Influence of Surface Features for Increased Heat Dissipation on Tool Wear

Abstract

:1. Introduction

2. Surface Features on the Regular Insert

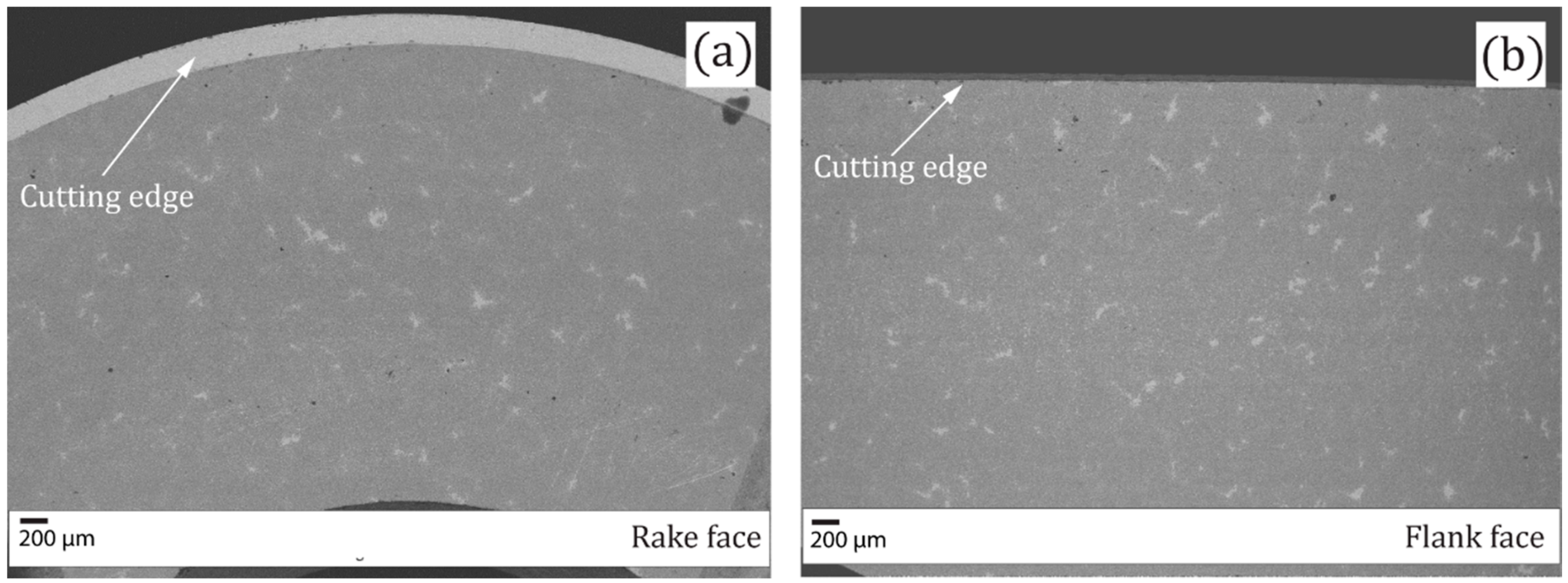

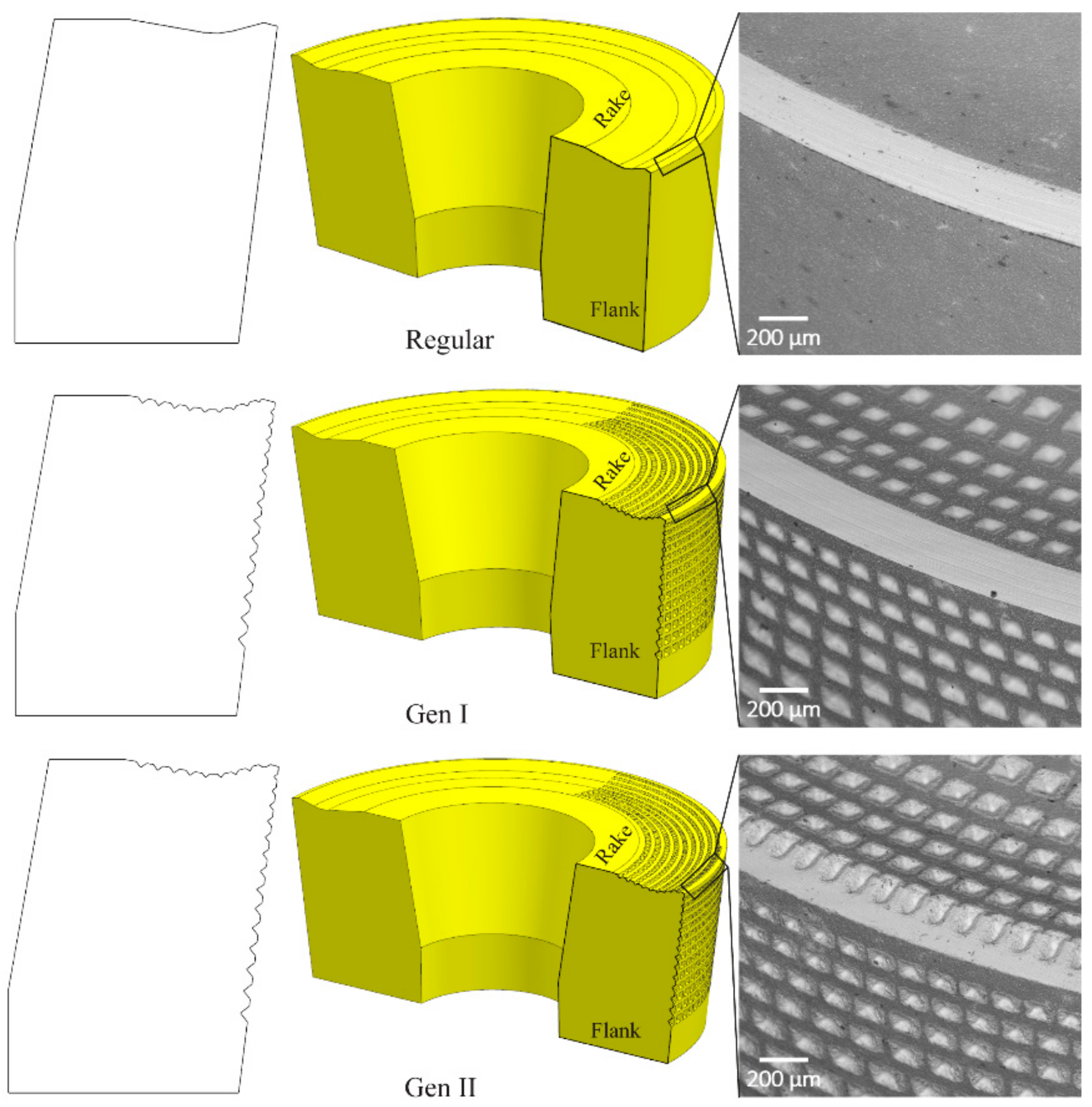

2.1. Regular Insert

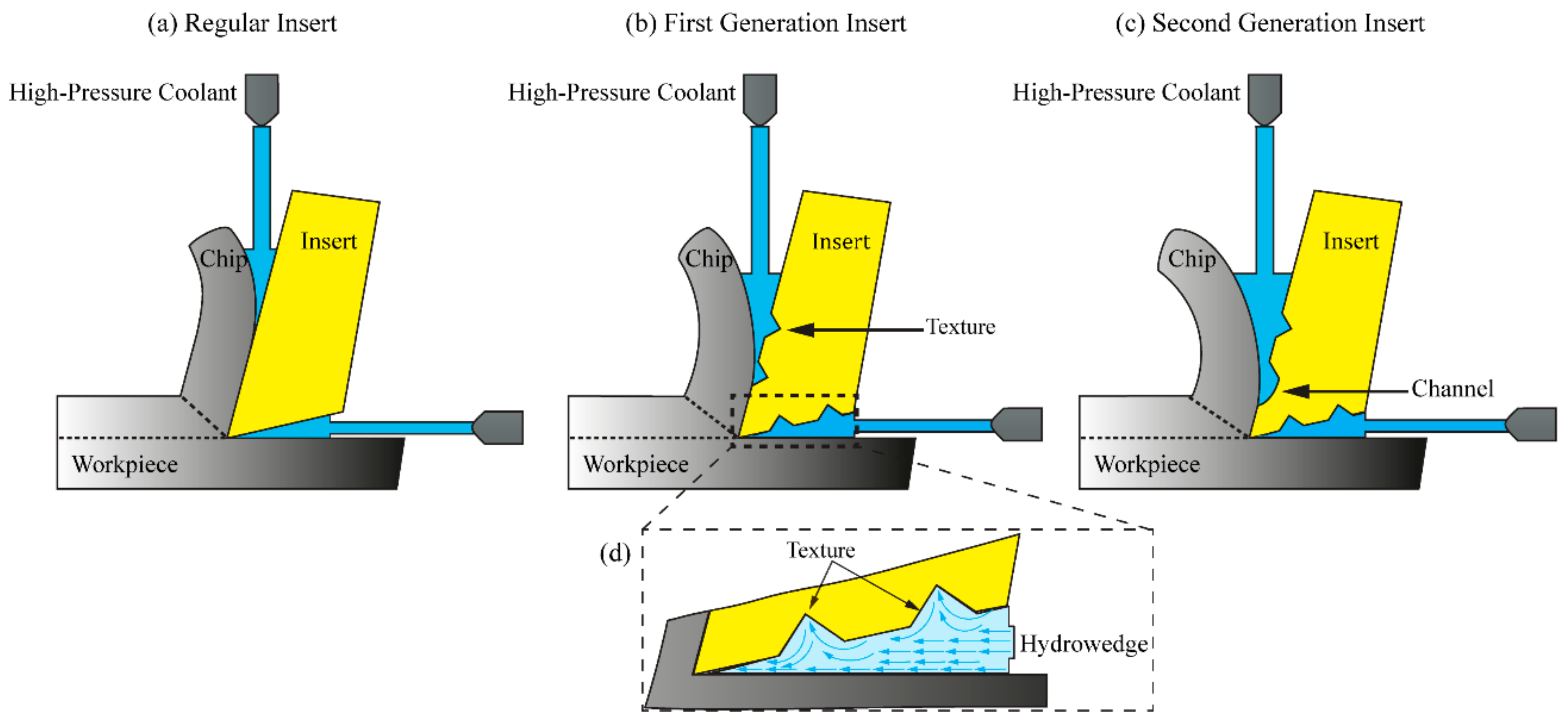

2.2. Surface Features and Design of Generation I Insert

2.3. Design of Generation II Insert

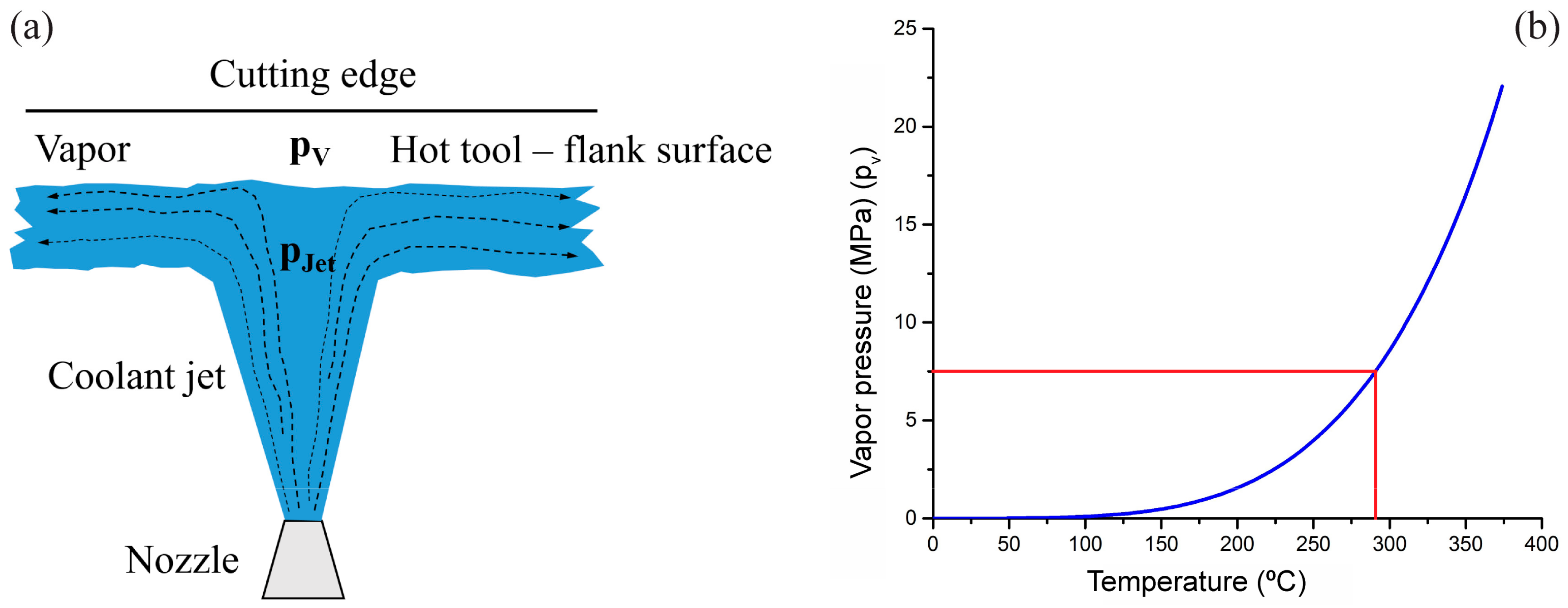

