Effects of T2 Heat Treatment on Microstructure and Properties of the Selective Laser Melted Aluminum Alloy Samples

Abstract

:1. Introduction

2. Experimental

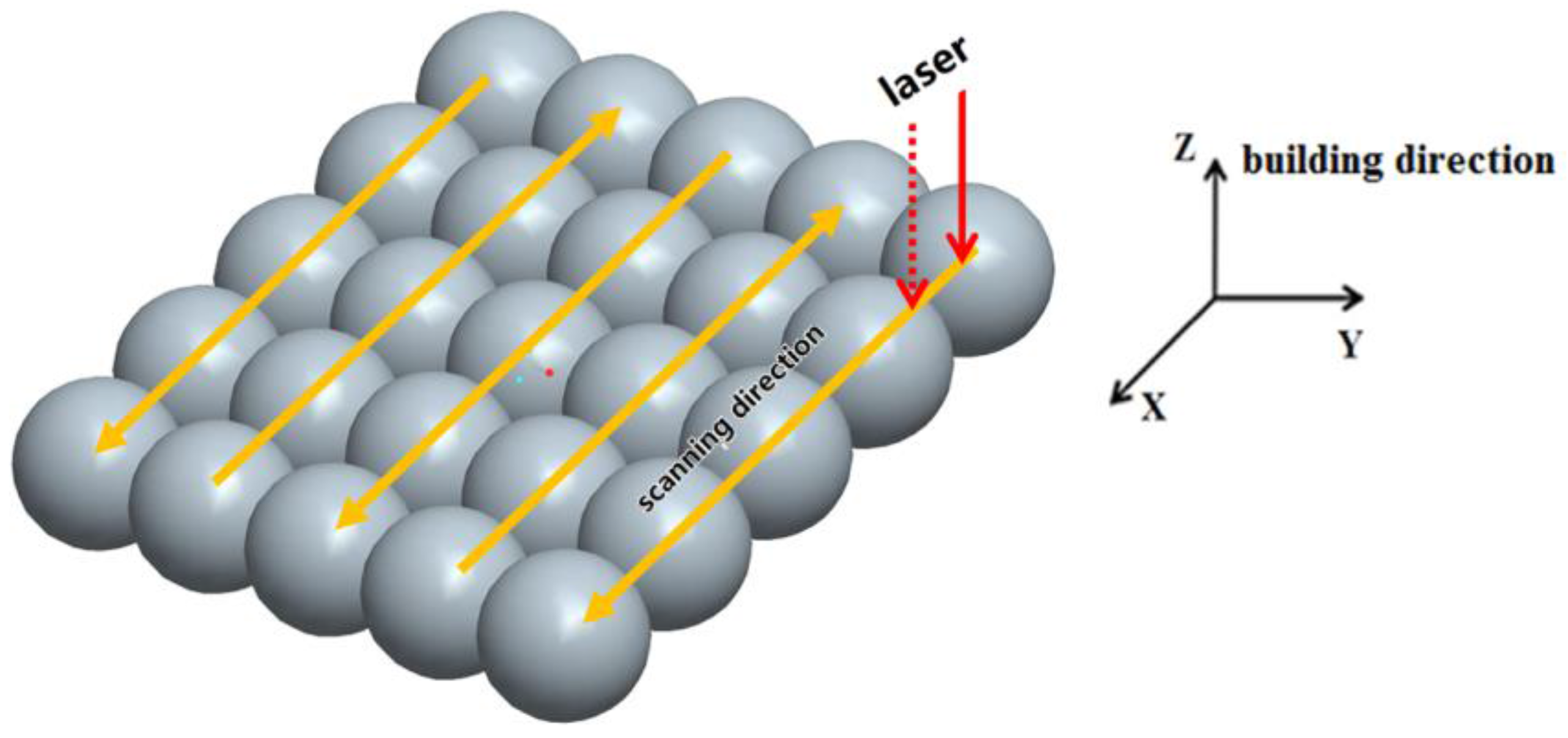

