The Synthesis of the Core/Shell Structured Diamond/Akageneite Hybrid Particles with Enhanced Polishing Performance

Abstract

:1. Introduction

2. Experimental Section

2.1. Synthesis of Diamond/Akageneite Hybrid Particles

2.2. Polishing Setup and Process Control

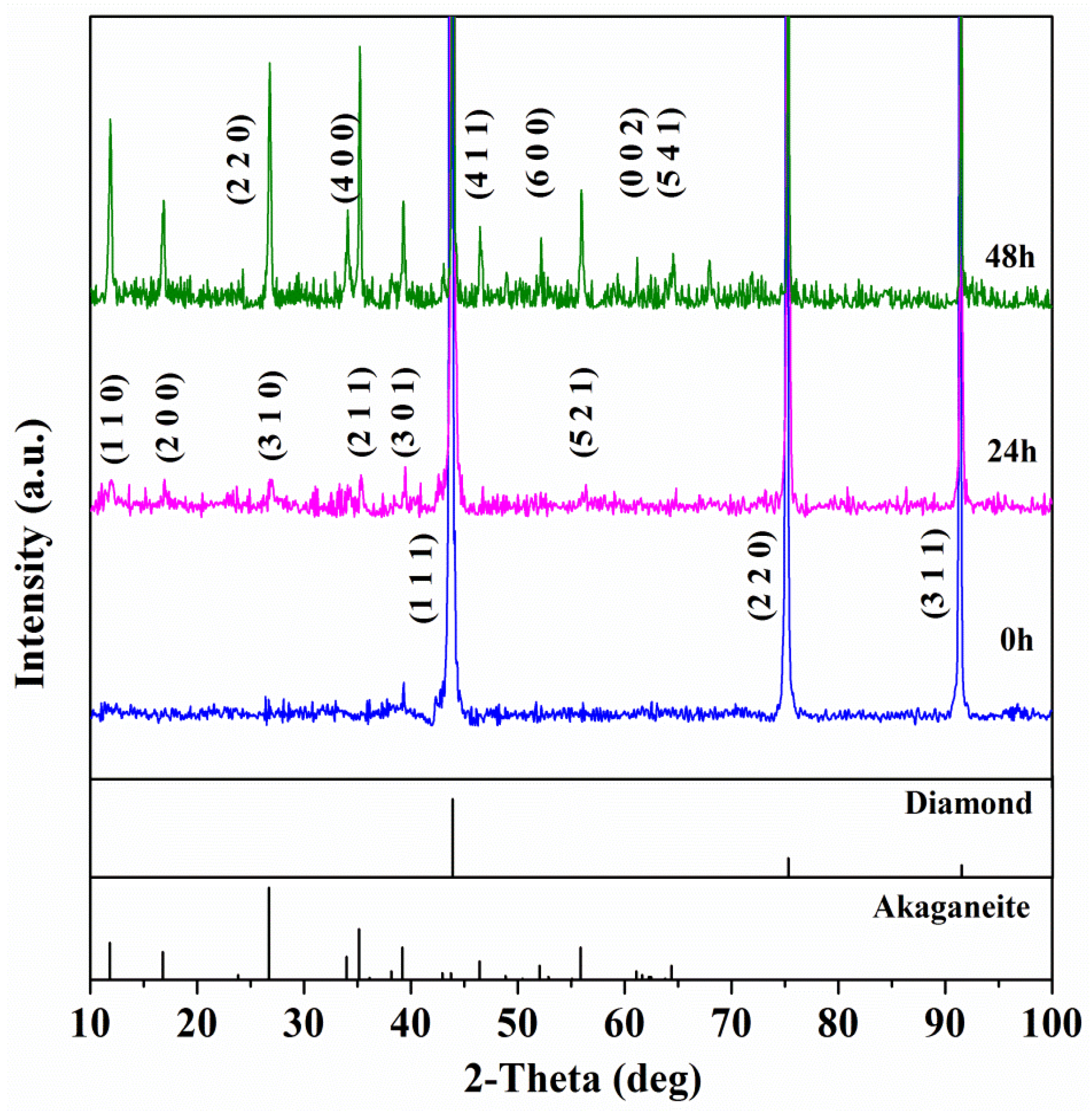

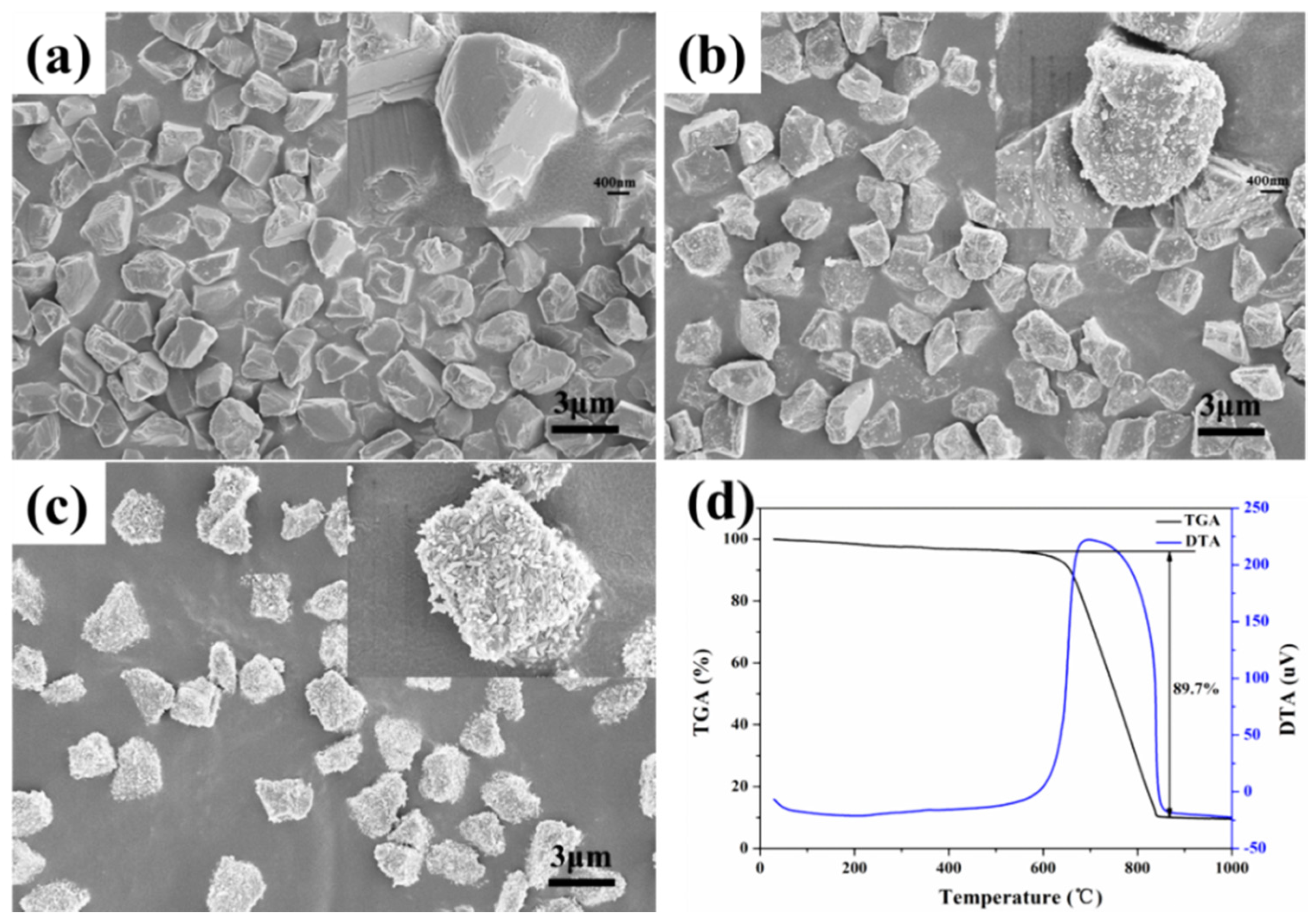

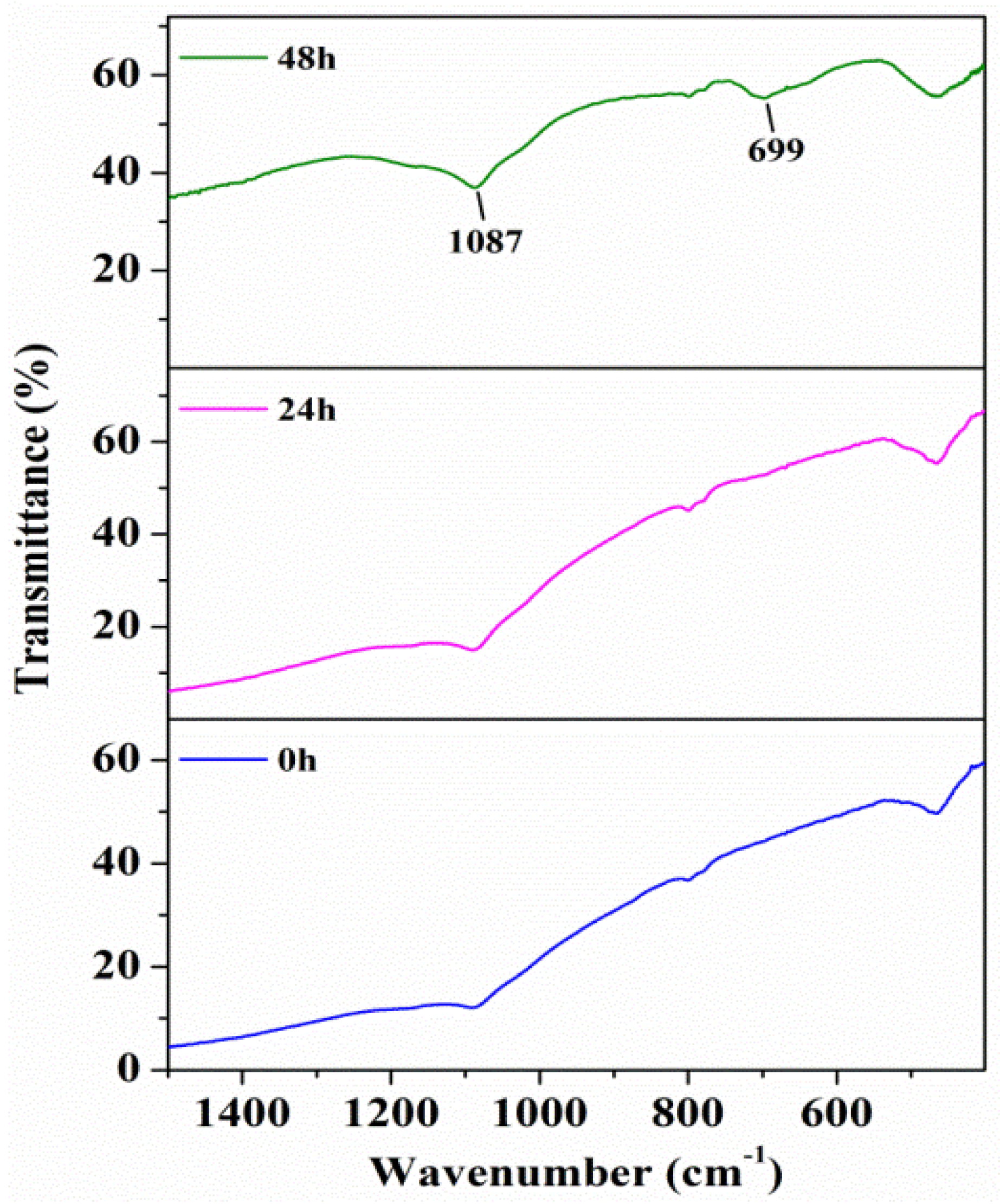

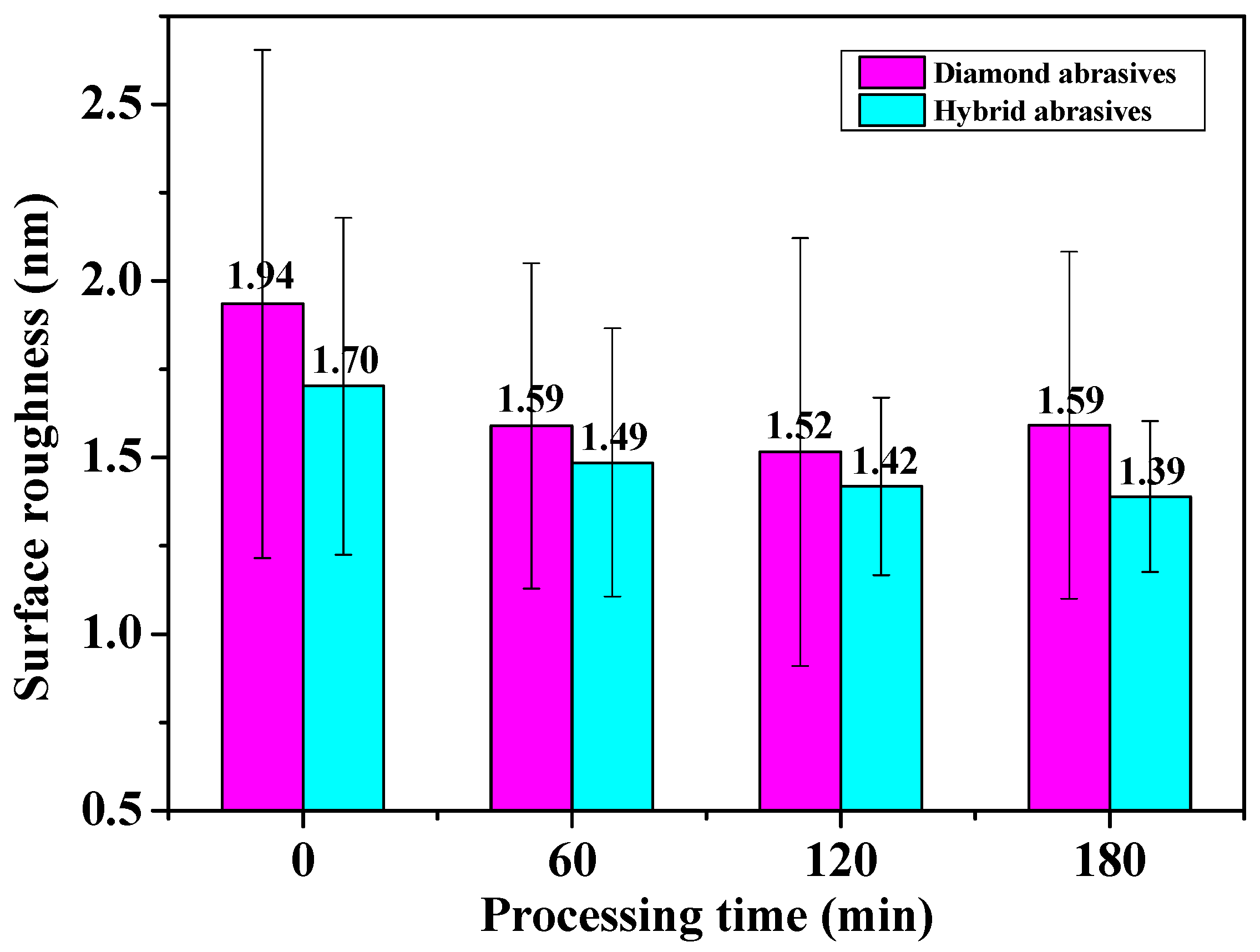

