Effect of Surface-Modified TiO2 Nanoparticles on the Anti-Ultraviolet Aging Performance of Foamed Wheat Straw Fiber/Polypropylene Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Preparation

2.2. Modification of TiO2 Nanoparticles with the A171 Coupling Agent

2.3. Modification of Wheat Straw Fiber with the A171 Coupling Agent and Modified TiO2 Nanoparticle Powder

2.4. Blend Design and Sample Fabrication

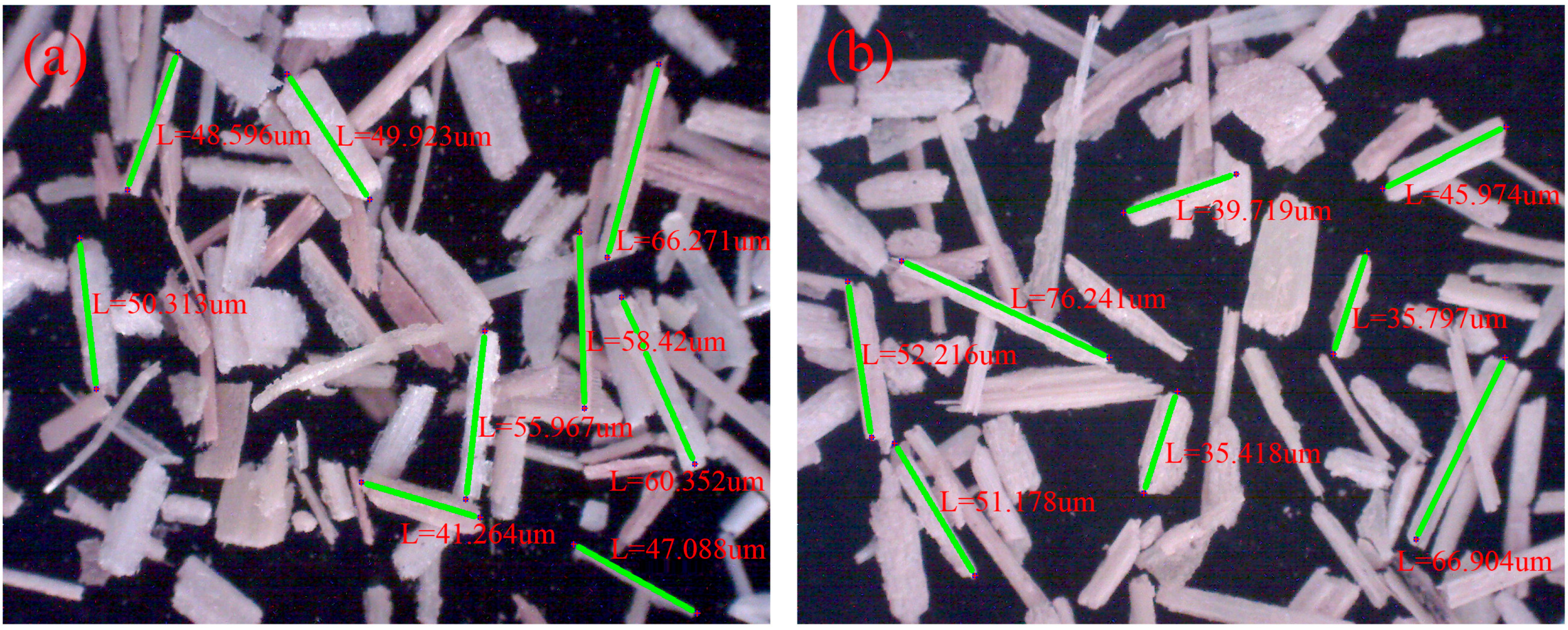

