Characterization of a Laser Surface-Treated Martensitic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Laser Treatment

2.2. Metallographic and Microstructural Analysis

2.3. Tribology Test

2.4. Impact Test

2.5. Potentiodynamic Corrosion Test

3. Results

3.1. Microstructural Analysis

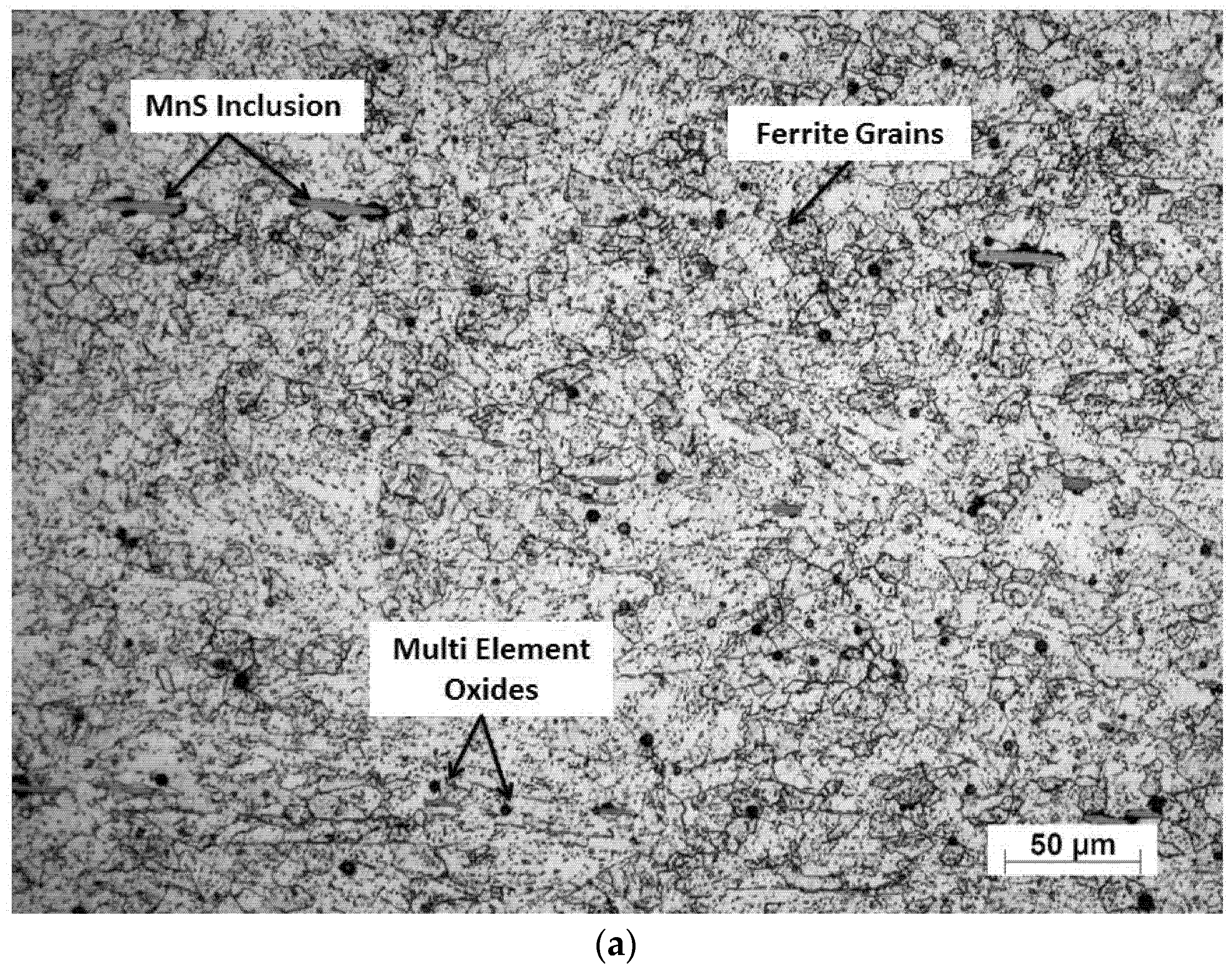

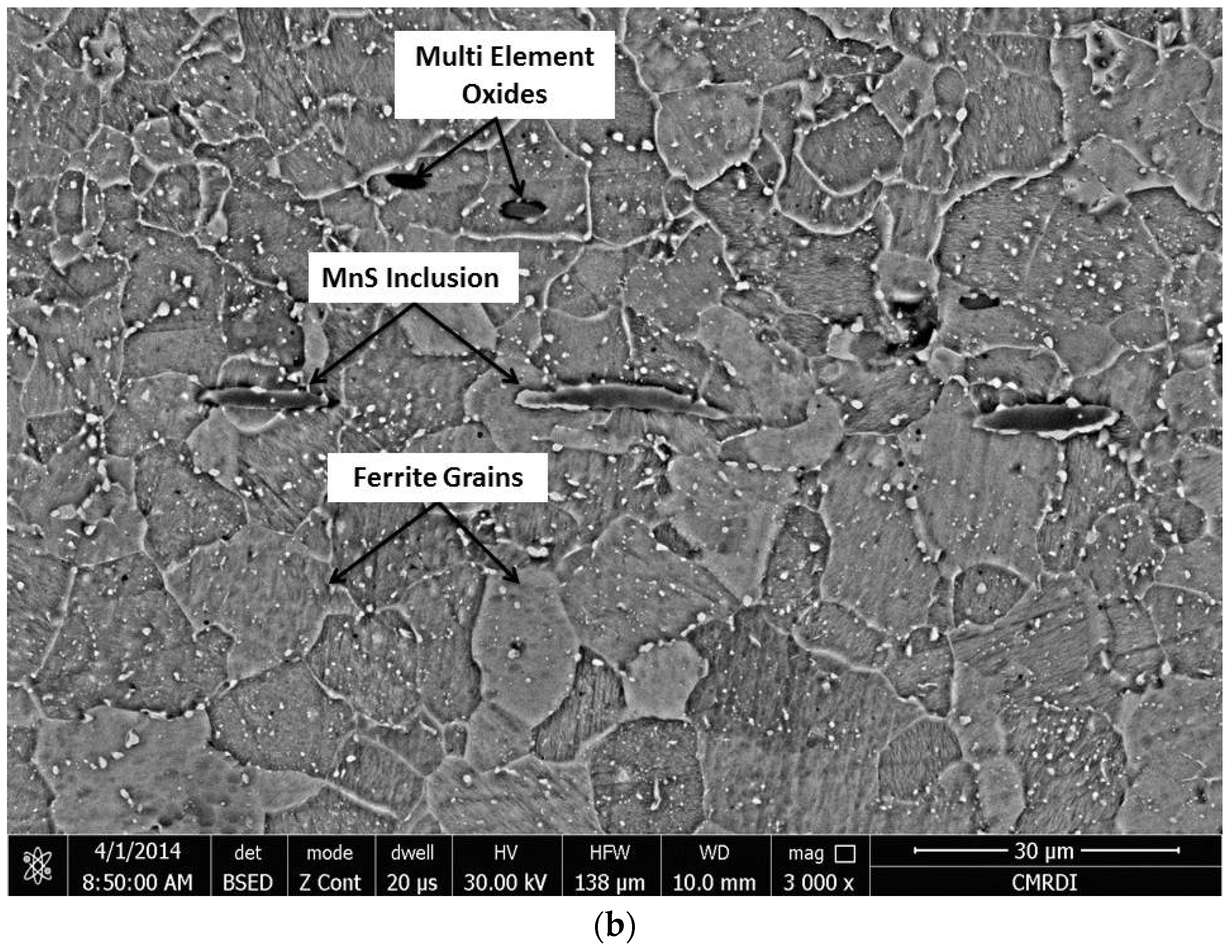

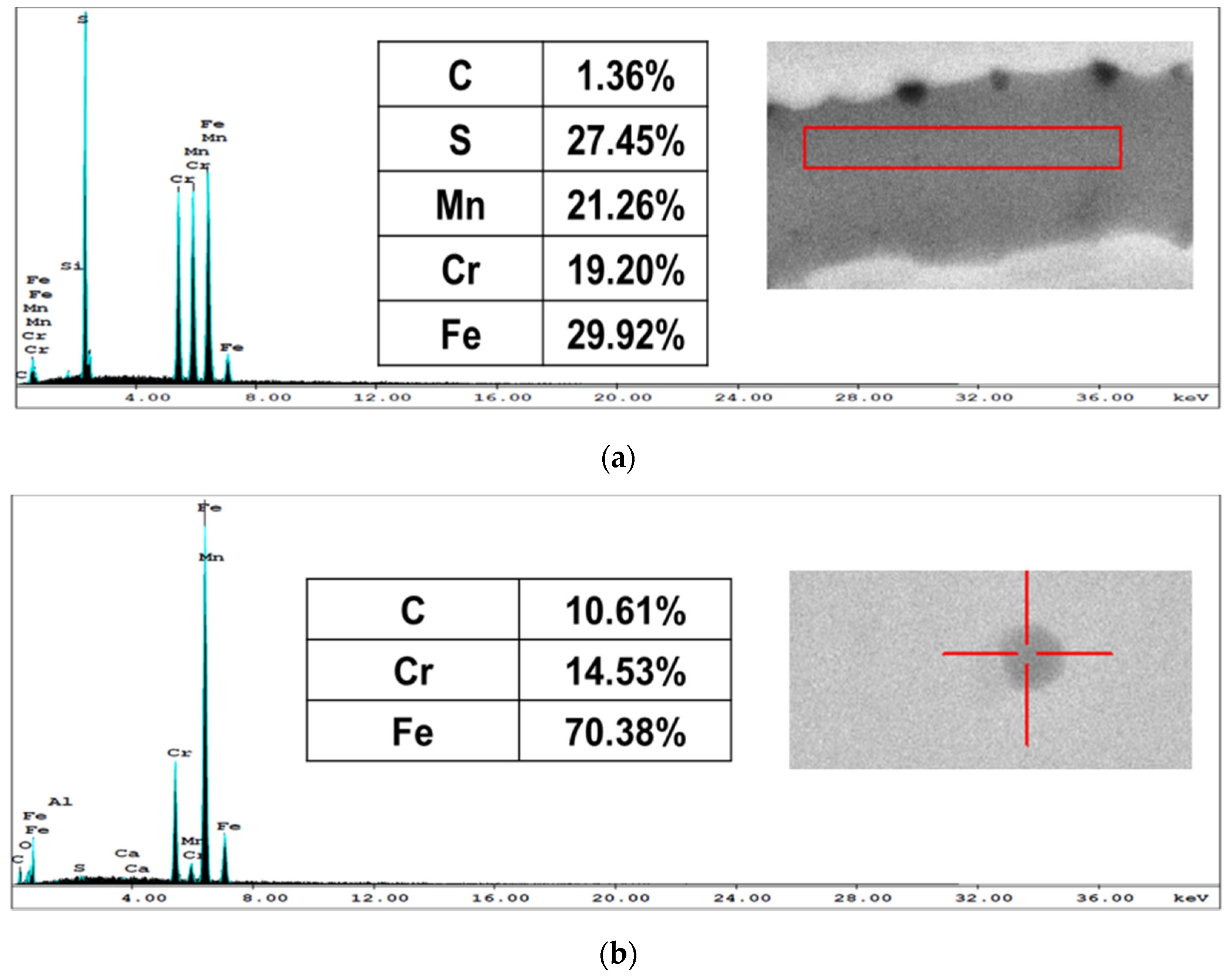

