1. Introduction

Modeling the behavior of concrete structures is a challenging research task, since the various significant physical phenomena are related to various spatial scales, from the cement paste scale up to the structure scale. Usually, the mechanical behavior of concrete is modeled macroscopically via plastic and/or damage constitutive relations (e.g., [

1,

2,

3,

4,

5,

6,

7,

8]) These macroscopic models are often characterized by numerous parameters that need to be calibrated so as to analyze the complex behavior of the concrete at the different stages of loading and damage modes. Since concrete comprises a considerable number of different microstructures, developing an alternative approach to macroscopic modeling is essential. Variations in the micro- to meso structures of concrete may include the addition of fibers made up of different materials; different sizes, shapes, and types of sand and aggregate; different water-to-cement ratios; and variations in the composition of the cement. Although a multiscale analysis of concrete structures is used, the development of down/up scaling formulations is required, especially in the nonlinear region of the structure response to fracture, friction, plasticity, etc. For example, several studies [

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22] developed a nonlinear meso scale model but did not deal with the down/up scaling issue, while others [

23,

24,

25,

26] developed an upscaling procedure but did not apply it to the nonlinear region. The main motivation for developing the upscaling methodology suggested in the current paper is the potential to elucidate the impact of the chemical composition of cement on the mechanical behavior of concrete, and to reduce the experimental efforts required for calibrating the parameters of the Lattice Discrete Particle Model (LDPM), as presented, for instance, in [

17].

The microstructure of a cement paste can be imaged either experimentally [

27] or numerically [

28,

29,

30,

31,

32]. Experimentally, X-ray computed microtomography (CT) [

27] can be used to collect microstructure information on cement paste in a non-destructive manner by way of digitized voxels. Numerically, models of cement hydration and microstructure formation processes were described previously [

28,

30,

31,

32]. The goal of this study is to bridge the microscopic cement paste scale and the concrete meso scale by upscaling the mechanical properties of the cement paste to obtain the LDPM concrete parameters. The proposed methodology is based on the following models: (1) The HYMOSTRUC3D model [

28,

30], which is capable of elucidating the mineralogical composition of cement clinkers and the chemical reaction of the cement paste; (2) the Anm material model [

33], which is used to generate the unit cell geometries, including irregular shaped aggregates, for the mortar scales; and (3) the lattice model suggested by [

34], which was chosen for its ability to simulate fracture processes at the cement paste and mortar scales. The LDPM was chosen to represent the meso scale behavior of concrete because it can take into account the concrete macroscopic size and shape effects.

The HYMOSTRUC3D numerical model [

28,

30] simulates both the reaction process and the formation of the microstructure in hydrating Portland cement—taking into account hydration kinetics and simulating the cement particles as spheres that develop during the hydration process. It is designed as a three-dimensional model, which is defined by multiple input parameters, including the water-to-cement ratio, the mineralogical composition of the cement, the size distribution of the cement particles (usually employing the Rosion–Rammler sieve curve [

35]), the curing temperature, and the specimen geometry [

36]. This model regards the hydration process and the microstructural formation of the cement paste.

The LDPM [

16,

17], numerical mechanical model, simulates the meso structure of concrete by a three-dimensional assemblage of particles that are generated randomly according to a given grain size distribution (which is usually determined using the Fuller curve approach [

37]). The LDPM has been extensively calibrated and validated [

17], and its superior functionality in reproducing and predicting concrete behavior under a wide range of loading conditions has been reported both qualitatively and quantitatively [

16,

17,

18]. The LDPM can be used to simulate the important mechanical response of concrete structures, including unconfined and confined uniaxial compression tests (considering also the effect of specimen slenderness and of loading platens friction); biaxial compression tests; triaxial compression tests with a reversal of softening into hardening for increasing confinement; hydrostatic compression tests that show no softening whatsoever; direct tensile tests; splitting tensile (Brazilian) tests; fracture tests; energetic size effects; cycle loading; the correct ratio between compressive strength and tensile strength; and the rate effect on concrete strength. The interaction between the various aggregates in the concrete is taken into account at the concrete scale, and the geometry of the elements is obtained by using the Delaunay triangulation, which provides volume subdivision by tetrahedrons. The mechanical interaction between adjacent aggregate particles through the embedding mortar is represented by the mechanical response of the elements, in which each element is characterized by the aggregate embedded in the mortar. Such interactions are governed by meso scale constitutive equations, which describe the tensile fracturing with strain-softening, cohesive, and frictional shearing, and the nonlinear compressive behavior with strain-hardening. The boundaries between two elements are represented by the outward triangular faces, called facets.

