Study of the Technical Feasibility of Increasing the Amount of Recycled Concrete Waste Used in Ready-Mix Concrete Production

Abstract

:1. Introduction

2. Methodology

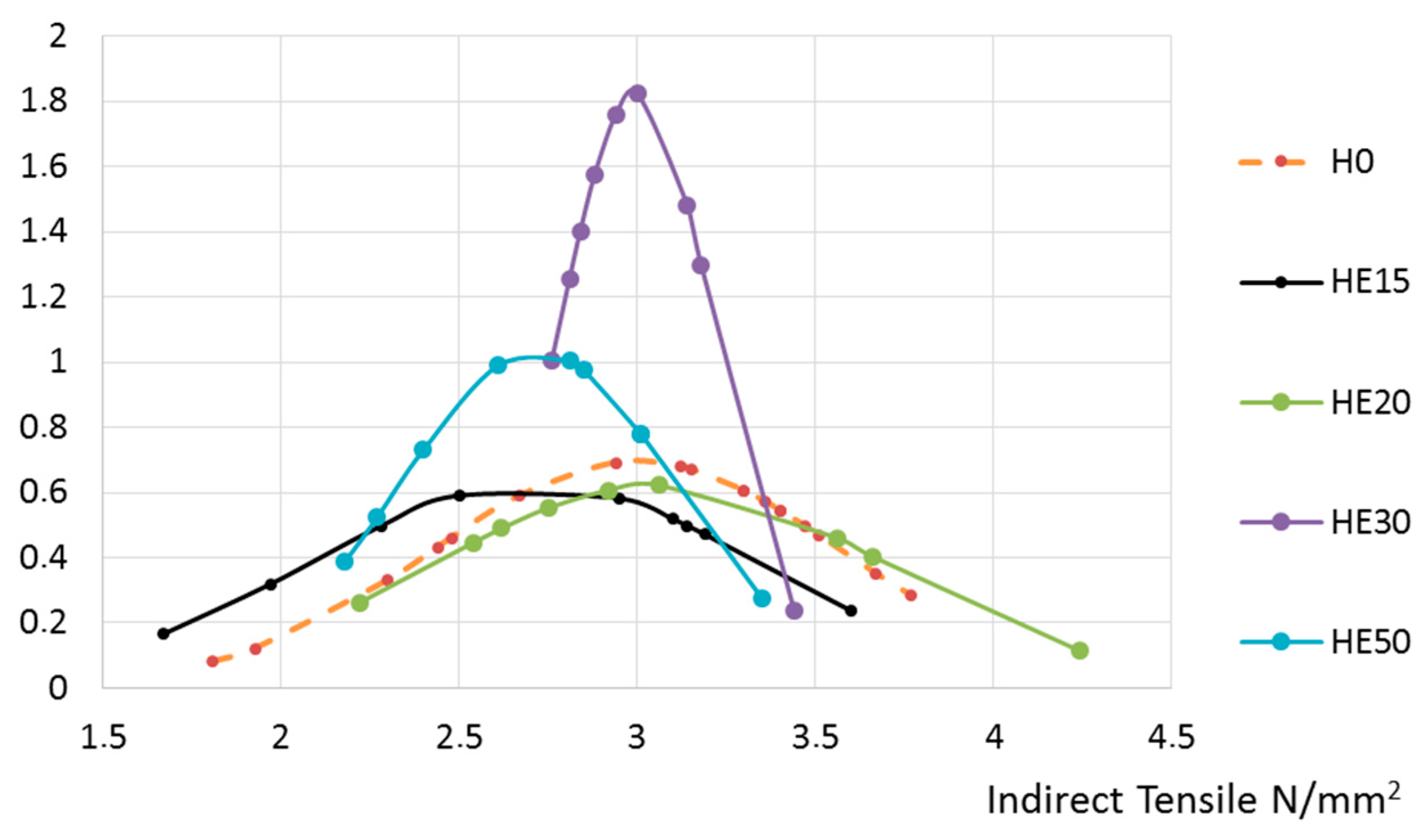

- Hormigones Ebro (HE). Aggregate made from the waste of concrete blocks that were not classified beforehand (Figure 1a).

