Catalytic CVD Synthesis of Carbon Nanotubes: Towards High Yield and Low Temperature Growth

Abstract

:1. Introduction

2. Results and Discussion

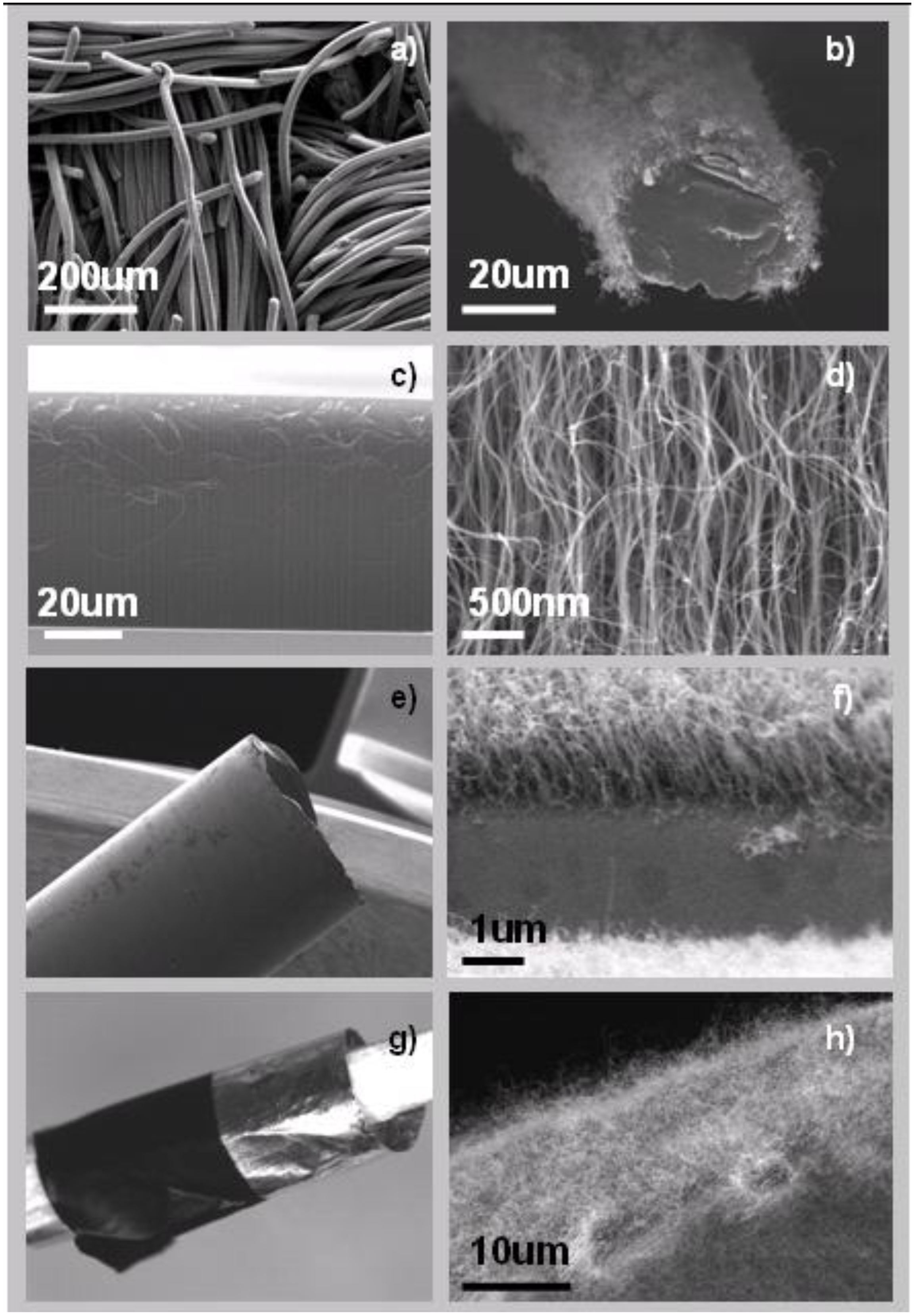

2.1. Catalyst

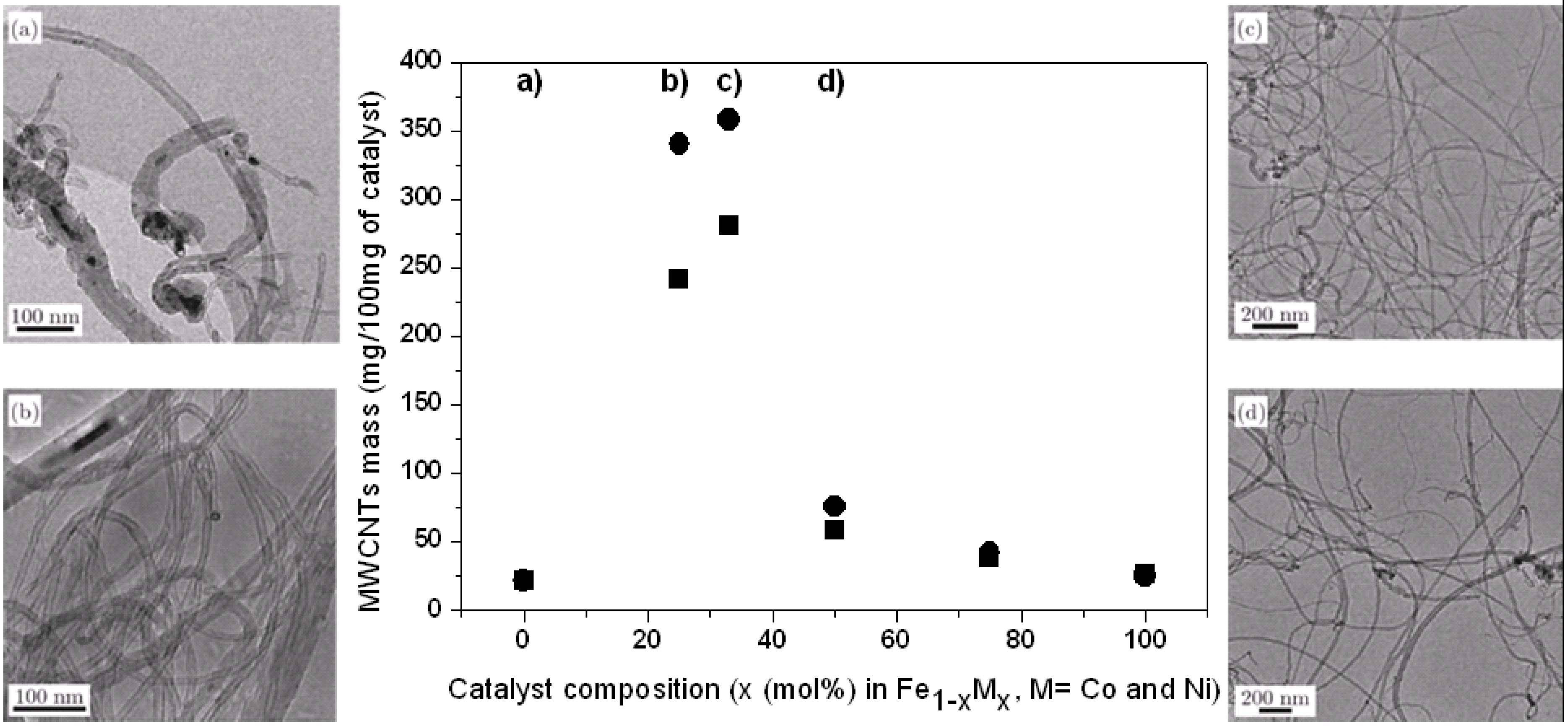

