A Novel Method for Fabricating Wearable, Piezoresistive, and Pressure Sensors Based on Modified-Graphite/Polyurethane Composite Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Surface Modification of Graphite

2.3. Fabrication of Composite Films

2.4. Testing Properties

2.4.1. Particle Size Analysis

2.4.2. Fourier Transform Infrared Spectroscopy

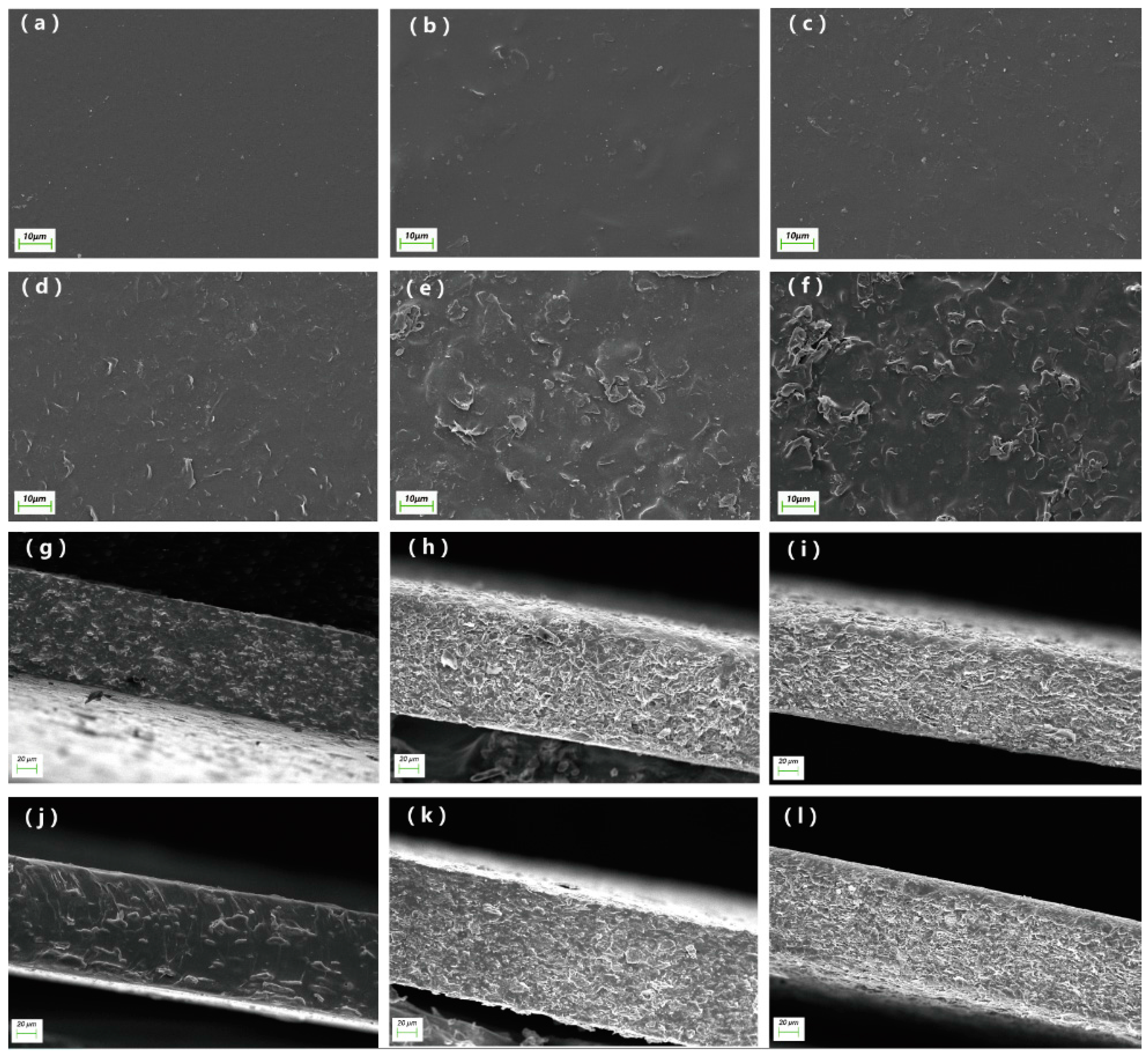

2.4.3. Morphological Analysis

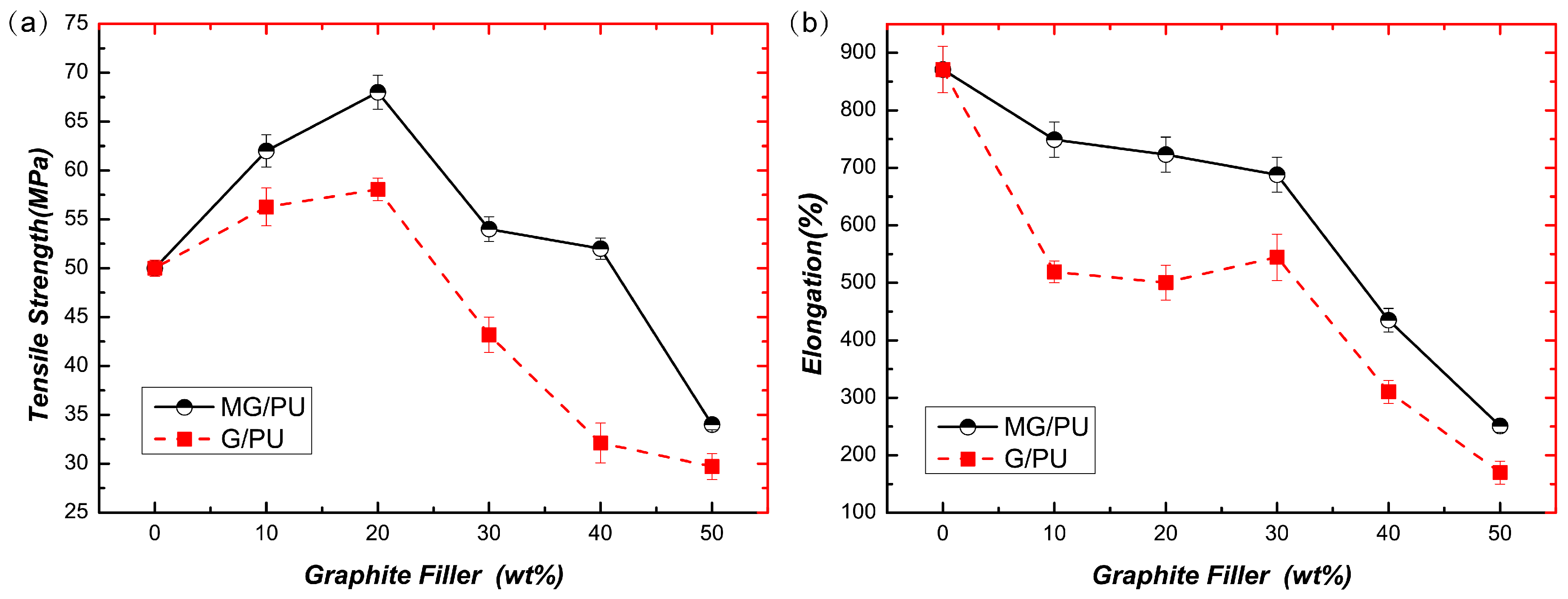

2.4.4. Mechanical Properties Analysis

