High-Temperature Hot Air/Silane Coupling Modification of Wood Fiber and Its Effect on Properties of Wood Fiber/HDPE Composites

Abstract

:1. Introduction

2. Material and Methods

2.1. Raw Materials

CH2OCH2CH2CH2(CH2)3Si(OCH3)3) with a boiling point of 290 °C (Quanxi Chemical Co., Ltd., Nanjing, China), industrial-grade paraffin (density 0.95 g/cm3, mol. wt. 3500) as lubricant, MgCl2, NaNO2, NaCl, KCl, Na2SO4, acetone, ethanol, and glacial acetic acid were used as raw materials in this study.

CH2OCH2CH2CH2(CH2)3Si(OCH3)3) with a boiling point of 290 °C (Quanxi Chemical Co., Ltd., Nanjing, China), industrial-grade paraffin (density 0.95 g/cm3, mol. wt. 3500) as lubricant, MgCl2, NaNO2, NaCl, KCl, Na2SO4, acetone, ethanol, and glacial acetic acid were used as raw materials in this study.2.2. High-Temperature Hot Air Treatment/Silane Coupling Agent Modification of Poplar Wood Fibers

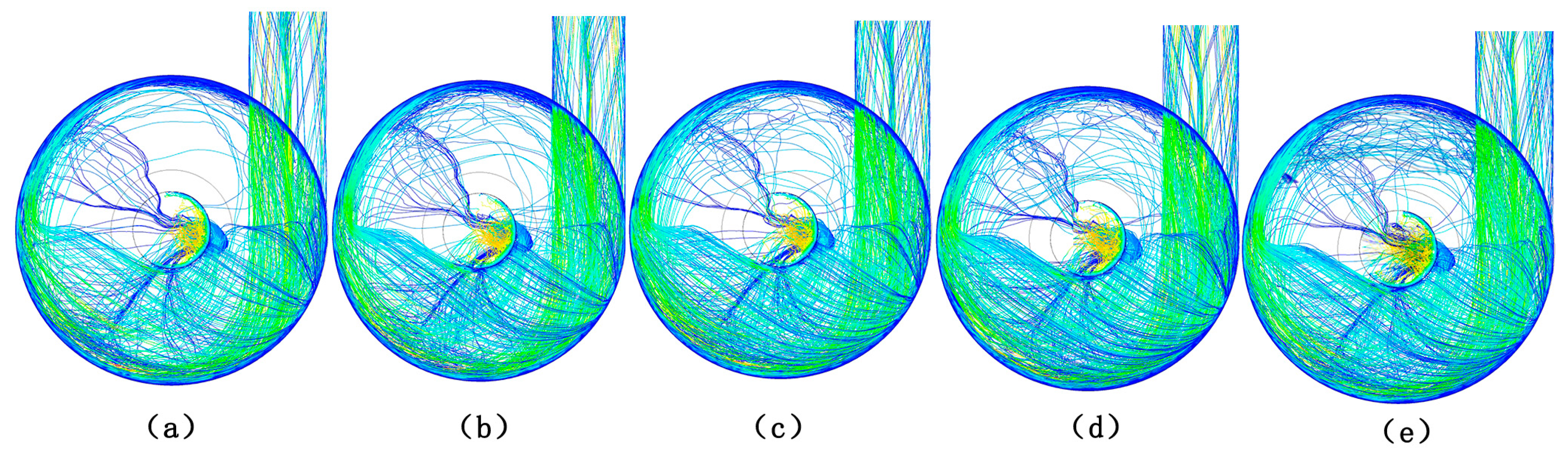

2.3. Preparation of Wood Fiber/HDPE Composites

