Study on the Characteristics of Walnut Shell/Co-PES/Co-PA Powder Produced by Selective Laser Sintering

Abstract

:1. Introduction

2. Materials and Methods

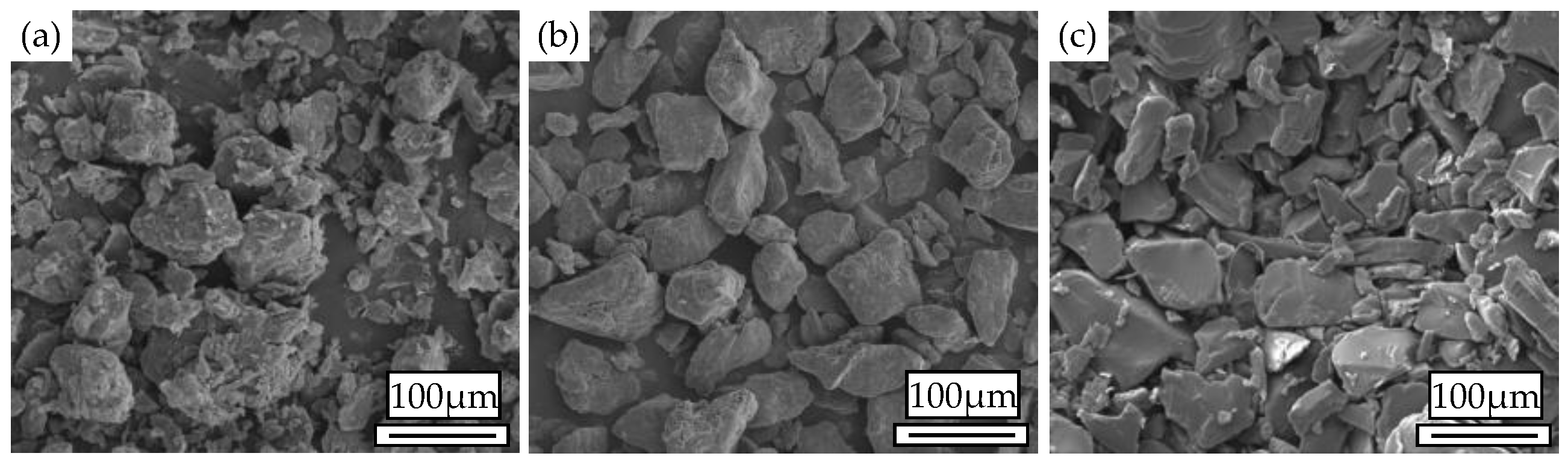

2.1. Experimental Materials

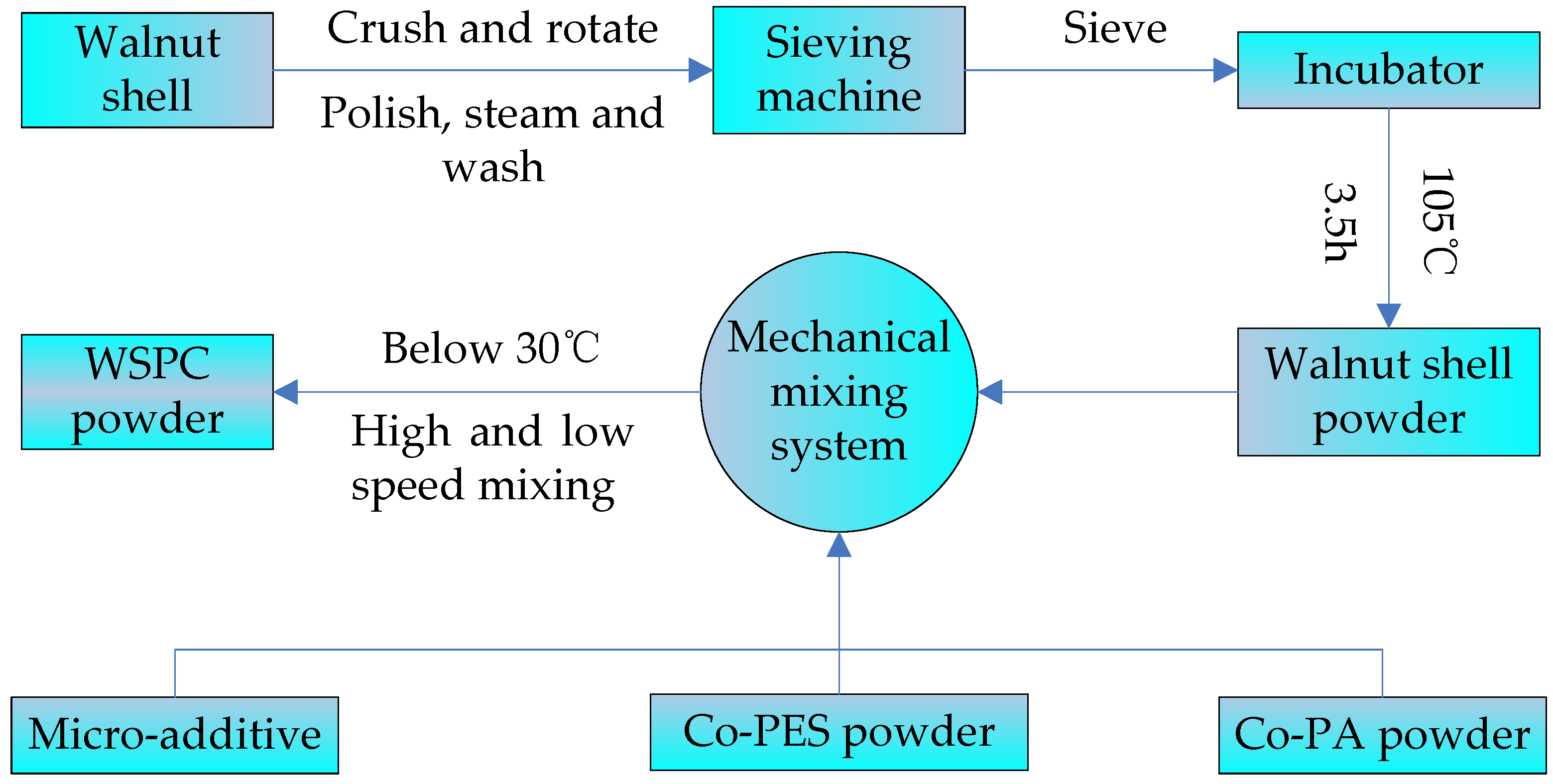

2.2. Preparation of WSPC Powder

2.3. Equipment and Process Principle of SLS

2.4. Characterization and Test

3. Results and Discussion

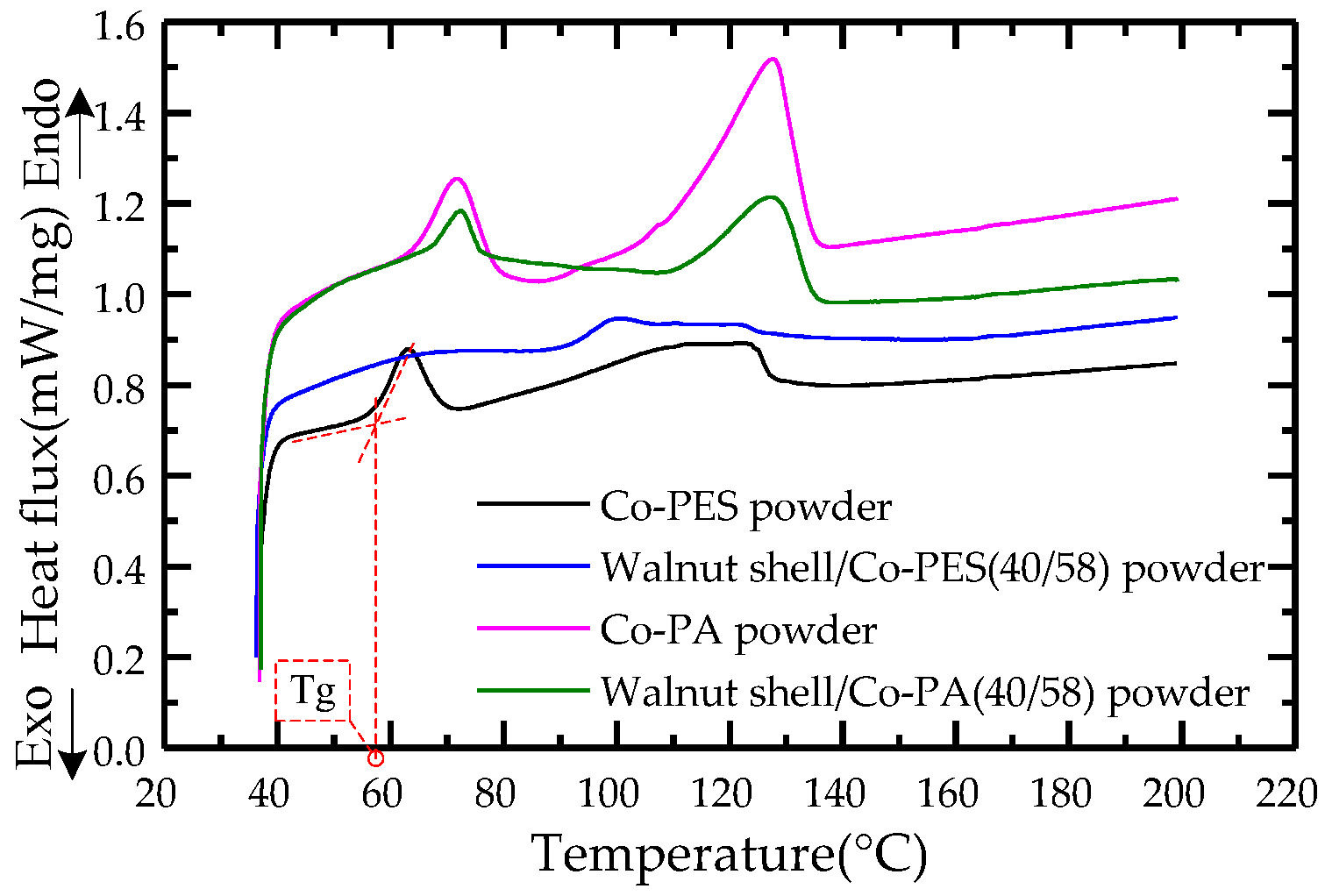

