Improvement in Fatigue Behavior of Dental Implant Fixtures by Changing Internal Connection Design: An In Vitro Pilot Study

Abstract

:1. Introduction

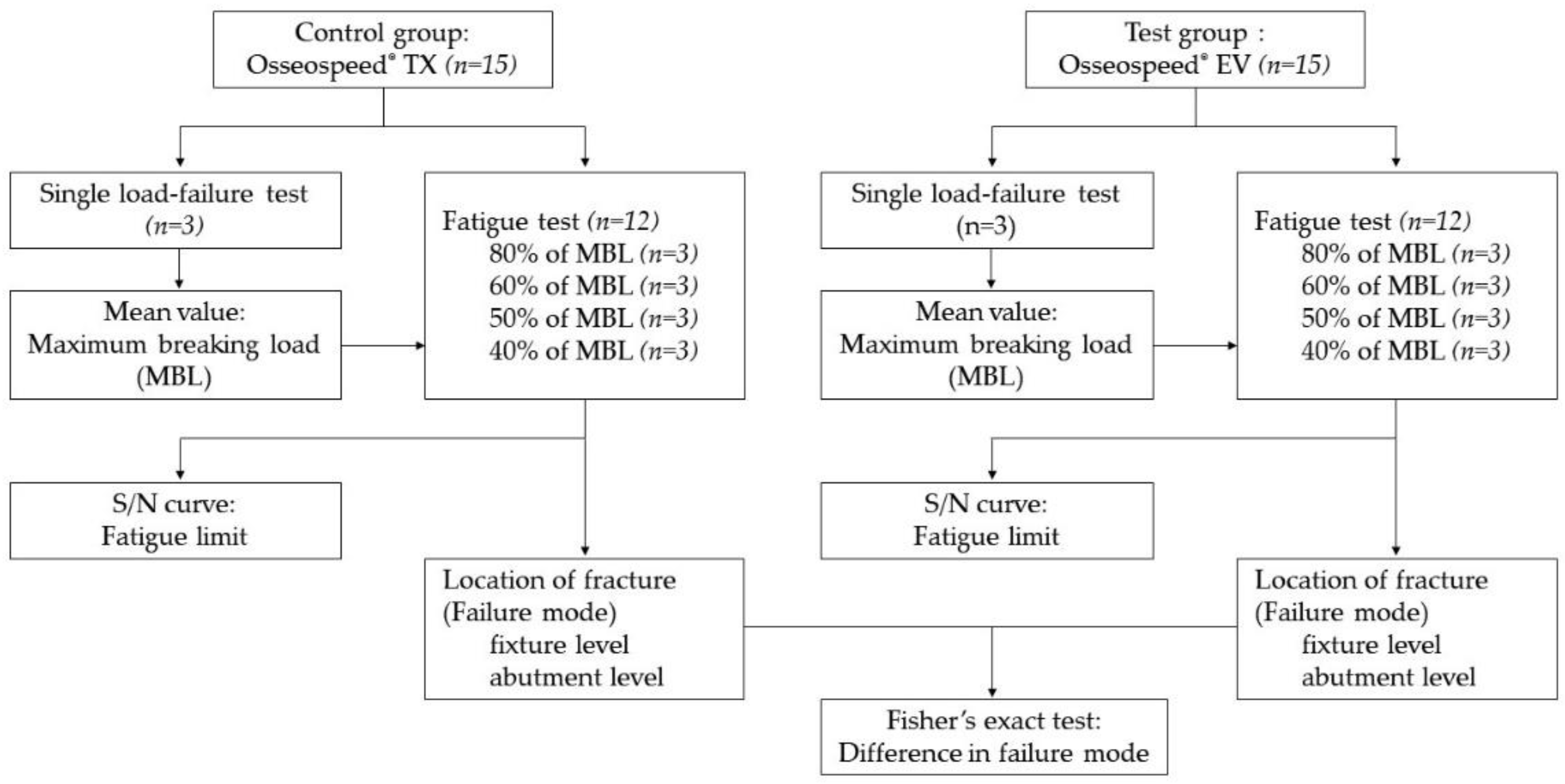

2. Materials and Methods

2.1. Preparation of Specimens

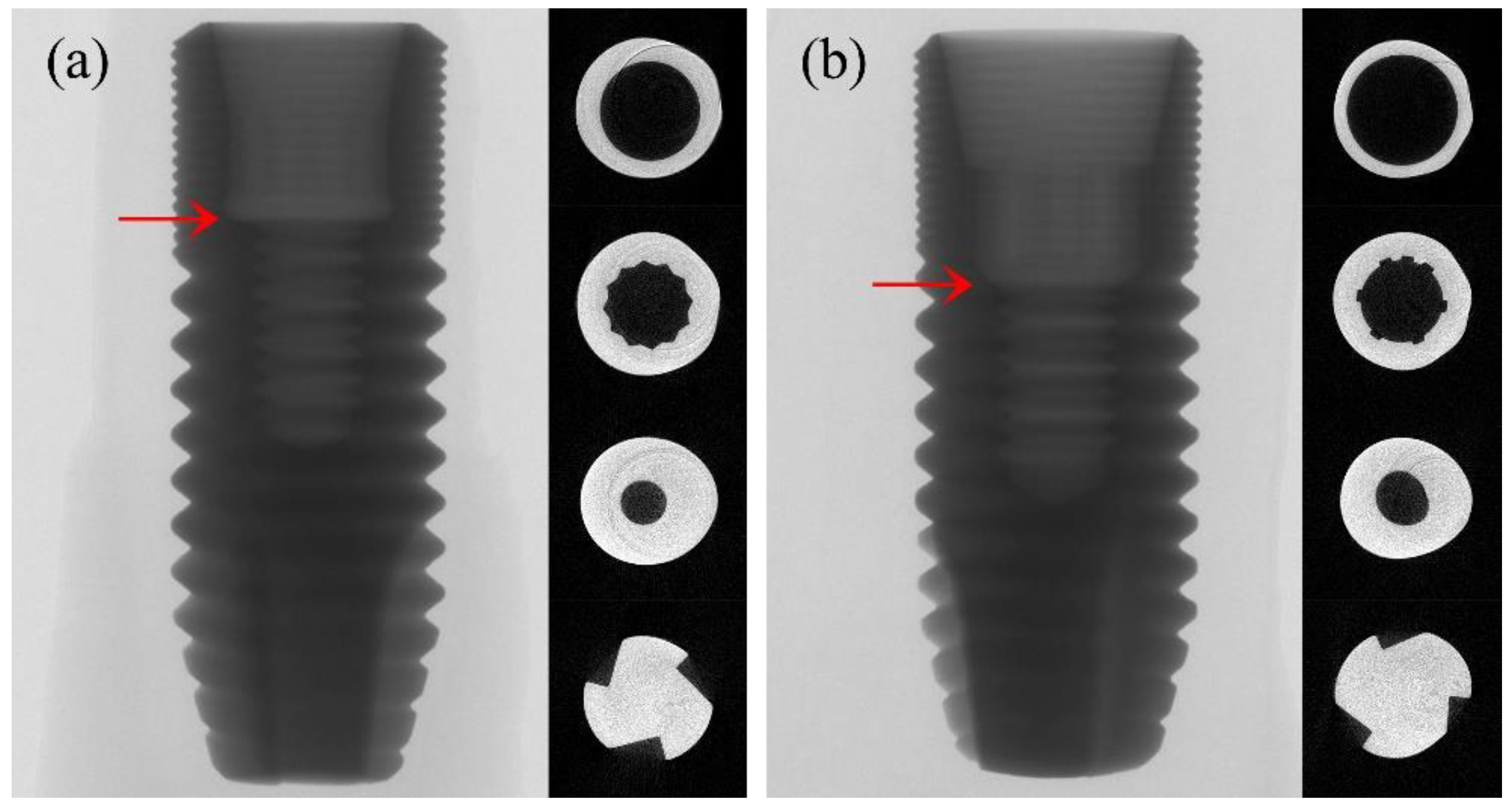

