Fracture Surface Morphology and Impact Strength of Cellulose/PLA Composites

Abstract

:1. Introduction

2. Materials and Method

2.1. Raw Materials and Cellulose Ball-Milling

2.2. Composite Materials Fabrication

2.3. Impact Test

2.4. Fractured Surface Imaging

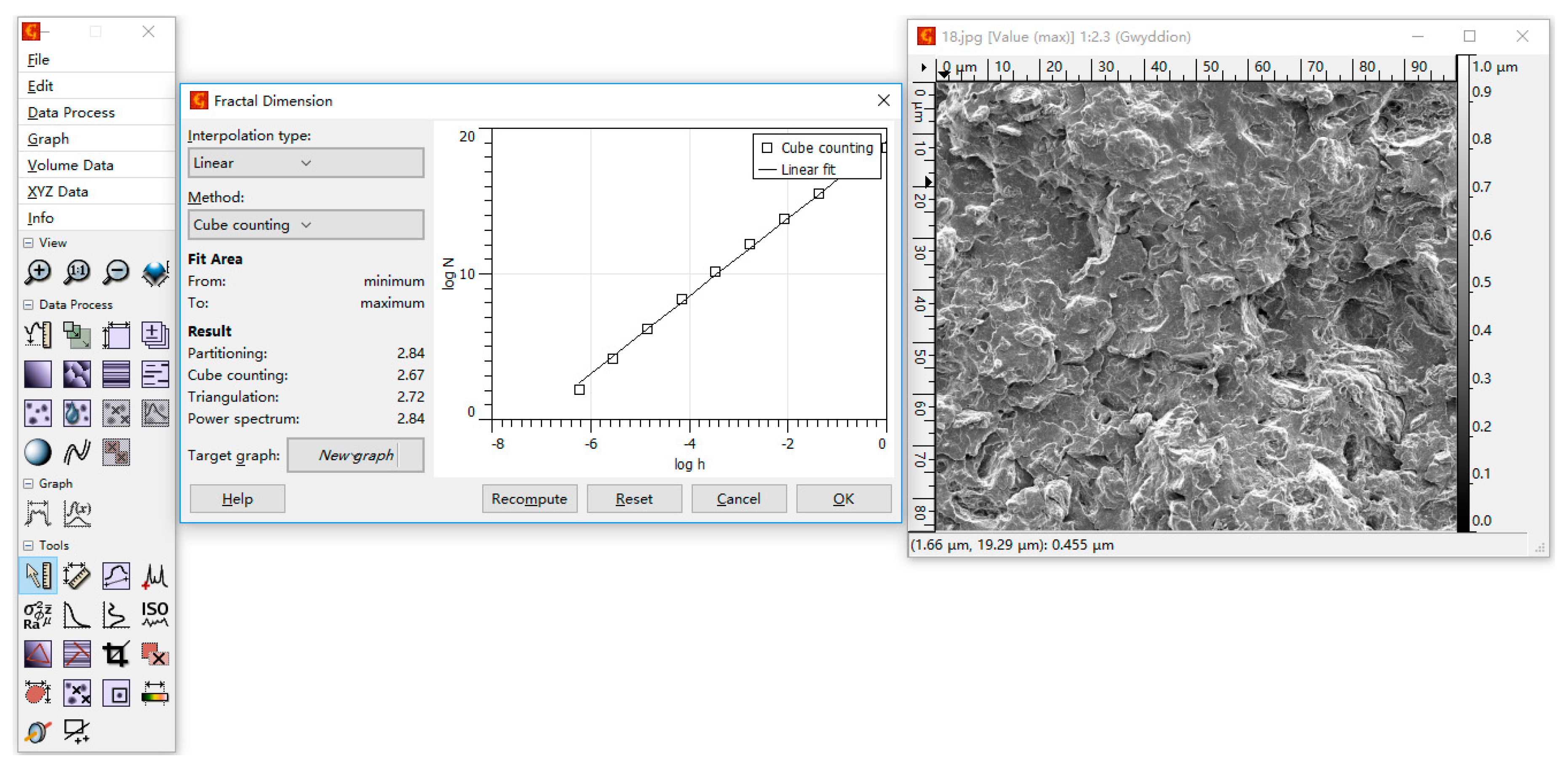

2.5. Fractal Analysis

3. Results and Discussion

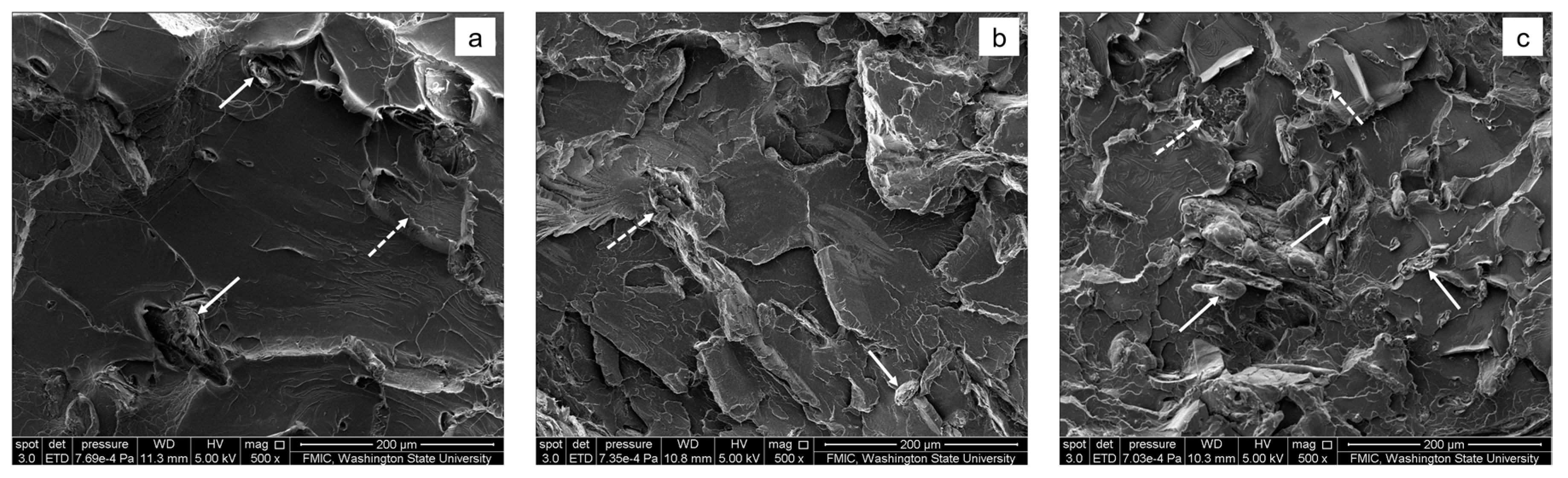

3.1. Fractured Surface Morphology

3.2. Impact Strength

3.3. Fractal Dimension

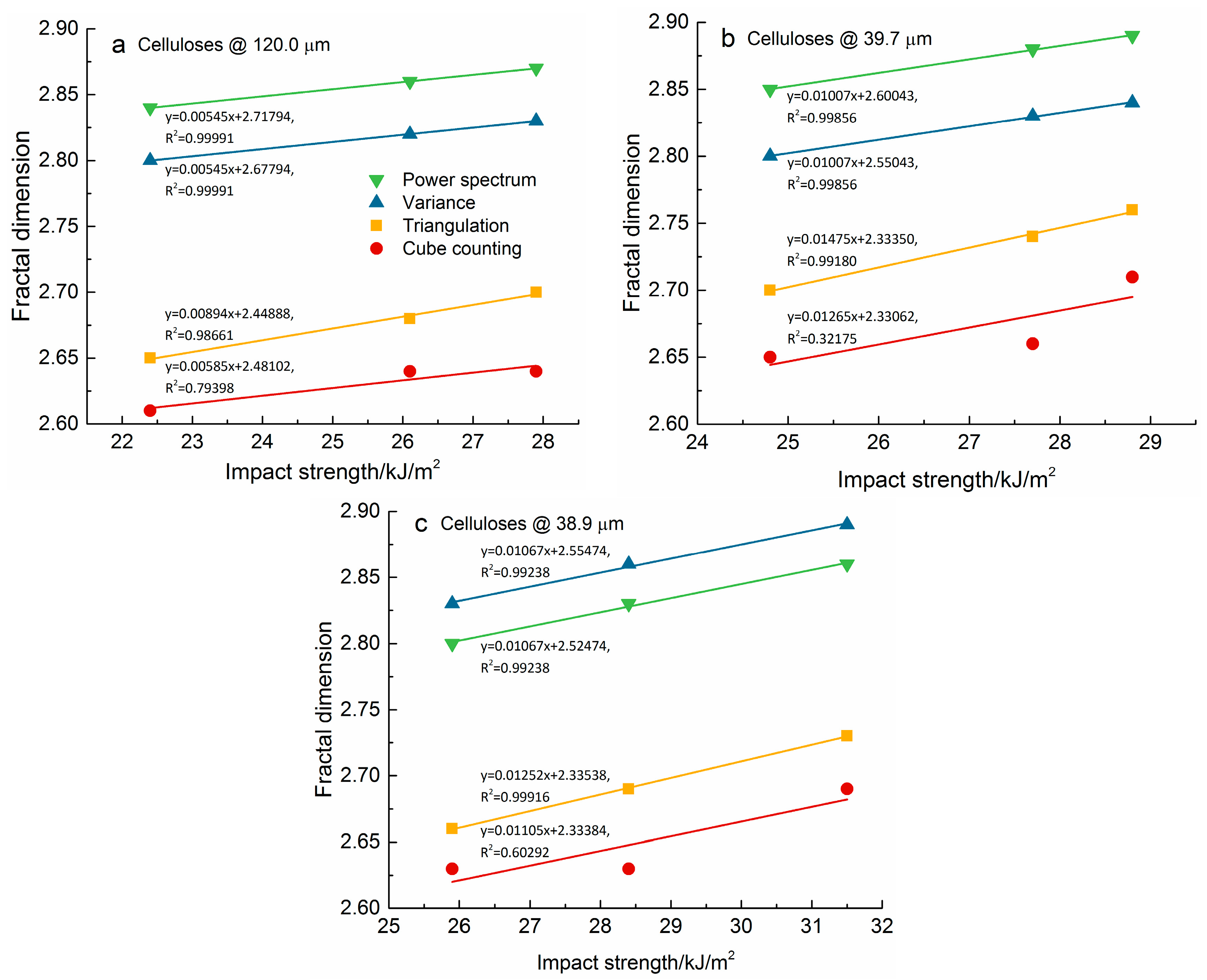

3.4. Correlation between Fractal Dimension and Impact Strength

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Raquez, J.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Qiang, T.; Yu, D.M.; Zhang, A.J.; Gao, H.H.; Li, Z.; Liu, Z.C.; Chen, W.X.; Han, Z. Life cycle assessment on polylactide-based wood plastic composites toughened with polyhydroxyalkanoates. J. Clean. Prod. 2014, 66, 139–145. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhang, J.W. Research progress in toughening modification of poly(lactic acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Balakrishnan, H.; Hassan, A.; Imran, M.; Wahit, M.U. Toughening of polylactic acid nanocomposites: A short review. Polym. Plast. Technol. Eng. 2012, 51, 175–192. [Google Scholar] [CrossRef]

