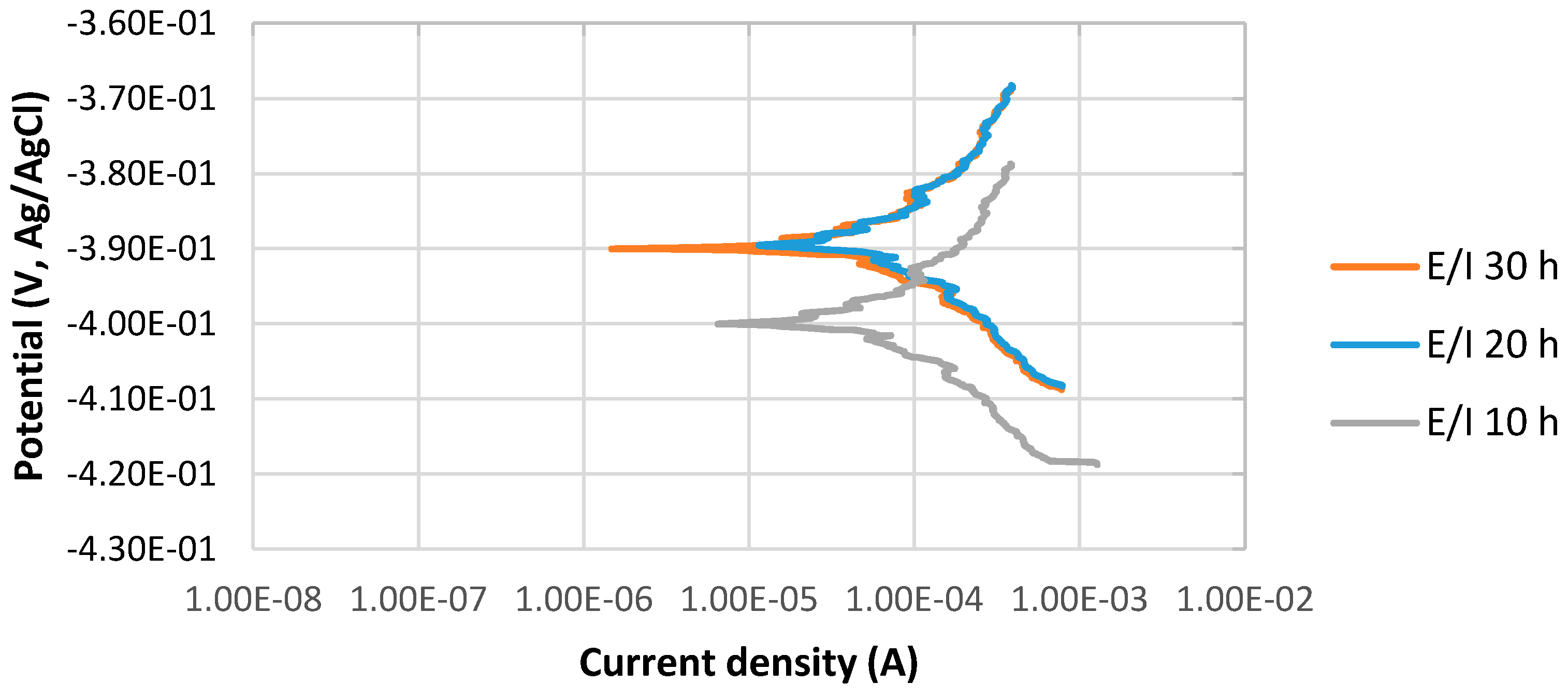

Figure 1.

The potentiodynamic curves of 4130 Cr-Mo alloy steel in thioacetamide solution at different immersion times: 10, 20 and 30 h at 80 °C, pH 2.

Figure 1.

The potentiodynamic curves of 4130 Cr-Mo alloy steel in thioacetamide solution at different immersion times: 10, 20 and 30 h at 80 °C, pH 2.