2.1.1. Catalyst composition

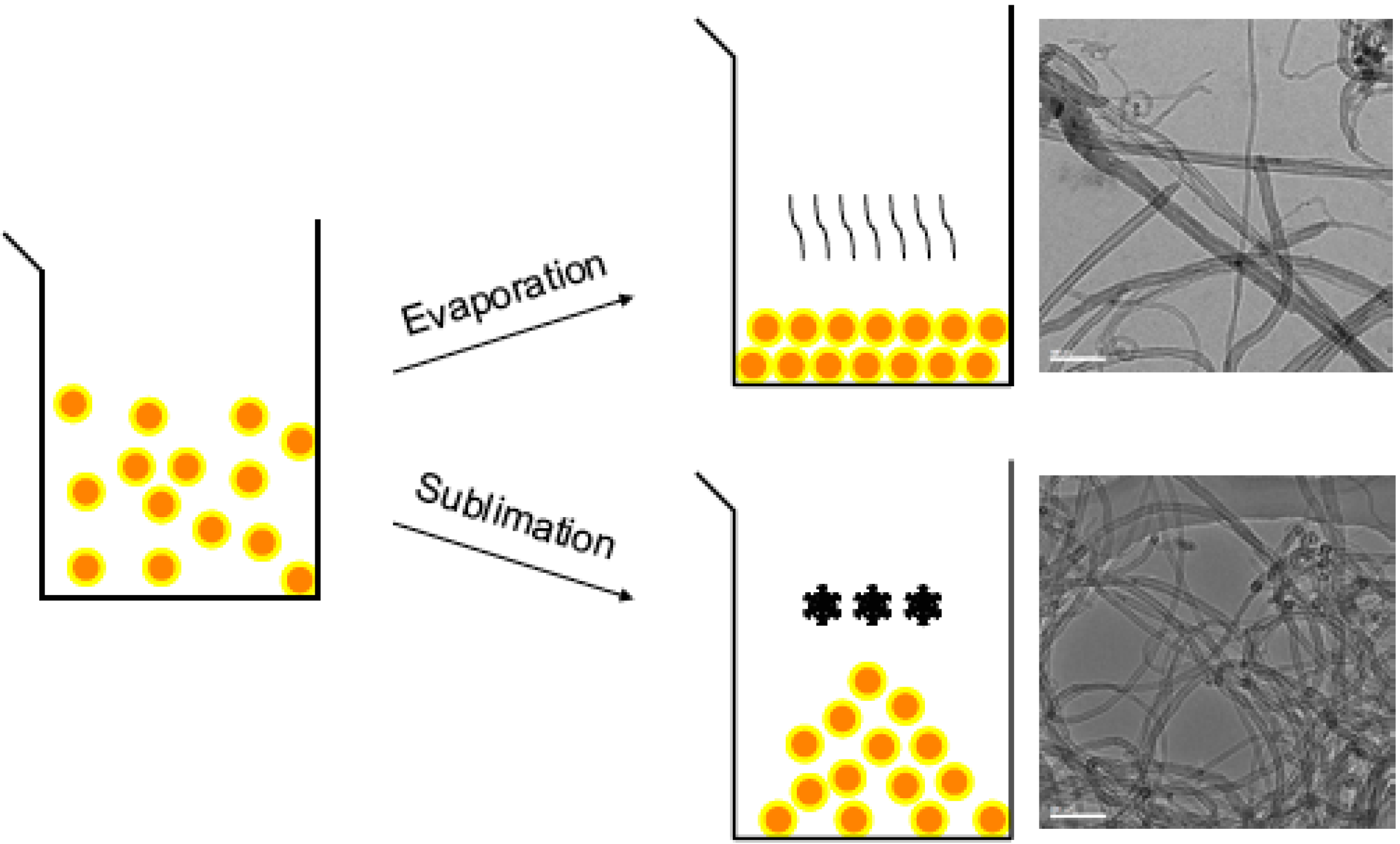

2.1.2. Catalyst drying process

2.2. Support

2.2.1. Alkaline earth carbonates

2.2.2. Size of support particles

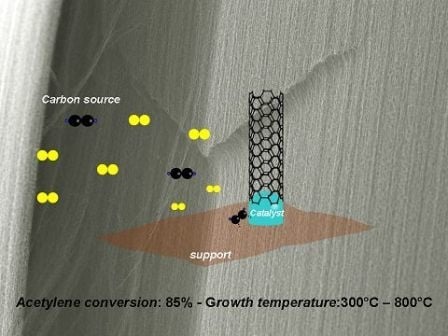