2.5. Material Characterization

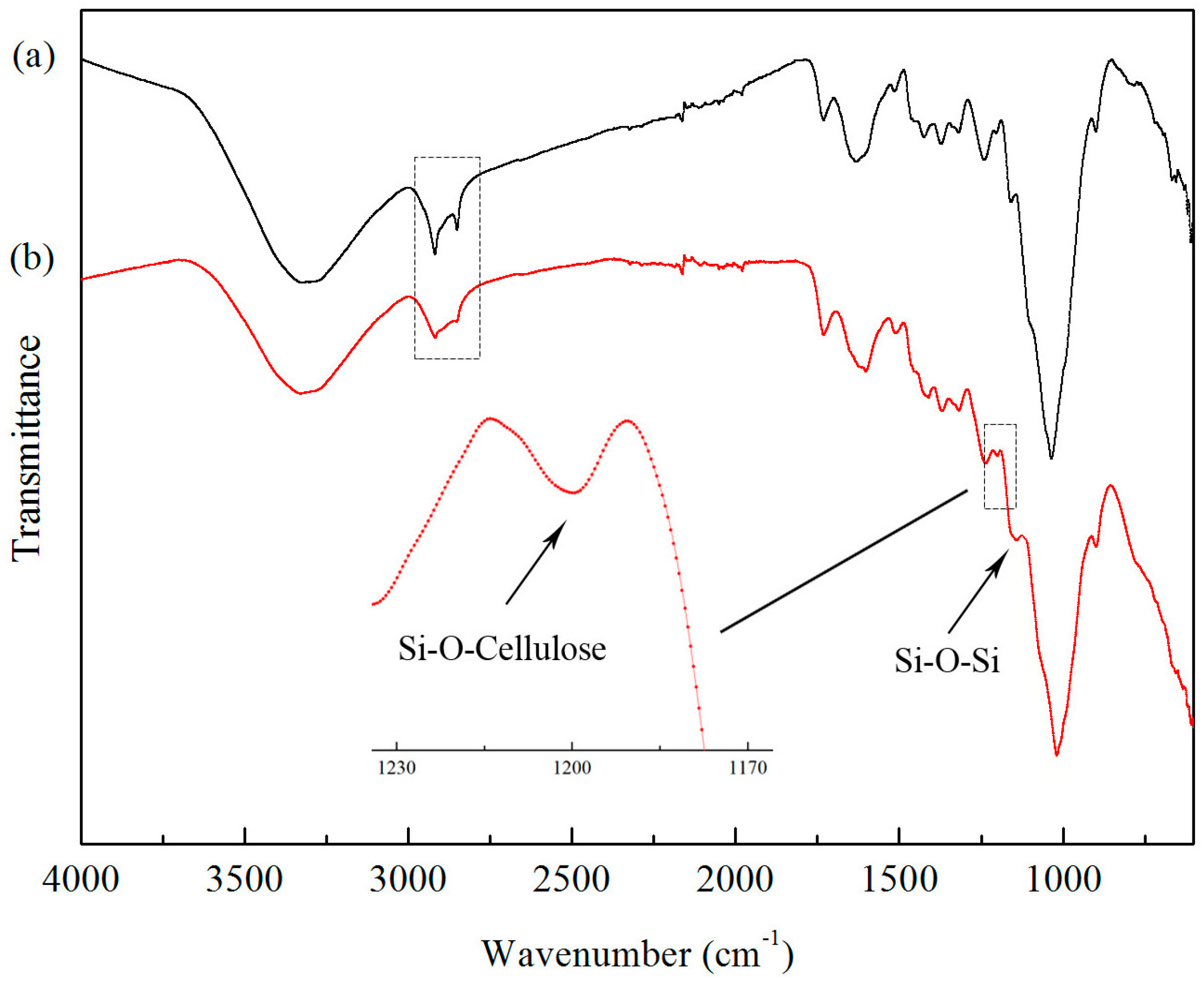

2.5.1. FTIR Study

2.5.2. Thermogravimetric Analysis

2.5.3. Accelerated Aging Test

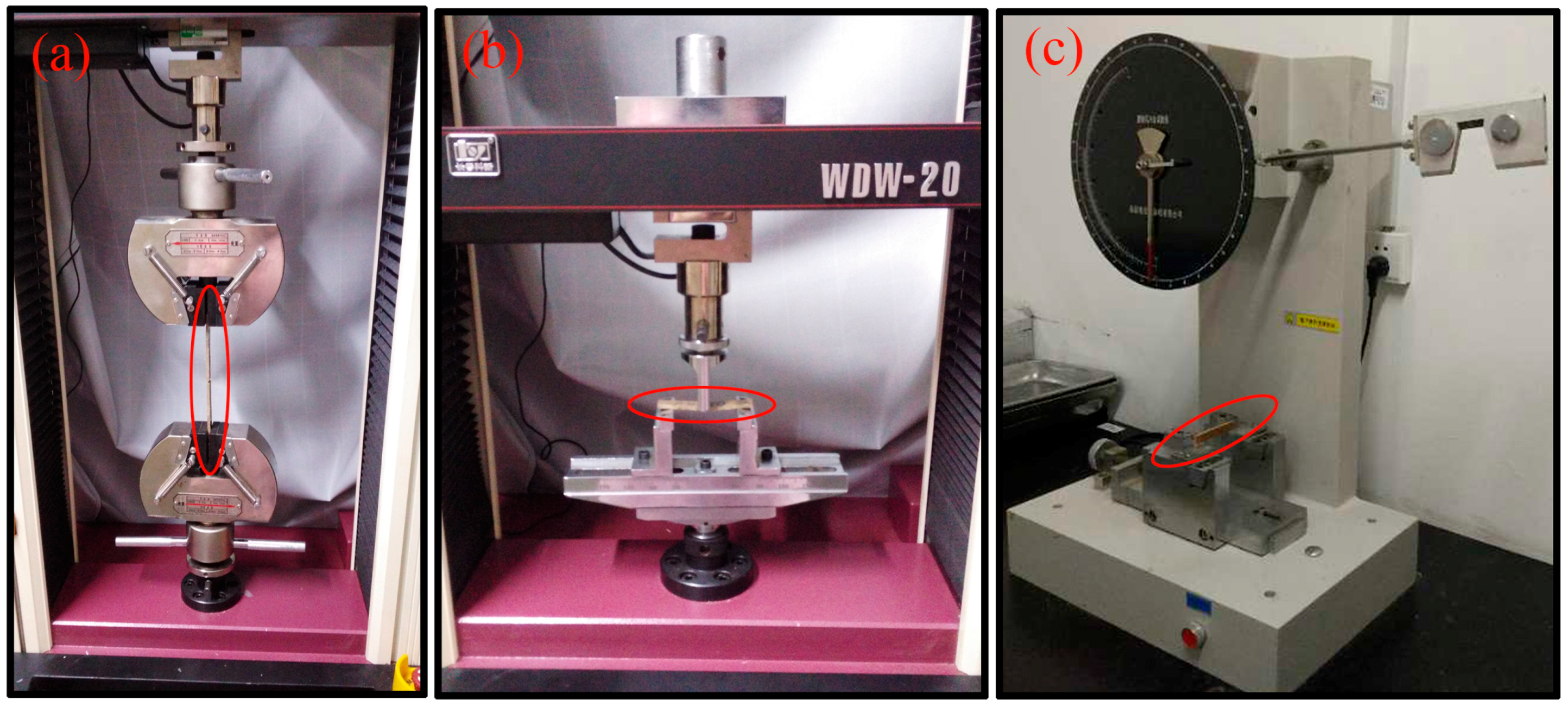

2.5.4. Mechanical Properties

3. Results and Discussion

3.1. FTIR Analysis

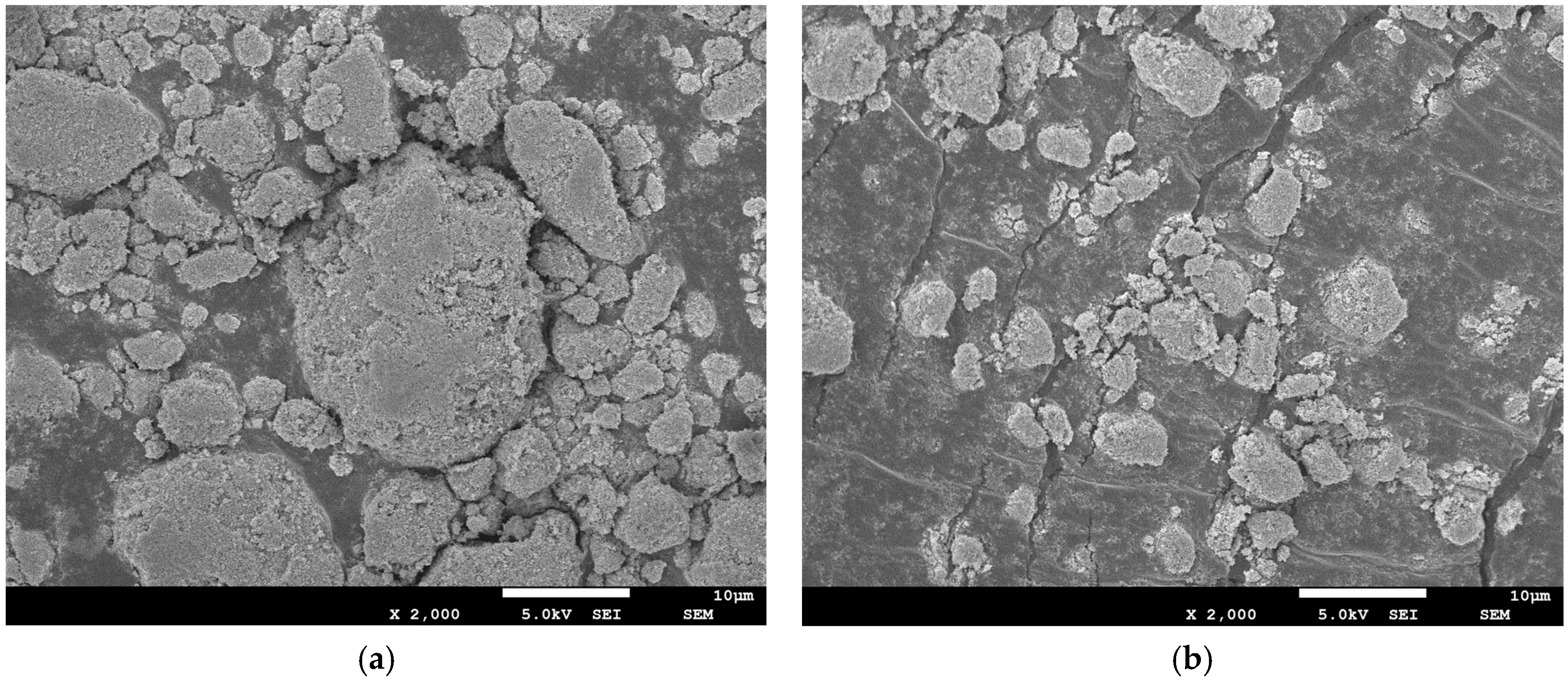

3.2. Morphology and Dispersibility of Surface-Modified TiO2 Nanoparticles

3.3. Thermogravimetric Analysis

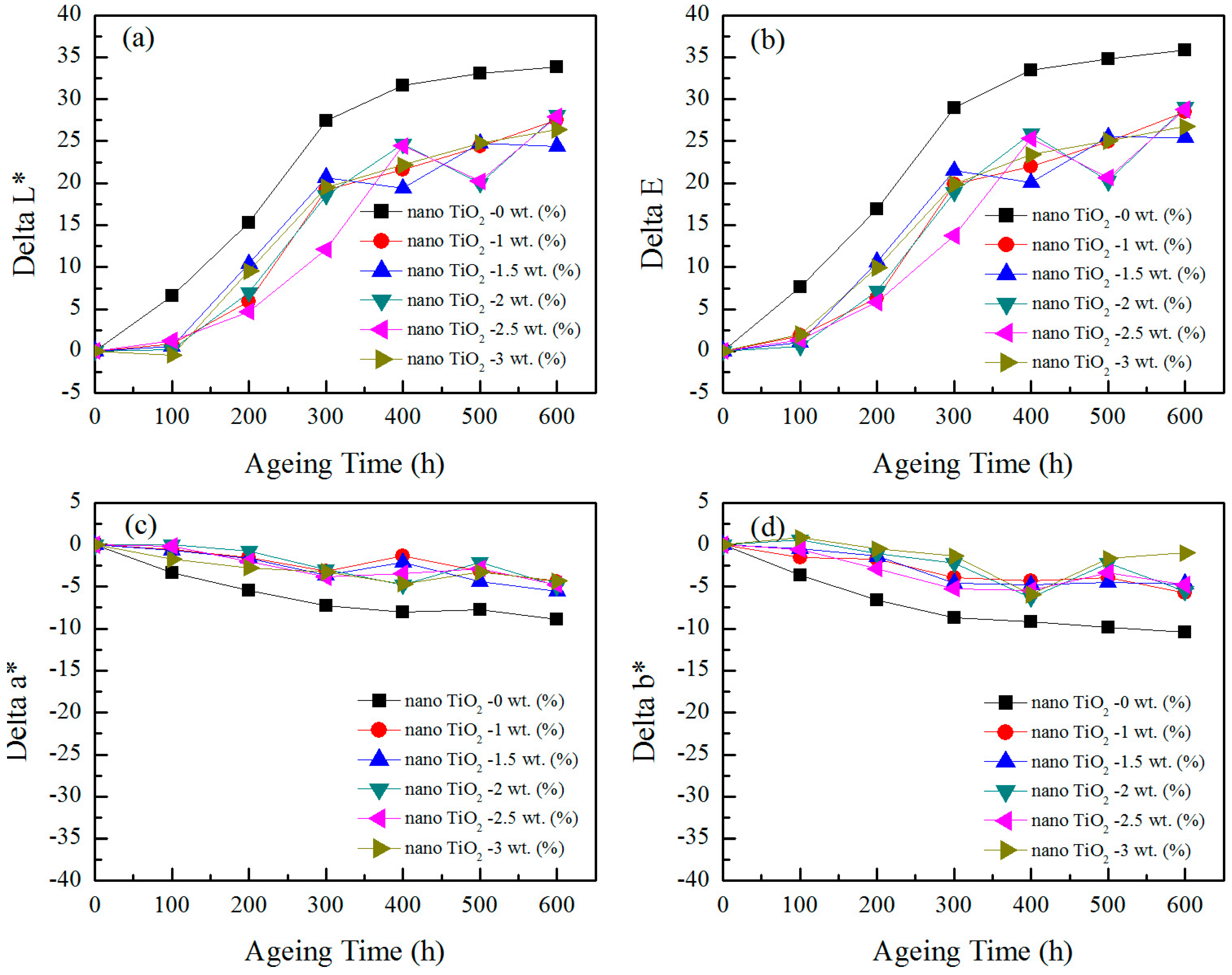

