Durability Assessment and Microstructure of High-Strength Performance Bricks Produced from PET Waste and Foundry Sand

Abstract

:1. Introduction

2. Materials and Methods

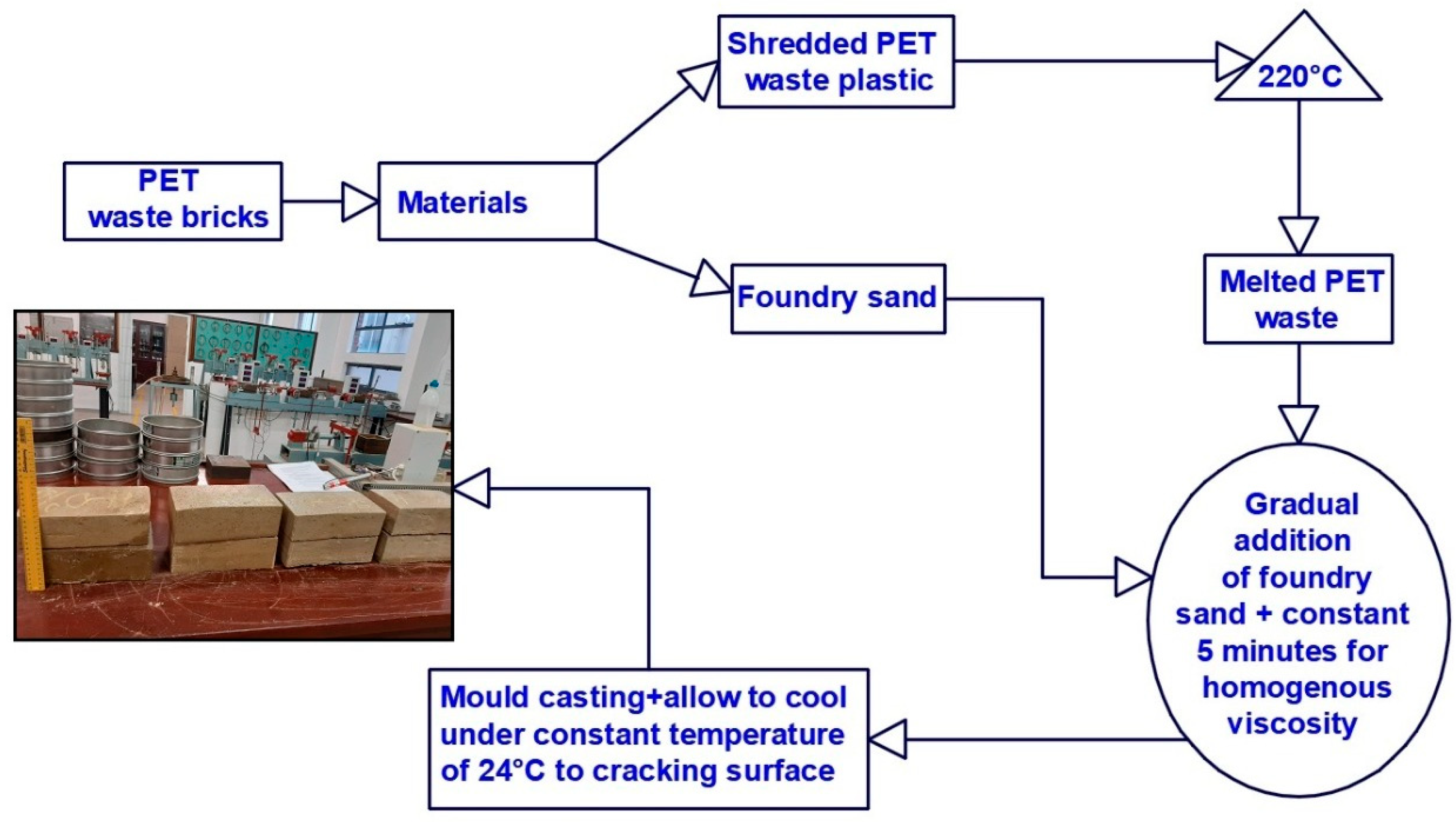

2.1. Plastic Waste Brick Preparation

2.2. Testing Methodology

2.2.1. Unconfined Compressive Strength (UCS) Test

2.2.2. Tensile Strength Test

2.2.3. Durability Test

2.2.4. Initial Rate of Absorption (IRA)

2.2.5. Scanning Electron Microscopy (SEM)

3. Results

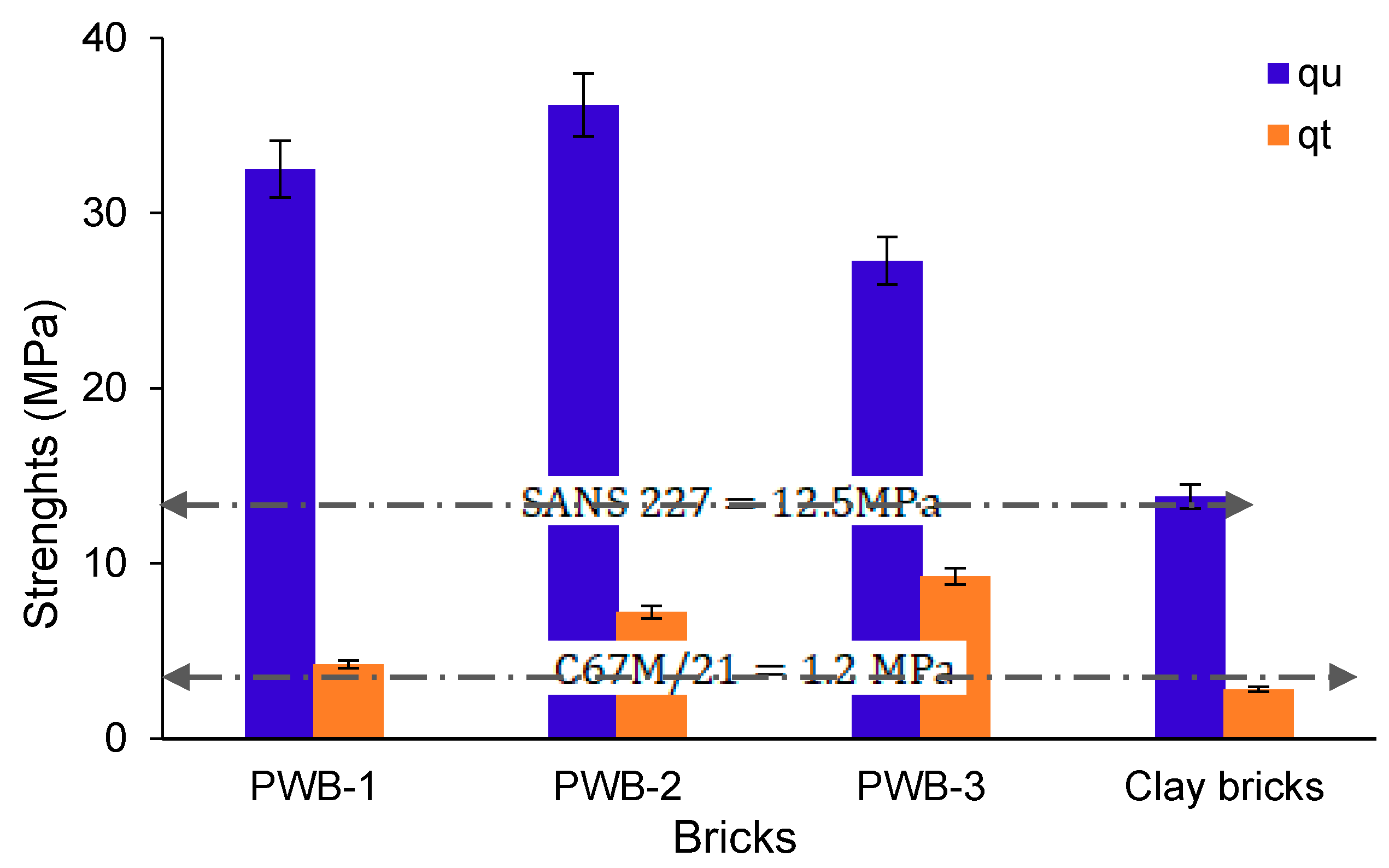

