Influence of Low-Frequency Vibration and Modification on Solidification and Mechanical Properties of Al-Si Casting Alloy

Abstract

:1. Introduction

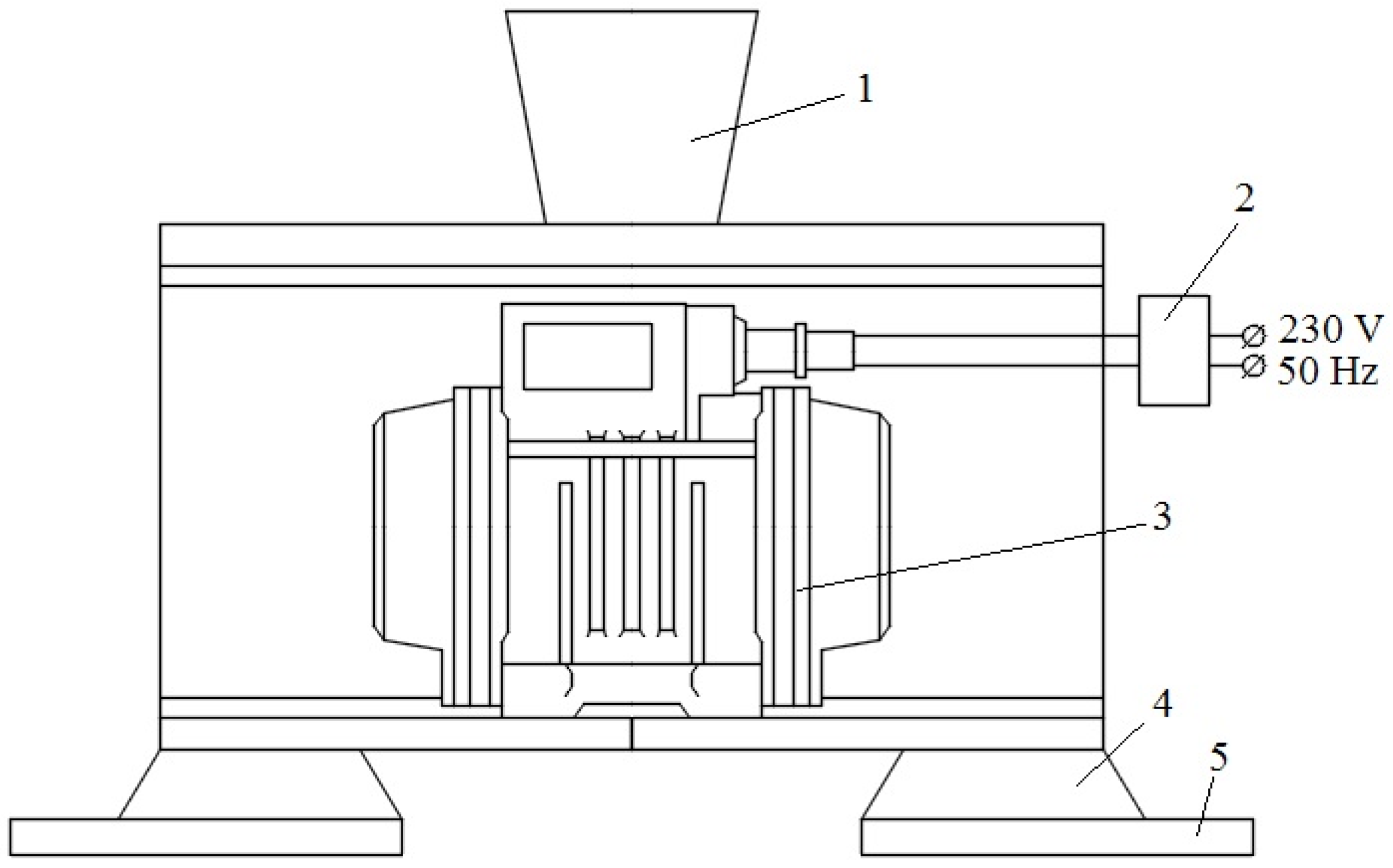

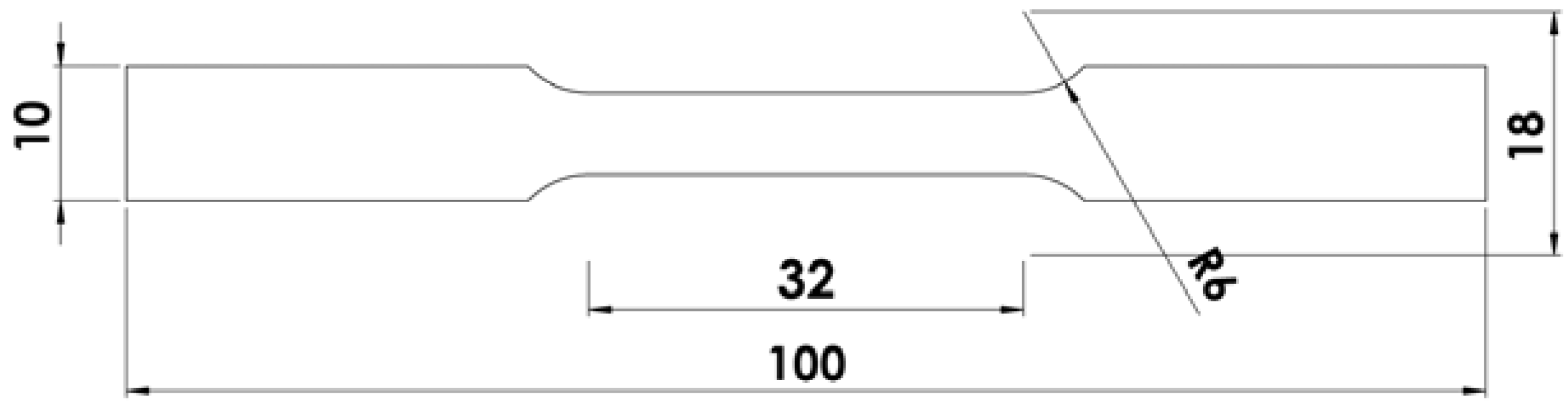

2. Materials and Methods

- ds—density of the sample (g/cm3);

- Рa—mass of the sample in the air (g);

- Рh—mass of the sample in ССl4 (g);

- dh—density of the CCl4 (g/cm3).