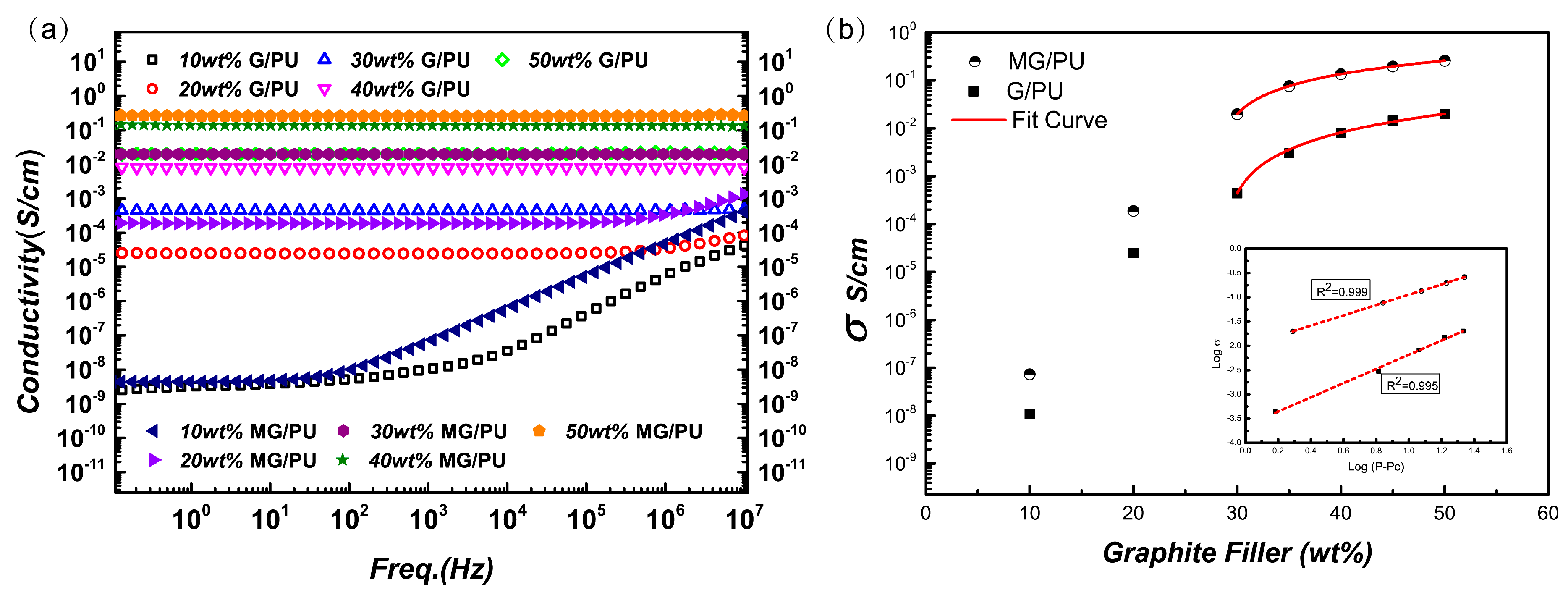

2.4.5. Electrical Characterization

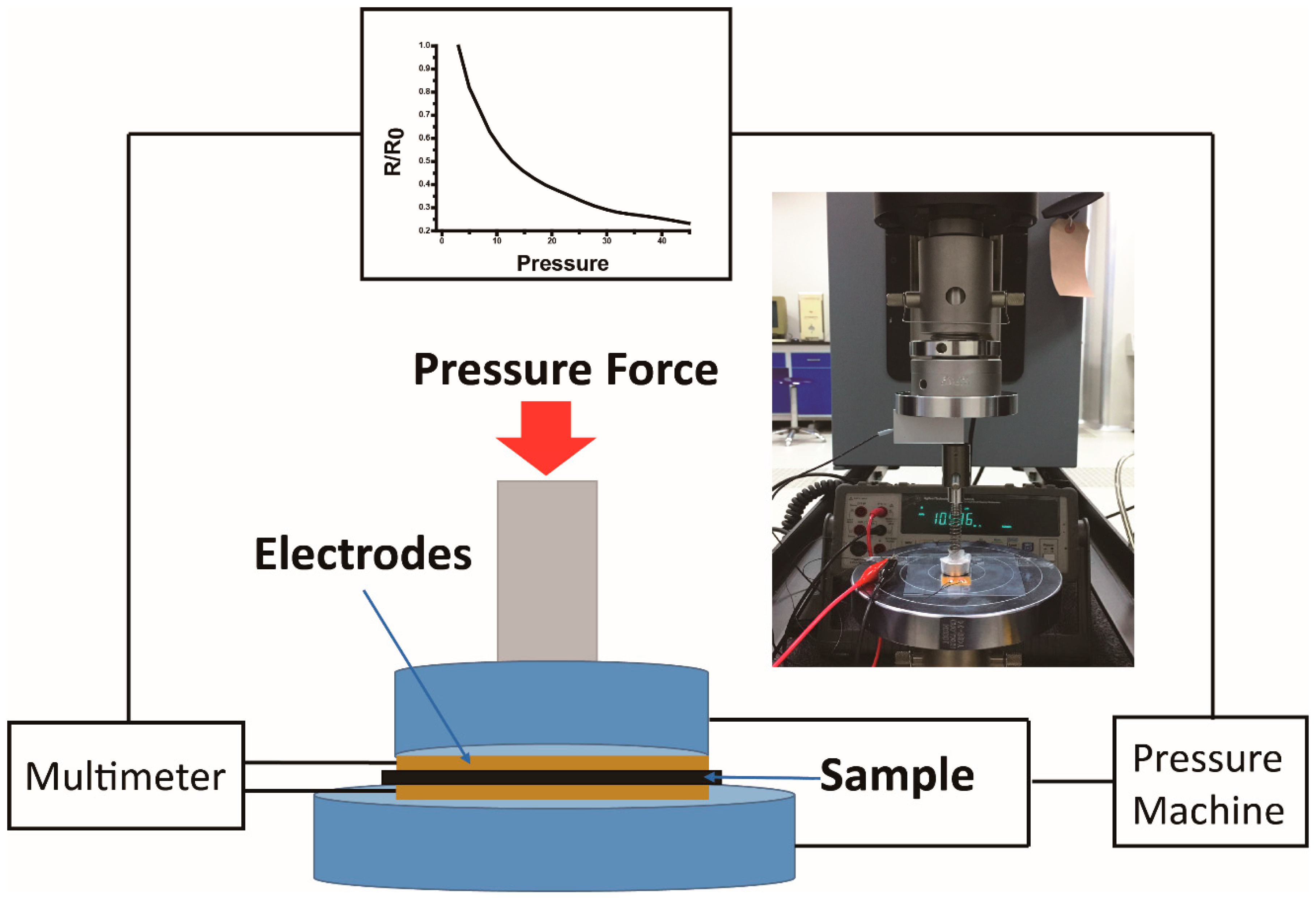

2.4.6. Pressure-Sensing Behavior of the Composite Films

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, W.; Zhu, Z. Flexible Actuators. In Handbook of Smart Textiles; Tao, X.M., Ed.; Springer: Singapore; New York, NY, USA, 2015; pp. 381–4110. [Google Scholar]

- Deng, H.; Skipa, T.; Bilotti, E.; Zhang, R.; Lellinger, D.; Mezzo, L.; Fu, Q.; Alig, I.; Peijs, T. Preparation of High-Performance Conductive Polymer Fibers through Morphological Control of Networks Formed by Nanofillers. Adv. Funct. Mater. 2010, 20, 1424–1432. [Google Scholar] [CrossRef]

- Zang, Y.P.; Zhang, F.J.; Di, C.A.; Zhu, D.B. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2015, 2, 140–156. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, N.S.; Shi, Y.L.; Liu, W.J.; Yue, Y.; Wang, S.L.; Ma, Y.N.; Wen, L.; Li, L.Y.; Long, F.; et al. Piezoresistive Sensor with High Elasticity Based on 3D Hybrid Network of Sponge@CNTs@Ag NPs. ACS Appl. Mater. Interfaces 2016, 8, 22374–22381. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhu, L.L.; He, Y.; Cheng, B.W. A novel method for fabricating elastic conductive polyurethane filaments by in-situ reduction of polydopamine and electroless silver plating. Mater. Des. 2017, 113, 254–263. [Google Scholar] [CrossRef]

- Sepúlveda, A.T. Flexible Pressure Sensors: Modeling and Experimental Characterization. Procedia Eng. 2012, 47, 1177–1180. [Google Scholar] [CrossRef]

