Evaluation of Titanium Alloys Fabricated Using Rapid Prototyping Technologies—Electron Beam Melting and Laser Beam Melting

Abstract

:1. Introduction

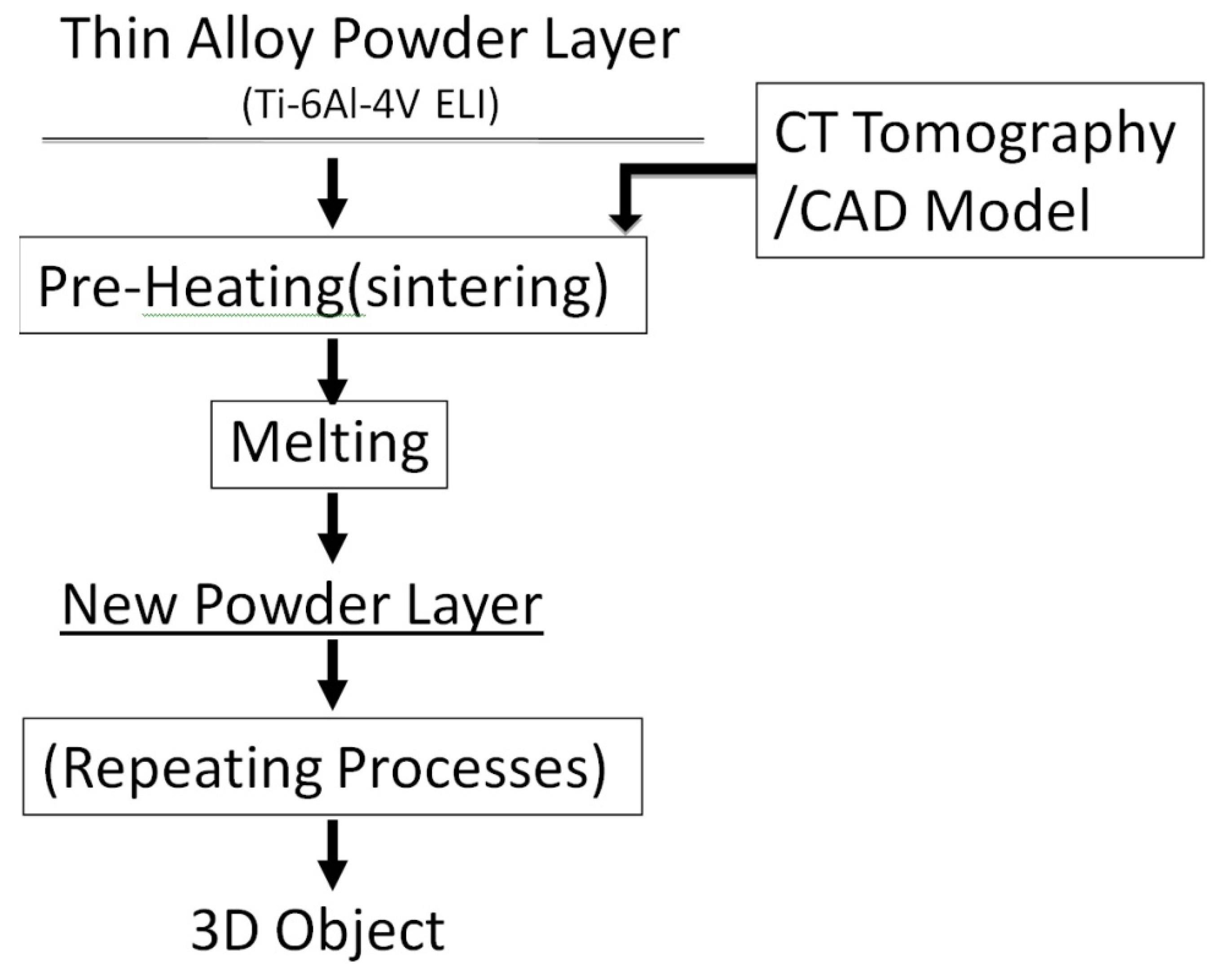

2. Materials and Methods

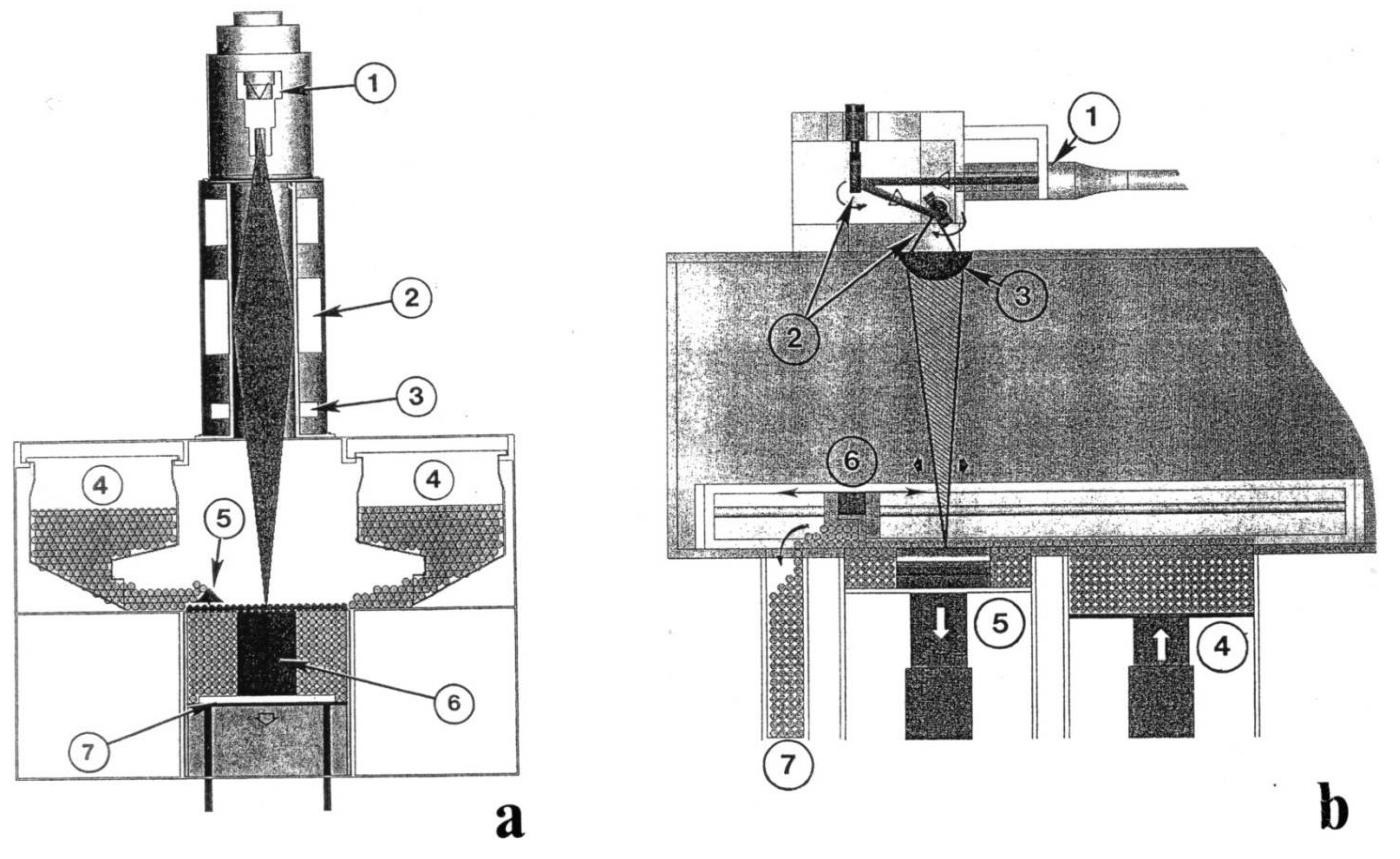

2.1. EBM and LBM Systems

| Process | Laser Beam Melting (EOSINT M270) | Electron Beam Melting (Arcam A2) |