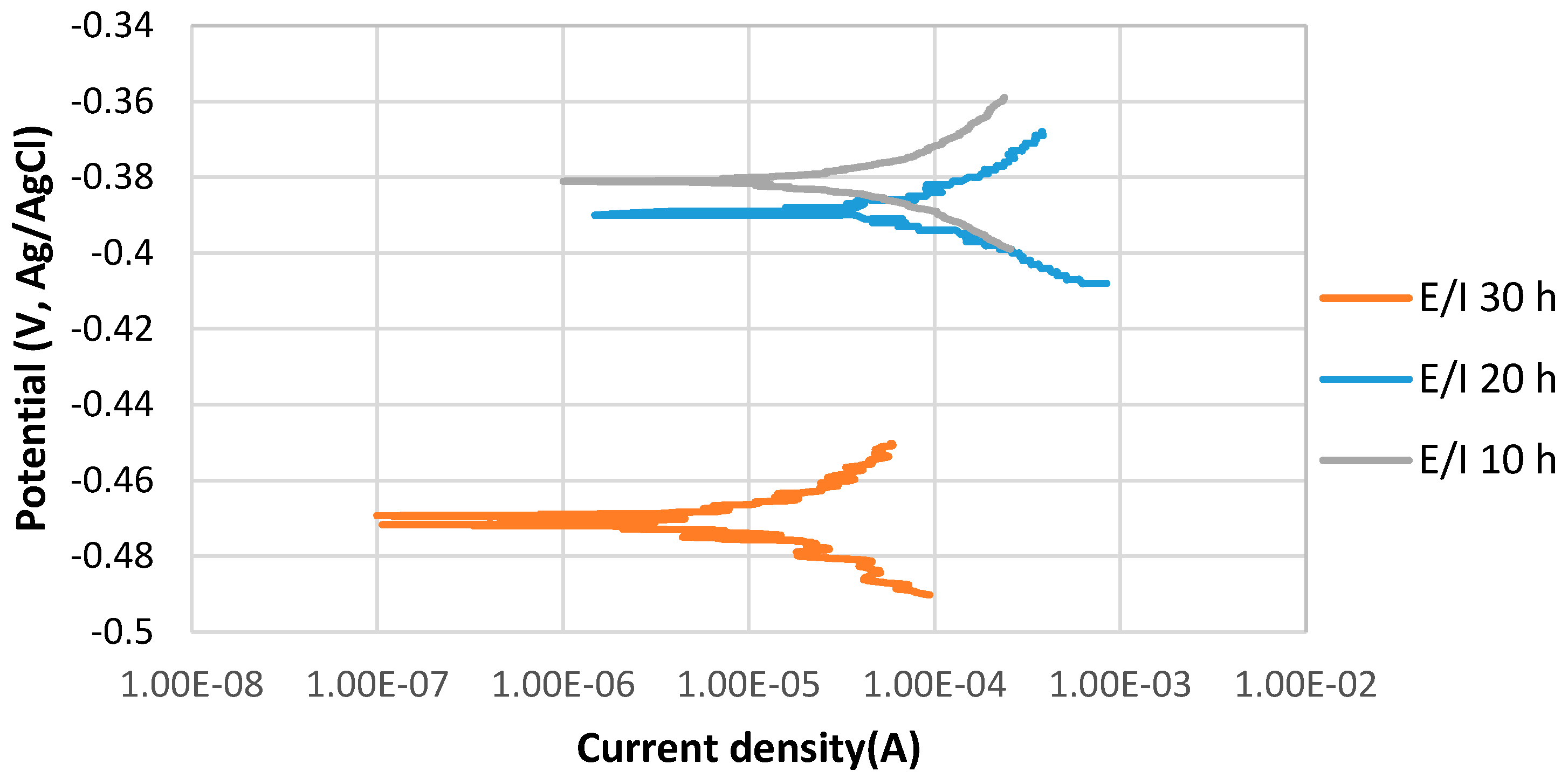

Figure 2.

The potentiodynamic curves of 4130 Cr-Mo alloy steel in thioacetamide solution at different immersion times: 10, 20 and 30 h at 80 °C, pH 5.

Figure 2.

The potentiodynamic curves of 4130 Cr-Mo alloy steel in thioacetamide solution at different immersion times: 10, 20 and 30 h at 80 °C, pH 5.