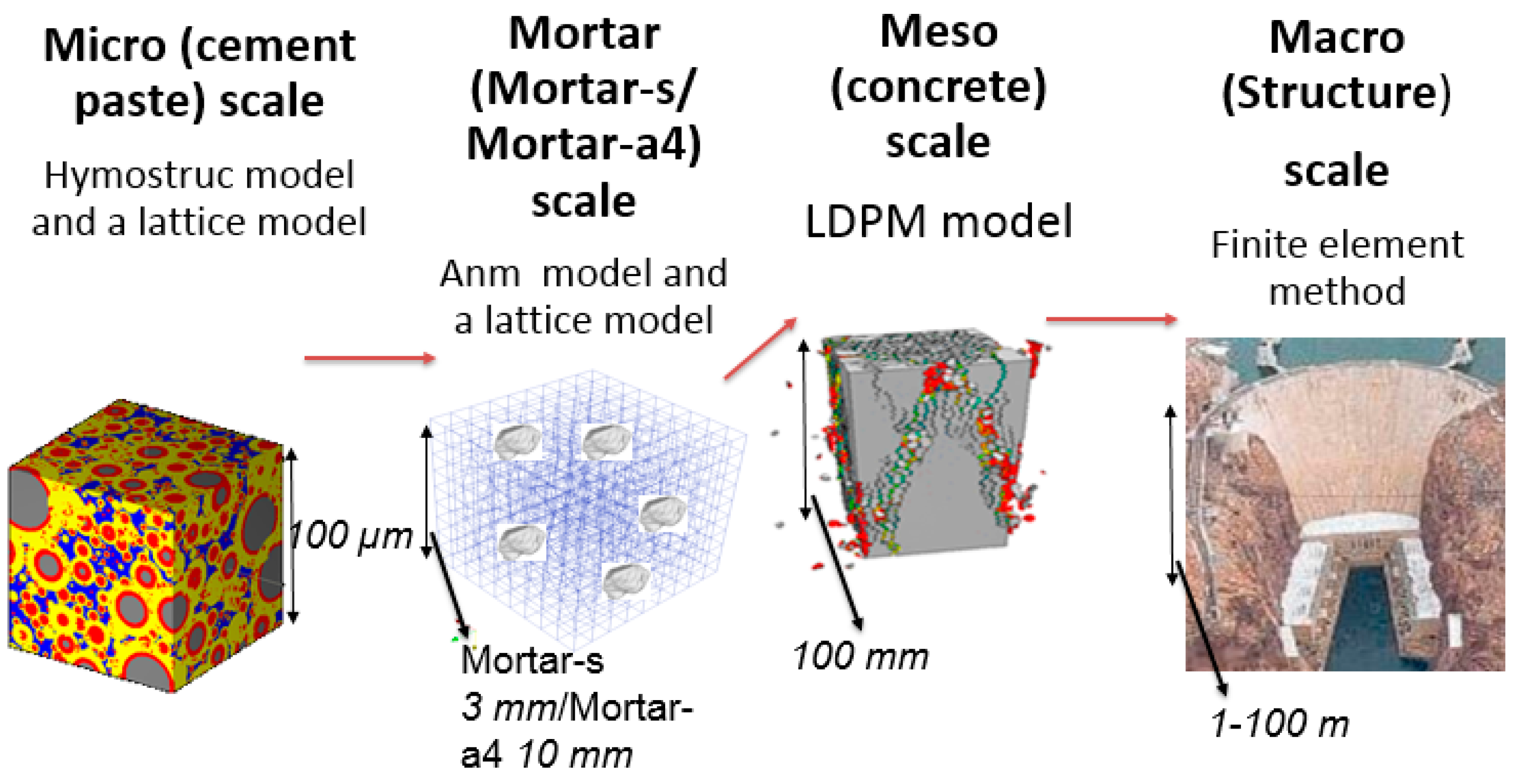

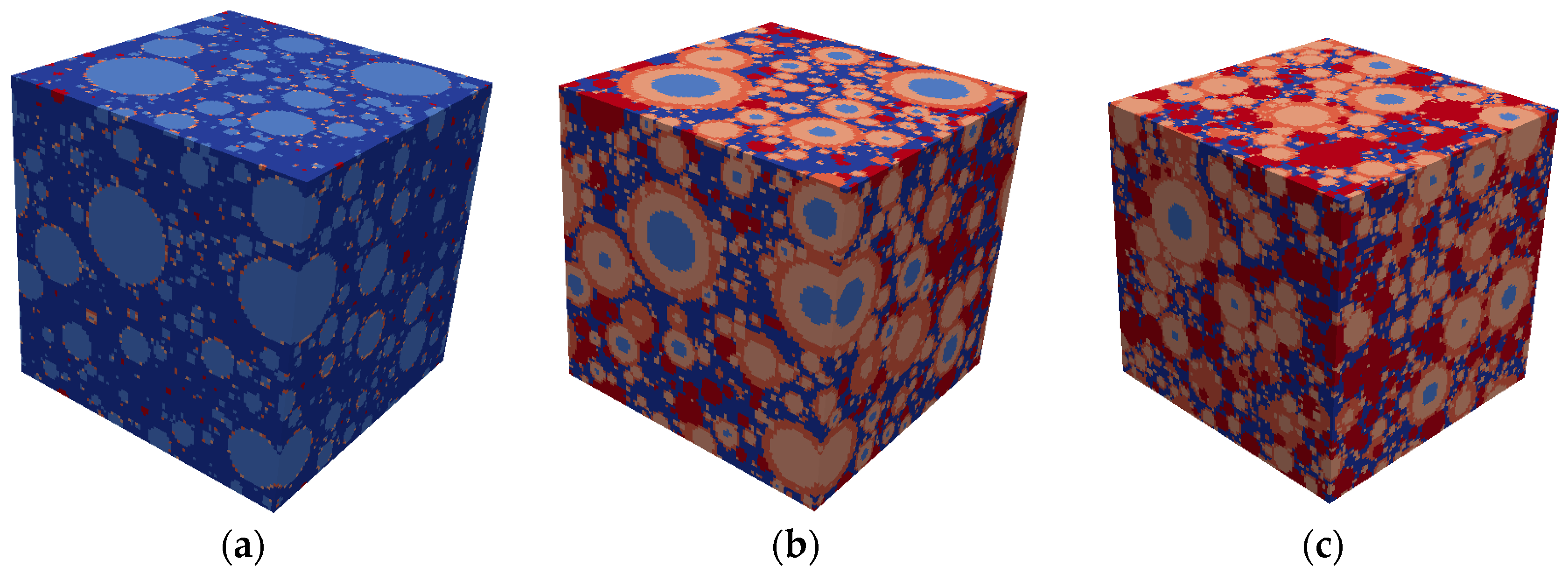

The various scales and models used in this study are depicted in

Figure 1. The cement paste scale is characterized by cement products prior to and following the hydration process; the cement grain particle size range is 1–50 μm. For this scale, we suggest using the HYMOSTRUC3D and lattice models. The mortar-s scale includes the cement paste as a matrix, sand, and an Interface Transition Zone (ITZ); the sand particle size range is 1.2–0.5 mm. For this scale, we suggest using the Anm and lattice models. The mortar-a4 scale includes the combination of mortar-s as a matrix, with aggregates smaller than 4 mm and an interface layer between them; the aggregate size range is 2.36–4 mm. The designation mortar-a4 was given to emphasize the fact that the aggregates are smaller than 4 mm. For this scale, we suggest using the Anm and lattice models. The concrete scale includes aggregates larger than 4 mm (and usually up to 20 mm) and mortar-a 4 as a matrix; we consider this scale to be the concrete scale. For this scale, we suggest using the LDPM. The structure scale is usually solved by using the Finite Element Method (FEM) and is beyond the scope of this study. The size of the unit cells in each scale was determined by a numerical study, which compares different sizes and mesh refinements [

38].

Finally, a validation process is presented by the comparison of the macro scale results to a uniaxial compression test. Although a macroscopic validation study of this procedure is presented here, it is recommended that future research includes a comparison to additional experiments in each scale.