2.4. Characterization of Wood Fibers

2.4.1. Fourier Transform Infrared Spectrometry Procedure and Analysis

2.4.2. Wide-Angle X-ray Diffraction (WXRD)

2.4.3. Holocellulose Extraction

2.4.4. The pH Value

2.4.5. Thermogravimetric Analysis (TGA)

2.5. Characterization of the Prepared Wood Fiber/HDPE Composites

2.5.1. Mechanical Properties

2.5.2. Dynamic Mechanical Analysis Test

2.5.3. Scanning Electron Microscopy (SEM)

2.5.4. Adsorption Measurements

3. Results and Discussion

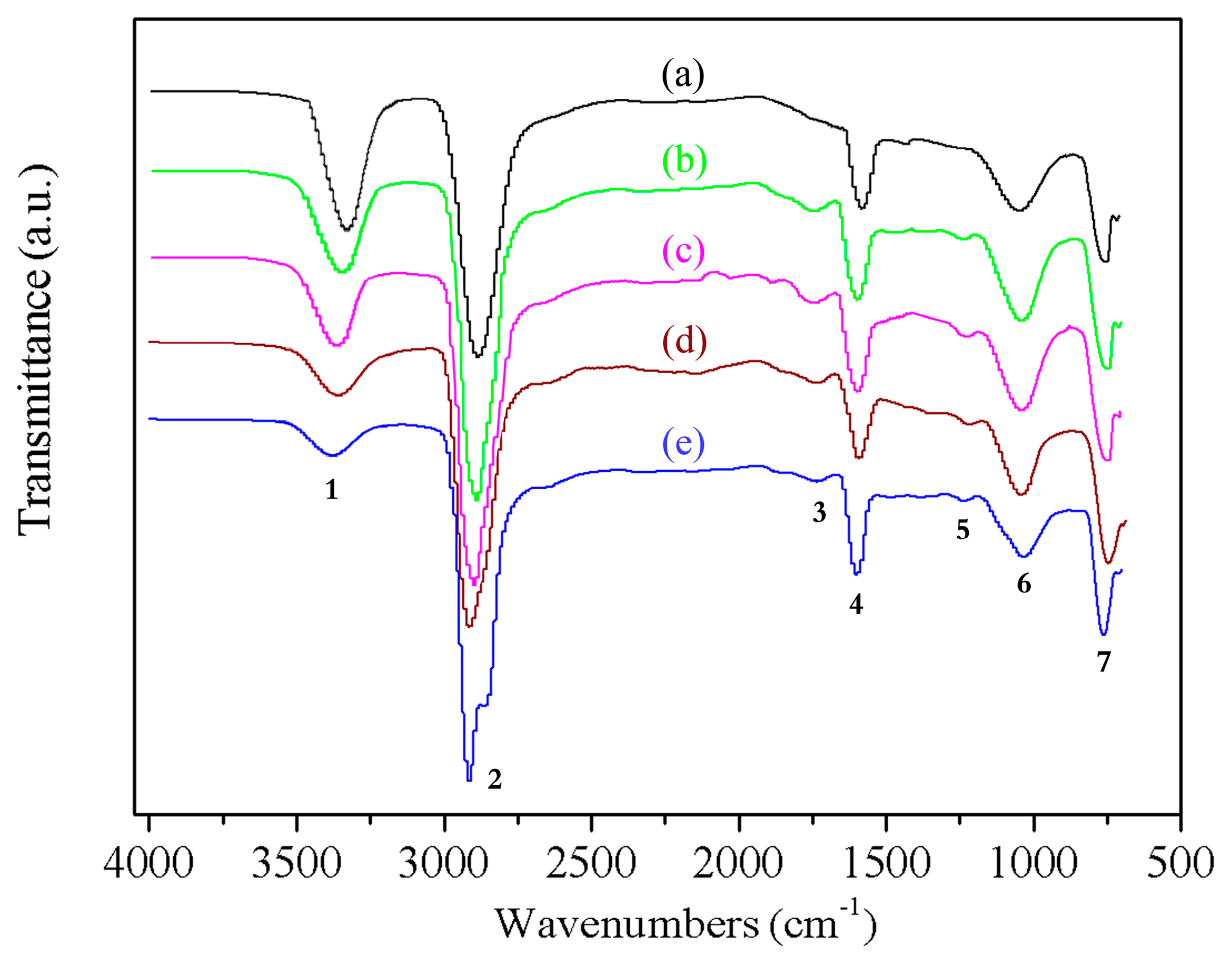