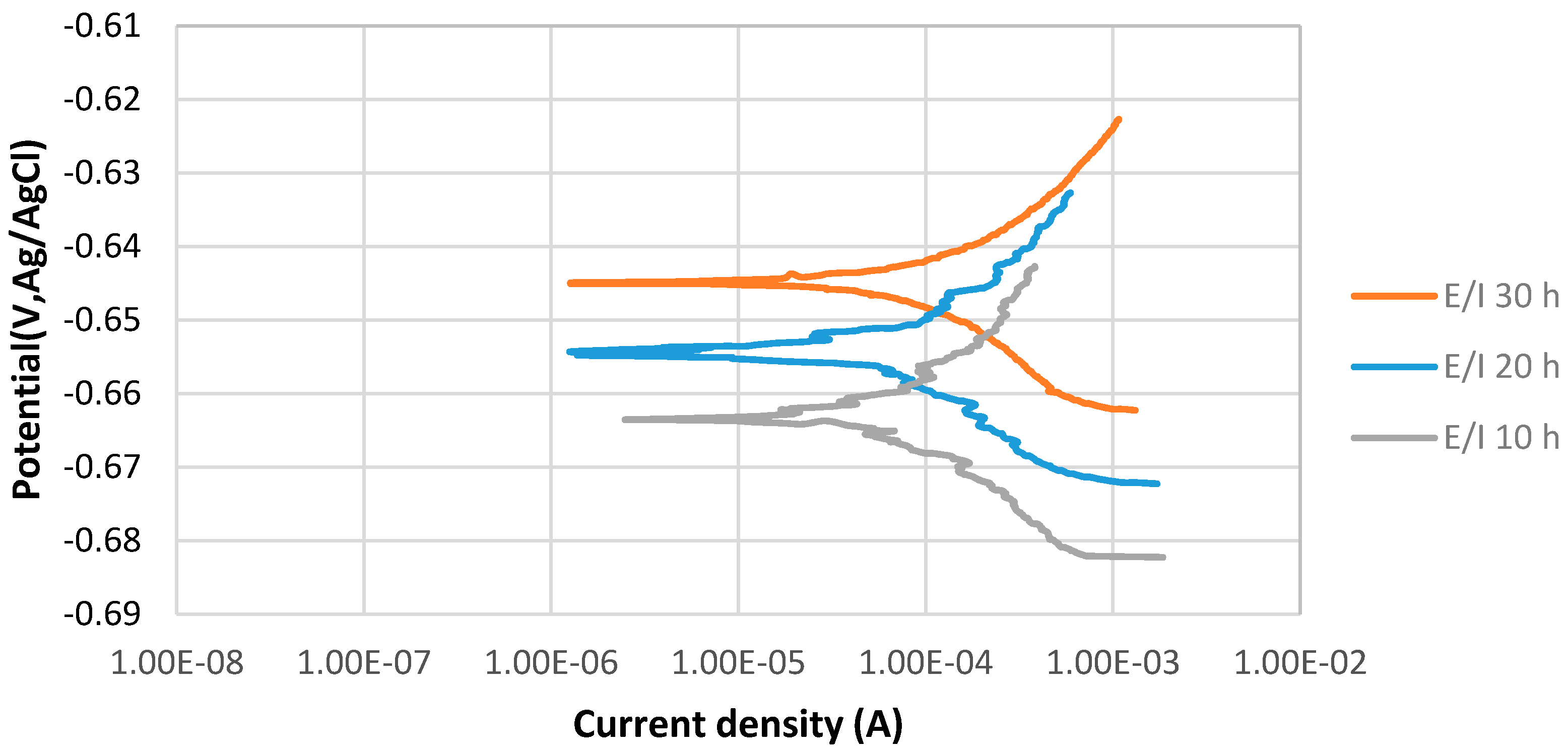

Figure 3.

The potentiodynamic curves of 4130 Cr-Mo alloy steel covered with elemental sulfur in 3.5% sodium chloride solution at different immersion times: 10, 20 and 30 h at 80 °C, pH 2.

Figure 3.

The potentiodynamic curves of 4130 Cr-Mo alloy steel covered with elemental sulfur in 3.5% sodium chloride solution at different immersion times: 10, 20 and 30 h at 80 °C, pH 2.

Figure 4.

The potentiodynamic curves of 4130 Cr-Mo alloy steel covered with elemental sulfur in 3.5% sodium chloride solution at different immersion times: 10, 20 and 30 hat pH 5.

Figure 4.

