Mechanical Properties of Nonwoven Reinforced Thermoplastic Polyurethane Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

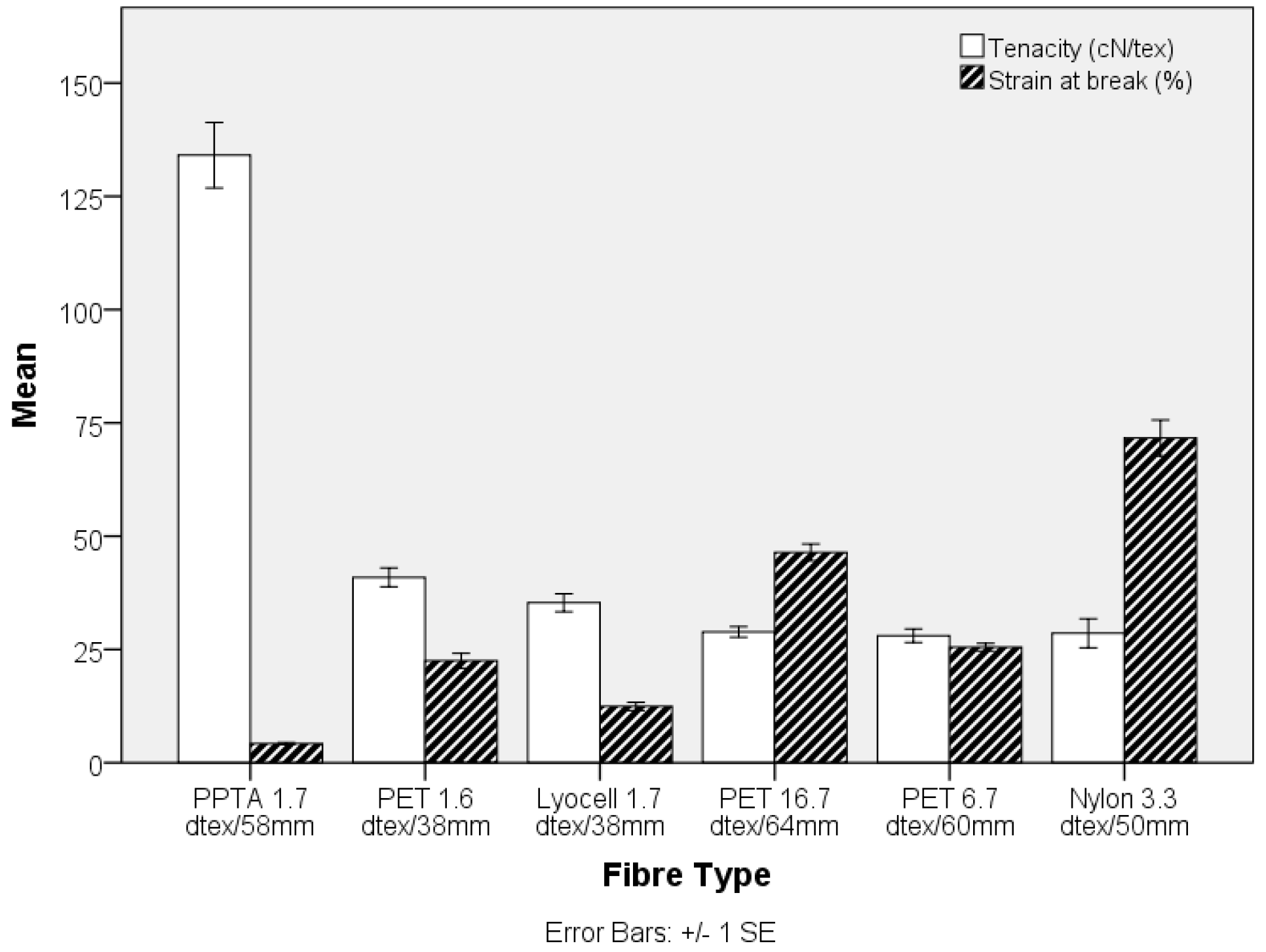

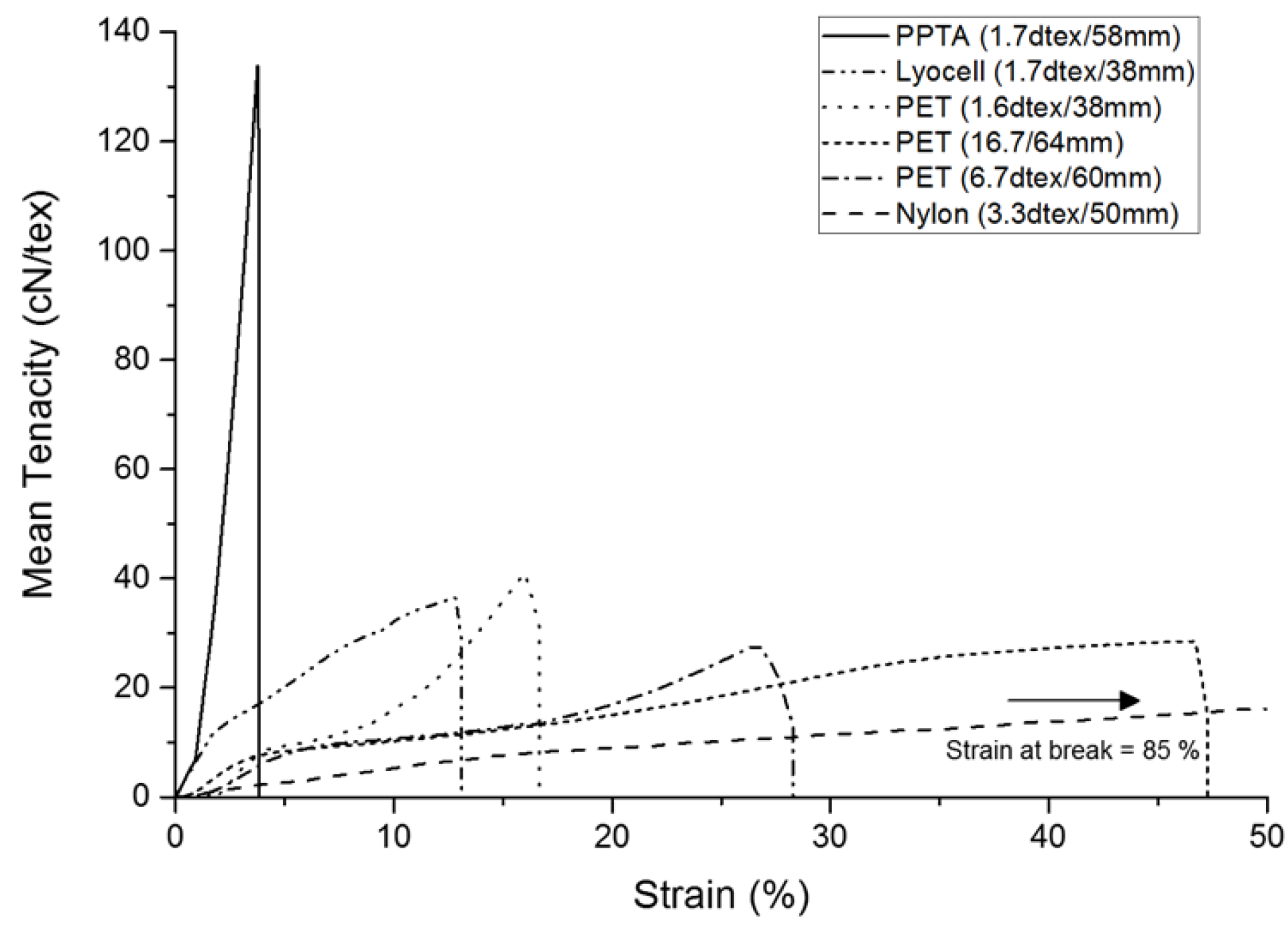