3.4. Color Change during UV Aging

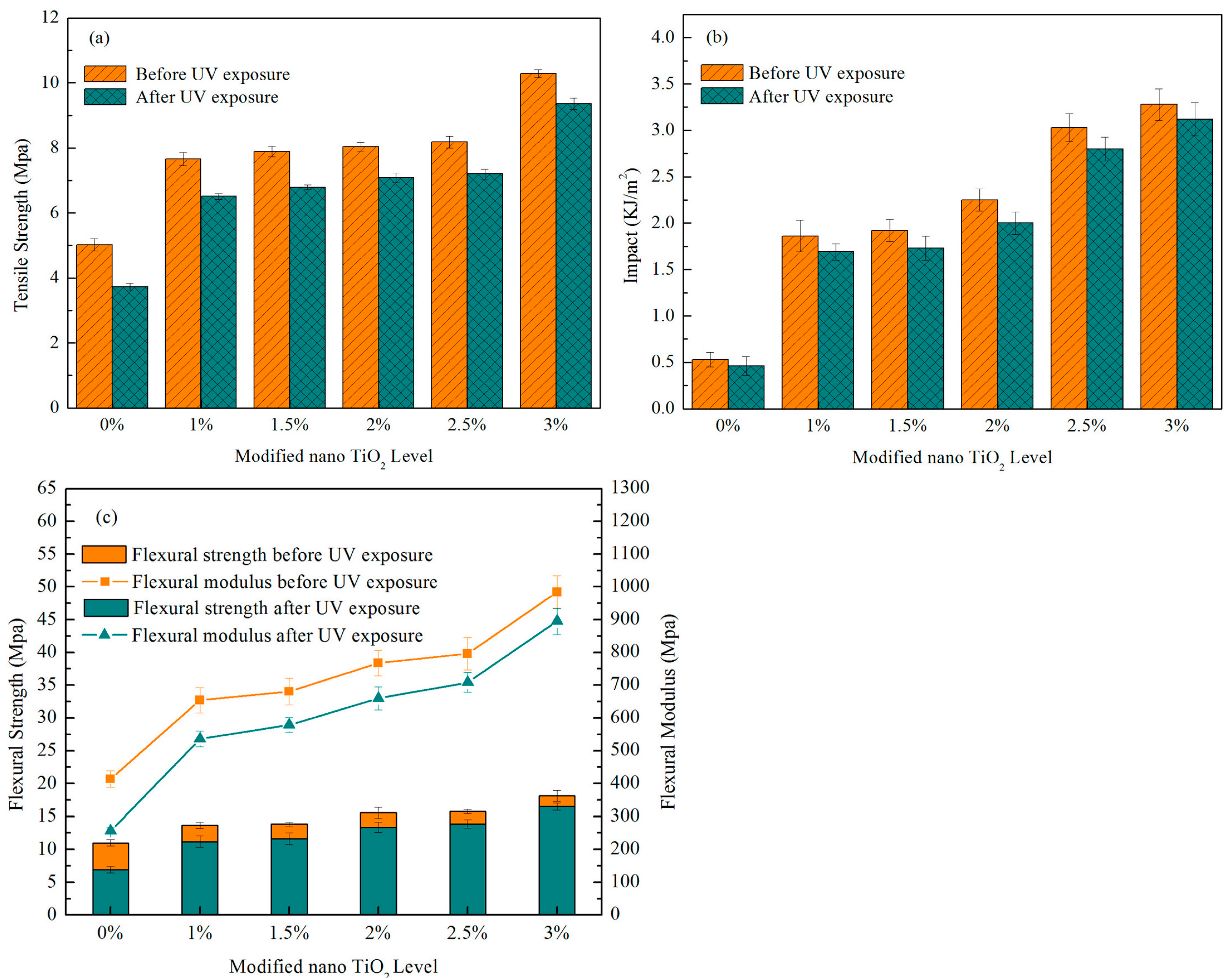

3.5. Mechanical Properties Study

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- El-Saied, H.; Basta, A.H.; Hassanen, M.E.; Korte, H.; Helal, A. Behaviour of rice byproducts and optimizing the conditions for production of high performance natural fiber polymer composites. J. Polym. Environ. 2012, 20, 838–847. [Google Scholar] [CrossRef]