The potentiodynamic curves of 4130 Cr-Mo alloy steel covered with elemental sulfur in 3.5% sodium chloride solution at different immersion times: 10, 20 and 30 hat pH 5.

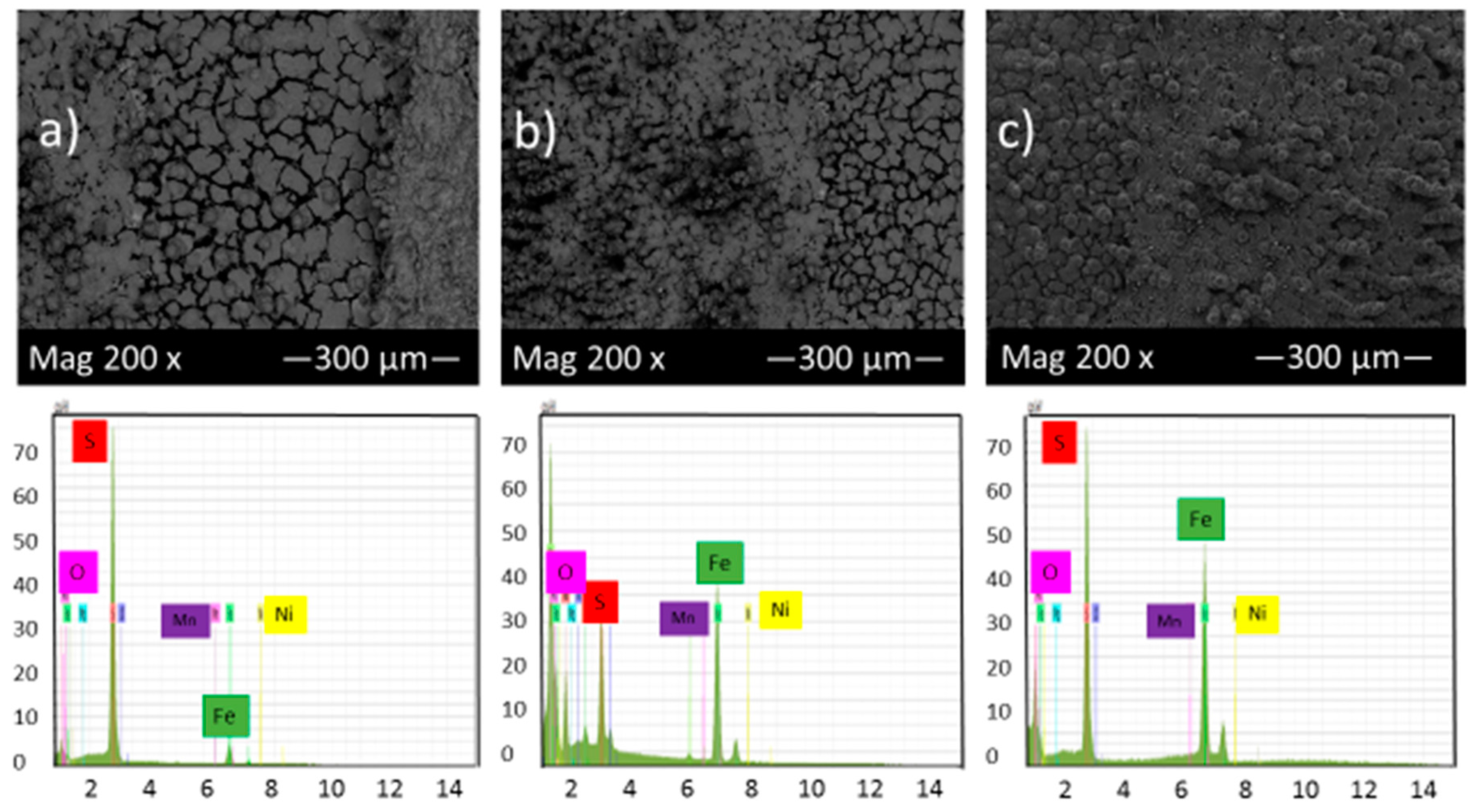

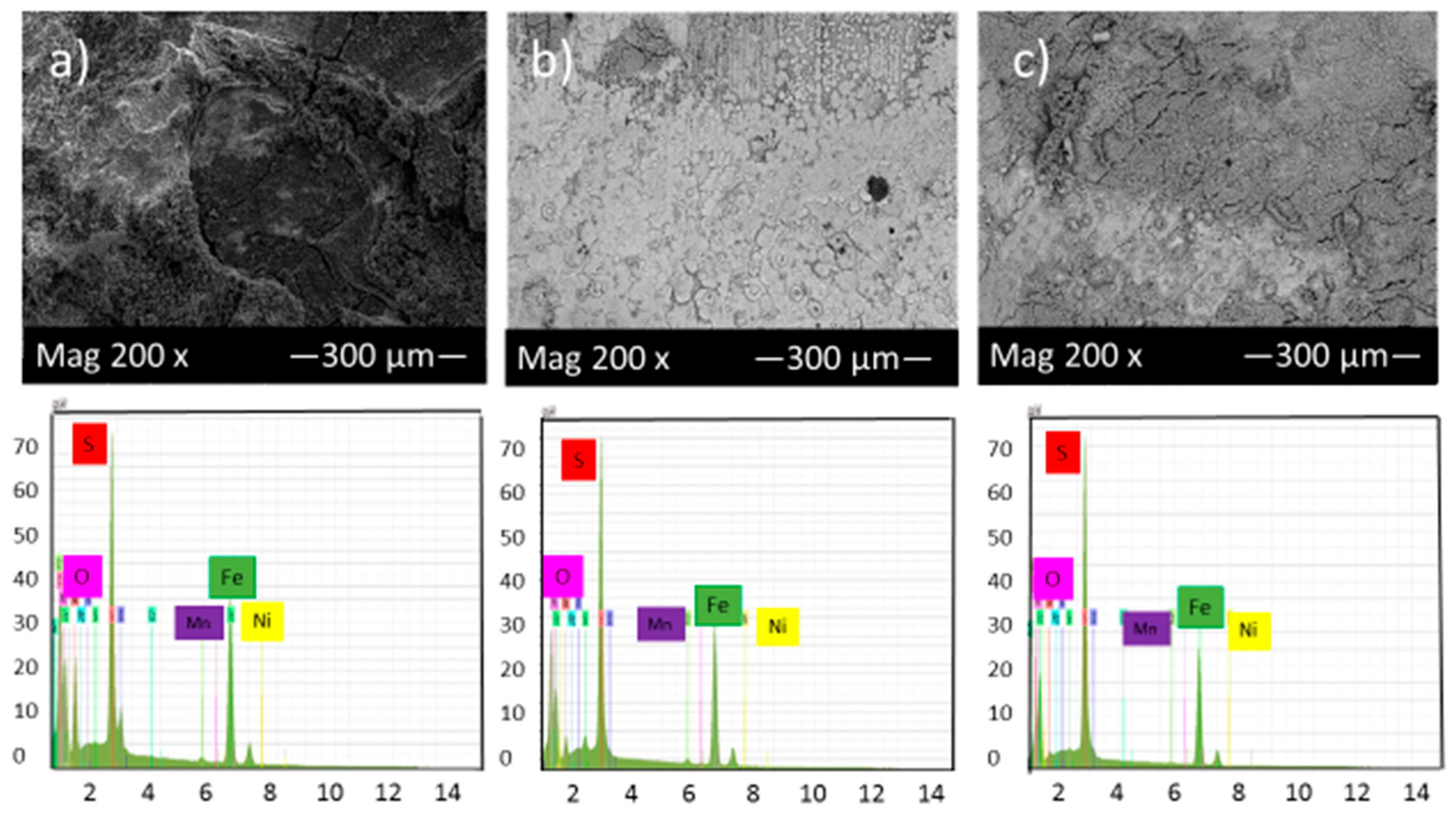

Figure 5.

SEM micrograph and EDS of the corrosion product layers that form on the surface of each sample at pH 2 under (a) 10, (b) 20 and (c) 30 h immersion time in thioacetamide solution.

Figure 5.

SEM micrograph and EDS of the corrosion product layers that form on the surface of each sample at pH 2 under (a) 10, (b) 20 and (c) 30 h immersion time in thioacetamide solution.

Figure 6.