3.1. Unconfined Compressive Strength of Bricks

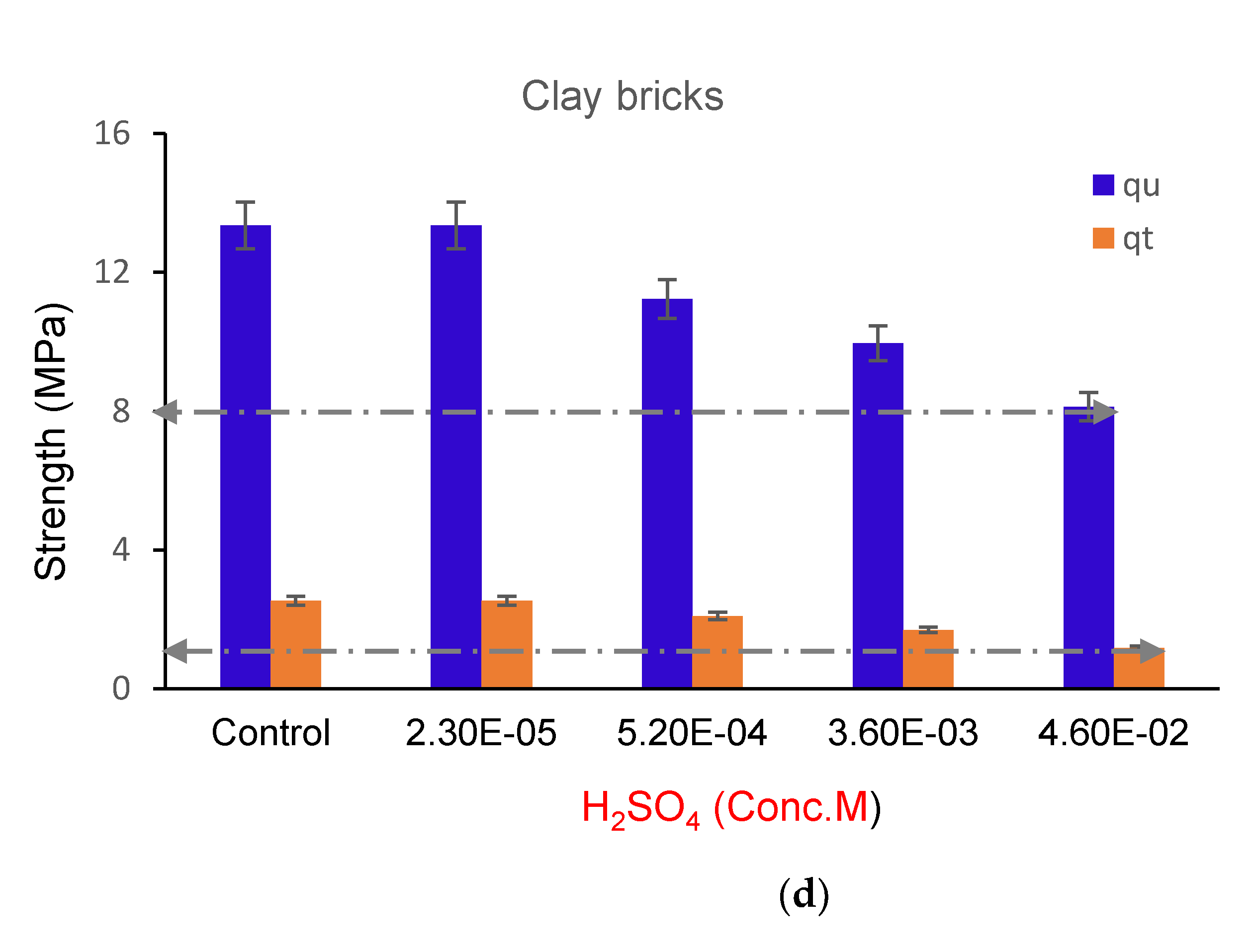

3.2. Effect of Acid Soaking on the qu and qt of the Bricks

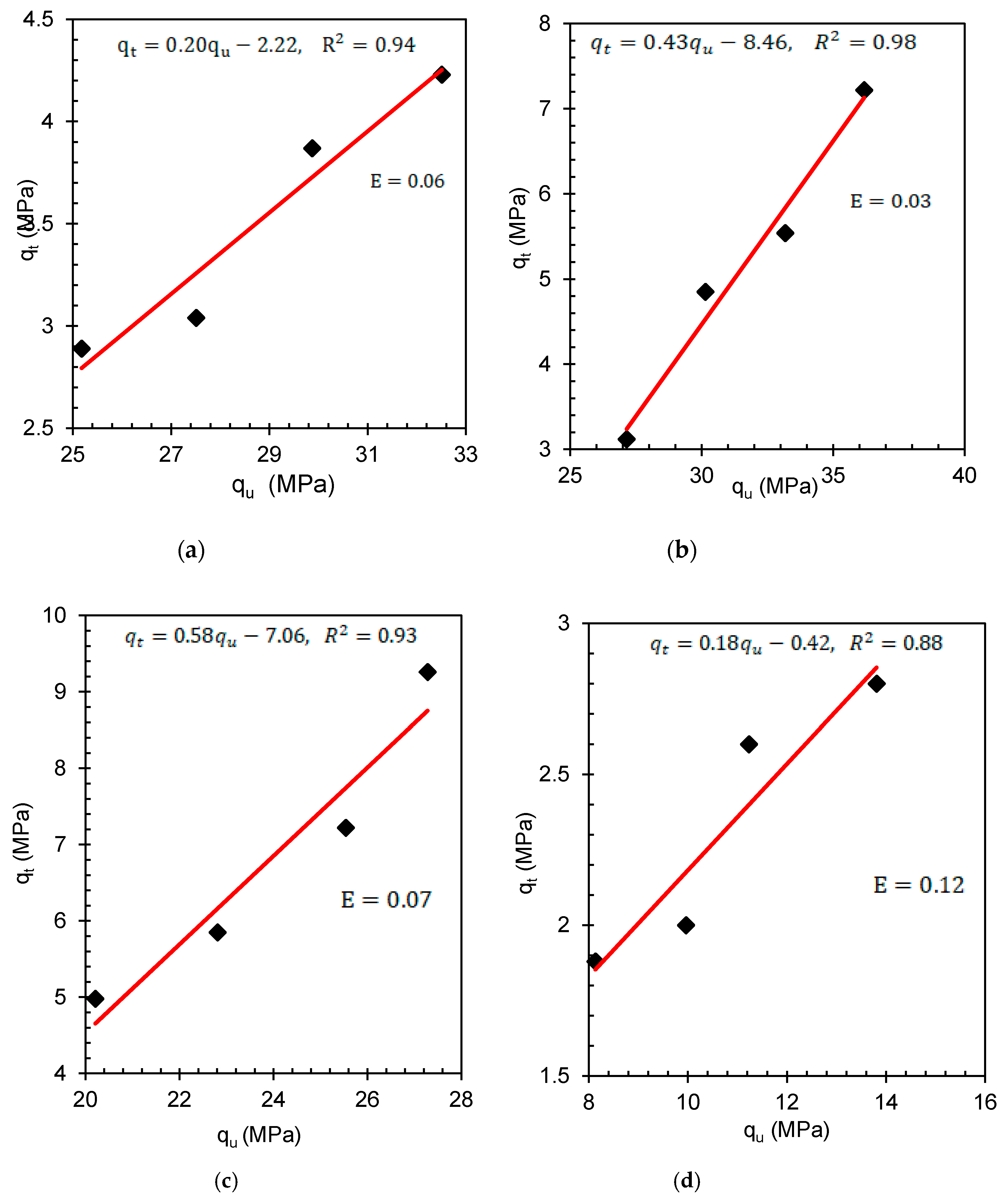

3.3. Interdependence of the qu and qt of the Bricks

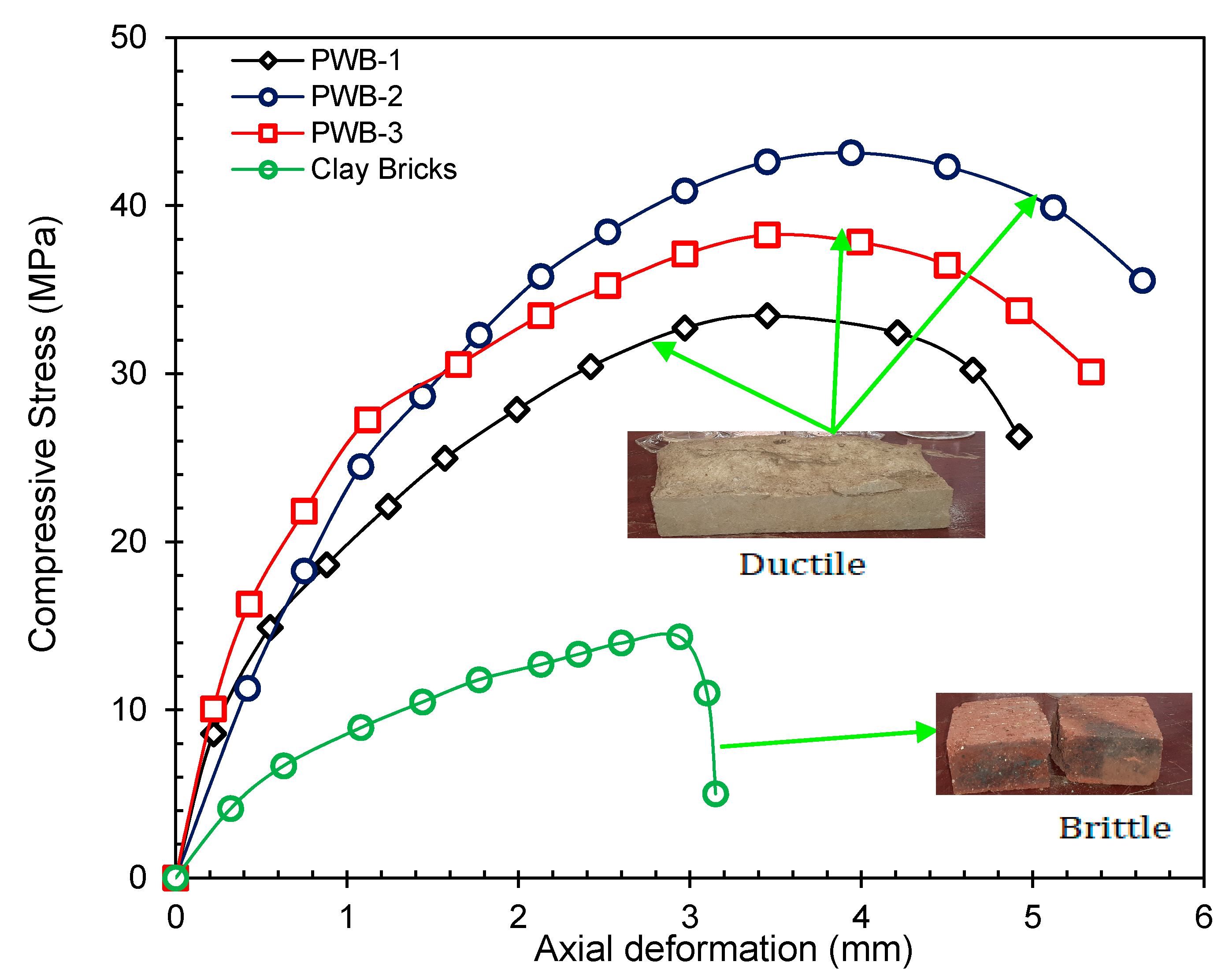

3.4. Load–Deformation Relationship and Failure Modes

3.5. Initial Rate of Absorption (IRA)

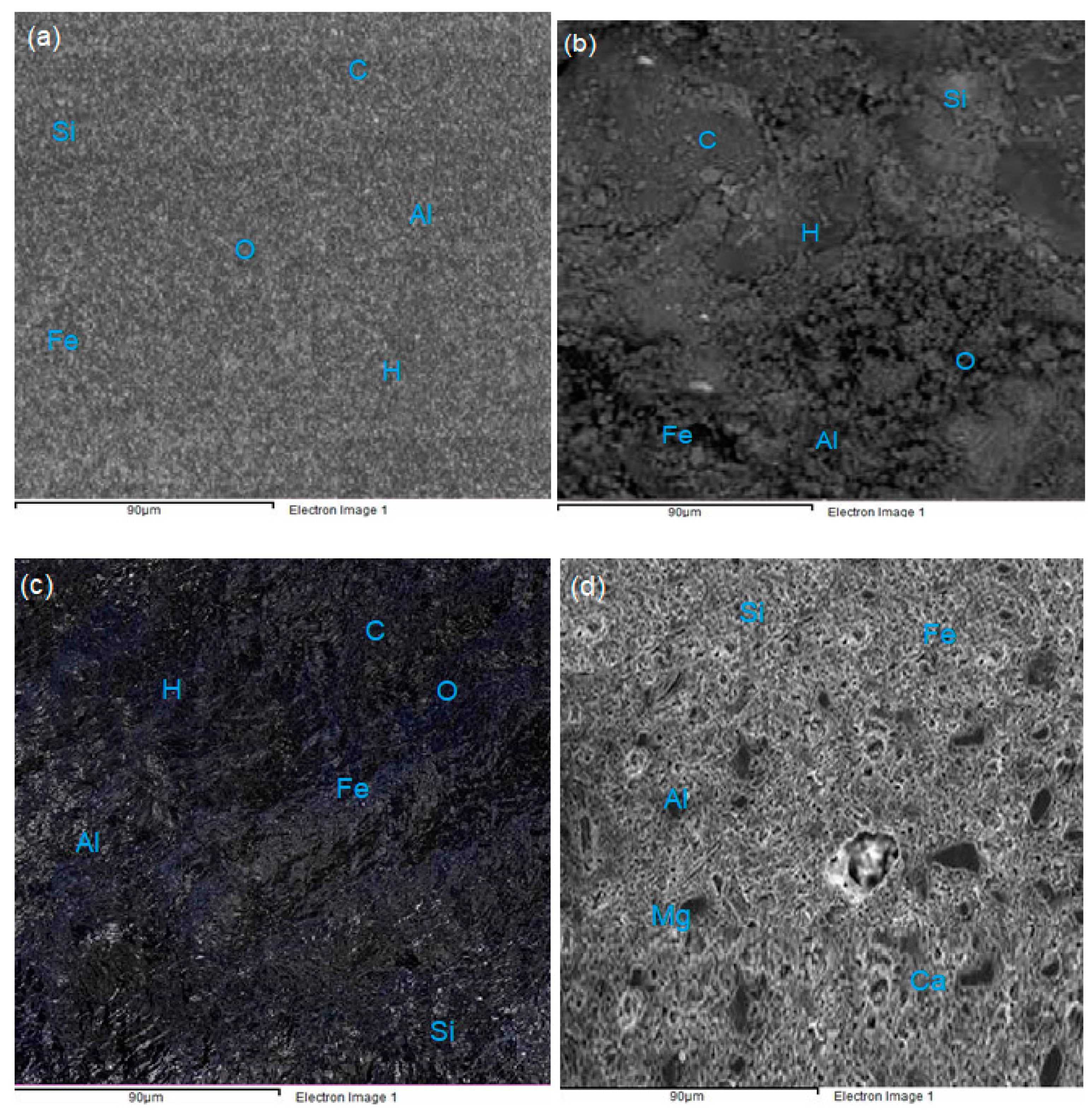

3.6. Scanning Electron Microscopy (SEM)

3.7. Sustainability Analysis of PET Waste