2.1. Materials and SLM Process

2.2. T2 Heat Treatment Process

2.3. Mechanical Tests

2.4. Microstructure Characterization

3. Results and Discussion

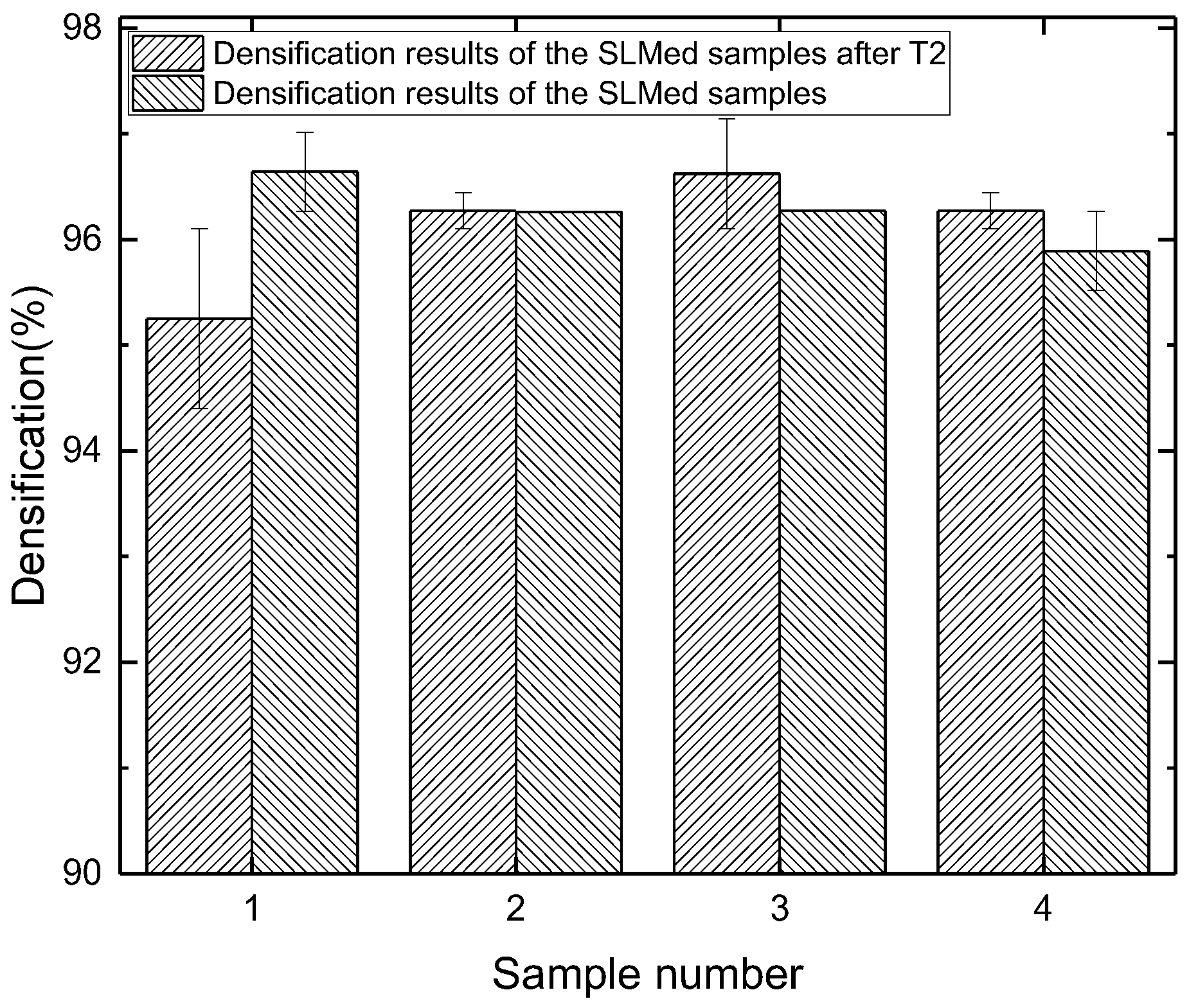

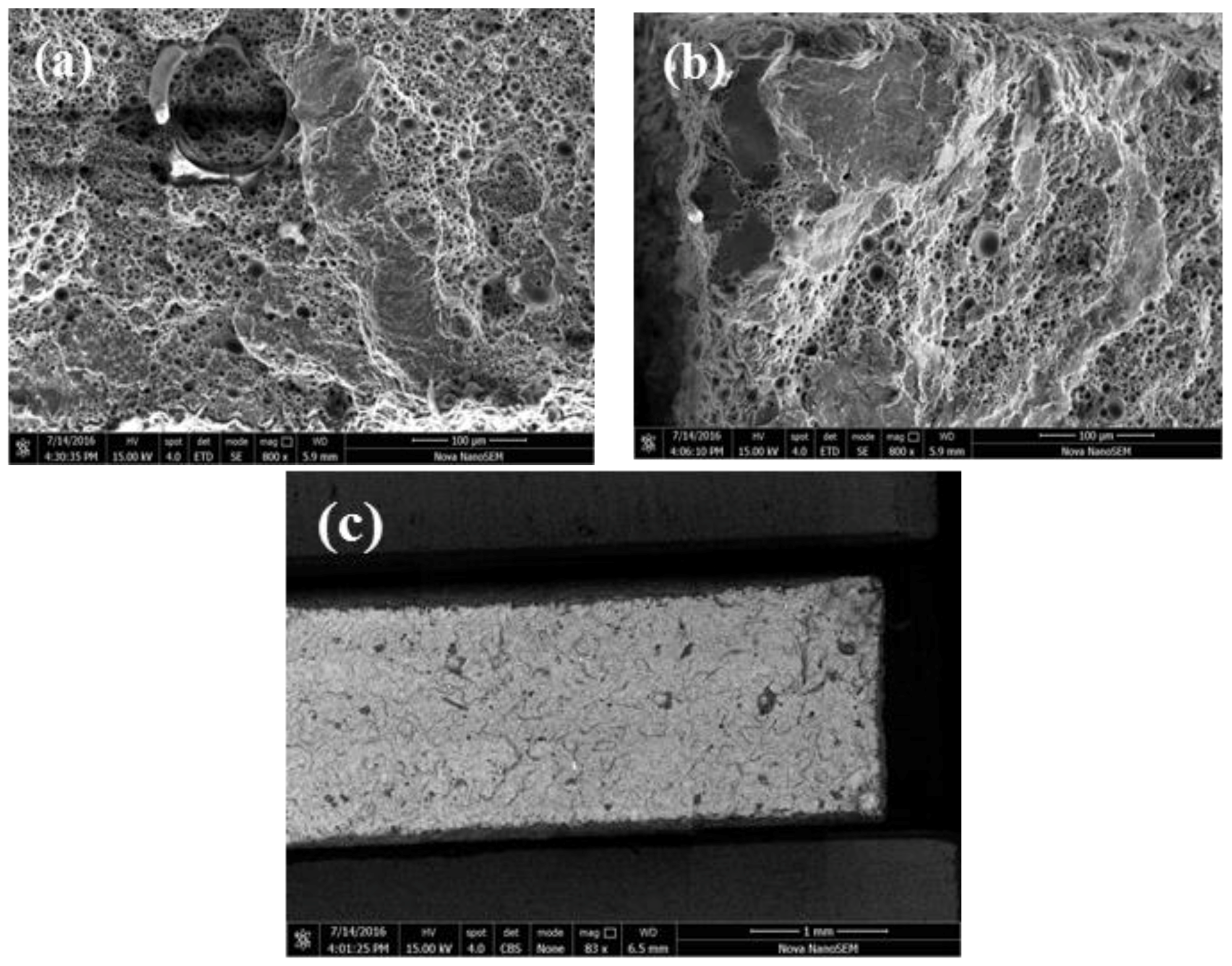

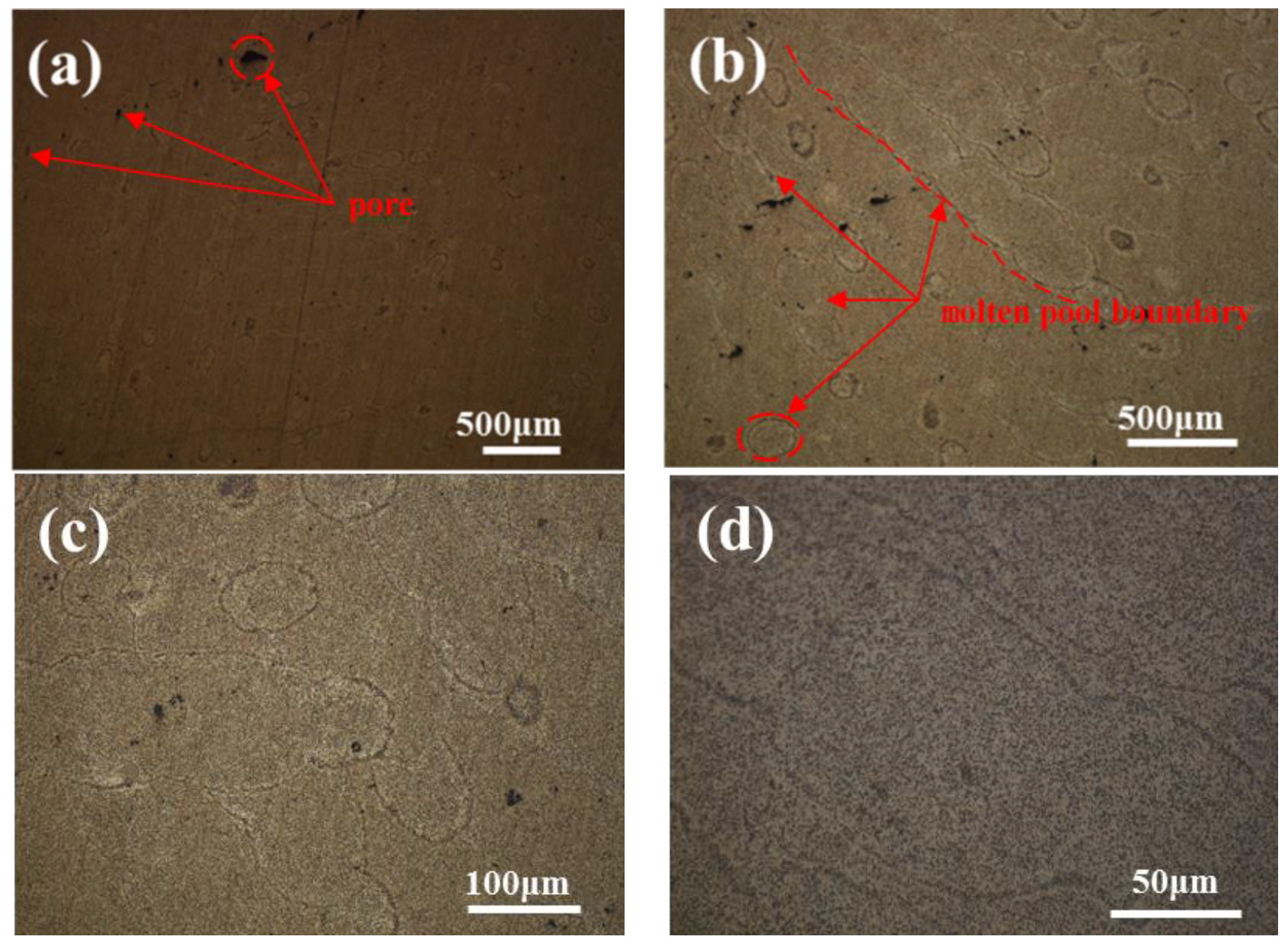

3.1. Effects of T2 Heat Treatment on the Densifications of the SLMed Samples