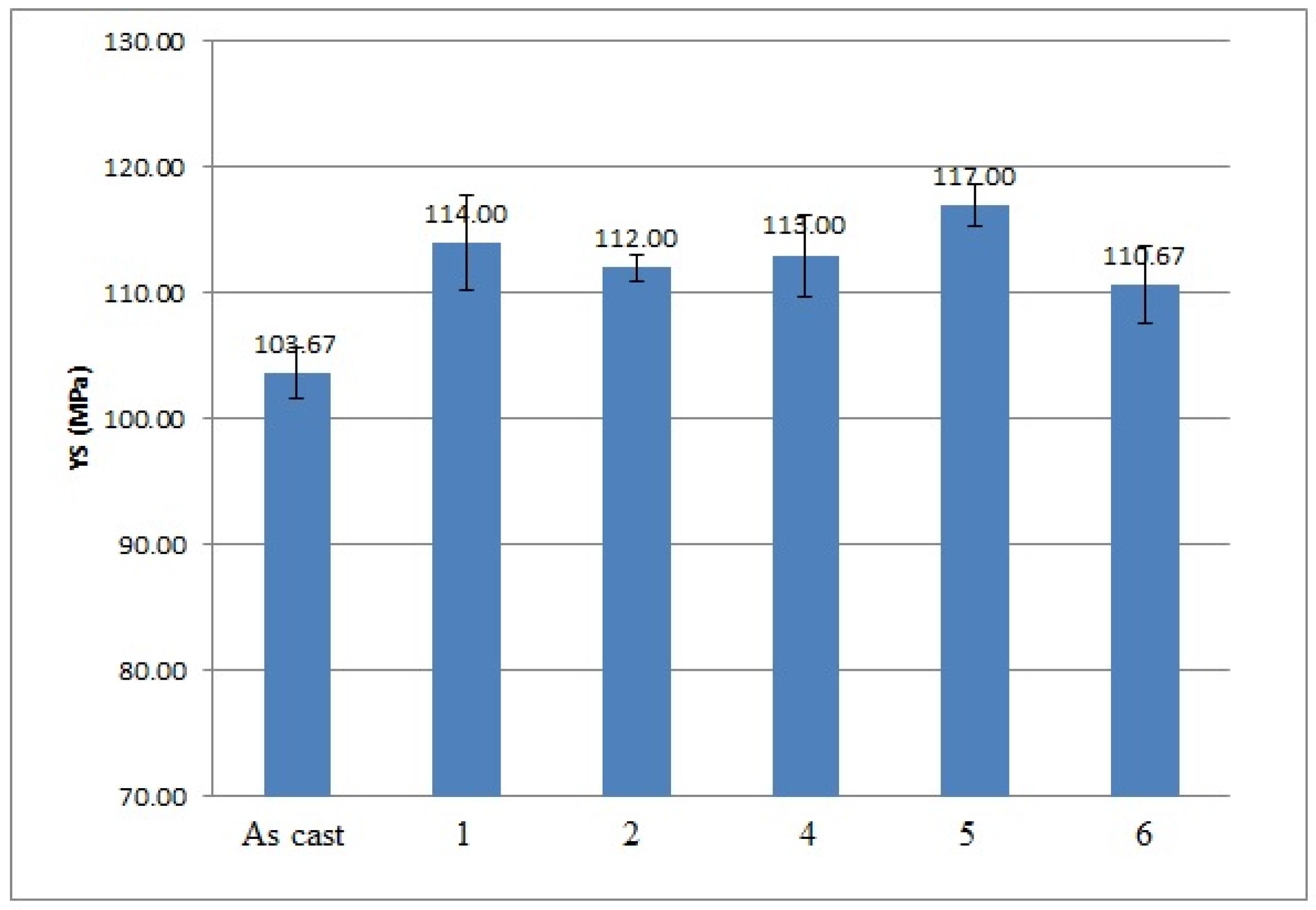

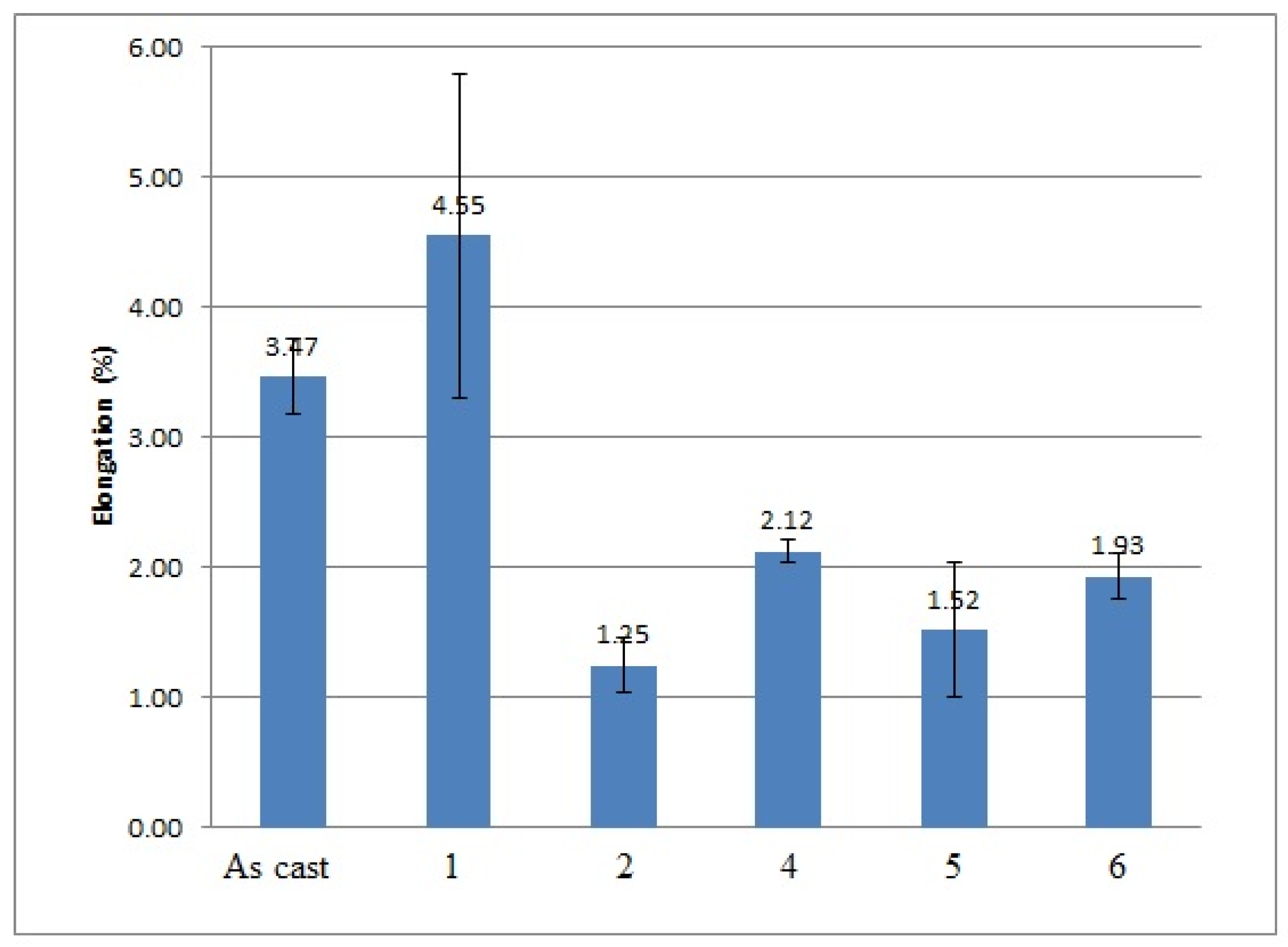

3. Results and Discussion

4. Conclusions

- Study of the mechanical properties revealed that the alloys subjected to 100 Hz and 150 Hz vibration treatment showed the highest properties, as the tensile and the yield strengths improved by 20% and 10% respectively.