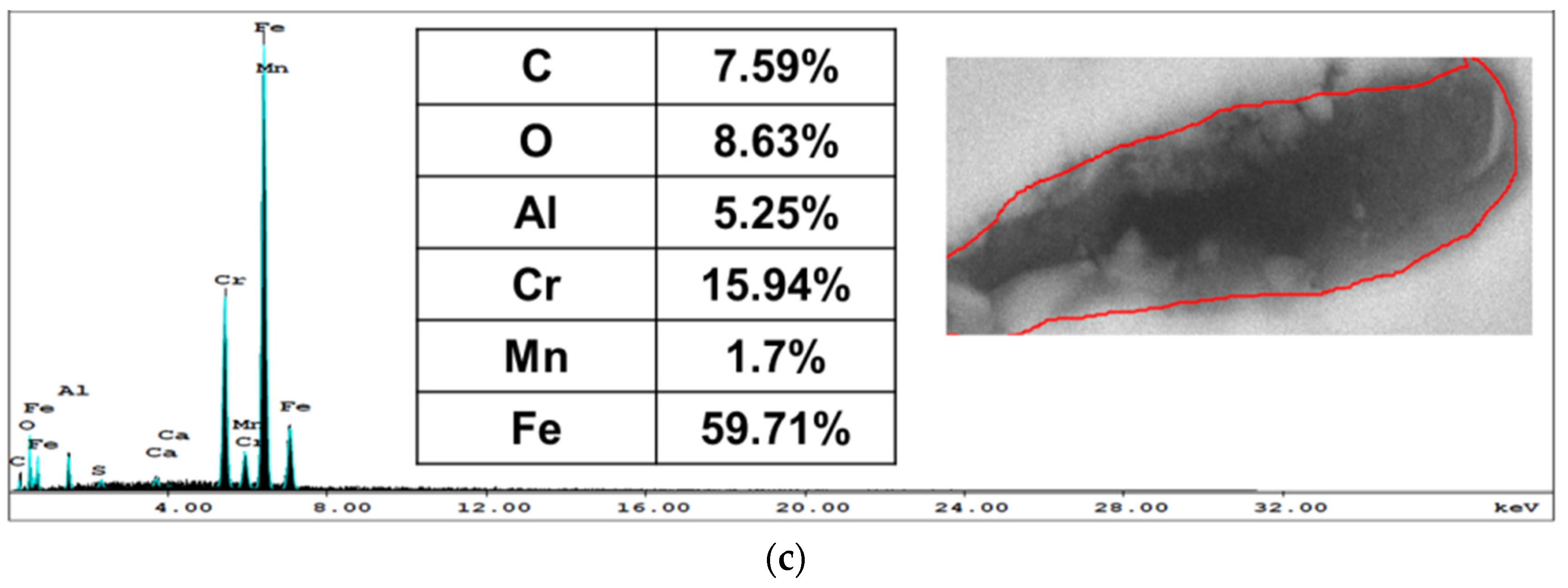

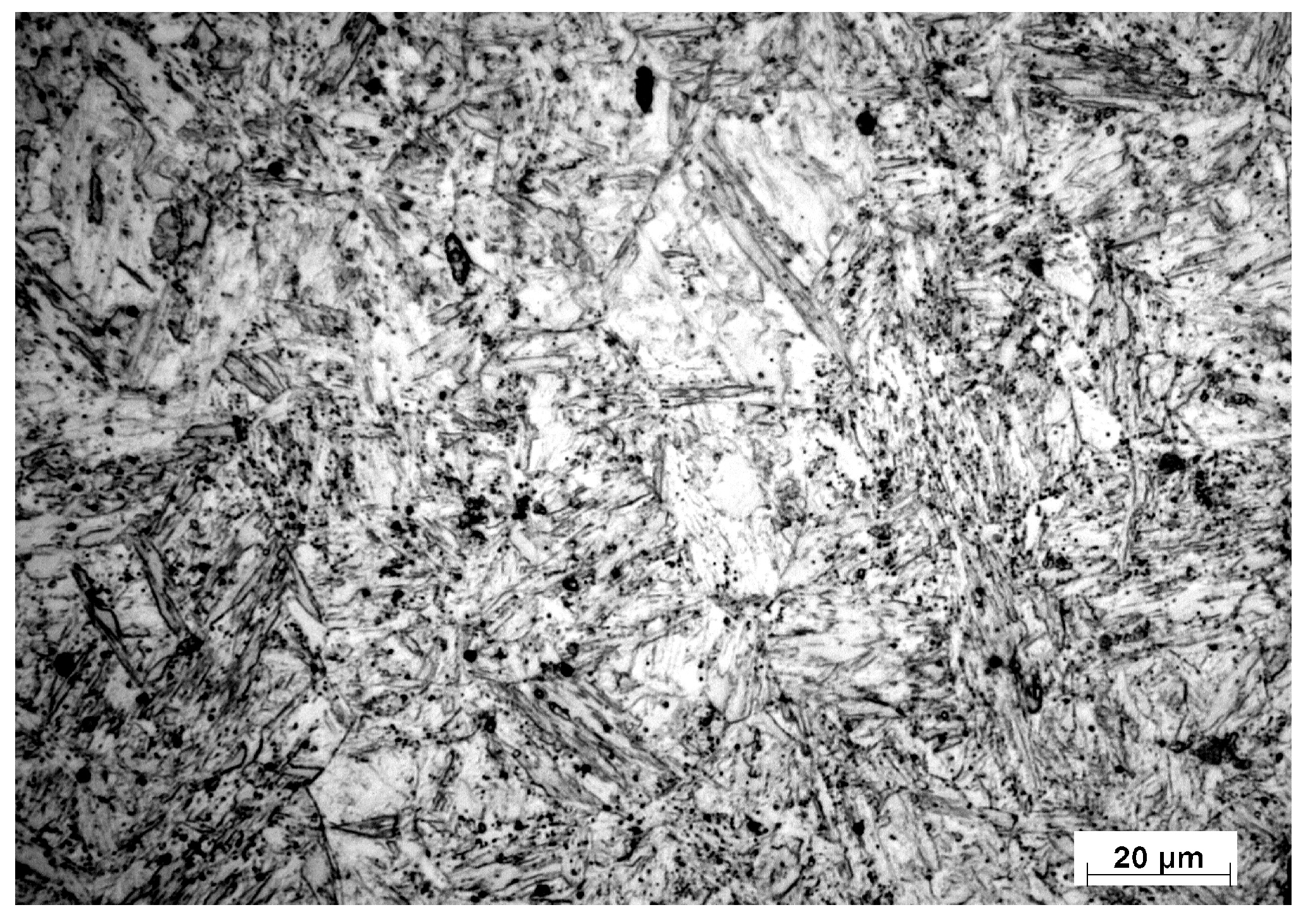

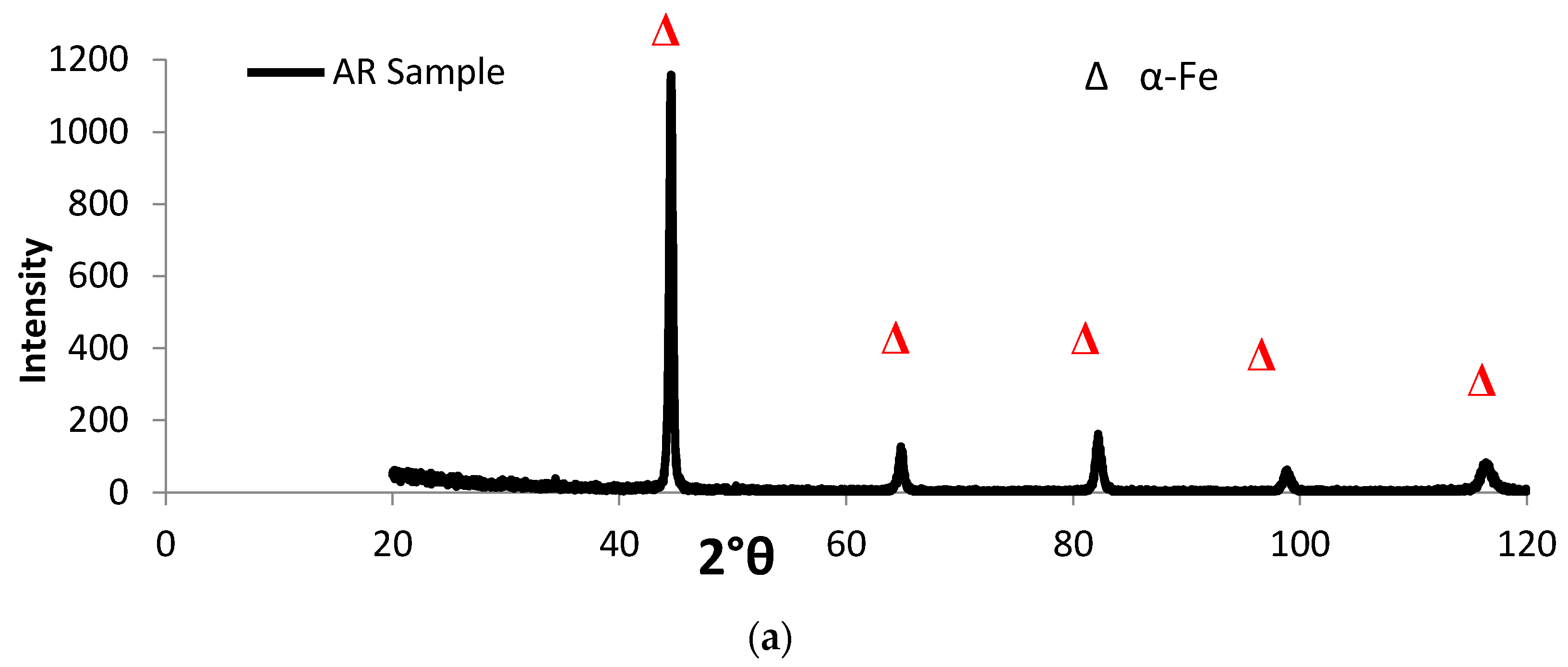

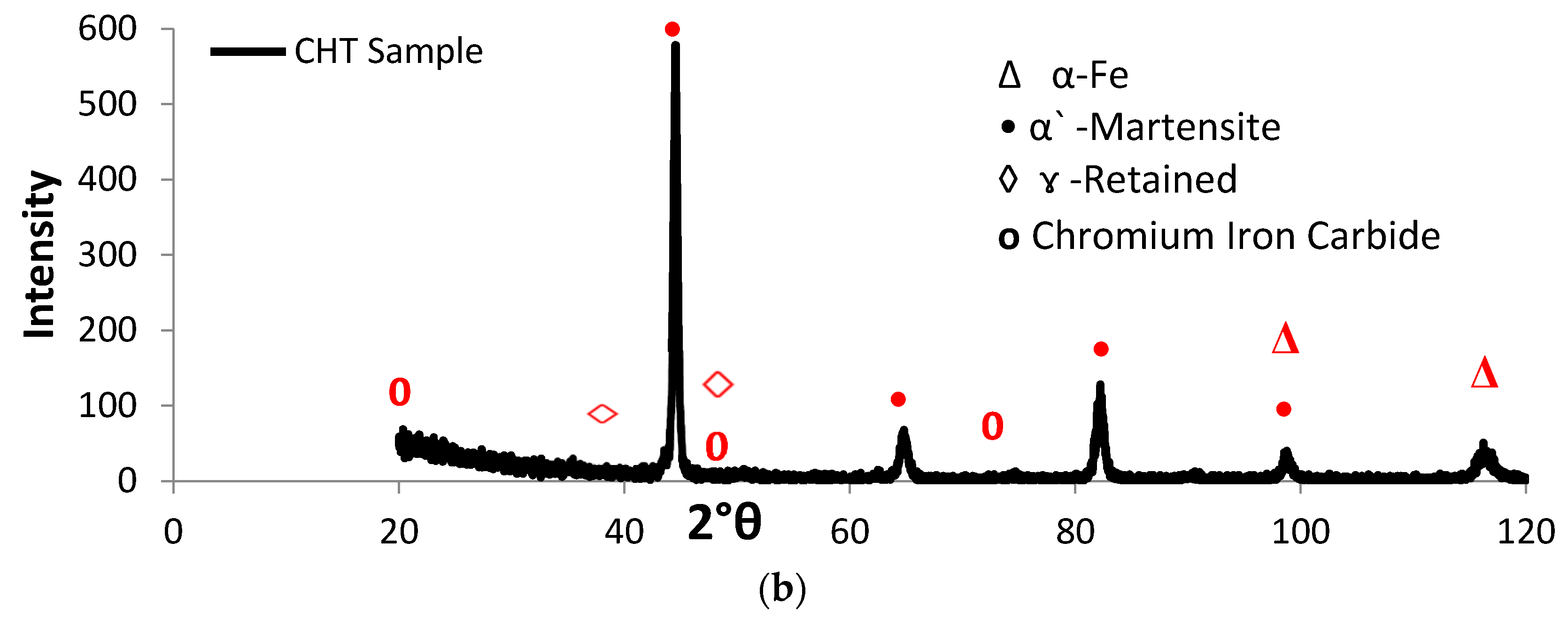

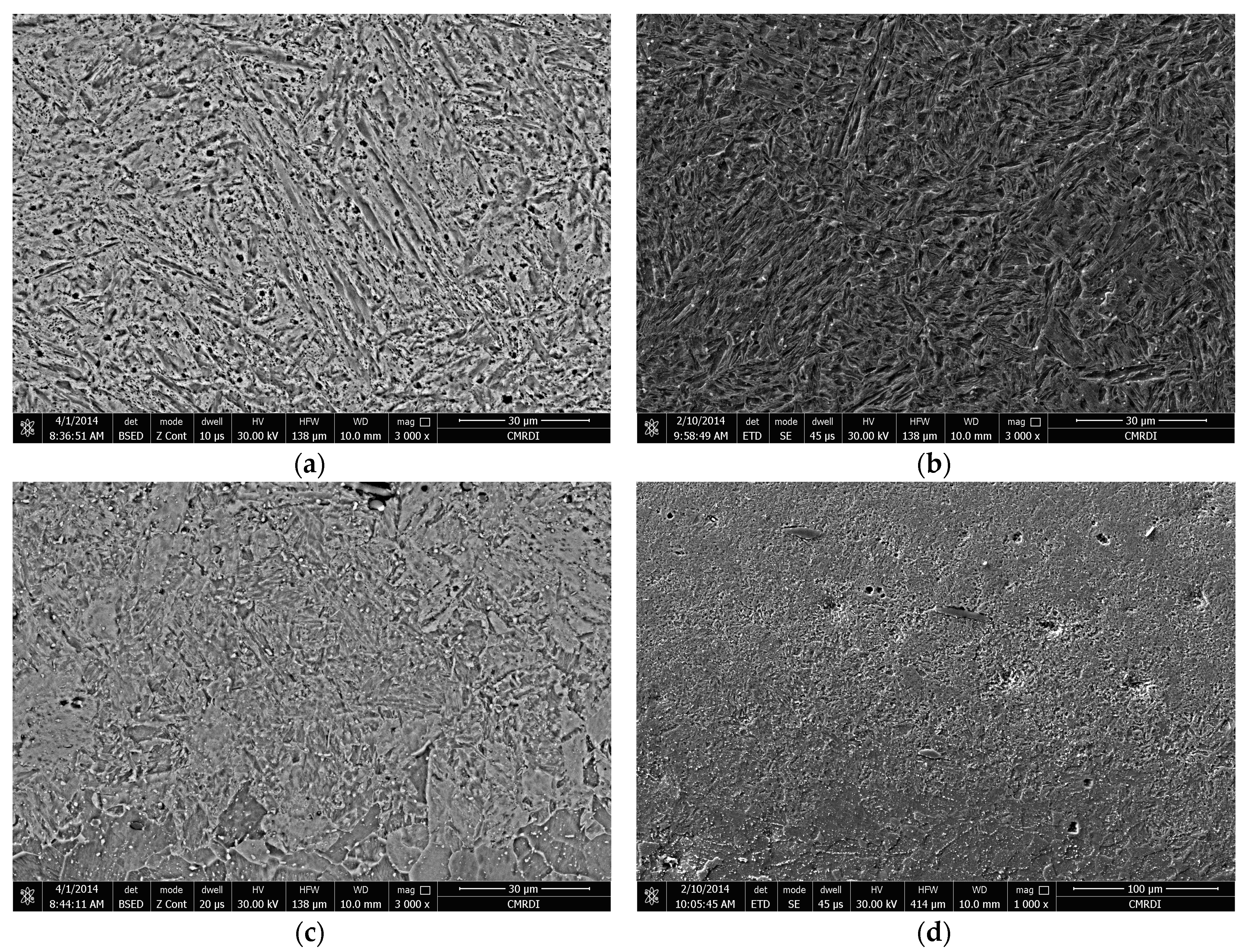

3.1.1. Microstructure of the As-Received Specimen

3.1.2. Microstructure of the CHT Specimens

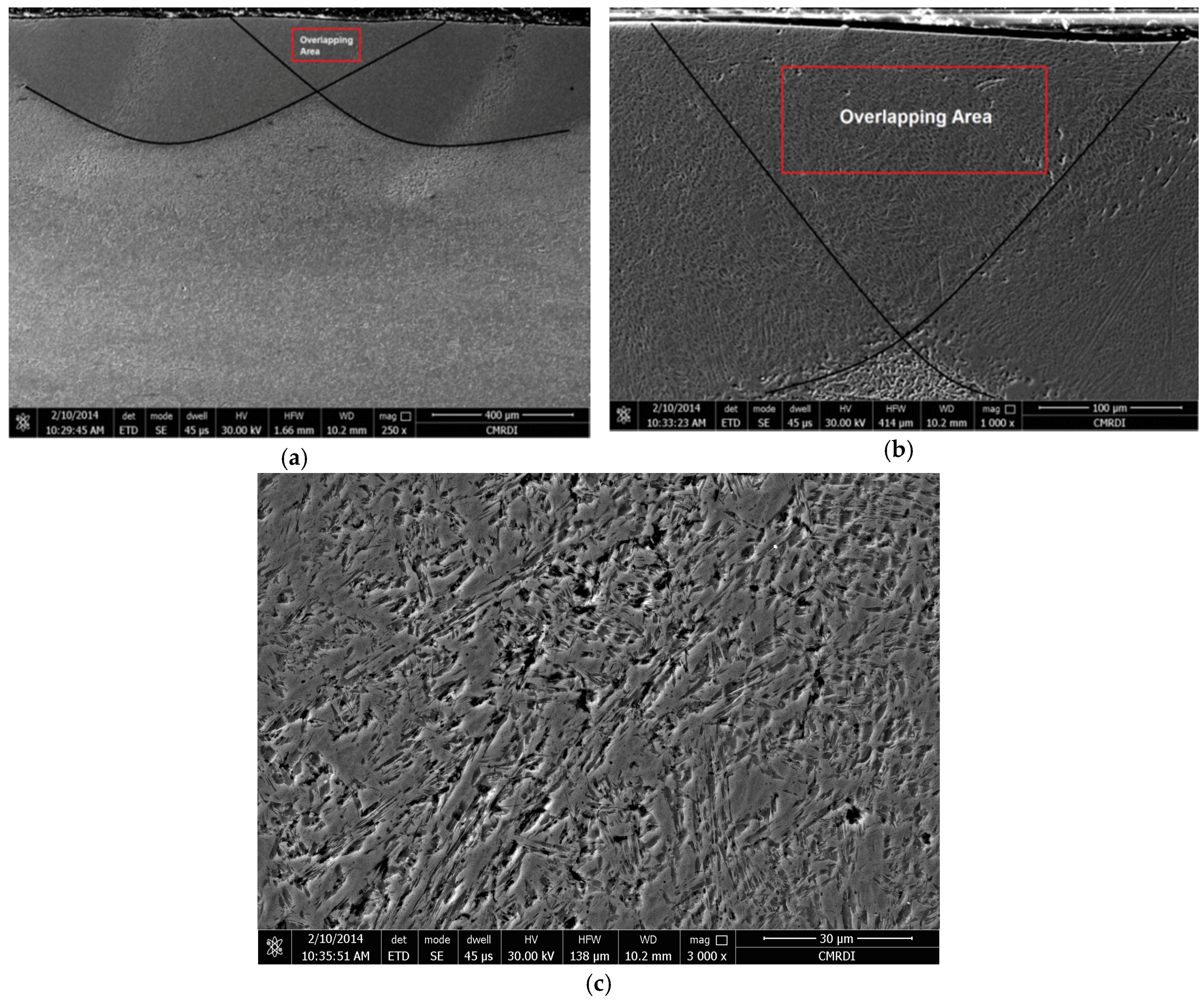

3.1.3. Microstructure of the LHT Specimens