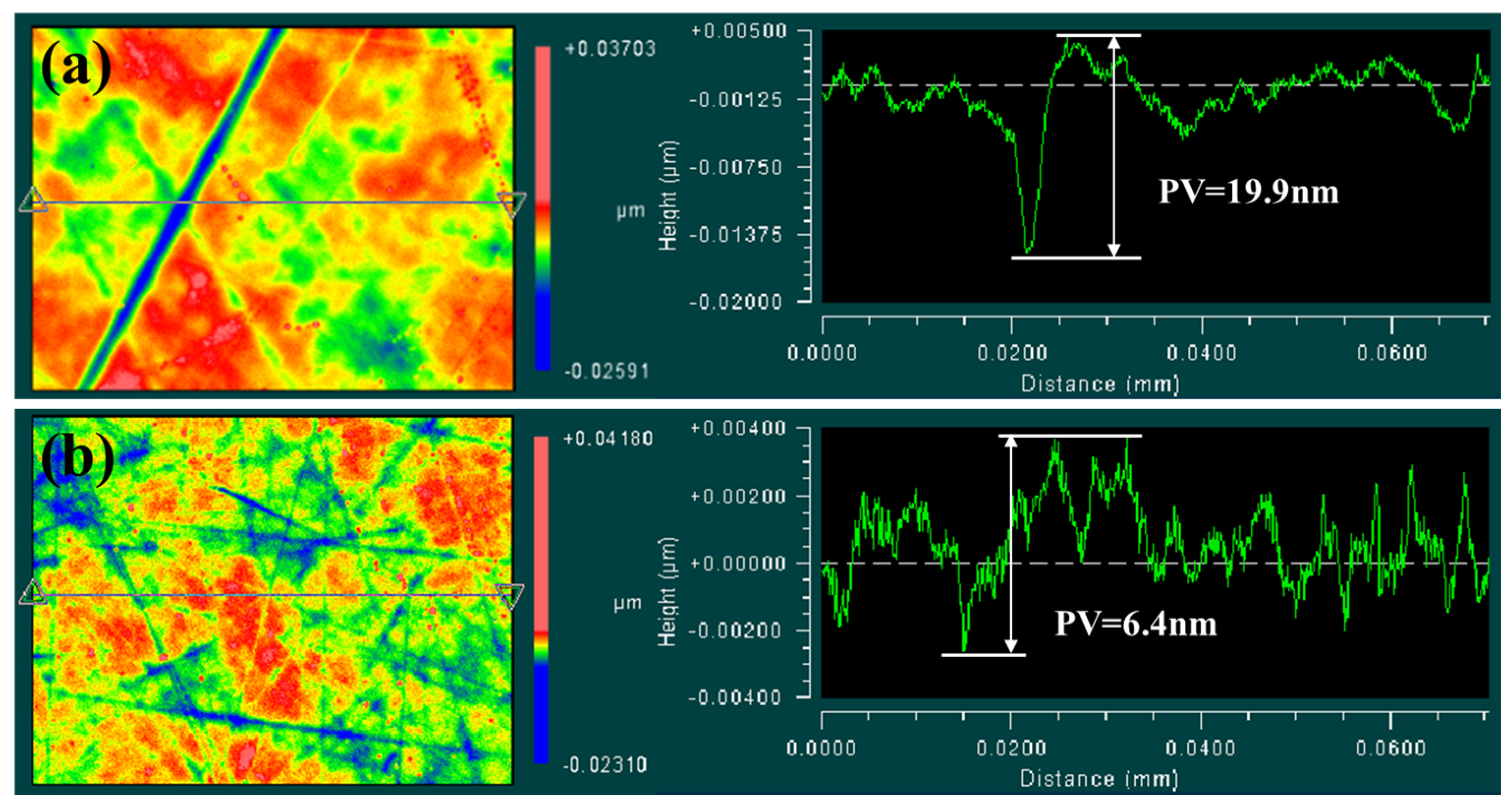

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bhattacharya, M.; Deyb, A.; Mukhopadhyay, A.K. Influence of loading rate on nanohardness of sapphire. Ceram. Int. 2016, 42, 13378–13386. [Google Scholar] [CrossRef]

