Image Analysis Technique for Material Behavior Evaluation in Civil Structures

Abstract

:1. Introduction

2. Contactless Methods

3. Results

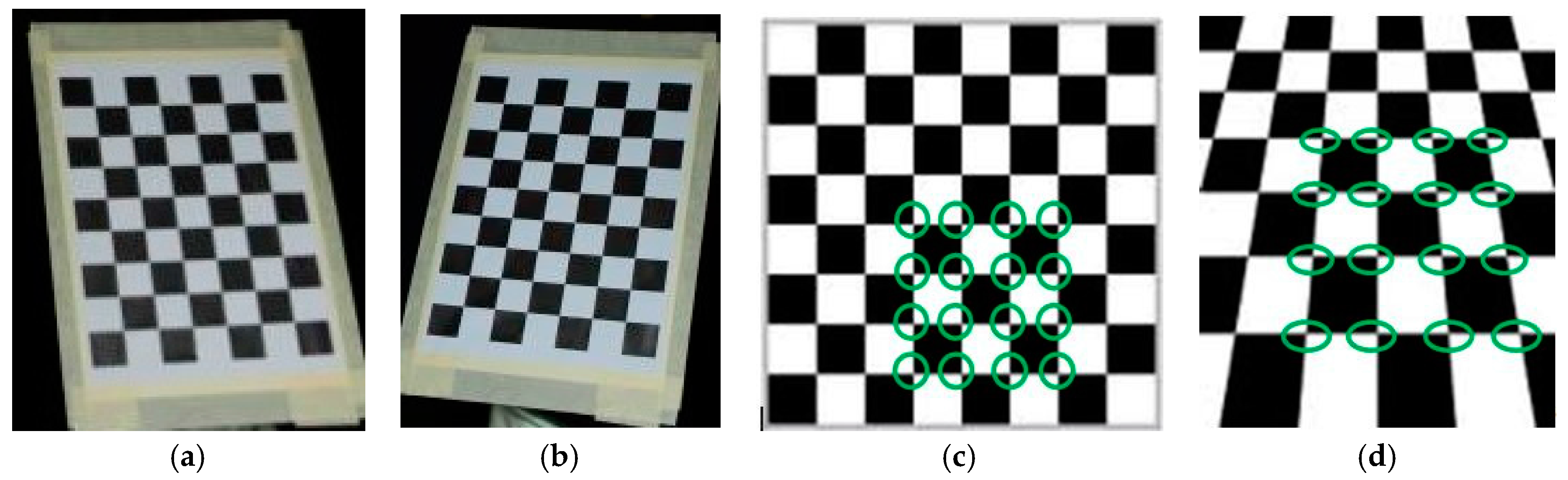

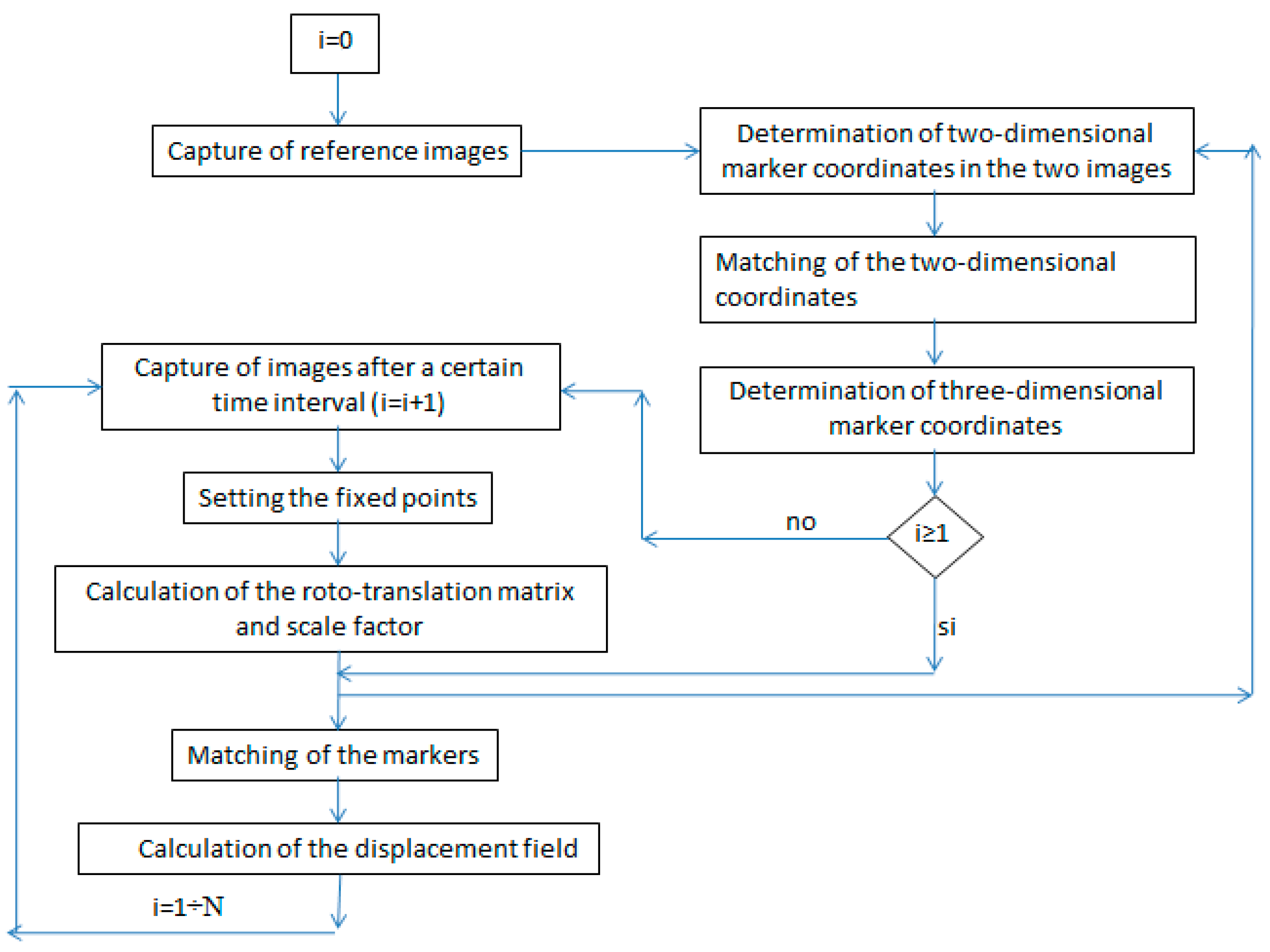

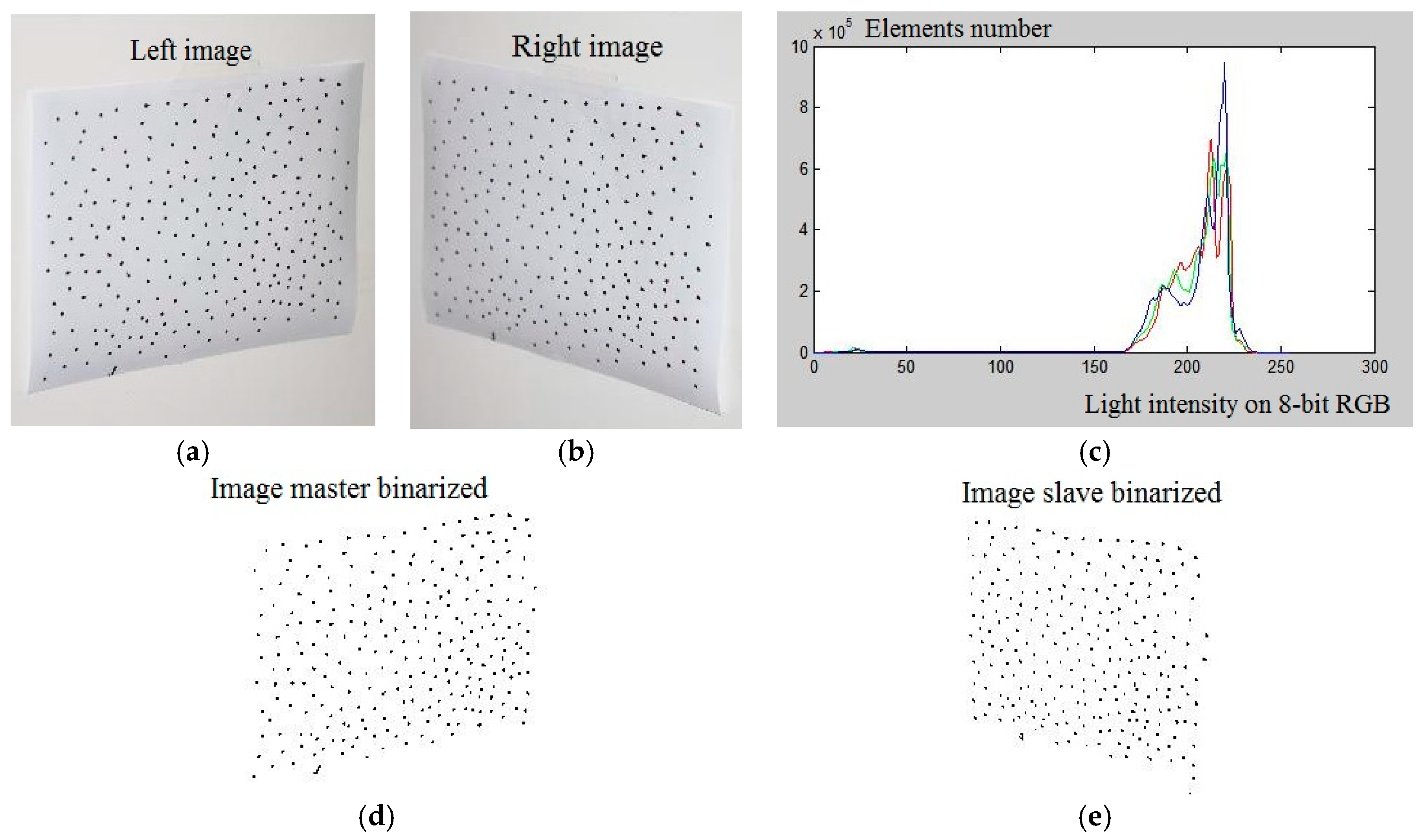

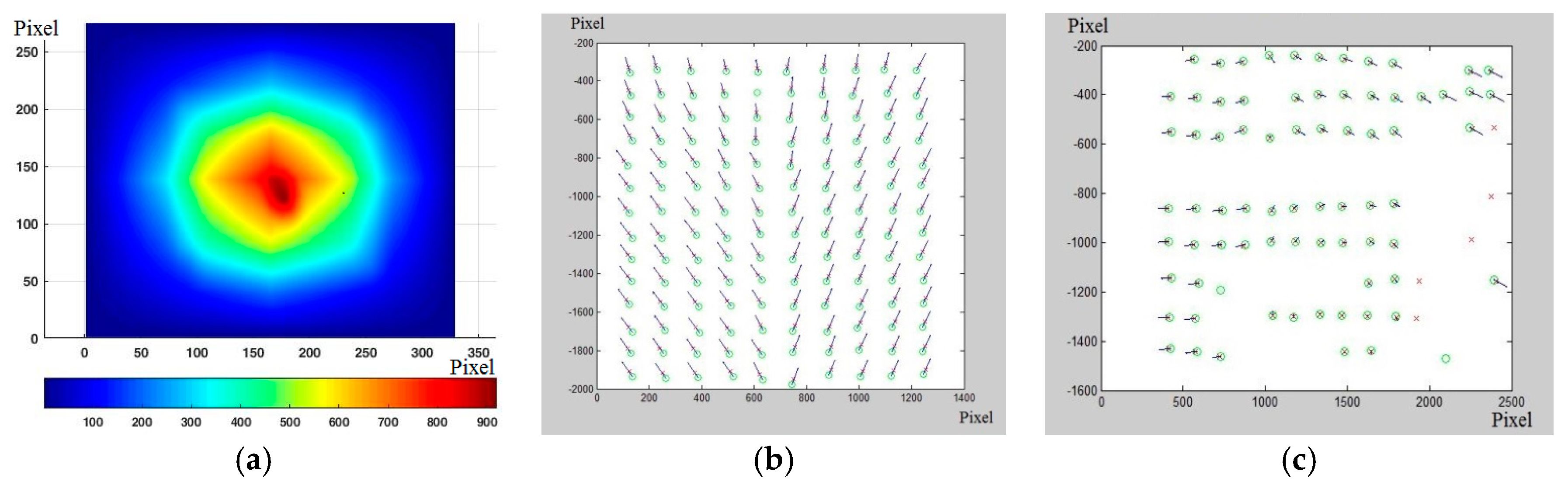

3.1. The Software Developed in This Research

3.2. Experiments on Masonry Structures for the Validation of the Investigation Methodology and Results

