KDP Aqueous Solution-in-Oil Microemulsion for Ultra-Precision Chemical-Mechanical Polishing of KDP Crystal

Abstract

:1. Introduction

2. Experimental Section

2.1. Partial Phase Diagram

2.2. Sample Preparation

2.3. Materials Characterizations of Microemulsion

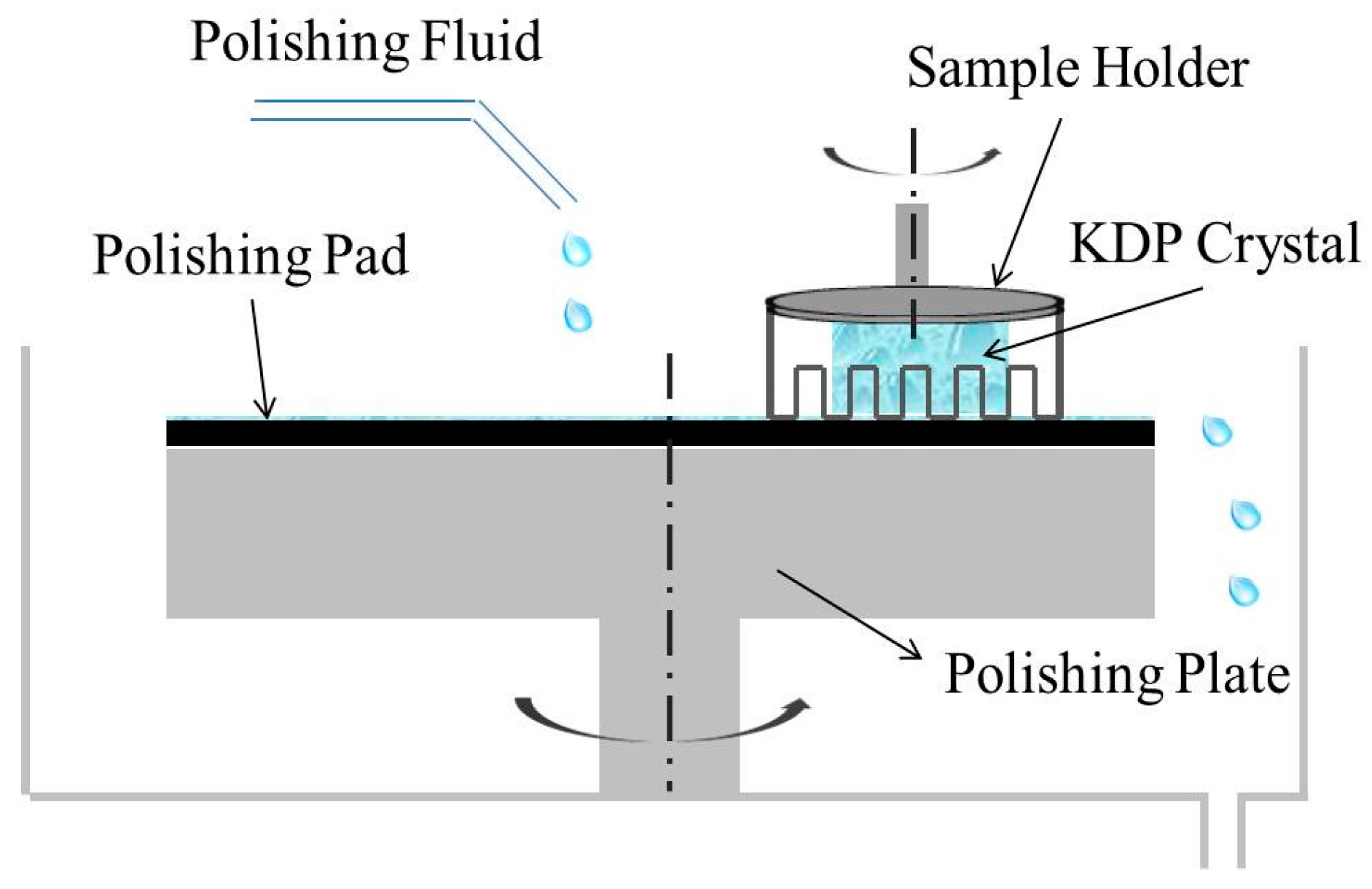

2.4. Chemical-Mechanical Polishing of KDP Crystal

3. Results and Discussion