|---|---|---|

| Environment | argon/nitrogen | |

| Vacuum/Helium | ||

| Temperature | 700 °C | 700 °C |

| Power | 5,500 W | 7,000 W |

| Efficiency | High | High |

| Powder (average size) | 20 µm | 40 µm |

| Scan Speed | 104 mm/s | 102 m/s |

| Charging | No | Yes |

| Beam/melt/pool | 0.1–0.5 mm | 0.2 mm–1.2 mm |

| Layer thickness | 50–100 µm | 100 µm |

| Building speed | 7–8 mm/h | 6–7 mm/h |

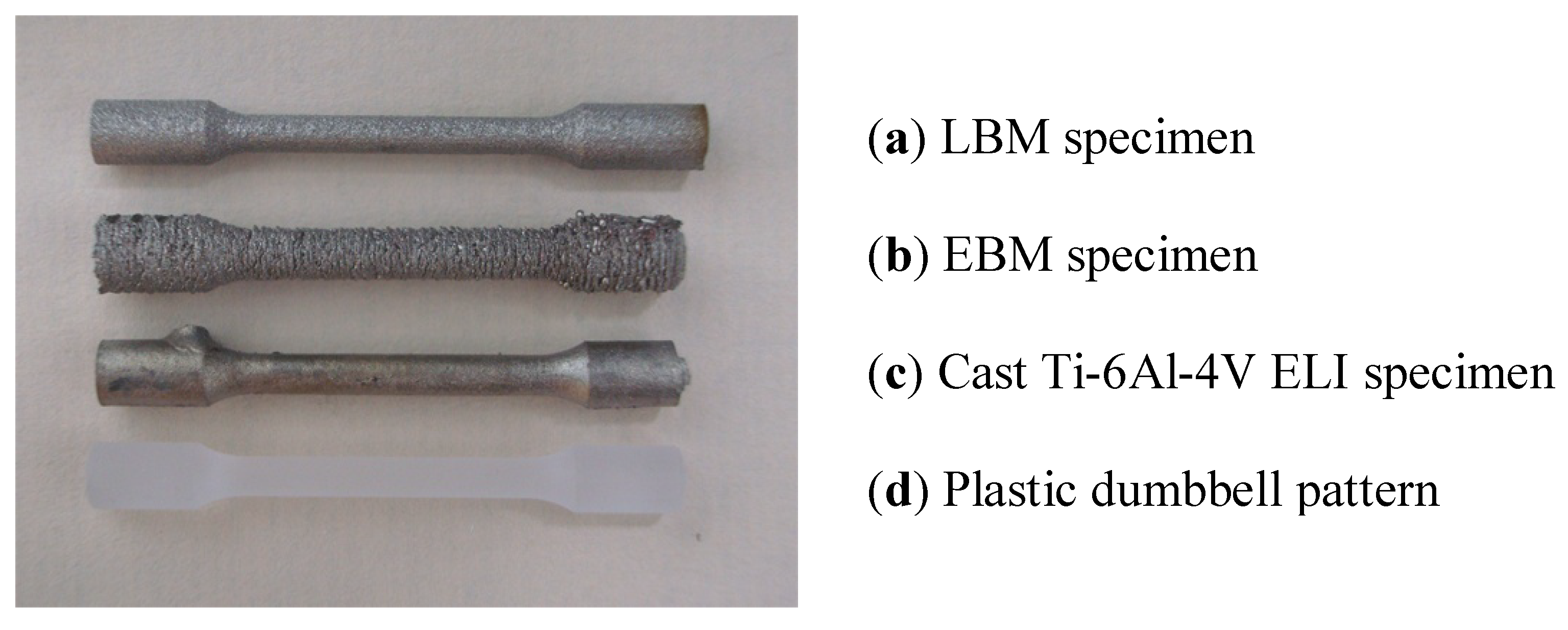

2.2. Fabrication of Specimens

| Process | Al | V | C | Fe | O | N | H | Ti |

|---|---|---|---|---|---|---|---|---|

| EBMPowder (ArcamAB) | 6.0 | 4.0 | 0.03 | 0.10 | 0.10 | 0.01 | <0.003 | Balance |