- Lan, X.D.; Zhang, S.Y.; Fan, L.; Wang, Y. Simulation of SAW humidity sensors based on (1 1 2 0) ZnO/R-sapphire structures. Sensors 2016, 16, 1112. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.H.; Hu, Z.F.; Li, B.; Wang, H.L.; Peng, Y.F.; Zhou, D.Z.; Zhang, X.Q. High-quality ZnO thin film grown on sapphire by hydrothermal method. Mater. Lett. 2015, 161, 565–567. [Google Scholar] [CrossRef]

- Alombert-Goget, G.; Li, H.; Guyot, Y.; Brenier, A.; Lebbou, K. Luminescence and coloration of undoped and Ti-doped sapphire crystals grown by Czochralski technique. J. Lumin. 2016, 169, 516–519. [Google Scholar] [CrossRef]

- Liu, T.T.; Lei, H. Nd3+-doped colloidal SiO2 composite abrasives: Synthesis and the effects on chemical mechanical polishing (CMP) performances of sapphire wafers. Appl. Surf. Sci. 2017, 413, 16–26. [Google Scholar] [CrossRef]

- Shi, G.S.; Pan, Y.; Zhou, L.; Xu, C.L. A study of chemical products formed on sapphire (0 0 0 1) during chemical-mechanical polishing. Surf. Coat. Technol. 2015, 270, 206–220. [Google Scholar] [CrossRef]

- Kumar, P.; Lee, J.; Lee, G.; Rao, S.; Singh, D.; Singh, R.K. Low temperature wet etching to reveal sub-surface damage in sapphire substrates. Appl. Surf. Sci. 2013, 273, 58–61. [Google Scholar] [CrossRef]

- Zhou, S.J.; Liu, S. Study on sapphire removal for thin-film LEDs fabricationusing CMP and dry etching. Appl. Surf. Sci. 2009, 255, 9469–9473. [Google Scholar] [CrossRef]

- Yang, M.; Lin, Z.J.; Zhao, J.T.; Wang, Y.T.; Li, Z.Y.; Lv, Y.J.; Feng, Z.H. Influence of sapphire substrate thickness on the characteristics of AlGaN/AlN/GaN heterostructure field-effect transistors. Superlattices Microstruct. 2015, 85, 43–49. [Google Scholar] [CrossRef]

- Zhou, Y.; Pan, G.S.; Shi, X.L.; Zhang, S.M.; Gong, H.; Luo, G.H. Effects of ultra-smooth surface atomic step morphology on chemical mechanical polishing (CMP) performances of sapphire and SiC wafers. Tribol. Int. 2015, 87, 145–150. [Google Scholar] [CrossRef]

- Xu, X.P.; Liu, J.; Yu, Y.Q.; Lu, J. Fabrication and application of Gel-bonded abrasive tools for grinding and polishing tools. J. Mech. Eng. 2013, 40, 156–162. [Google Scholar] [CrossRef]

- Xu, Y.C.; Lu, J.; Xu, X.P. Study on planarization machining of sapphire wafer with soft-hard mixed abrasive through mechanical chemical polishing. Appl. Surf. Sci. 2016, 389, 713–720. [Google Scholar] [CrossRef]

- Luo, Q.F.; Lu, J.; Xu, X.P. A comparative study on the material removal mechanisms of 6H-SiC polished by semi-fixed and fixed diamond abrasive tools. Wear 2016, 350–351, 99–106. [Google Scholar] [CrossRef]

- Xu, Y.C.; Lu, J.; Xu, X.P. The Research of reactivity between nano-abrasives and sapphire during polishing process. Integr. Ferroelectr. 2015, 159, 41–48. [Google Scholar] [CrossRef]

- Lu, J.; Li, Y.; Xu, X.P. The effects of abrasive yielding on the polishing of SiC wafers using a semi-fixed flexible pad. Proc. Inst. Mech. Eng. B J. Eng. 2015, 229, 170–177. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.N.; Miao, N.M. Polymethylmethacrylate (PMMA)/CeO2 hybrid particles for enhanced chemical mechanical polishing performance. Tribol. Int. 2015, 82, 211–217. [Google Scholar] [CrossRef]