3.1. Fourier Transform Infrared Spectrometry (FTIR) Analysis

3.2. Wide-Angle X-ray Diffraction (WXRD)

3.3. Effect of the High-Temperature Hot Air Treatment on the Holocellulose Content of the Wood Fibers

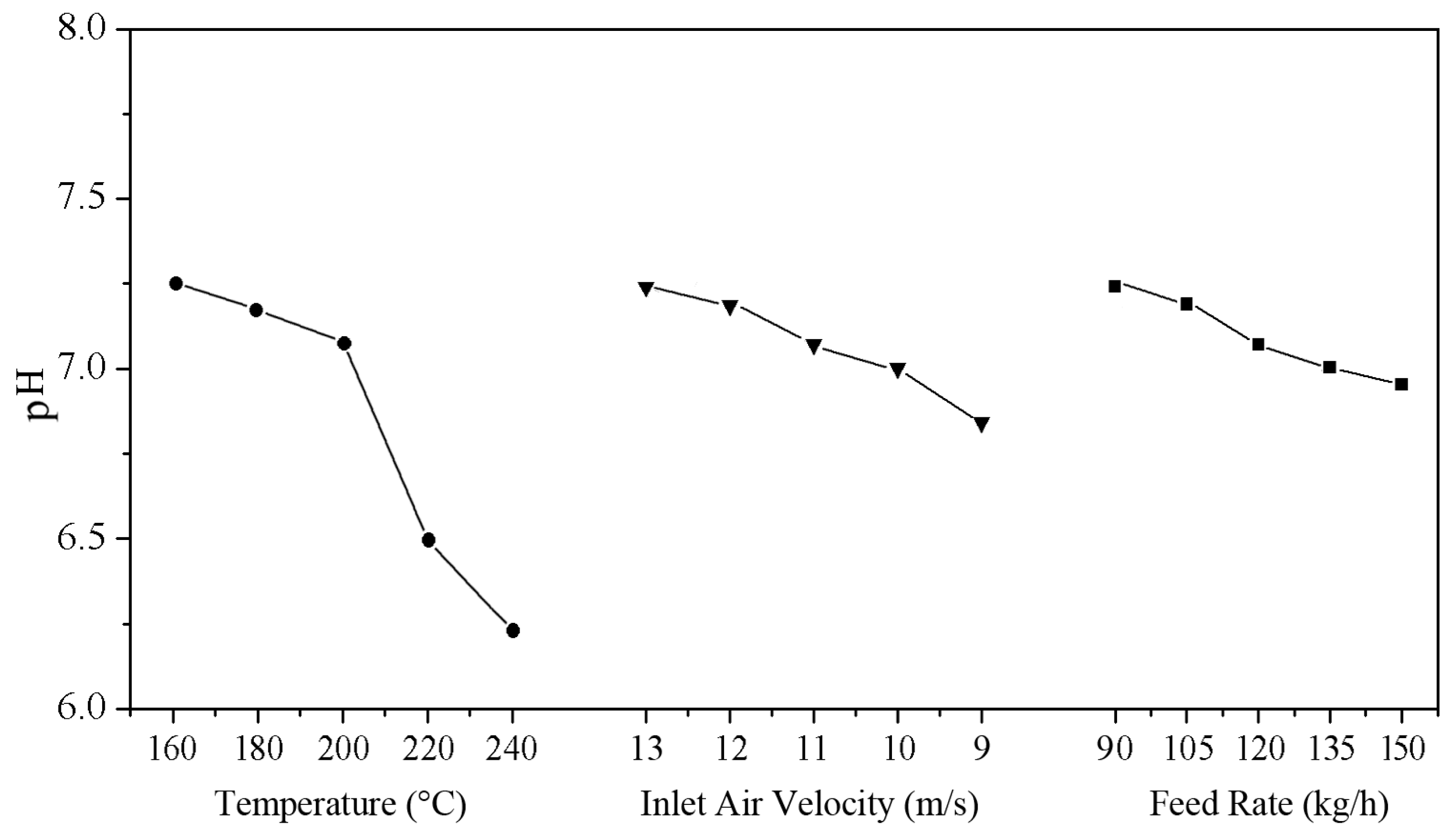

3.4. Effect of the High-Temperature Hot Air Treatment on pH of Wood Fibers

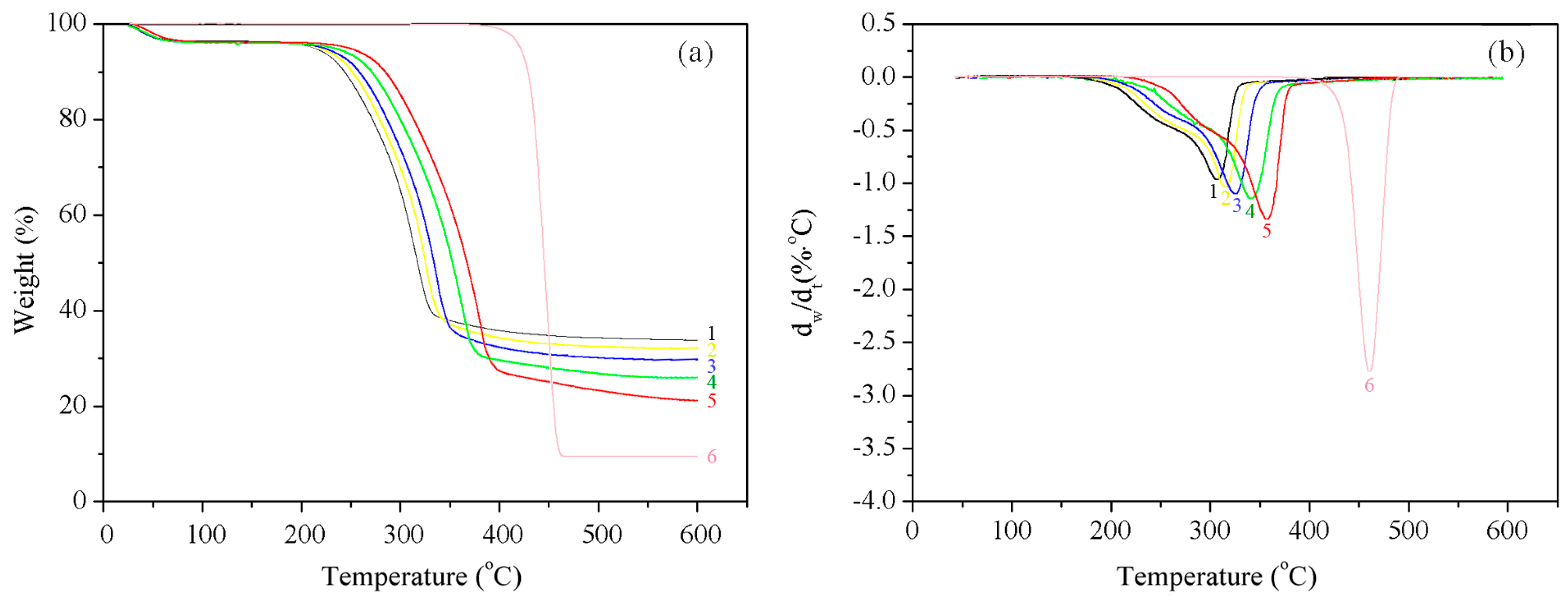

3.5. Thermal Analysis

3.6. Effect of High-Temperature Hot Air Treatment on Mechanical Properties of Wood Fiber/HDPE Composites