2.3. CCVD Process

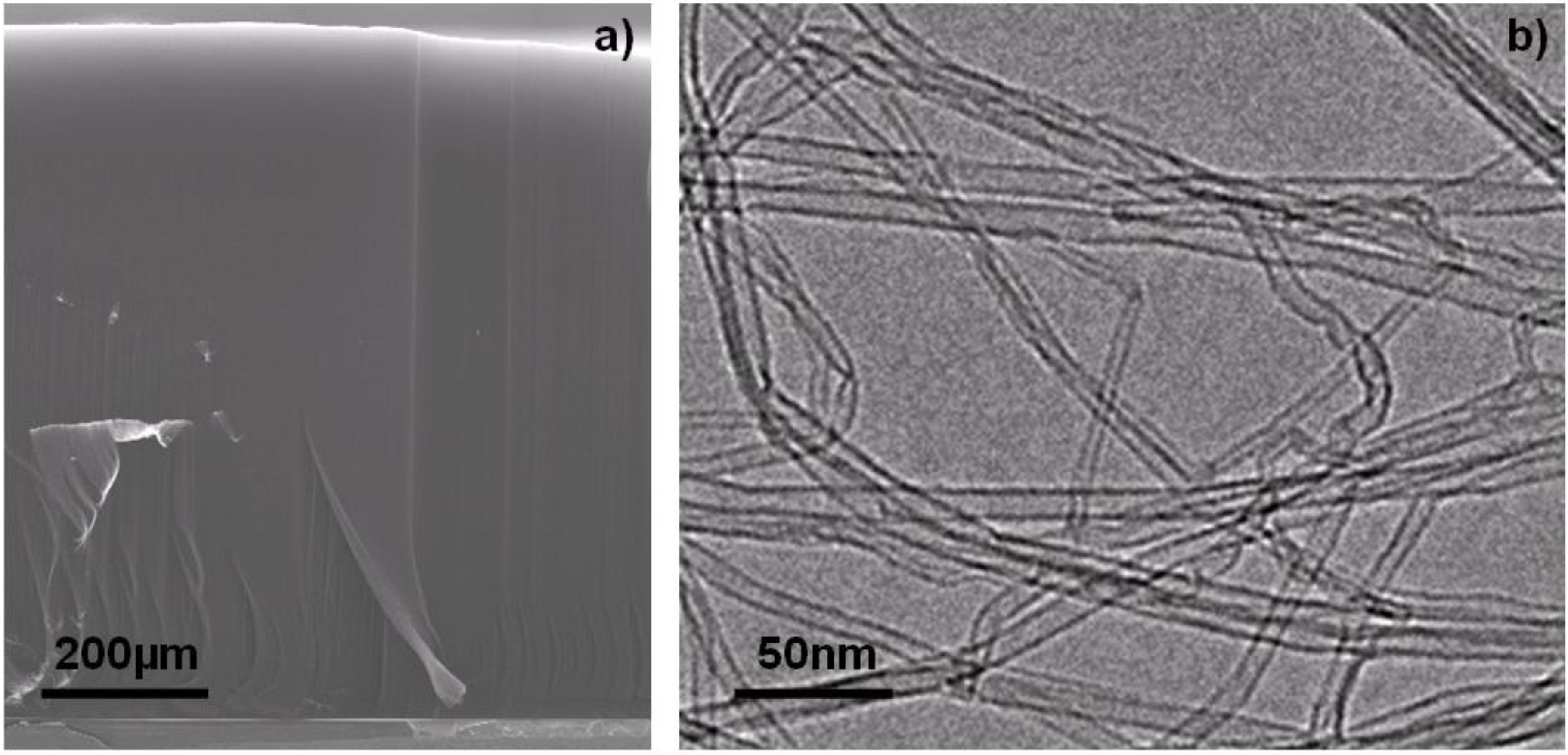

2.3.1. Water assisted growth

| Mean Eb (GPa) | Max. Eb (GPa) | Min. Eb (GPa) | |

| Water assisted grown carbon nanotubes | 570 | 1,200 | 240 |