Bricks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aslani, H.; Pashmtab, P.; Shaghaghi, A.; Mohammadpoorasl, A.; Taghipour, H.; Zarei, M. Tendencies towards bottled drinking water consumption: Challenges ahead of polyethylene terephthalate (PET) waste management. Health Promot. Perspect. 2021, 11, 60. [Google Scholar] [CrossRef]

- Ayeleru, O.O.; Dlova, S.; Akinribide, O.J.; Ntuli, F.; Kupolati, W.K.; Marina, P.F.; Blencowe, A.; Olubambi, P.A. Challenges of plastic waste generation and management in sub-Saharan Africa: A review. Waste Manag. 2020, 110, 24–42. [Google Scholar] [CrossRef] [PubMed]

- Aryan, Y.; Yadav, P.; Samadder, S.R. Life Cycle Assessment of the existing and proposed plastic waste management options in India: A case study. J. Clean. Prod. 2019, 211, 1268–1283. [Google Scholar] [CrossRef]

- Perera, S.; Arulrajah, A.; Wong, Y.C.; Horpibulsuk, S.; Maghool, F. Utilizing recycled PET blends with demolition wastes as construction materials. Constr. Build. Mater. 2019, 221, 200–209. [Google Scholar] [CrossRef]

- Rhodes, C.J. Plastic pollution and potential solutions. Sci Prog. 2018, 101, 207–260. [Google Scholar] [CrossRef] [PubMed]

- Dlamini, S.; Simatele, M.D.; Serge Kubanza, N. Municipal solid waste management in South Africa: From waste to energy recovery through waste-to-energy technologies in Johannesburg. Local Environ. 2019, 24, 249–257. [Google Scholar] [CrossRef]

- Simatele, D.M.; Dlamini, S.; Kubanza, N.S. From informality to formality: Perspectives on the challenges of integrating solid waste management into the urban development and planning policy in Johannesburg, South Africa. Habitat Int. 2017, 63, 122–130. [Google Scholar] [CrossRef]

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. Waste Manag. 2013, 33, 220–232. [Google Scholar] [CrossRef]

- Aneke, F.I.; Celumusa, S. Strength and durability performance of masonry bricks produced with crushed glass and melted PET plastics. Case Stud. Constr. Mater. 2021, 14, e00542. [Google Scholar] [CrossRef]

- Barra, R.; Leonard, S.A.; Whaley, C.; Bierbaum, R. Plastics and the Circular Economy. Available online: https://www.thegef.org/sites/default/files/publications/PLASTICS%20for%20posting.pdf (accessed on 4 August 2021).