3.1. Phase Diagram and Microemulsion Selection

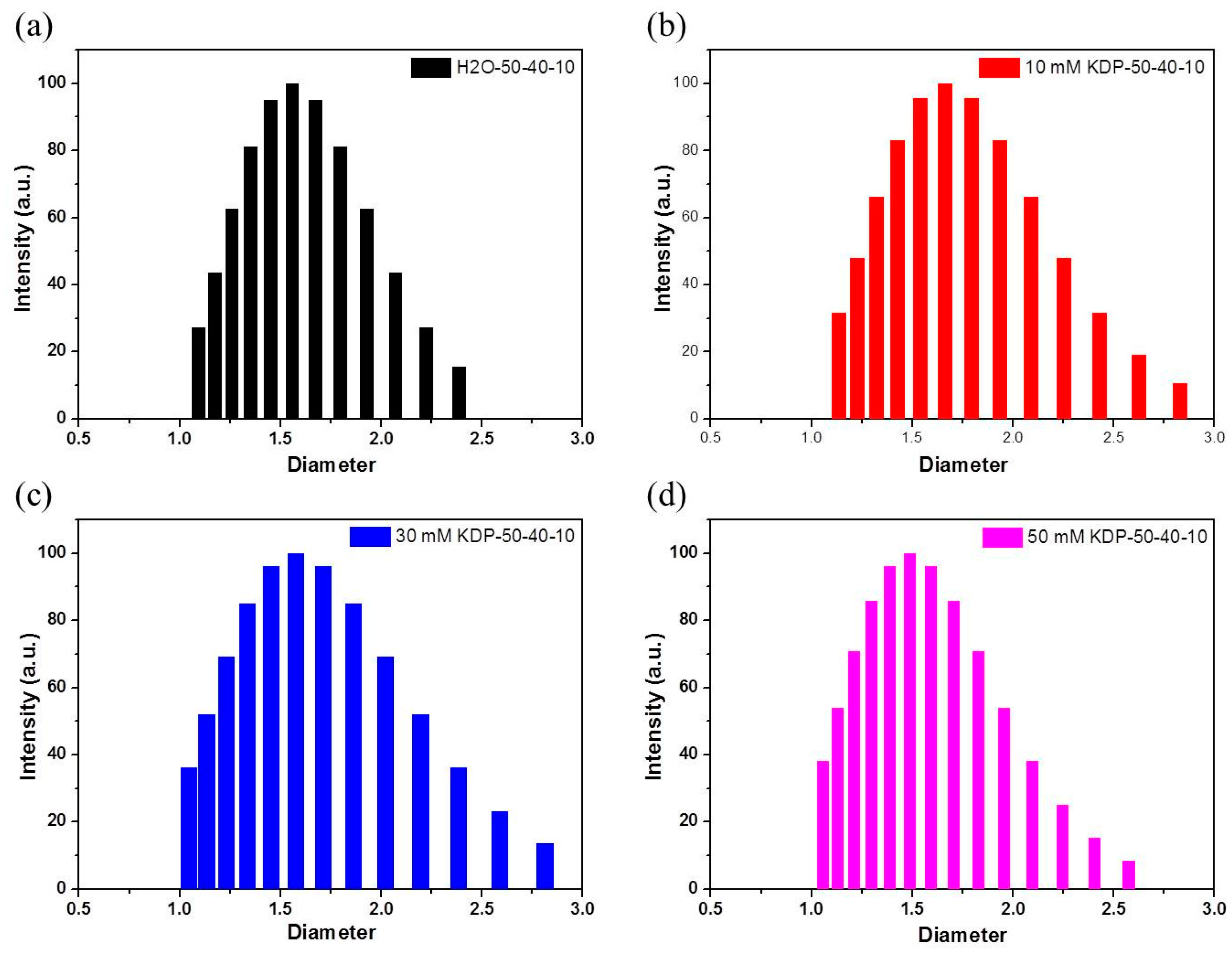

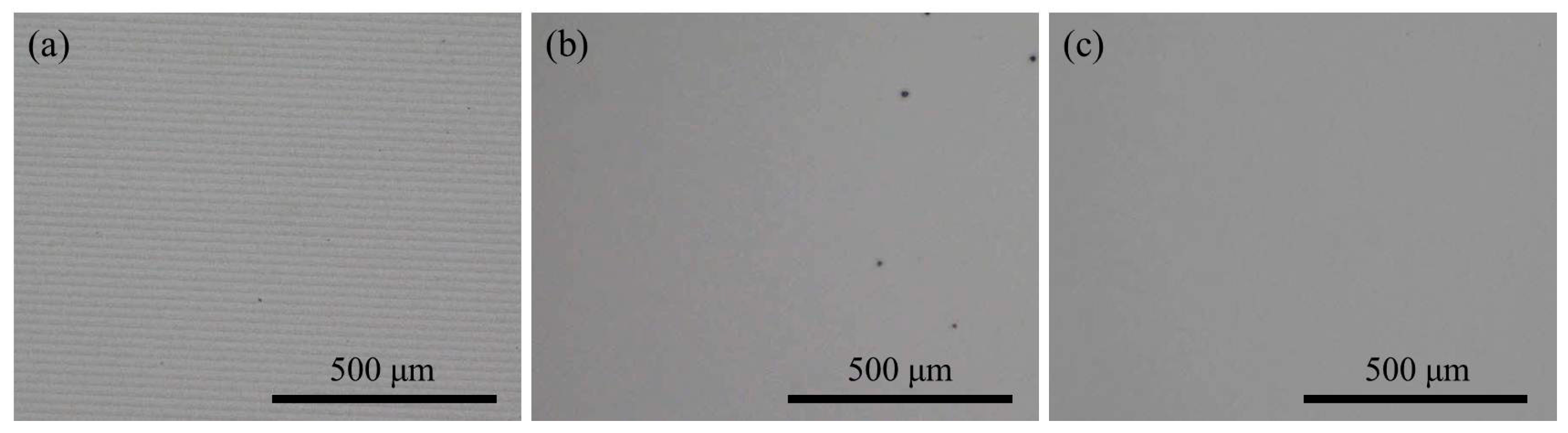

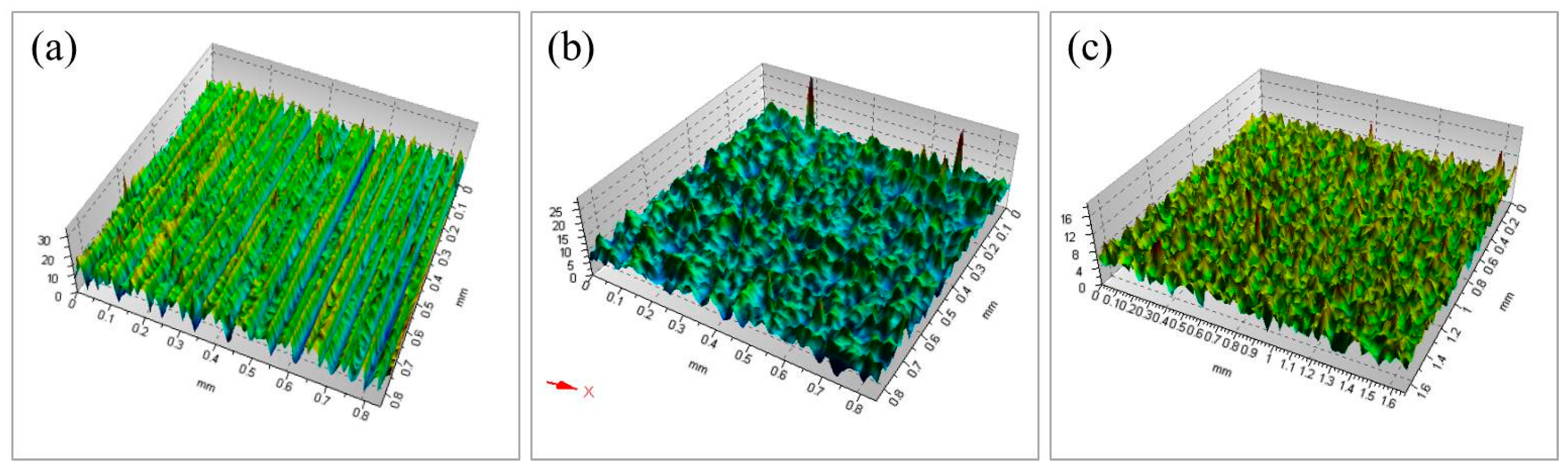

3.2. CMP Based on Controlled Deliquescent Mechanism

3.3. Research of Material Removal Rate (MRR)

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Campbell, J.H.; Hawley-Fedder, R.A.; Stolz, C.J.; Menapace, J.A.; Borden, M.R.; Whitman, P.K.; Yu, J.; Runkel, M.; Riley, M.O.; Feit, M.D.; et al. NIF optical materials and fabrication technologies: An overview. SPIE 2004, 5341, 84–101. [Google Scholar]

- Walid, J.; Victor, S.; Philippe, B. Surface finish and residual stresses induced by orthogonal dry machining of AA7075-T651. Materials 2014, 7, 1603–1624. [Google Scholar]