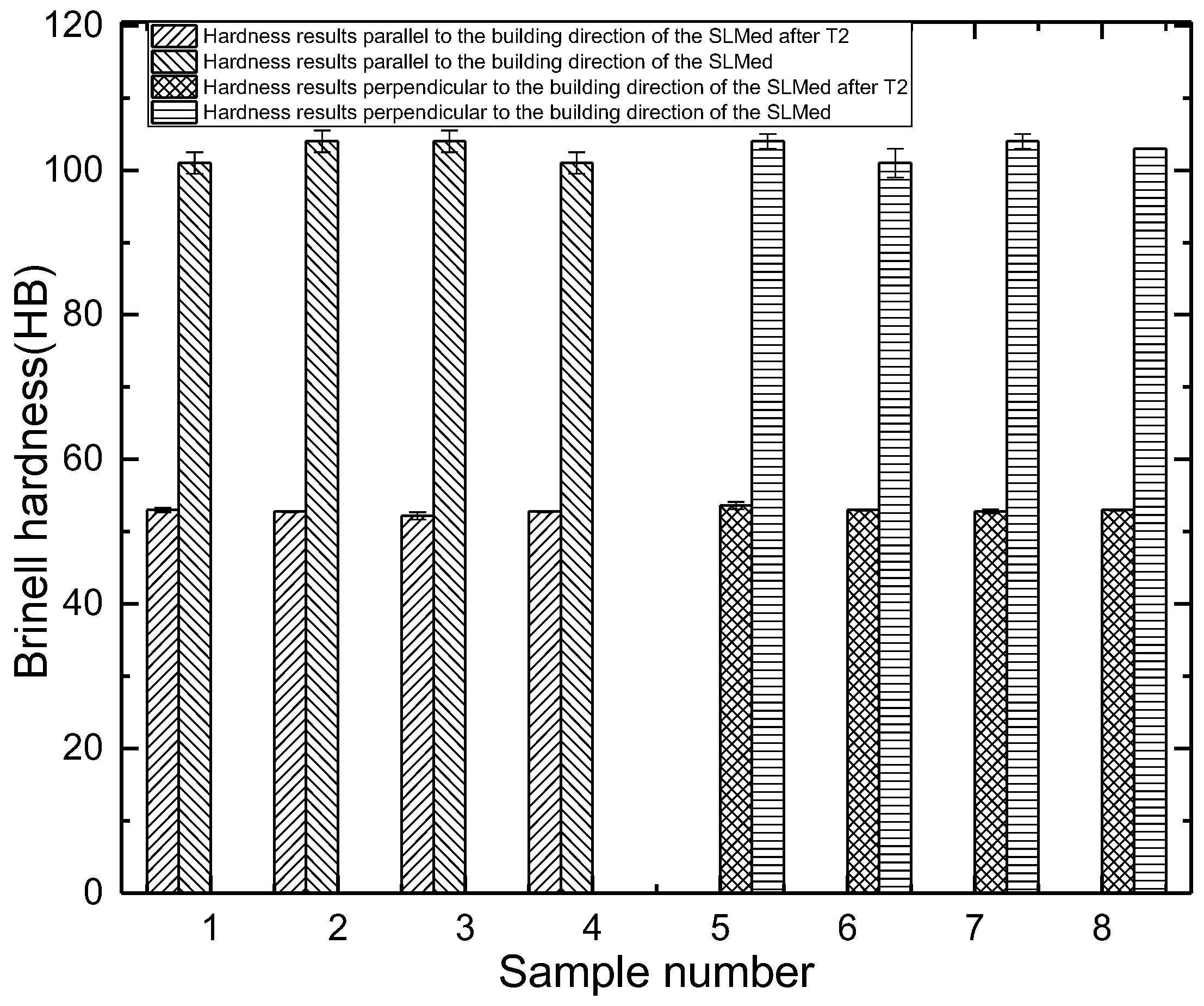

3.2. Effects of T2 Heat Treatment on the Hardness of the SLMed Samples

3.3. Effects of T2 Heat Treatment on the Tensile of the SLMed Samples