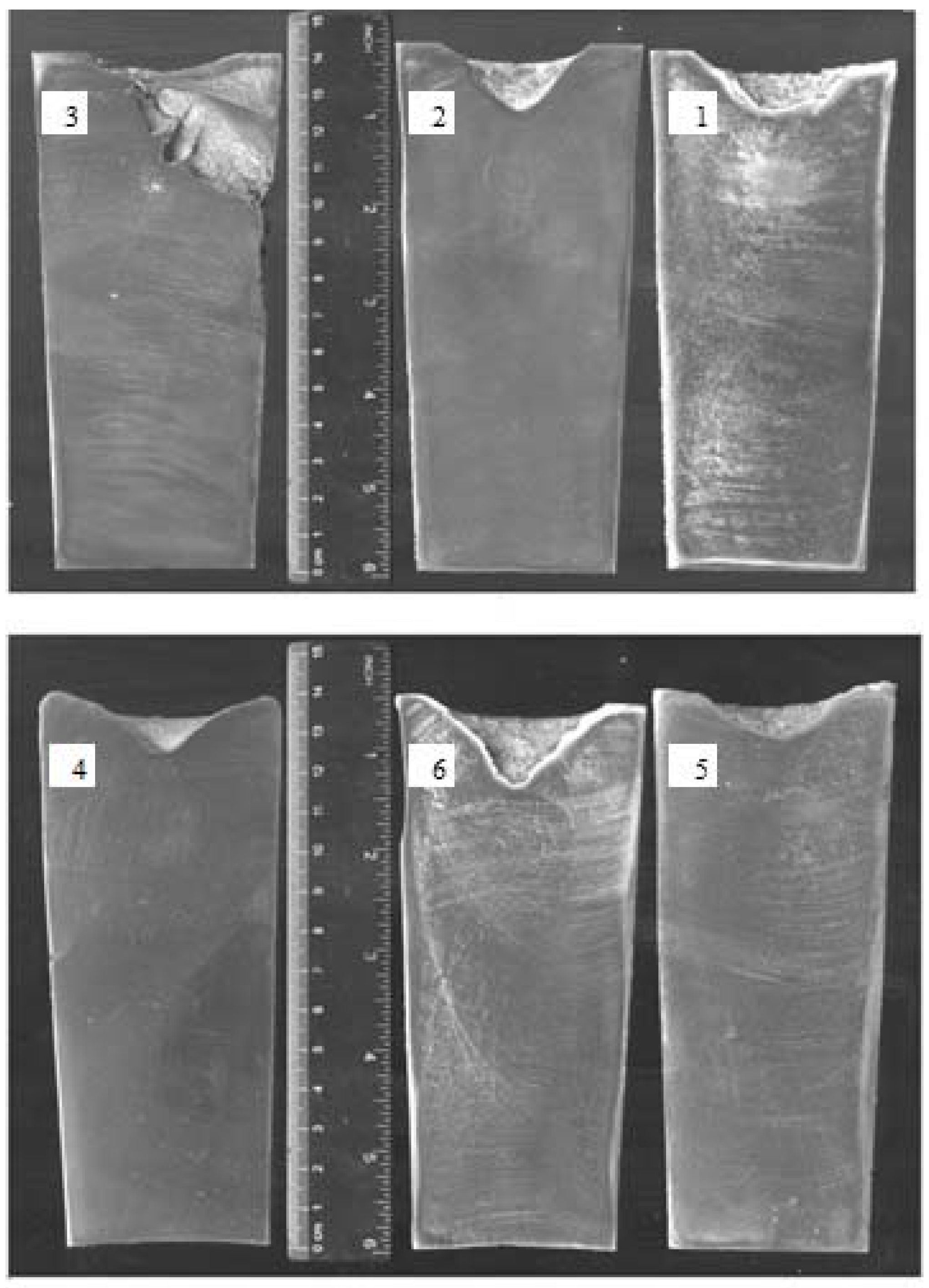

- The densities of the alloys subjected to the vibration treatment varied in the range of 2.5–3.7% as a result of the presence of segregation areas in the obtained cast ingots.

- The use of relatively high vibration frequencies (200 Hz) caused the formation of a high porosity microstructure and therefore caused major defects and the failure of the alloy.