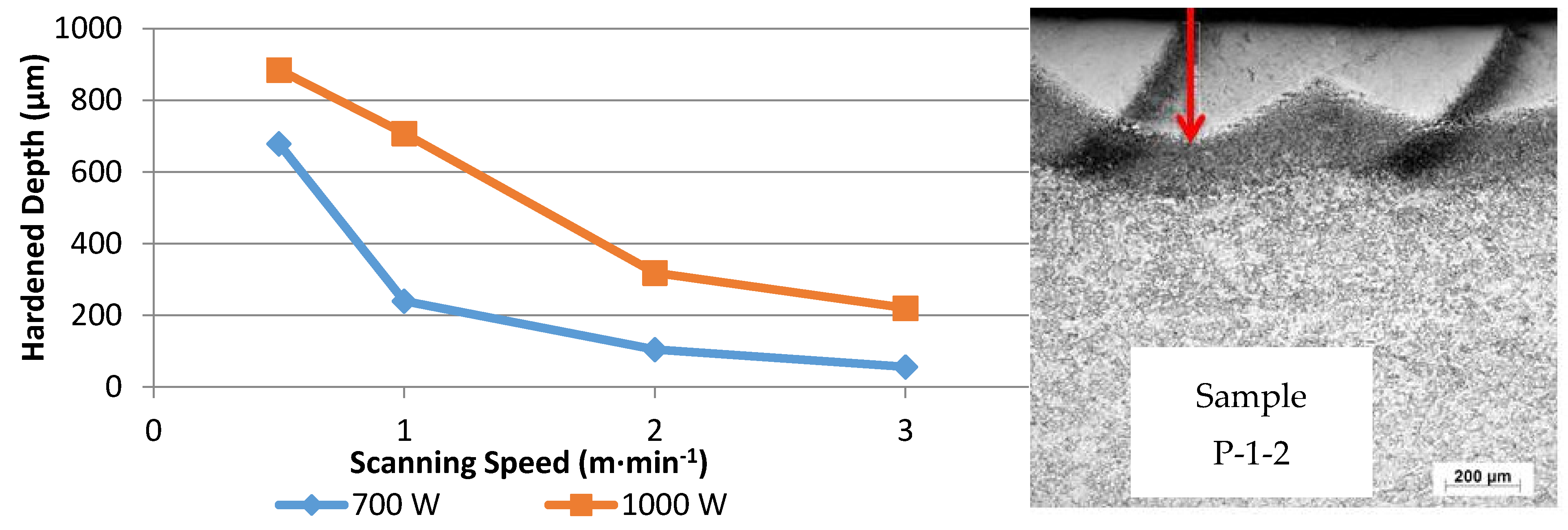

3.2. Hardened Depth

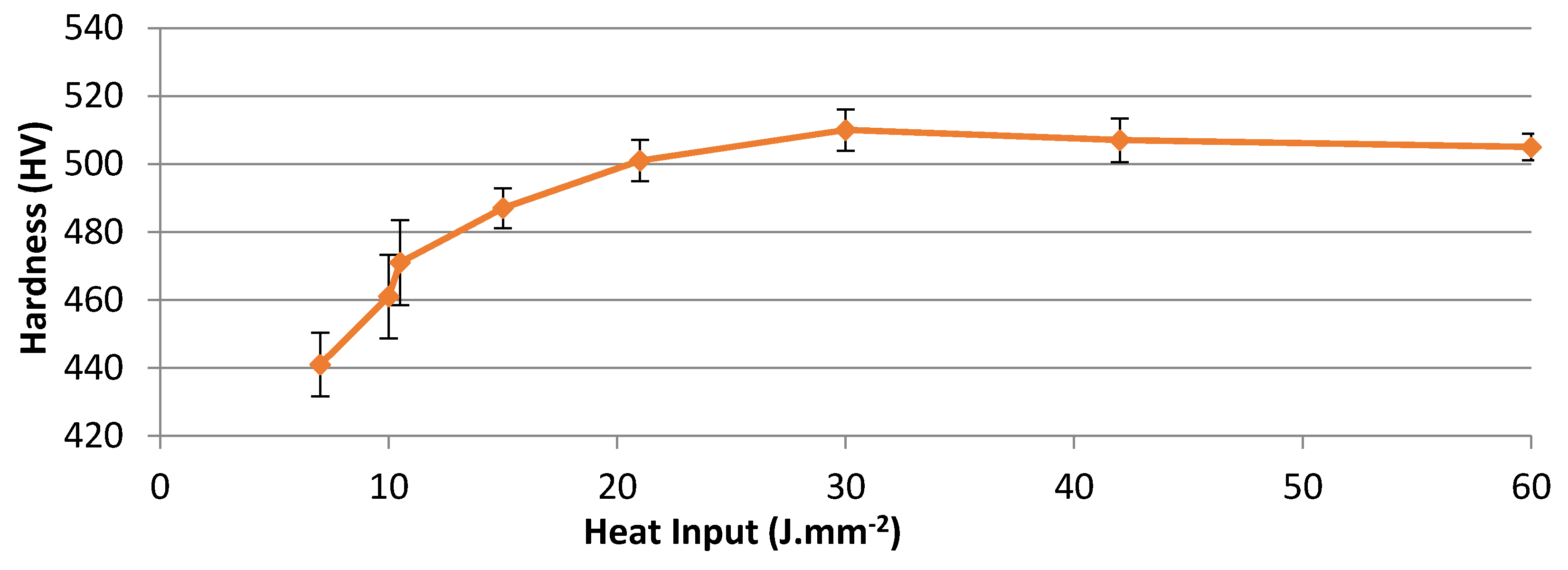

3.3. Macrohardness

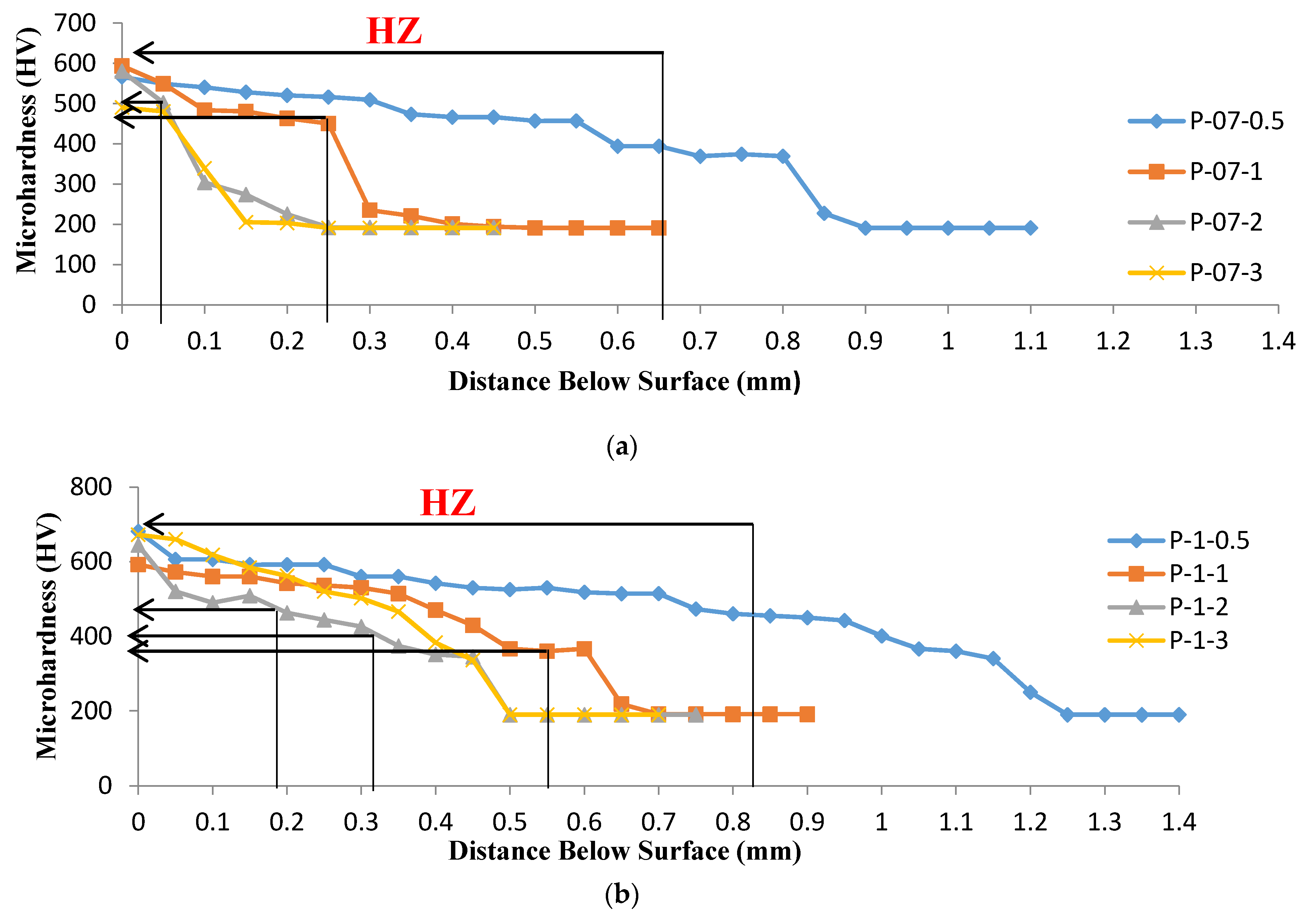

3.4. Microhardness Distribution

3.5. Wear Behavior

3.6. Impact Results

3.7. Corrosion Results

4. Discussion

4.1. Microstructural Analysis

4.2. Hardness and Wear Behavior

4.3. Impact Toughness

4.4. Corrosion Resistance