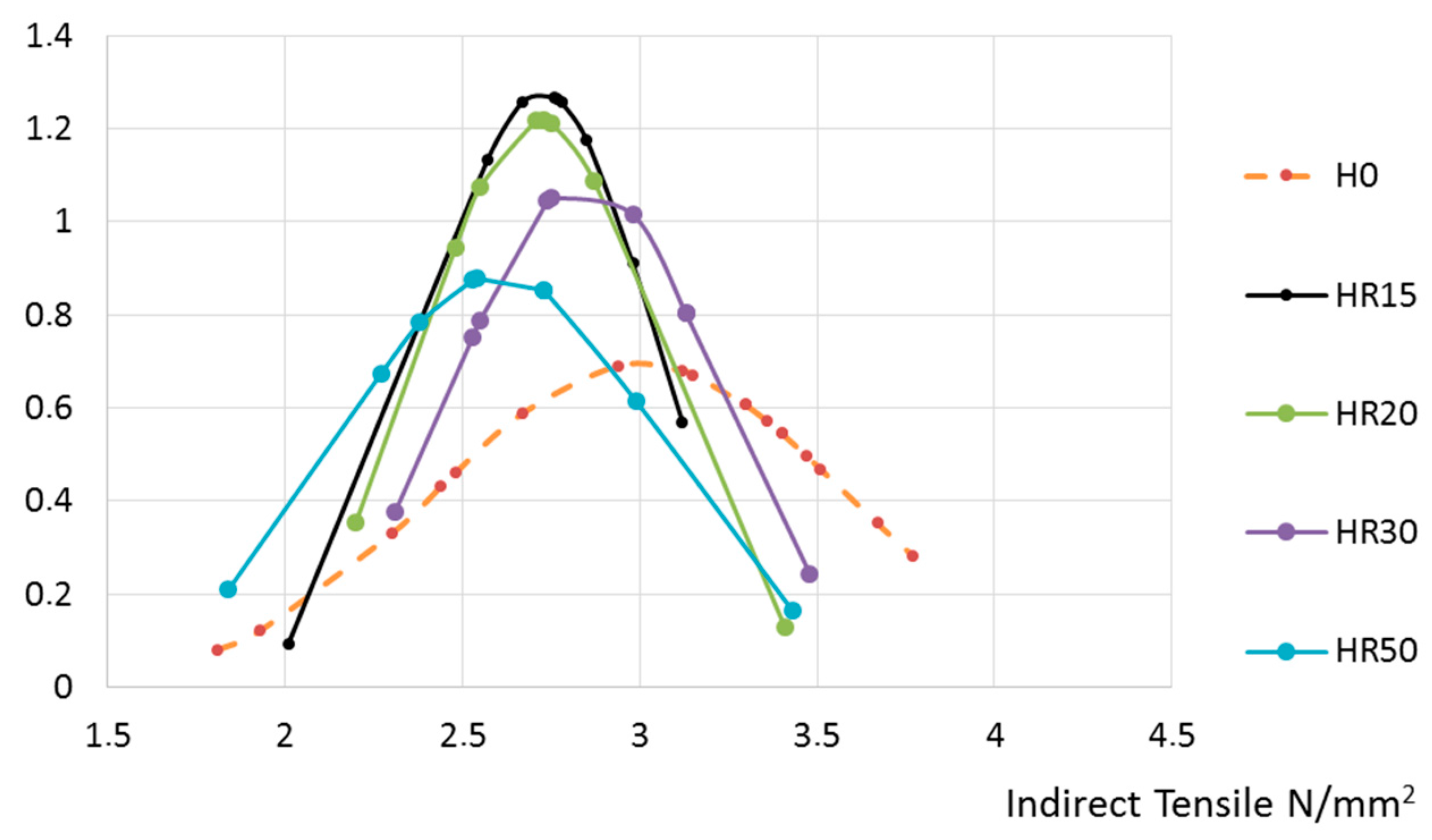

- Hormigones Rioja (HR). These aggregates come from the rejection stage of the industrial process for recycling demolition materials to obtain artificial aggregate.

