A Novel Manufacturing Process for Compact, Low-Weight and Flexible Ultra-Wideband Cavity Backed Textile Antennas

Abstract

:1. Introduction

2. Antenna Design and Material Selection

2.1. Antenna Design

2.1.1. Design Goals

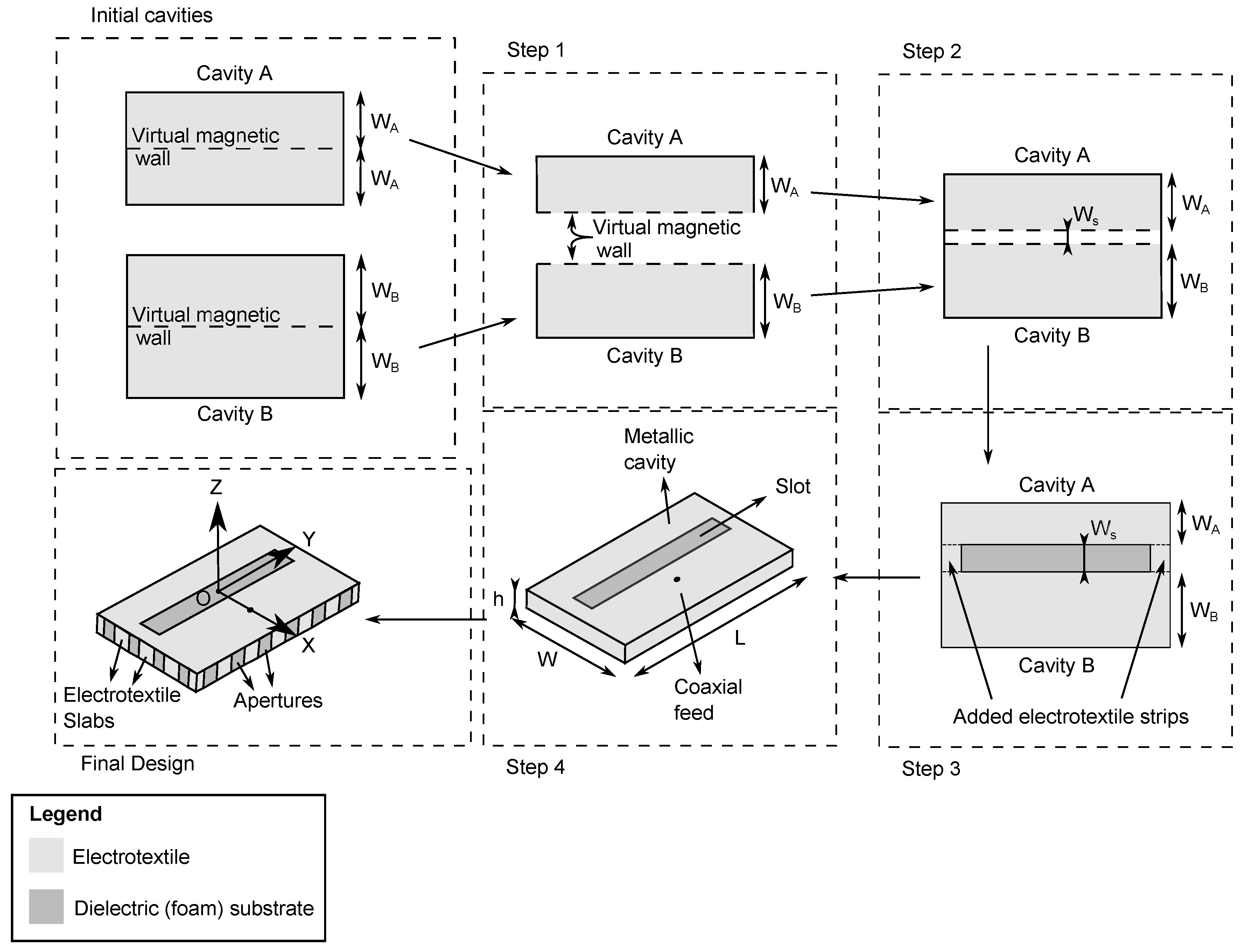

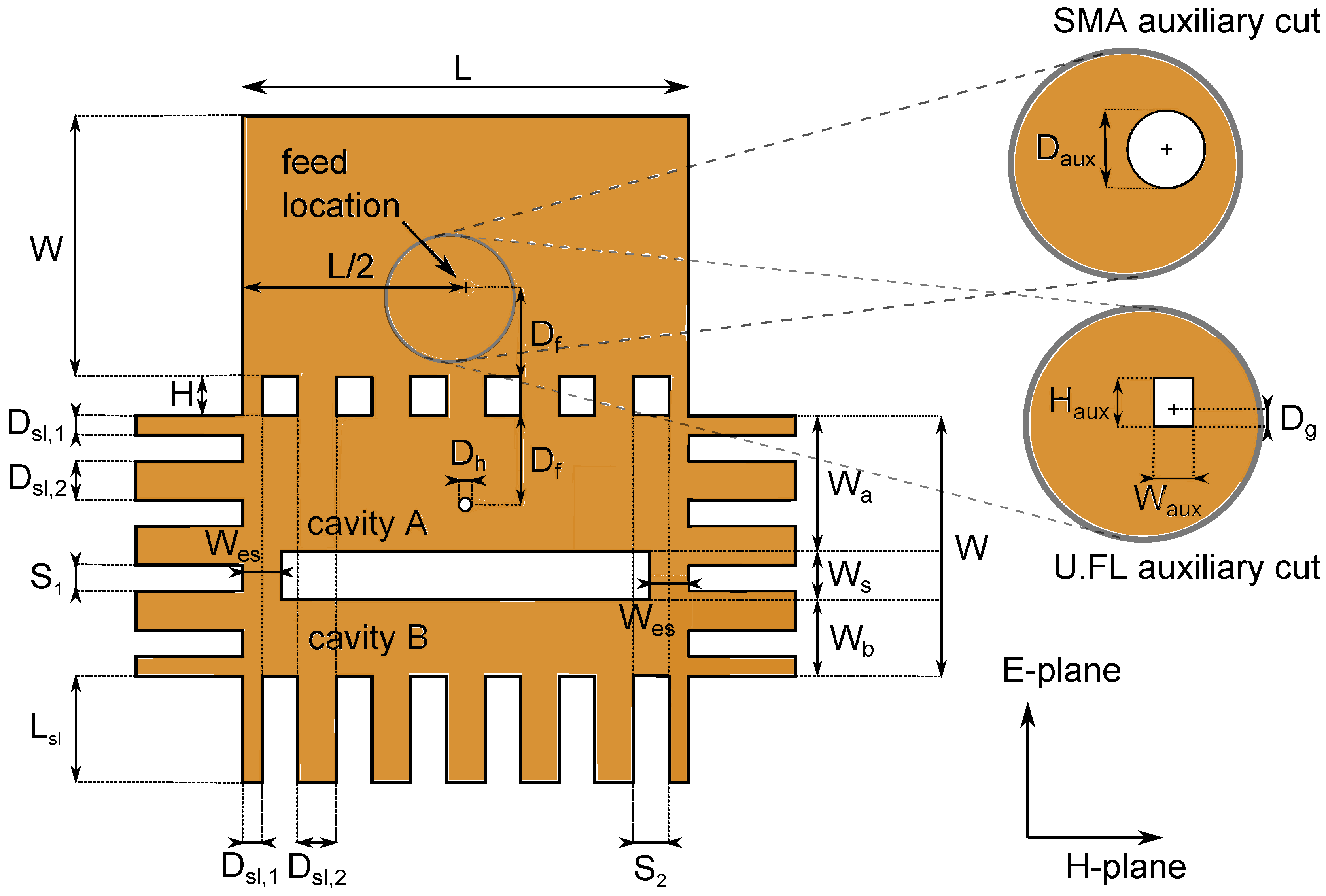