- Sinha, P.; Mathur, S.; Sharma, P.; Kumar, V. Potential of pine needles for PLA-based composites. Polym. Compos. 2016. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Sullivan, M.E.; Moon, J.R.; Kalaitzidou, K. Processing and characterization of cellulose nanocrystals/polylactic acid nanocomposite films. Materials 2015, 8, 8106–8116. [Google Scholar] [CrossRef]

- Qiu, X.Y.; Hu, S.W. “Smart” materials based on cellulose: A review of the preparations, properties, and applications. Materials 2013, 6, 738–781. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Graupner, N.; Albrecht, K.; Ziegmann, G.; Enzler, H.; Muessig, J. Influence of reprocessing on fibre length distribution, tensile strength and impact strength of injection moulded cellulose fibre-reinforced polylactide (PLA) composites. Express Polym. Lett. 2016, 10, 647–663. [Google Scholar] [CrossRef]

- Botta, L.; Fiore, V.; Scalici, T.; Valenza, A.; Scaffaro, R. New polylactic acid composites reinforced with artichoke fibers. Materials 2015, 8, 7770–7779. [Google Scholar] [CrossRef]

- Ambrosio-Martin, J.; Lopez-Rubio, A.; Fabra, M.J.; Gorrasi, G.; Pantani, R.; Lagaron, J.M. Assessment of ball milling methodology to develop polylactide-bacterial cellulose nanocrystals nanocomposites. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Passoja, D.E.; Paullay, A.J. Fractal character of fracture surfaces of metals. Nature 1984, 308, 721–722. [Google Scholar] [CrossRef]

- Li, J.M.; Lu, L.; Su, Y.; Lai, M.O. Self-affine nature of thin film surface. Appl. Surf. Sci. 2000, 161, 187–193. [Google Scholar] [CrossRef]

- Alexandrov, S.E.; Kretusheva, I.V.; Mishin, M.V.; Yasenovets, G.M. Formation of fractal structures from Silicon dioxide nanoparticles synthesized by RF atmospheric pressure plasma enhanced chemical vapor deposition. J. Nanosci. Nanotechnol. 2011, 11, 7969–7973. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.Z.; Duan, D.; Tang, C.; Tsui, C. Correlation between impact strength and fractal dimensions of fracture surface for PLLA/nano-CaCO3 composites. Polym. Test. 2014, 35, 109–115. [Google Scholar] [CrossRef]