- Aneke, F.I.; Awuzie, B. Conversion of industrial wastes into marginal construction materials. Acta Structilia 2018, 25, 119–137. [Google Scholar] [CrossRef]

- Serge Kubanza, N.; Simatele, M.D. Sustainable solid waste management in developing countries: A study of institutional strengthening for solid waste management in Johannesburg, South Africa. J. Environ. Plan. Manag. 2020, 63, 175–188. [Google Scholar] [CrossRef]

- Godfrey, L.; Oelofse, S. Historical review of waste management and recycling in South Africa. Resources 2017, 6, 57. [Google Scholar] [CrossRef] [Green Version]

- Aneke, F.I.; Okonta, F.N.; Ntuli, F. Geotechnical Properties of Marginal Highway Backfill Stabilized With Activated Fly Ash. Master’s Dissertation, University of Johannesburg, Johannesburg, South Africa, 18 September 2015. [Google Scholar]

- Aneke, F.I.; Shabangu, C. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 2021, 14, e00515. [Google Scholar]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.; Klarissa, M. Circular economy on construction and demolition waste: A literature review on material recovery and production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef] [PubMed]

- Lederer, J.; Gassner, A.; Kleemann, F.; Fellner, J. Potentials for a circular economy of mineral construction materials and demolition waste in urban areas: A case study from Vienna. Resour. Conserv. Recycl. 2020, 161, 104942. [Google Scholar] [CrossRef]

- Tomaszewska, J. Polish transition towards circular economy: Materials management and implications for the construction sector. Materials 2020, 13, 5228. [Google Scholar] [CrossRef]

- Mahpour, A. Prioritizing barriers to adopt circular economy in construction and demolition waste management. Resour. Conserv. Recycl. 2018, 134, 216–227. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Saadaoui, M.; Khaldoun, A. Thermal performance of unfired lightweight clay bricks with HDPE & PET waste plastics additives. J. Build. Eng. 2020, 30, 101251. [Google Scholar]

- Vasudevan, R.; Sekar, A.R.C.; Sundarakannan, B.; Velkennedy, R. A technique to dispose waste plastics in an ecofriendly way–Application in construction of flexible pavements. Constr. Build. Mater. 2012, 28, 311–320. [Google Scholar] [CrossRef]

- Gürü, M.; Çubuk, M.K.; Arslan, D.; Farzanian, S.A.; Bilici, I. An approach to the usage of polyethylene terephthalate (PET) waste as roadway pavement material. J. Hazard. Mater. 2014, 279, 302–310. [Google Scholar] [CrossRef]

- Hassani, A.; Ganjidoust, H.; Maghanaki, A.A. Use of plastic waste (poly-ethylene terephthalate) in asphalt concrete mixture as aggregate replacement. Waste Manag. Res. 2005, 23, 322–327. [Google Scholar] [CrossRef] [PubMed]

- Alonso-Santurde, R.; Andrés, A.; Viguri, J.; Raimondo, M.; Guarini, G.; Zanelli, C.; Dondi, M. Technological behaviour and recycling potential of spent foundry sands in clay bricks. J. Environ. Manag. 2011, 92, 994–1002. [Google Scholar] [CrossRef] [PubMed]

- Patil, A.R.; Sathe, S.B. Feasibility of sustainable construction materials for concrete paving blocks: A review on waste foundry sand and other materials. Mater. Today Proc. 2020, 43, 1552–1561. [Google Scholar]

- Yeo, J.S.; Koting, S.; Onn, C.C.; Mo, K.H. An overview on the properties of eco-friendly concrete paving blocks incorporating selected waste materials as aggregate. Environ. Sci. Pollut. Res. 2021, 28, 29009–29036. [Google Scholar] [CrossRef] [PubMed]

- Arulrajah, A.; Yaghoubi, E.; Imteaz, M.; Horpibulsuk, S. Recycled waste foundry sand as a sustainable subgrade fill and pipe-bedding construction material: Engineering and environmental evaluation. Sustain. Cities Soc. 2017, 28, 343–349. [Google Scholar] [CrossRef]

- Bakis, R.; Koyuncu, H.; Demirbas, A. An investigation of waste foundry sand in asphalt concrete mixtures. Waste Manag. Res. 2006, 24, 269–274. [Google Scholar] [CrossRef] [PubMed]

- de Matos, P.R.; Marcon, M.F.; Schankoski, R.A.; Prudêncio, L.R., Jr. Novel applications of waste foundry sand in conventional and dry-mix concretes. J. Environ. Manag. 2019, 244, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Petri, S.; Timo, K. Recycled construction and demolition waste as a possible source of materials for composite manufacturing. J. Build. Eng. 2019, 24, 100742. [Google Scholar] [CrossRef]

- Moghayedi, A.; Awuzie, B.; Omotayo, T.; Le Jeune, K.; Massyn, M.; Ekpo, C.O.; Braune, M.; Byron, P. A Critical Success Factor Framework for Implementing Sustainable Innovative and Affordable Housing: A Systematic Review and Bibliometric Analysis. Buildings 2021, 11, 317. [Google Scholar] [CrossRef]

- ASTM D792-20. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM D1140-17. Standard Test Methods for Determining the Amount of Material Finer than 75-μm (No. 200) Sieve in Soils by Washing; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C67/C67M-21. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- ASTM D559/D559M-15. Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM E986-04(2017). Standard Practice for Scanning Electron Microscope Beam Size Characterization; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- SANS 227:2007 and SANS 1 575. The South African National Standard for Burnt Clay Paving Units. 2007. Available online: http://docplayer.net/194277397-South-african-national-standard.html (accessed on 15 August 2021).

