York, NY, USA, 1980. [Google Scholar]

- True, W.R. Global ethylene capacity continues to advance in 2011. Available online: http://www.ogj.com/articles/print/vol-110/issue-07/special-report-ethylene-report/global-ethylene-capacity.html (accessed on 23 July 2012).

- Conti, L. An alternative route for ethanol use. Available online: http://www.eubia.org/uploads/media/Sardegnambiente_Conti_01.pdf (accessed on 23 July 2012).

- Voegle, E. Feeding the chemical market. Ethanol Producer Magazine. 5 March 2012. Available online: http://www.ethanolproducer.com/articles/8617/feeding-the-chemical-market (accessed on 23 July 2012).

- Chen, Y.; Wu, Y.; Tao, L.; Dai, B.; Yang, M.; Chen, Z.; Zhu, X. Dehydration reaction of bio-ethanol to ethylene over modified SAPO catalysts. J. Ind. Eng. Chem. 2010, 16, 717–722. [Google Scholar] [CrossRef]

- Wu, L.; Shi, X.; Cui, Q.; Wang, H.; Huang, H. Effects of the SAPO-11 synthetic process on dehydration of ethanol to ethylene. Front. Chem. Sci. Eng. 2011, 5, 60–66. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, R.; Yang, X.; Zhang, F. Comparison of four catalysts in the catalytic dehydration of ethanol to ethylene. Microporous Mesoporous Mater. 2008, 116, 210–215. [Google Scholar] [CrossRef]

- Takahara, I.; Saito, M.; Inaba, M.; Murata, K. Dehydration of ethanol into ethylene over solid acid catalysts. Catal. Lett. 2005, 105, 249–252. [Google Scholar] [CrossRef]

- Bokade, V.V.; Yadav, G.D. Heteropolyacid supported on montmorillonite catalyst for dehydration of dilute bio-ethanol. Appl. Clay Sci. 2011, 53, 263–271. [Google Scholar] [CrossRef]

- Zhan, N.; Hu, Y.; Li, H.; Yu, D.; Han, Y.; Huang, H. Lanthanum-phosphorous modified HZSM-5 catalysts in dehydration of ethanol to ethylene: A comparative analysis. Catal. Commun. 2010, 11, 633–637. [Google Scholar] [CrossRef]

- Braskem Ethanol-to-Ethylene Plant, Brazil. Available online: http://www.chemicals-technology.com/projects/braskem-ethanol/ (accessed on 23 July 2012).

- Chen, G.; Li, S.; Jiao, F.; Yuan, Q. Catalytic dehydration of bioethanol to ethylene over TiO2/γ-Al2O3 catalysts in microchannel reactors. Catal. Today 2007, 125, 111–119. [Google Scholar] [CrossRef]

- Doheim, M.M.; Hanafy, S.A.; El-Shobaky, G.A. Catalytic conversion of ethanol and isopropanol over the Mn2O3/Al2O3 system doped with Na2O. Mater. Lett. 2002, 55, 304–311. [Google Scholar] [CrossRef]

- Madeira, F.F.; Gnep, N.S.; Magnoux, P.; Maury, S.; Cadran, N. Ethanol transformation over HFAU, HBEA and HMFI zeolites presenting similar Brønsted acidity. Appl. Catal. A 2009, 367, 39–46. [Google Scholar] [CrossRef]

- Ramesh, K.; Hui, L.M.; Han, Y.; Borgna, A. Structure and reactivity of phosphorous modified H-ZSM-5 catalysts for ethanol dehydration. Catal. Commun. 2009, 10, 567–571. [Google Scholar] [CrossRef]

- Ramesh, K.; Jie, C.; Han, Y.; Borgna, A. Synthesis, characterization, and catalytic activity of phosphorous modified H-ZSM-5 catalysts in selective ethanol dehydration. Ind. Eng. Chem. Res. 2010, 49, 4080–4090. [Google Scholar] [CrossRef]

- Ramesh, K.; Goh, Y.L.E.; Gwie, C.G.; Jie, C.; White, T.J.; Borgna, A. Ethanol dehydration activity on hydrothermally stable LaPxOy catalysts synthesized using CTAP template. J. Porous Mater. 2012, 19, 423–431. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, R.; Yang, X. Effect of P content on the catalytic performance of P-modified HZSM-5 catalysts in dehydration of ethanol to ethylene. Catal. Lett. 2008, 124, 384–391. [Google Scholar] [CrossRef]

- Mao, R.L.V.; Nguyen, T.M.; McLaughlin, G.P. The bioethanol-to-ethylene (B.E.T.E.) process. Appl. Catal. 1989, 48, 265–277. [Google Scholar] [CrossRef]

- Ouyang, J.; Kong, F.; Su, G.; Hu, Y.; Song, Q. Catalytic conversion of bio-ethanol to ethylene over La-modified HZSM-5 catalysts in a bioreactor. Catal. Lett. 2009, 132, 64–74. [Google Scholar] [CrossRef]

- Sun, L.; Guo, X.; Liu, M.; Wang, X. Ethylation of coking benzene over nanoscale HZSM-5 zeolites: Effects of hydrothermal treatment, calcination and La2O3 modification. Appl. Catal. A 2009, 355, 184–191. [Google Scholar] [CrossRef]

- Bi, J.; Guo, X.; Liu, M.; Wang, X. High effective dehydration of bio-ethanol into ethylene over nanoscale HZSM-5 zeolite catalysts. Catal. Today 2010, 149, 143–147. [Google Scholar] [CrossRef]