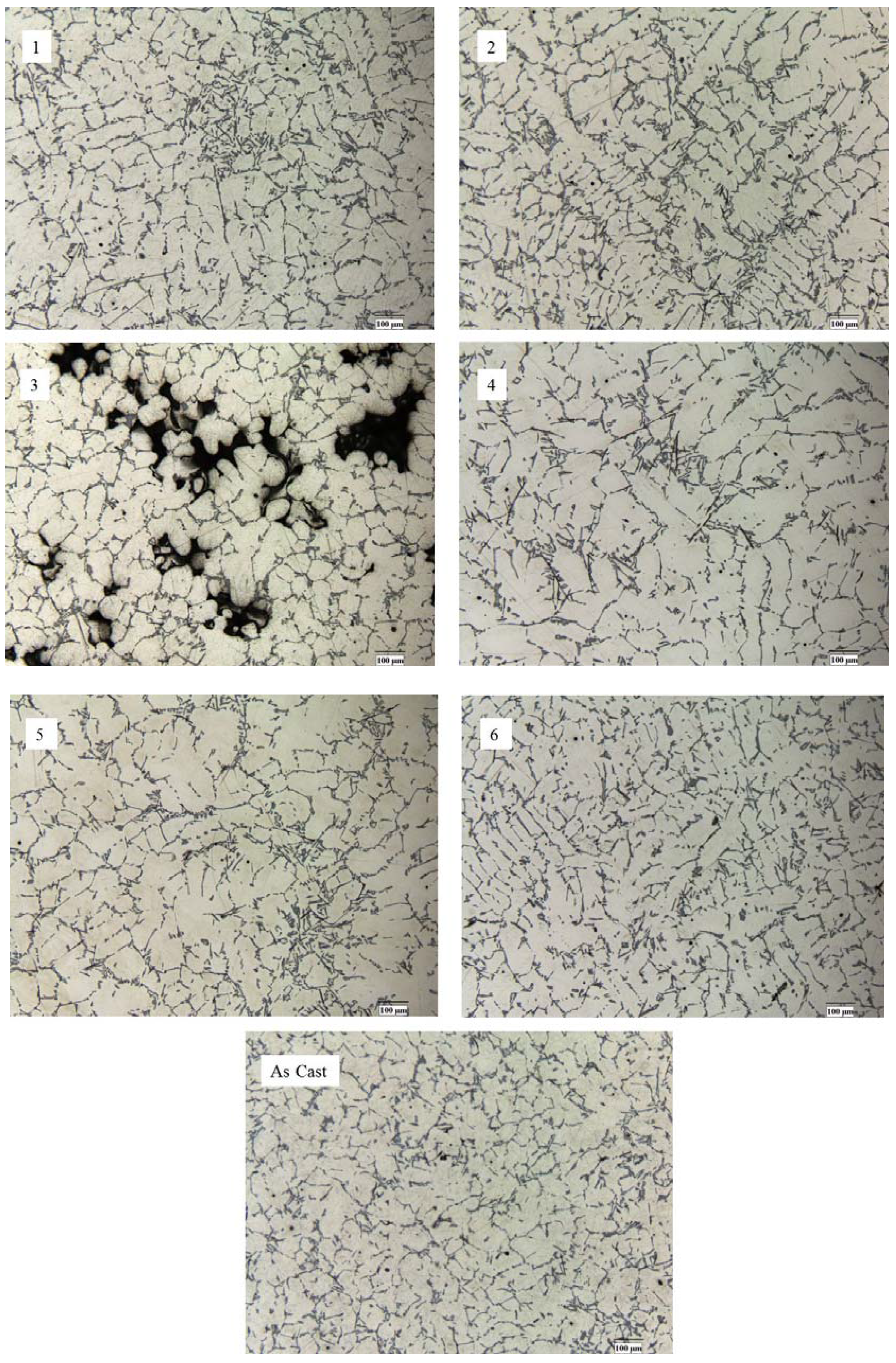

- The microstructural studies followed by an image analysis evaluated that the alloys subjected to the vibration treatment showed the refinement of α-Al grains with an increase in the Si network area around them.