2.1.2. Antenna Topology

2.1.3. Operation Principle

2.2. Antenna Materials

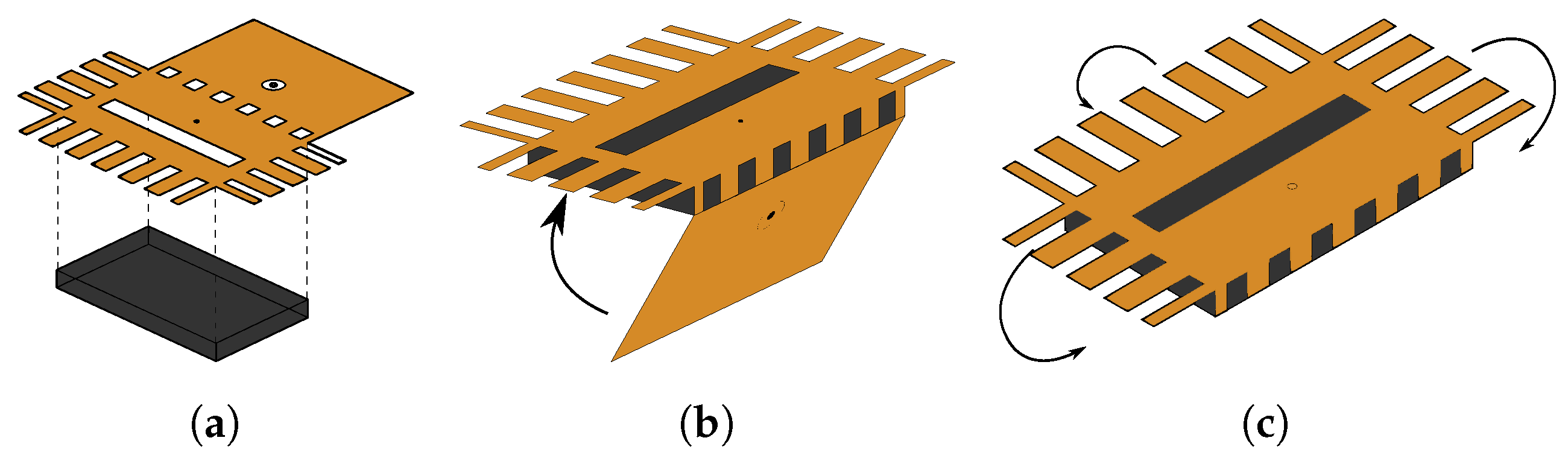

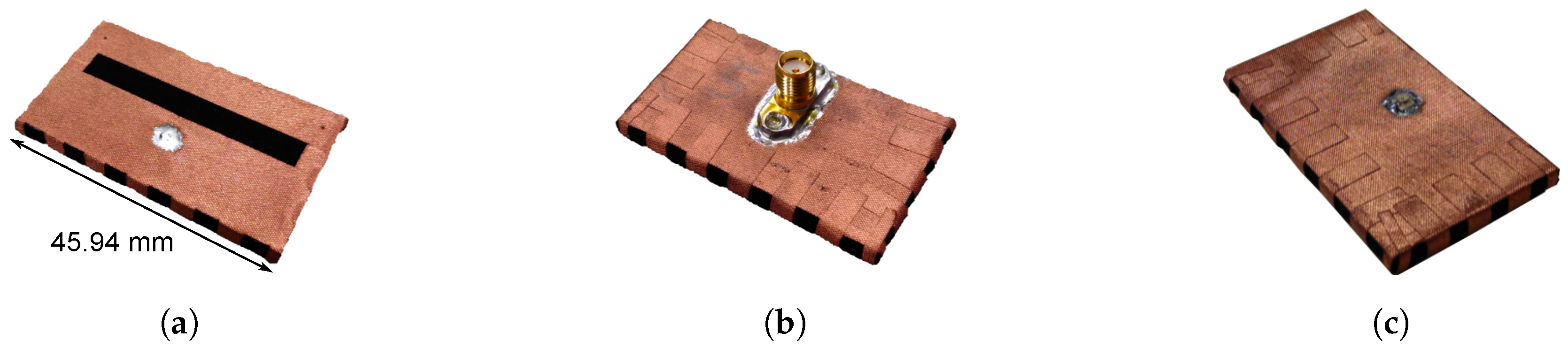

3. Manufacturing Process

3.1. Vacuum Lamination

3.2. Laser-Cutting

3.3. Alignment Procedure

3.4. Connector Placement