2. Methodology of Research

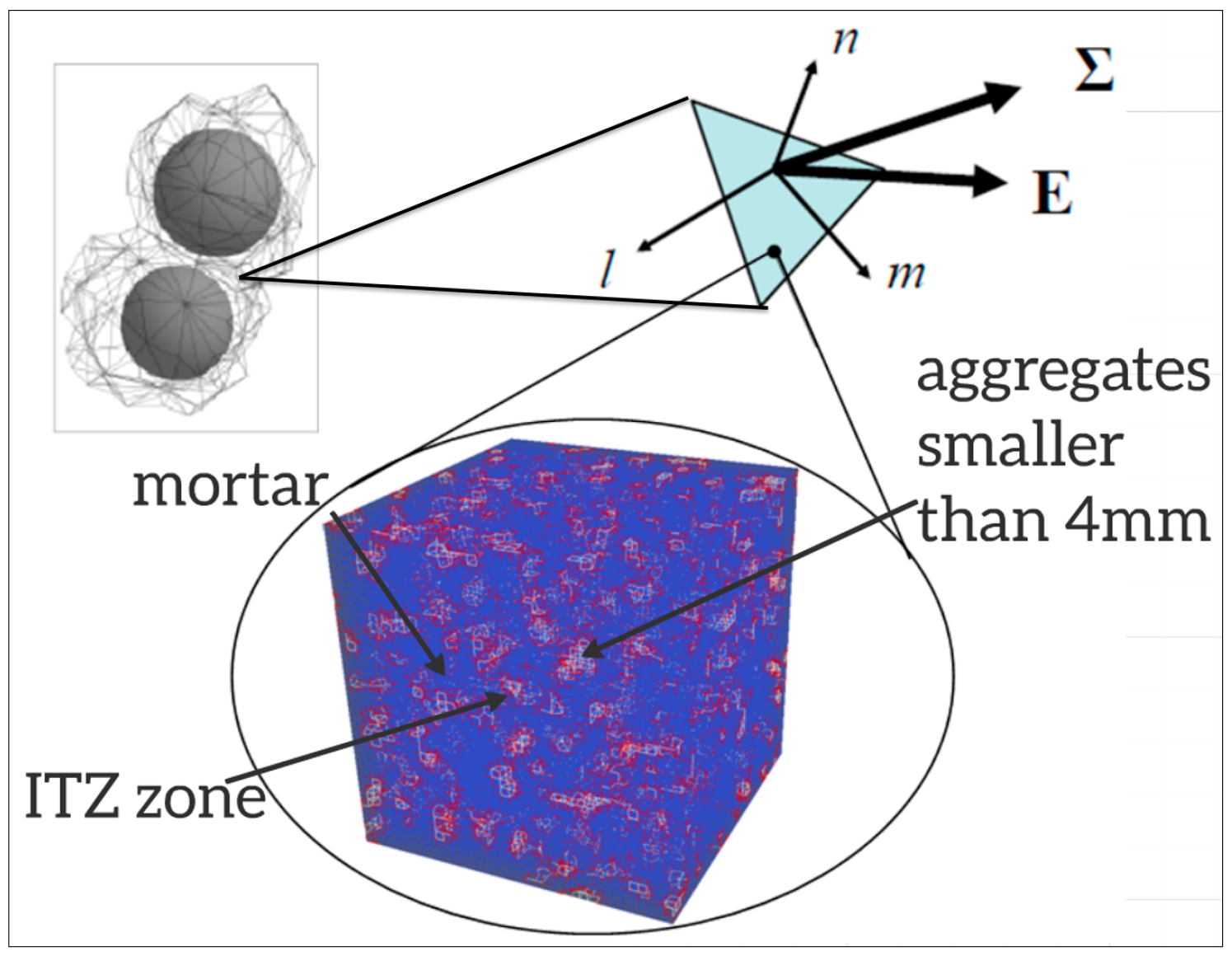

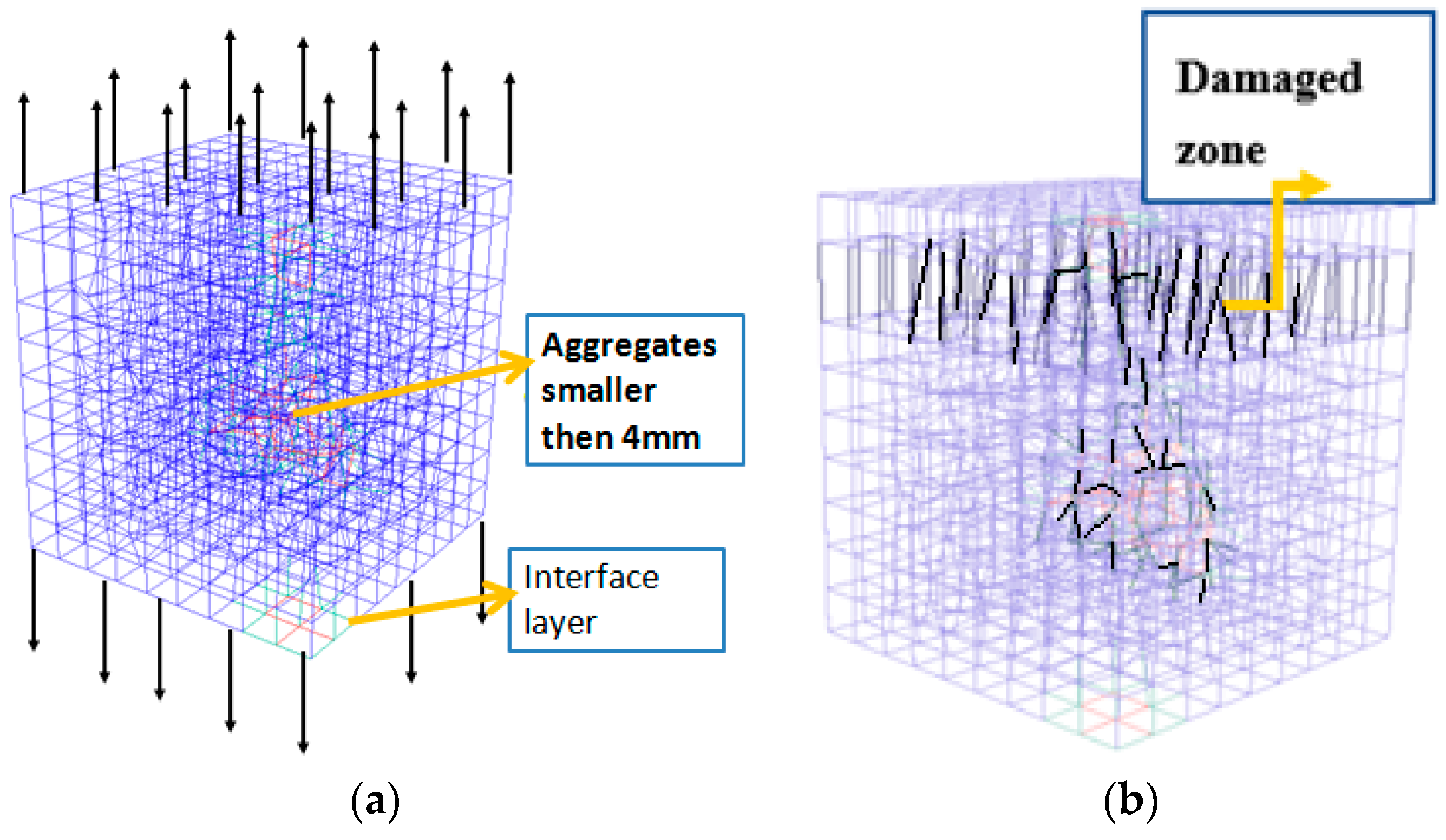

The upscaling procedure presented here bridges the scales by deriving the elastic, tensile, and shear parameters required for the LDPM from the characteristics of the lower scale. Each LDPM parameter relates to a different failure mode and can, therefore, be derived from a different set of simulations. The constitutive equations of the LDPM represent the mechanical behavior at the facets in which the mortar is located; therefore, it can be assumed that the facet failure modes can be characterized by a unit cell of the mortar, which includes aggregates smaller than 4 mm; this is shown in

Figure 2, which depicts the location of the facet between two aggregates and the mortar-a4 unit cell, which represents its mechanical behavior.