5. Conclusions

- Laser surface treatment of AISI 416 martensitic stainless steel considerably increased the surface hardness from 155 to 510 HV. The obtained hardness values were found to strongly depend on the heat input values. The hardness values increased with increasing heat input, or decreased with the increasing laser scanning speed.

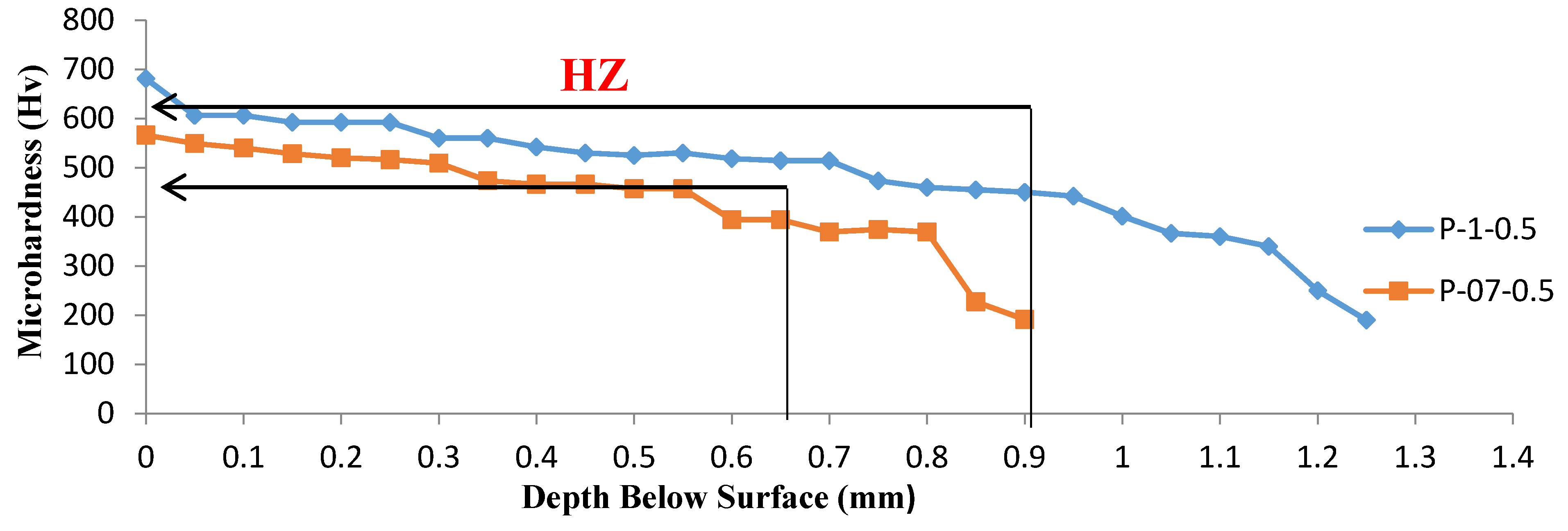

- The microhardness distribution in the laser affected region showed a stepwise profile. The average microhardness in the hardened zone reached HV 700, and in the heat affected zone it reached HV 450. The size of the shallowest hardened layer was 57 μm, and was associated with the lowest heat input (7 J·mm−2), while the deepest hardened layer was 885 μm and was achieved with the highest heat input value (60 J·mm−2), both with the lowest laser scanning speed of 0.5 m·min−1.

- The laser affected region could be divided into two zones based on different microstructures: (i) the hardened zone and (ii) the heat affected zone.

- As for heat input above 21 J·mm−2, heat was sufficient to obtain complete austenitization, and the carbon completely dissolved in austenite and caused an increase in hardness values and vice versa.