| LBM powder(EOS) | 6.0 | 4.1 | 0.02 | 0.10 | 0.08 | 0.01 | 0.0024 | Balance |

2.3. Optical Metallography

2.4. Electron Microscopy

2.5. Mechanical Properties

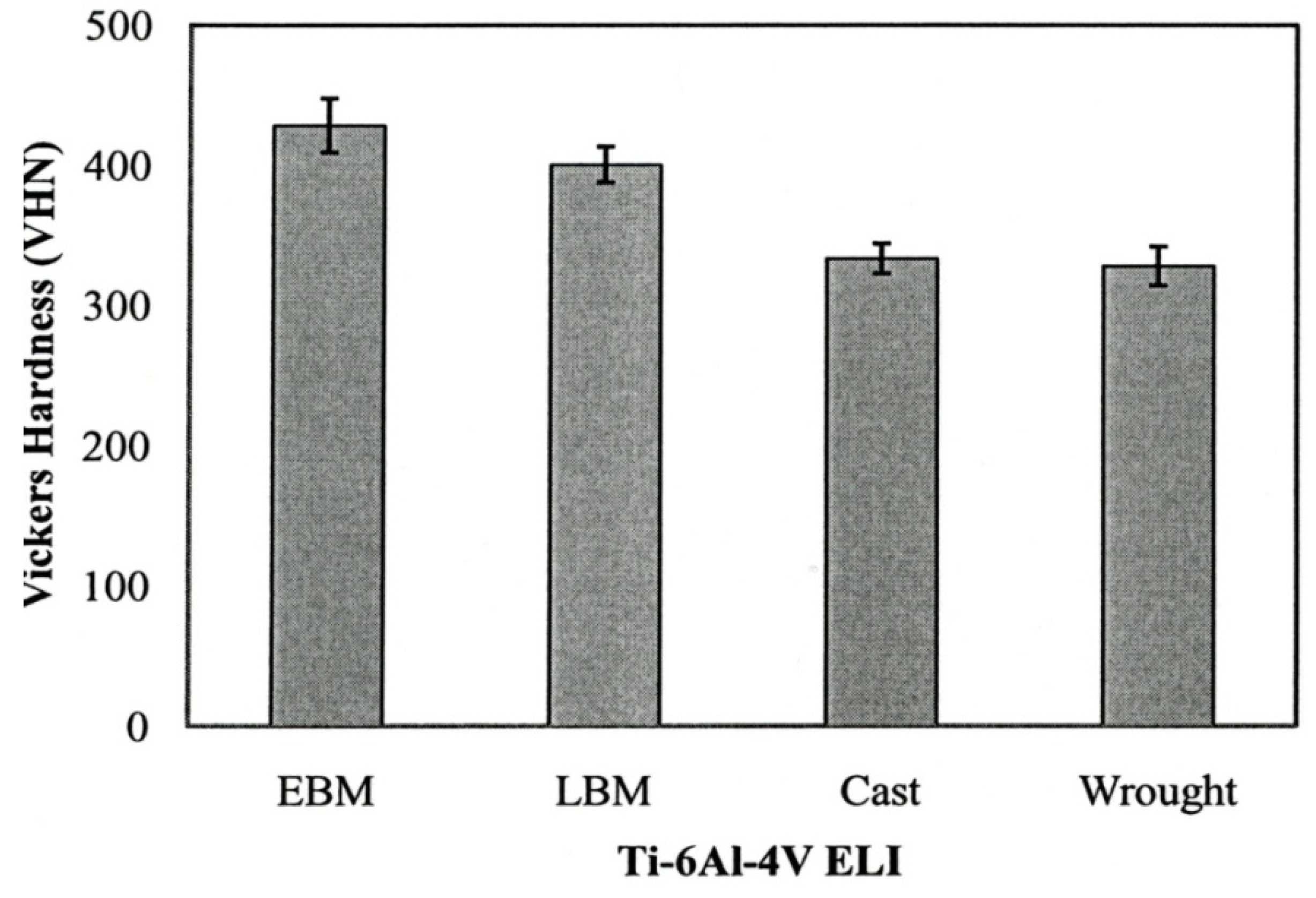

2.6. Microhardness

2.7. Grindability

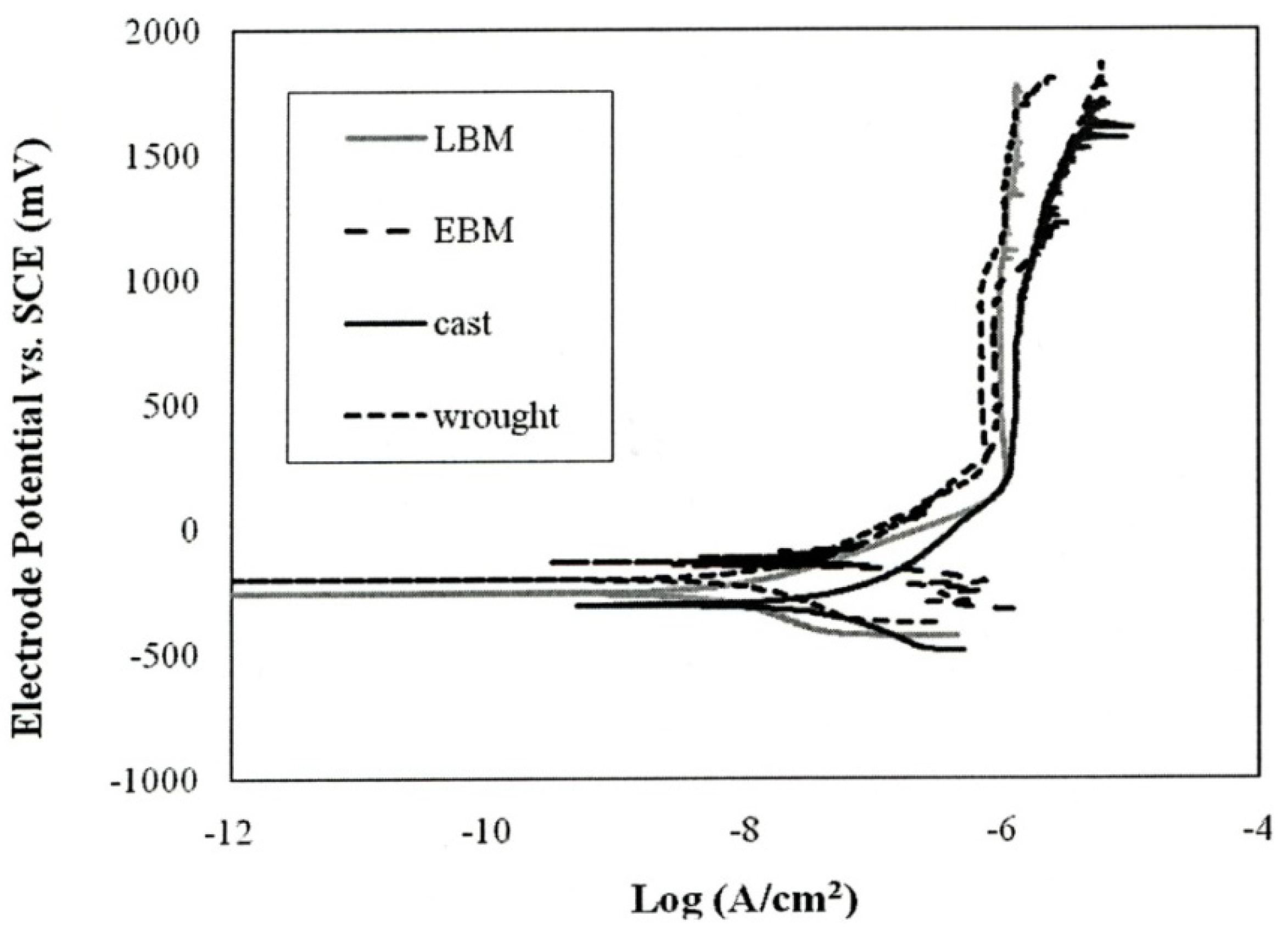

2.8. Corrosion Behavior

| Methods | Atmosphere | Potential ranges (mV) | Scan rate (mV/sec) | Corrosion parameters |

|---|---|---|---|---|

| Open-circuit potential (OCP) | - | - | - | OCP: OCP (mV) 16 h |

| Linear polarization | Aerated (Air + 10% CO2 ) | −8 < OCP to OCP < +8 | 0.1 | Polarization resistance: RP (MΩ·cm2) |

| Potentiodynamic cathodic polarization | - | OCP to 300 < OCP | 0.167 | Cathodic Tafel slope: βc (V/decade) |

| Potentiodynamic anodic polarization | Deaerated (N2 + 10% CO2 ) | 20 0< OCP to 2000 > OCP | 0.167 | Anodic Tafel slope: βa (V/decade) Corrosion current density: Icorr (A/cm2) Icorr = βaβc/2.3 RP (βa+βc) Pasive current density at 500 mV: Ipass (A/cm2) |