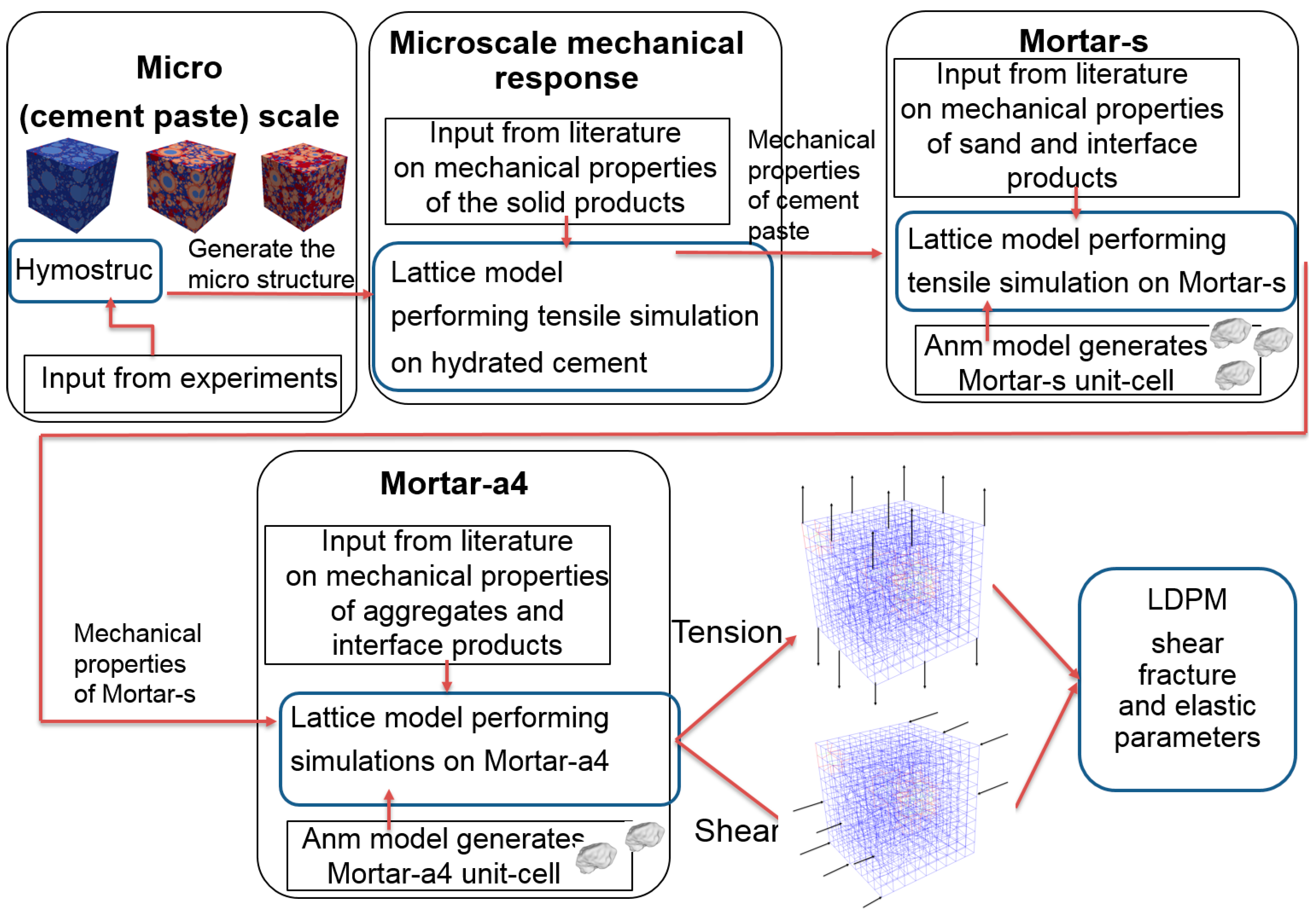

The suggested methodology involves chemical simulation, mechanical simulation of the hydrated cement, mechanical simulation of the mortar-s unit cell, and mechanical simulation of the mortar-a4 unit cell, which provide the parameters used as inputs into the LDPM. A flowchart of the suggested methodology is illustrated in

Figure 3. The mineralogical and chemical composition of the cement is required as input to the HYMOSTRUC3D model, and the output of this step is the microstructure of the hydrated cement paste. The microstructure of the cement paste, together with the mechanical properties of the microstructure constituents, are then used to perform a tension simulation using the lattice model [

34], which results in an output of the mechanical properties of the cement paste. Next, the mechanical properties of the cement paste are used, together with the mechanical properties of sand, as an input for a lattice model that simulates the mechanical performance of mortar-s under tensile testing. The mechanical properties of the mortar-s, together with the properties of the aggregate, are then used as inputs for a lattice model that simulates the mechanical performance of mortar-a4. In the current study, two simulations (tension and pure shear) of the mortar-a4 unit cell are used to evaluate the elastic, fracture, and shear parameters of the LDPM.

This paper presents a successful upscaling of five LDPM parameters from the lower scales; these are related to the fracture, shear, and elastic modes. The upscaling of the remaining ten parameters requires further study related to the compression microscale model and, therefore, is not presented in this paper. The experimental data needed as input have been collected from [

39,

40] and include the following information: At the cement paste (microscopic) scale, the chemical composition was obtained from inductively coupled plasma mass spectrometry (ICP); and the mineralogical composition of the cement was obtained using X-ray analysis (XRD). At the macroscopic level, a uniaxial compression test (at the age of 169 days) was performed on a concrete specimen to calibrate and validate the numerical models at the concrete meso scale. It is recommended that future research includes a comparison to additional macroscopic experiments, such as fracture tests, to ensure the uniqueness of the set of the obtained parameters.

The following subsections provide more details related to the LDPM parameters.

2.1. Mix Design Parameters

Mix-design parameters are required to create the geometrical definition of the concrete meso structure, including cement content (c), water-to-cement ratio (w/c), aggregate-to-cement ratio (a/c), maximum aggregate size (da), Fuller’s curve coefficient (nF), and minimum aggregate size (d0). The first four parameters are obtained directly from the mix design, while the Fuller coefficient is obtained by performing a best fit procedure of the Fuller curve to the sieve analysis experimental data. The parameter d0 governs the resolution of the model and was chosen, here, to be 4 mm so as to avoid excessive computing demands and to include aggregates in the mortar-a4 scale and take into account failure through the ITZ in the mortar scale, which is more realistic when representing the mechanical behavior of the facet.

2.2. Upscaling the LDPM Mechanical Parameters

The LDPM comprises fifteen parameters, which are used in the facet constitutive law. The LDPM is formulated through the relative displacements (and rotations) of adjacent nodes (particles), where, in each facet, there are two directions for shear strains and normal strains. Therefore, different simulation types represent different failure criterions. For convenience, the parameters of the constitutive laws have been divided into the following groups (for more details, see [

16]):

2.2.1. Elastic Parameters

The first group of parameters contains two elastic parameters:

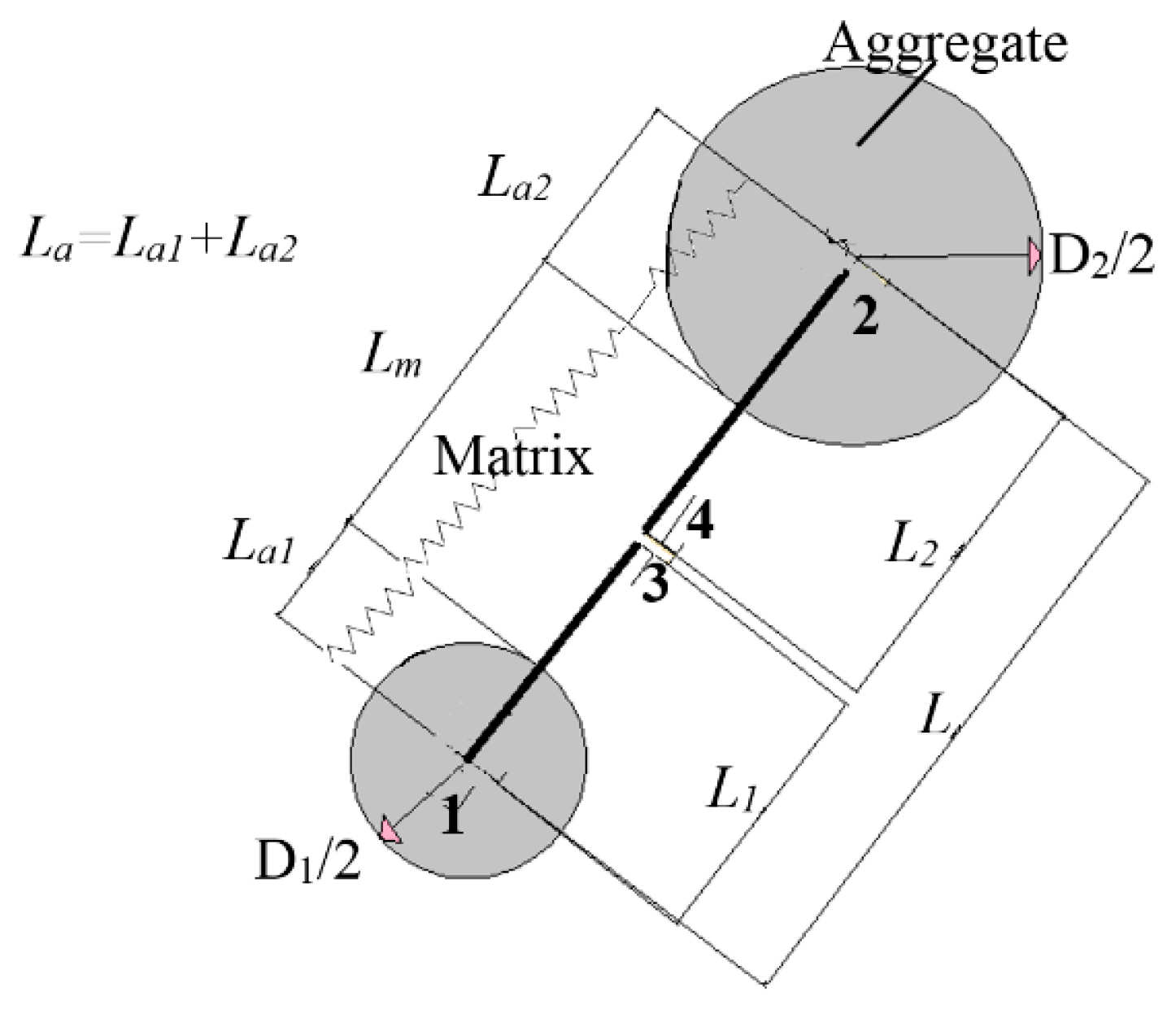

is the normal elastic modulus (stiffness of the normal facet behavior), presented in Equation (1), which governs the LDPM response in the elastic mode of operation.

where

Em and

Ea are the mortar and aggregate modules of elasticity, respectively;

Lm and

La are the normal length of the mortar and aggregates, respectively; L

a1 is the radius of aggregate 1;

La2 is the radius of aggregate 2,

La =

La1 +

La2; and

L is the distance between two adjacent aggregates (elements), as presented in

Figure 4.

α is the shear-normal coupling parameter represented in Equation (2)

where

is the assumed Poisson’s ratio parameter of concrete.

In this paper, the upscaling of these parameters is suggested. The upscaling from a numerical uniaxial tension simulation of the mortar-a4 scale is achieved using the lattice model, as suggested by [

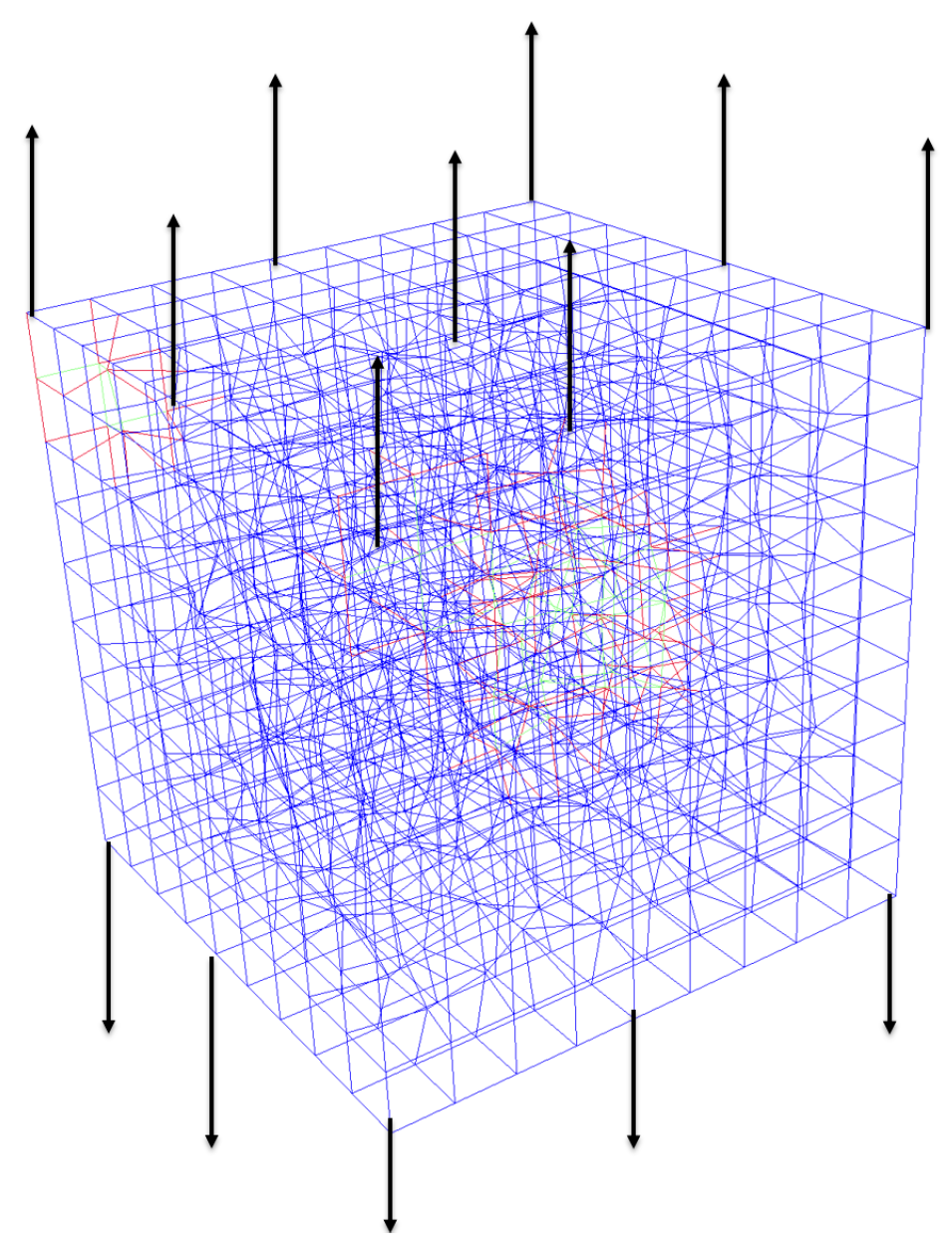

41] and shown in

Figure 5.