2.4. Coolant Interaction with Regular, Gen I and Gen II Inserts

3. Experimental

3.1. Workpiece Material—Alloy 718

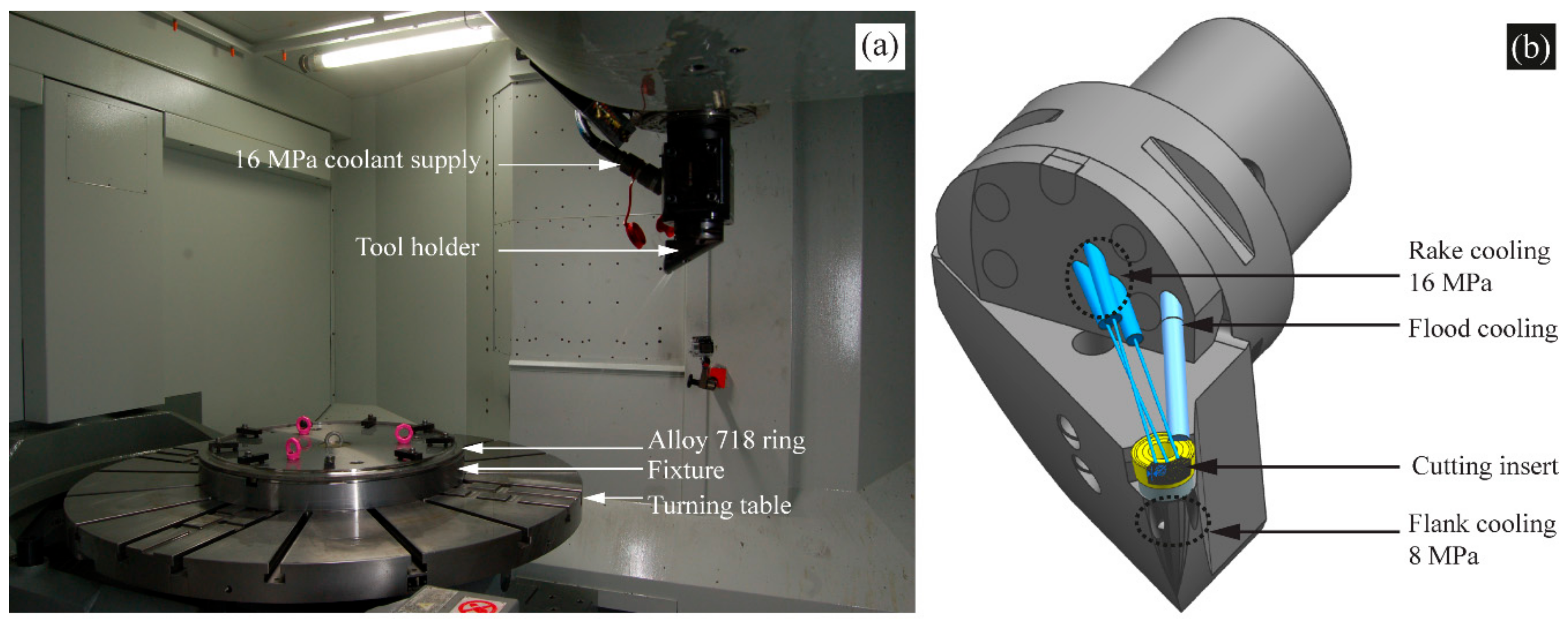

3.2. Machine Tool and High-Pressure Coolant Supply

3.3. Spiral Cutting Length Calculation

3.4. Design of Experiments Based on Spiral Cutting Length and Cutting Speed

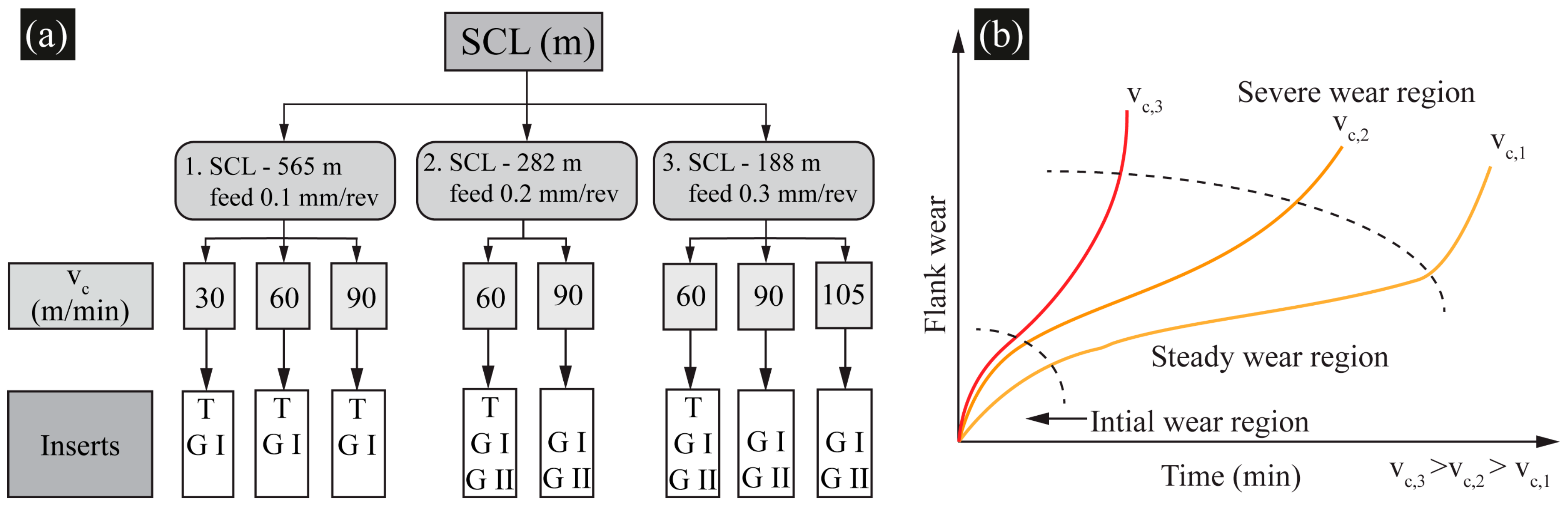

4. Measurement Techniques

- LOM was used to measure the flank wear and flank wear land profiles. Flank wear profiles were generated from 36 vertical measurements of the flank wear along the linear contact length of 3.6 mm. The individual vertical measurements were plotted into a graph.

- SEM was used to examine the tool wear at higher magnification on both rake and flank faces.

- EDS was used for elemental analysis of cutting tools after machining.