- El-Shekeil, Y.; Sapuan, S.; Abdan, K.; Zainudin, E. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 2012, 40, 299–303. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Anderson, D.P.; Chang, P.R.; Hua, Y. Bamboo fiber and its reinforced composites: Structure and properties. Cellulose 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S.; Chanakul, S. Mechanical properties, thermal degradation and natural weathering of high desity polyethylene/rice hull composites compatibilized with maleic anhydride grafted polyethylene. J. Polym. Res. 2012, 19, 9921. [Google Scholar] [CrossRef]

- Kord, B. Effect of chemical blowing agent on the hygroscopic behavior of HDPE/rice husk flour composites. J. Thermoplast. Compos. Mater. 2013, 26, 1114–1126. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S. Influeces of modified chemical blowing agents on foaming of wood plastic composites prepared from poly (viyl chloride) and rice hull. Adv. Mater. Res. 2011, 306, 869–873. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, L.; Zhang, J.Y. The mechanism of thermal decomposition of azodicarbonamide and the influence of zinc oxide. J. Beijing Univ. Chem. Technol. 2011, 3, 39–43. (In Chinese) [Google Scholar]

- Du, H.; Wang, W.; Wang, Q.; Zhang, Z.; Sui, S.; Zhang, Y. Effects of pigments on the UV degradation of wood-flour/HDPE composites. J. Appl. Polym. Sci. 2010, 118, 1068–1076. [Google Scholar] [CrossRef]