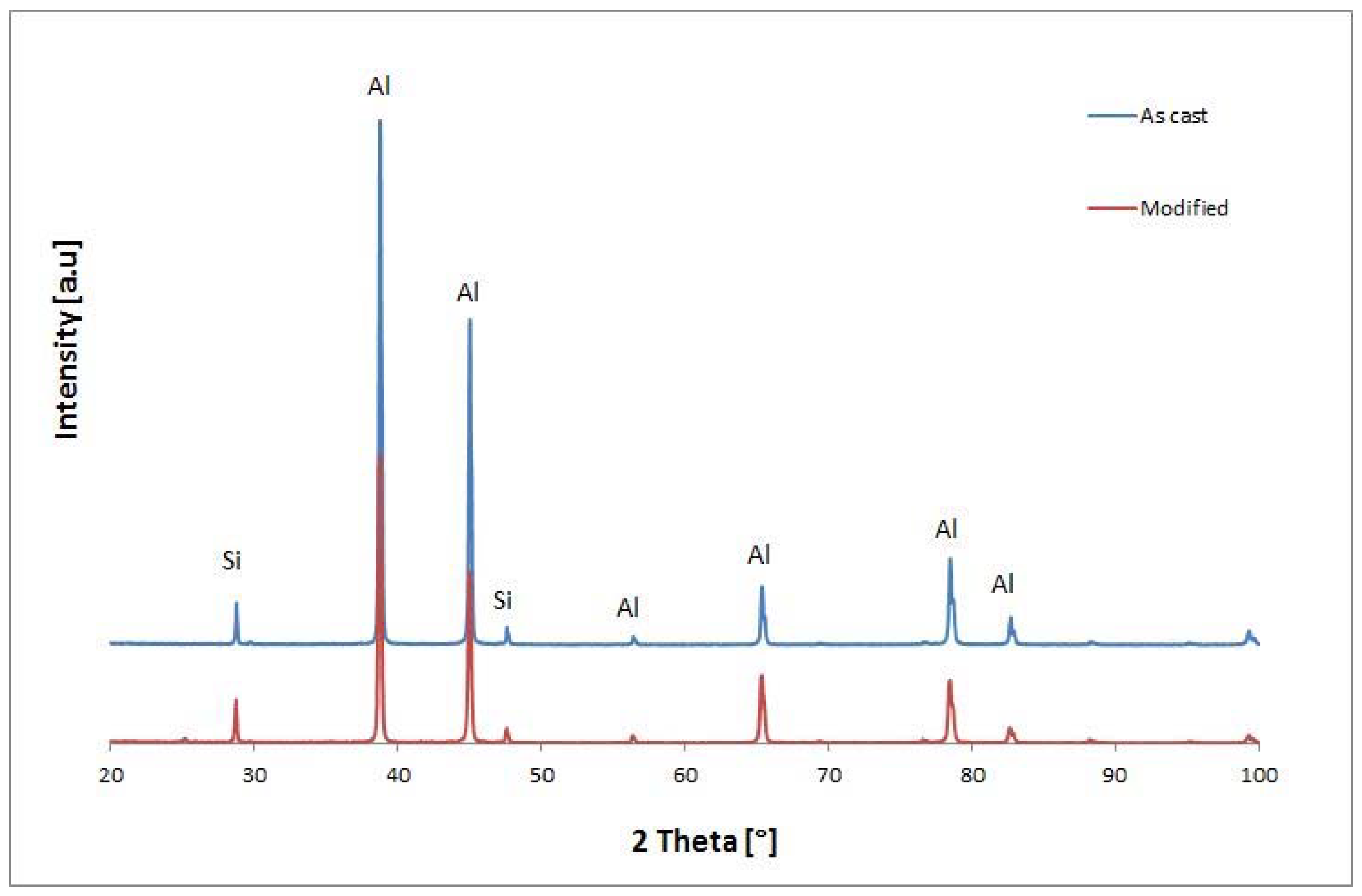

- XRD results demonstrated that there was no formation of any new phase after the modification process.

Author Contributions

Conflicts of Interest

References

- Callister, W.D. Materials Science and Engineering, 7th ed.; John Wiley & Sons Inc.: Hoboken, NY, USA, 2007. [Google Scholar]

- Birol, Y. AlB3 master alloy to grain refine AlSi10Mg and AlSi12Cu aluminum foundry alloys. J. Alloy. Compd. 2012, 513, 150–153. [Google Scholar] [CrossRef]

- Schaffer, P.L.; Dahle, A.K. Settling behavior of different grain refiners in aluminum. Mater. Sci. Eng. A 2005, 413–414, 373–378. [Google Scholar] [CrossRef]

- Mohanty, P.S.; Gruzleski, J.E. Mechanism of grain refinement in aluminum. Acta Metall. Mater. 1995, 43, 2001–2012. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M.; Yu, B.; Chen, D.; Qin, P.; Feng, M.; Dai, Q. The grain refinement behavior of TiB2 particles prepared with in situ technology. Mater. Sci. Eng. A 2007, 459, 238–243. [Google Scholar] [CrossRef]

- Daoud, A.; Abo-Elkhar, M. Influence of Al2O3 or ZrO2 particulate addition on the microstructure aspects of AlNi and AlSi alloys. J. Mater. Process. Technol. 2002, 120, 296–302. [Google Scholar] [CrossRef]

- Chou, S.-N.; Huang, J.-L.; Lii, D.-F.; Lu, H.-H. The mechanical properties of Al2O3/aluminum alloy A356 composite manufactured by squeeze casting. J. Alloy. Compd. 2006, 419, 98–102. [Google Scholar] [CrossRef]