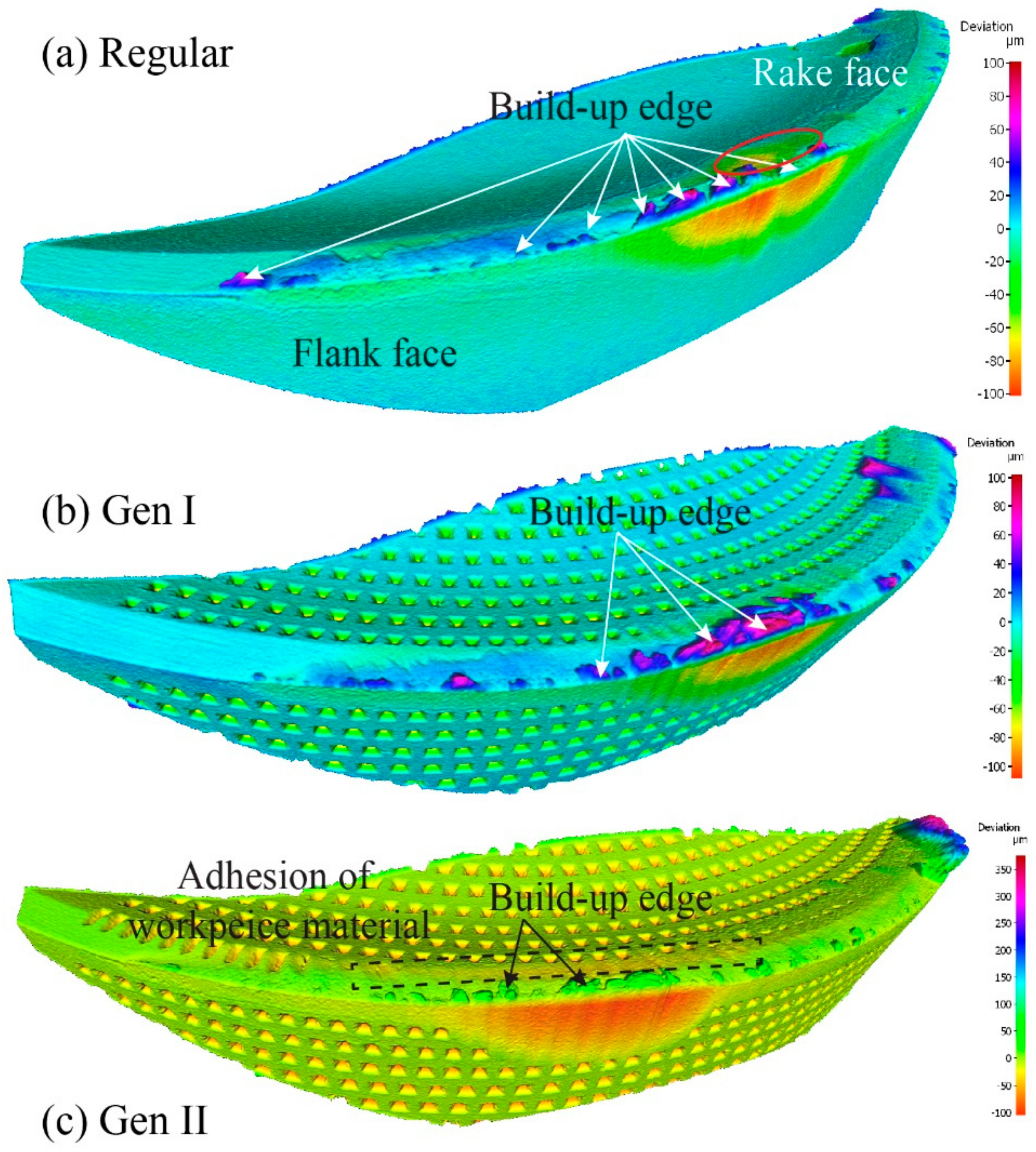

- Focus variation was used to investigate the area of the flank and rake wear, and for performing volume difference measurement.