- Qiang, T.; Yu, D.M. Correlation between fractal dimension and impact strength for wood plastic composites. In Proceedings of the 2011 International Conference on Precision Engineering and Non-Traditional Machining, Xi’an, China, 9–11 December 2011; pp. 548–551. [Google Scholar]

- Qiang, T.; Yu, D.M.; Gao, H.H. Impact strength and fractal characteristic of PLA-based wood plastic composites. In Proceedings of the 2nd International Conference on Civil Engineering, Architecture and Building Materials, Yantai, China, 25–27 May 2012; pp. 683–686. [Google Scholar]

- Qiang, T.; Yu, D.M.; Gao, H.H. Fractal characteristic and impact strength of PLA-based wood plastic composites. In Proceedings of the 2nd International Symposium on Chemical Engineering and Material Properties, Taiyuan, China, 22–24 June 2012; pp. 49–52. [Google Scholar]

- Klapetek, P.; Něcas, D.; Anderson, C. Gwyddion User Guide; Czech Metrology Institute: Brno, Czech Republic, 2017; pp. 87–88. [Google Scholar]

- Nogués, J.; Costa, J.L.; Rao, K.V. Fractal dimension of thin film surfaces of gold sputter deposited on mica: A scanning tunneling microscopic study. Phys. A Stat. Mech. Appl. 1992, 182, 532–541. [Google Scholar] [CrossRef]

- Pavlovic, Z.; Risovic, D.; Novakovic, D. Comparative study of direct and indirect image-based profilometry in characterization of surface roughness. Surf. Interface Anal. 2012, 44, 825–830. [Google Scholar] [CrossRef]

- Pezzotti, G.; Sakai, M.; Okamoto, Y.; Nishida, T. Fractal character of fracture surfaces and boundary values of toughness in a simple ceramic-ceramic system. Mater. Sci. Eng. A 1995, 197, 109–112. [Google Scholar] [CrossRef]

- Alipour, R.; Riazifar, M.R.; Afsari, T. The effect of pressure on morphological features and quality of synthesized graphene. Res. Chem. Intermed. 2016, 42, 8261–8272. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, K.W. Characterization of surface morphology of copper tungsten thin film by surface fractal geometry and resistivity. Thin Solid Films 2004, 468, 310–315. [Google Scholar] [CrossRef]

| Materials Code | Ball-Milled Cellulose | Filling Content/wt % | |

|---|---|---|---|

| Ball-Milling Time/min | Average Particle Size/μm | ||

| Sample a | 10 | 120.0 | 4.8 |

| Sample b | 13.0 | ||

| Sample c | 20.0 | ||

| Sample d | 30 | 39.7 | 4.8 |

| Sample e | 13.0 | ||

| Sample f | 20.0 | ||

| Sample g | 60 | 38.9 | 4.8 |

| Sample h | 13.0 | ||

| Sample i | 20.0 | ||

| Materials Code | Fractal Dimension | |||

|---|---|---|---|---|

| Cube Counting | Triangulation | Variance | Power Spectrum | |

| Sample a | 2.61 | 2.65 | 2.80 | 2.84 |

| Sample b | 2.64 | 2.68 | 2.82 | 2.86 |

| Sample c | 2.64 | 2.70 | 2.83 | 2.87 |

| Sample d | 2.65 | 2.70 | 2.80 | 2.85 |

| Sample e | 2.66 | 2.74 | 2.83 | 2.88 |

| Sample f | 2.71 | 2.76 | 2.84 | 2.89 |

| Sample g | 2.63 | 2.66 | 2.83 | 2.80 |

| Sample h | 2.63 | 2.69 | 2.86 | 2.83 |

| Sample i | 2.69 | 2.73 | 2.89 | 2.86 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Qiang, T. Fracture Surface Morphology and Impact Strength of Cellulose/PLA Composites. Materials 2017, 10, 624. https://doi.org/10.3390/ma10060624

Gao H, Qiang T. Fracture Surface Morphology and Impact Strength of Cellulose/PLA Composites. Materials. 2017; 10(6):624. https://doi.org/10.3390/ma10060624

Chicago/Turabian StyleGao, Honghong, and Tao Qiang. 2017. "Fracture Surface Morphology and Impact Strength of Cellulose/PLA Composites" Materials 10, no. 6: 624. https://doi.org/10.3390/ma10060624