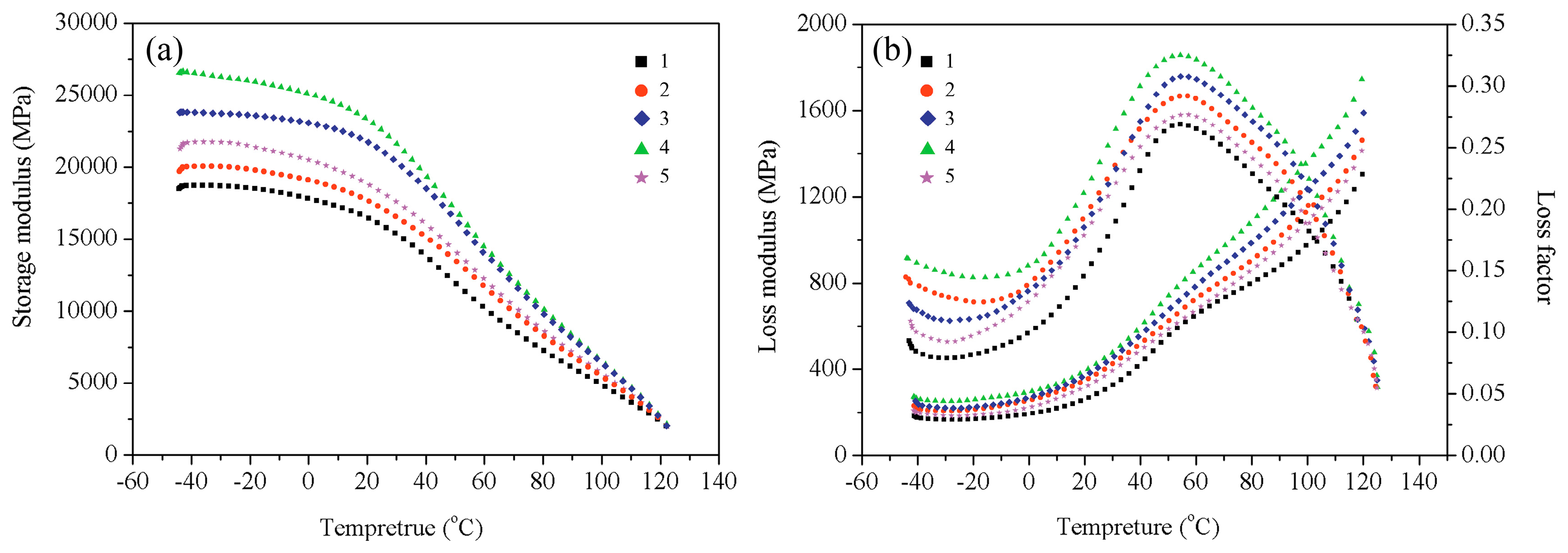

3.7. Dynamic Mechanical Analysis

3.8. Moisture Adsorption Characteristics

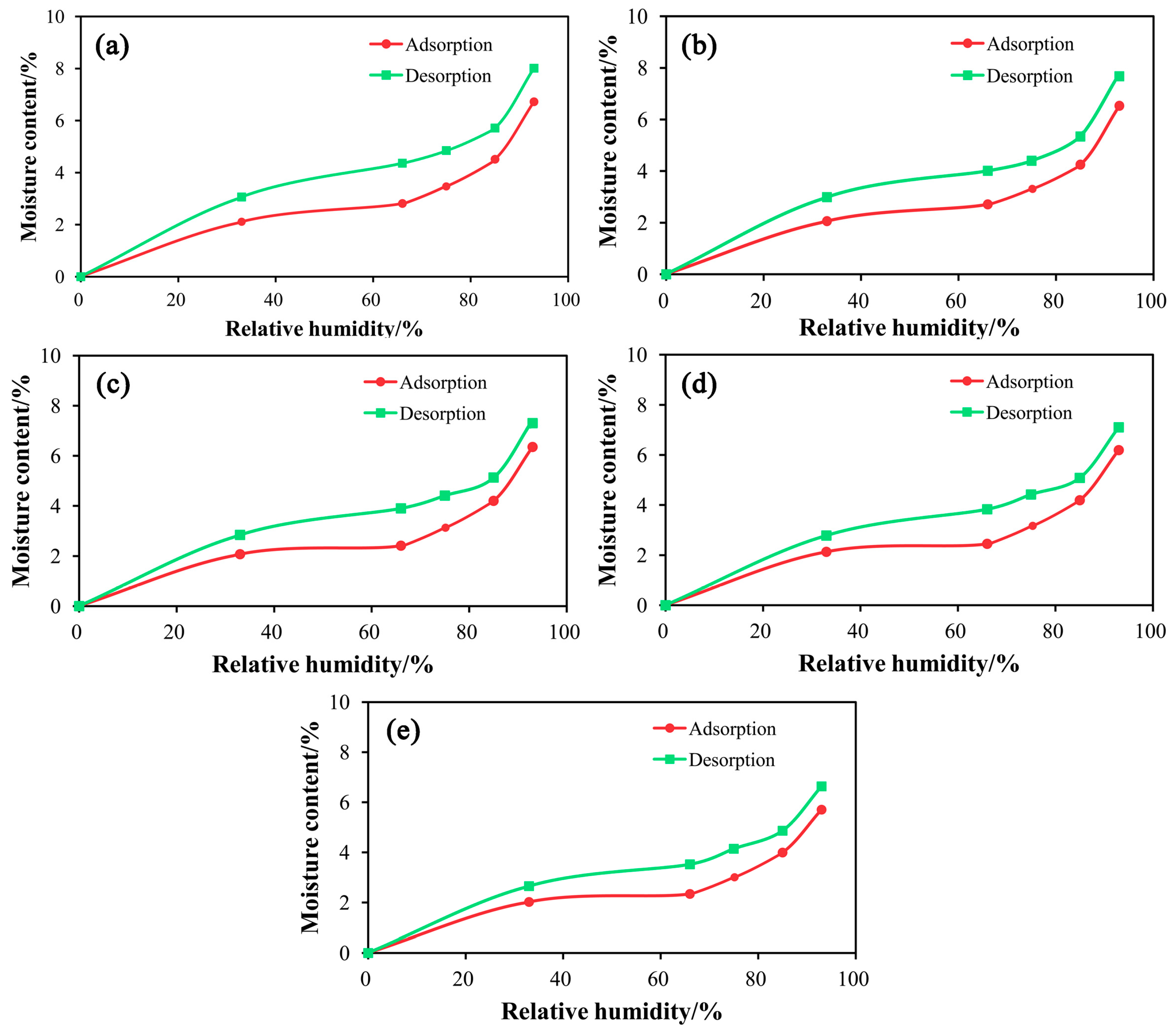

3.9. Scanning Electron Microscopy (SEM)

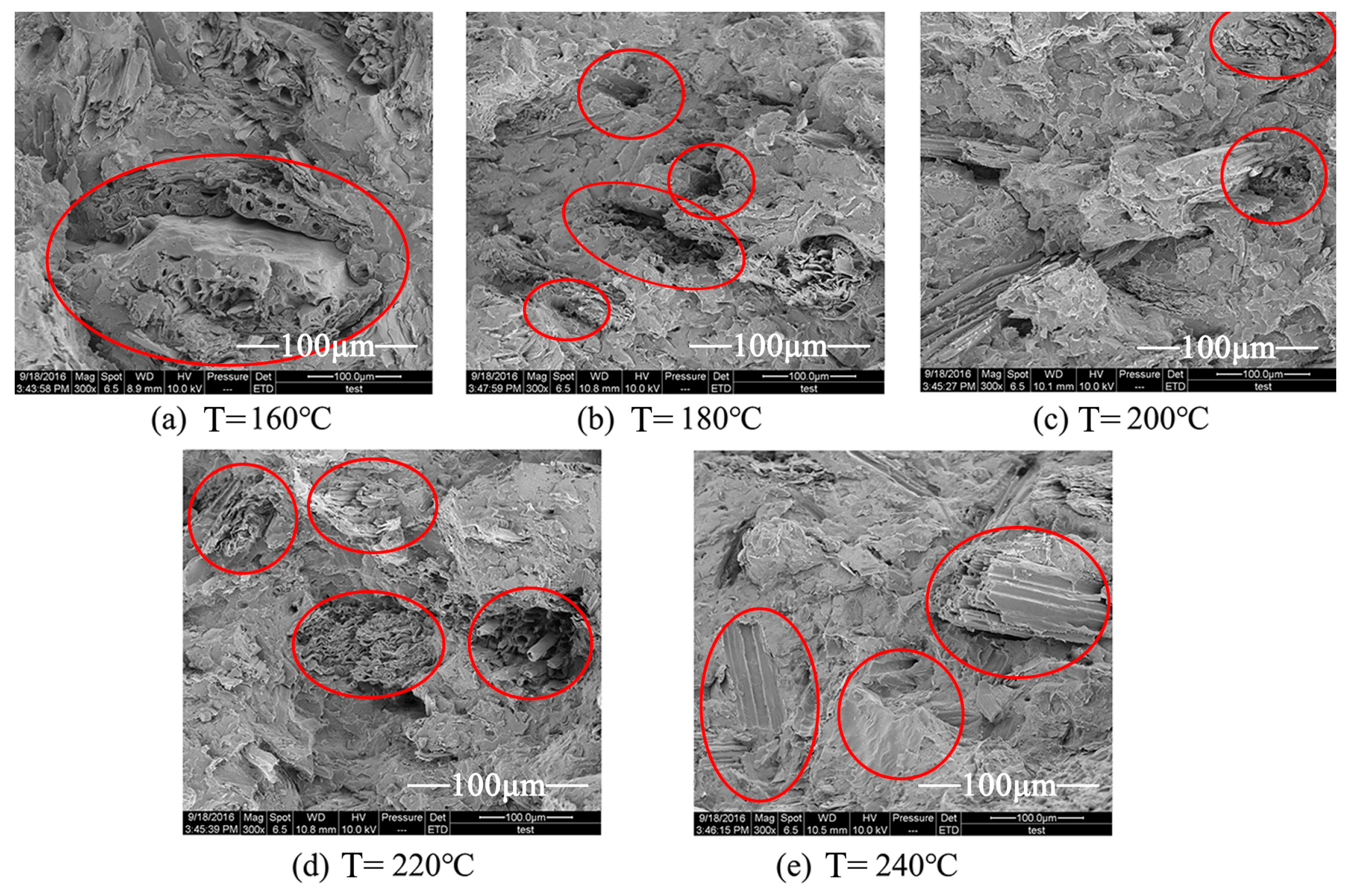

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Butylina, S.; Martikka, O.; Kärki, T. Properties of wood fibre-polypropylene composites: Effect of wood fibre source. Appl. Compos. Mater. 2011, 18, 101–111. [Google Scholar] [CrossRef]