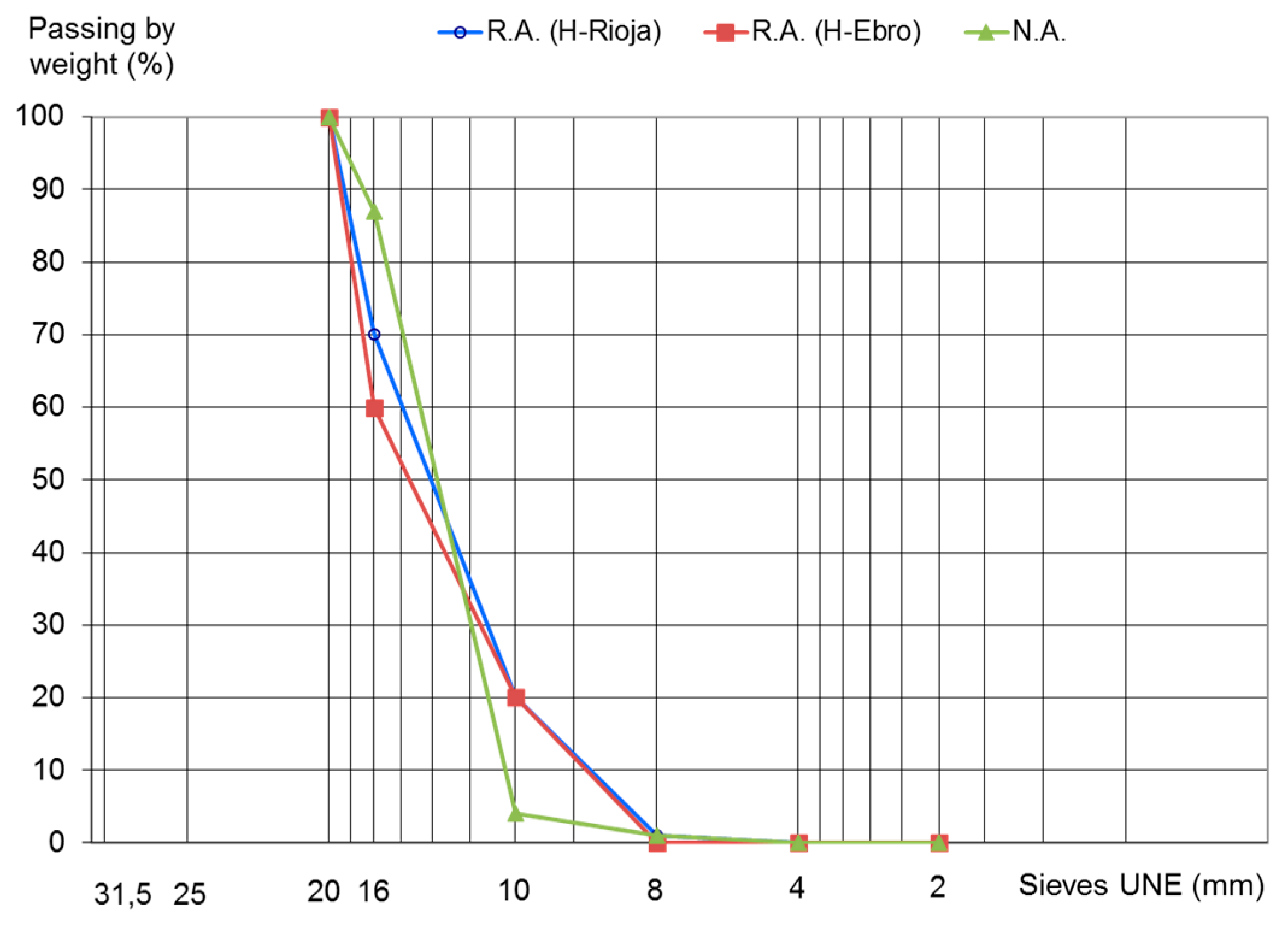

2.1. Characterization of Recycled Aggregate

2.1.1. Physical Properties of RCA

2.1.2. Chemical Properties of RCA

2.2. Characterization of Recycled Concrete

2.2.1. Concrete Mix Design

2.2.2. Concrete Manufacturing Process

- CA-12/20-T-S-L, mixer rotated for 3 s to evenly distribute material. In the substitution mixes, the corresponding fraction of CA-12/20-T-R was added at the same time.

- CA-6/12-T-S-L, mixer rotated for 3 s to evenly distribute material.

- FA-0/6-T-S-L, mixer rotated for 3 s to completely mix materials.

- Cement was added and evenly distributed manually; the mixer was then switched on and rotated for 2 s.

- Half the total water quantity was added and mixing resumed.

- The remaining quantity of water was added with the mixer in motion during a period of time no greater than 30 s. This first mixing stage lasted 3 min and 30 s.

- Let mix stand for 3 min with the mixer cover open.

- After two minutes the mixing process was finished. Then ambient temperature and humidity were recorded, as well as the temperature of the cement mix.