The Young’s modulus of the mortar matrix (Em) is obtained from the slope of the stress–strain curve, which is obtained from the tensile simulation.

2.2.2. Fracture Parameters

The second group of parameters contains two parameters, which represent the tensile forces between the aggregates at a facet point (normal direction). The parameters are:

, tensile strength; and

, modified characteristic length for concrete using the LDPM (for more details see [

16,

42]), as depicted in Equation (3).

The tensile strength and fracture energy have been upscaled from a uniaxial tension simulation of the mortar-a4, as shown in

Figure 5. The peak value at the stress–strain curve is the tensile strength, and the fracture energy is calculated from the area under the stress–strain curve. The characteristic length is evaluated from Equation (3).

2.2.3. Compressive Parameters

The third group of parameters contains six parameters, which represent a pore collapse and material compaction behavior. The upscaling of this group of parameters is not shown in this paper.

2.2.4. Friction Parameters

The fourth group of parameters contains three parameters, which represent the shear forces between the aggregates at the facet due to frictional effects. The upscaling of this group of parameters is not shown in this paper.

2.2.5. Shear Parameters

The fifth group of parameters contains two parameters, which represent the interaction between shear and tensile behavior.

is the softening exponent, which governs the interaction between shear and tensile behavior during softening at the facet level. The upscaling of this parameter is not shown in this paper.

is the shear-to-tensile strength ratio, where is the facet strength for pure shear.

In this study, the shear strength parameter is evaluated by performing a simulation test on the mortar-a4 with shear load.

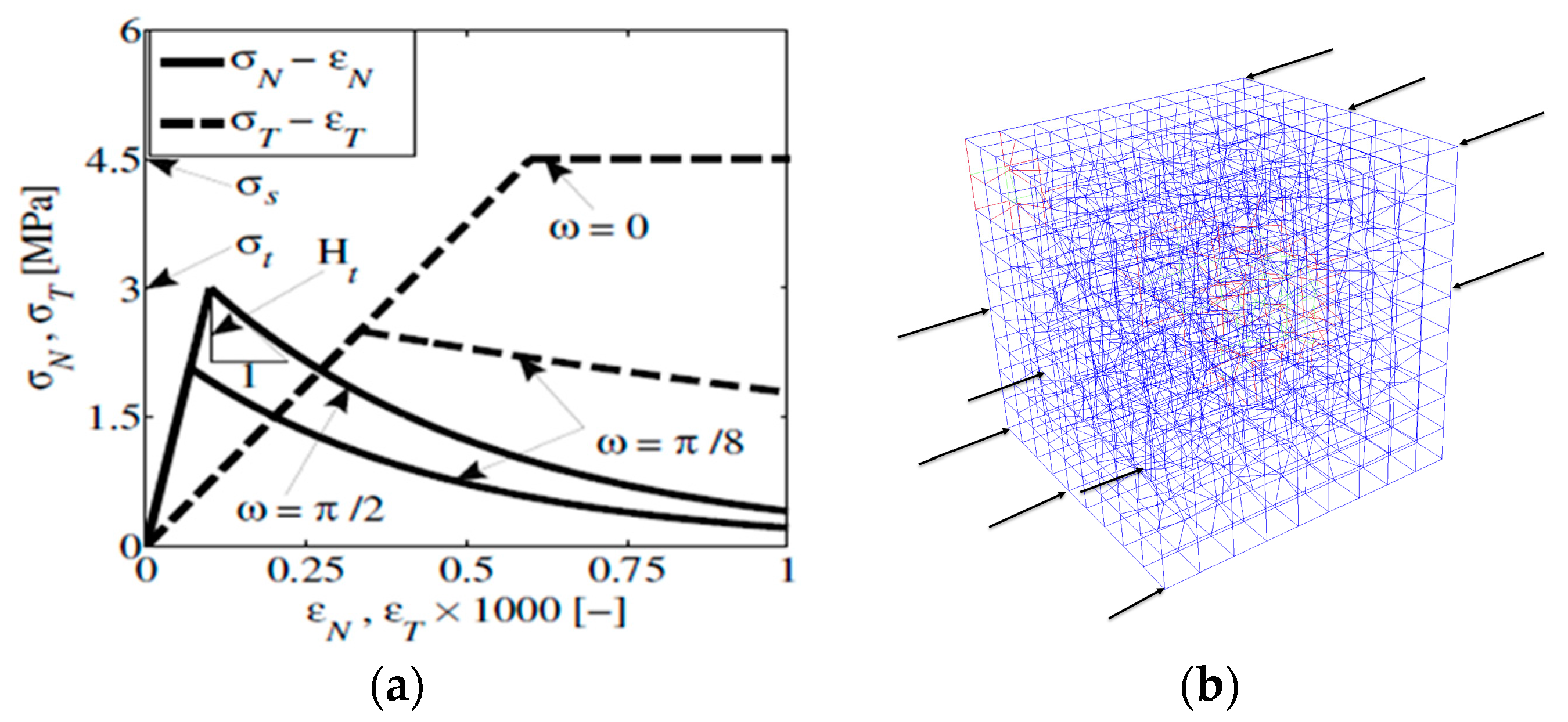

Figure 6a describes typical tension and shear stress–strain curves followed by failure behavior, as reported by Cusatis [

16], where

is the shear stress,

is the shear strain,

is the normal stress,

is the normal strain, and

ω represents the degree of interaction between shear and normal loading, such that

ω = 0 represents pure shear and

ω =

π/2 represents pure tension.

Figure 6b presents a pure shear simulation needed to obtain the value of the shear strength.

The pure shear test is suitable to describe the failure criterion theory of the LDPM, as the discrete compatibility equations (strain vs. displacements) are formulated through the relative displacements of adjacent nodes (particles), where, in each facet, there are two directions for shear strains.

The parameter is estimated from the peak value of the shear stress–shear strain curve. From the simulation results of pure shear and pure tension, the shear-to-tensile strength ratio is calculated.