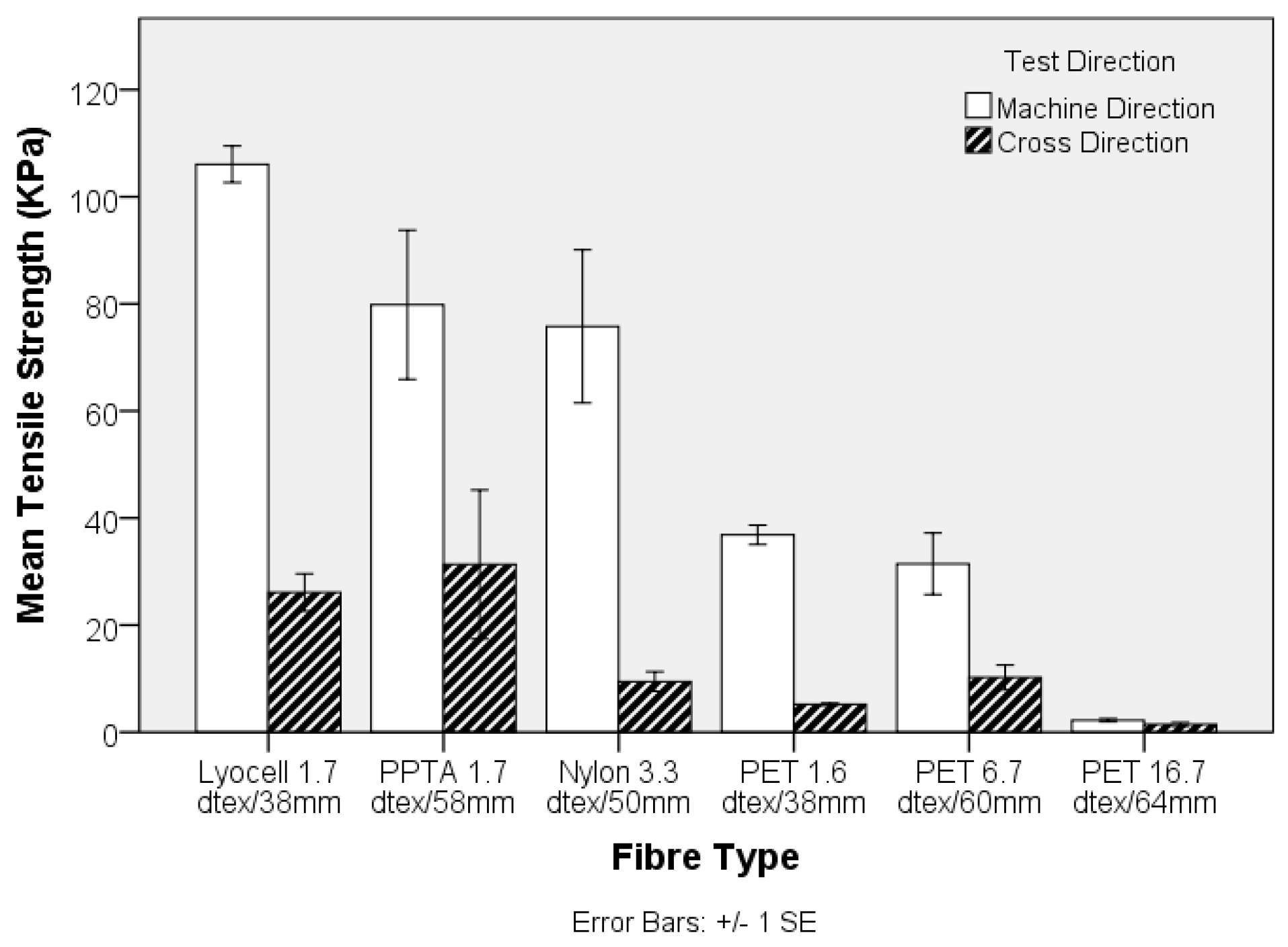

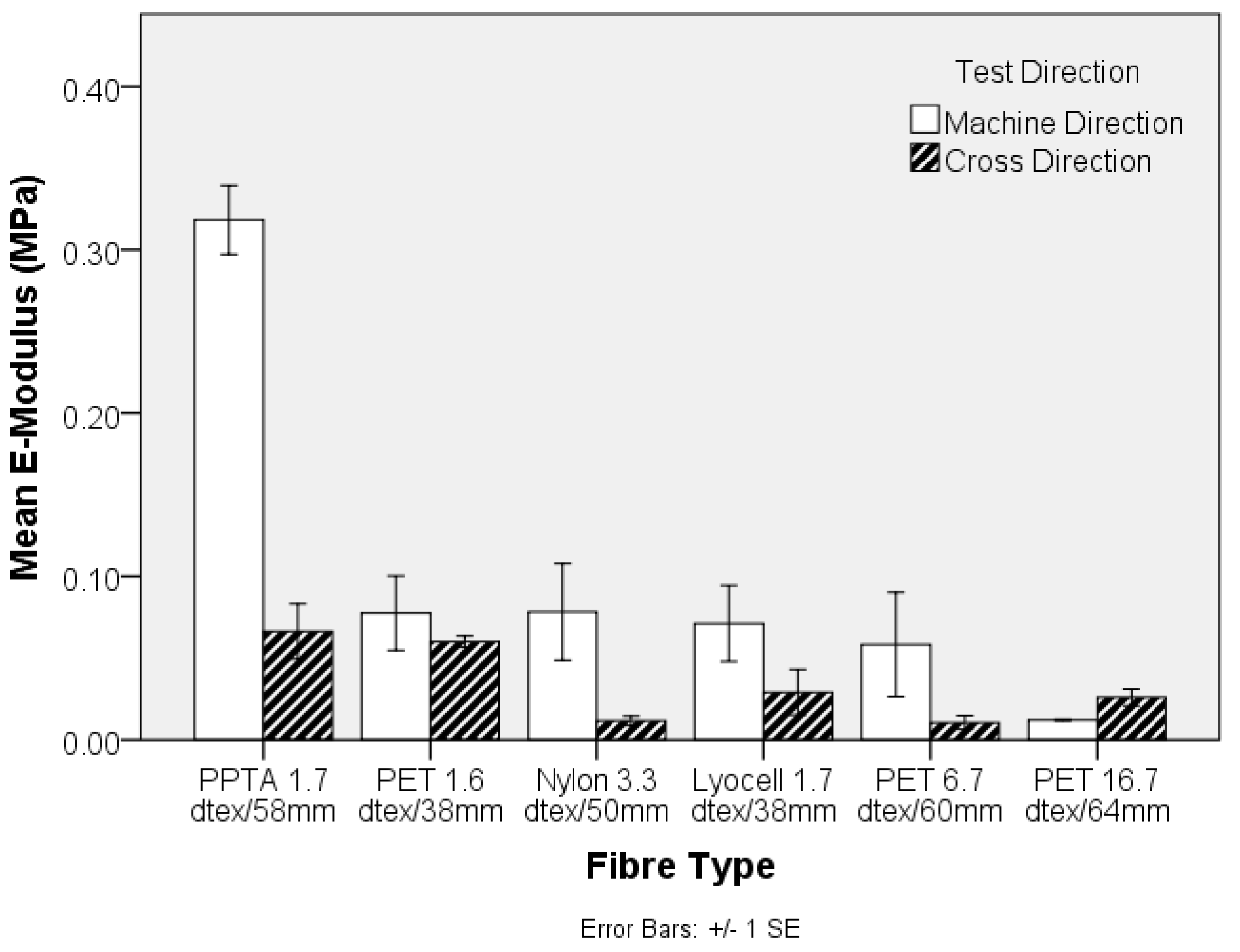

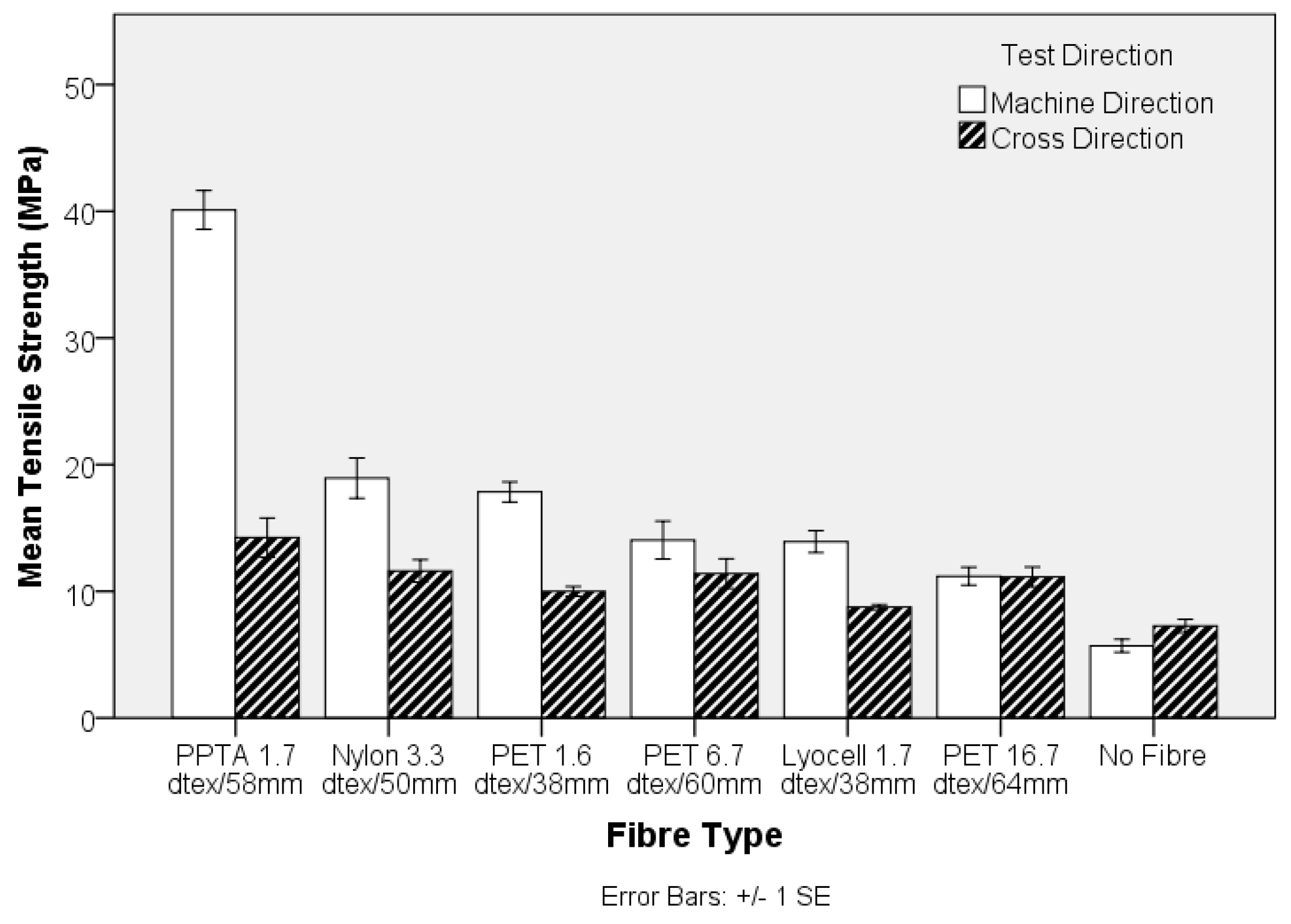

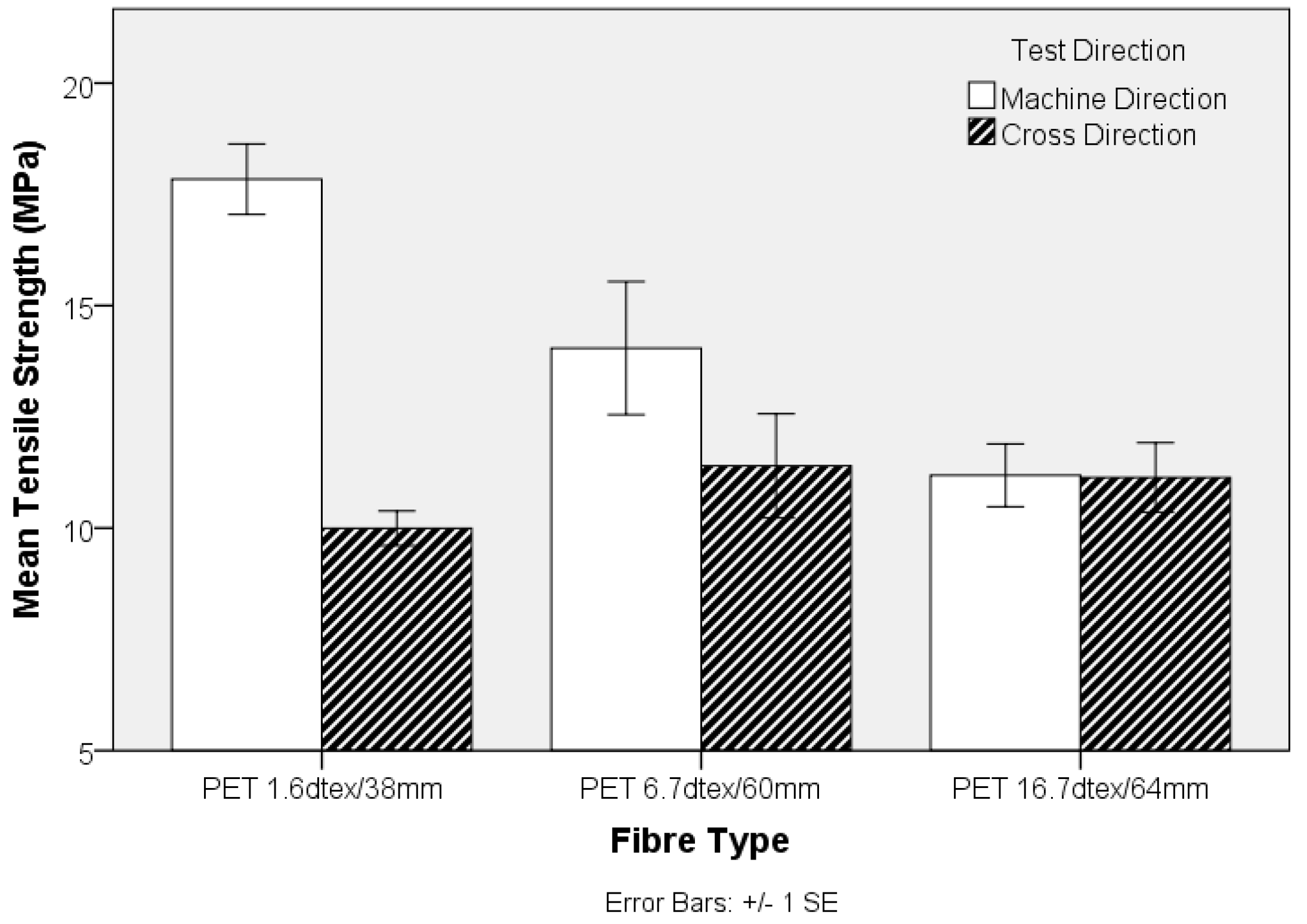

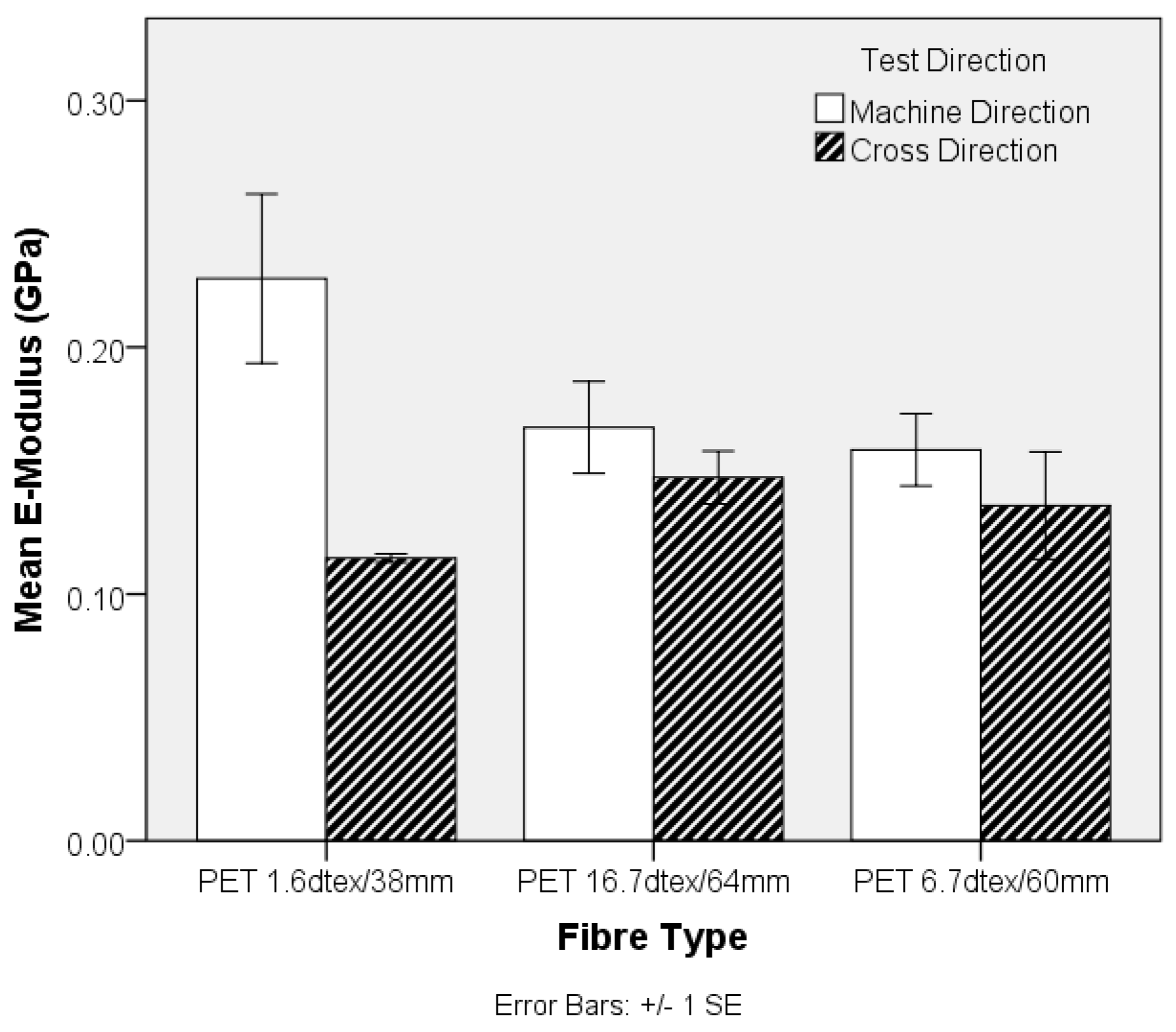