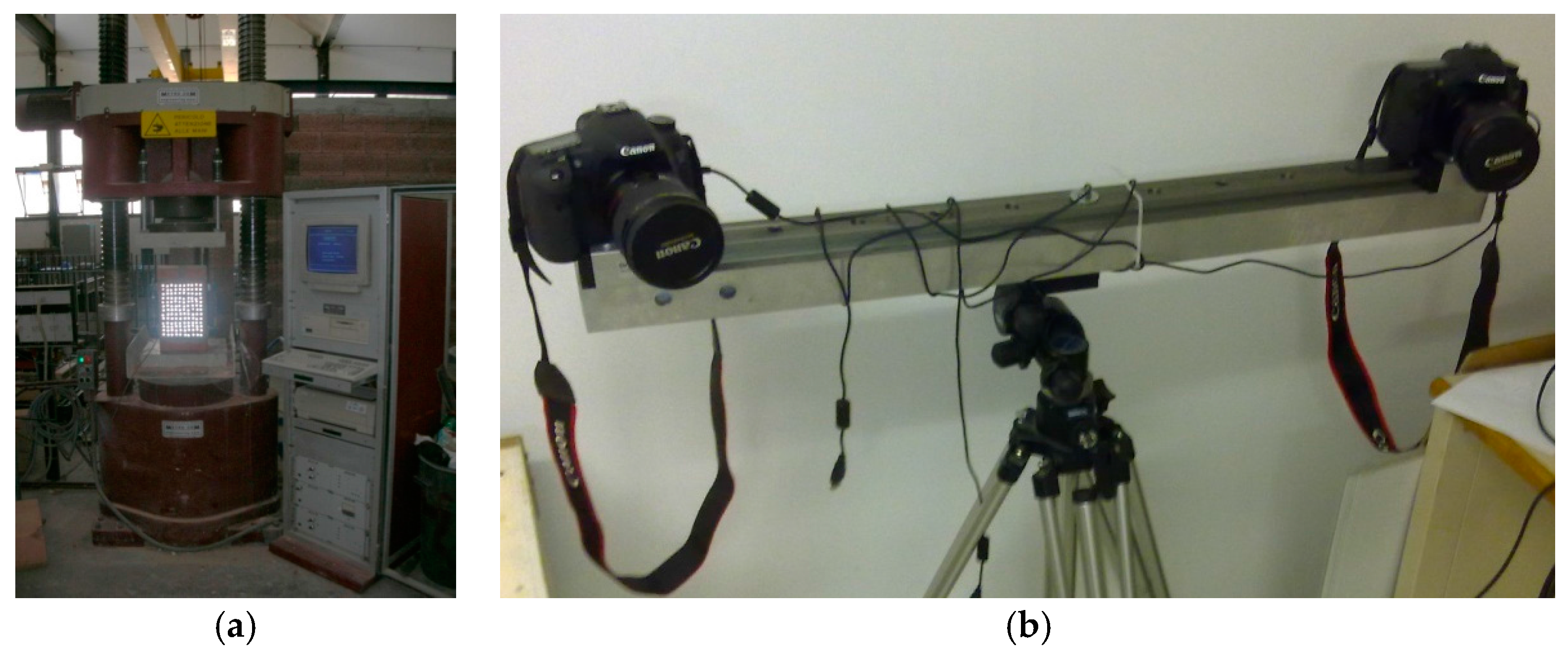

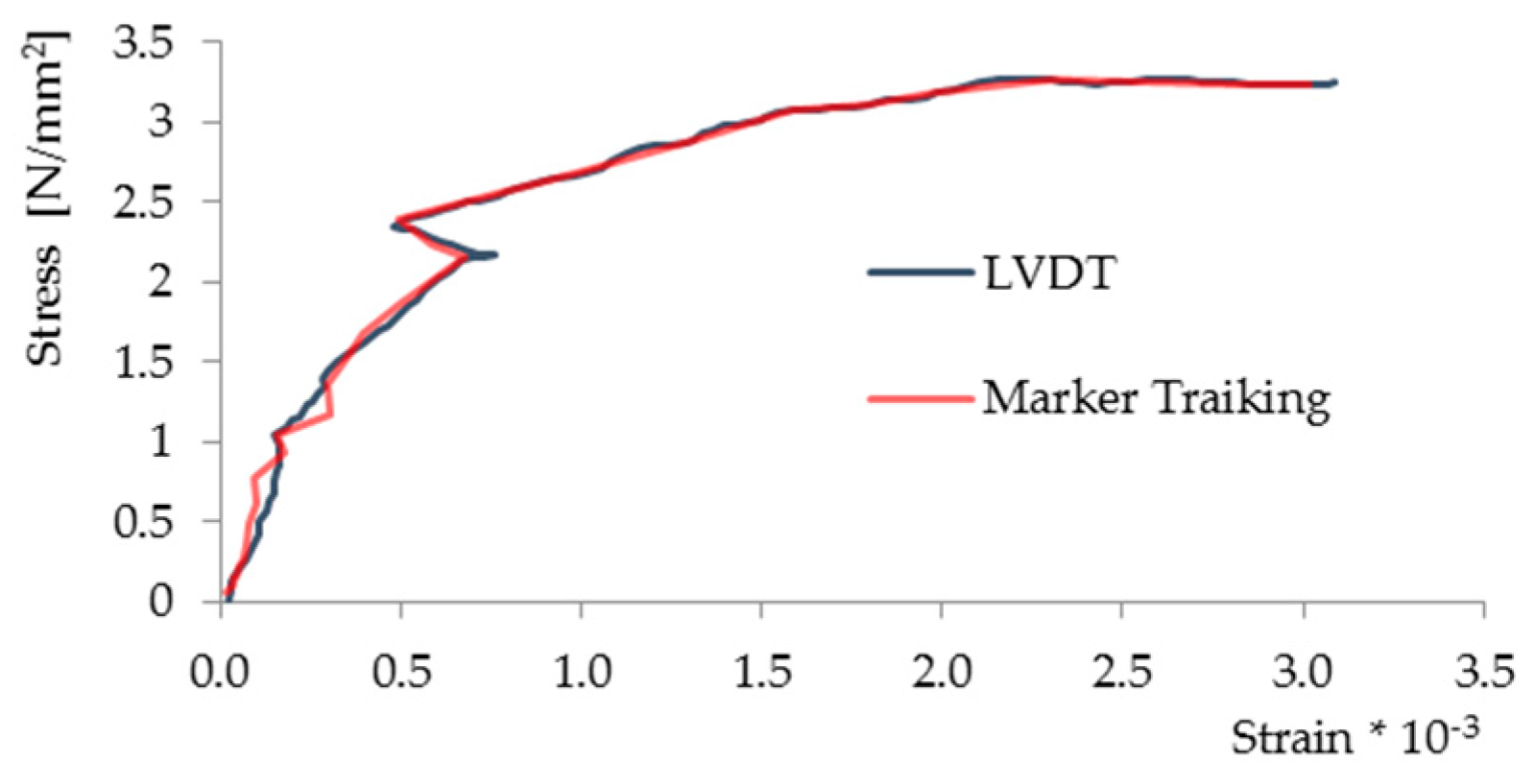

3.2.1. Laboratory Experiments on Masonry Samples

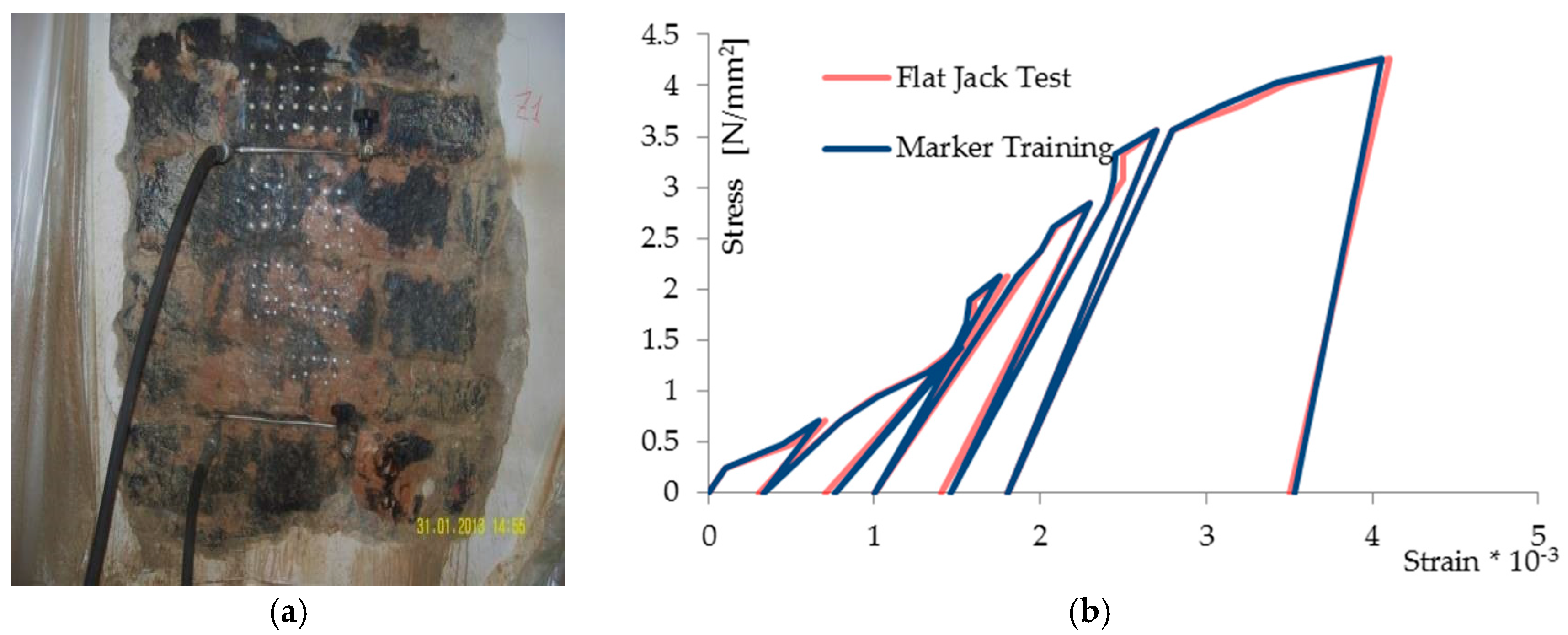

3.2.2. Experiments on Masonry In Situ

4. Reliability of the Measurements and Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Yen, K.S.; Ratnam, M.M. 2-D crack growth measurement using circular grating moiré fringes and pattern matching. Struct. Control Health Monit. 