2.2.3. Concrete Characterization Tests

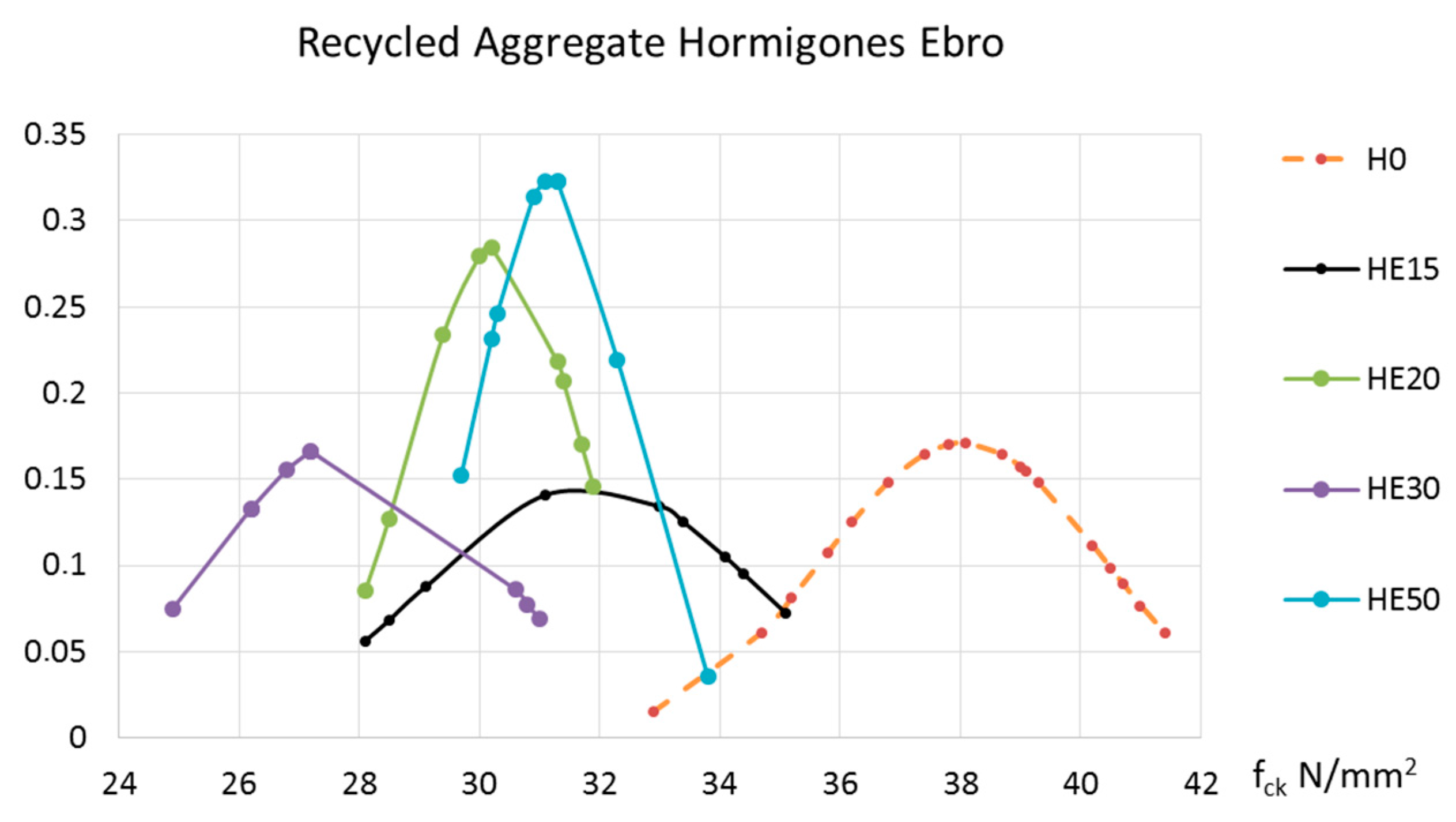

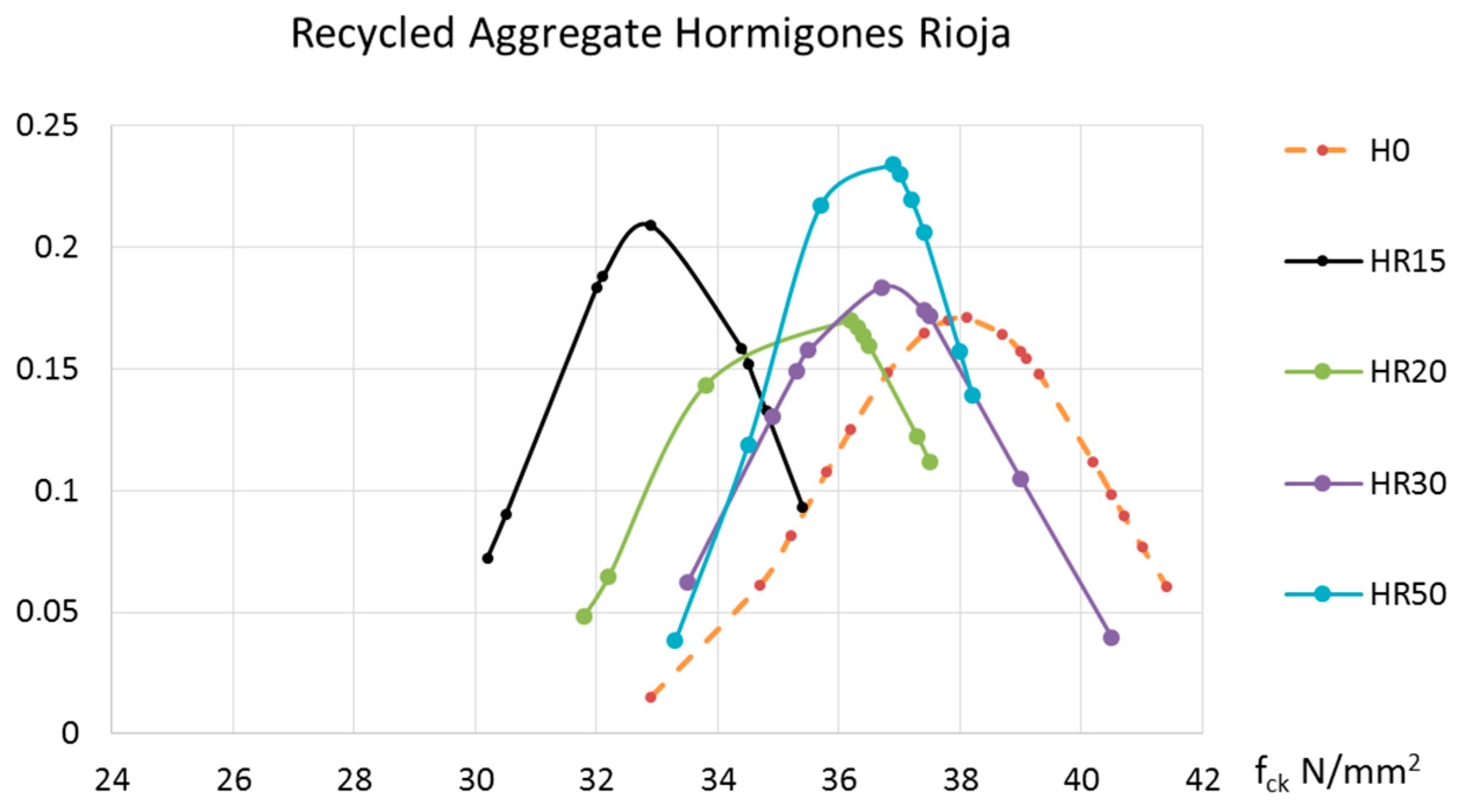

3. Results and Discussion

4. Conclusions

- The two treatments realized on the demolition waste entail significant costs. However, these treatments have been proven to contribute added value to the recycled aggregate obtained.

- The concrete produced with recycled aggregate at the HR plant obtained results similar to those of the control concrete.

- This study demonstrates that recycled aggregates that are made from concrete and undergo prior treatment can replace natural aggregate by up to 50% without provoking significant modifications in the produced concrete’s strength performance.

- There is a greater negative impact on the compressive strength of the concrete produced.

- The presence of low strength concrete in the HE source presents an obstacle for recycling with the aim of producing structural concrete.

- The concrete block aggregate was derived from concrete with a strength less than 25 N/mm2 at age 28 days. This type of waste, which undergoes a simple prior treatment of crushing and sieving, presents a significant quantity of adhered mortar.

- This undesirable effect can be remedied by introducing an initial classification step to categorize waste according to its strength. Thus, one could select only those recycled materials of equal or greater strength than the strength of the concrete to be made.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Poon, C.-S.; Chan, D. The use of recycled aggregate in concrete in Hong Kong. Resour. Conserv. Recycl. 2007, 50, 293–305. [Google Scholar] [CrossRef]

- American Concrete Institute (ACI). Use of Recycled Concrete Aggregates IR 19-4; California Code of Regulations (CCR), Title 24 Part 2: California Building Code (CBC), Section 1903A, 1903.1*, American Concrete Institute (ACI) 318-05; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Kim, H.; Goulias, D.G. Shrinkage behavior of sustainable concrete with crushed returned concrete aggregate. J. Mater. Civ. Eng. 2015, 27, 04014204. [Google Scholar] [CrossRef]