3.1. Effect of Fibre Type and Linear Density

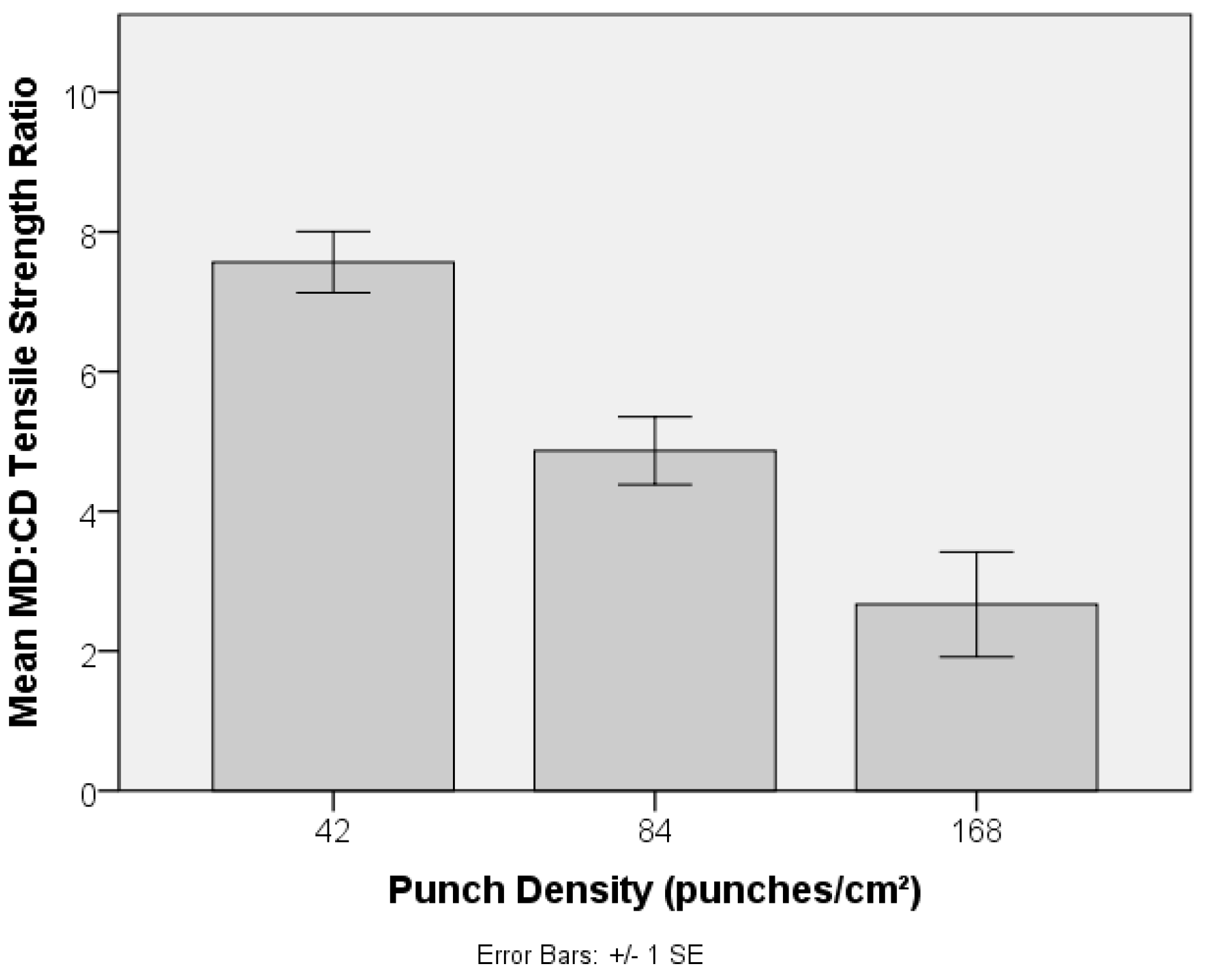

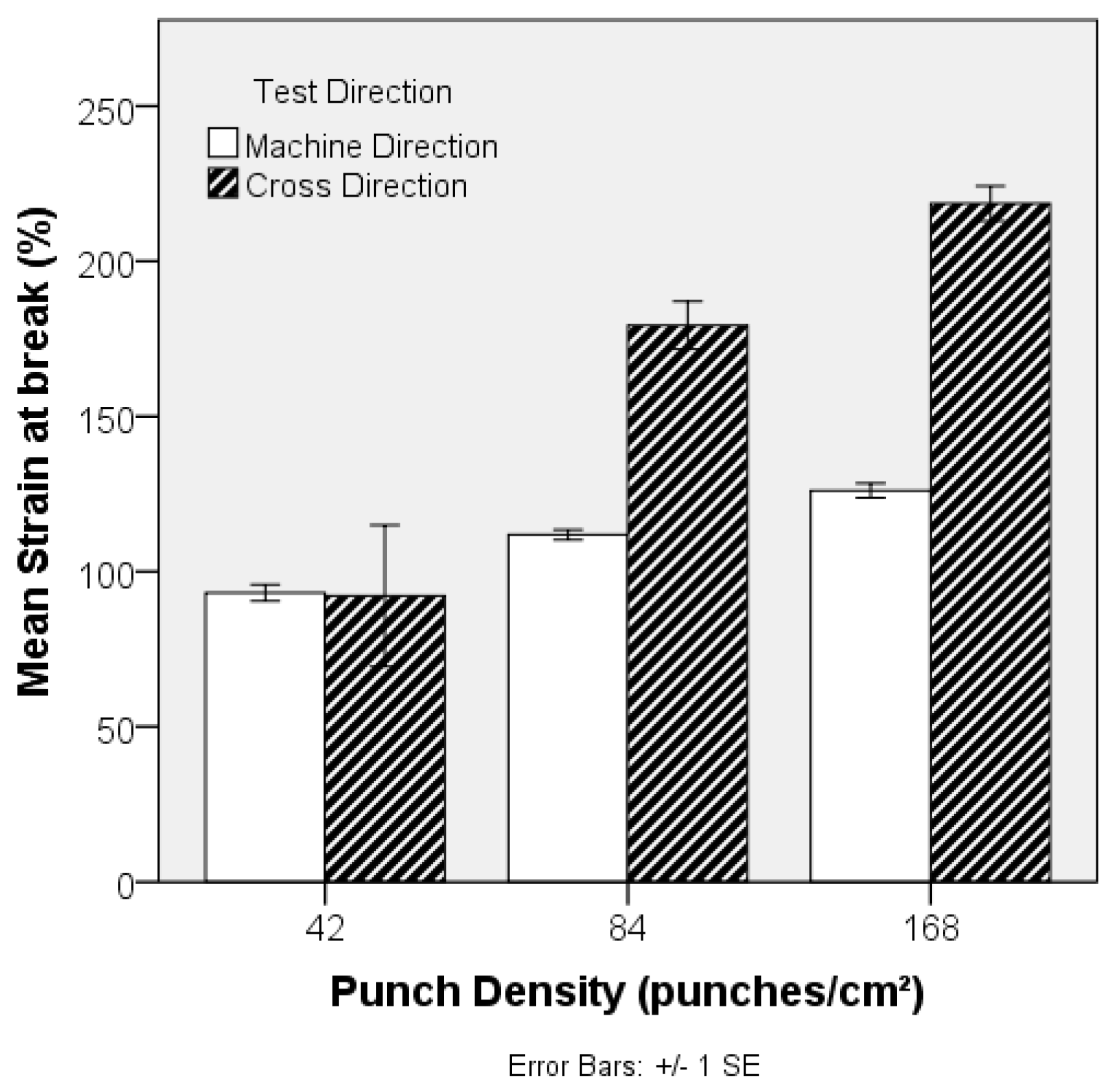

3.2. Effect of Needlepunching Density

4. Conclusions

- Conventional textile fibres such as PET and lyocell have the potential to increase, six and nine times respectively, the tensile modulus of compression moulded TPU composites when introduced as nonwoven preforms with solid volume fractions of <10%. In addition, reinforcement of TPU moulded composites with PET- and lyocell nonwovens led to a minimum 2.5 fold increase in tensile strength compared to unreinforced TPU. This is substantially lower than can be achieved with comparable nonwoven PPTA fibre preforms, but there may be cost benefits in selecting lower cost reinforcements for less demanding applications.