2011, 18, 404–415. [Google Scholar] [CrossRef]

- Aben, H.; Guillement, C. Photoelasticity of Glass; Springer: Berlin, Germany, 1993. [Google Scholar]

- Ferretti, D.; Royer-Carfagni, G.; Rossi, M.; Silvestri, M. An experimental study of crack propagation in glass with the Electronic Speckle Pattern Interferometry. In Proceedings of the International Conference Glass Performance Days, Tampere, Finland, 12–15 June 2009; pp. 208–212. [Google Scholar]

- Zhu, Y.; Shukla, A.; Sadd, M.H. The effect of microstructural fabric on dynamic load transfer in two dimensional assemblies of elliptical particles. J. Mech. Phys. Solids 1996, 44, 1283–1303. [Google Scholar] [CrossRef]

- Bigoni, D.; Noselli, G. Localized stress percolation through dry masonry walls Part I—Modelling. Eur. J. Mech. A Solid 2010, 29, 291–298. [Google Scholar] [CrossRef]

- Bigoni, D.; Noselli, G. Localized stress percolation through dry masonry walls Part II—Experiments. Eur. J. Mech. A Solid 2010, 29, 299–307. [Google Scholar] [CrossRef]

- Chu, T.C.; Ranson, W.F.; Sutton, M.A.; Peters, W.H. Application of digital image correlation techniques to experimental mechanics. Exp. Mech. 1985, 25, 232–244. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.J.; Schreier, H.W. Image Correlation for Shape, Motion and Deformation Measurements. In Basic Concepts, Theory and Applications; Springer Science, Business Media: Berlin, Germany, 2009. [Google Scholar] [CrossRef]

- Foraboschi, P. Structural layout that takes full advantage of the capabilities and opportunities afforded by two-way RC floors, coupled with the selection of the best technique, to avoid serviceability failures. Eng. Fail. Anal. 2016, 70, 387–418. [Google Scholar] [CrossRef]