3.1. Thermal Analysis of the WSPC Powder

3.2. Dimensional Precision

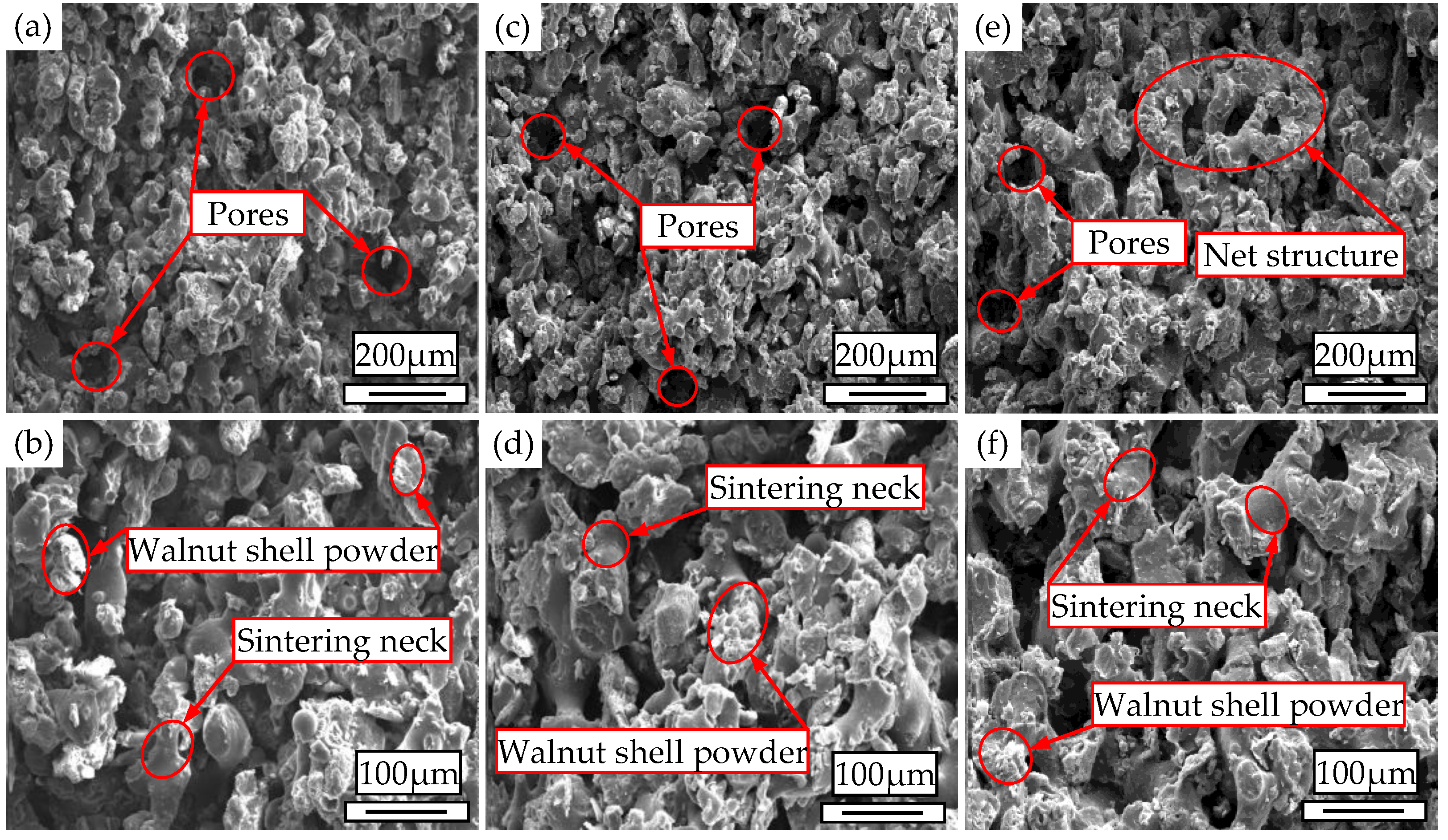

3.3. Morphologies

3.4. Mechanical Properties

3.5. Density of the WSPC Parts

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, S.P.; Yi, H.P.; Luo, Z.H.; Zhuge, X.Q.; Luo, K. The 3D printing polymers and their printing technologies. Mater. Rev. 2016, 54–59. [Google Scholar] [CrossRef]