| Equimolar grown carbon nanotubes | 390 | 1,040 | 56 |

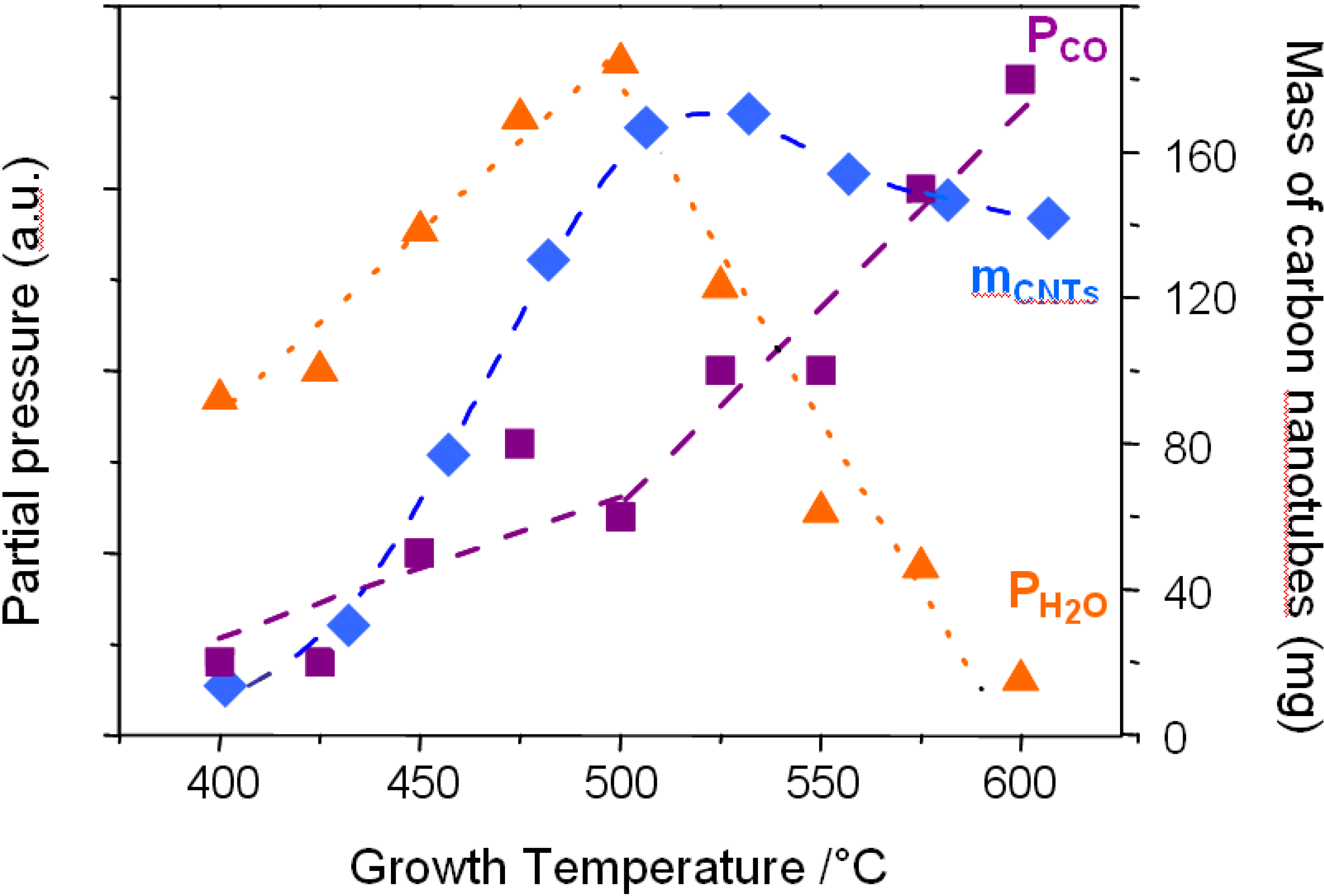

2.3.2. Equimolar C2H2-CO2 reaction

| Support material | Maximum yield growth temperature / °C | Support material | Maximum yield growth temperature / °C |