SEM micrograph and EDS of the corrosion product layers that form on the surface of each sample at pH 5 under (a) 10, (b) 20 and (c) 30 h immersion time in thioacetamide solution.

Figure 6.

SEM micrograph and EDS of the corrosion product layers that form on the surface of each sample at pH 5 under (a) 10, (b) 20 and (c) 30 h immersion time in thioacetamide solution.

Figure 7.

SEM micrograph and EDS of the corrosion product layers that form on the surface of each sample covered with elemental sulfur at pH 2 under (a) 10, (b) 20 and (c) 30 h immersion time.

Figure 7.

SEM micrograph and EDS of the corrosion product layers that form on the surface of each sample covered with elemental sulfur at pH 2 under (a) 10, (b) 20 and (c) 30 h immersion time.

Figure 8.

SEM micrograph of the corrosion product layers that form on the surface of each sample covered with elemental sulfur at pH 5 under (a) 10, (b) 20 and (c) 30 h immersion time.

Figure 8.

SEM micrograph of the corrosion product layers that form on the surface of each sample covered with elemental sulfur at pH 5 under (a) 10, (b) 20 and (c) 30 h immersion time.

Figure 9.

Cross-section of corrosion product layer of the (a) first and (b) second series of experiments at pH 5 after 10 h immersion time.

Figure 9.

Cross-section of corrosion product layer of the (a) first and (b) second series of experiments at pH 5 after 10 h immersion time.