- Gross, B.C.; Lockwood, S.Y.; Spence, D.M. Recent Advances in Analytical Chemistry by 3D Printing. Anal. Chem. 2017, 89, 57–70. [Google Scholar] [CrossRef] [PubMed]

- Deckard, C.R. Selective Laser Sintering. Ph.D. Thesis, The University of Texas, Austin, TX, USA, 1988. [Google Scholar]

- Zhao, H.L.; Feng, T.; Hou, X.L. RPM for engine parts. Manuf. Technol. Mach. Tool 2015, 24–26. [Google Scholar] [CrossRef]

- Rokicki, P.; Kozik, B.; Budzik, G.; Dziubek, T.; Bernaczek, J.; Przeszlowski, L.; Markowska, O.; Sobolewski, B.; Rzucidlo, A. Manufacturing of aircraft engine transmission gear with SLS (DMLS) method. Aircr. Eng. Aerosp. Technol. 2016, 88, 397–403. [Google Scholar] [CrossRef]

- Liang, X.W.; Xu, Z.F.; Zhao, K.F.; Nie, M.M.; Rao, J.H.; Wang, D.J. Interfacial reaction of zirconium sand mold with alloy castings based on SLS method. Spec.-Cast Non-Ferr. Alloys 2017, 37, 518–521. [Google Scholar] [CrossRef]