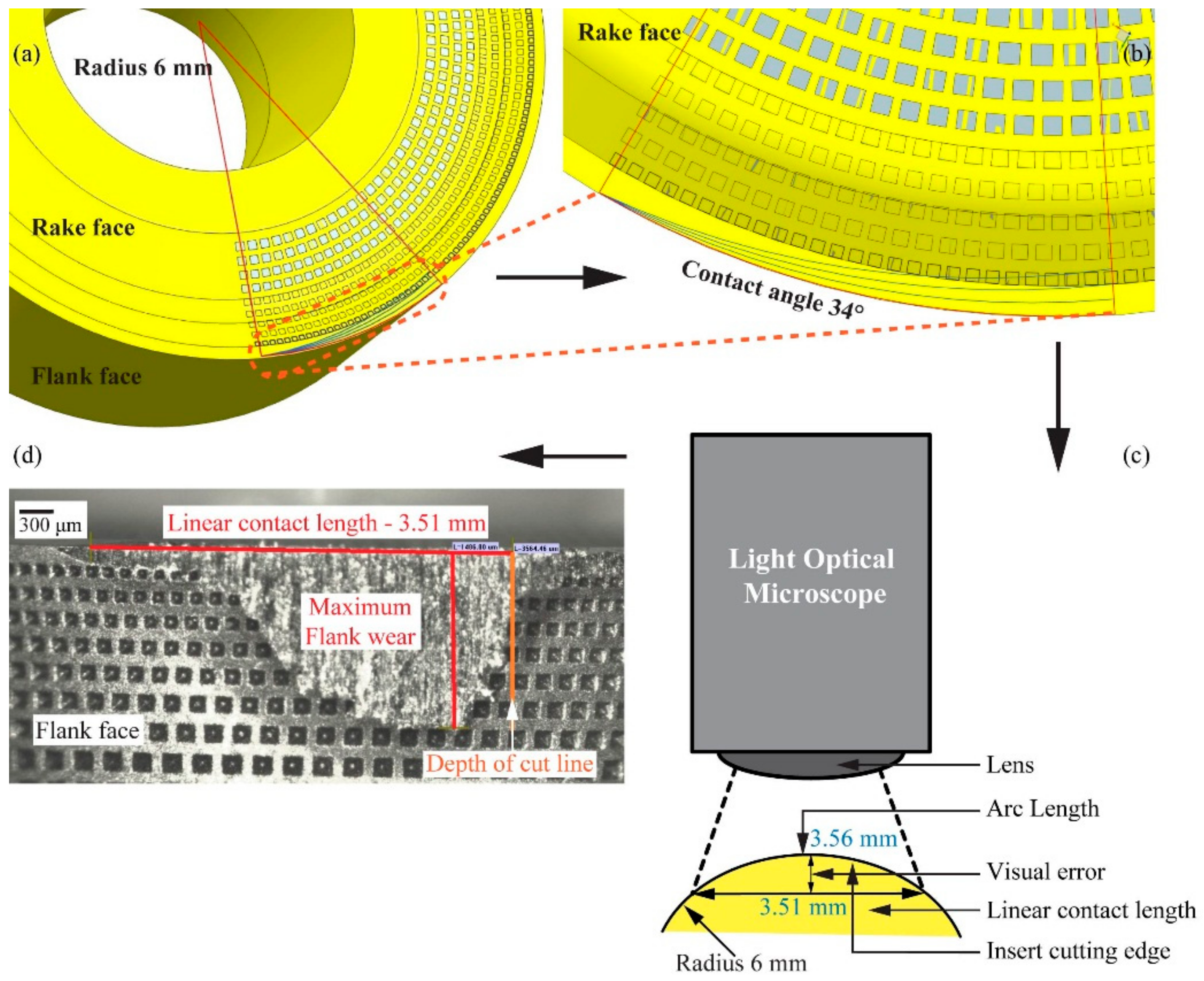

4.1. Standard for Flank Wear and Notch Wear Measurements on Round Insert

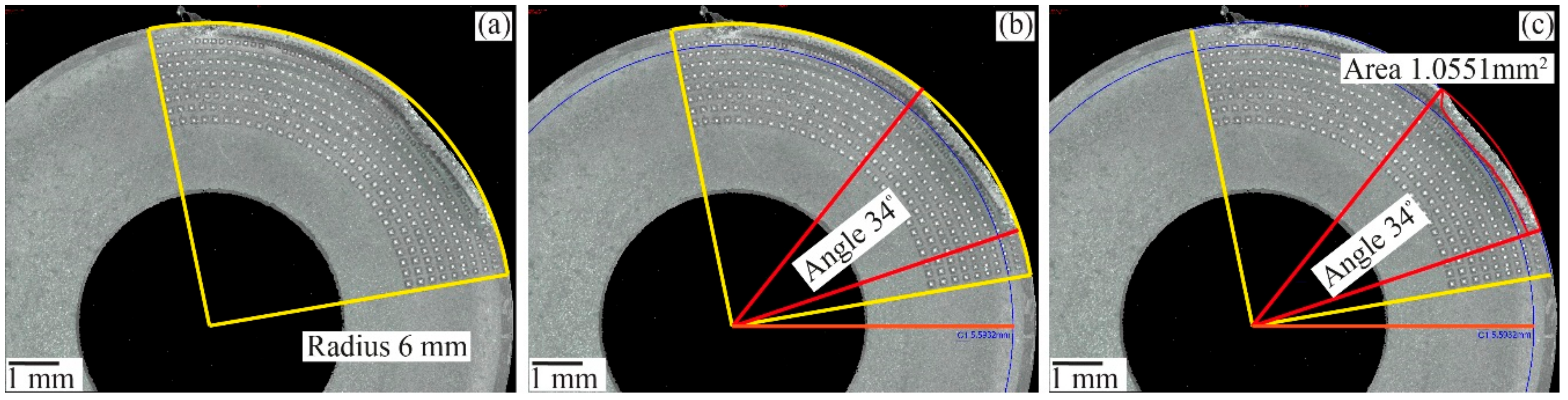

4.2. Standard for Tool-Chip Contact Area Measurements on Worn Round Insert

5. Tool Wear Analysis

5.1. Spiral Cutting Length 565 m and Feed Rate 0.1 mm/rev

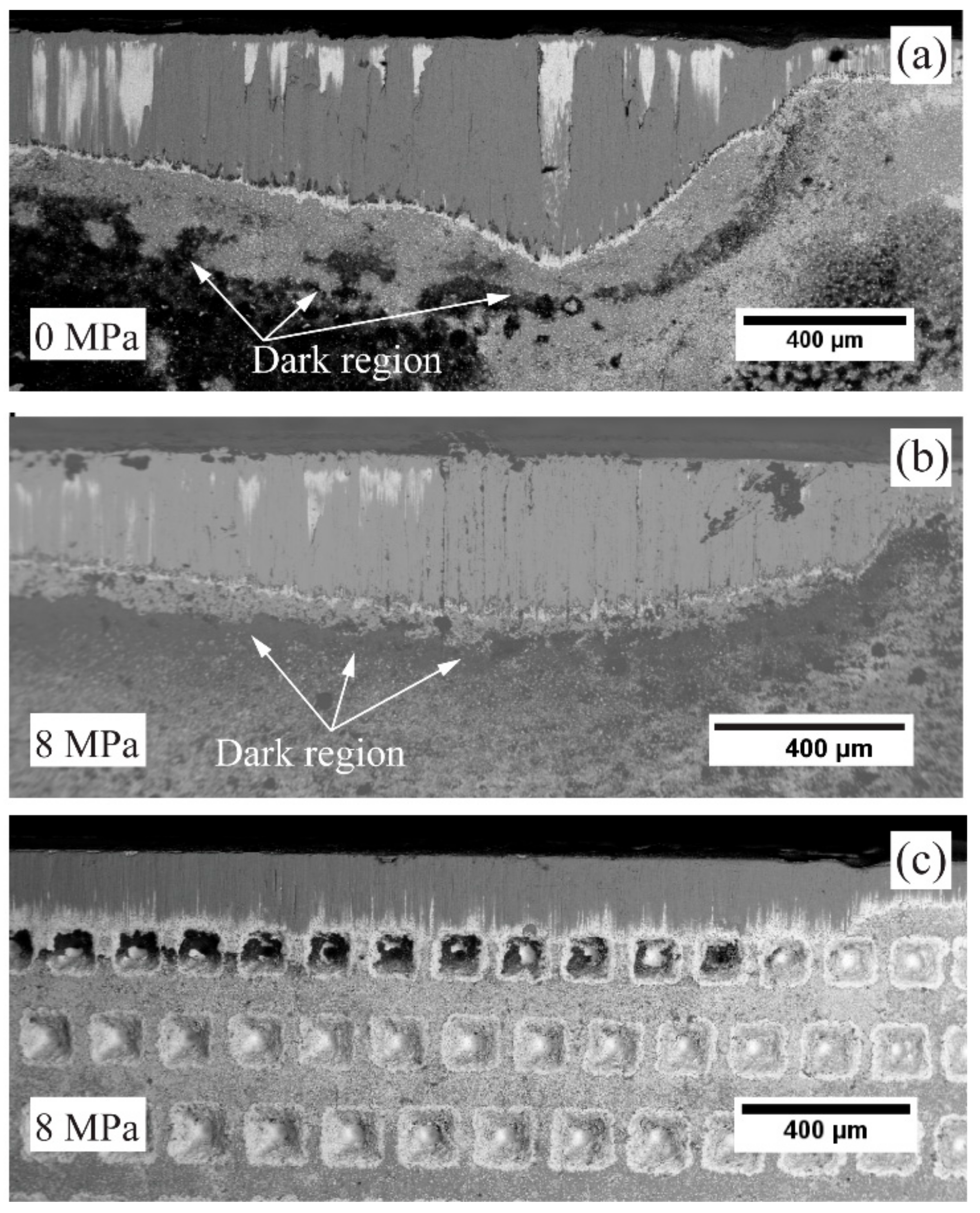

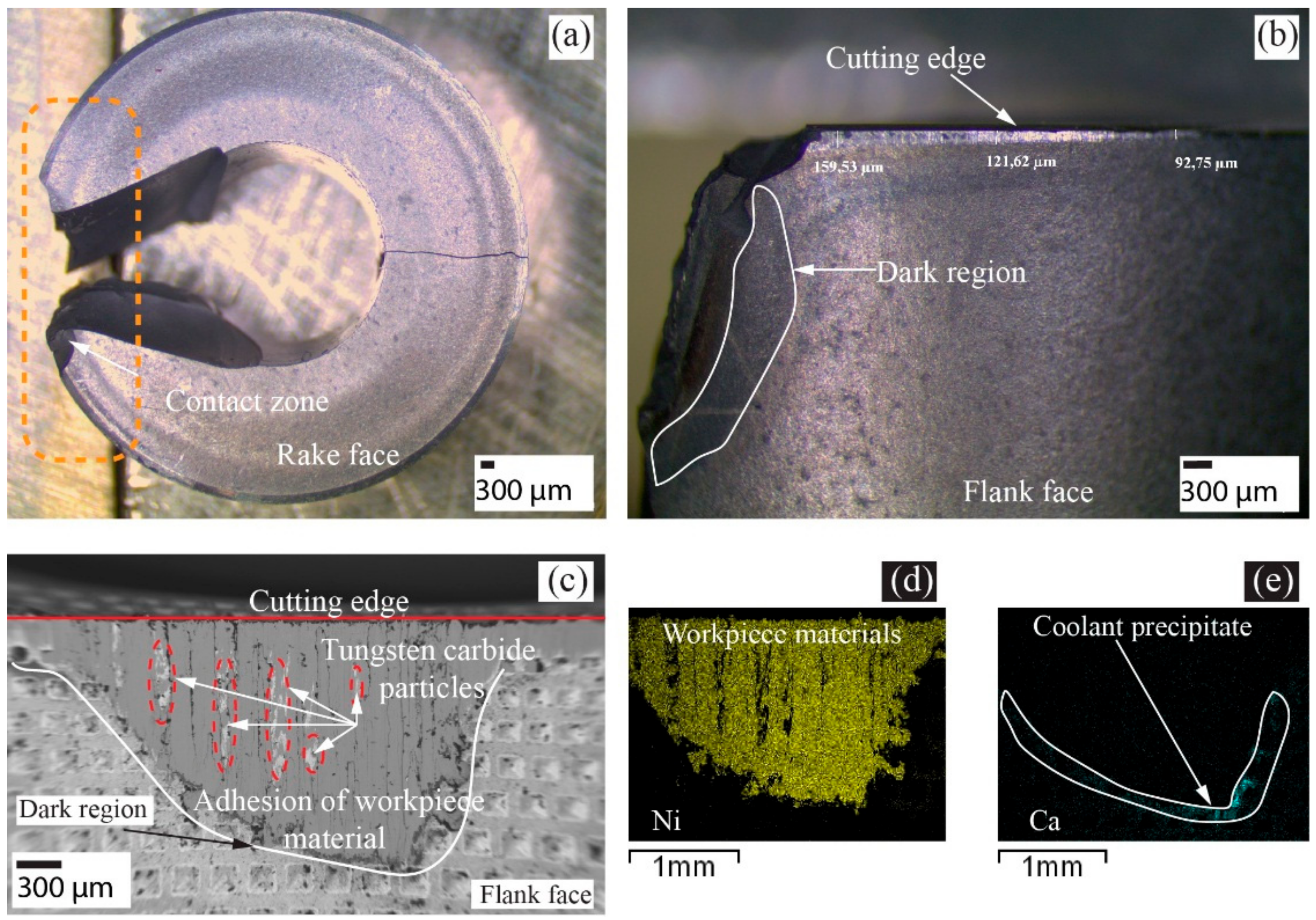

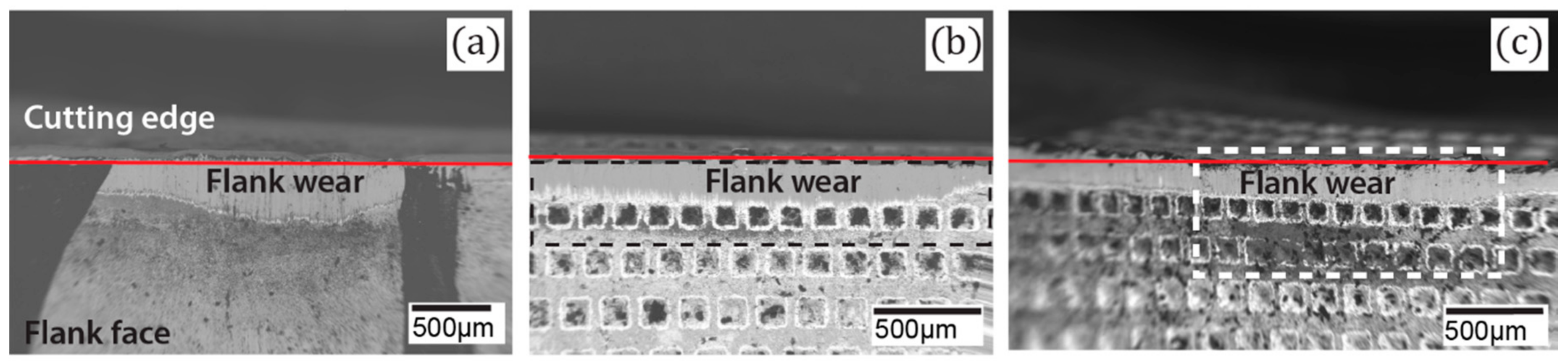

5.1.1. Flank and Rake Wear

5.1.2. Elemental Analysis

5.2. Spiral Cutting Length 282 m and Feed Rate 0.2 mm/rev

5.3. Spiral Cutting Length 188 m and Feed Rate 0.3 mm/rev

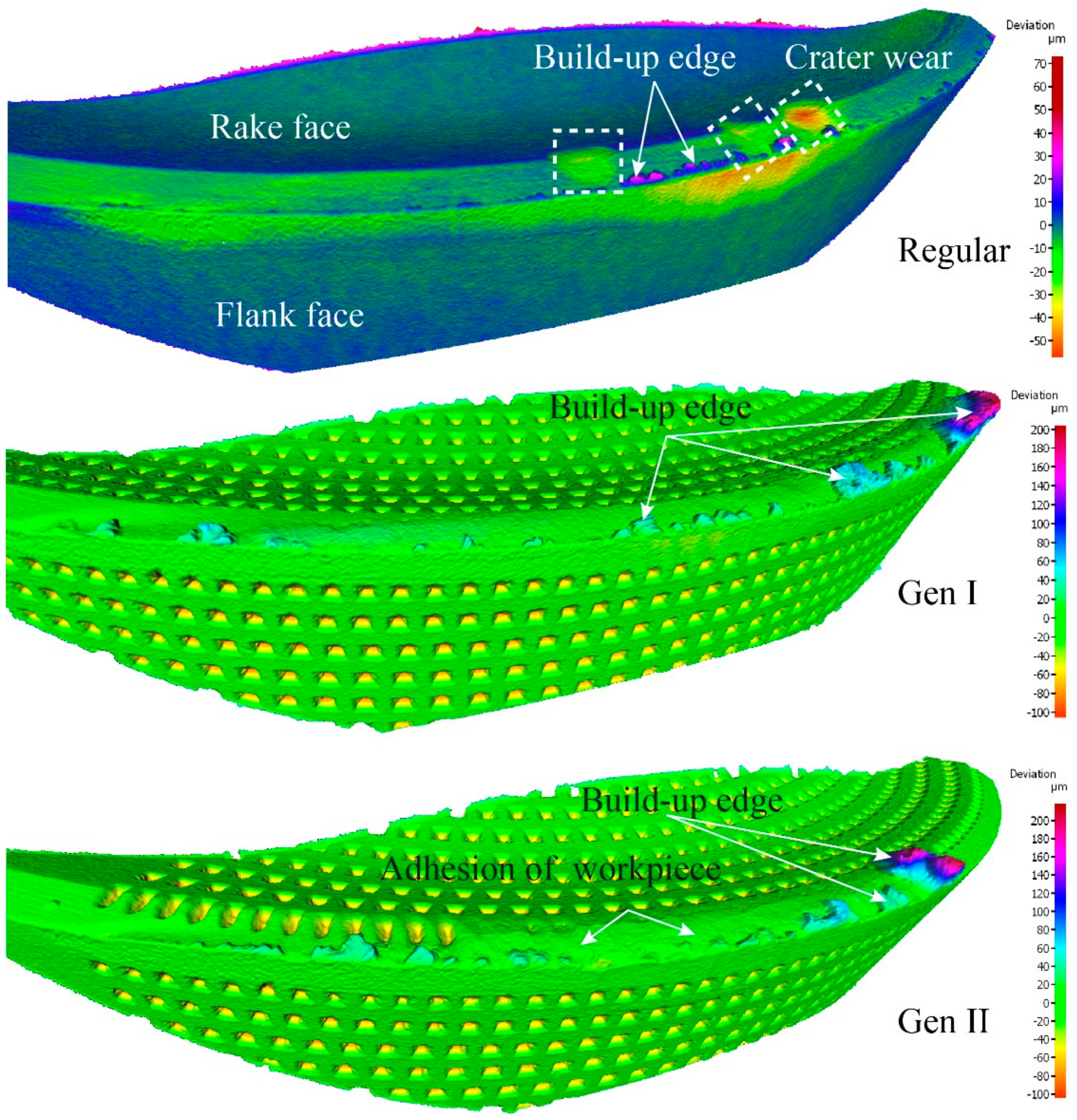

5.3.1. Volumetric Analysis