- Huang, S.H.; Cortes, P.; Cantwell, W.J. The influence of moisture on the mechanical properties of wood polymer composites. J. Mater. Sci. 2006, 41, 5386–5390. [Google Scholar] [CrossRef]

- Ndiaye, D.; Gueye, M.; Diop, B. Characterization, physical, and mechanical properties of polypropylene/wood-flour composites. Arab. J. Sci. Eng. 2013, 38, 59–68. [Google Scholar] [CrossRef]

- Pelaez-Samaniego, M.R.; Yadama, V.; Lowell, E.; Espinoza-Herrera, R. A review of wood thermal pretreatments to improve wood composite properties. Wood Sci. Technol. 2013, 47, 1285–1319. [Google Scholar] [CrossRef]

- Wang, C.; Ying, S. A novel strategy for the preparation of bamboo fiber reinforced polypropylene composites. Fibers Polym. 2014, 15, 117–125. [Google Scholar] [CrossRef]

- Han, S.H.; Oh, H.J.; Kim, S.S. Evaluation of fiber surface treatment on the interfacial behavior of carbon fiber-reinforced polypropylene composites. Compos. Part B Eng. 2014, 60, 98–105. [Google Scholar] [CrossRef]

- Li, L.; Zhu, S.; Liu, Z.; Chen, Z. Effect of drying treatment on properties of wood flour/PE composite. China Synth. Resin Plast. 2005, 22–25. [Google Scholar]

- Li, J.; Liang, Q.C.; Bennamoun, L. Superheated steam drying: Design aspects, energetic performances, and mathematical modeling. Renew. Sustain. Energy Rev. 2016, 60, 1562–1583. [Google Scholar] [CrossRef]

- Liu, X.; Lee, D.J. Some recent research and development in drying technologies: Product perspective. Dry Technol. 2015, 33, 1339–1349. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P. Effect of thermal-treatment of wood fibres on properties of flat-pressed wood plastic composites. Polym. Degrad. Stabil. 2011, 96, 818–822. [Google Scholar] [CrossRef]

- Li, Y.; Du, L.; Kai, C.; Wu, Q. Bamboo and high density polyethylene composite with heat-treated bamboo fiber: Thermal decomposition properties. BioResources 2013, 8, 901–912. [Google Scholar] [CrossRef]

- Xun, G.; Wanli, C.; Haigang, W.; Zhuo, L. Effect of wood fiber on properties of wood-plastic composites. J. Northeast For. Univ. 2014, 42, 100–103. [Google Scholar]

- Sommerhuber, P.F.; Welling, J.; Krause, A. Substitution potentials of recycled HDPE and wood particles from post-consumer packaging waste in Wood-Plastic Composites. Waste Manag. 2015, 46, 76–85. [Google Scholar] [CrossRef] [PubMed]

- Ou, R.X.; Wang, Q.W.; Yuan, F.P.; Liu, B.Y.; Yang, W.J. Mechanical and interfacial properties of hydrolyzed Kevlar fiber reinforced wood flour/HDPE composites. Adv. Mater. Res. 2011, 221, 27–31. [Google Scholar] [CrossRef]

- Bula, K.; Knitter, M. Properties of high-density polyethylene reinforced with pine-wood fillers. Drewno 2016, 59, 205–211. [Google Scholar]

- Li, X.; Lei, B.; Lin, Z.; Huang, L.; Tan, S.; Cai, X. The utilization of organic vermiculite to reinforce wood-plastic composites with higher flexural and tensile properties. Ind. Crop. Prod. 2013, 51, 310–316. [Google Scholar] [CrossRef]

- Zhang, L.P.; Wang, S.Q.; Sun, X.J.; Gao, H. Pulping and papermaking performance of lumber residues of Pseudotsuga menziesii. J. Fujian Agric. For. Univ. 2014, 43, 327–331. [Google Scholar]

- Wenji, Z.Y.Y. Effect of Thermal Treatment on the Properties of Bamboo-Based Fiber Composites. Sci. Silvae Sin. 2013, 49, 160–168. [Google Scholar]

- Yang, T.; Fu, J.; Chen, Q.; Shen, X. Orthogonal array design for the optimization of stripping Sr (II) from ionic liquids using supercritical CO2. Chin. J. Chem. Eng. 2016, 5, 326–332. [Google Scholar] [CrossRef]

- Qingde, L.; Xun, G.; Wanli, C.; Guangping, H. Effect of Modified Red Pottery Clay on the Moisture Absorption Behavior and Weatherability of Polyethylene-Based Wood-Plastic Composites. Materials 2017, 10, 111. [Google Scholar]