- Vieira, J.P.B.; Correia, J.R.; De Brito, J. Post-fire residual mechanical properties of concrete made with recycled concrete coarse aggregates. Cem. Concr. Res. 2011, 41, 533–541. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Courard, L.; Michel, F.; Delhez, P. Use of concrete road recycled aggregates for Roller Compacted Concrete. Constr. Build. Mater. 2010, 24, 390–395. [Google Scholar] [CrossRef]

- Hiller, J.E.; Deshpande, Y.S.; Qin, Y.; Shorkey, C.J. Efficient Use of Recycled Concrete in Transportation Infrastructure; Michigan Technological University Department Civil Environmental Engineering: Houghton, MI, USA, 2011. [Google Scholar]

- Tobergte, D.R.; Curtis, S. Batching effects on properties of recycled concrete aggregates for airfield rigid pavements. J. Chem. Inf. Model. 2013, 53, 1689–1699. [Google Scholar] [CrossRef]

- Zulkati, A.; Wong, Y.; Sun, D. Mechanistic performance of asphalt-concrete mixture incorporating coarse recycled concrete aggregate. J. Mater. Civ. Eng. 2016, 25, 864–870. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Chakradhara Rao, M.; Bhattacharyya, S.K.; Barai, S.V. Behaviour of recycled aggregate concrete under drop weight impact load. Constr. Build. Mater. 2011, 25, 69–80. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Grdic, Z.J.; Toplicic-Curcic, G.A.; Despotovic, I.M.; Ristic, N.S. Properties of self-compacting concrete prepared with coarse recycled concrete aggregate. Constr. Build. Mater. 2010, 24, 1129–1133. [Google Scholar] [CrossRef]

- Xiao, J.; Falkner, H. Bond behaviour between recycled aggregate concrete and steel rebars. Constr. Build. Mater. 2007, 21, 395–401. [Google Scholar] [CrossRef]

- Yaprak, H.; Aruntas, H.Y.; Demir, I.; Simsek, O. Effects of the fine recycled concrete aggregates on the concrete properties. Int. J. Phys. Sci. 2011, 6, 2455–2461. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Tang, K.; Millard, S.G. Concrete building blocks made with recycled demolition aggregate. Constr. Build. Mater. 2011, 25, 726–735. [Google Scholar] [CrossRef]