- Du, H.; Wang, W.; Wang, Q.; Sui, S.; Song, Y. Effects of ultraviolet absorbers on the UV-degradation of rice-hull/HDPE composites. J. Appl. Polym. Sci. 2012, 126, 906–915. [Google Scholar] [CrossRef]

- Li, X.W.; Song, R.G.; Jiang, Y.; Wang, C.; Jiang, D. Surface modification of TiO2 nanoparticles and its effect on the properties of fluoropolymer/TiO2 nanocomposite coatings. Appl. Surf. Sci. 2013, 276, 761–768. [Google Scholar] [CrossRef]

- Zhao, J.; Milanova, M.; Warmoeskerken, M.M.; Dutschk, V. Surface modification of TiO2 nanoparticles with silane coupling agents. Colloid Surf. A 2012, 413, 273–279. [Google Scholar] [CrossRef]

- Devi, R.R.; Maji, T.K. Interfacial effect of surface modified TiO2 and SiO2 nanoparticles reinforcement in the properties of wood polymer clay nanocomposites. J. Taiwan Inst. Chem. Eng. 2013, 44, 505–514. [Google Scholar] [CrossRef]

- Li, X.G. Structure and properties of wet modified titanium dioxide with silane coupling agent KH-570. Adhesion 2012, 9, 39–41. (In Chinese) [Google Scholar]

- Chen, Q.; Yakovlev, N.L. Assorption and interaction of organosilanes on TiO2 nanoparticles. Appl. Surf. Sci. 2010, 257, 1395–1400. [Google Scholar] [CrossRef]

- Sabzi, M.; Mirabedini, S.M.; Zohuriaan-Mehr, J.; Atai, M. Surface modification of TiO2 nano-particles with silane coupling agent and investigation of its effect on the properties of polyurethane composite coating. Prog. Org. Coat. 2009, 65, 222–228. [Google Scholar] [CrossRef]

- He, C.X.; Fu, L.M.; Xiong, J. Study on the microstructure and properties of wheat straw with different treatments. J. Nanjing Agric. Univ. 2016, 39, 325–331. (In Chinese) [Google Scholar]

- Sun, Q.F.; Lu, Y.; Liu, Y. Growth of hydrophobic TiO2 on wood surface using a hydrothermal method. J. Mater. Sci. 2011, 46, 7706–7712. [Google Scholar] [CrossRef]

- Huang, K.; Zhang, G.Z.; Hou, X.L. Preparation and Characterization of Acetylated Rice Straw. J. Cellulose Sci. Technol. 2011, 19, 28–34. [Google Scholar]

- Fabiyi, J.S.; McDonald, A.G. Effect of wood species on property and weathering performance of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1434–1440. [Google Scholar] [CrossRef]

- Hou, R.Y.; He, C.X.; Xue, J.; Min, Y.; Chuanchuan, D. UV accelerated ageing properties of wheat straw/PP wood plastic composite. Acta Mater. Compos. Sin. 2013, 5, 86–93. (In Chinese) [Google Scholar]

- Rong, Y.; Chen, H.Z.; Wu, G.; Wang, M. Preparation and characterization of titanium dioxide nanoparticles/polystyrene composites via radical polymerization. Mater. Chem. Phys. 2005, 91, 370–374. [Google Scholar] [CrossRef]

- Jaya, V.S.; Mohanty, S.; Rahail Parvaiz, M.; Nayak, S.K. Influence of nanoclays and nano-tio2 on the mechanical and thermal properties of polycarbonate nanocomposites. Macromol. Res. 2012, 20, 1006. [Google Scholar] [CrossRef]

- Xiao, L.X.; Yuan, G.M.; He, X. Study on the mechanical properties of nano-Al2O3/PP/wood fiber composites. J. Cent. South Univ. For. Technol. 2016, 2, 130–134. (In Chinese) [Google Scholar]