- Haniff, M.A.S.M.; Hafiz, S.M.; Wahid, K.A.A.; Endut, Z.; Wah Lee, H.; Bien, D.C.S.; Azid, I.A.; Abdullah, M.Z.; Huang, N.M.; Rahman, S.A. Piezoresistive effects in controllable defective HFTCVD graphene-based flexible pressure sensor. Sci. Rep. 2015, 5, 14751. [Google Scholar] [CrossRef] [PubMed]

- Bai, X.; Wan, C.; Zhang, Y.; Zhai, Y. Reinforcement of hydrogenated carboxylated nitrile-butadiene rubber with exfoliated graphene oxide. Carbon 2011, 49, 1608–1613. [Google Scholar] [CrossRef]

- Al-solamy, F.R.; Al-Ghamdi, A.A.; Mahmoud, W.E. Piezoresistive behavior of graphite nanoplatelets based rubber nanocomposites. Polym. Adv. Technol. 2012, 23, 478–482. [Google Scholar] [CrossRef]

- Yang, J.; Tian, M.; Jia, Q.; Shi, J.; Zhang, L.; Lim, S.; Yu, Z.; Mai, Y. Improved mechanical and functional properties of elastomer/graphite nanocomposites. Acta Mater. 2007, 55, 6372–6382. [Google Scholar] [CrossRef]

- Chen, L.; Lu, L.; Wu, D.J.; Chen, G.H. Silicone rubber/graphite nanosheet electrically conducting nanocomposite with a low percolation threshold. Polym. Compos. 2007, 28, 493–498. [Google Scholar] [CrossRef]

- Song, S.H.; Jeong, H.K.; Kang, Y.G. Preparation and characterization of exfoliated graphite and its styrene butadiene rubber nanocomposites. J. Ind. Eng. Chem. 2010, 16, 1059–1065. [Google Scholar] [CrossRef]

- Ozbas, B.; O’Neill, C.D.; Register, R.A.; Aksay, L.A.; Prud’homme, R.K.; Adamson, D.H. Multifunctional elastomer nanocomposites with functionalized graphene single sheets. J. Polym. Sci. Part B 2012, 50, 910–916. [Google Scholar] [CrossRef]

- Ismail, M.N.; Khalaf, A.I. Styrene–butadiene rubber/graphite powder composites: Rheometrical, physicomechanical, and morphological properties. J. Appl. Polym. Sci. 2011, 120, 298–304. [Google Scholar] [CrossRef]

- Kujawski, M.; Pearse, J.D.; Smela, E. Elastomers filled with exfoliated graphite as compliant electrodes. Carbon 2010, 48, 2409–2417. [Google Scholar] [CrossRef]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- Lozano-Pérez, C.; Cauich-Rodríguez, J.V.; Avilés, F. Influence of rigid segment and carbon nanotube concentration on the cyclic piezoresistive and hysteretic behavior of multiwall carbon nanotube/segmented polyurethane composites. Compos. Sci. Technol. 2016, 128, 25–32. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, H.L.; Yao, G.; Liao, F.Y.; Gao, M.; Huang, Z.L.; Li, K.Y.; Lin, Y. Highly stretchable, sensitive, and flexible strain sensors based on silver nanoparticles/carbon nanotubes composites. J. Alloys Compd. 2015, 652, 48–54. [Google Scholar] [CrossRef]

- Yao, H.B.; Ge, J.; Wang, C.F.; Wang, X.; Hu, W.; Zheng, Z.J.; Ni, Y.; Yu, S.H. A Flexible and Highly Pressure-Sensitive Graphene-Polyurethane Sponge Based on Fractured Microstructure Design. Adv. Mater. 2013, 25, 6692–6698. [Google Scholar] [CrossRef] [PubMed]

- Yi, W.J.; Wang, Y.Y.; Wang, G.F.; Tao, X.M. Investigation of carbon black/silicone elastomer/dimethylsilicone oil composites for flexible strain sensors. Polym. Test. 2012, 31, 677–684. [Google Scholar] [CrossRef]

- Chen, L.; Chen, G.H.; Lu, L. Piezoresistive Behavior Study on Finger-Sensing Silicone Rubber/Graphite Nanosheet Nanocomposites. Adv. Funct. Mater. 2007, 17, 898–904. [Google Scholar] [CrossRef]