- Xiao, Z.; Ling, T.C.; Kou, S.C.; Wang, Q.; Poon, C.S. Use of wastes derived from earthquakes for the production of concrete masonry partition wall blocks. Waste Manag. 2011, 31, 1859–1866. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Xiao, J.; Zhu, C.; Zhong, Z. Experimental study on mechanical behaviors of concrete with large-size recycled coarse aggregate. Constr. Build. Mater. 2016, 120, 321–328. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Letelier, V.; Moriconi, G. Behaviour of beam-column joints made of recycled-aggregate concrete under cyclic loading. Constr. Build. Mater. 2011, 25, 1877–1882. [Google Scholar] [CrossRef]

- Liang, Y.; Ye, Z.; Vernerey, F.; Xi, Y. Development of processing methods to improve strength of concrete with 100% recycled coarse aggregate. J. Mater. Civ. Eng. 2015, 27, 4014163. [Google Scholar] [CrossRef]

- Marthong, C.; Marthong, S. Enhancing mechanical properties of concrete prepared with coarse recycled aggregates. IES J. Part A 2015, 8, 175–183. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Zaharieva, R.; Buyle-Bodin, F.; Skoczylas, F.; Wirquin, E. Assessment of the surface permeation properties of recycled aggregate concrete. Cem. Concr. Compos. 2003, 25, 223–232. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- AEN/CTN 146—ÁRIDOS. UNE-EN 12620:2003+A1:2009. In Aggregates for Concrete; AENOR: Madrid, Spain, 2009. [Google Scholar]

- DIN. DIN 4226-100:2002-02. In Aggregates for Concrete and Mortar—Part 100: Recycled Aggregates; DIN: Berlin, Germany, 2002. [Google Scholar]

- British Standards. BS 8500-2:2015+A1:2016. Concrete. Complementary British Standard to BS EN 206. Specification for Constituent Materials and Concrete; BS8500; British Standards: London, UK, 2016. [Google Scholar]

- RILEM. Draft of Spanish regulations for the use of recycled aggregate in the production of structural concrete. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Building and Structures, Spain, 8–11 November 2004. Vázquez, E., Hendriks, C.F., Janssen, G.M.T., Eds.; RILEM Publications SARL: Barcelona, Spain, 2004; pp. 511–525. [Google Scholar] [CrossRef]

- National Laboratory for Civil Engineering (LNEC). E 471:2009—Guide for the Use of Coarse Recycled Aggregates in Concrete; LNEC: Lisbon, Portugal, 2009. [Google Scholar]

- Ministry of Public Works Spain. Code on Structural Concrete (Spanish Abbreviation—EHE-08); Ministry of Public Works Spain: Madrid, Spain, 2008.

- Berndt, M.L. Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Dollimore, D.; Lerdkanchanaporn, S.; Gupta, J.D.; Nippani, S. An examination of recycled Portland cement concrete rich in dolomite and low in calcite obtained from various locations in Ohio. Thermochim. Acta 2001, 367–368, 311–319. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Recycling of rubble from building demolition for low-shrinkage concretes. Waste Manag. 2010, 30, 655–659. [Google Scholar] [CrossRef] [PubMed]

- Corinaldesi, V. Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates. Constr. Build. Mater. 2010, 24, 1616–1620. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Wijayasundara, M.; Mendis, P.; Zhang, L.; Sofi, M. Financial assessment of manufacturing recycled aggregate concrete in ready-mix concrete plants. Resour. Conserv. Recycl. 2016, 109, 187–201. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Lapko, A.; Grygo, R. Studies of RC beams made of recycling aggregate concrete strengthened with the HSC-HPC inclusions. Procedia Eng. 2013, 57, 678–686. [Google Scholar] [CrossRef]

- Lapko, A.; Grygo, R. Improving the structural behaviour RC precast concrete beams made of recycled aggregate concrete. J. Civ. Eng. Manag. 2016, 22, 234–242. [Google Scholar] [CrossRef]

- Torres, A.; Burkhart, A. Developing sustainable high strength concrete mixtures using local materials and recycled concrete. Mater. Sci. Appl. 2016, 7, 128–137. [Google Scholar] [CrossRef]

- Gómez-Soberón, J.M. Porosity of recycled concrete with substitution of recycled concrete aggregate. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.H.; Tyan, Y.Y.; Chang, T.P.; Chang, C.Y. An assessment of optimal mixture for concrete made with recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 1373–1380. [Google Scholar] [CrossRef]

- Wijayasundara, M.; Crawford, R.H.; Mendis, P. Comparative assessment of embodied energy of recycled aggregate concrete. J. Clean. Prod. 2017, 152, 406–419. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H.J. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Ministerio de Medio Ambiente Rural y Marino. II Plan Nacional Integrado de Residuos de España; Ministerio de Medio Ambiente Rural y Marino: Marino, Spain, 2007. [Google Scholar]