- Pinto, D.; Bernardo, L.; Amaro, A.; Lopes, S. Mechanical Properties of Epoxy Nanocomposites using Titanium Dioxide as Reinforcement—A Review. Constr. Build. Mater. 2015, 95, 506–524. [Google Scholar] [CrossRef]

| E | Modified TiO2 Nanoparticles (wt.%) | Silane Coupling Agent (wt.%) | Wheat Straw Fiber (wt.%) | PP (wt.%) | AC (wt.%) | ZnO (wt.%) | CaCO3 (wt.%) | Paraffin (wt.%) |

|---|---|---|---|---|---|---|---|---|

| A | 0 | 1 | 29 | 62.5 | 2 | 0.5 | 4 | 1 |

| B | 1 | 1 | 29 | 61.5 | 2 | 0.5 | 4 | 1 |

| C | 1.5 | 1 | 29 | 61 | 2 | 0.5 | 4 | 1 |

| D | 2 | 1 | 29 | 60.5 | 2 | 0.5 | 4 | 1 |

| E | 2.5 | 1 | 29 | 60 | 2 | 0.5 | 4 | 1 |

| F | 3 | 1 | 29 | 59.5 | 2 | 0.5 | 4 | 1 |

| Modified Nano TiO2 Level (wt.%) | 0 | 1 | 1.5 | 2 | 2.5 | 3 | ||

|---|---|---|---|---|---|---|---|---|

| Flexural properties | Before UV exposure | Flexural strength (MPa) | 11.02 | 13.66 | 13.85 | 15.56 | 15.74 | 18.13 |

| Flexural modulus (MPa) | 413.59 | 653.62 | 680.33 | 767.42 | 795.99 | 984.05 | ||

| After UV exposure | Flexural strength (MPa) | 6.89 | 11.2 | 11.63 | 13.38 | 13.85 | 16.5 | |

| Flexural strength loss (%) | 37.48 | 18.01 | 16.03 | 14.01 | 12.01 | 8.99 | ||

| Flexural modulus (MPa) | 256.06 | 535.97 | 578.28 | 659.98 | 708.43 | 895.49 | ||

| Flexural modulus loss (%) | 38.09 | 18.00 | 15.00 | 14.00 | 11.00 | 9.00 | ||

| Tensile properties | Before UV exposure | Tensile strength (MPa) | 5.02 | 7.66 | 7.89 | 8.04 | 8.18 | 10.29 |

| After UV exposure | Tensile strength (MPa) | 3.72 | 6.51 | 6.79 | 7.08 | 7.2 | 9.36 | |

| Tensile strength loss (%) | 25.90 | 15.01 | 13.94 | 11.94 | 11.98 | 9.04 | ||

| Impact properties | Before UV exposure | Impact (KJ/m2) | 0.53 | 1.86 | 1.92 | 2.25 | 3.03 | 3.28 |

| After UV exposure | Impact (KJ/m2) | 0.46 | 1.69 | 1.73 | 2 | 2.8 | 3.12 | |

| Impact loss (%) | 13.21 | 9.14 | 9.90 | 11.11 | 7.59 | 4.88 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xuan, L.; Han, G.; Wang, D.; Cheng, W.; Gao, X.; Chen, F.; Li, Q. Effect of Surface-Modified TiO2 Nanoparticles on the Anti-Ultraviolet Aging Performance of Foamed Wheat Straw Fiber/Polypropylene Composites. Materials 2017, 10, 456. https://doi.org/10.3390/ma10050456

Xuan L, Han G, Wang D, Cheng W, Gao X, Chen F, Li Q. Effect of Surface-Modified TiO2 Nanoparticles on the Anti-Ultraviolet Aging Performance of Foamed Wheat Straw Fiber/Polypropylene Composites. Materials. 2017; 10(5):456. https://doi.org/10.3390/ma10050456

Chicago/Turabian StyleXuan, Lihui, Guangping Han, Dong Wang, Wanli Cheng, Xun Gao, Feng Chen, and Qingde Li. 2017. "Effect of Surface-Modified TiO2 Nanoparticles on the Anti-Ultraviolet Aging Performance of Foamed Wheat Straw Fiber/Polypropylene Composites" Materials 10, no. 5: 456. https://doi.org/10.3390/ma10050456