- Du, Y.; Liu, H.; Yang, Q.; Wang, S.; Wang, J.L.; Ma, J.; Noh, I.; Mikos, A.G.; Zhang, S.M. Selective laser sintering scaffold with hierarchical architecture and gradient composition for osteochondral repair in rabbits. Biomaterials 2017, 137, 37–48. [Google Scholar] [CrossRef] [PubMed]

- Bourell, D.L. Sintering in laser sintering. JOM 2016, 68, 885–889. [Google Scholar] [CrossRef]

- Xie, F.X.; He, X.B.; Cao, S.L.; Mei, M.; Qu, X.H. Influence of pore characteristics on microstructure, mechanical properties and corrosion resistance of selective laser sintered porous Ti–Mo alloys for biomedical applications. Electrochim. Acta 2013, 105, 121–129. [Google Scholar] [CrossRef]

- Pace, M.L.; Guarnaccio, A.; Dolce, P.; Mollica, D.; Parisi, G.P.; Lettino, A.; Medici, L.; Summa, V.; Ciancio, R.; Santagata, A. 3D additive manufactured 316L components microstructural features and changes induced by working life cycles. Appl. Surf. Sci. 2017, 418, 437–445. [Google Scholar] [CrossRef]

- Danezan, A.; Delaizir, G.; Tessier-Doyen, N.; Gasgnier, G.; Gaillard, J.M.; Duport, P.; Nait-Ali, B. Selective Laser Sintering of porcelain. J. Eur. Ceram. Soc. 2017, 38, 769–775. [Google Scholar] [CrossRef]

- Chang, S.; Li, L.Q.; Lu, L.; Fuh, J.Y.H. Selective laser sintering of porous silica enabled by carbon additive. Materials 2017, 10, 1313. [Google Scholar] [CrossRef] [PubMed]

- Pavan, M.; Craeghs, T.; Kruth, J.P.; Dewulf, W. Investigating the influence of X-ray CT parameters on porosity measurement of laser sintered PA12 parts using a design-of-experiment approach. Polym. Test. 2018, 66, 203–212. [Google Scholar] [CrossRef]

- Bai, J.; Zhang, B.; Song, J.; Bi, G.J.; Wang, P.; Wei, J. The effect of treatment conditions on the mechanical properties of polyethylene produced by selective laser sintering. Polym. Test. 2016, 52, 89–93. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Lauth, V.R.; Cardenuto, M.R.; Magnago, R.F. Characterization of PA12/PBT specimens prepared by Selective Laser Sintering. Opt. Laser Technol. 2017, 98, 92–96. [Google Scholar] [CrossRef]

- Guo, Y.L.; Jiang, K.Y.; Bourell, D.L. Accuracy and mechanical property analysis of LPA12 parts fabricated by laser sintering. Polym. Test. 2015, 42, 175–180. [Google Scholar] [CrossRef]

- Qi, F.W.; Chen, N.; Wang, Q. Preparation of PA11/BaTiO3, nanocomposite powders with improved processability, dielectric and piezoelectric properties for use in selective laser sintering. Mater. Des. 2017, 131, 135–143. [Google Scholar] [CrossRef]

- Guo, Y.L.; Jiang, K.Y.; Yu, Z.X.; Xin, Z.S.; Zeng, W.L. The preparation technology and forming properties of wood-plastic composite powder used in selective laser sintering. J. Shanghai Jiaotong Univ. 2011, 45, 1327–1331. [Google Scholar]

- Zeng, W.L.; Guo, Y.L.; Jiang, K.Y.; Yu, Z.X.; Liu, Y.; Shen, Y.D.; Deng, J.R.; Wang, P.X. Laser intensity effect on mechanical properties of wood-plastic composite parts fabricated by selective laser sintering. J. Thermoplast. Compos. Mater. 2012, 26, 125–136. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, Y.L.; Zhao, D.J.; Yu, Z.X. Preparation and selective laser sintering of Pine/Polyether sulfone composite. J. Northeast For. Univ. 2014, 42, 150–152, 157. [Google Scholar] [CrossRef]

- Zeng, W.L.; Guo, Y.L.; Jiang, K.Y.; Yu, Z.X.; Liu, Y. Preparation and selective laser sintering of rice husk-plastic composite powder and post treatment. Dig. J. Nanomater. Biostruct. 2012, 7, 1063–1070. [Google Scholar]