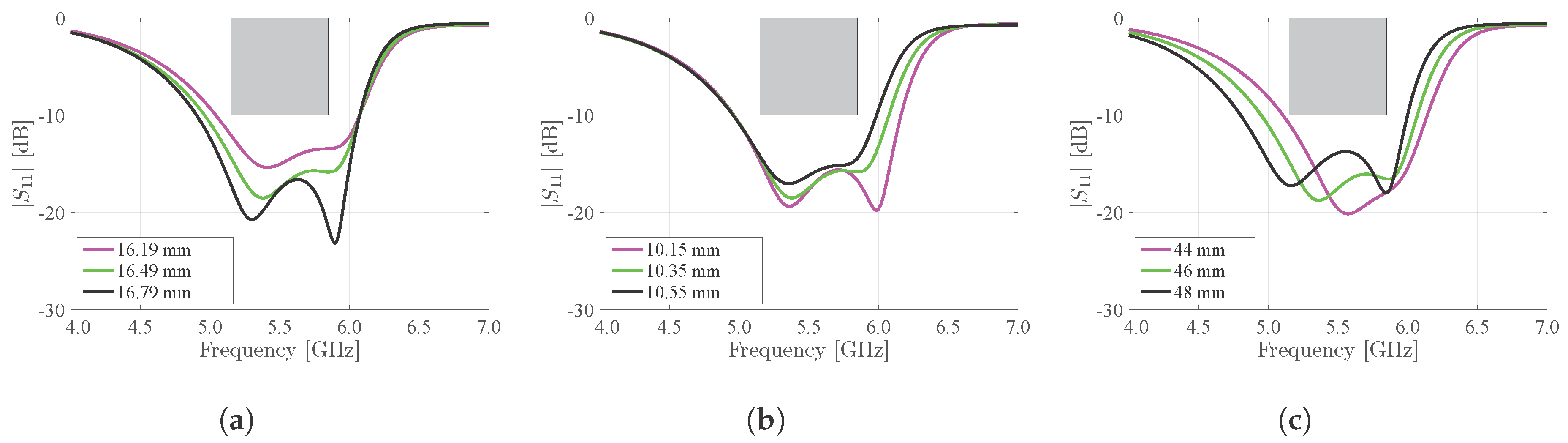

4. Simulation and Optimization

5. Experimental Results

5.1. Antenna Validation

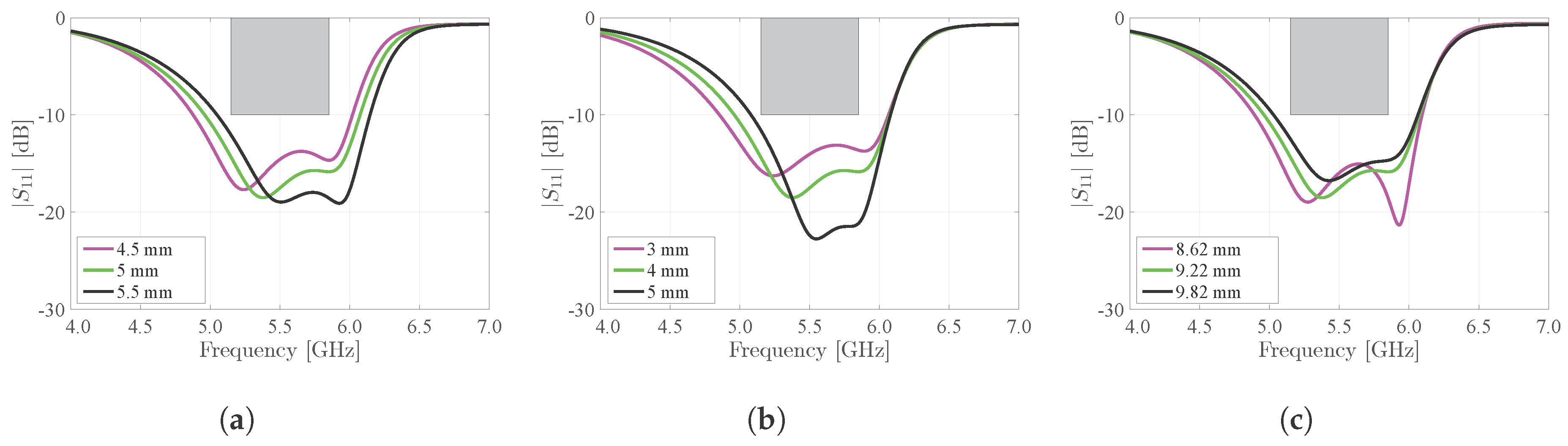

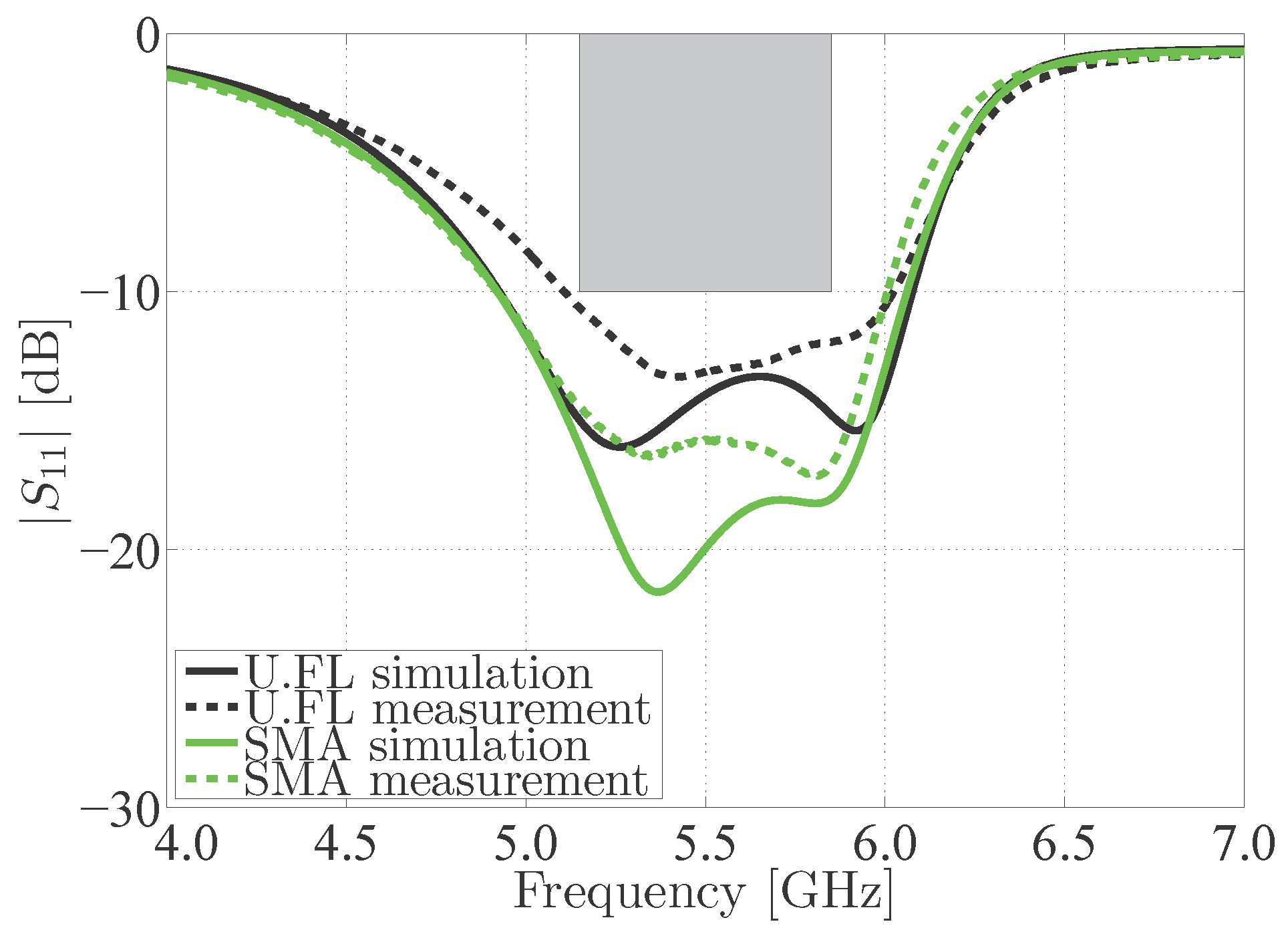

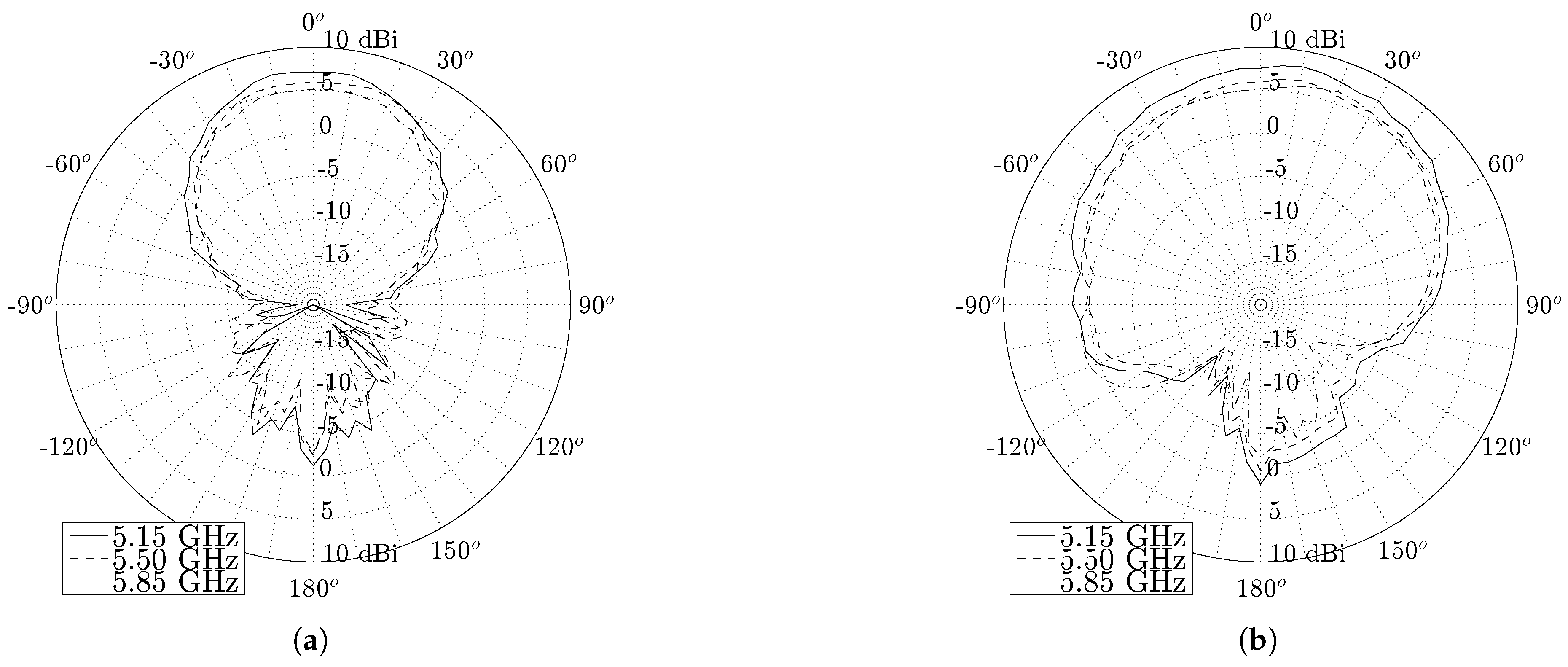

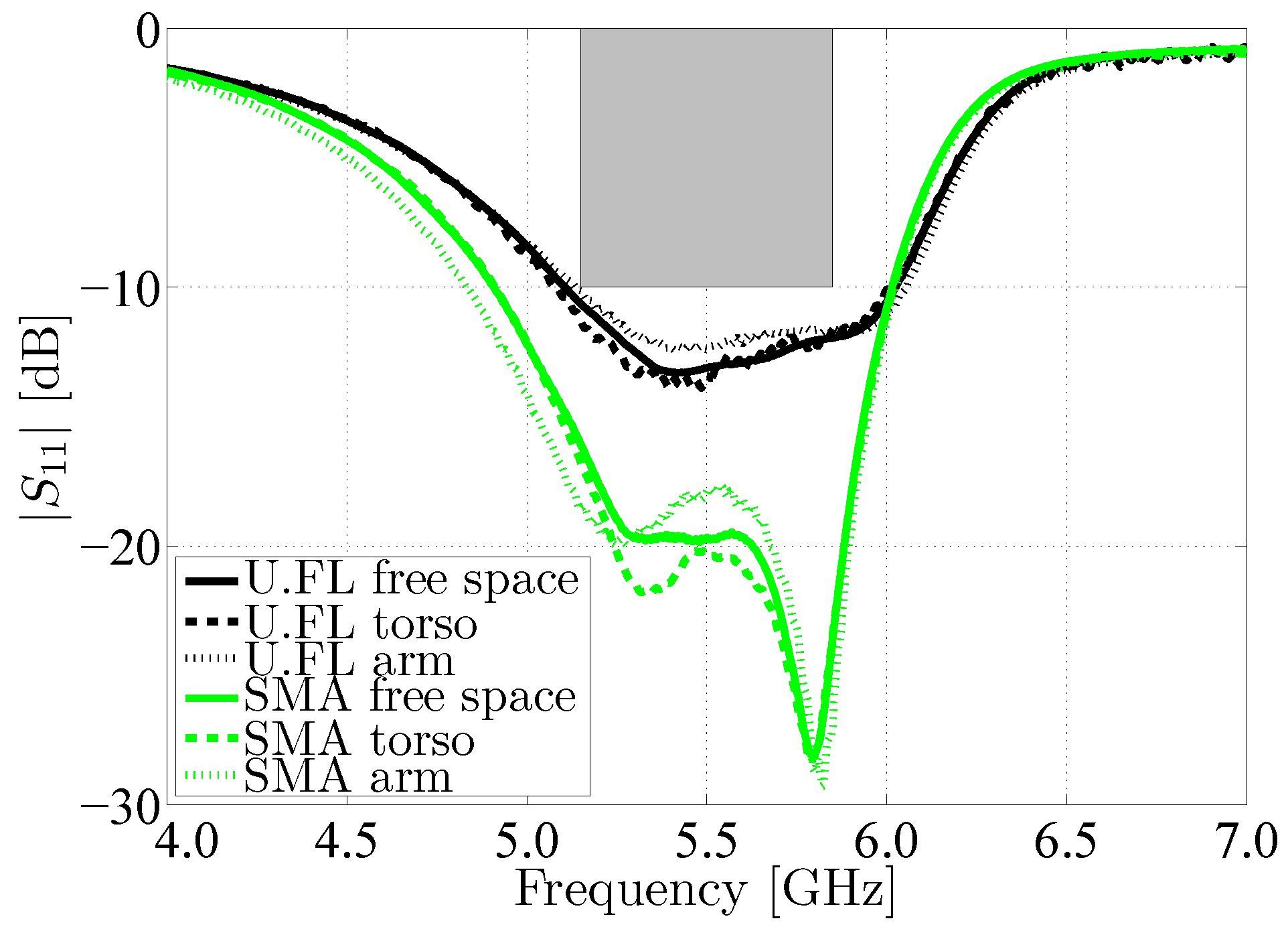