- Chen, D.; Ji, F.; Chen, H. Research on the low speed stability control technology of fly-cutting machine for KDP crystals. SPIE 2014, 9281, 92810P1-7. [Google Scholar]

- Fuchs, B.A.; Hed, P.P.; Baker, P.C. Fine diamond turning of KDP crystals. Appl. Opt. 1986, 25, 1733–1735. [Google Scholar] [CrossRef] [PubMed]

- Kordonski, W.I.; Jacobs, S.D. Magnetorheological finishing. Int. J. Mod. Phys. B 1996, 10, 2837–2848. [Google Scholar] [CrossRef]

- Golini, D.; Kordonski, W.I.; Dumas, P.; Hogan, S.J. Magnetorheological finishing (MRF) in commercial precision optics manufacturing. SPIE 1999, 3782, 80–91. [Google Scholar]

- Chen, S.; Li, S.; Peng, X.; Hu, G.; Tie, G. Research of polishing process to control the iron contamination on the magnetorheological finished KDP crystal surface. Appl. Opt. 2015, 54, 1478–1484. [Google Scholar] [CrossRef] [PubMed]

- Ji, F.; Xu, M.; Wang, B.; Wang, C.; Li, X.; Zhang, Y.; Zhou, M.; Huang, W.; Wei, Q.; Tang, G.; et al. Preparation of methoxyl poly(ethylene glycol) (MPEG)-coated carbonyl iron particles (CIPs) and their application in potassium dihydrogen phosphate (KDP) magnetorheological finishing (MRF). Appl. Surf. Sci. 2015, 353, 723–727. [Google Scholar] [CrossRef]

- Katagiri, M.; Namba, Y. Optical surface generation of KDP inorganic nonlinear optical crystals by ultraprecision surface grinding. J. Jpn. Soc. Precis. Eng. 1999, 65, 888–892. [Google Scholar] [CrossRef]

- Kaufman, F.B.; Thompson, D.B.; Broadie, R.E.; Jaso, M.A.; Guthrie, W.L.; Pearson, D.J.; Small, M.B. Tures as chip interconnects. J. Electrochem. Soc. 1991, 138, 3460–3465. [Google Scholar] [CrossRef]

- Shi, F.; Zhao, B. Modeling of chemical-mechanical polishing with soft pads. Appl. Phys. A 1998, 67, 249–252. [Google Scholar] [CrossRef]

- Wang, X.; Gao, H.; Guo, D. Experimental study on micro-deliquescence ultra-precision polishing with fine water mist for KDP crystal. Adv. Mater. Res. 2013, 797, 423–427. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, F.; Zhang, Y.; Luan, D. Research on deliquescent polishing fluid for KDP crystals. Adv. Mater. Manuf. Sci. Technol. 2009, 1, 53–58. [Google Scholar] [CrossRef]

- Wang, B.; Gao, H. Experimental study on KDP crystal polishing. SPIE 2007, 6722, 672209–672214. [Google Scholar]

- Wang, B.; Li, Y.; Gao, H. Water-in-oil dispersion for KH2PO4 (KDP) crystal CMP. J. Dispers. Sci. Technol. 2010, 31, 1611–1617. [Google Scholar] [CrossRef]

- Wang, X.; Gao, H.; Chen, Y.; Guo, D. A water dissolution method for removing micro-waviness caused by SPDT process on KDP crystals. Int. J. Adv. Manuf. Technol. 2016, 85, 1347–1360. [Google Scholar] [CrossRef]