2.2. Micro-CT Image Observation

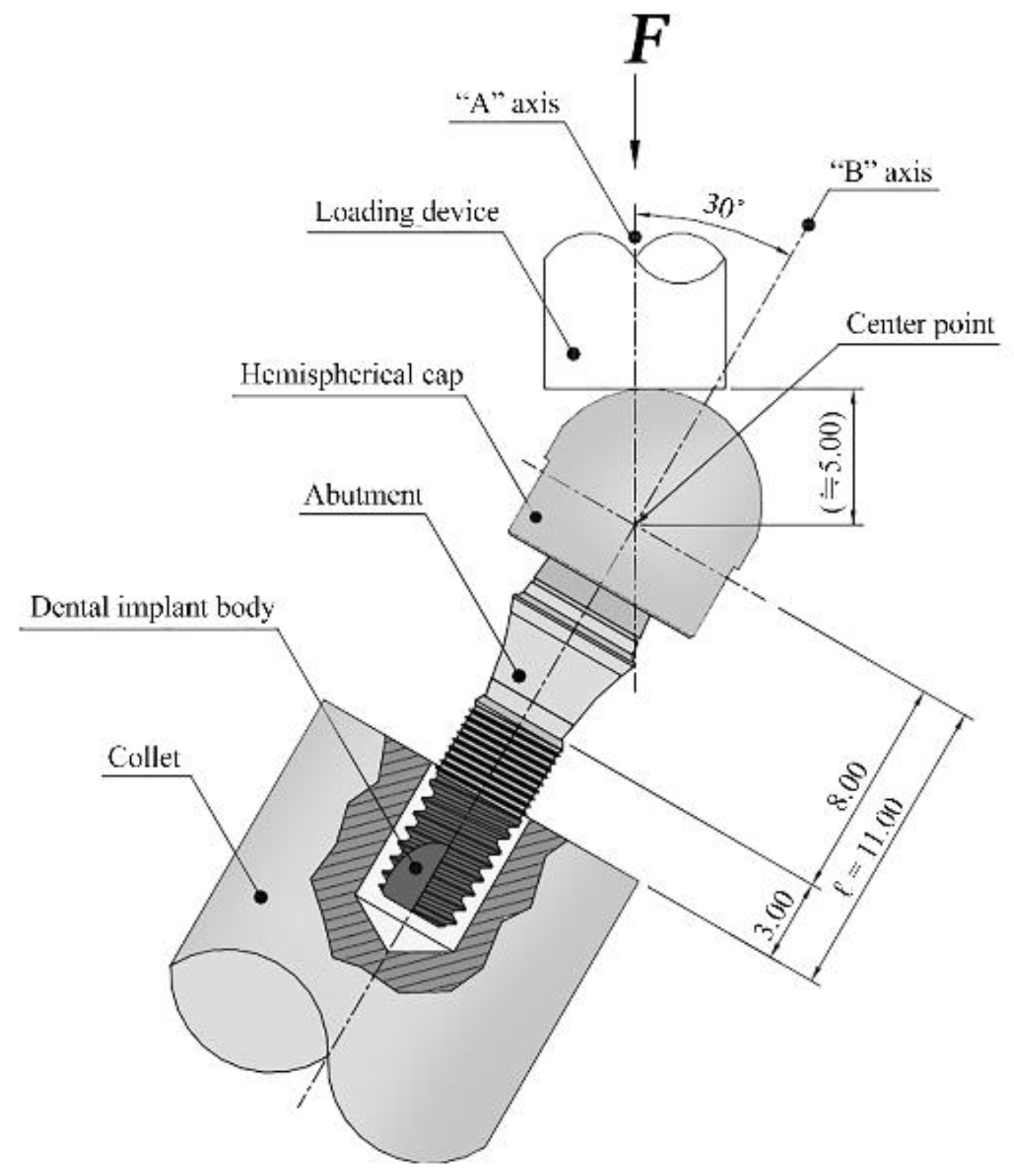

2.3. Single-Load Failure Test and Fatigue

2.4. Failure Modes and Microscopic Observation

2.5. Statistical Analysis

3. Results

3.1. Micro-CT Image Observation

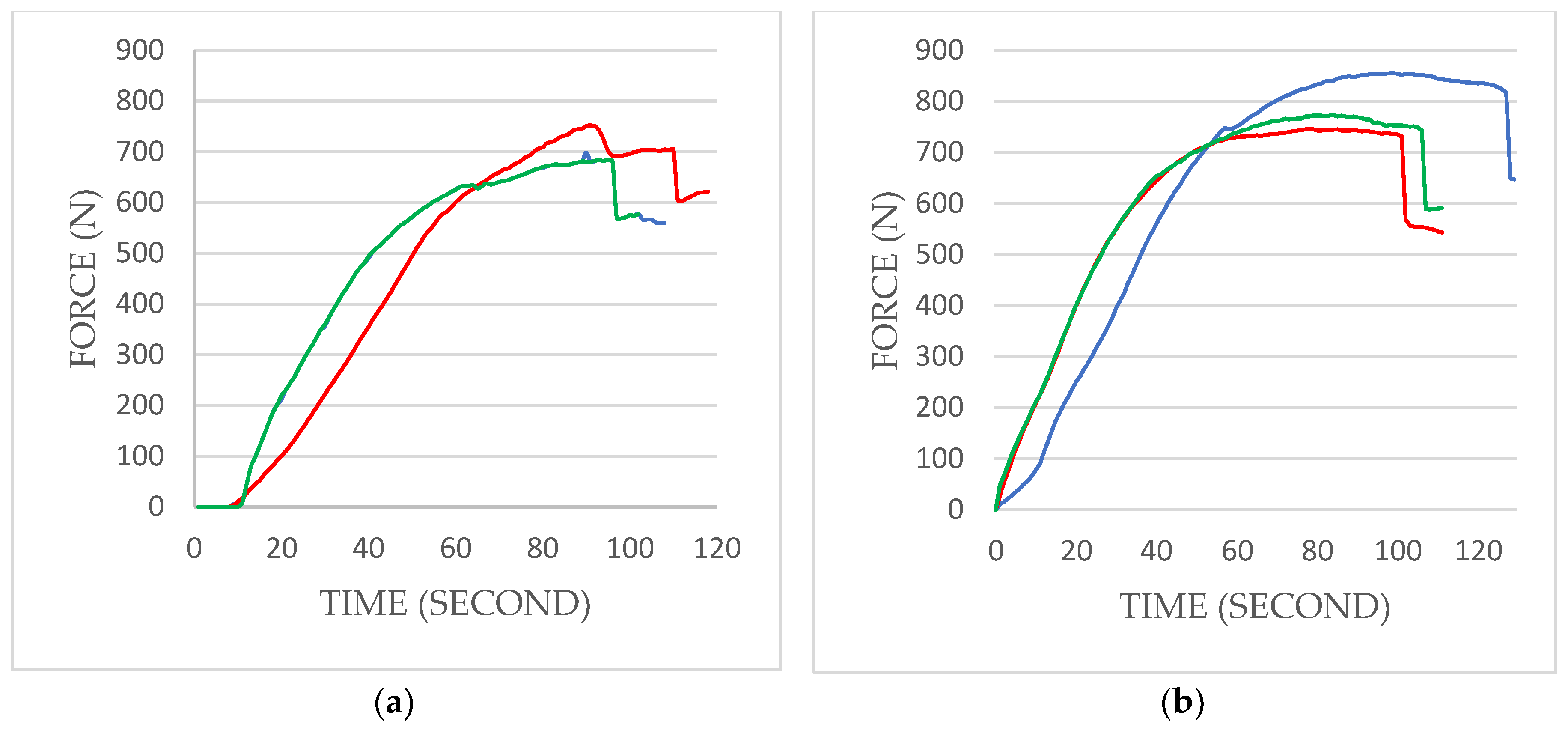

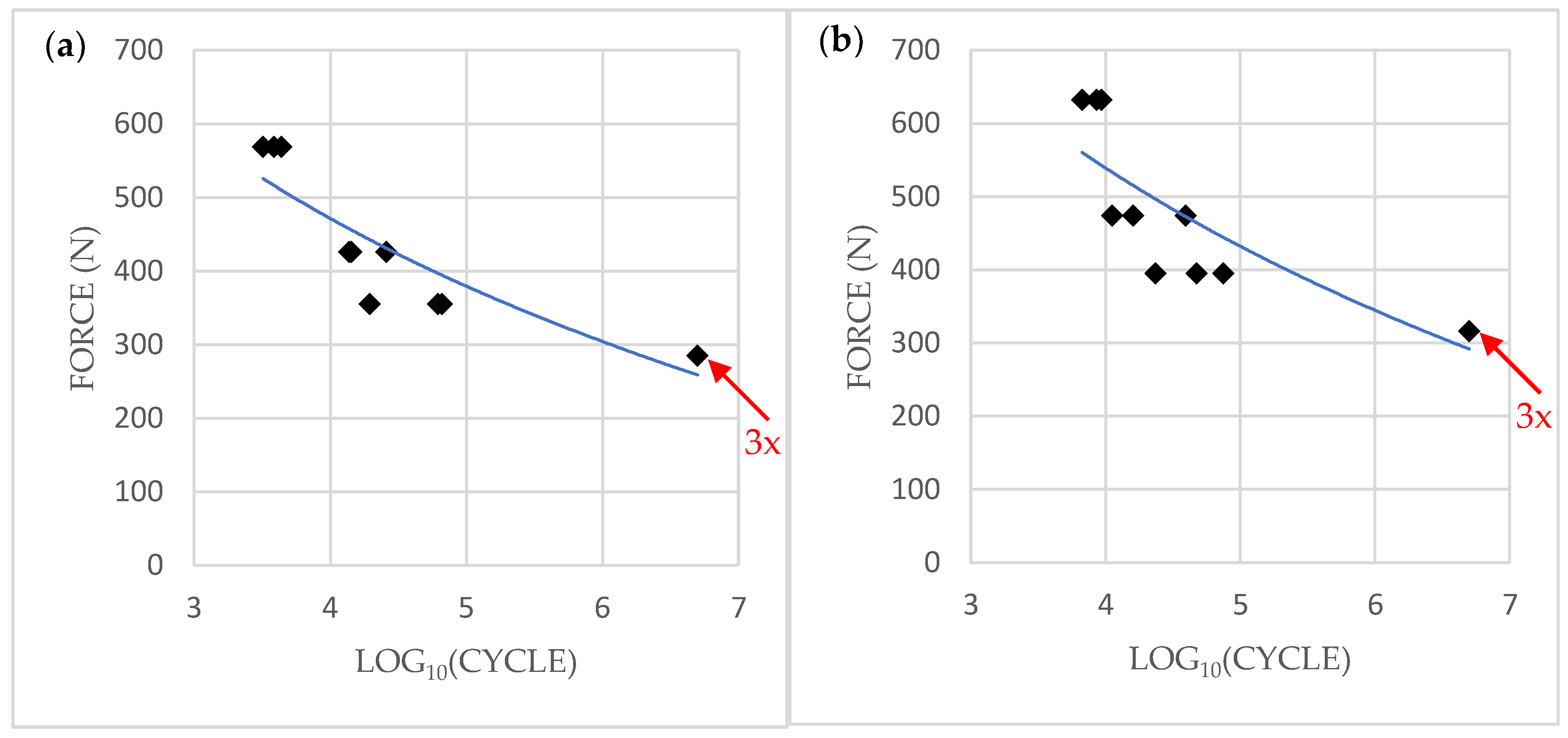