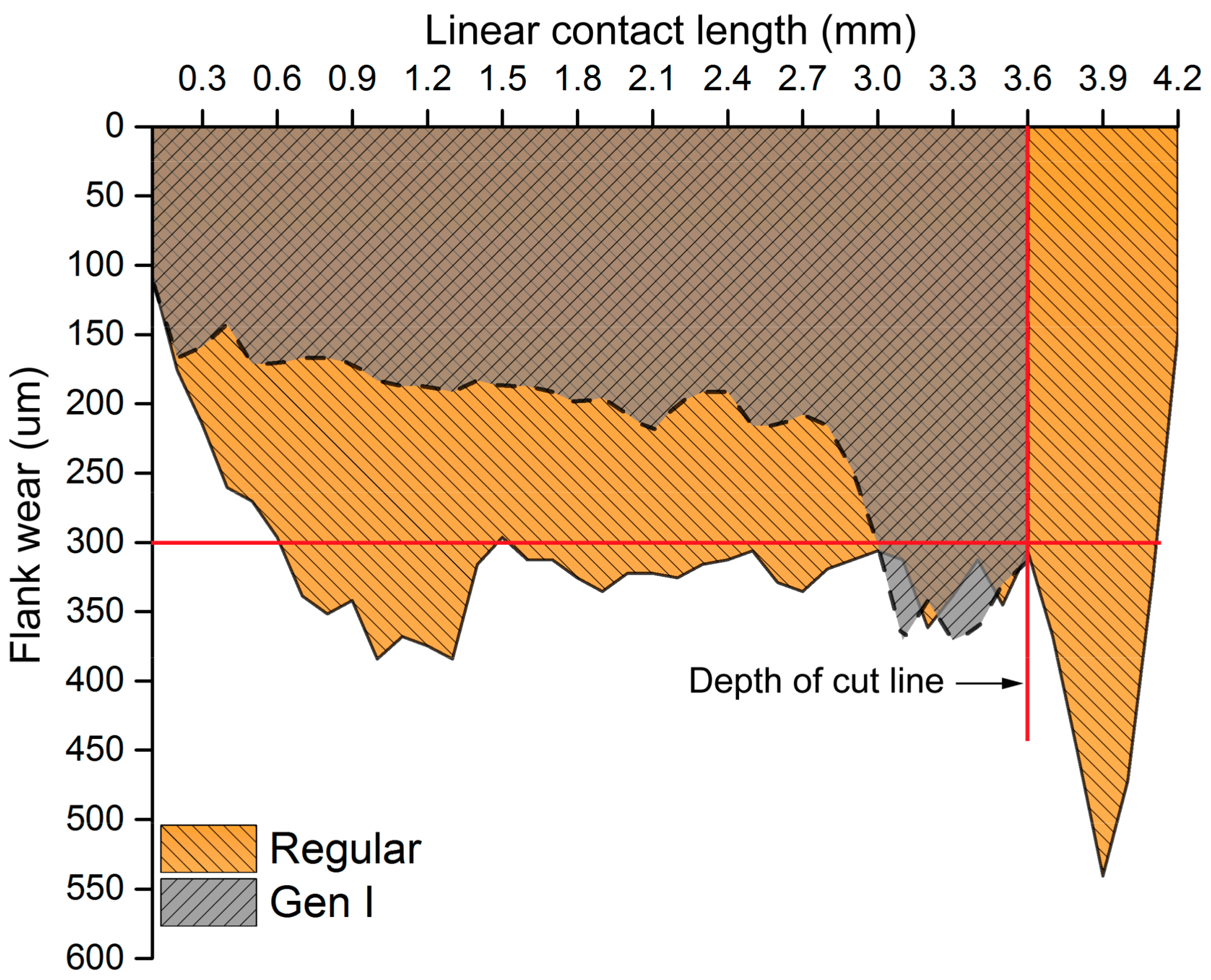

5.3.2. Flank Wear Profile Measurement and Flank Wear Area Calculations

5.4. Tool-Chip Contact Area

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Rahim, E.; Warap, N.; Mohid, Z. Thermal-assisted machining of nickel-based alloy. In Superalloys; Aliofkhazraei, M., Ed.; InTechOpen: London, UK, 2015; ISBN 978-953-51-2212-8. [Google Scholar] [CrossRef]

- Pigott, R.J.S.; Colwell, A.T. Hi-jet system for increasing tool life. SAE Tech. Pap. 1952. [Google Scholar] [CrossRef]

- Courbon, C.; Kramar, D.; Krajnik, P.; Pusavec, F.; Rech, J.; Kopac, J. Investigation of machining performance in high-pressure jet assisted turning of Inconel 718: An experimental study. Int. J. Mach. Tools Manuf. 2009, 49, 1114–1125. [Google Scholar] [CrossRef]

- Krämer, A.; Klocke, F.; Sangermann, H.; Lung, D. Influence of the lubricoolant strategy on thermo-mechanical tool load. CIRP J. Manuf. Sci. Technol. 2014, 7, 40–47. [Google Scholar] [CrossRef]

- Courbon, C.; Sajn, V.; Kramar, D.; Rech, J.; Kosel, F.; Kopac, J. Investigation of machining performance in high pressure jet assisted turning of Inconel 718: A numerical model. J. Mater. Process. Technol. 2011, 211, 1834–1851. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Influence of surface texture on boundary lubricated sliding contacts. Tribol. Int. 2003, 36, 857–864. [Google Scholar] [CrossRef]

- Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I. Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Lei, S.; Devarajan, S.; Chang, Z. A study of micropool lubricated cutting tool in machining of mild steel. J. Mater. Process. Technol. 2009, 209, 1612–1620. [Google Scholar] [CrossRef]

- Tamil Alagan, N.; Beno, T.; Wretland, A. Next Generation Insert for Forced Coolant Application in Machining of Inconel 718. Mater. Sci. Forum 2016, 836–837, 340–347. [Google Scholar] [CrossRef]

- Tamil Alagan, N.; Beno, T.; Wretland, A. Investigation of Modified Cutting Insert with Forced Coolant Application in Machining of Alloy 718. Procedia CIRP 2016, 42, 481–486. [Google Scholar] [CrossRef]

- Jäger, H.; Alagan, N.T.; Holmberg, J.; Beno, T.; Wretland, A. EDS Analysis of Flank Wear and Surface Integrity in Machining of Alloy 718 with Forced Coolant Application. Procedia CIRP 2016, 45, 271–274. [Google Scholar] [CrossRef]

- Fang, Z.; Obikawa, T. Cooling performance of micro-texture at the tool flank face under high pressure jet coolant assistance. Precis. Eng. 2017, 49, 41–51. [Google Scholar] [CrossRef]

- Rahman, M.; Seah, W.K.H.; Teo, T.T. The machinability of inconel 718. J. Mater. Process. Technol. 1997, 63, 199–204. [Google Scholar] [CrossRef]

- Trent, E.M. Metal Cutting; Butterworth-Heinemann: Burlington, MA, USA, 2000. [Google Scholar]

- Sørby, K.; Tønnessen, K. High-pressure cooling of face-grooving operations in Ti6Al4V. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1621–1627. [Google Scholar] [CrossRef]

- Van Limbeek, M.A.J.; Shirota, M.; Sleutel, P.; Sun, C.; Prosperetti, A.; Lohse, D. Vapour cooling of poorly conducting hot substrates increases the dynamic Leidenfrost temperature. Int. J. Heat Mass Transf. 2016, 97, 101–109. [Google Scholar] [CrossRef]

- Straub, J. NBS/NRC steam tables. VonL. Haar, J. S. Gallagher undG. S. Kell. Hemisphere Publishing Corp., Washington-New York-London 1984. 1. Aufl., XII, 320 S., geb., $ 34.50. Chem. Ing. Tech. 1985, 57, 812. [Google Scholar] [CrossRef]

- Çolak, O. Investigation on machining performance of Inconel 718 under high pressure cooling conditions. Strojniski Vestnik J. Mech. Eng. 2012, 58, 683–690. [Google Scholar] [CrossRef]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering and Technology; Schmid, S.R., Vijay Sekar, K.S., Eds.; Pearson: Upper Saddle River, NJ, USA, 2010; ISBN 978-981-06-8144-9. [Google Scholar]

| Inserts | Regular/T Gen I/G I Gen II/G II |

|---|---|

| Insert thickness (mm) | 4.76 |

| Inscribed circle diameter (mm) | 12 |

| Face land width (mm) | 0.2 |

| Rake angle (°) | 0 |

| Clearance angle (°) | 7 |

| Face land angle (°) | 15 |

| Type of insert | Uncoated carbide insert |

| Insert shape | Round |

| Chip breaker | No |

| S.no | Geometry | Input (mm) | Total Surface Area (T.S.A) (mm2) | Results (mm2) (TSA-BSA) |

|---|---|---|---|---|

| 1 | Square pyramid | a = 4; h = 9 | 89.76 − 16 = 73.76 | |

| 2 | Cone | r = 2.2567; h = 9 | 81.78 − 16 = 65.78 | |

| 3 | Cylinder | r = 2.2567; h = 3 | 74.54 − 16 = 58.54 |

| Elements | Ni | Cr | Nb | Mo | Ti | Al | Co. | Si | Mn-Cu | C | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt % | 53.4 | 18.8 | 5.27 | 2.99 | 1.02 | 0.50 | 0.17 | 0.12 | 0.07 | 0.03 | Bal |

| SCL (m) | ap (mm) | vc (m/min) | fn (mm/rev) | Pressure (MPa) | Tests Conducted | |||

|---|---|---|---|---|---|---|---|---|

| Rake | Flank | Regular | Gen I | Gen II | ||||

| 565 | 1 | 30 | 0.1 | 16 | 0 | X | X | - |

| 565 | 1 | 60 | 0.1 | 16 | 0 | X | - | - |

| 565 | 1 | 60 | 0.1 | 16 | 8 | X | X | - |

| 565 | 1 | 90 | 0.1 | 16 | 8 | X | X | - |

| 282 | 1 | 60 | 0.2 | 16 | 8 | X | X | X |

| 282 | 1 | 90 | 0.2 | 16 | 8 | - | X | X |

| 188 | 1 | 60 | 0.3 | 16 | 8 | X | X | X |

| 188 | 1 | 90 | 0.3 | 16 | 8 | - | X | X |

| 188 | 1 | 105 | 0.3 | 16 | 8 | - | X | X |

| S.no | SCL (m) | Cutting Speed (m/min) | Feed Rate (mm/rev) | Gen I (mm2) | Gen II (mm2) | Difference in Percentage (%) |

|---|---|---|---|---|---|---|

| 1 | 282 | 90 | 0.2 | 3.8161 | 3.1380 | 17.8 |

| 2 | 188 | 90 | 0.3 | 3.5583 | 2.9307 | 17.6 |

| 3 | 188 | 105 | 0.3 | 4.4782 | 3.9027 | 12.9 |

| S.no | SCL (m) | Cutting Speed (m/min) | Feed Rate (mm/rev) | Gen I (mm2) | Gen II (mm2) | Difference in Percentage (%) |

|---|---|---|---|---|---|---|

| 1 | 282 | 90 | 0.2 | 1.2831 | 1.0551 | 17.7 |

| 2 | 188 | 90 | 0.3 | 1.4849 | 1.3029 | 12.3 |

| 3 | 188 | 105 | 0.3 | 1.6165 | 1.4232 | 12 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamil Alagan, N.; Beno, T.; Hoier, P.; Klement, U.; Wretland, A. Influence of Surface Features for Increased Heat Dissipation on Tool Wear. Materials 2018, 11, 664. https://doi.org/10.3390/ma11050664

Tamil Alagan N, Beno T, Hoier P, Klement U, Wretland A. Influence of Surface Features for Increased Heat Dissipation on Tool Wear. Materials. 2018; 11(5):664. https://doi.org/10.3390/ma11050664

Chicago/Turabian StyleTamil Alagan, Nageswaran, Tomas Beno, Philipp Hoier, Uta Klement, and Anders Wretland. 2018. "Influence of Surface Features for Increased Heat Dissipation on Tool Wear" Materials 11, no. 5: 664. https://doi.org/10.3390/ma11050664