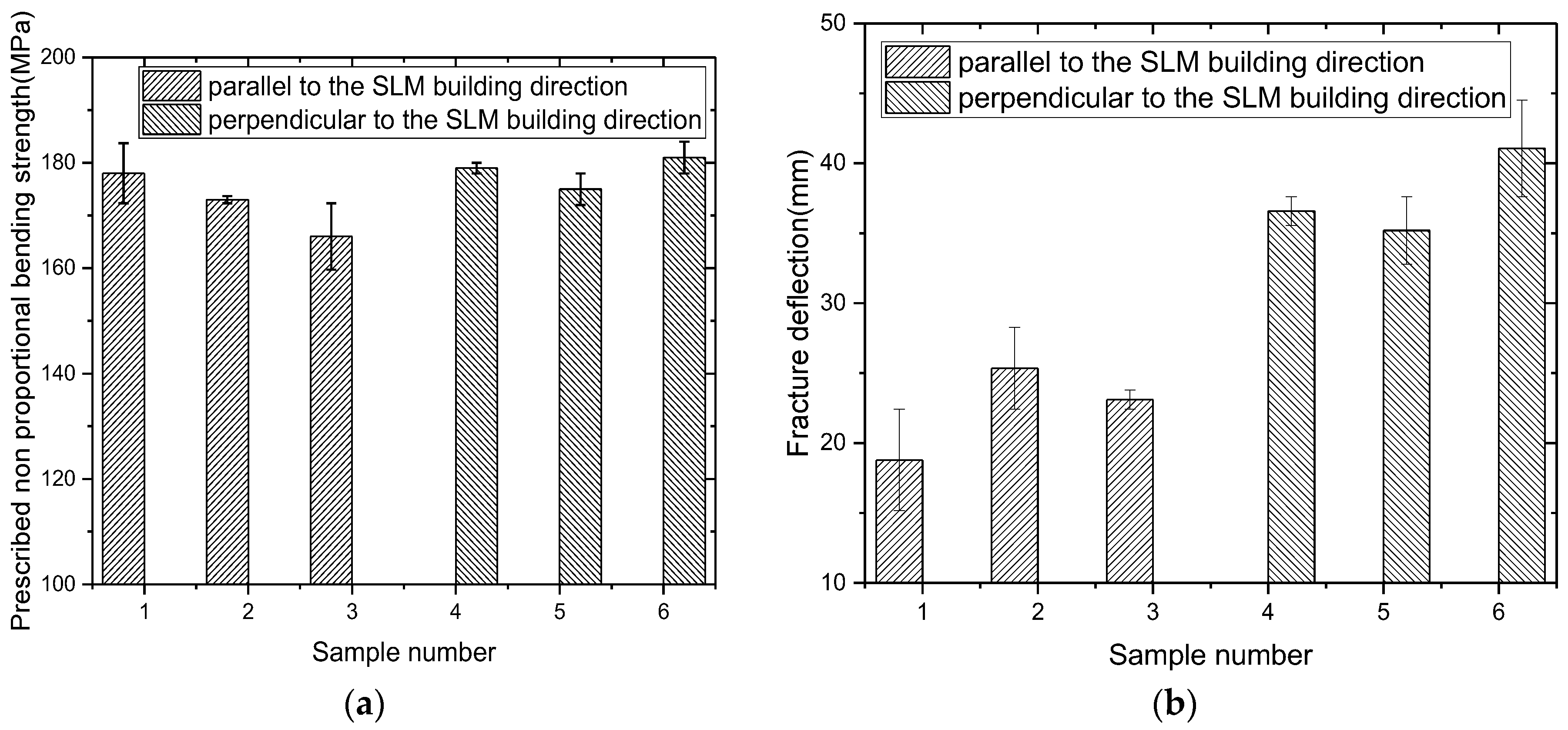

3.4. Effects of T2 Heat Treatment on the Bending of the SLMed Samples

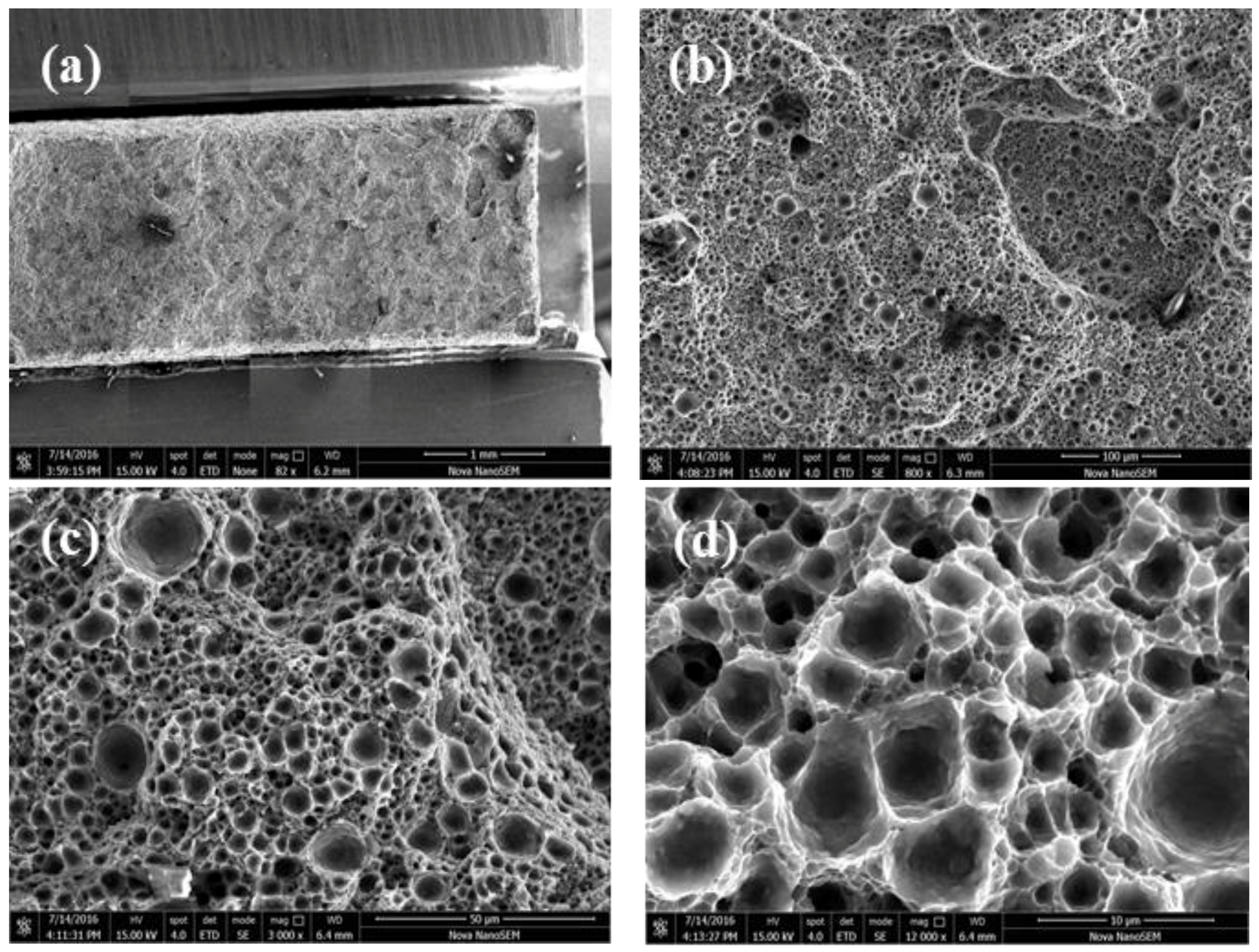

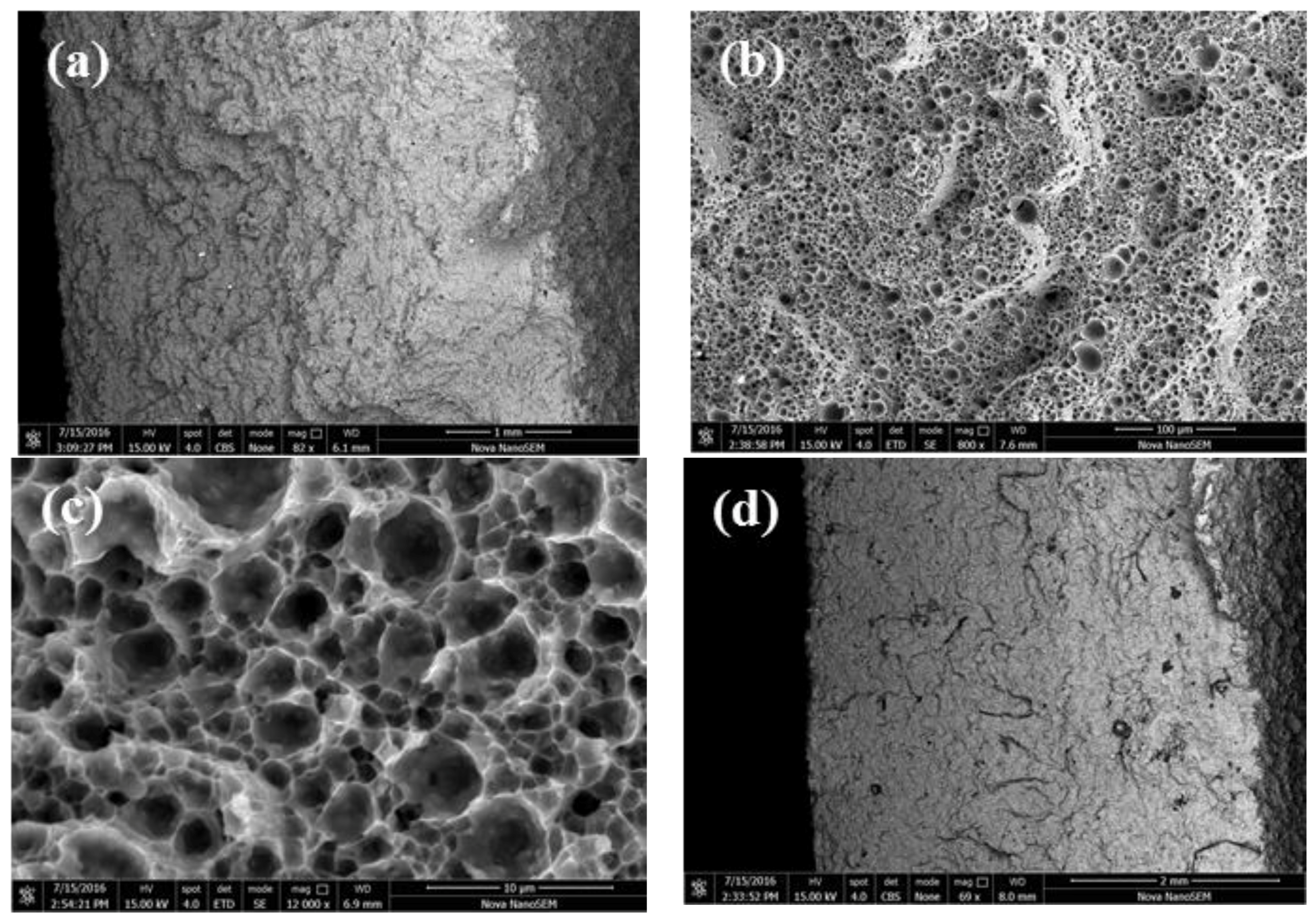