3.2. Maximum Breaking Load and Fatigue Limit

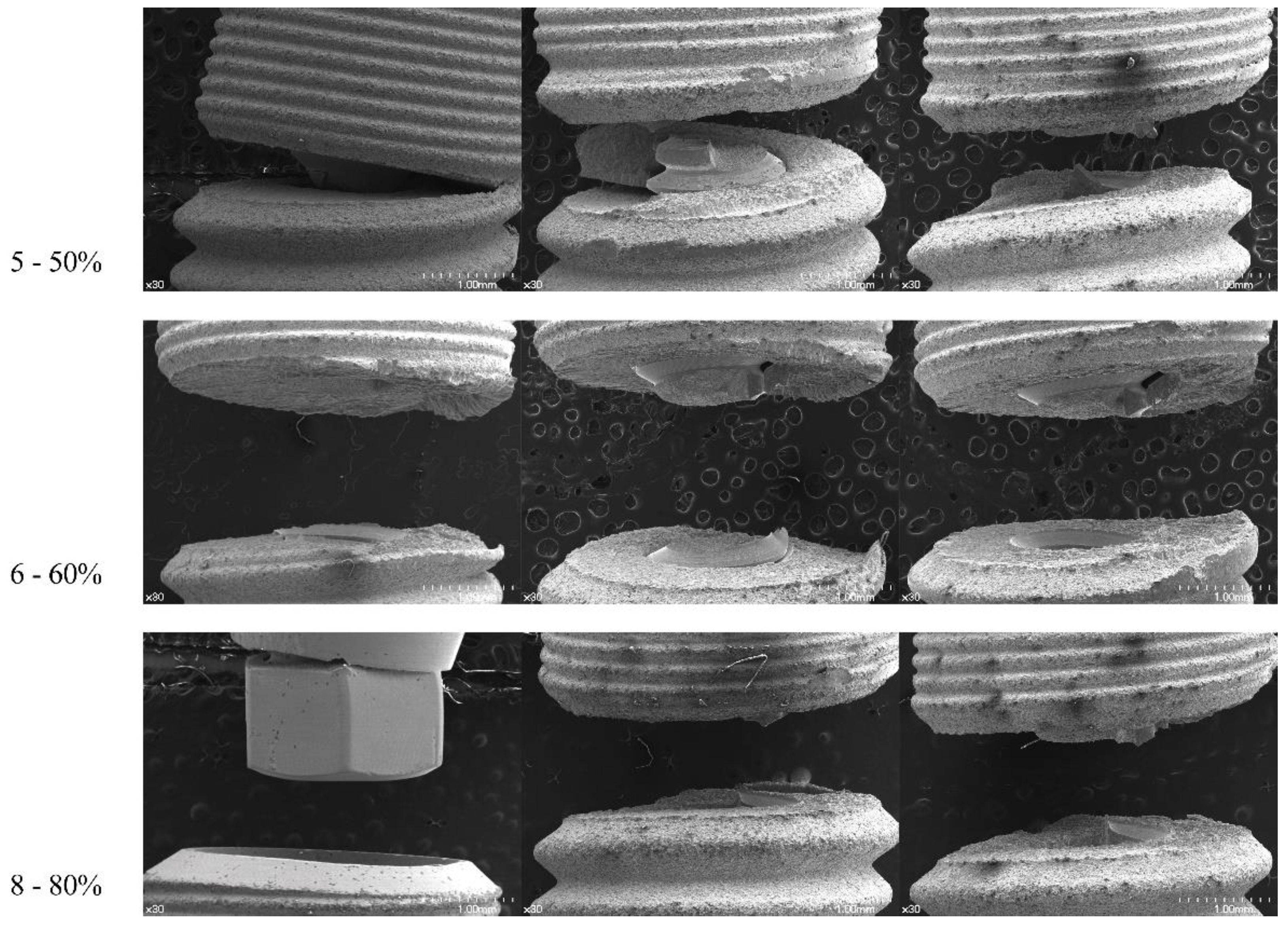

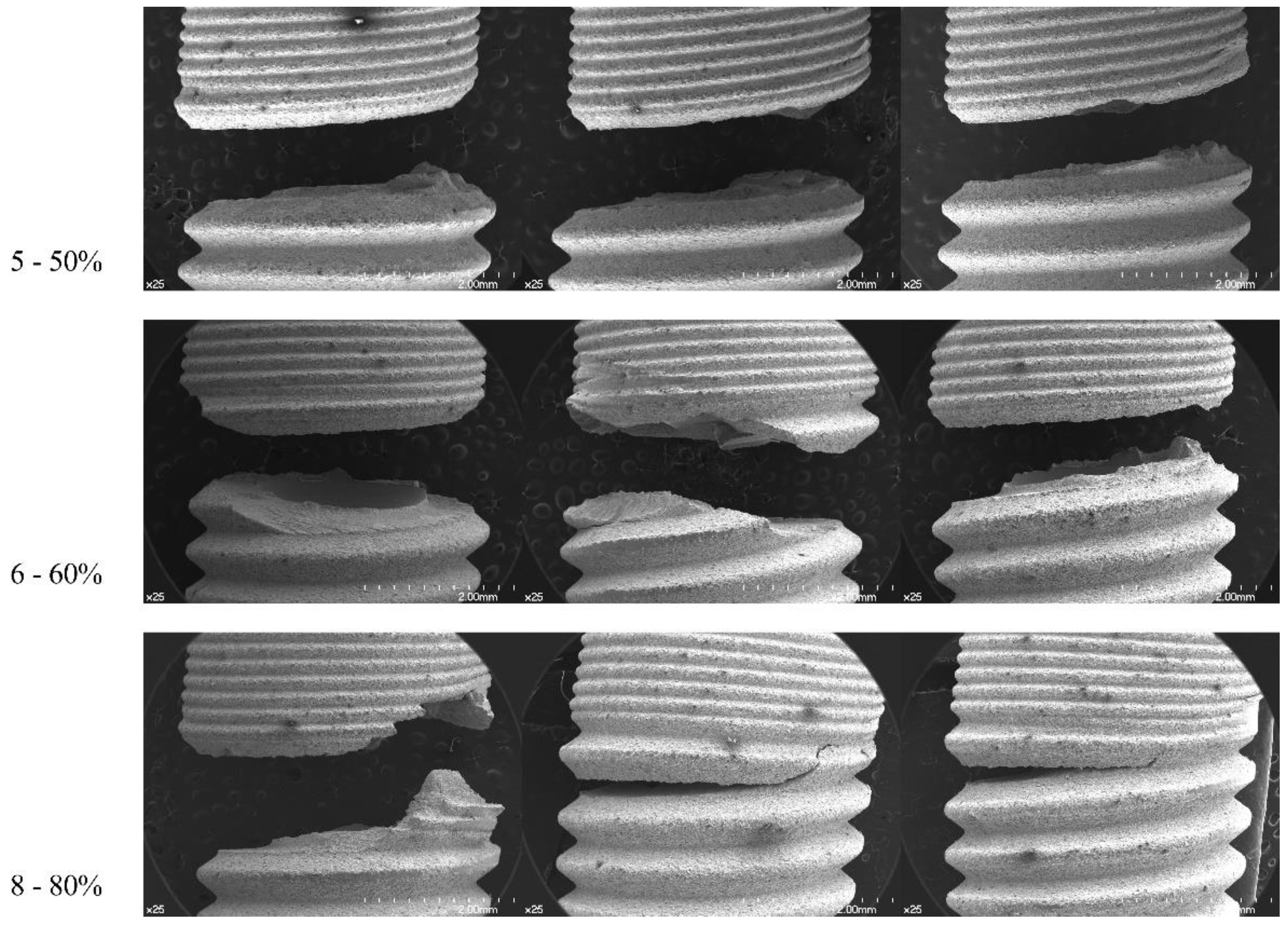

3.3. Failure Modes

3.4. Microscopic Observation

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Buser, D.; Janner, S.F.M.; Wittneben, J.G.; Brägger, U.; Ramseier, C.A.; Salvi, G.E. 10-Year Survival and Success Rates of 511 Titanium Implants with a Sandblasted and Acid-Etched Surface: A Retrospective Study in 303 Partially Edentulous Patients. Clin. Implant Dent. Relat. Res. 2012, 14, 839–851. [Google Scholar] [CrossRef] [PubMed]

- Pjetursson, B.E.; Thoma, D.; Jung, R.; Zwahlen, M.; Zembic, A. A Systematic Review of the Survival and Complication Rates of Implant-Supported Fixed Dental Prostheses(FDPs) after a Mean Observation Period of at Least 5 Years. Clin. Oral Implants Res. 2012, 23, 22–38. [Google Scholar] [CrossRef] [PubMed]

- Jung, R.E.; Zembic, A.; Pjetursson, B.E.; Zwahlen, M.; Thoma, D.S. Systematic Review of the Survival Rate and the Incidence of Biological, Technical, and Aesthetic Complications of Single Crowns on Implants Reported in Longitudinal Studies with a Mean Follow-up of 5 Years. Clin. Oral Implants Res. 2012, 23, 2–21. [Google Scholar] [CrossRef] [PubMed]