4. Results

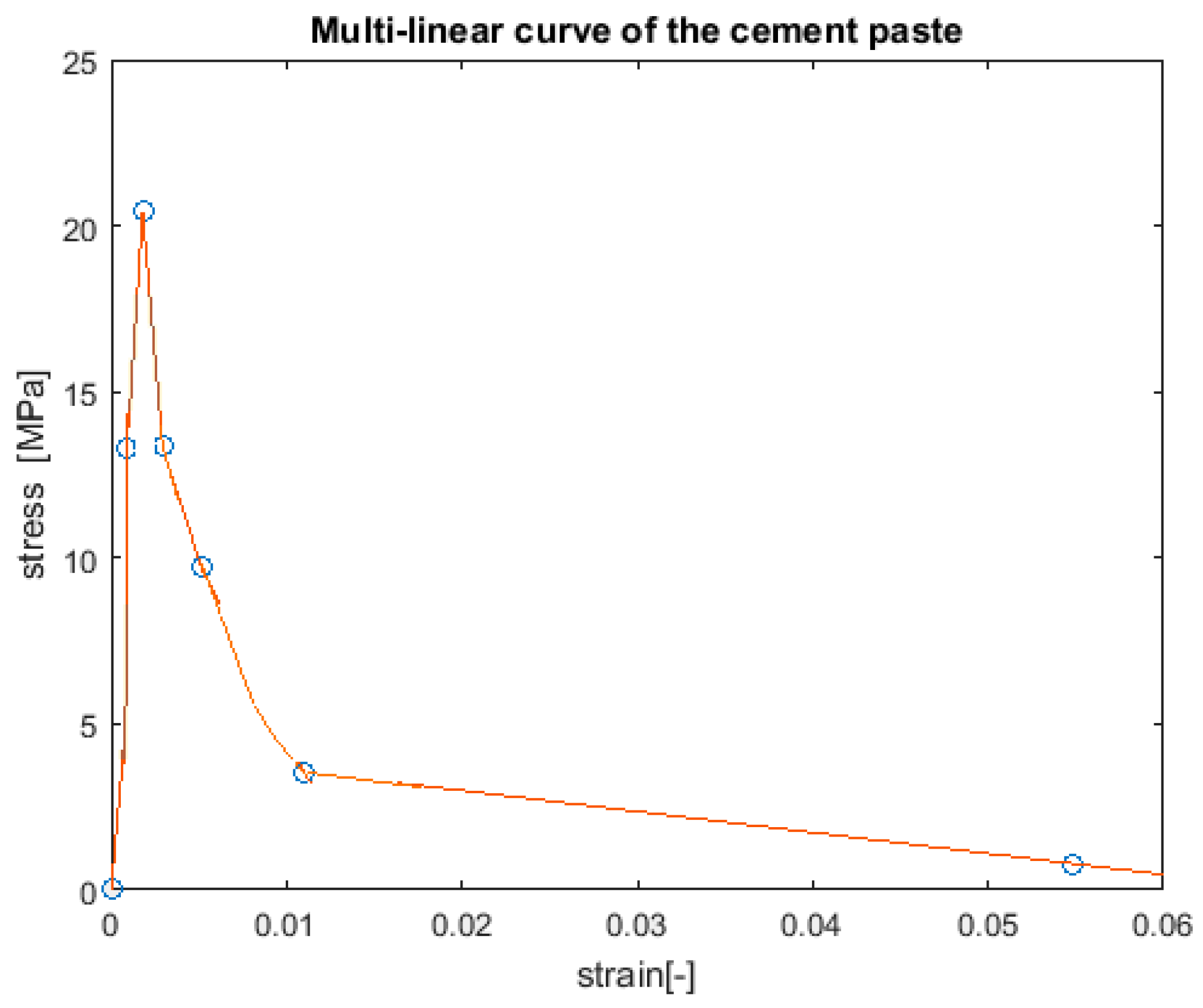

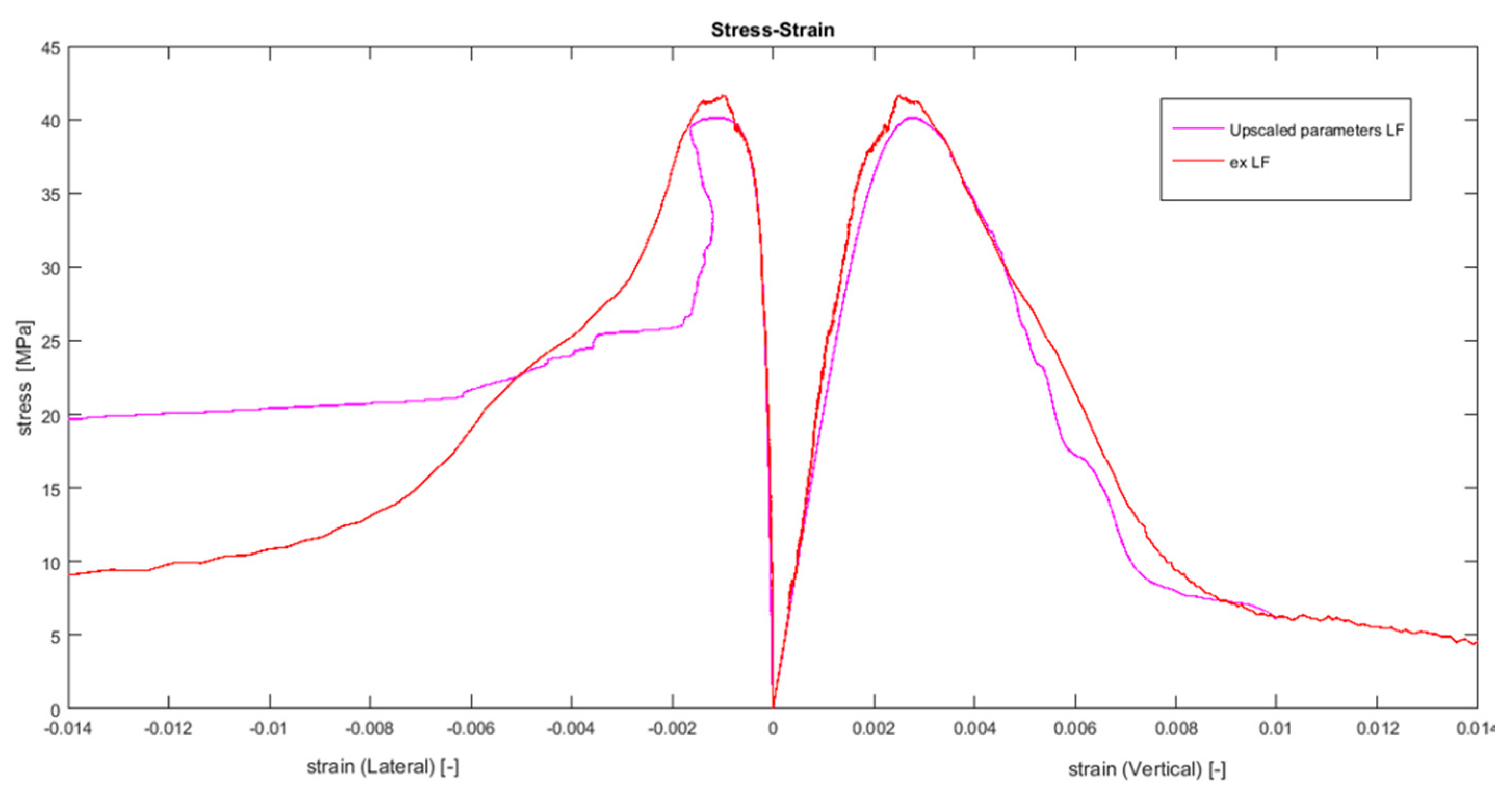

In this section, a macroscopic fit (

Figure 14) was compared to the suggested upscaled strategy. The LDPM comprises two sets of parameters, as described in

Section 2. The mix-design parameters are described in

Section 2.1 and the mechanical parameters are described in

Section 2.2. The LDPM has been widely validated for the analysis of concrete specimens using a comparison to experimental results (e.g., [