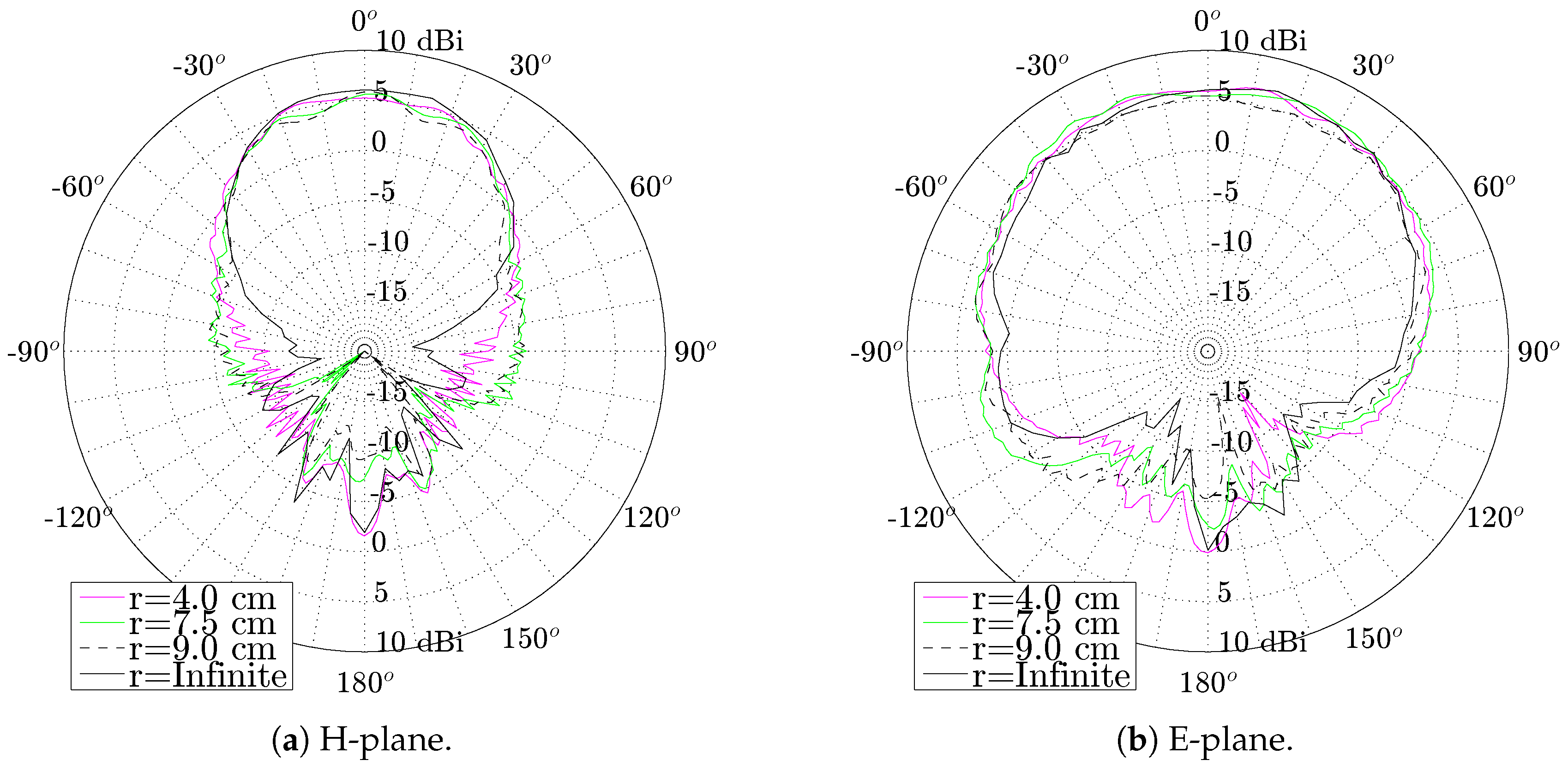

5.1.1. Figures of Merit in Free Space

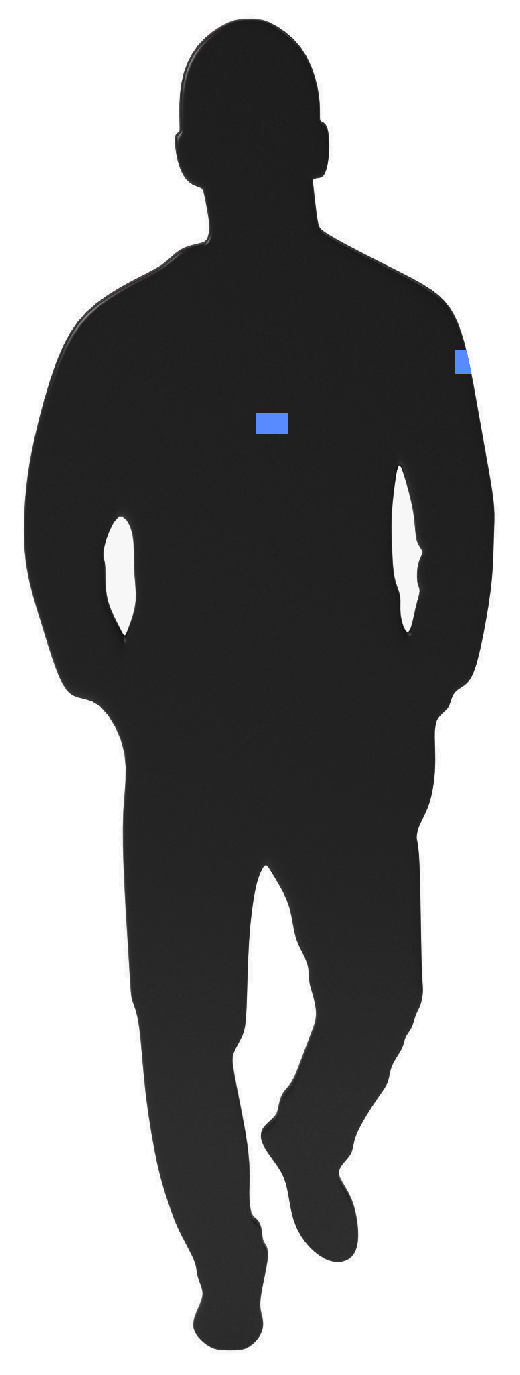

5.1.2. Figures of Merit on Body

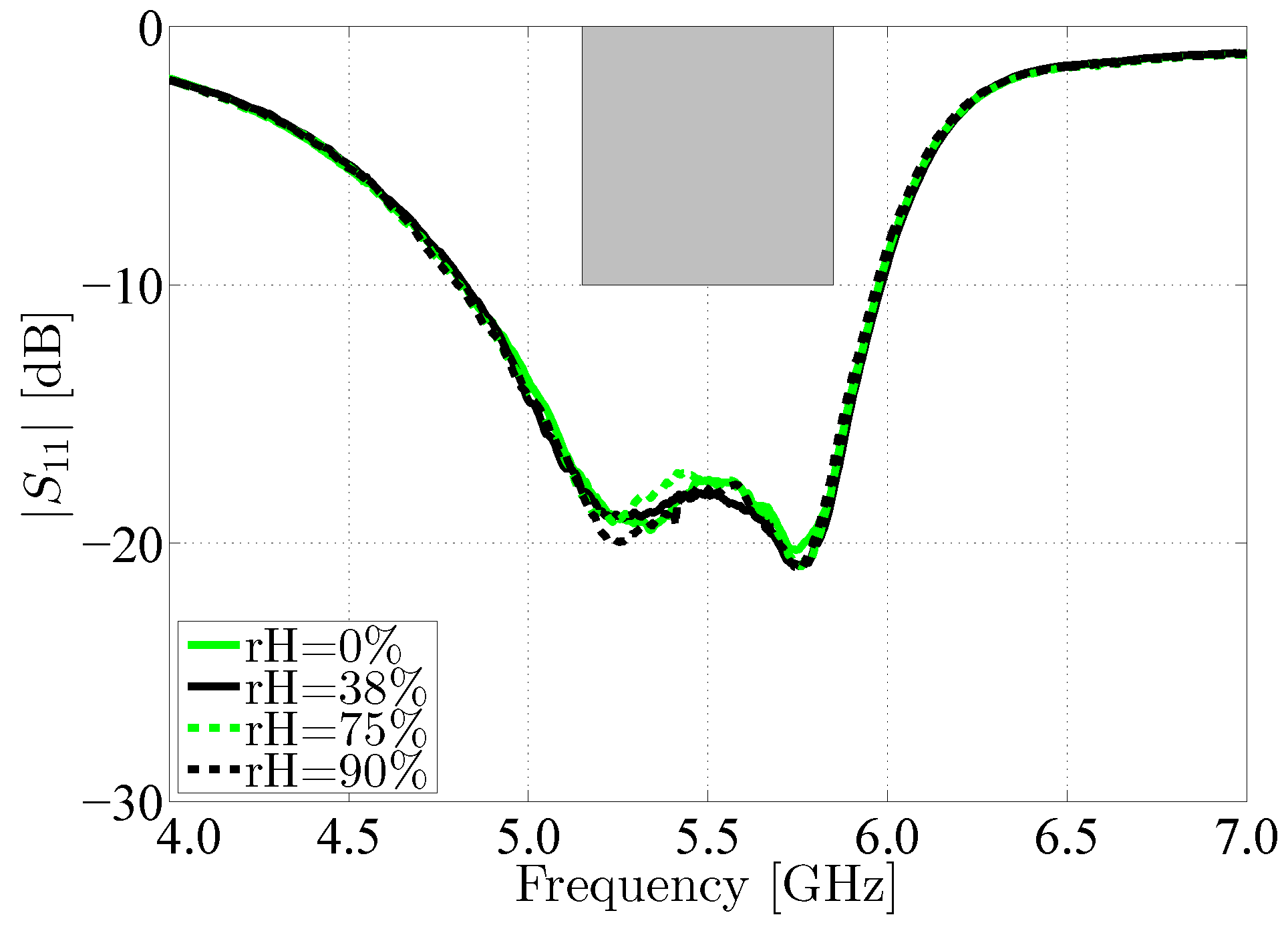

5.1.3. Effects of Humidity Content

5.2. Effects of Antenna Deformation

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Vanveerdeghem, P.; Van Torre, P.; Stevens, C.; Knockaert, J.; Rogier, H. Synchronous Wearable Wireless Body Sensor Network Composed of Autonomous Textile Nodes. Sensors 2014, 14, 18583–18610. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dierck, A.; Agneessens, S.; Declercq, F.; Spinnewyn, B.; Stockman, G.J.; Van Torre, P.; Vallozzi, L.; Vande Ginste, D.; Vervust, T.; Vanfleteren, J.; et al. Active textile antennas in professional garments for sensing, localisation an communication. Int. J. Microw. Wirel. Technol. 2014, 6, 331–341. [Google Scholar] [CrossRef]