| C | 400 | La2O3 | 550 |

| V2O5 | 450 | Bi2O3 | 600 |

| TaB2 | 500 | TiO2 | 625 |

| TiN | 500 | Al2O3 | 650 |

| Nb2O5 | 500 | SiC | 650 |

3. Experimental Section

3.1. Catalyst Preparation

3.2. Carbon Nanotubes Synthesis and Characterization

4. Conclusions

Acknowledgements

References and Notes

- Dai, H.J.; Kong, J.; Zhou, C.W.; Franklin, N.; Tombler, T.; Cassell, A.; Fan, S.S.; Chapline, M. Controlled chemical routes to nanotube architectures, physics, and devices. J. Phys. Chem. B 1999, 103, 11246–11255. [Google Scholar] [CrossRef]

- De Jong, K.P.; Geus, J.W. Carbon nanofibers: Catalytic synthesis and applications. Catal. Rev. - Sci. Eng. 2000, 42, 481–510. [Google Scholar] [CrossRef]

- Dai, H.J. Carbon nanotubes: Synthesis, integration, and properties. Acc. Chem. Res. 2002, 35, 1035–1044. [Google Scholar] [CrossRef] [PubMed]

- See, C.H.; Harris, A.T. A review of carbon nanotubes synthesis via fluidized-bad chemical vapor deposition. Ind. Eng. Chem. Res. 2007, 46, 997–1012. [Google Scholar] [CrossRef]

- Joselevich, E.; Dai, H.J.; Liu, J.; Hata, K.; Windle, A.H. Carbon nanotubes synthesis and organization. In Carbon Nantubes, Topics in Applied Physics; Jorio, A., Dresselhaus, G., Dresselhaus, M.S., Eds.; Springer-Verlag: Berlin Heidelberg, Germany, 2008; Volume 111, pp. 101–164. [Google Scholar]

- Liu, J.; Jiao, L.; Yao, Y.; Xian, X.; Zhang, J. Aligned, ultralong single-walled carbon nanotubes: From synthesis, sorting, to electronic devices. Adv. Mater. 2010, 22, 2285–2310. [Google Scholar] [CrossRef] [PubMed]

- Moisala, A.; Nasibulin, A.G.; Kauppinen, E.I. The role of metal nanoparticles in the catalytic production of single-walled carbon nanotubes - a review. J. Phys.: Condens. Matter 2003, 14, S3011–S3035. [Google Scholar] [CrossRef]

- Dupuis, A.C. The catalyst in the CCVD of carbon nanotubes - a review. Prog. Mater. Sci. 2005, 50, 929–961. [Google Scholar] [CrossRef]

- Harutyunyan, A.R. The catalyst for growing single-walled carbon nanotubes by catalytic chemical vapor deposition method. J. Nanosci. Nanotech. 2009, 9, 2480–2495. [Google Scholar] [CrossRef]

- Charlier, J.C.; Iijima, S. Growth mechanisms of carbon nanotubes. In Carbon Nantubes, Topics in Applied Physics; Dresselhaus, M.S., Dresselhaus, G., Avouris, Ph., Eds.; Springer-Verlag: Berlin Heidelberg, Germany, 2008; Volume 80, pp. 55–80. [Google Scholar]

- Bajwa, N.; Li, X.S.; Ajayan, P.M.; Vajtai, R. Mechanisms of catalytic CVD growth of multiwalled carbon nanotubes. J. Nanosci. Nanotechnol. 2008, 8, 6054–6064. [Google Scholar] [CrossRef]

- Kumar, M.; Ando, Y. Chemical vapor deposition of carbon nanotubes: A review on growth mechanism and mass production. J. Nanosci. Nanotechnol. 2010, 10, 3739–3758. [Google Scholar] [CrossRef] [PubMed]

- MacKenzie, K.J.; Dunens, O.M.; Harris, A.T. An updated review of synthesis parameters and growth mechanisms for carbon nanotubes in fluidized beds. Ind. Eng. Chem. Res. 2010, 49, 5323–5338. [Google Scholar] [CrossRef]

- Nessim, G.D. Properties, synthesis, and growth mechanisms of carbon nanotubes with special focus on thermal chemical vapor deposition. Nanoscale 2010, 2, 1306–1323. [Google Scholar] [CrossRef] [PubMed]

- Maruyama, S.; Kojima, R.; Miyauchi, Y.; Chiashi, S.; Kohno, M. Low-temperature synthesis of high-purity single-walled carbon nanotubes from alcohol. Chem. Phys. Lett. 2002, 360, 229–234. [Google Scholar] [CrossRef]

- Seidel, R.; Duesberg, G.S.; Unger, E.; Graham, A.P.; Liebau, M.; Kreupl, F. Chemical vapor deposition growth of single-walled carbon nanotubes at 600 °C and a simple growth model. J. Phys. Chem. B 2004, 108, 1888–1893. [Google Scholar] [CrossRef]