- Han, Y.; Le, K.; Wang, J.; Shu, D.; Sun, B. Influence of high-intensity ultrasound on grain refining performance of Al–5Ti–1B master alloy on aluminum. Mater. Sci. Eng. A 2005, 405, 306–312. [Google Scholar] [CrossRef]

- Das, A.; Kotadia, H.R. Effect of high-intensity ultrasonic irradiation on the modification of solidification microstructure in a Si-rich hypoeutectic Al–Si alloy. Mater. Chem. Phys. 2011, 125, 853–859. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Y.; Cheng, X.; Chen, G.; Dai, Q. High-energy ultrasonic field effects on the microstructure and mechanical behaviors of A356 alloy. J. Alloy. Compd. 2009, 470, 168–172. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Torabi Parizi, M.; Ezatpour, H.R.; Sedghic, A. Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties. J. Alloy. Compd. 2012, 511, 226–231. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Baharvandi, H.R.; Shirvanimoghaddam, K. Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater. Des. 2015, 66, 150–161. [Google Scholar] [CrossRef]

- Borodianskiy, K.; Kossenko, A.; Zinigrad, M. Improvement of the mechanical properties of Al-Si alloys by TiC nanoparticles. Metall. Mater. Trans. A 2013, 44, 4948–4953. [Google Scholar] [CrossRef]

- Borodianskiy, K.; Zinigrad, M. Modification performance of WC nanoparticles in aluminum and an Al-Si casting alloy. Metall. Mater. Trans. B 2016, 47, 1302–1308. [Google Scholar] [CrossRef]