| Experiments | Surface Quality | RMS Roughness/nm |

|---|---|---|

| SPDT | Micro-scale ripples | 4.6 |

| CMP-W/O | Corrosion pits | 3.1 |

| CMP-KDP aq/O | Smooth | 1.5 |

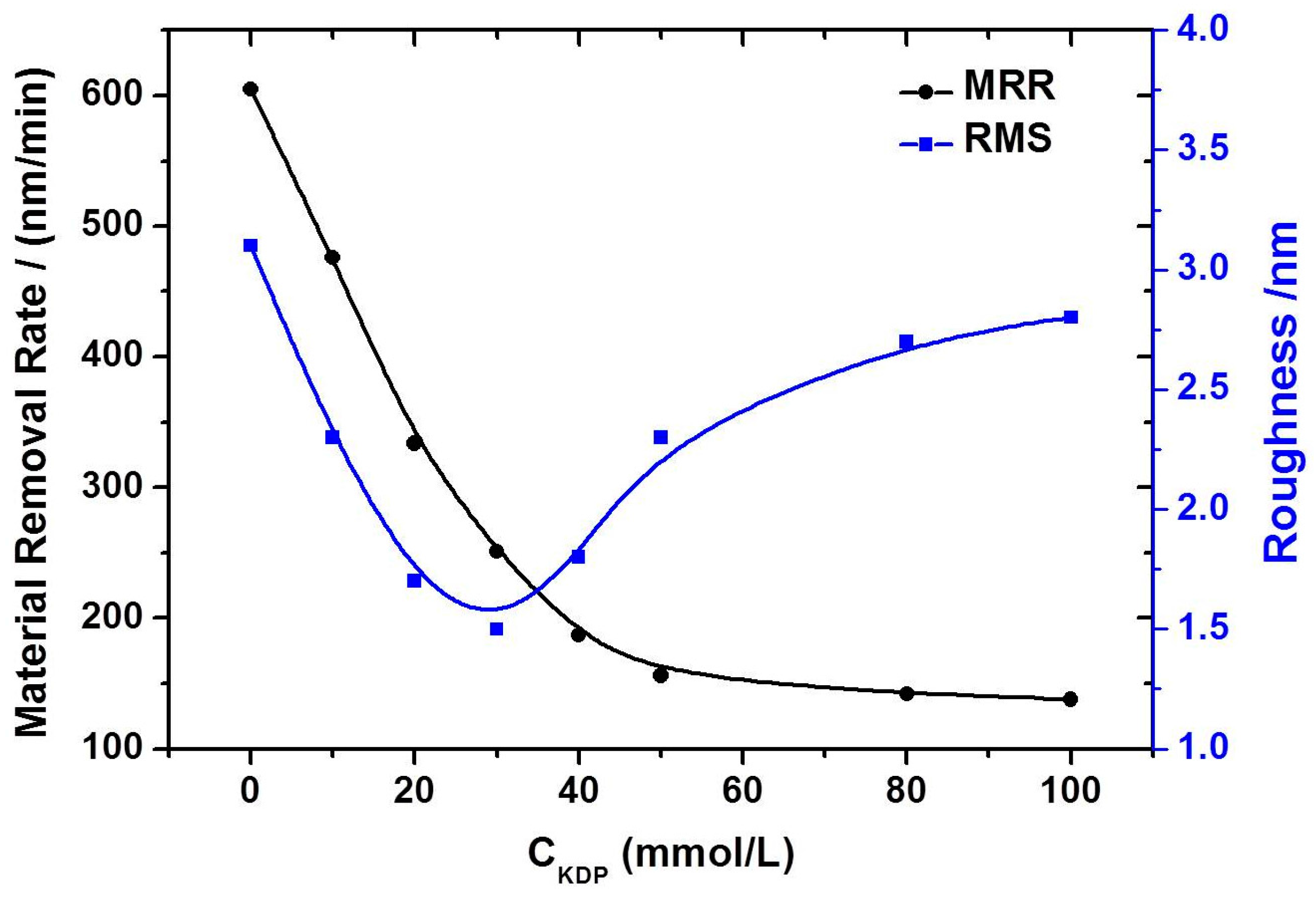

| CMP Solutions | cKDP/mM | MRR/(nm/min) | RMS/nm |

|---|---|---|---|

| 1 | 0 | 605 | 3.1 |

| 2 | 10 | 476 | 2.3 |

| 3 | 20 | 334 | 1.7 |

| 4 | 30 | 251 | 1.5 |

| 5 | 40 | 187 | 1.8 |

| 6 | 50 | 156 | 2.3 |

| 7 | 80 | 142 | 2.7 |

| 8 | 100 | 138 | 2.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, H.; Wang, L.; Gao, W.; Li, X.; Wang, C.; Ji, F.; Pan, J.; Wang, B. KDP Aqueous Solution-in-Oil Microemulsion for Ultra-Precision Chemical-Mechanical Polishing of KDP Crystal. Materials 2017, 10, 271. https://doi.org/10.3390/ma10030271

Dong H, Wang L, Gao W, Li X, Wang C, Ji F, Pan J, Wang B. KDP Aqueous Solution-in-Oil Microemulsion for Ultra-Precision Chemical-Mechanical Polishing of KDP Crystal. Materials. 2017; 10(3):271. https://doi.org/10.3390/ma10030271

Chicago/Turabian StyleDong, Hui, Lili Wang, Wei Gao, Xiaoyuan Li, Chao Wang, Fang Ji, Jinlong Pan, and Baorui Wang. 2017. "KDP Aqueous Solution-in-Oil Microemulsion for Ultra-Precision Chemical-Mechanical Polishing of KDP Crystal" Materials 10, no. 3: 271. https://doi.org/10.3390/ma10030271