- Domingo-Cabo, A.; Lazaro, C.; Lopez-Gayarre, F.; Serrano-Lopez, M.A.; Serna, P.; Castaño-Tabares, J.O. Creep and shrinkage of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2545–2553. [Google Scholar] [CrossRef]

- Lopez-Gayarre, F.; Lopez-Colina, C.; Serrano-Lopez, M.A.; Garcia Taengua, E.; Lopez Martinez, A. Assessment of properties of recycled concrete by means of a highly fractioned factorial design of experiment. Constr. Build. Mater. 2011, 25, 3802–3809. [Google Scholar] [CrossRef]

- AEN/CTN 146—ÁRIDOS. UNE-EN 13242:2003+A1:2008. In Aggregates for Unbound and Hydraulically Bound Materials for Use in Civil Engineering Work and Road Construction; AENOR: Madrid, Spain, 2008. [Google Scholar]

- AEN/CTN 146—ÁRIDOS. UNE-EN 933-1. In Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method; AENOR: Madrid, Spain, 2012. [Google Scholar]

- AEN/CTN 146—ÁRIDOS. UNE-EN 1097-6:2014. In Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption; AENOR: Madrid, Spain, 2014. [Google Scholar]

- AEN/CTN 146—ÁRIDOS. UNE-EN 1097-2:2010. In Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation; AENOR: Madrid, Spain, 2010. [Google Scholar]

- AEN/CTN 146—ÁRIDOS. UNE-EN 1367-2:2010. In Tests for Thermal and Weathering Properties of Aggregates—Part 2: Magnesium Sulfate Test; AENOR: Madrid, Spain, 2010. [Google Scholar]

- AEN/CTN 146—ÁRIDOS. UNE-EN 1744-1:2010. In Tests for Chemical Properties of Aggregates—Part 1: Chemical Analysis; AENOR: Madrid, Spain, 2010. [Google Scholar]

- AEN/CTN 146—ÁRIDOS. UNE 146901:2008. In Aggregates. Designation; AENOR: Madrid, Spain, 2008. [Google Scholar]

- AEN/CTN 83—HORMIGÓN. UNE-EN 12350-2:2009. In Testing Fresh Concrete—Part 2: Slump-Test; AENOR: Madrid, Spain, 2009. [Google Scholar]

- AEN/CTN 83—HORMIGÓN. UNE-EN 12350-7:2010. In Testing Fresh Concrete—Part 7: Air content—Pressure Methods; AENOR: Madrid, Spain, 2010. [Google Scholar]

- AEN/CTN 83—HORMIGÓN. UNE-EN 12390-2:2009/1M:2015. In Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests; AENOR: Madrid, Spain, 2015. [Google Scholar]

- AEN/CTN 83—HORMIGÓN. UNE-EN 12390-3:2009/AC:2011. In Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; AENOR: Madrid, Spain, 2011. [Google Scholar]

- AEN/CTN 83—HORMIGÓN. UNE-EN 12390-7:2009. In Testing Hardened Concrete—Part 7: Density of Hardened Concrete; AENOR: Madrid, Spain, 2009. [Google Scholar]

- AEN/CTN 83—HORMIGÓN. UNE-EN 12390-6:2010. In Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens; AENOR: Madrid, Spain, 2010. [Google Scholar]

- AEN/CTN 83—HORMIGÓN. UNE-EN 12390-8:2009/1M:2011. In Testing Hardened Concrete—Part 8: Depth of Penetration of Water under Pressure; AENOR: Madrid, Spain, 2011. [Google Scholar]

| Contaminants and Impurities | Maximum % of Total Sample Weight |

|---|---|

| Ceramic material | 5 |

| Lightweight particles | 1 |

| Asphalt | 1 |

| Glass, plastic, metal | 1 |

| Material | Denomination | kg/m3 | kg/0.06 m3 | ||||

|---|---|---|---|---|---|---|---|

| H0 | 15% | 20% | 30% | 50% | |||

| Cement | CEM I-32.5R | 300.0 | 18 | 18 | 18 | 18 | 18 |

| Natural Aggregates | FA-0/6-T-S-L | 765.0 | 50 | 50 | 50 | 50 | 50 |

| CA-6/12-T-S-L | 405.6 | 24 | 24 | 24 | 24 | 24 | |

| CA-12/20-T-S-L | 601.5 | 36 | 30.6 | 28.8 | 25.2 | 18 | |

| Recycled Aggregates | CA-12/20-T-R | 5.4 | 7.2 | 10.8 | 18 | ||

| Water | Water supply network | 163.0 | 9.78 | 9.78 | 9.78 | 9.78 | 9.78 |

| Num. Cylindrical Specimens | Tests |

|---|---|

| 1 | Compressive strength, aged seven days [65]. |

| 2, 3, 4 | Density [66], Absorption, and compressive strength, aged 28 days [65]. |

| 5, 6, 7 | Density [66], indirect tensile strength [67] and water penetration [68] |

| CA-12/20-T-R (HE) | CA-12/20-T-R (HR) | CA-12/20-T-S-L (La Peña) | Limits EHE-08 [34] | |