- Yilmaz, T.; Foster, R.; Hao, Y. Detecting Vital Signs with Wearable Wireless Sensors. Sensors 2010, 10, 10837–10862. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Van den Brand, J.; de Kok, M.; Koetse, M.; Cauwe, M.; Verplancke, R.; Bossuyt, F.; Jablonski, M.; Vanfleteren, J. Flexible and stretchable electronics for wearable health devices. Solid-State Electron. 2015, 113, 116–120. [Google Scholar] [CrossRef]

- Lilja, J.; Pynttäri, V.; Kaija, T.; Mäkinen, R.; Halonen, E.; Sillanpää, H.; Heikkinen, J.; Mäntysalo, M.; Salonen, P.; de Maagt, P. Body-Worn Antennas Making a Splash: Lifejacket-Integrated Antennas for Global Search and Rescue Satellite System. IEEE Antennas Propag. Mag. 2013, 55, 324–341. [Google Scholar] [CrossRef]

- Dierck, A.; Rogier, H.; Declercq, F. A wearable active antenna for global positioning system and satellite phone. IEEE Trans. Antennas Propag. 2013, 61, 532–538. [Google Scholar] [CrossRef]

- Loss, C.; Gonçalves, R.; Lopes, C.; Pinho, P.; Salvado, R. Smart Coat with a Fully-Embedded Textile Antenna for IoT Applications. Sensors 2016, 16, 938. [Google Scholar] [CrossRef] [PubMed]

- Lemey, S.; Castel, T.; Torre, P.V.; Vervust, T.; Vanfleteren, J.; Demeester, P.; Vande Ginste, D.; Rogier, H. Threefold Rotationally Symmetric SIW Antenna Array for Ultra-Short-Range MIMO Communication. IEEE Trans. Antennas Propag. 2016, 64, 1689–1699. [Google Scholar] [CrossRef]

- Lemey, S.; Rogier, H. SIW textile antennas as a novel technology for UWB RFID tags. In Proceedings of the 2014 IEEE RFID Technology and Applications Conference (RFID-TA), Tampere, Finland, 8–9 September 2014; pp. 256–260. [Google Scholar]

- Moro, R.; Agneessens, S.; Rogier, H.; Dierck, A.; Bozzi, M. Textile Microwave Components in Substrate Integrated Waveguide Technology. IEEE Trans. Microw. Theory Tech. 2015, 63, 422–432. [Google Scholar] [CrossRef]

- Bozzi, M.; Georgiadis, A.; Wu, K. Review of substrate-integrated waveguide circuits and antennas. IET Microw. Antennas Propag. 2011, 5, 909–920. [Google Scholar] [CrossRef]

- Agneessens, S.; Rogier, H. Compact Half Diamond Dual-Band Textile HMSIW On-Body Antenna. IEEE Trans. Antennas .Propag. 2014, 62, 2374–2381. [Google Scholar] [CrossRef] [Green Version]

- Kaufmann, T.; Fumeaux, C. Wearable Textile Half-Mode Substrate-Integrated Cavity Antenna Using Embroidered Vias. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 805–808. [Google Scholar] [CrossRef]

- Kaufmann, T.; Fumeaux, I.M.; Fumeaux, C. Comparison of fabric and embroidered dipole antennas. In Proceedings of the 2013 7th European Conference on Antennas and Propagation (EuCAP), Gothenburg, Sweden, 8–12 April 2013; pp. 3252–3255. [Google Scholar]

- Seager, R.; Zhang, S.; Chauraya, A.; Whittow, W.; Vardaxoglou, Y.; Acti, T.; Dias, T. Effect of the fabrication parameters on the performance of embroidered antennas. IET Microw. Antennas Propag. 2013, 7, 1174–1181. [Google Scholar] [CrossRef]

- Hirose Electric Co., Ltd. Ultra Small Surface Mount Coaxial Connectors; Hirose Electric Co., Ltd.: Tokyo, Japan, 2017. [Google Scholar]

- Wang, Y.; Lu, Y. The Strip-Ground Rectangular Patch Antenna. Int. J. Antennas Propag. 2017, 2017, 7. [Google Scholar] [CrossRef]

- Van den Brande, Q.; Lemey, S.; Vanfleteren, J.; Rogier, H. Highly-Efficient Impulse-Radio Ultra-Wideband Cavity-Backed Slot Antenna in Stacked Air-Filled Substrate-Integrated-Waveguide Technology. IEEE Trans. Antennas Propag. Under review.

- Planar slot antenna backed by substrate integrated waveguide cavity. IEEE Antennas Wirel. Propag. Lett. 2008, 7, 236–239.

- Hong, J.S.; Lancaster, M.J. Couplings of microstrip square open-loop resonators for cross-coupled planar microwave filters. IEEE Trans. Microw. Theory Tech. 1996, 44, 2099–2109. [Google Scholar] [CrossRef]

- Javaux. Closed Cell Expanded Rubber NBR 41–42; Javaux: Maintenon, France, 2017. [Google Scholar]

- Less EMF Inc. Pure Copper Polyester Taffeta Fabric; Less EMF Inc.: Latham, NY, USA, 2017. [Google Scholar]

- Liu, F.X.; Kaufmann, T.; Xu, Z.; Fumeaux, C. Wearable Applications of Quarter-Wave Patch and Half-Mode Cavity Antennas. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1478–1481. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- N5242A PNA-X Microwave Network Analyzer, 26.5 GHz; Agilent Technologies: Santa Clara, CA, USA, 2017.