- Luo, S.D.; Liu, T. Graphite Nanoplatelet Enabled Embeddable Fiber Sensor for in Situ Curing Monitoring and Structural Health Monitoring of Polymeric Composites. ACS Appl. Mater. Interfaces 2014, 6, 9314–9320. [Google Scholar] [CrossRef] [PubMed]

- Oliva-Avilés, A.I.; Avilés, F.; Sosa, V. Electrical and piezoresistive properties of multi-walled carbon nanotube/polymer composite films aligned by an electric field. Carbon 2011, 49, 2989–2997. [Google Scholar] [CrossRef]

- Kwon, D.; Lee, T.I.; Shim, J.; Ryu, S.; Kim, M.S.; Kim, S.; Kim, T.S.; Park, I. Highly Sensitive, Flexible, and Wearable Pressure Sensor Based on a Giant Piezocapacitive Effect of Three-Dimensional Microporous Elastomeric Dielectric Layer. ACS Appl. Mater. Interfaces 2016, 8, 16922–16931. [Google Scholar] [CrossRef] [PubMed]

- Dolleman, R.J.; Davidovik, D.; Cartamil-Bueno, S.J.; van der Zan, H.S.J.; Steeneken, P.G. Graphene Squeeze-Film Pressure Sensors. Nano Lett. 2016, 16, 568–571. [Google Scholar] [CrossRef] [PubMed]

- Kishor, K.S.; Deepalekshmi, P.; Sabu, T.; Yves, G. Evolution from graphite to graphene elastomer composites. Prog. Polym. Sci. 2014, 39, 749–780. [Google Scholar]

- Bulut Coskun, M.; Akbari, A.; Lai, D.T.H.; Neild, A.; Majumder, M.; Alan, T. Ultrasensitive Strain Sensor Produced by Direct Patterning of Liquid Crystals of Graphene Oxide on a Flexible Substrate. ACS Appl. Mater. Interfaces 2016, 8, 22501–22505. [Google Scholar] [CrossRef] [PubMed]

- Fernandez-d’Arlas, B.; Corcuera, M.A.; Eceiza, A. Comparison between exfoliated graphite, graphene oxide and multiwalled carbon nanotubes as reinforcing agents of a polyurethane elastomer. J. Thermoplast. Compos. 2015, 28, 705–716. [Google Scholar] [CrossRef]

- Gómez, C.M.; Culebras, M.; Cantarero, A. An experimental study of dynamic behaviour of graphite-polycarbonatediol polyurethane composites for protective coatings. Appl. Surf. Sci. 2013, 275, 295–302. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Wu, Z. The fabrication and properties of a graphite nanosheet/polystyrene composite based on graphite nanosheets treated with supercritical water. Compos. Sci. Technol. 2015, 112, 50–57. [Google Scholar] [CrossRef]

- Chung, Y.C.; Khiem, N.D.; Chun, B.C. Characterization of a polyurethane copolymer covalently linked to graphite and the influence of graphite on electric conductivity. J. Compos. Mater. 2015, 49, 1689–1703. [Google Scholar] [CrossRef]

- Rubinger, C.P.L.; Leyva, M.E.; Soares, B.G.; Ribeiro, G.M.; Rubinger, R.M. Hopping conduction on carbon black/styrene-butadiene-styrene composites. J. Mater. Sci. 2012, 47, 860–865. [Google Scholar] [CrossRef]

- Duan, L.; Fu, S.; Deng, H.; Zhang, Q.; Wang, K.; Chen, F.; Fu, Q.J. The resistivity–strain behavior of conductive polymer composites: Stability and sensitivity. Mater. Chem. A 2014, 2, 17085–17098. [Google Scholar] [CrossRef]

- Aharony, A.; Stauffer, D. Introduction to Percolation Theory, 2nd ed.; Taylor and Francis: London, UK, 1993. [Google Scholar]