- Rümmeli, M.H.; Borowiak-Palen, E.; Gemming, T.; Pichler, T.; Knupfer, M.; Kalbac, M.; Dunsch, L.; Jost, O.; Silva, S.R.P.; Pompe, W.; Büchner, B. Novel catalysts, room temperature, and the importance of oxygen for the synthesis of single-walled carbon nanotubes. Nano Lett. 2005, 5, 1209–1215. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cantoro, M.; Hofmann, S.; Pisana, S.; Scardaci, V.; Parvez, A.; Ducati, C.; Ferrari, A.C.; Blackburn, A.M.; Wang, K.-Y.; Robertson, J. Catalytic chemical vapor deposition of single-wall carbon nanotubes at low temperature. Nano Lett. 2006, 6, 1107–1112. [Google Scholar] [CrossRef] [PubMed]

- Meshot, E.R.; Plata, D.L.; Tawfick, S.; Zhang, Y.Y.; Verploegen, E.A.; Hart, A.J. Engineering vertically aligned carbon nanotube growth by decoupled thermal treatment of precursor and catalyst. ACS Nano 2009, 3, 2477–2486. [Google Scholar] [CrossRef]

- Hata, K.; Futaba, D.N.; Mizumo, K.; Namai, T.; Yumura, M.; Iijima, S. Water-assisted highly efficient synthesis of impurity-free single-waited carbon nanotubes. Science 2004, 306, 1362–1365. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Mann, D.; Zhang, L.; Javey, A.; Li, Y.; Yenilmez, E.; Wang, Q.; McVittie, J.P.; Nishi, Y.; Gibbons, J.; Dai, H.J. Ultra-high-yield growth of vertical single-walled carbon nanotubes: Hidden roles of hydrogen and oxygen. Proc. Natl. Acad. Sci. U. S. A. 2005, 102, 16141–16145. [Google Scholar] [CrossRef] [PubMed]

- Futaba, D.N.; Hata, K.; Yamada, T.; Mizumo, K.; Yumura, M.; Iijima, S. Kinetics of water-assisted single-walled carbon nanotube synthesis revealed by a time-evolution analysis. Phys. Rev. Lett. 2005, 95, 056104. [Google Scholar] [CrossRef] [PubMed]

- McNicholas, T.P.; Ding, L.; Yuan, D.N.; Liu, J. Density enhancement of aligned single-walled carbon nanotube thin films on quartz substrates by sulfur-assisted synthesis. Nano Lett. 2009, 9, 3646–3650. [Google Scholar] [CrossRef] [PubMed]

- Magrez, A.; Seo, J.W.; Smajda, R.; Korbely, B.; Andresen, J.C.; Mionic, M.; Casimirius, S.; Forró, L. Low-temperature, highly efficient growth of carbon nanotubes on functional materials by an oxidative dehydrogenation reaction. ACS Nano 2010, 4, 3702–3708. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, W.E.; Kitiyanan, B.; Borgna, A.; Resasco, D.E. Synergism of Co and Mo in the catalytic production of single-wall carbon nanotubes by decomposition of CO. Carbon 2001, 39, 547–558. [Google Scholar] [CrossRef]

- Harutyunyan, A.R.; Pradhan, B.K.; Kim, U.J.; Chen, G.; Eklund, P.E. CVD synthesis of single wall carbon nanotubes under "soft" conditions. Nano Lett. 2002, 2, 525–530. [Google Scholar] [CrossRef]

- Flahaut, E.; Govindaraj, A.; Peigney, A.; Laurent, Ch.; Rousset, A.; Rao, C.N.R. Synthesis of single-walled carbon nanotubes using binary (Fe, Co, Ni) alloy nanoparticles prepared in situ by the reduction of oxide solid solutions. Chem. Phys. Lett. 1999, 300, 236–242. [Google Scholar] [CrossRef]

- Magrez, A.; Seo, J.W.; Mikó, Cs.; Hernadi, K.; Forró, L. Growth of carbon nanotubes with alkaline earth carbonate as support. J. Phys. Chem. B 2005, 109, 10087–10091. [Google Scholar] [CrossRef] [PubMed]

- Smajda, R.; Mionic, M.; Duchamp, M.; Andresen, J.C.; Forró, L.; Magrez, A. Production of high quality carbon nanotubes for less than $1 per gram. Phys. Status Solidi C 2010, 3, 1236–1240. [Google Scholar]

- Mionic, M.; Duncan, T.L.; Forró, L.; Magrez, A. Influence of the catalyst drying process and catalyst support particle size on the carbon nanotubes produced by CCVD. Phys. Status Solidi B 2008, 10, 1915–1918. [Google Scholar] [CrossRef]

- Chiang, W.H.; Sankaran, R.M. Linking catalyst composition to chirality distributions of as-grown single-walled carbon nanotubes by tuning NixFe1-x nanoparticles. Nat. Mater. 2009, 8, 882–886. [Google Scholar] [CrossRef] [PubMed]

- de los Arcos, T.; Vonau, F.; Garnier, M.G.; Thommen, V.; Boyen, H.-G.; Oelhafen, P.; Düggelin, M.; Mathis, D.; Guggenheim, R. Influence of iron–silicon interaction on the growth of carbon nanotubes produced by chemical vapor deposition. Appl. Phys. Lett. 2002, 80, 2383–2385. [Google Scholar] [CrossRef]