- Meerten, Y.; Swolfs, Y.; Baets, J.; Gorbatikh, L.; Verpoest, I. Penetration impact testing of self-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2015, 68, 289–295. [Google Scholar] [CrossRef]

- Nörnberg, B.; Borchardt, E.; Luinstra, G.A.; Fromm, J. Wood plastic composites from poly (propylene carbonate) and poplar wood flour–Mechanical, thermal and morphological properties. Eur. Polym. J. 2014, 51, 167–176. [Google Scholar] [CrossRef]

- Wang, H.G.; Song, Y.M.; Wang, Q.W. Mechanical Properties of Needle-Shaped Wood-Fiber HDPE Composites. Sci. Silvae Sin. 2016, 42, 108–116. [Google Scholar]

- Dang, W.; Song, Y.; Wang, Q.; Wang, W. Improvement in compatibility and mechanical properties of modified wood fiber/polypropylene composites. Front. For. China 2008, 3, 243–247. [Google Scholar] [CrossRef]

- Östman, B.; Voss, A.; Hughes, A.; Grexa, O. Durability of fire retardant treated wood products at humid and exterior conditions review of literature. Fire Mater. 2001, 25, 95–104. [Google Scholar] [CrossRef]

- Weihong, S.Y.L.C.W.; Yanjun, W.Q.X. Coupling Effects of Silane on the Mechanical Properties and Water Absorption of Wood Flour/HDPE Composites. Sci. Silvae Sin. 2011, 6, 20. [Google Scholar]

- Migneault, S.; Koubaa, A.; Perré, P.; Riedl, B. Effects of wood fiber surface chemistry on strength of wood-plastic composites. Appl. Surf. Sci. 2015, 343, 11–18. [Google Scholar] [CrossRef]

- Yang, W.; Xie, Y.; Wang, H.; Liu, B.Y.; Wang, Q.W. Impacts of freezing and thermal treatments on dimensional and mechanical properties of wood flour-HDPE composite. J. For. 2013, 24, 143–147. [Google Scholar] [CrossRef]

- White, R.H. Effect of lignin content and extractives on the higher heating value of wood. Wood Fiber Sci. 2007, 19, 446–452. [Google Scholar]

- Huachun, Q.; Wanli, C.; Yixing, L. Mechanical characteristics and chemical compositions of superheated steam-treated wood under high temperature and pressure. J. Northeast For. Univ. 2005, 33, 44–46. [Google Scholar]

- Huang, L.; Ou, Z.; Boving, T.B.; Xing, B. Sorption of copper by chemically modified aspen wood fibers. Chemosphere 2009, 76, 1056–1061. [Google Scholar] [CrossRef] [PubMed]

- Deka, B.K.; Maji, T.K.; Mandal, M. Study on properties of nanocomposites based on HDPE, LDPE, PP, PVC, wood and clay. Polym. Bull. 2011, 67, 1875–1892. [Google Scholar] [CrossRef]

- Guo, D. Effect of electron beam radiation processing on mechanical and thermal properties of fully biodegradable crops straw/poly(vinyl alcohol) biocomposites. Radiat. Phys. Chem. 2017, 130, 202–207. [Google Scholar] [CrossRef]

- Kuo, P.Y.; Wang, S.Y.; Chen, J.H.; Hsueh, H.C.; Tsai, M.J. Effects of material compositions on the mechanical properties of wood-plastic composites manufactured by injection molding. Mater. Des. 2009, 30, 3489–3496. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G.; Freitag, C.; Morrell, J.J. Effects of wood fiber esterification on properties, weatherability and biodurability of wood plastic composites. Polym. Degrad. Stab. 2013, 98, 1348–1361. [Google Scholar] [CrossRef]

- Popescu, C.M.; Hill, C.A.; Curling, S.; Ormondroyd, G.; Xie, Y. The water vapour sorption behaviour of acetylated birch wood: How acetylation affects the sorption isotherm and accessible hydroxyl content. J. Mater. Sci. 2014, 49, 2362–2371. [Google Scholar] [CrossRef]

- Ikram, S.; Das, O.; Bhattacharyya, D. A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 177–188. [Google Scholar] [CrossRef]

| Property Measured | Charateristics |

|---|---|

| Fiber morphology (mesh) | 60 to 80 |

| Fiber length (mm) | 1.36 (0.20) |

| Fiber diameter (μm) | 223 (31) |

| Length-diameter Ratio | 6.1 (1.87) |

| MC at 23 °C (%) | 12.4 (0.19) |

| Wavenumber (cm−1) | Spectra Attribution |

|---|---|

| 3350 | Hydroxyl (–OH) stretching vibration |

| 2890 | Methyl (–CH3), methylene (=CH2) stretching vibration |

| 1730 | Carbonyl (C=O) stretching vibration in xylan (hemicellulose) |

| 1600 | Benzene ring carbon skeleton stretching (lignin) |

| 1240 | Benzene-oxygen bond stretching vibration (lignin); acyl-oxygen bond (CO–OR) stretching vibration (hemicellulose) |

| 1030 | Secondary alcohols and aromatic ether (C–O) stretching vibration (cellulose, hemicellulose, and lignin) |