- Pan, G.S.; Gu, Z.H.; Zhou, Y.; Li, T.; Gong, H.; Liu, Y. Preparation of silane modified SiO2 abrasive particles and their Chemical Mechanical Polishing (CMP) performances. Wear 2011, 273, 100–104. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Yu, L.; Liu, W.L.; Song, Z.T. Surface modification of ceria nanoparticles and their chemical mechanical polishing behavior on glass substrate. Appl. Surf. Sci. 2010, 256, 3856–3861. [Google Scholar] [CrossRef]

- Chen, Y.; Mu, W.; Lu, J. Young’s modulus of PS/CeO2 composite with core/shell structure microspheres measured using atomic force microscopy. J. Nanopart. Res. 2012, 14, 696. [Google Scholar] [CrossRef]

- Peng, S.M.; Yu, L.; Sun, M.; Cheng, G.; Lin, T.; Mo, Y.D.; Li, Z.S. Bunched akaganeite nanorod arrays: Preparation and highperformance for flexible lithium-ion batteries. J. Power Sources 2015, 296, 237–244. [Google Scholar] [CrossRef]

- Musić, S.; Krehula, S.; Popović, S. Effect of HCl additions on forced hydrolysis of FeCl3 solutions. Mater. Lett. 2004, 58, 2640–2645. [Google Scholar] [CrossRef]

- Han, C.L.; Xie, C.; Wang, R.L.; Deng, C.H.; Zhao, P.P. Glucose assisted synthesis of the BiOCl/β-FeOOH composite with enhanced photocatalytic performance. Mater. Lett. 2016, 181, 16–20. [Google Scholar] [CrossRef]

- Villalba, J.C.; Berezoski, S.; Cavicchiolli, K.A.; Galvani, V.; Anaissi, F.J. Structural refinement and morphology of synthetic akaganèite crystals, [β-FeO(OH)]. Mater. Lett. 2013, 104, 17–20. [Google Scholar] [CrossRef]

- Lu, J.; Zang, J.B.; Shan, S.X.; Huang, H.; Wang, Y.H. Synthesis and characterization of core-shell structural MWNT-zirconia nanocomposites. Nano. Lett. 2008, 8, 4070–4074. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Zang, J.B.; Wang, Y.H.; Xu, Y.C.; Xu, X.P. Preparation and characterization of Zirconia-coated nanodiamonds as a Pt catalyst support for methanol electro-oxidation. Nanomaterials 2016, 6, 234. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Xu, Z.; Liang, J.; Zhou, L.; Zhang, C. Potential application of novel TiO2/β-FeOOH composites for photocatalytic reduction of Cr(VI) with an analysis of statistical approach. Int. J. Environ. Sci. Technol. 2015, 12, 1669–1676. [Google Scholar] [CrossRef]

- Xiao, F.; Lia, W.T.; Fang, L.P.; Wang, D.S. Synthesis of akageneite (beta-FeOOH)/reduced graphene oxide nanocomposites for oxidative decomposition of 2-chlorophenol by Fenton-like reaction. J. Hazard. Mater. 2016, 308, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.C.; Zhao, Y.W.; Wang, Y.G. Modeling the effects of particle deformation in chemical mechanical polishing. Appl. Surf. Sci. 2012, 258, 8469–8474. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Xu, Y.; Zhang, D.; Xu, X. The Synthesis of the Core/Shell Structured Diamond/Akageneite Hybrid Particles with Enhanced Polishing Performance. Materials 2017, 10, 673. https://doi.org/10.3390/ma10060673

Lu J, Xu Y, Zhang D, Xu X. The Synthesis of the Core/Shell Structured Diamond/Akageneite Hybrid Particles with Enhanced Polishing Performance. Materials. 2017; 10(6):673. https://doi.org/10.3390/ma10060673

Chicago/Turabian StyleLu, Jing, Yongchao Xu, Dayu Zhang, and Xipeng Xu. 2017. "The Synthesis of the Core/Shell Structured Diamond/Akageneite Hybrid Particles with Enhanced Polishing Performance" Materials 10, no. 6: 673. https://doi.org/10.3390/ma10060673