- ASTM C67. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Gumaste, K.S.; Nanjunda, R.K.S.; Venkatarama, R.B.V.; Jagadish, K.S. Strength and elasticity of brick masonry prisms and wallets under compression. Mater. Struct. 2007, 40, 241–253. [Google Scholar] [CrossRef]

- Wight, J.K.; MacGregor, J.G. Reinforced Concrete: Mechanics and Design; Pearson Education: Cranbury, NJ, USA, 2012. [Google Scholar]

- McCormac, J.C.; Brown, R.H. Design of Reinforced Concrete; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Knutson, H.H. The stress-strain relationship for masonry. Mason. Int. 2003, 7, 31–33. [Google Scholar]

- Ewing, B.D.; Kowalsky, M.J. Compressive behaviour of unconfined and confined clay brick masonry. J. Struct. Eng. 2004, 130, 650–661. [Google Scholar] [CrossRef]

- Yorkdale, A. Initial Rate of Absorption and Mortar Bond. In Masonry: Materials, Properties, and Performance; Borchelt, J., Ed.; West ASTM International: Conshohocken, PA, USA, 1982; pp. 91–98. [Google Scholar] [CrossRef]

- ESKOM 2000–2008-Our Recent Past-“Shift performance and Grow Sustainably”. 2009. Available online: www.eskom.co.za (accessed on 15 August 2021).

| Series | Concentration (M) | H3O+ | pH | Soaking Time (Days) |

|---|---|---|---|---|

| 1 | 2.30 × 10−5 | 2.30 × 10−5 | 4.64 | 90 |

| 2 | 5.20 × 10−4 | 5.20 × 10−4 | 3.28 | 90 |

| 3 | 3.60 × 10−3 | 3.60 × 10−3 | 2.44 | 90 |

| 4 | 4.60 × 10−2 | 4.60 × 10−2 | 1.34 | 90 |

| Bricks | Compressive Strength (MPa) | Tensile Strength (MPa) | ||||

|---|---|---|---|---|---|---|

| - | 1st trial | 2nd trial | 1st trial | 2nd trial | 15.56 | 13.32 |

| PWB-1 | 32.58 | 31.84 | 4.03 | 3.28 | ||

| PWB-2 | 37.00 | 35.00 | 7.88 | 6.32 | ||

| PWB-3 | 25.22 | 28.88 | 8.32 | 9.60 | ||

| CB | 6.00 | 8.00 | 2.00 | 3.08 | ||

| Bricks | Heat (°C) | Production Time | Average Density (kg/m3) | CO2 Emission (kg) | Price/Energy Cost | Sustainability |

|---|---|---|---|---|---|---|

| PWB-1 | 220 | (Minutes) | 1887 | 1373 | ZAR 0.286/brick | Favorable |

| PWB-2 | 220 | 10 | 1828 | 2060 | ZAR 0.286/brick | Favorable |

| PWB-3 | 220 | 10 | 1784 | 2746 | ZAR 0.286/brick | Favorable |

| Clay bricks | 1100 | 10 | 1894 | 41,239 | ZAR 1.34/brick | Not Favorable |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aneke, F.I.; Awuzie, B.O.; Mostafa, M.M.H.; Okorafor, C. Durability Assessment and Microstructure of High-Strength Performance Bricks Produced from PET Waste and Foundry Sand. Materials 2021, 14, 5635. https://doi.org/10.3390/ma14195635

Aneke FI, Awuzie BO, Mostafa MMH, Okorafor C. Durability Assessment and Microstructure of High-Strength Performance Bricks Produced from PET Waste and Foundry Sand. Materials. 2021; 14(19):5635. https://doi.org/10.3390/ma14195635

Chicago/Turabian StyleAneke, Frank Ikechukwu, Bankole Osita Awuzie, Mohamed M. H. Mostafa, and Chikezirim Okorafor. 2021. "Durability Assessment and Microstructure of High-Strength Performance Bricks Produced from PET Waste and Foundry Sand" Materials 14, no. 19: 5635. https://doi.org/10.3390/ma14195635