- Redondo-Foj, B.; Ortiz-Serna, P.; Carsí, M.; Sanchis, M.J.; Culebras, M.; Gómez, C.M.; Cantarero, A. Electrical conductivity properties of expanded graphite-polycarbonatediol polyurethane composites. Polym. Int. 2015, 64, 284–292. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Wang, X.F.; Mohammad, M.A.; Bie, Z.; Xie, Q.Y.; Li, C.; Mi, W.T.; Yang, Y.; Ren, T.L. Graphene-Based Resistive Pressure Sensor with Record-High Sensitivity in a Wide Pressure Range. Sci. Rep. 2015, 5, 8603. [Google Scholar] [CrossRef] [PubMed]

- Quan, Y.; Wei, X.B.; Xiao, L.; Wu, T.; Pang, H.Y.; Liu, T.F.; Huang, W.; Wu, S.H.; Li, S.B.; Chen, Z. Highly sensitive and stable flexible pressure sensors with micro-structured electrodes. J. Alloys Compd. 2017, 699, 827–831. [Google Scholar] [CrossRef]

- Wang, Z.R.; Wang, S.; Zeng, J.F.; Ren, X.C.; Chee, A.J.Y.; Yiu, B.Y.S.; Chung, W.C.; Yang, Y.; Yu, A.C.H.; Roberts, R.C.; et al. High Sensitivity, Wearable, Piezoresistive Pressure Sensors Based on Irregular Microhump Structures and Its Applications in Body Motion Sensing. Small 2016, 12, 3827–3836. [Google Scholar] [CrossRef] [PubMed]

- Sengupta, R.; Bhattacharya, M.; Bandyopadhyay, S.; Bhowmick, A.K. A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog. Polym. Sci. 2011, 36, 638–670. [Google Scholar] [CrossRef]

| Sample Name | Polyurethane (g) | Modified Graphite (g) | Filler Content by Weight (wt %) |

|---|---|---|---|

| Pure PU | 4.8 | – | 0 |

| 10 wt % MG/PU | 4.8 | 0.53 | 10 |

| 20 wt % MG/PU | 4.8 | 1.2 | 20 |

| 30 wt % MG/PU | 4.8 | 2.1 | 30 |

| 40 wt % MG/PU | 4.8 | 3.2 | 40 |

| 50 wt % MG/PU | 4.8 | 4.8 | 50 |

| Modified Graphite Content (wt %) | 0 | 10 | 20 | 30 | 40 | 50 |

|---|---|---|---|---|---|---|

| Thickness (mm) | 0.096 | 0.105 | 0.110 | 0.128 | 0.135 | 0.151 |

| Coefficient of Variation (%) | 0.10 | 0.11 | 0.06 | 0.06 | 0.06 | 0.09 |

| Experiments | Before Settlement (a) | After 12 h Settlement (b) | ||||||

|---|---|---|---|---|---|---|---|---|

| Graphite | Modified Graphite | Graphite | Modified Graphite | |||||

| Diameter | Std. Dev. | Diameter | Std. Dev. | Diameter | Std. Dev. | Diameter | Std. Dev. | |

| 1st | 21,203 | 899.1 | 3443.5 | 27.8 | 53,500 | 1896.6 | 6924.3 | 122.3 |

| 2nd | 19,422 | 881.9 | 3924.3 | 37.5 | 53,274 | 1902.7 | 6543.7 | 97.9 |

| Mean Size | 20,312.5 | 890.5 | 3683.5 | 32.65 | 53,387 | 1899.65 | 6734 | 110.1 |