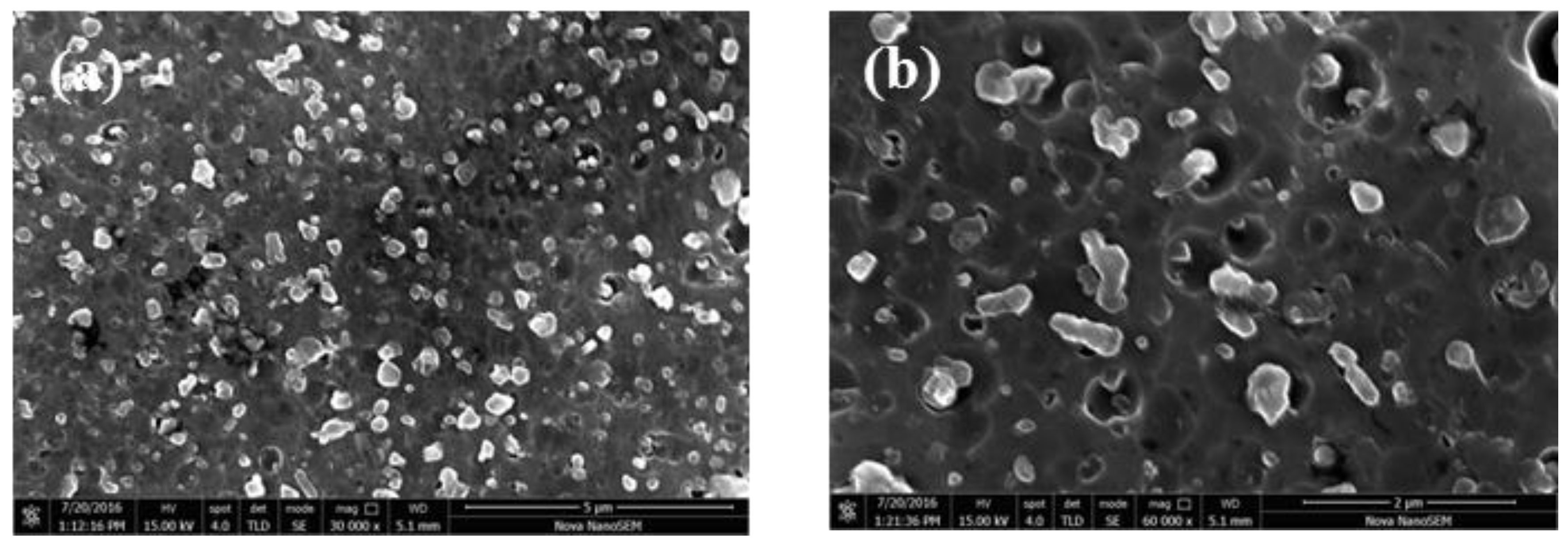

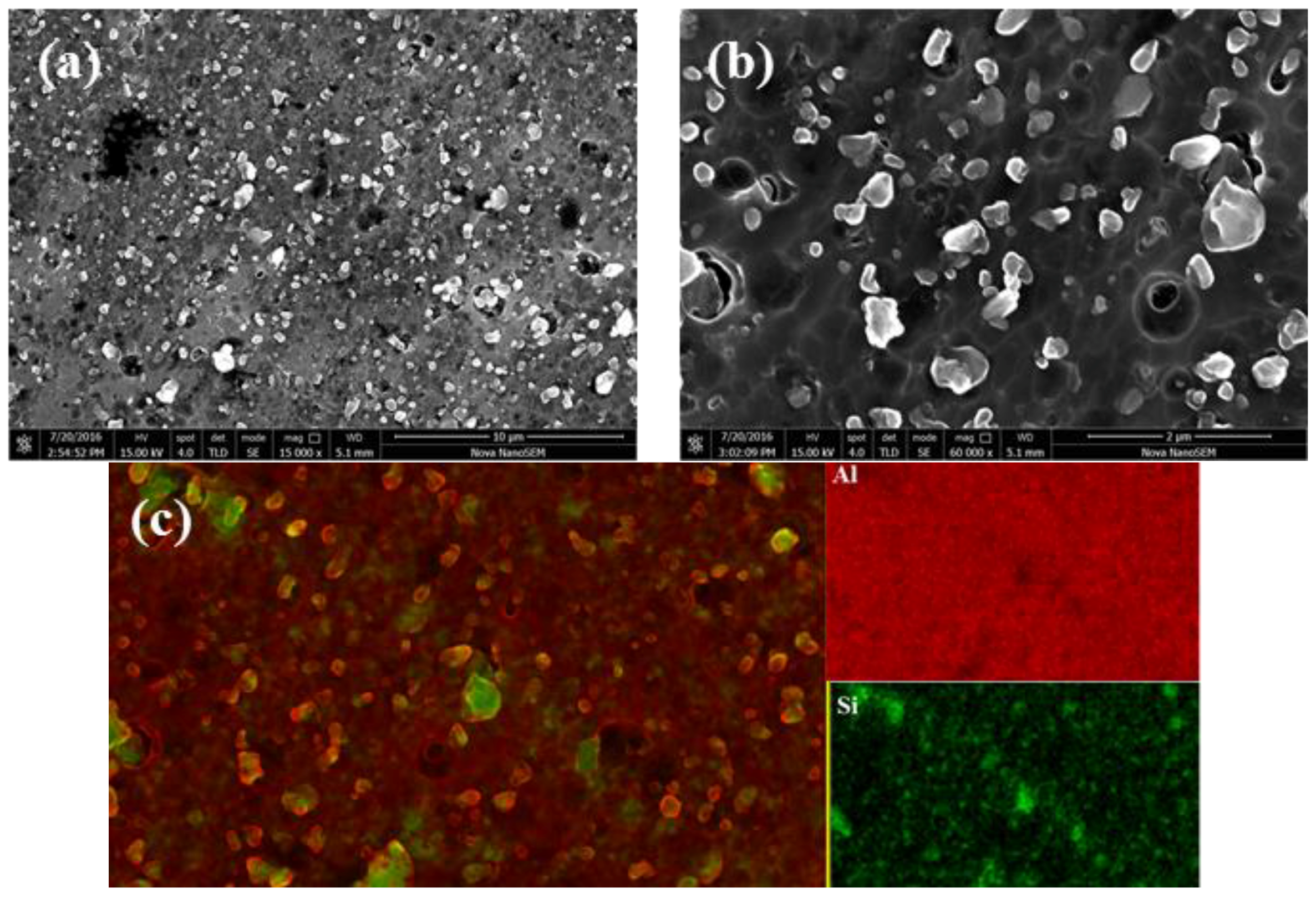

3.5. Effects of T2 Heat Treatment on the Microstructure of the SLMed Samples

4. Conclusions

- (1)

- Compared with the SLMed samples, the densification is not very different. T2 heat treatment has no obvious influence on the densification of the SLMed samples.