- Foraboschi, P. Analytical model to predict the lifetime of concrete members externally reinforced with FRP. Theor. Appl. Fract. Mech. 2015, 75, 137–145. [Google Scholar] [CrossRef]

- Lanzoni, L.; Soragni, M.; Tarantino, A.M.; Vivianic, M. Concrete beams stiffened by polymer-based mortar layers: Experimental investigation and modelling. Constr. Build. Mater. 2016, 105, 321–335. [Google Scholar] [CrossRef]

- Corradi, M.; Borri, A.; Castori, G.; Speranzini, E. Fully reversible reinforcement of softwood beams with unbounded composite plates. Compos. Struct. 2016, 149, 54–68. [Google Scholar] [CrossRef]

- Nobili, A.; Lanzoni, L.; Tarantino, A.M. Experimental investigation and monitoring of a polypropylene-based fiber reinforced concrete road pavement. Constr. Build. Mater. 2013, 47, 888–895. [Google Scholar] [CrossRef]

- Bazant, K.P.; Planas, J. Fracture and Size Effect in Concrete and Other Quasi Brittle Materials; CRC Press: Boca Raton, FL, USA, 1997; ISBN 084938284X, 9780849382840. [Google Scholar]

- Speranzini, E.; Agnetti, S. Post-cracking behaviour of reinforced glass beams. In Proceedings of the COST Action TU0905, Mid-Term Conference on Structural Glass, Poreč, Croatia, 18–19 April 2013; ISBN 9781138000445. WOS: 000342677300032, SCOPUS: 2-s2.0-84878794371. [Google Scholar]

- Becchetti, M.; Marsili, R.; Moretti, M.; Rossi, G.L. Mechanical components dynamic characterization using thermoelastic stress analysis and digital image correlation. In Proceedings of Eurodyn 8°. In Proceedings of the International Conference on Structural Dynamics, Leuven, Belgium, 4–6 July 2011; pp. 3537–3543, ISBN 978-90-760-1931-4. [Google Scholar]

- Nobili, A.; Signorini, C. On the effect of curing time and environmental exposure on impregnated Carbon Fabric Reinforced Cementitious Matrix (CFRCM) composite with design considerations. Compos. Part B Eng. 2017, 112, 300–311. [Google Scholar] [CrossRef]

- Ghiassi, B.; Xavier, J.; Oliveira, D.V.; Lourenço, P.B.; Zalac, B. Evaluation of the bond performance in FRP-brick componenets re-bondedafter initial delamination. Compos. Struct. 2015, 123, 271–281. [Google Scholar] [CrossRef]

- Ghiassi, B.; Xavier, J.; Oliveira, D.V.; Lourenço, P.B. Application of digital image correlation in investigating the bond between FRP and masonry. Compos. Struct. 2013, 106, 331–340. [Google Scholar] [CrossRef]

- Garzón-Roca, J.; Sena-Cruz, J.M.; Fernandez, P.; Xavier, J. Effect of wet-dry cycles on the bond behaviour of concrete elements strengthened with NSM CFRP laminate strips. Compos. Struct. 2015, 132, 340–349. [Google Scholar] [CrossRef]

- Speranzini, E.; Agnetti, S.; Corradi, M. Experimental analysis of adhesion phenomena in fibre-reinforced glass structures. Compos. Part B Eng. 2016, 101, 155–166. [Google Scholar] [CrossRef]

- Speranzini, E.; Agnetti, S. The technique of digital image correlation to identify defects in glass structures. Struct. Control Health Monit. 2014, 21, 1015–1029. [Google Scholar] [CrossRef]

- Marsili, R.; Garinei, A. Design of an optical measurement system for dynamic testing. Measurement 2013, 46, 1715–1721. [Google Scholar] [CrossRef]

- Marsili, R.; Garinei, R. Thermoelastic stress analysis of the contact between a flat plate and a cylinder. Measurement 2014, 52, 102–110. [Google Scholar] [CrossRef]

- Colla, C.; Gabrielli, E. Photoelasticity and DIC as optical techniques for monitoringmasonry specimens under mechanical loads. J. Phys. Conf. Ser. 2017, 778, 012003. [Google Scholar] [CrossRef]