- Talapatra, S.; Kar, S.; Pal, S.K.; Vajtai, R.; Ci, L.; Victor, P.; Shaijumon, M.M.; Kaur, S.; Nalamasu, O.; Ajayan, P.M. Direct growth of aligned carbon nanotubes on bulk metals. Nat. Nanotechnol. 2006, 1, 112–116. [Google Scholar] [CrossRef] [PubMed]

- Nessim, G.D.; Seita, M.; O'Brien, K.P.; Hart, A.J.; Bonaparte, R.K.; Mitchell, R.R.; Thompson, C.V. Low temperature synthesis of vertically aligned carbon nanotubes with electrical contact to metallic substrates enabled by thermal decomposition of the carbon feedstock. Nano Lett. 2009, 9, 3398–3405. [Google Scholar] [CrossRef]

- de los Arcos, T.; Garnier, M.G.; Oelhafen, P.; Mathis, D.; Seo, J.W.; Domingo, C.; García-Ramos, J.V.; Sánchez-Cortés, S. Strong influence of buffer layer type on carbon nanotube characteristics. Carbon 2004, 42, 187–190. [Google Scholar] [CrossRef]

- de los Arcos, T.; Garnier, M.G.; Seo, J.W.; Oelhafen, P.; Thommen, V.; Mathis, D. The influence of catalyst chemical state and morphology on carbon nanotube growth. J. Phys. Chem. B 2004, 108, 7728–7734. [Google Scholar] [CrossRef]

- Nagaraju, N.; Fonseca, A.; Konya, Z.; Nagy, J.B. Alumina and silica supported metal catalysts for the production of carbon nanotubes. J. Mol. Catal. A: Chem. 2002, 181, 57–62. [Google Scholar] [CrossRef]

- Kathyayini, H.; Nagaraju, N.; Fonseca, A.; Nagy, J.B. Catalytic activity of Fe, Co and Fe/Co supported on Ca and Mg oxides, hydroxides and carbonates in the synthesis of carbon nanotubes. J. Mol. Catal. A: Chem. 2004, 223, 129–136. [Google Scholar] [CrossRef]

- Kathyayini, H.; Willems, I.; Fonseca, A.; Nagy, J.B.; Nagaraju, N. Catalytic materials based on aluminum hydroxide, for the large scale production of bundles of multi-walled carbon nanotubes. Catal. Commun. 2006, 7, 140–147. [Google Scholar] [CrossRef]

- Couteau, E.; Hernadi, K.; Seo, J.W.; Thien-Nga, L.; Mikó, Cs.; Gáal, R.; Forró, L. CVD synthesis of high-purity multiwalled carbon nanotubes using CaCO3 catalyst support for large-scale production. Chem. Phys. Lett. 2003, 378, 9–17. [Google Scholar] [CrossRef]

- Schmitt, T.C.; Biris, A.C.; Miller, D.W.; Biris, A.R.; Lupu, D.; Trigwell, S.; Rahman, Z.U. Analysis of effluent gases during the CCVD growth of multi-wall carbon nanotubes from acetylene. Carbon 2006, 44, 2032–2038. [Google Scholar] [CrossRef]

- Seo, J.W.; Couteau, E.; Umek, P.; Hernadi, K.; Marcoux, P.; Lukic, B.; Mikó, Cs.; Milas, M.; Gáal, R.; Forró, L. Synthesis and manipulation of carbon nanotubes. New J. Phys. 2003, 5, 120:1–120:22. [Google Scholar]

- Magrez, A.; Seo, J.W.; Kuznetsov, V.L.; Forró, L. Evidence of an equimolar C2H2-CO2 reaction in the synthesis of carbon nanotubes. Angew. Chem., Int. Ed. 2007, 46, 441–444. [Google Scholar] [CrossRef]

- Seo, J.W.; Magrez, A.; Milas, M.; Lee, K.; Lukovac, V.; Forró, L. Catalytically grown carbon nanotubes: from synthesis to toxicity. J. Phys. D 2007, 40, R109–R120. [Google Scholar] [CrossRef]

- Patil, K.C. Advanced ceramics - Combustion synthesis and properties. Bull. Mater. Sci. 1993, 16, 533–541. [Google Scholar] [CrossRef]

- Flahaut, E.; Peigney, A.; Laurent, C.; Rousset, A. Synthesis of single-walled carbon nanotube-Co-MgO composite powders and extraction of the nanotubes. J. Mater. Chem. 2000, 10, 249–252. [Google Scholar] [CrossRef]

- Futaba, D.N.; Hata, K.; Namai, T.; Yamada, T.; Mizumo, K.; Hayamizu, Y.; Yumura, M.; Iijima, S. Catalyst activity of water-assisted growth of single walled carbon nanotube forest characterization by a statistical and macroscopic approach. J. Phys. Chem. B 2006, 110, 8035–8038. [Google Scholar] [CrossRef] [PubMed]