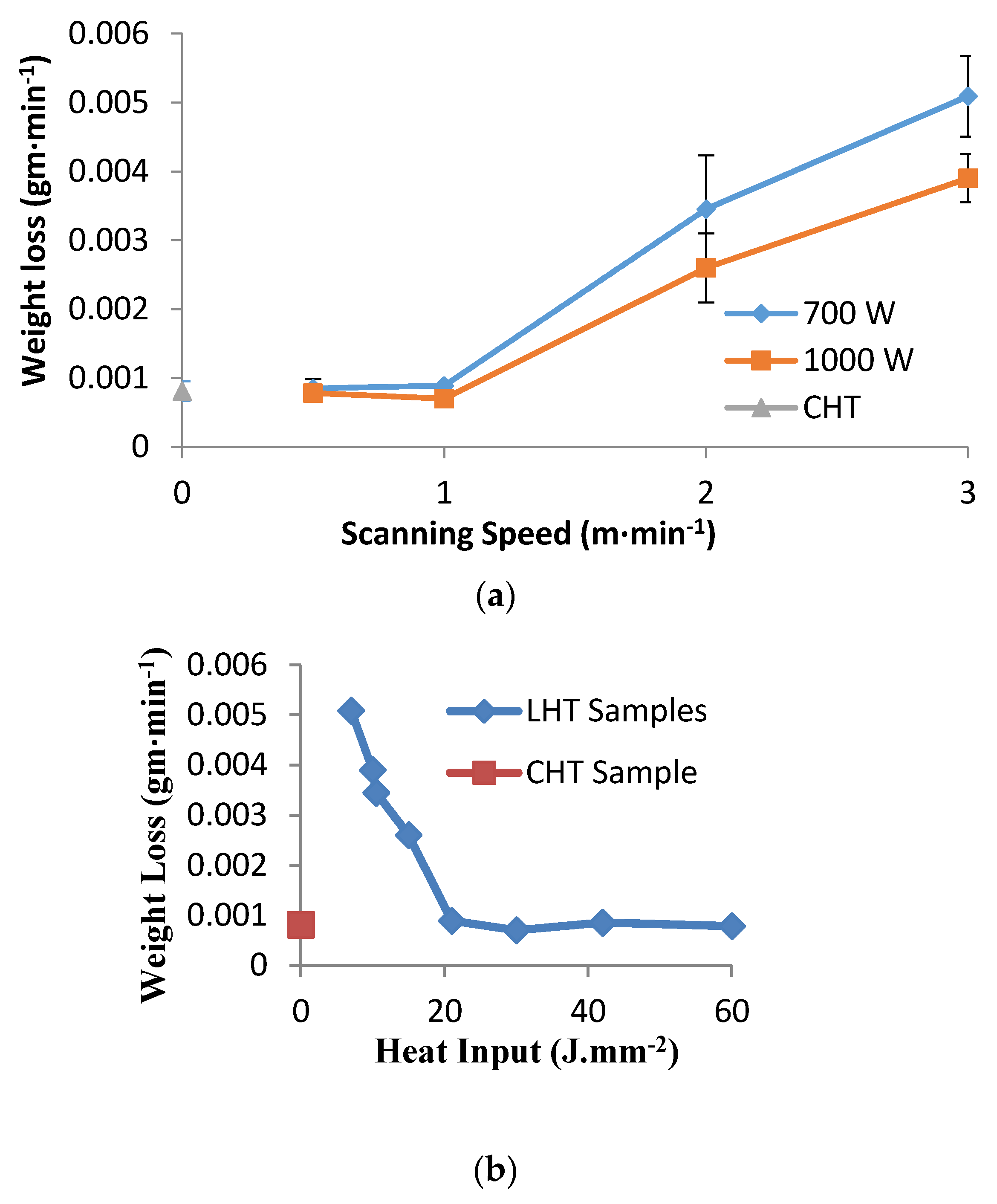

- Wear results showed that up to scanning speed of 1 m·min−1, the wear resistance of samples processed at both laser powers was comparable to the conventionally hardened samples. On the other hand, at higher speeds, LHT samples showed a decrease in wear resistance as the scanning speed increased; this may have partially been related to a shallower hardened depth, which might have entirely worn out during the wear test. The weight loss decreased with the increase in heat input. This was reflected through the surface hardness values after laser surface treatment.

- The wear resistance depended on the hardened depth, the amount of heat input, hardness levels, and compressive stresses.

- A significant result concerning the impact toughness and hardness values of laser heat treated samples, as compared to conventional heat treated samples, was reported. At the same level of hardness, laser treated samples experienced more than double the improvement in impact toughness. The reason for this increase was due to residual compressive stress induced by a laser surface treatment, which was able to restrain the growth of cracks.

- The CHT samples tempered at 600 °C had comparable impact energy with LHT samples, but at much lower hardness levels (280 Hv vs. 510 Hv), with correspondingly higher wear resistance in LHT samples.

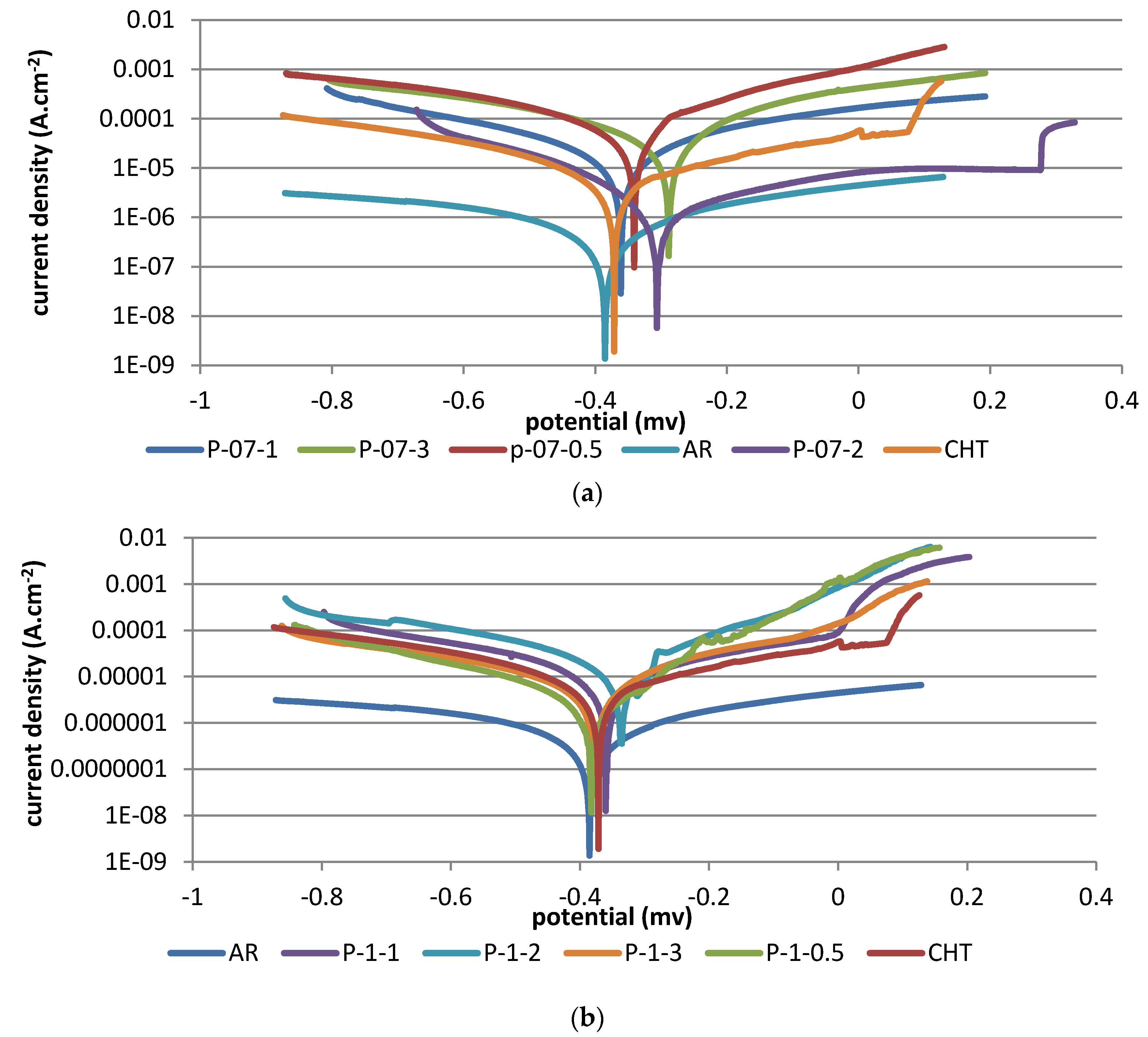

- The corrosion potentials of the LHT samples improved by 80 and 70 mV over those recorded for the AR and CHT samples respectively.

- The optimum condition for wear resistance, impact toughness and corrosion resistance was recorded at a heat input value of 21 J·mm−2. This may not have been the maximum value for each property, but it was the general optimum, consideringall of the properties as a whole.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Budinski, K.G. Surface Engineering for Wear Resistance; Prentice Hall: Englewood Cliffs, NJ, USA, 1988. [Google Scholar]

- Purushothaman, D.B.; Gengusamynaidu, B.; Karupuudaiyar, R.B. Experimental studies on the microstructure and hardness of laser-treated steel specimens. Trans. Can. Soc. Mech. Eng. 2012, 36, 241–258. [Google Scholar]

- Kusinski, J.; Kac, S.; Kopia, A.; Radziszewska, A.; Rozmus-Górnikowska, M.; Major, B.; Major, L.; Marczak, J.; Lisiecki, A. Laser modification of the materials surface layer—A review paper. Bull. Pol. Acad. Sci. Tech. Sci. 2012, 60, 711–728. [Google Scholar] [CrossRef]

- Steen, W.M. Laser Surface Treatment. In Laser Material Processing; Springer: London, UK, 1991; pp. 172–232. [Google Scholar]

- Majumdara, J.D.; Nath, A.K.; Manna, I. Studies on laser surface melting of tool steel-Part II: Mechanical properties of the surface. Surf. Coat. Technol. 2010, 204, 1326–1329. [Google Scholar] [CrossRef]

- Lovejoy, P.T. Structure and constitution of wrought martensitic stainless steels. In Handbook of Stainless Steels, 1st ed.; Packner, D., Bernstein, I.M., Eds.; McGraw-Hill: New York, NY, USA, 1977; p. 800. [Google Scholar]