- Vorozhtsov, S.; Kudryashova, O.; Promakhov, V.; Dammer, V.; Vorozhtsov, A. Theoretical and experimental investigations of the process of vibration treatment of liquid metals containing nanoparticles. JOM 2016, 68, 3094–3100. [Google Scholar] [CrossRef]

- Taghavi, F.; Saghafian, H.; Kharrazi, Y.H.K. Study on the effect of prolonged mechanical vibration on the grain refinement and density of A356 aluminum alloy. Mater. Des. 2009, 30, 1604–1611. [Google Scholar] [CrossRef]

- Jian, X.; Meek, T.T.; Han, Q. Refinement of eutectic silicon phase of aluminum A356 alloy using high-intensity ultrasonic vibration. Scr. Mater. 2006, 54, 893–896. [Google Scholar] [CrossRef]

- Gencalp, S.; Saklakoglu, N. Semisolid microstructure evolution during cooling slope casting under vibration of A380 aluminum alloy. Mater. Manuf. Process. 2010, 25, 943–947. [Google Scholar] [CrossRef]

- Limmaneevichitr, C.; Pongananpanya, S.; Kajornchaiyakul, J. Metallurgical structure of A356 aluminum alloy solidified under mechanical vibration: An investigation of alternative semi-solid casting routes. Mater. Des. 2009, 30, 3925–3930. [Google Scholar] [CrossRef]

- Barbosa, J.; Puga, H. Ultrasonic melt processing in the low pressure investment casting of Al alloys. J. Mater. Process. Technol. 2017, 244, 150–156. [Google Scholar] [CrossRef]

- Okayasu, M.; Miyamoto, Y.; Morinaka, K. Material properties of various cast aluminum alloys made using a heated mold continuous casting technique with and without ultrasonic vibration. Metals 2015, 5, 1440–1453. [Google Scholar] [CrossRef]

| Si | Mg | Fe | Cu | Zn | Ni | Al |

|---|---|---|---|---|---|---|

| 8.35 | 0.39 | 0.48 | 0.05 | 0.03 | 0.01 | Base |

| Al2O3 | Fe2O3 | CaO | K2O + Na2O | MgO | C | TiO2 | S | FeO | SiO2 |

|---|---|---|---|---|---|---|---|---|---|

| 25 | 8 | 4 | 4 | 3 | 1.5 | 1 | 1 | 0.5 | Base |

| Sample No. | Vibration Frequency (Hz) | Modifier |

|---|---|---|

| 1 | 100 | - |

| 2 | 150 | - |

| 3 | 200 | - |

| 4 | - | + |

| 5 | 100 | + |

| 6 | 150 | + |

| As cast | - | - |

| Sample No. | Average Density (g/cm3) |

|---|---|

| As cast | 2.752 ± 0.015 |

| 1 | 2.733 ± 0.004 |

| 2 | 2.786 ± 0.047 |

| 3 | 2.784 ± 0.020 |

| 4 | 2.736 ± 0.000 |

| 5 | 2.768 ± 0.027 |

| 6 | 2.734 ± 0.002 |

| As Cast | 1 | 2 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|

| Length of α-Al grains (μm) | 38.97 | 33.64 | 32.67 | 38.73 | 35.07 | 36.19 |

| Eutectic phase area (%) | 15.18 | 17.27 | 21.73 | 12.51 | 16.61 | 13.32 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selivorstov, V.; Dotsenko, Y.; Borodianskiy, K. Influence of Low-Frequency Vibration and Modification on Solidification and Mechanical Properties of Al-Si Casting Alloy. Materials 2017, 10, 560. https://doi.org/10.3390/ma10050560

Selivorstov V, Dotsenko Y, Borodianskiy K. Influence of Low-Frequency Vibration and Modification on Solidification and Mechanical Properties of Al-Si Casting Alloy. Materials. 2017; 10(5):560. https://doi.org/10.3390/ma10050560

Chicago/Turabian StyleSelivorstov, Vadim, Yuri Dotsenko, and Konstantin Borodianskiy. 2017. "Influence of Low-Frequency Vibration and Modification on Solidification and Mechanical Properties of Al-Si Casting Alloy" Materials 10, no. 5: 560. https://doi.org/10.3390/ma10050560