- Guerrero, N.; Martínez, M.; Picón, R.; Marante, M.E.; Hild, F.; Roux, S.; Flórez-López, J. Experimental analysis of masonry infilled frames using digital image correlation. Mater. Struct. 2014, 47, 873–884. [Google Scholar] [CrossRef]

- Ghorbani, R.; Matta, F.; Sutton, M.A. Full-Field Deformation Measurement and Crack Mapping on Confined Masonry Walls Using Digital Image Correlation. Exp. Mech. 2015, 55, 227–243. [Google Scholar] [CrossRef]

- Rossi, G.L.; Speranzini, E. Fiber Bragg Grating Strain Sensors for in situ analysis and monitoring of fiber-reinforced Historic Civil Structures. In Vibration Measurements by Laser Techniques 2008; SPIE: Ancona, Italy. [CrossRef]

- Moretti, M.; Rossi, G.L.; Speranzini, E. Structural Integrity Detection of Hystorical Structures by Dynamic Digital Image Correlation. In Proceedings of the 4th International Conference on Experimental Vibration Analysis for Civil Engineering Structures EVACES 2011, Varenna, Italy, 3–5 October 2011. [Google Scholar]

- Albitar, C.; Graebling, P.; Doignon, C. Robust structured light coding for 3D reconstruction. In Proceedings of the 2007 IEEE 11th International Conference on Computer Vision, Rio de Janeiro, Brazil, 14–21 October 2007; pp. 1–6. [Google Scholar] [CrossRef]

- Cardelli, E.; Faba, A.; Marsili, R.; Rossi, G.; Tomassini, R. Magnetic nondestructive testing. J. Appl. Phys. 2015, 117, 17A705. [Google Scholar] [CrossRef]

- Borri, A.; Castori, G.; Corradi, M.; Speranzini, E. Durability analysis for FRP and SRG composites in civil applications. Key Eng. Mater. 2015, 624, 421–428. [Google Scholar] [CrossRef]

- Speranzini, E.; Agnetti, S. Structural performance of natural fibers reinforced timber beams. In Proceedings of the 6th International Conference on FRP Composites in Civil Engineering—CICE2012, Roma, Italy, 13–15 June 2012. Scopus: 2-s2.0-84924402118. [Google Scholar]

- Speranzini, E.; Tralascia, S. Engineered Lumber: LVL and Solid Wood Reinforced with Natural Fibres. In Proceedings of the WCTE 2010—Word Conference on Timber Engineering, Trento, Italy, 20–24 June 2010; pp. 1685–1690, Scopus: 2-s2.0-84870414692. [Google Scholar]

- Borri, A.; Corradi, M.; Speranzini, E. Bending tests on natural fiber reinforced fir wooden elements. Adv. Mater. Res. 2013, 778, 537–544. [Google Scholar] [CrossRef]

| Characteristic | Marker Tracking | Digital Image Correlation | ||

|---|---|---|---|---|

| Resolution | 1 pixel | 1/100 pixel | ||

| Surface preparation | High contrast target, stickers | High contrast speckle, area of interest must be painted | ||

| Sensitivity to environmental variables, light | Poor | High | ||

| Sensitivity to repositioning | 2D | Very high (it is not possible to correct changes in perspective | 2D | Very high (it is not possible to correct changes in perspective |

| 3D | Poor (the stereo camera can be “recalibrated” provided that the angle of perspective does not change too much) | 3D | Poor (the stereo camera can be “recalibrated” provided that the angle of perspective does not change too much) | |

| Calculation time | Very rapid calculation | Calculation speed depends on the desired spatial resolution | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Speranzini, E.; Marsili, R.; Moretti, M.; Rossi, G. Image Analysis Technique for Material Behavior Evaluation in Civil Structures. Materials 2017, 10, 770. https://doi.org/10.3390/ma10070770

Speranzini E, Marsili R, Moretti M, Rossi G. Image Analysis Technique for Material Behavior Evaluation in Civil Structures. Materials. 2017; 10(7):770. https://doi.org/10.3390/ma10070770

Chicago/Turabian StyleSperanzini, Emanuela, Roberto Marsili, Michele Moretti, and Gianluca Rossi. 2017. "Image Analysis Technique for Material Behavior Evaluation in Civil Structures" Materials 10, no. 7: 770. https://doi.org/10.3390/ma10070770