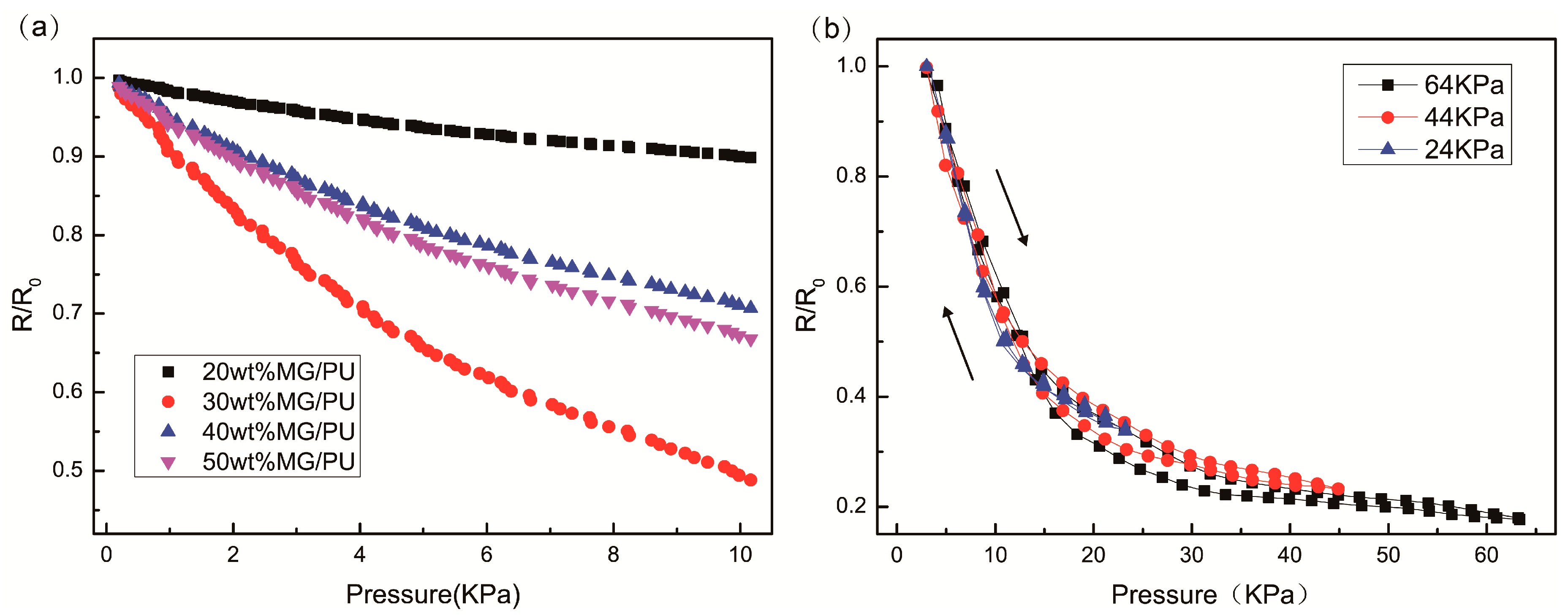

| Types of MG/PU Composites | Corresponding Pressure | |||

|---|---|---|---|---|

| 0–0.2 KPa | 0.2–1 KPa | 1–5 KPa | 5–10 KPa | |

| 20 wt % MG/PU | 0.047 | 0.016 | 0.012 | 0.007 |

| 30 wt % MG/PU | 0.274 | 0.091 | 0.063 | 0.031 |

| 40 wt % MG/PU | 0.149 | 0.050 | 0.035 | 0.019 |

| 50 wt % MG/PU | 0.163 | 0.054 | 0.039 | 0.022 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Li, W.; Yang, G.; Liu, H.; Lu, J.; Zheng, T.; Li, X. A Novel Method for Fabricating Wearable, Piezoresistive, and Pressure Sensors Based on Modified-Graphite/Polyurethane Composite Films. Materials 2017, 10, 684. https://doi.org/10.3390/ma10070684

He Y, Li W, Yang G, Liu H, Lu J, Zheng T, Li X. A Novel Method for Fabricating Wearable, Piezoresistive, and Pressure Sensors Based on Modified-Graphite/Polyurethane Composite Films. Materials. 2017; 10(7):684. https://doi.org/10.3390/ma10070684

Chicago/Turabian StyleHe, Yin, Wei Li, Guilin Yang, Hao Liu, Junyu Lu, Tongtong Zheng, and Xiaojiu Li. 2017. "A Novel Method for Fabricating Wearable, Piezoresistive, and Pressure Sensors Based on Modified-Graphite/Polyurethane Composite Films" Materials 10, no. 7: 684. https://doi.org/10.3390/ma10070684