- High strength fibres do not essentially produce high strength nonwoven preforms, with all other parameters constant. The tensile properties of nonwoven-reinforced composites are mainly dependent upon fibre tensile properties and fibre segment orientation distribution. Though the tensile strength of the nonwoven preform does not markedly contribute to the tensile strength of the composite, the structural and dimensional modifications associated with increased levels of bonding such as greater fibre entanglement, fibre re-orientation, fabric density and fibre volume fractions can influence resulting mechanical properties.

- Cross-sectional analysis of nonwoven-reinforced composite parts, revealed void-free embedding of conventional fibres in the TPU matrix.

- Modulating the degree of fibre entanglement and mechanical bonding in the nonwoven preform by adjusting the level of needling resulted in a small but significant decrease in tensile strength of the TPU composite. Based on a fixed fibre type and solid volume fraction, increasing fibre linear density reduced the strength of the nonwoven-reinforced TPU composite.

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reinhart, T.J. Overview of composite materials. In Handbook of Composites, 2nd ed.; Peters, S.T., Ed.; Chapman & Hall: London, UK, 1998. [Google Scholar]

- Shalaby, S.W.; Latour, R.A. Composite biomaterials. In Handbook of Composites, 2nd ed.; Peters, S.T., Ed.; Chapman & Hall: London, UK, 1998. [Google Scholar]

- Das, D.; Pradhan, A.K.; Chattopadhyay, R.; Singh, S.N. Composite nonwovens. Text. Prog. 2012, 44, 1–84. [Google Scholar] [CrossRef]

- Epstein, M.; Shishoo, R. A new process for fabricating nonwoven fibrous-reinforced elastomer composites. J. Appl. Polym. Sci. 1992, 45, 1693–1704. [Google Scholar] [CrossRef]

- Peters, S.T. Introduction, composite basics and road map. In Handbook of Composites, 2nd ed.; Peters, S.T., Ed.; Chapman & Hall: London, UK, 1998. [Google Scholar]

- Matsuo, T. Advanced technical textile products. Text. Prog. 2008, 40, 123–181. [Google Scholar] [CrossRef]

- Kuo, C.M.; Takahashi, K.; Chou, T.W. Effect of fiber waviness on the nonlinear elastic behavior of flexible composites. J. Compos. Mater. 1988, 22, 1004–1025. [Google Scholar] [CrossRef]

- Andersson, C.-H.; Dartman, T.; Gredinger, P.; Asplund, J.; Strandqvist, H. Flexible composites, strength, deformation, and fracture processes. 1. Reinforcement structures and tensile strength. Mech. Compos. Mater. 1998, 34, 525–536. [Google Scholar]

- Chou, T.-W. Flexible composites. J. Mater. Sci. 1989, 24, 761–783. [Google Scholar] [CrossRef]

- Zia, K.M.; Bhatti, H.N.; Bhatti, I.A. Methods for polyurethane and polyurethane composites, recycling and recovery: A review. React. Funct. Polym. 2007, 67, 675–692. [Google Scholar] [CrossRef]

- El-Shekeil, Y.; Sapuan, S.; Abdan, K.; Zainudin, E. Influence of fiber content on the mechanical and thermal properties of kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 2012, 40, 299–303. [Google Scholar] [CrossRef]

- Kumar, S.; Manjula, K. Castor oil-based polyurethane–polyester nonwoven fabric composites: Mechanical properties, chemical resistance, and water sorption behavior at different temperatures. J. Appl. Polym. Sci. 2007, 105, 3153–3161. [Google Scholar] [CrossRef]

- Zdrahala, R.; Gerkin, R.; Hager, S.; Critchfield, F. Polyether-based thermoplastic polyurethanes. I. Effect of the hard-segment content. J. Appl. Polym. Sci. 1979, 24, 2041–2050. [Google Scholar]

- Jiang, S.; Greiner, A.; Agarwal, S. Short nylon-6 nanofiber reinforced transparent and high modulus thermoplastic polymeric composites. Compos. Sci. Technol. 2013, 87, 164–169. [Google Scholar] [CrossRef]

- Jiang, S.; Duan, G.; Zussman, E.; Greiner, A.; Agarwal, S. Highly flexible and tough concentric triaxial polystyrene fibers. ACS appl. Mater. Interfaces 2014, 6, 5918–5923. [Google Scholar] [CrossRef] [PubMed]

- Vaidya, U.; Chawla, K. Processing of fibre reinforced thermoplastic composites. Int. Mater. Rev. 2008, 53, 185–218. [Google Scholar] [CrossRef]

- Thermoplastic Polyurethane Elastomers (tpu) Elastollan®—Product Range. BASF SE. Available online: http://www.polyurethanes.basf.com/pu/solutions/en/function/conversions:/publish/content/group/News_und_Medien/Spezialelastomere/Thermoplastic_Polyurethane_Elastomers_Product_Range_EN.pdf (accessed on 4 May 2017).