- Jung, R.E.; Pjetursson, B.E.; Glauser, R.; Zembic, A.; Zwahlen, M.; Lang, N.P. A Systematic Review of the 5-Year Survival and Complication Rates of Implant-Supported Single Crowns. Clin. Oral Implants Res. 2008, 19, 119–130. [Google Scholar] [CrossRef] [PubMed]

- Åstrand, P.; Ahlqvist, J.; Gunne, J.; Nilson, H. Implant Treatment of Patients with Edentulous Jaws: A 20-Year Follow-Up. Clin. Implant Dent. Relat. Res. 2008, 10, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Blanes, R.J.; Bernard, J.P.; Blanes, Z.M.; Belser, U.C. A 10-Year Prospective Study of ITI Dental Implants Placed in the Posterior Region. I: Clinical and Radiographic Results. Clin. Oral Implants Res. 2007, 18, 699–706. [Google Scholar] [CrossRef] [PubMed]

- Lekholm, U.; Gröndahl, K.; Jemt, T. Outcome of Oral Implant Treatment in Partially Edentulous Jaws Followed 20 Years in Clinical Function. Clin. Implant Dent. Relat. Res. 2006, 8, 178–186. [Google Scholar] [CrossRef] [PubMed]

- Tabrizi, R.; Behnia, H.; Taherian, S.; Hesami, N. What Are the Incidence and Factors Associated With Implant Fracture? J. Oral Maxillofac. Surg. 2017, 75, 1866–1872. [Google Scholar] [CrossRef]

- Balik, A.; Karatas, M.O.; Keskin, H. Effects of Different Abutment Connection Designs on the Stress Distribution Around Five Different Implants: A 3-Dimensional Finite Element Analysis. J. Oral Implantol. 2012, 38, 491–496. [Google Scholar] [CrossRef]

- Shemtov-Yona, K.; Rittel, D.; Levin, L.; Machtei, E.E. Effect of Dental Implant Diameter on Fatigue Performance. Part I: Mechanical Behavior. Clin. Implant Dent. Relat. Res. 2014, 16, 172–177. [Google Scholar] [CrossRef]

- ASTM. ASTM E1823-10-Standard Terminology Relating to Fatigue and Fracture Testing; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Imakita, C.; Shiota, M.; Yamaguchi, Y.; Kasugai, S.; Wakabayashi, N. Failure Analysis of an Abutment Fracture on Single Implant Restoration. Implant Dent. 2013, 22, 326–331. [Google Scholar] [CrossRef] [PubMed]

- ISO14801. Fatigue Test for Endosseous Dental Implants; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Kelly, J.R.; Benetti, P.; Rungruanganunt, P.; Bona, A.D. The Slippery Slope-Critical Perspectives on in Vitro Research Methodologies. Dent. Mater. 2012, 28, 41–51. [Google Scholar] [CrossRef] [PubMed]

- Chieruzzi, M.; Pagano, S.; Cianetti, S.; Lombardo, G.; Kenny, J.M.; Torre, L. Effect of Fibre Posts, Bone Losses and Fibre Content on the Biomechanical Behaviour of Endodontically Treated Teeth: 3D-Finite Element Analysis. Mater. Sci. Eng. C 2017, 74, 334–346. [Google Scholar] [CrossRef] [PubMed]

- Geng, J.P.A.; Tan, K.B.C.; Liu, G.R. Application of Finite Element Analysis in Implant Dentistry: A Review of the Literature. J. Prosthet. Dent. 2001, 85, 585–598. [Google Scholar] [CrossRef] [PubMed]

- van der Bilt, A. Assessment of Mastication with Implications for Oral Rehabilitation: A Review. J. Oral Rehabil. 2011, 38, 754–780. [Google Scholar] [CrossRef] [PubMed]

- Richter, E.-J. In Vivo Vertical Forces on Implants. Int. J. Oral Maxillofac. Implants 1995, 10, 99–108. [Google Scholar] [PubMed]

- Gibbs, C.H.; Mahan, P.E.; Mauderli, A.; Lundeen, H.C.; Walsh, E.K. Limits of Human Bite Strength. J. Prosthet. Dent. 1986, 56, 226–229. [Google Scholar] [CrossRef]

- Helkimo, E.; Carlsson, G.E.; Helkimo, M. Bite Forces Used during Chewing of Food. J. Dent. Res. 1959, 29, 133–136. [Google Scholar]

- Waltimo, A.; Könönen, M. A Novel Bite Force Recorder and Maximal Isometric Bite Force Values for Healthy Young Adults. Eur. J. Oral Sci. 1993, 101, 171–175. [Google Scholar] [CrossRef]