| 767 | Si–O stretching vibrations |

| Condition 1 | Temperature (°C) | 160 | 180 | 200 | 220 | 240 |

| Residence time (s) | 19.3 ± 2.3 | 19.1 ± 1.6 | 19.0 ± 2.5 | 18.6 ± 2.1 | 18.1 ± 1.9 | |

| Condition 2 | Inlet air velocity (m/s) | 9 | 10 | 11 | 12 | 13 |

| Residence time (s) | 31.2 ± 3.7 | 25.3 ± 2.9 | 19.0 ± 2.5 | 12.4 ± 3.2 | 7.9 ± 2.1 | |

| Condition 3 | Feed rate (kg/h) | 90 | 105 | 120 | 135 | 150 |

| Residence time (s) | 12.1 ± 3.2 | 17.1 ± 3.1 | 19.0 ± 2.5 | 20.7 ± 2.6 | 21.1 ± 4.7 |

| Condition 1 | Temperature (°C) | 160 | 180 | 200 | 220 | 240 |

| Air flow humidity (g·kg−1) | 38 ± 3.7 | 39 ± 4.3 | 42 ± 5.7 | 45 ± 5.8 | 49 ± 6.1 | |

| Condition 2 | Inlet air velocity (m/s) | 9 | 10 | 11 | 12 | 13 |

| Air flow humidity (g·kg−1) | 75 ± 7.1 | 63 ± 6.4 | 42 ± 5.7 | 37 | 35 | |

| Condition 3 | Feed rate (kg/h) | 90 | 105 | 120 | 135 | 150 |

| Air flow humidity (g·kg−1) | 31 ± 3.4 | 37 ± 4.3 | 42 ± 5.7 | 66 ± 6.7 | 73 ± 6.8 |

| RH/% | Sample 1 (160 °C mPWF) | Sample 2 (180 °C mPWF) | Sample 3 (200 °C mPWF) | Sample 4 (220 °C mPWF) | Sample 5 (240 °C mPWF) |

|---|---|---|---|---|---|

| 33 | 2.05 ± 0.18 | 2.01 ± 0.19 | 1.99 ± 0.16 | 1.98 ± 0.13 | 1.93 ± 0.14 |

| 66 | 2.75 ± 0.19 | 2.65 ± 0.18 | 2.32 ± 0.17 | 2.28 ± 0.15 | 2.21 ± 0.15 |

| 75 | 3.51 ± 0.24 | 3.49 ± 0.23 | 3.35 ± 0.22 | 3.23 ± 0.23 | 3.08 ± 0.20 |

| 85 | 4.45 ± 0.29 | 4.19 ± 0.25 | 4.11 ± 0.24 | 4.02 ± 0.25 | 3.86 ± 0.24 |

| 93 | 6.66 ± 0.38 | 6.47 ± 0.34 | 6.26 ± 0.37 | 6.03 ± 0.38 | 5.57 ± 0.33 |

| RH/% | Sample 1 (160 °C mPWF) | Sample 2 (180 °C mPWF) | Sample 3 (200 °C mPWF) | Sample 4 (220 °C mPWF) | Sample 5 (240 °C mPWF) |

|---|---|---|---|---|---|

| 33 | 3.01 ± 0.20 | 2.93 ± 0.21 | 2.75 ± 0.21 | 2.61 ± 0.18 | 2.56 ± 0.18 |

| 66 | 4.30 ± 0.28 | 3.95 ± 0.23 | 3.81 ± 0.23 | 3.66 ± 0.21 | 3.43 ± 0.22 |

| 75 | 4.92 ± 0.34 | 4.34 ± 0.22 | 4.32 ± 0.23 | 4.25 ± 0.21 | 4.06 ± 0.25 |

| 85 | 5.65 ± 0.33 | 5.29 ± 0.34 | 5.04 ± 0.34 | 5.01 ± 0.30 | 4.78 ± 0.30 |

| 93 | 7.98 ± 0.46 | 7.41 ± 0.40 | 7.23 ± 0.42 | 6.93 ± 0.39 | 6.54 ± 0.38 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Han, G.; Li, Q.; Gao, X.; Cheng, W. High-Temperature Hot Air/Silane Coupling Modification of Wood Fiber and Its Effect on Properties of Wood Fiber/HDPE Composites. Materials 2017, 10, 286. https://doi.org/10.3390/ma10030286

Chen F, Han G, Li Q, Gao X, Cheng W. High-Temperature Hot Air/Silane Coupling Modification of Wood Fiber and Its Effect on Properties of Wood Fiber/HDPE Composites. Materials. 2017; 10(3):286. https://doi.org/10.3390/ma10030286

Chicago/Turabian StyleChen, Feng, Guangping Han, Qingde Li, Xun Gao, and Wanli Cheng. 2017. "High-Temperature Hot Air/Silane Coupling Modification of Wood Fiber and Its Effect on Properties of Wood Fiber/HDPE Composites" Materials 10, no. 3: 286. https://doi.org/10.3390/ma10030286

APA StyleChen, F., Han, G., Li, Q., Gao, X., & Cheng, W. (2017). High-Temperature Hot Air/Silane Coupling Modification of Wood Fiber and Its Effect on Properties of Wood Fiber/HDPE Composites. Materials, 10(3), 286. https://doi.org/10.3390/ma10030286