- Mouritz, A.; Bannister, M.; Falzon, P.; Leong, K. Review of applications for advanced three-dimensional fibre textile composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1445–1461. [Google Scholar] [CrossRef]

- Russell, S.J. Handbook of Nonwovens; Woodhead Publishing Limited: Cambridge, UK, 2007; p. 544. [Google Scholar]

- Tausif, M.; Russell, S.J. Characterisation of the z-directional tensile strength of composite hydroentangled nonwovens. Polym. Test. 2012, 31, 944–952. [Google Scholar] [CrossRef]

- Wang, Y. Effect of consolidation method on the mechanical properties of nonwoven fabric reinforced composites. Appl. Compos. Mater. 1999, 6, 19–34. [Google Scholar] [CrossRef]

- Epstein, M.; Shishoo, R. Studies related to in-plane flow behavior of elastomer matrix in nonwoven fibrous structures. J. Appl. Polym. Sci. 1994, 51, 1629–1646. [Google Scholar] [CrossRef]

- Acar, M.; Harper, J. Textile composites from hydro-entangled non-woven fabrics. Comput. Struct. 2000, 76, 105–114. [Google Scholar] [CrossRef]

- O'connor, J. Short-fiber-reinforced elastomer composites. Rubber Chem. Technol. 1977, 50, 945–958. [Google Scholar] [CrossRef]

- Nando, G.; Gupta, B. Short Fibre-Thermoplastic Elastomer Composites; Woodhead Publishing: Cambridge, UK, 1996. [Google Scholar]

- Hyer, M.W. Stress Analysis of Fiber-Reinforced Composite Materials; DEStech Publications, Inc: Lancaster, PA, USA, 2009. [Google Scholar]

- Gindl, W.; Reifferscheid, M.; Adusumalli, R.-B.; Weber, H.; Röder, T.; Sixta, H.; Schöberl, T. Anisotropy of the modulus of elasticity in regenerated cellulose fibres related to molecular orientation. Polymer 2008, 49, 792–799. [Google Scholar] [CrossRef]

- Monette, L.; Anderson, M.; Ling, S.; Grest, G. Effect of modulus and cohesive energy on critical fibre length in fibre-reinforced composites. J. Mater. Sci. 1992, 27, 4393–4405. [Google Scholar] [CrossRef]

- Tausif, M.; O’Haire, T.; Pliakas, A.; Goswami, P.; Russell, S.J. Effect of fibre type on mechanical properties of nonwoven reinforced tpu composites. In Proceedings of the 16th World Textile Conference AUTEX 2016, Ljubljana, Slovenia, 8–10 June 2016. [Google Scholar]

- Astrom, B.T. Manufacturing of Polymer Composites; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- ASTM D3822-14 Standard Test Method for Tensile Properties of Single Textile Fibers; ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D 5035 Breaking Force and Elongation of Nonwoven Materials (Strip Method); ASTM International: West Conshohocken, PA, USA, 2015.

- ISO 527-4 Plastics—Determination of Tensile Properties—Part 4—Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites; International Organization for Standardization: Geneva, Switzerland, 1997.

- Huang, H.; Talreja, R. Effects of void geometry on elastic properties of unidirectional fiber reinforced composites. Compos. Sci. Technol. 2005, 65, 1964–1981. [Google Scholar] [CrossRef]

- Epstein, M.; Shishoo, R. Studies of the effect of fiber surface and matrix rheological properties on nonwoven reinforced elastomer composites. J. Appl. Polym. Sci. 1995, 57, 751–765. [Google Scholar] [CrossRef]

- Martin, N.; Davies, P.; Baley, C. Evaluation of the potential of three non-woven flax fiber reinforcements: Spunlaced, needlepunched and paper process mats. Ind. Crop. Prod. 2016, 83, 194–205. [Google Scholar] [CrossRef]

- Hearle, J.W.S.; Wilkins, A.H. Movement of fibers in assemblies. J. Text. Inst. 2006, 97, 1–9. [Google Scholar] [CrossRef]

- Ghosh, P. Fibre Science and Technology; Tata McGraw-Hill Education: New York, NY, USA, 2004. [Google Scholar]

- Tausif, M.; Ahmad, F.; Hussain, U.; Basit, A.; Hussain, T. A comparative study of mechanical and comfort properties of bamboo viscose as an eco-friendly alternative to conventional cotton fibre in polyester blended knitted fabrics. J. Clean. Prod. 2015, 89, 110–115. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Licence, P.; Clifford, M.J. Determining the minimum, critical and maximum fibre content for twisted yarn reinforced plant fibre composites. Compos. Sci. Technol. 2012, 72, 1909–1917. [Google Scholar] [CrossRef]

- Tvergaard, V. Effect of fibre debonding in a whisker-reinforced metal. Mater. Sci. Eng. A 1990, 125, 203–213. [Google Scholar] [CrossRef]

- Epstein, M.; Shishoo, R. A new process for fabricating nonwoven fibrous-reinforced elastomer composites. J. Appl. Polym. Sci. 1992, 45, 1693–1704. [Google Scholar] [CrossRef]

- Hearle, J.; Purdy, A. The structure of needle punched fabric. Fibre Sci. Technol. 1971, 4, 81–100. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tausif, M.; Pliakas, A.; O’Haire, T.; Goswami, P.; Russell, S.J. Mechanical Properties of Nonwoven Reinforced Thermoplastic Polyurethane Composites. Materials 2017, 10, 618. https://doi.org/10.3390/ma10060618

Tausif M, Pliakas A, O’Haire T, Goswami P, Russell SJ. Mechanical Properties of Nonwoven Reinforced Thermoplastic Polyurethane Composites. Materials. 2017; 10(6):618. https://doi.org/10.3390/ma10060618

Chicago/Turabian StyleTausif, Muhammad, Achilles Pliakas, Tom O’Haire, Parikshit Goswami, and Stephen J. Russell. 2017. "Mechanical Properties of Nonwoven Reinforced Thermoplastic Polyurethane Composites" Materials 10, no. 6: 618. https://doi.org/10.3390/ma10060618