- Zhang, C.; Guo, X.; Song, C.; Zhao, S.; Wang, X. Effects of steam and TEOS modification on HZSM-5 zeolite for 2,6-dimethylnaphthalene synthesis by methylation of 2-methylnaphthalene with methanol. Catal. Today 2010, 149, 196–201. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, H.; Tan, W.; Zhang, M.; Liu, M.; Song, C.; Wang, X.; Guo, X. Effect of metal modification of HZSM-5 on catalyst stability in the shape-selective methylation of toluene. Catal. Today 2010, 156, 69–73. [Google Scholar] [CrossRef]

- Sendesi, T.S.M.; Towfighi, J.; Keyvanloo, K. The effect of Fe, P and Si/Al molar ratio on stability of HZSM-5 catalyst in naphtha thermal-catalytic cracking to light olefins. Catal. Commun. 2012, 27, 114–118. [Google Scholar] [CrossRef]

- Gurgul, J.; Zimowska, M.; Mucha, D.; Socha, R.P.; Matachowski, L. The influence of surface composition of Ag3PW12O40 and Ag3PMo12O40 salts on their catalytic activity in dehydration of ethanol. J. Mol. Catal. A 2011, 351, 1–10. [Google Scholar] [CrossRef]

- Okuhara, T.; Mizuno, N.; Misono, M.; Eley, D.D.; Haag, W.O. Catalytic chemistry of heteropoly compounds. Adv. Catal. 1996, 41, 113–252. [Google Scholar]

- Ciftci, A.; Varisli, D.; Tokay, K.C.; Sezgi, N.A.; Dogu, T. Dimethyl ether, diethyl ether & ethylene from alcohols over tungstophosphoric acid based mesoporous catalysts. Chem. Eng. J. 2012, in press. [Google Scholar]

- Varisli, D.; Dogu, T.; Dogu, G. Ethylene and diethyl-ether production by dehydration reaction of ethanol over different heteropolyacid catalysts. Chem. Eng. Sci. 2007, 62, 5349–5352. [Google Scholar] [CrossRef]

- Varisli, D.; Dogu, T.; Dogu, G. Silicotungstic acid impregnated MCM-41-like mesoporous solid acid catalysts for dehydration of ethanol. Ind. Eng. Chem. Res. 2008, 47, 4071–4076. [Google Scholar] [CrossRef]

- Varisli, D.; Dogu, T.; Dogu, G. Petrochemicals from ethanol over a W-Si-based nanocomposite bidisperse solid acid catalyst. Chem. Eng. Sci. 2010, 65, 153–159. [Google Scholar] [CrossRef]

- Kochar, N.K.; Merims, R.; Padia, A.S. Ethylene from Ethanol. Chem. Eng. Prog. 1981, 6, 66–70. [Google Scholar]

- Matachowski, L.; Zimowska, M.; Mucha, D.; Machej, T. Ecofriendly production of ethylene by dehydration of ethanol over Ag3PW12O40 salt in nitrogen and air atmospheres. Appl. Catal. B 2012, 123–124, 448–456. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, K.; Xue, J.; Zhang, J. Optimization of ethylene production from ethanol dehydration using Zn-Mn-Co/HZSM-5 by response surface methodology. Chin. J. Biotechnol. 2011, 27, 412–418. [Google Scholar]

- Suo, H.; Jiang, X.; Hu, Y.; Su, G. Optimization of the reaction conditions of ethanol dehydration to ethylene based on RBF neural network simulation. Pet. Proc. Petrochem. 2010, 41, 69–73. [Google Scholar]

- Algenol company description. Available online: http://www.algenolbiofuels.com (accessed on 13 August 2012).

- Biorenewable Business Platform. Economical feasibility of the sugarbeet-to-ethylene value chain in Zuid-West Nederland. Available online: http://www.biobasedeconomy.nl/wp-content/uploads/2012/06/Van-suiker-tot-ethyleen-BBP-2012.pdf (accessed on 23 July 2012).

- Seddon, D. Petrochemical Economics: Technology Section in a Carbon Constrained World; Imperial College Press: London, UK, 2010; Volume 8, pp. 1–19. [Google Scholar]

- Parker, M. Ethanol drops from eight-month high as corn prices decline. Available online: http://www.businessweek.com/news/2012-07-19/ethanol-drops-from-eight-month-high-as-corn-prices-decline (accessed on 23 July 2012).

- IEA-ETSAP and IRENA. Production of Bio-ethylene. Available online: http://iea-etsap.org/web/HIGHLIGHTS%20PDF/I13_HL_Bioethylene_Broeren_Mar2012_FINAL9_GSOK.pdf (access on 23 July 2012).

- Ethylene prices reach seven-year high in April. http://www.prnewswire.com/news-releases/ethylene-prices-reach-seven-year-high-in-april-149491835.html (accessed on 23 July 2012).

- Arvidsson, M.; Lundin, B. Process Integration Study of a Biorefinery Producing Ethylene from Lignocellulosic Feedstock for a Chemical Cluster. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2011. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Fan, D.; Dai, D.-J.; Wu, H.-S. Ethylene Formation by Catalytic Dehydration of Ethanol with Industrial Considerations. Materials 2013, 6, 101-115. https://doi.org/10.3390/ma6010101

Fan D, Dai D-J, Wu H-S. Ethylene Formation by Catalytic Dehydration of Ethanol with Industrial Considerations. Materials. 2013; 6(1):101-115. https://doi.org/10.3390/ma6010101

Chicago/Turabian StyleFan, Denise, Der-Jong Dai, and Ho-Shing Wu. 2013. "Ethylene Formation by Catalytic Dehydration of Ethanol with Industrial Considerations" Materials 6, no. 1: 101-115. https://doi.org/10.3390/ma6010101

APA StyleFan, D., Dai, D.-J., & Wu, H.-S. (2013). Ethylene Formation by Catalytic Dehydration of Ethanol with Industrial Considerations. Materials, 6(1), 101-115. https://doi.org/10.3390/ma6010101