|---|---|---|---|---|

| % fine content | Free | 0.10% | 0.40% | <1.5% |

| Absorption | 4.7% | 3.3% | 0.90% | RA < 20% Absorption < 7% (CA natural < 4.5%) |

| RA > 20% Absorption < 5% (CA natural + CA recycled) | ||||

| Clay lumps | 0.08% | 0.11% | Free | RA < 20% Clay Lumps < 0.6% (CA natural < 0.15%) |

| Maximum amount 0.25% | ||||

| Aggregate abrasion resistance | 35% | 24% | 21% | <40% |

| Lightweight particles | Free | 0.14% | Free | <1% |

| Determination of total chloride | 0.015% | 0.039% | 0.006 | Reinforced Concrete CA < 0.05% Pre-stressed Concrete CA < 0.03% |

| Alkali-aggregate reactivity | Aggregate not reactive | Aggregate not reactive | Aggregate not reactive | Recycled aggregates will not be reactive |

| Weight loss % magnesium sulphate | 8.20% | 1.00% | 0.30% | <18% (CA) |

| Determination of sulphur compound | 0.49 | 0.20 | <0.10% | <1% |

| Determination of acid-soluble sulfates | 0.28% | 0.25% | 0.02% | <0.80% |

| RF | Tests | H0 | 15% | 20% | 30% | 50% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M | SD | M | SD | M | SD | M | SD | M | SD | ||

| HR | fck 7 days (N/mm2) | 27.17 | 3.55 | 27.53 | 2.06 | 26.87 | 2.66 | 28.33 | 1.55 | 28.90 | 1.22 |

| fck 28 days (N/mm2) | 36.54 | 2.27 | 32.98 | 1.91 | 35.33 | 2.16 | 36.70 | 2.17 | 36.47 | 1.65 | |

| Density (g/cm3) | 2.36 | 0.02 | 2.31 | 0.02 | 2.34 | 0.02 | 2.35 | 0.02 | 2.33 | 0.02 | |

| Absorption (%) | 2.09 | 0.12 | 2.45 | 0.30 | 2.12 | 0.28 | 2.09 | 0.20 | 2.11 | 0.17 | |

| Indirect tensile (N/mm2) | 3.23 | 0.44 | 2.72 | 0.31 | 2.71 | 0.33 | 2.84 | 0.37 | 2.60 | 0.45 | |

| Water penetration (mm) | 25.89 | 4.81 | 26.22 | 3.35 | 24.78 | 4.89 | 23.89 | 4.08 | 27.22 | 2.49 | |

| HE | fck 7 days (N/mm2) | 31.07 | 1.62 | 28.83 | 4.27 | 27.63 | 2.08 | 25.40 | 1.87 | 28.00 | 1.04 |

| fck 28 days (N/mm2) | 39.54 | 1.43 | 31.87 | 2,72 | 30.28 | 1.40 | 27.88 | 2.30 | 31.21 | 1.23 | |

| Density (g/cm3) | 2.38 | 0.02 | 2.37 | 0.02 | 2.36 | 0.02 | 2.34 | 0.04 | 2.33 | 0.02 | |

| Absorption (%) | 1.20 | 0.24 | 1.34 | 0.23 | 1.44 | 0.30 | 1.66 | 0.35 | 1.89 | 0.29 | |

| Indirect tensile (N/mm2) | 2.77 | 0.66 | 2.71 | 0.64 | 3.06 | 0.64 | 3.00 | 0.22 | 2.72 | 0.39 | |

| Water penetration (mm) | 29.67 | 5.36 | 34.56 | 12.13 | 30.00 | 2.18 | 28.44 | 3.28 | 26.67 | 2.50 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fraile-Garcia, E.; Ferreiro-Cabello, J.; López-Ochoa, L.M.; López-González, L.M. Study of the Technical Feasibility of Increasing the Amount of Recycled Concrete Waste Used in Ready-Mix Concrete Production. Materials 2017, 10, 817. https://doi.org/10.3390/ma10070817

Fraile-Garcia E, Ferreiro-Cabello J, López-Ochoa LM, López-González LM. Study of the Technical Feasibility of Increasing the Amount of Recycled Concrete Waste Used in Ready-Mix Concrete Production. Materials. 2017; 10(7):817. https://doi.org/10.3390/ma10070817

Chicago/Turabian StyleFraile-Garcia, Esteban, Javier Ferreiro-Cabello, Luis M. López-Ochoa, and Luis M. López-González. 2017. "Study of the Technical Feasibility of Increasing the Amount of Recycled Concrete Waste Used in Ready-Mix Concrete Production" Materials 10, no. 7: 817. https://doi.org/10.3390/ma10070817

APA StyleFraile-Garcia, E., Ferreiro-Cabello, J., López-Ochoa, L. M., & López-González, L. M. (2017). Study of the Technical Feasibility of Increasing the Amount of Recycled Concrete Waste Used in Ready-Mix Concrete Production. Materials, 10(7), 817. https://doi.org/10.3390/ma10070817