- Dardari, D.; D’Errico, R.; Roblin, C.; Sibille, A.; Win, M.Z. Ultrawide Bandwidth RFID: The Next Generation? Proc. IEEE 2010, 98, 1570–1582. [Google Scholar] [CrossRef]

- Rossi, M.; Dierck, A.; Rogier, H.; Vande Ginste, D. A Stochastic Framework for the Variability Analysis of Textile Antennas. IEEE Trans. Antennas Propag. 2014, 62, 6510–6514. [Google Scholar] [CrossRef] [Green Version]

- Rossi, M.; Agneessens, S.; Rogier, H.; Vande Ginste, D. Assembly-Line-Compatible Electromagnetic Characterization of Wearable Antenna Substrates. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 1365–1368. [Google Scholar] [CrossRef]

- Declercq, F.; Georgiadis, A.; Rogier, H. Wearable aperture-coupled shorted solar patch antenna for remote tracking and monitoring applications. In Proceedings of the 5th European Conference on Antennas and Propagation (EUCAP), Rome, Italy, 11–15 April 2011; pp. 2992–2996. [Google Scholar]

- Boeykens, F.; Rogier, H.; Vallozzi, L. An efficient technique based on polynomial chaos to model the uncertainty in the resonance frequency of textile antennas due to bending. IEEE Trans. Antennas Propag. 2014, 62, 1253–1260. [Google Scholar] [CrossRef]

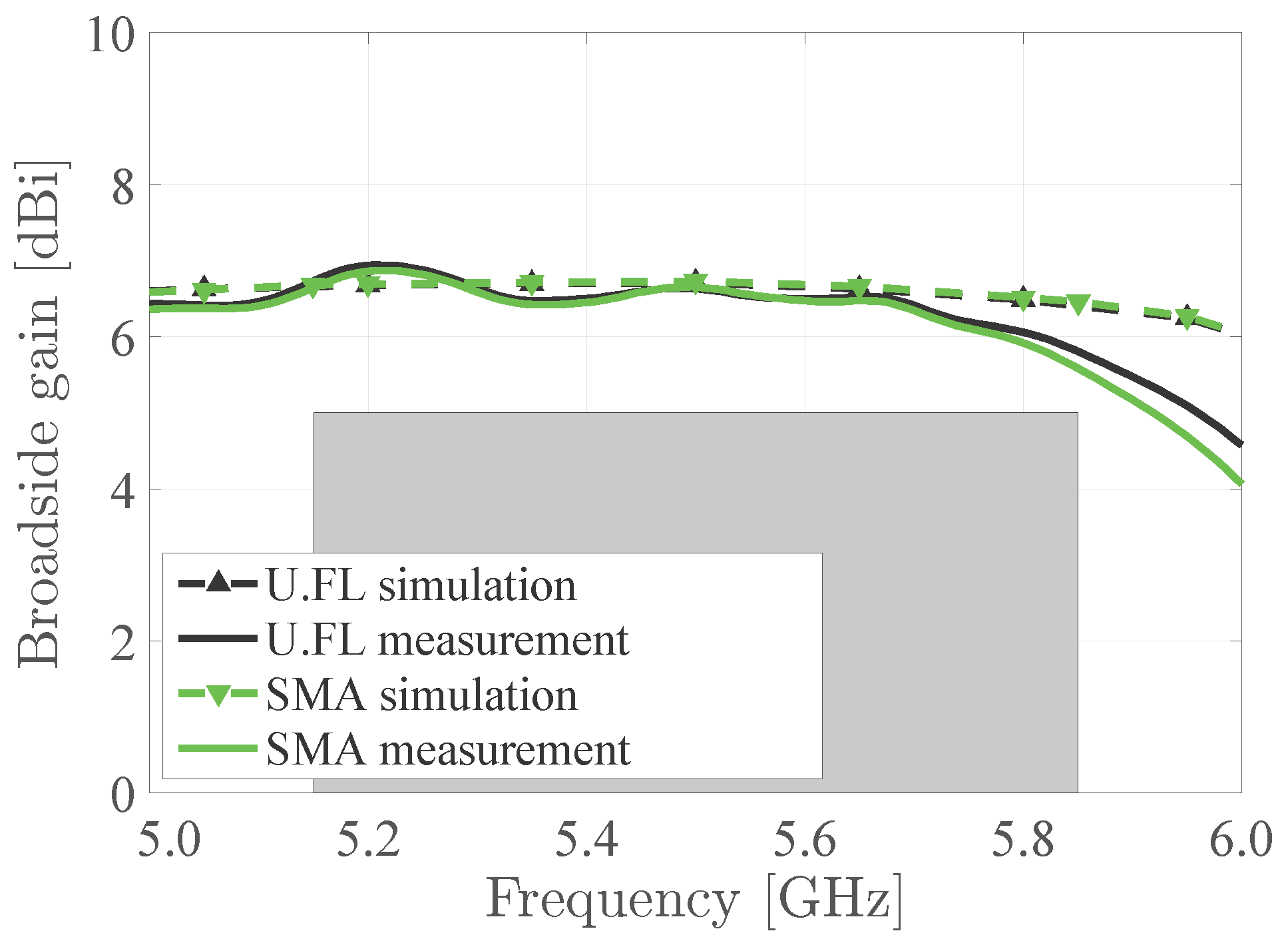

| Antenna Connector | U.FL | SMA | ||||

|---|---|---|---|---|---|---|

| Frequency [GHz] | 5.15 | 5.50 | 5.85 | 5.15 | 5.50 | 5.85 |

| Simulated total radiation efficiency [%] | 91 | 89 | 82 | 90 | 92 | 87 |

| Measured total radiation efficiency [%] | 94 | 90 | 74 | 92 | 90 | 70 |

| Simulated maximum gain [dBi] | 6.72 | 6.83 | 6.62 | 6.71 | 6.79 | 6.60 |

| Measured maximum gain [dBi] | 6.73 | 6.64 | 5.81 | 6.65 | 6.66 | 5.59 |

| Simulated FTBR [dB] | 10.47 | 11.99 | 14.38 | 10.09 | 11.65 | 13.69 |

| Measured FTBR [dB] | 8.39 | 8.50 | 7.85 | 7.90 | 7.97 | 7.93 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Baelen, D.; Lemey, S.; Verhaevert, J.; Rogier, H. A Novel Manufacturing Process for Compact, Low-Weight and Flexible Ultra-Wideband Cavity Backed Textile Antennas. Materials 2018, 11, 67. https://doi.org/10.3390/ma11010067

Van Baelen D, Lemey S, Verhaevert J, Rogier H. A Novel Manufacturing Process for Compact, Low-Weight and Flexible Ultra-Wideband Cavity Backed Textile Antennas. Materials. 2018; 11(1):67. https://doi.org/10.3390/ma11010067

Chicago/Turabian StyleVan Baelen, Dries, Sam Lemey, Jo Verhaevert, and Hendrik Rogier. 2018. "A Novel Manufacturing Process for Compact, Low-Weight and Flexible Ultra-Wideband Cavity Backed Textile Antennas" Materials 11, no. 1: 67. https://doi.org/10.3390/ma11010067