2.9. Statistical Analysis

3. Results

3.1. Exterior Appearance

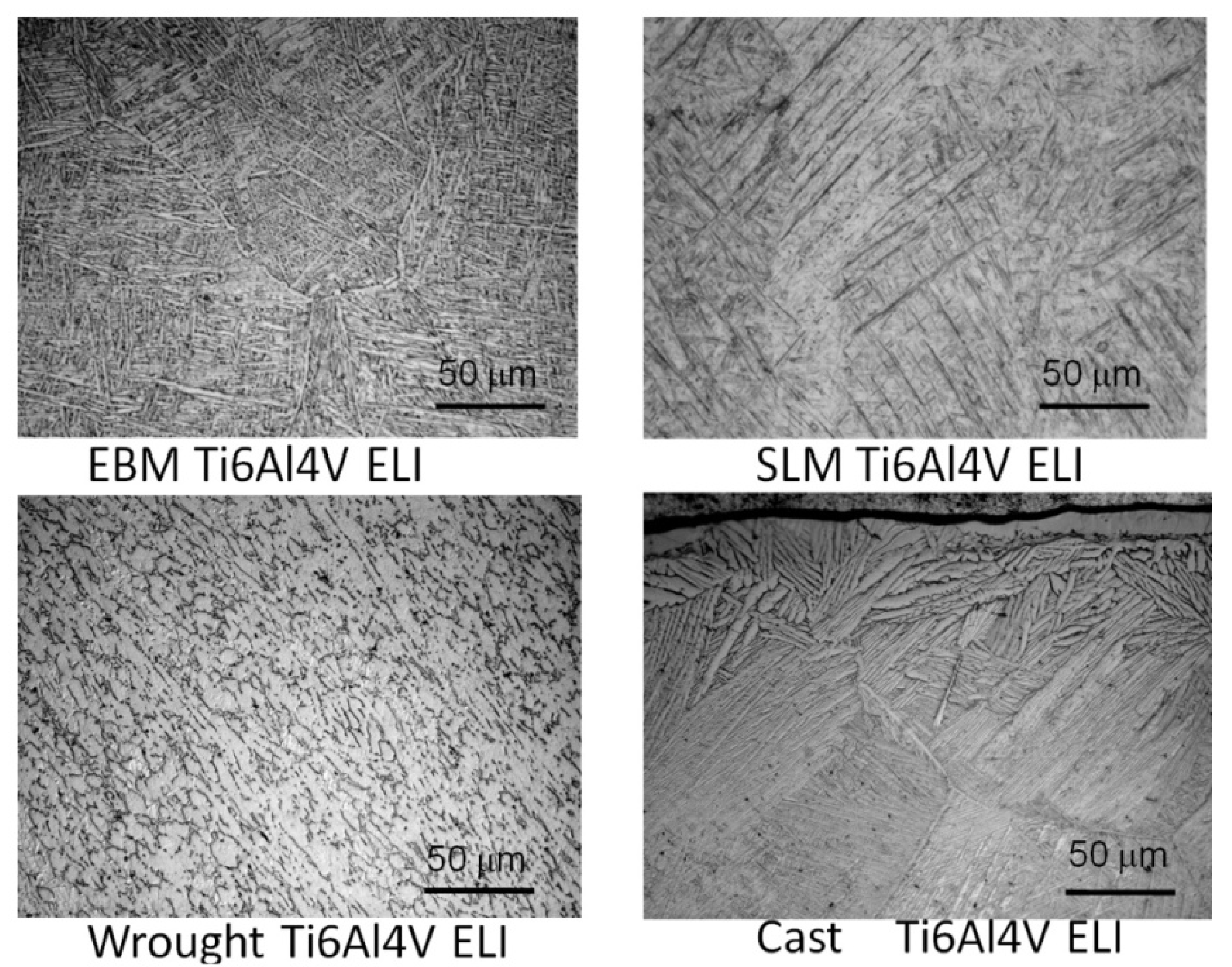

3.2. Microstructures by Optical Microscopy

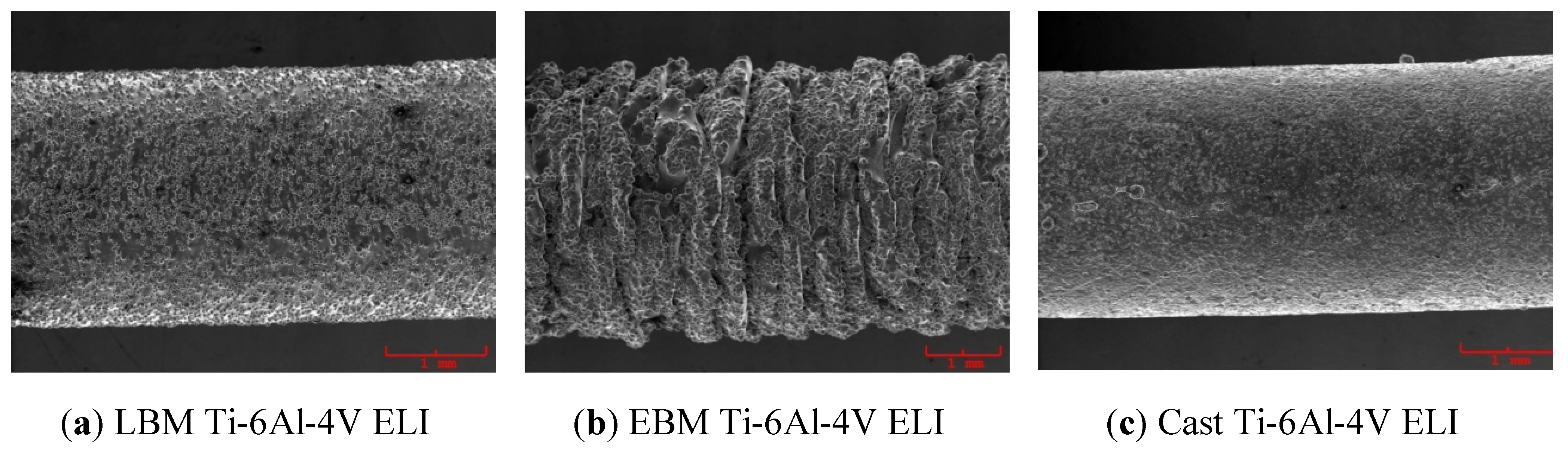

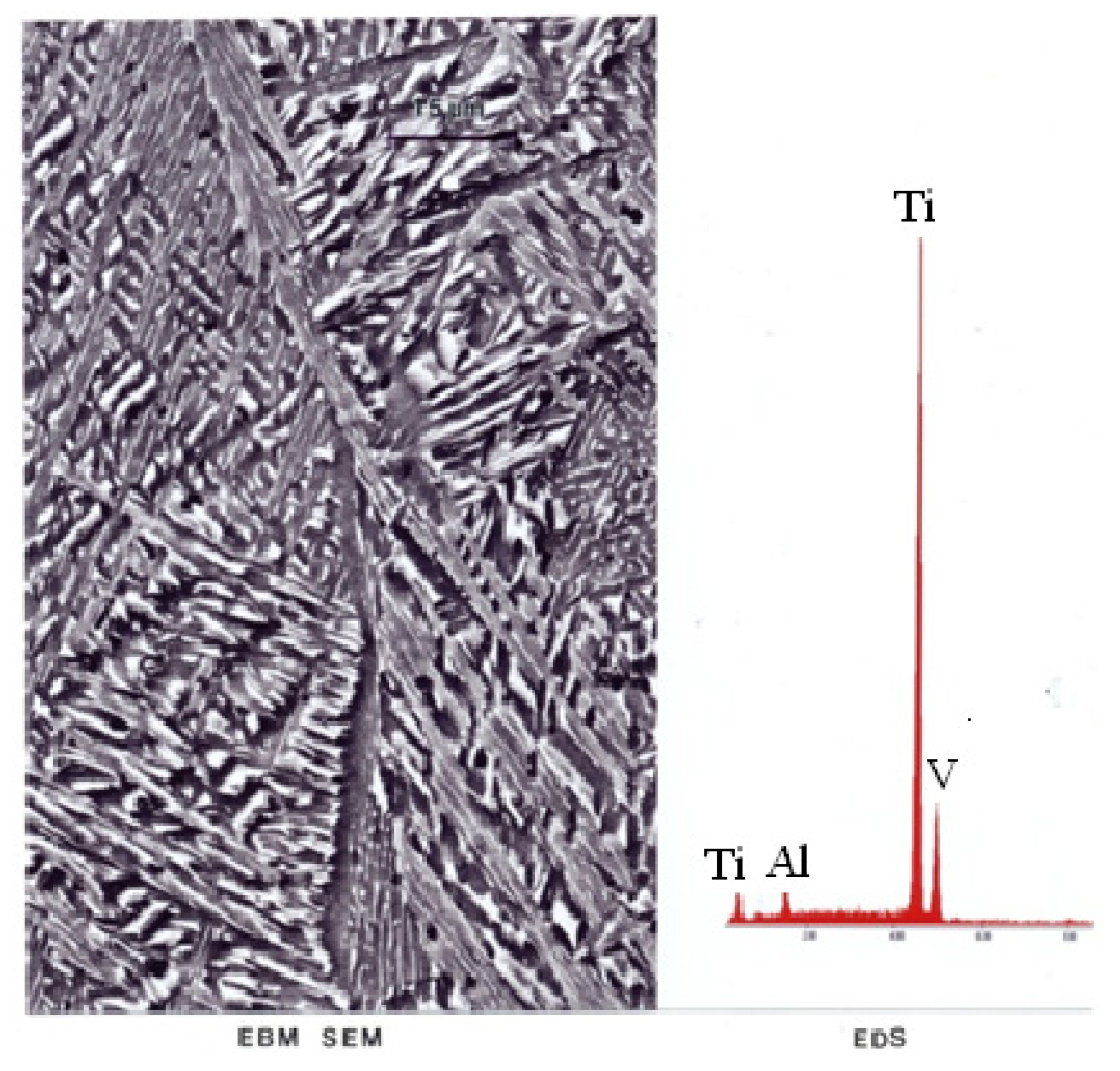

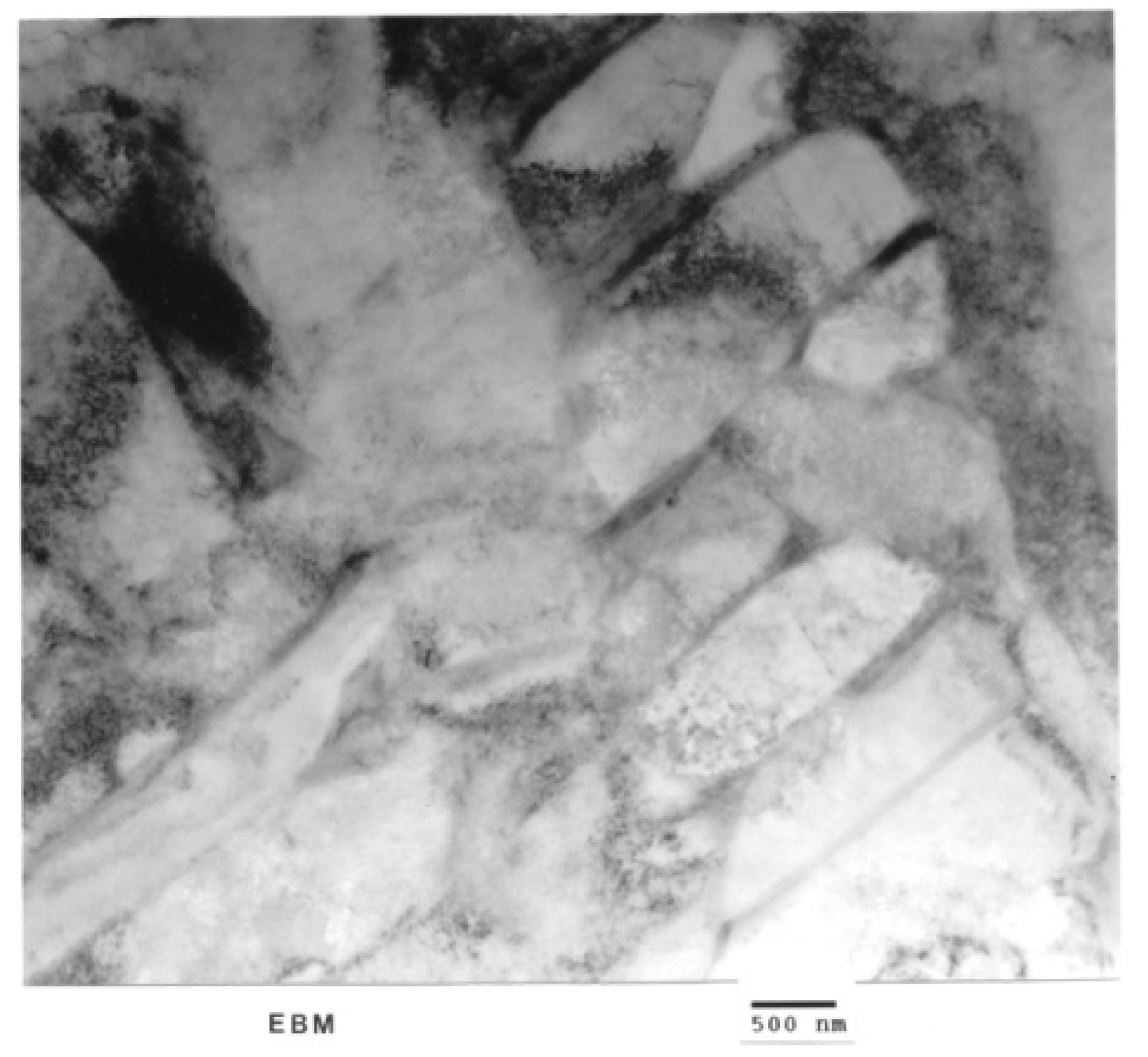

3.3. Microstructures by Electron Microscopy

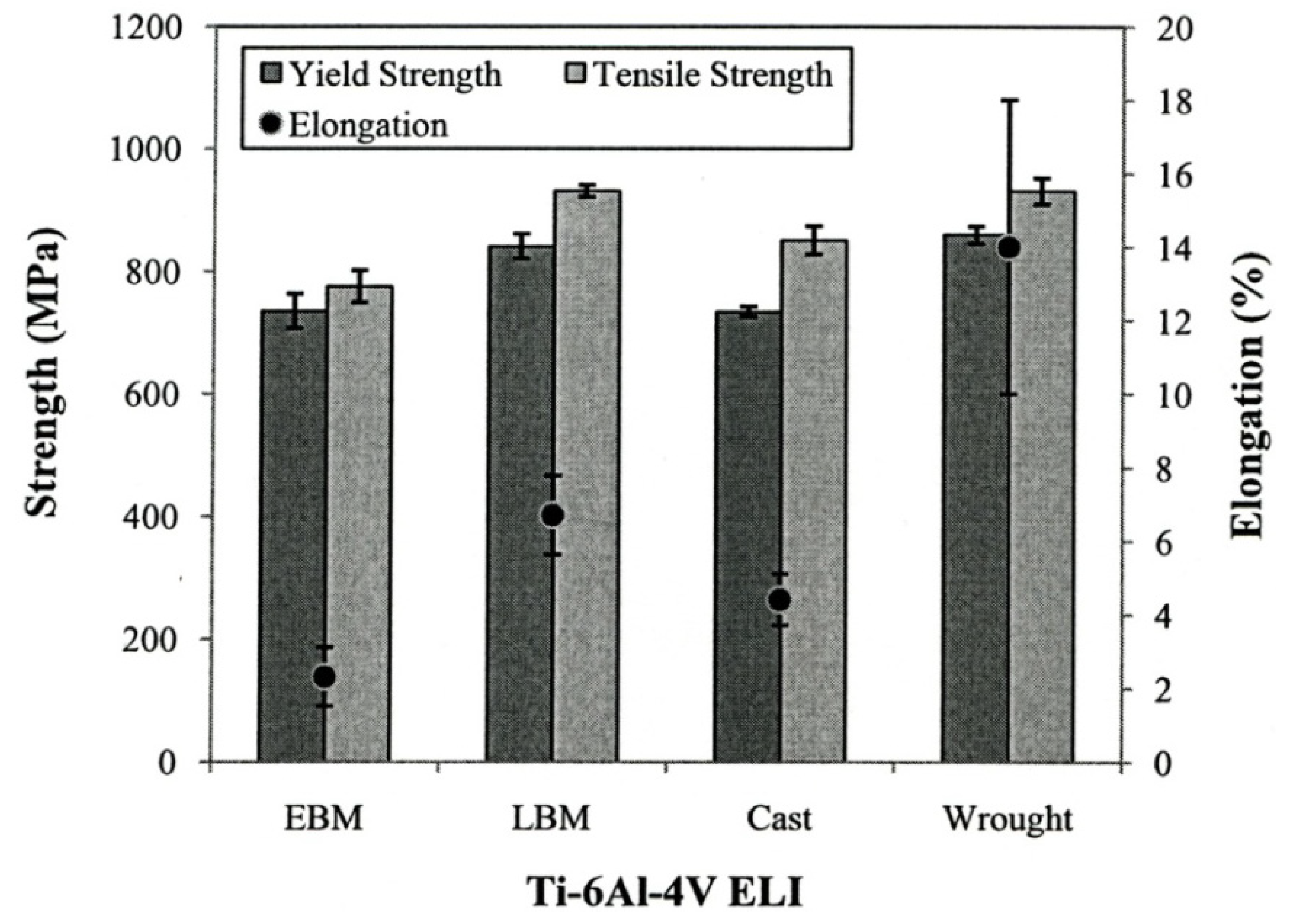

3.4. Mechanical Properties

3.5. Grindability

3.6. Corrosion Behavior

| OCP (mV) | Rp (MW) | icorr (nA/cm2) | ipassive (nA/cm2) | |||||

|---|---|---|---|---|---|---|---|---|

| LBM | −239 | (18) a | 1.81 | (0.5) a | 23 | (8) a | 870 | (179) a |

| EBM | −246 | (81) a | 0.44 | (0.3) b | 199 | (90) b | 1645 | (583) a |

| Cast | −243 | (18) a | 0.75 | (0.7) b,c | 199 | (158) b | 1137 | (752) a |

| Wrought | −159 | (18) a | 1.36 | (0.5) a,c | 49 | (25) a | 837 | (249) a |

4. Discussion

5. Conclusions

Acknowledgments

References