- Zhao, D.J.; Guo, Y.L.; Song, W.L.; Jiang, K.Y. Preparation and forming characteristics of bamboo powder/co-polyamide laser sintering composite materials. J. Northeast For. Univ. 2015, 43, 107–109, 115. [Google Scholar] [CrossRef]

- Yu, Y.Q.; Guo, Y.L.; Jiang, T.; Jiang, K.Y.; Guo, S. Study on particle scale of selective laser sintering walnut shell/Co-PES composites powder. Appl. Laser 2017, 4, 509–514. [Google Scholar] [CrossRef]

- Yu, Y.Q.; Guo, Y.L.; Jiang, T.; Jiang, K.Y.; Guo, S. Laser sintering and post-processing of a walnut shell/Co-PES composite. RSC Adv. 2017, 7, 23176–23181. [Google Scholar] [CrossRef]

- Yu, Y.; Guo, Y.; Jiang, T.; Li, J.; Jiang, K.Y.; Zhang, H. Study on the Ingredient Proportions and after-Treatment of Laser Sintering Walnut Shell Composites. Materials 2017, 10, 1381. [Google Scholar] [CrossRef] [PubMed]

- Drummer, D.; Rietzel, D.; Kühnlein, F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys. Procedia 2010, 5, 533–542. [Google Scholar] [CrossRef]

- Zarringhalam, H.; Hopkinson, N.; Kamperman, N.F.; Vileger, J.J. Effects of processing on microstructure and properties of SLS Nylon 12. Mater. Sci. Eng. A 2006, 435, 172–180. [Google Scholar] [CrossRef] [Green Version]

| Serial Number | Walnut Shell Powder (vol %) | Co-PES Powder (vol %) | Co-PA Powder (vol %) | Micro-Additive (vol %) |

|---|---|---|---|---|

| Ⅰ | 40 | 58 | 0 | 2 |

| Ⅱ | 40 | 50 | 8 | 2 |

| Ⅲ | 40 | 40 | 18 | 2 |

| Ⅳ | 40 | 29 | 29 | 2 |

| Ⅴ | 40 | 18 | 40 | 2 |

| Ⅵ | 40 | 8 | 50 | 2 |

| Ⅶ | 40 | 0 | 58 | 2 |

| Laser Power (W) | Scan Speed (mm/s) | Layer Thickness (mm) | Scan Spacing (mm) | Preheating Temperature (°C) | Processing Temperature (°C) | ||||

|---|---|---|---|---|---|---|---|---|---|

| 12 | 2000 | 0.15 | 0.2 | 76 | 80 | 84 | 88 | 92 | 75 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Guo, Y.; Jiang, T.; Li, J.; Jiang, K.; Zhang, H.; Zhuang, Y. Study on the Characteristics of Walnut Shell/Co-PES/Co-PA Powder Produced by Selective Laser Sintering. Materials 2018, 11, 784. https://doi.org/10.3390/ma11050784

Yu Y, Guo Y, Jiang T, Li J, Jiang K, Zhang H, Zhuang Y. Study on the Characteristics of Walnut Shell/Co-PES/Co-PA Powder Produced by Selective Laser Sintering. Materials. 2018; 11(5):784. https://doi.org/10.3390/ma11050784

Chicago/Turabian StyleYu, Yueqiang, Yanling Guo, Ting Jiang, Jian Li, Kaiyi Jiang, Hui Zhang, and Yu Zhuang. 2018. "Study on the Characteristics of Walnut Shell/Co-PES/Co-PA Powder Produced by Selective Laser Sintering" Materials 11, no. 5: 784. https://doi.org/10.3390/ma11050784

APA StyleYu, Y., Guo, Y., Jiang, T., Li, J., Jiang, K., Zhang, H., & Zhuang, Y. (2018). Study on the Characteristics of Walnut Shell/Co-PES/Co-PA Powder Produced by Selective Laser Sintering. Materials, 11(5), 784. https://doi.org/10.3390/ma11050784