- Park, S.-J.; Lee, S.-W.; Leesungbok, R.; Ahn, S.-J. Influence of the Connection Design and Titanium Grades of the Implant Complex on Resistance under Static Loading. J. Adv. Prosthodont. 2016, 8, 388–395. [Google Scholar] [CrossRef]

- Marchetti, E.; Ratta, S.; Mummolo, S.; Tecco, S.; Pecci, R.; Bedini, R.; Marzo, G. Mechanical Reliability Evaluation of an Oral Implant-Abutment System According to UNI En ISO 14801 Fatigue Test Protocol. Implant Dent. 2016, 25, 613–618. [Google Scholar] [CrossRef] [PubMed]

- Johansson, H.; Hellqvist, J. Functionality of a Further Developed Implant System: Mechanical Integrity. Clin. Oral Implants Res. 2013, 24, 166. [Google Scholar]

- Sakaguchi, R.L.; Douglas, W.H.; DeLong, R.; Pintado, M.R. The Wear of a Posterior Composite in an Artificial Mouth: A Clinical Correlation. Dent. Mater. 1986, 2, 235–240. [Google Scholar] [CrossRef]

- DeLong, R.; Douglas, W.H. Development of an Artificial Oral Environment for the Testing of Dental Restoratives: Bi-Axial Force and Movement Control. J. Dent. Res. 1983, 62, 32–36. [Google Scholar] [CrossRef] [PubMed]

- Stimmelmayr, M.; Edelhoff, D.; Güth, J.-F.; Erdelt, K.; Happe, A.; Beuer, F. Wear at the Titanium–Titanium and the Titanium–Zirconia Implant–Abutment Interface: A Comparative in Vitro Study. Dent. Mater. 2012, 28, 1215–1220. [Google Scholar] [CrossRef]

| Components | Test Group | Control Group |

|---|---|---|

| Implant Fixture | OsseoSpeed® EV (4.2 mm × 11 mm) | OsseoSpeed® TX (4.0 mm × 11 mm) |

| Abutment | TiDesign® EV Abutment height: 5.5 mm Gingival height: 2.5 mm | TiDesign® Abutment height: 5.5 mm Gingival height: 1.5 mm |

| TX Ø4.0 | Load at Break (N) | EV Ø4.2 | Load at Break (N) |

|---|---|---|---|

| 698 N | 856 N | ||

| 684 N | 772 N | ||

| 752 N | 745 N | ||

| Mean ± SD | 711 ± 36 N | Mean ± SD | 791 ± 58 N |

| TX Ø4.0 | |||

| Loading Level (%) | Sinusoidal Loading (N) | Number of Performed Cycles | Mean |

| 80 | 57–569 | 3209; 4369; 3851 | 3810 |

| 60 | 43–426 | 25,884; 14,353; 13,742 | 17,993 |

| 50 | 36–355 | 19,549; 66,014; 61,825 | 49,129 |

| 40 | 29–285 | 5,000,000; 5,000,000; 5,000,000 | 5,000,000 |

| EV Ø4.2 | |||

| Loading Level (%) | Sinusoidal Loading (N) | Number of Performed Cycles | Mean |

| 80 | 63–632 | 6696; 8567; 9333 | 8199 |

| 60 | 47–474 | 16,118; 39,423; 11,219 | 22,253 |

| 50 | 40–395 | 75,210; 23,584; 47,651 | 48,815 |

| 40 | 32–316 | 5,000,000; 5,000,000; 5,000,000 | 5,000,000 |

| Fractured Area | Failure Aspect (TX Ø4.0) | Failure Aspect (EV Ø4.2) | ||

|---|---|---|---|---|

| Static Load | Cyclic Load | Static Load | Cyclic Load | |

| Abutment Fracture | 0 | 1 | 0 | 0 |

| Fixture Fracture | 3 | 8 | 3 | 9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, N.-H.; Yoon, H.-I.; Kim, T.-H.; Park, E.-J. Improvement in Fatigue Behavior of Dental Implant Fixtures by Changing Internal Connection Design: An In Vitro Pilot Study. Materials 2019, 12, 3264. https://doi.org/10.3390/ma12193264

Choi N-H, Yoon H-I, Kim T-H, Park E-J. Improvement in Fatigue Behavior of Dental Implant Fixtures by Changing Internal Connection Design: An In Vitro Pilot Study. Materials. 2019; 12(19):3264. https://doi.org/10.3390/ma12193264

Chicago/Turabian StyleChoi, Nak-Hyun, Hyung-In Yoon, Tae-Hyung Kim, and Eun-Jin Park. 2019. "Improvement in Fatigue Behavior of Dental Implant Fixtures by Changing Internal Connection Design: An In Vitro Pilot Study" Materials 12, no. 19: 3264. https://doi.org/10.3390/ma12193264