- Das, S.; Wohlert, M.; Beaman, J.J.; Bourell, D.L. Producing metal parts with selective laser sintering/hot isostatic pressing. J. Manag. 1998, 50, 17–20. [Google Scholar]

- Lü, L.; Fuh, J.Y.H.; Wong, Y.S. Laser-Induced Materials Sand Processes for Rapid Prototyping; Kluwer Academic Publishers: Boston, MA, USA, 2001. [Google Scholar]

- Murr, L.E.; Esquivel, E.V.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Martinez, E.Y.; Medina, F.; Hernandez, D.H.; Martinez, E.; Martinez, J.L.; et al. Microstructures and mechanical properties of electron beam-rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V. Mater. Char. 2009, 60, 96–105. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behaviorof Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef] [PubMed]

- ASM Handbook Committee. Metals Handbook, 9th ed.; Metallography and Microstructures, American Society for Metals: Metals Park, OH, USA, 1985; Volume 9. [Google Scholar]

- Koike, M.; Ohkubo, C.; Sato, H.; Fujii, H.; Okabe, T. Evaluation of cast Ti-Fe-O-N alloys for dental applications. Mater. Sci. Eng. C 2005, 25, 349–356. [Google Scholar] [CrossRef]

- Koike, M.; Chan, K.S.; Okabe, T. Dental titanium casting at baylor college of dentistry—Update. In Innovations in Titanium Technology; Gungor, M.H., Imam, M.A., Froes, F.H., Eds.; TMS: Warrendale, PA, USA, 2007; pp. 199–208. [Google Scholar]

- Koike, M.; Cai, Z.; Fujii, H.; Brezner, M.; Okabe, T. Corrosion behavior of cast titanium with reduced surface reaction layer made by a face-coating method. Biomaterials 2003, 24, 4541–4549. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Martinez, E.; Martinez, J.L.; Hernandez, D.H.; Machado, B.I.; Ramirez, D.A.; Wicker, R.B. Characterization of Ti-6Al-4V open cellular foams fabricated by additive manufacturing usingelectron beam melting. Mater. Sci. Eng. A 2010, 527, 1861–1868. [Google Scholar] [CrossRef]

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of Titanium Alloys Fabricated Using Rapid Prototyping Technologies—Electron Beam Melting and Laser Beam Melting. Materials 2011, 4, 1776-1792. https://doi.org/10.3390/ma4101776

Koike M, Greer P, Owen K, Lilly G, Murr LE, Gaytan SM, Martinez E, Okabe T. Evaluation of Titanium Alloys Fabricated Using Rapid Prototyping Technologies—Electron Beam Melting and Laser Beam Melting. Materials. 2011; 4(10):1776-1792. https://doi.org/10.3390/ma4101776

Chicago/Turabian StyleKoike, Mari, Preston Greer, Kelly Owen, Guo Lilly, Lawrence E. Murr, Sara M. Gaytan, Edwin Martinez, and Toru Okabe. 2011. "Evaluation of Titanium Alloys Fabricated Using Rapid Prototyping Technologies—Electron Beam Melting and Laser Beam Melting" Materials 4, no. 10: 1776-1792. https://doi.org/10.3390/ma4101776

APA StyleKoike, M., Greer, P., Owen, K., Lilly, G., Murr, L. E., Gaytan, S. M., Martinez, E., & Okabe, T. (2011). Evaluation of Titanium Alloys Fabricated Using Rapid Prototyping Technologies—Electron Beam Melting and Laser Beam Melting. Materials, 4(10), 1776-1792. https://doi.org/10.3390/ma4101776