- Yasuda, S.; Futaba, D.N.; Yamada, T.; Satou, J.; Shibuya, A.; Takai, H.; Arakawa, K.; Yumura, M.; Hata, K. Improved and large area single-walled carbon nanotubes forest growth by controlling the gas flow direction. ACS Nano 2009, 3, 4164–4170. [Google Scholar] [CrossRef] [PubMed]

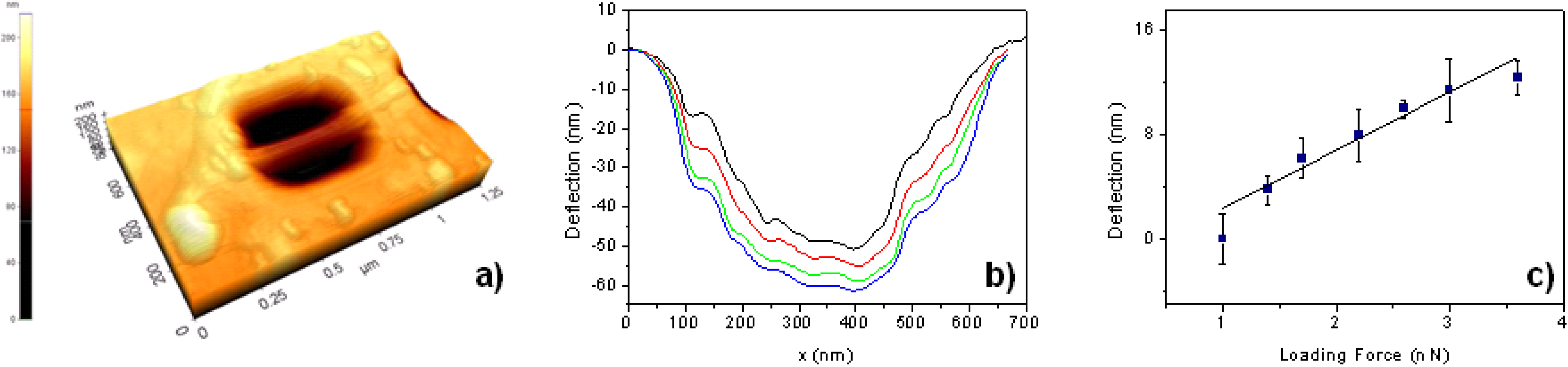

- Smajda, R.; Andresen, J.C.; Duchamp, M.; Meunier, R.; Casimirius, S.; Hernadi, K.; Forró, L.; Magrez, A. Synthesis and mechanical properties of carbon nanotubes produced by the water assisted CVD process. Phys. Status Solidi B 2009, 246, 2457–2460. [Google Scholar] [CrossRef]

- Yamada, T.; Namai, T.; Hata, K.; Futaba, D.N.; Mizumo, K.; Fan, J.; Yudasaka, M.; Yumura, M.; Iijima, S. Size-selective growth of double-walled carbon nanotube forests from engineered iron catalysts. Nat. Nanotechnol. 2006, 1, 131–136. [Google Scholar] [CrossRef] [PubMed]

- Lukic, B.; Seo, J.W.; Couteau, E.; Lee, K.; Gradecak, S.; Berkecz, R.; Hernadi, K.; Delpeux, S.; Cacciaguerra, T.; Beguin, F.; Fonseca, A.; Nagy, J.B.; Csanyi, G.; Kis, A.; Kulik, A.J.; Forró, L. Elastic modulus of multi-walled carbon nanotubes produced by catalytic chemical vapour deposition. Appl. Phys. A: Mater. Sci. Process. 2005, 80, 695–700. [Google Scholar] [CrossRef]

- Lee, K.; Lukić, B.; Magrez, A.; Seo, J.W.; Briggs, G.A.D.; Kulik, A.J.; Forró, L. Diameter-dependent elastic modulus supports the metastable-catalyst growth of carbon nanotubes. Nano Lett. 2007, 7, 1598–1602. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhu, Z.H. Catalytic conversion of alkanes to olefins by carbon dioxide oxidative dehydrogenation - A review. Energy Fuels 2004, 18, 1126–1139. [Google Scholar] [CrossRef]

© 2010 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Magrez, A.; Seo, J.W.; Smajda, R.; Mionić, M.; Forró, L. Catalytic CVD Synthesis of Carbon Nanotubes: Towards High Yield and Low Temperature Growth. Materials 2010, 3, 4871-4891. https://doi.org/10.3390/ma3114871

Magrez A, Seo JW, Smajda R, Mionić M, Forró L. Catalytic CVD Synthesis of Carbon Nanotubes: Towards High Yield and Low Temperature Growth. Materials. 2010; 3(11):4871-4891. https://doi.org/10.3390/ma3114871

Chicago/Turabian StyleMagrez, Arnaud, Jin Won Seo, Rita Smajda, Marijana Mionić, and László Forró. 2010. "Catalytic CVD Synthesis of Carbon Nanotubes: Towards High Yield and Low Temperature Growth" Materials 3, no. 11: 4871-4891. https://doi.org/10.3390/ma3114871