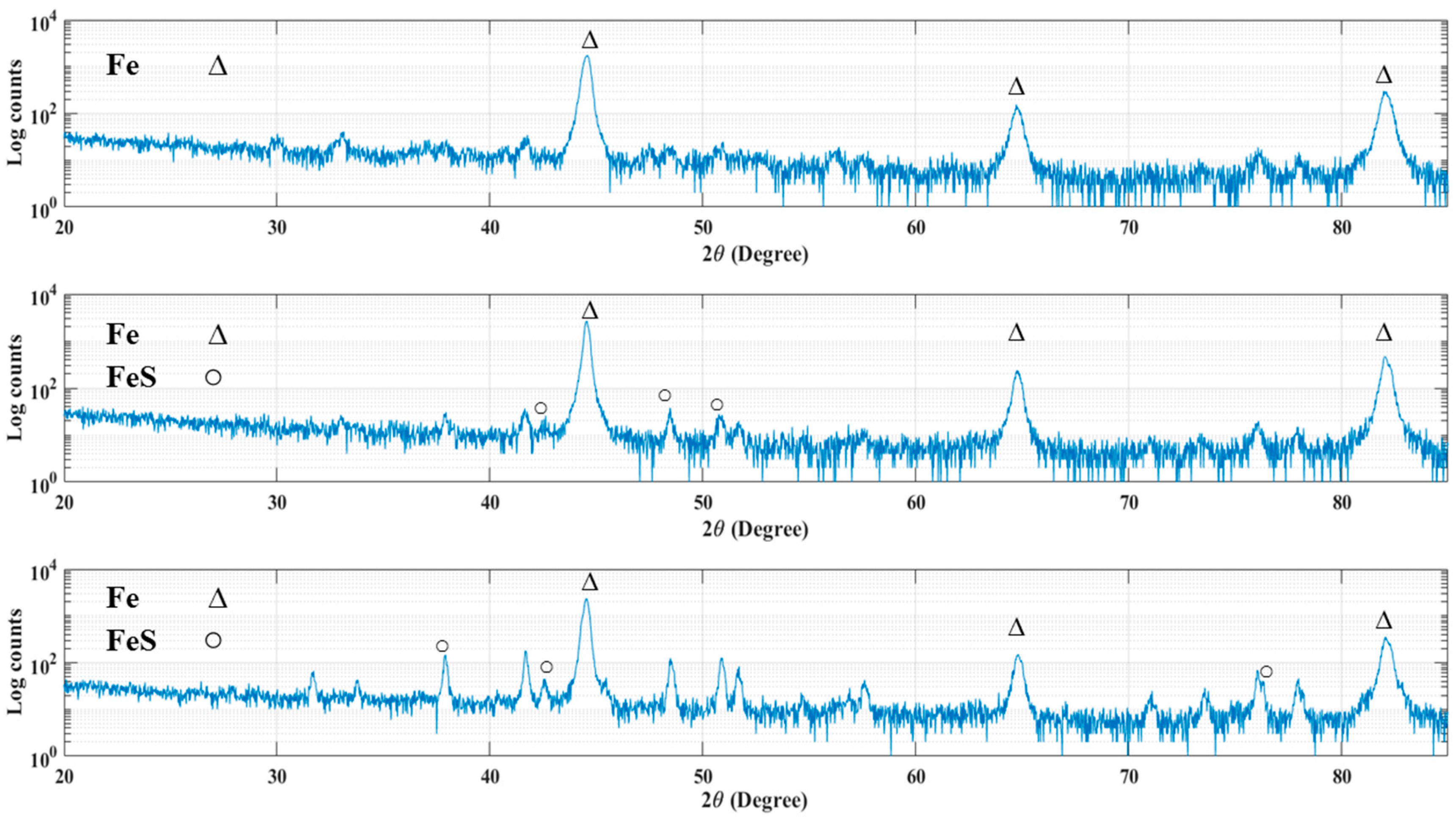

Figure 10.

XRD pattern for the samples in (a) the second series of experiment at pH 5 after 30 h immersion, (b) the first series of experiments at pH 5 after 10 h immersion and (c) the second series of experiment at pH 5 after 10 h immersion.

Figure 10.

XRD pattern for the samples in (a) the second series of experiment at pH 5 after 30 h immersion, (b) the first series of experiments at pH 5 after 10 h immersion and (c) the second series of experiment at pH 5 after 10 h immersion.

Table 1.

Experimental condition of the first series.

Table 1.

Experimental condition of the first series.

| Condition No. | T (°C) | pH | Immersion Time (h) |

|---|

| 1 | 80 | 2 | 10 |

| 2 | 80 | 2 | 20 |

| 3 | 80 | 2 | 30 |

| 4 | 80 | 5 | 10 |

| 5 | 80 | 5 | 20 |

| 6 | 80 | 5 | 30 |

Table 2.

Experimental condition of the second series.

Table 2.

Experimental condition of the second series.

| Condition No. | T (°C) | PH | Immersion Time (h) |

|---|

| 7 | 80 | 2 | 10 |

| 8 | 80 | 2 | 20 |

| 9 | 80 | 2 | 30 |

| 10 | 80 | 5 | 10 |

| 11 | 80 | 5 | 20 |

| 12 | 80 | 5 | 30 |

Table 3.

The values of anodic () and cathodic () Tafel slopes of first series.

Table 3.

The values of anodic () and cathodic () Tafel slopes of first series.

| Experiment | (mV·Decade−1) | (mV·Decade−1) |

|---|

| 1 | 0.022 | 0.019 |

| 2 | 0.029 | 0.020 |

| 3 | 0.020 | 0.019 |

| 4 | 0.034 | 0.023 |

| 5 | 0.021 | 0.018 |

| 6 | 0.028 | 0.020 |

Table 4.

The corrosion rate of the first series.

Table 4.

The corrosion rate of the first series.

| Experiment | 1 | 2 | 6 | 4 | 5 | 6 |

|---|

| pH | 2 | 2 | 2 | 5 | 5 | 5 |

| Corrosion Rate (CR) (mm/year) | 0.368 | 0.325 | 0.318 | 0.066 | 0.044 | 0.224 |

Table 5.

The values of anodic () and cathodic () Tafel slopes of second series.

Table 5.

The values of anodic () and cathodic () Tafel slopes of second series.

| Experiment | (mV·Decade−1) | (mV·Decade−1) |

|---|

| 7 | 0.032 | 0.015 |

| 8 | 0.030 | 0.013 |

| 9 | 0.023 | 0.020 |

| 10 | 0.022 | 0.021 |

| 11 | 0.022 | 0.019 |

| 12 | 0.020 | 0.019 |

Table 6.

The corrosion rates of second series.

Table 6.

The corrosion rates of second series.

| Experiment | 7 | 8 | 9 | 10 | 11 | 12 |

|---|

| pH | 2 | 2 | 2 | 5 | 5 | 5 |

| Corrosion Rate (CR) (mm/year) | 0.615 | 0.605 | 0.595 | 0.381 | 0.367 | 0.318 |