- Berns, H. Manufacture and application of high nitrogen steels. ISI Int. 1996, 36, 909–914. [Google Scholar] [CrossRef]

- Krishna, B.V.; Bandyopadhyay, A. Surface modification of AISI 410 stainless steel using laser engineered net shaping (LENSTM). Mater. Des. 2009, 30, 1490–1496. [Google Scholar] [CrossRef]

- Bommi, V.C.; Mohan, M.K.; Prakash, S. Surface Modification of Martensitic Stainless steel Using Metal Working CO2 Laser. In Proceedings of the International Symposium of Research Students on Materials Science and Engineering, Chennai, India, 20–22 December; 2004; pp. 1–30. [Google Scholar]

- Ready, J.F.; Farson, D.F.; Feeley, T. Surface Treatment: Heat Treatment. In LIA Handbook of Laser Material Processing; Laser Institute of America; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2001. [Google Scholar]

- Loa, K.H.; Chenga, F.T.; Kwoka, C.T.; Man, H.C. Effects of laser treatments on cavitation erosion and corrosion of AISI 440C martensitic stainless steel. Mater. Lett. 2003, 58, 88–93. [Google Scholar] [CrossRef]

- Kwok, C.T.; Man, H.C.; Cheng, F.T. Cavitation erosion and pitting corrosion behaviour of laser surface-melted martensitic stainless steel UNS S42000. Surf. Coat. Technol. 2000, 126, 238–255. [Google Scholar] [CrossRef]

- Klar, E.; Samal, P.K. Powder Metallurgy Stainless Steels: Processing, Microstructures, and Properties; ASM International: Materials Park, OH, USA, 2007; pp. 5–18. [Google Scholar]

- Ion, J.C.; Moisio, T. Laser surface modification of a 13.5% Cr, 0.6% C steel. J. Mater. Sci. 1991, 26, 43–48. [Google Scholar] [CrossRef]

- Tsay, L.W.; Chang, Y.M.; Torng, S.; Wu, H.C. Improved Impact Toughness of 13Cr Martensitic Stainless Steel Hardened by Laser. J. Mater. Eng. Perform. 2002, 11, 422–427. [Google Scholar] [CrossRef]

- Tianmin, S.; Meng, H.; Yuen, T.H. Impact wear behavior of laser hardened hypoeutectoid 2Cr13 martensite stainless steel. Wear 2003, 255, 444–455. [Google Scholar] [CrossRef]

- Escudero, M.L.; Bello, J.M. Laser surface treatment and corrosion behaviour of martensitic stainless AISI 420 steel. Mater. Sci. Eng. A 1992, 158, 227–233. [Google Scholar] [CrossRef]

- Ingelgem, Y.V.; Vandendae, I.; van den Broek, D.; Hubin, A.; Vereecken, J. Influence of laser surface hardening on the corrosion resistance of martensitic stainless steel. Electrochim. Acta 2007, 52, 7796–7801. [Google Scholar] [CrossRef]

- Conde, A.; Colac, R.; Vilar, R.; de Damborenea, J. Corrosion behaviour of steels after laser surface melting. Mater. Des. 2000, 21, 441–445. [Google Scholar] [CrossRef]

- Kwok, C.T.; Lo, K.H.; Cheng, F.T.; Man, H.C. Effect of processing conditions on the corrosion performance of laser surface-melted AISI 440C martensitic stainless steel. Surf. Coat. Technol. 2003, 166, 221–230. [Google Scholar] [CrossRef]

- Yong, T.T.; Sudesh, L.W.; Gary, K.L.N.; Daniel, J.B. Investigation into the influence of laser melting on the sulphide inclusions in AISI 416 stainless steel. Corros. Sci. 2011, 53, 3950–3955. [Google Scholar]

- Charschan, S.S. Lasers in Industry; Van Nostrand Reinhold Company: New York, NY, USA, 1972. [Google Scholar]

- Rana, J.; Goswami, G.L.; Jha, S.K.; Mishra, P.K.; Prasad, B.V.S.S.S. Experimental studies on the microstructure and hardness of laser-treated steel specimens. Opt. Laser Technol. 2007, 39, 385–393. [Google Scholar] [CrossRef]

- Jeffrey, A. ASM Handbook Volume 8: Mechanical Testing and Evaluation; Kuhn, H., Medlin, D., Eds.; ASM International: Materials Park, OH, USA, 2004; Volume 8. [Google Scholar]

- Navasa, C.; Condea, A.; Fernándeza, B.J.; Zubirib, F.; Damborenea, J. Laser coatings to improve wear resistance of mould steel. Surf. Coat. Technol. 2005, 194, 136–142. [Google Scholar] [CrossRef]

- Asibu, E.K., Jr. Laser surface modification. In Principles of Laser Materials Processing; John Wiley & Sons: Hoboken, NJ, USA, 2009; pp. 409–427. [Google Scholar]

- Katsamas, A.I.; Haidemenopoulos, G.N. Surface hardening of low-alloy 15CrNi6 steel by CO2 laser beam. Surf. Coat. Technol. 1999, 115, 249–255. [Google Scholar] [CrossRef]

- National Technical Committee for Standardization of Heat Treatment. Applied Standard Handbook of Metal Heat Treatment; Machinery Industry: Beijing, China, 1994. [Google Scholar]

- Selvan, J.S.; Subramanian, K.; Nath, A.K. Effect of laser surface hardening on En18 (AISI 5135) steel. J. Mater. Process. Technol. 1999, 91, 249–255. [Google Scholar] [CrossRef]

- Hussein, H.T.; Kadhim, A.; Al-Amiery, A.A.; Kaghum, A.A.H.; Mohamad, A.B. Enhancement of the Wear Resistance and Microhardness of Aluminum Alloy by Nd:YaG Laser Treatment. Sci. World J. 2014, 2014, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Xia, W.G.; Li, L.; Wei, Y.P.; Zhao, A.M.; Guo, Y.C.; Huang, C.G.; Yin, H.X.; Zhang, L.C. Impact toughness of a gradient hardened layer of Cr5Mo1V steel treated by laser shock peening. Acta Mech. Sin. 2016, 32, 301–308. [Google Scholar]

- Ulrike, T.; Veronika, C.; Ute, S.; Michael, J.H. ASM Handbook Volume 9: Metallography and Microstructures; ASM International: Materials Park, OH, USA, 2004. [Google Scholar]

| Sample No. P-X-Y | Laser Power P (KW) | Laser Scanning Speed v (m·min−1) |

|---|---|---|

| P-07-0.5 | 0.7 | 0.5 |

| P-07-1 | 0.7 | 1 |

| P-07-2 | 0.7 | 2 |

| P-07-3 | 0.7 | 3 |

| P-1-0.5 | 1 | 0.5 |

| P-1-1 | 1 | 1 |

| P-1-2 | 1 | 2 |

| P-1-3 | 1 | 3 |

| Condition | AR | CHT | P-07-0.5 | P-07-1 | P-07-2 | P-07-3 | P-1-0.5 | P-1-1 | P-1-2 | P-1-3 |

|---|---|---|---|---|---|---|---|---|---|---|

| Corrosion potential (mV vs. SRE) | −385 | −372 | −340 | −359 | −307 | −328 | −380 | −361 | −335 | −378 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Sayed, S.R.; Hussein, A.A.; Nofal, A.A.; Hassab Elnaby, S.I.; Elgazzar, H. Characterization of a Laser Surface-Treated Martensitic Stainless Steel. Materials 2017, 10, 595. https://doi.org/10.3390/ma10060595

Al-Sayed SR, Hussein AA, Nofal AA, Hassab Elnaby SI, Elgazzar H. Characterization of a Laser Surface-Treated Martensitic Stainless Steel. Materials. 2017; 10(6):595. https://doi.org/10.3390/ma10060595

Chicago/Turabian StyleAl-Sayed, S.R., A.A. Hussein, A.A. Nofal, S.I. Hassab Elnaby, and H. Elgazzar. 2017. "Characterization of a Laser Surface-Treated Martensitic Stainless Steel" Materials 10, no. 6: 595. https://doi.org/10.3390/ma10060595