- (2)

- After T2 heat treatment, the Brinell hardness, tensile strength, and bending strength of the SLMed samples decrease about 50%. The plasticity and fracture deflection clearly increases, and the anisotropy decreases.

- (3)

- The T2 heat treatment promotes the homogenization of elements, and the precipitates in the molten pool boundary dissolves in the matrix. The samples undergo recrystallization, Si particle size grows and tends to form spherical. The internal stress of the samples is effectively released.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chlebus, E.; Kuźnicka, B.; Kurzynowski, T.; Dybała, B. Microstructure and mechanical behavior of Ti-6A1-7Nb alloy produced by selective laser melting. Mater. Charact. 2011, 62, 488–495. [Google Scholar] [CrossRef]

- Kempen, K.; Yasa, E.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Microstructure and mechanical properties of selective laser melted 18Ni-300 steel. Phys. Procedia 2011, 12, 255–263. [Google Scholar] [CrossRef]

- Zhai, W.; Song, X.; Li, T.; Yu, B.; Lu, W.; Zeng, K. Ti reactive sintering of electrically conductive Al2O3–TiN composites: Influence of Ti particle size and morphology on electrical and mechanical properties. Materials 2017, 10, 1348. [Google Scholar] [CrossRef]

- Ye, X.T.; Leeflang, S.; Wu, C.T.; Chang, J.; Zhou, J.; Huan, Z.G. Mesoporous bioactive glass functionalied 3D Ti-6Al-4V scaffolds with improved surface bioactivity. Materials 2017, 10, 1244. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Jue, J.; Xia, M.; Guo, L.; Yan, B.; Gu, D. Effect of the Thermodynamic Behavior of Selective Laser Melting on the Formation of In situ Oxide Dispersion-Strengthened Aluminum-Based Composites. Metals 2016, 6, 286. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Krutha, J.-P. Mechanical properties of A1Sil0Mgproduced by selective laser melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured A1Sil0Mg samples using selective laser melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.P.; Van Humbeeck, J. Fine-structured aluminum products with controllable texture by selective laser melting of pre-alloyed A1Sil0Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.J.; Zhang, L.C.; Fang, M.H.; Sercombe, T.B. The Effect of atmosphere on the structure and properties of selective laser melted Al-12Sialloy. Mater. Sci. Eng. A. 2014, 597, 370–375. [Google Scholar] [CrossRef]

- Wong, K.K.; Ho, J.Y.; Leong, K.C.; Wong, T.N. Fabrication of heat sinks by Selective Laser Melting for convective heat transfer applications. Virtual Phys. Prototyp. 2016, 11, 159–165. [Google Scholar] [CrossRef]

- Cai, X.; Malcolm, A.A.; Wong, B.S.; Fan, Z. Measurement and characterization of porosity in aluminium selective laser melting parts using X-ray CT. Virtual Phys. Prototyp. 2015, 10, 195–206. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E. History of residual stresses during the production phases of AlSi10Mg parts processed by powder bed additive manufacturing technology. Virtual Phys. Prototyp. 2017, 12, 153–160. [Google Scholar] [CrossRef]

- Lam, L.P.; Zhang, D.Q.; Liu, Z.H.; Chua, C.K. Phase analysis and microstructure characterisation of AlSi10Mg parts produced by Selective Laser Melting. Virtual Phys. Prototyp. 2015, 10, 207–215. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, X.; Guo, M.; Zhu, X.; Yan, B. Characterisation of structural properties for AlSi10Mg alloys fabricated by selective laser melting. Mater. Sci. Technol. 2017, 33, 2274–2282. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the selective laser melting (SLM) of the AlSi10Mg alloy: Microstructucre and the mechanical properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Hitzler, L.; Hirsch, J.; Heine, B.; Merkel, M.; Hall, W.; Öchsner, A. On the anisotropic mechanical properties of selective laser-melted stainless steel. Materials 2017, 10, 1136. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Sun, J.; Zhu, X.; Cheng, L.; Shi, Y.; Guo, L.; Yan, B. Effects of T2 Heat Treatment on Microstructure and Properties of the Selective Laser Melted Aluminum Alloy Samples. Materials 2018, 11, 66. https://doi.org/10.3390/ma11010066

Wang L, Sun J, Zhu X, Cheng L, Shi Y, Guo L, Yan B. Effects of T2 Heat Treatment on Microstructure and Properties of the Selective Laser Melted Aluminum Alloy Samples. Materials. 2018; 11(1):66. https://doi.org/10.3390/ma11010066

Chicago/Turabian StyleWang, Lianfeng, Jing Sun, Xiaogang Zhu, Lingyu Cheng, Yun Shi, Lijie Guo, and Biao Yan. 2018. "Effects of T2 Heat Treatment on Microstructure and Properties of the Selective Laser Melted Aluminum Alloy Samples" Materials 11, no. 1: 66. https://doi.org/10.3390/ma11010066