16,

17,

39,

40]). In our study, we calibrated the LDPM mechanical parameters by using two methods. First, the calibration of the 15 LDPM parameters was achieved by comparing the macroscopic numerical results with the macroscopic experimental results (see [

39,

40] and

Figure 14). Second, the elastic, fracture, and shear parameters were evaluated by using the suggested upscaling methodology, while the remainder of the LDPM parameters were estimated by using a curve-fitting procedure. The calibration process, depicted in

Figure 14, commenced by assuming initial values based on the work of [

17] and changing the parameters to fit the curve. The macroscopic tests and the simulation were conducted on a 100 mm specimen size, and were restricted to low friction boundary conditions (

μs = 0.03,

μd = 0.0084, s

0 = 0.0195 mm) between the loading plates and the concrete specimen. HF conditions gives rise to the stress peak value, which is higher than the low friction (LF) conditions, due to the shear stress between the loading platen and the specimen. The post-peak slope of the stress–strain curve is also strongly dependent on the type of boundary restraint; a steeper slope under LF conditions is associated with a lower ductility. In the case of HF tests, parts of the specimen were confined, with the result that these areas are less likely to fail. As a result, the fracturing is forced to occur in the unconfined parts of the specimen. Selecting LF conditions results in a lower peak value and a steeper slope at the post-peak region; however, the numerical simulation and the experiments are compared under the same conditions. In addition, the LF experimental results have a narrow scattering profile, and, therefore, we prefer to use them for the calibration process. In [

17], one type of experiment was used to calibrate the parameters, but various other types of experiments are required to validate the model, as has been done in [

16,

17,

39,

40]. The calibrated results are presented in

Figure 14.

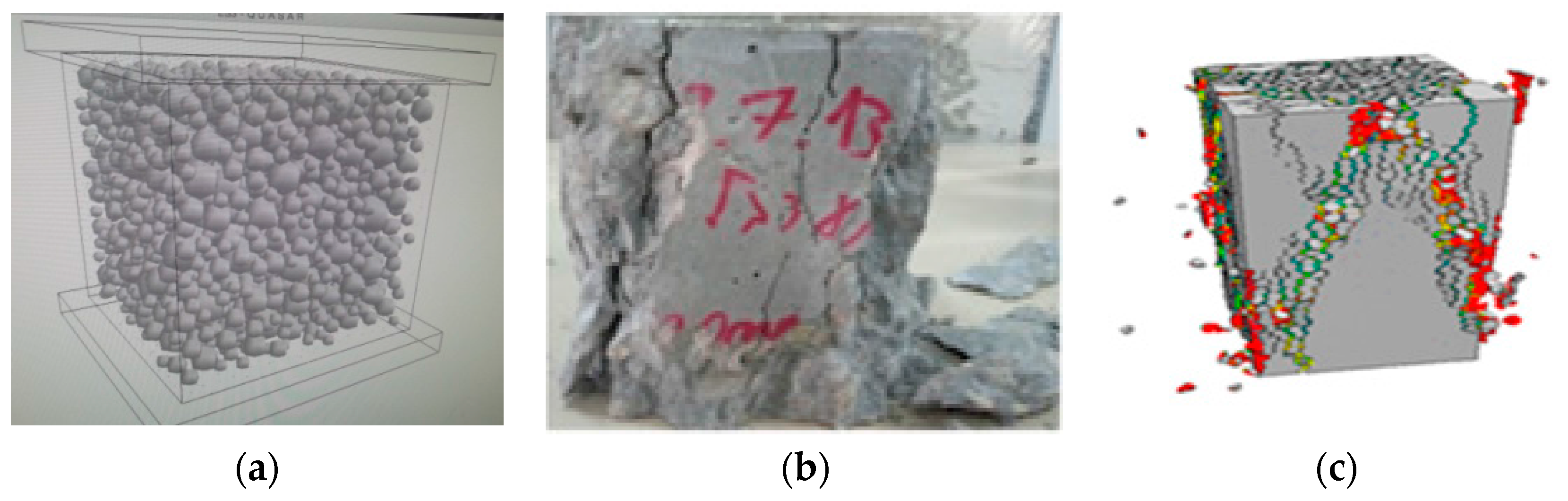

The experimental crack pattern is presented in

Figure 15b, the crack pattern obtained by the LDPM simulation is presented in

Figure 15c, and a scheme of the particle size distribution of aggregates is presented in

Figure 15a.

The parameters that govern the generation of concrete meso structures are presented in

Table 9, as reported in [

39,

40], and the macroscopic-calibrated LDPM mechanical parameters are presented in

Table 10.

To validate the five parameters that were upscaled using the suggested methodology, we replaced the appropriate values, shown in

Table 10, and present the new values in

Table 11. The remaining ten parameters that appear in

Table 12 were calibrated again using curve fitting.

A comparison of the values in

Table 11 to the appropriate value in

Table 10, which were obtained by two very different methods, shows an excellent fit. It is important to note that further experiments, such as fracture tests, are required to ensure the uniqueness of the set of parameters that were obtained by using the suggested inverse analysis. Note that the normal elastic modulus,

, for each facet was evaluated separately in this paper and, therefore, it cannot be compared to the macroscopic value. The aggregate module of elasticity was chosen from a range of values, as published in [

47]. This value was calibrated according to the experimental results. Since the aggregate module of elasticity is higher than expected, at this stage of the research, we suggest using the value of

from the macroscopic experiment. Another comparison is presented at the macroscopic scale in

Figure 16, which shows the comparison of the macroscopic longitudinal and transverse displacements, which were evaluated by using the upscaled LDPM parameters, to the experimental results. The good fit of the stress–strain curves, presented in

Figure 16, demonstrates that the discrepancy of parameters obtained by the different methods is negligible and that the proposed method of bridging the scales is an effective way to provide accurate results.

5. Discussion and Conclusions

This study provides a methodology for bridging the cement and concrete scales. Scaling down to the chemical composition of the cement paste can, potentially, illuminate the influence of the lower scales on the concrete macroscopic strength.

We suggest an upscaling procedure between the cement paste scale and the elastic, fracture, and shear concrete LDPM parameters using existing validated models. The LDPM was chosen to represent the concrete behavior at the mesoscale level due to its ability to capture the concrete macroscopic size and shape effects, and because of its ability to take into account the influence of concrete mix components. The three lower-scale models chosen for the suggested upscaling procedure are the HYMOSTRUC3D model, which was used for the cement hydration analysis to obtain the cement paste microstructure; the Anm model, which was used for the morphology of the mortar unit cells; and a lattice model, based on Timoshenko beam elements, which was used for the mechanical analysis of the cement paste and mortar scales.

The presented upscaling procedure is expected to reduce the demand of experimental studies for the calibration process of the LDPM. Moreover, the LDPM is expected to be enhanced by including important lower-scale phenomena, which have not previously been considered in this manner. The upscaling procedure was conceptually presented; however, due to lack of experimental data at the different scales, it could not be fully validated.

This study involves the upscaling of the elastic, fracture, and shear LDPM parameters, which suggests new calibration abilities by starting the calibration process with a number of parameters obtained by the multiscale analysis of the lower scales. Calibrating the entire set of 15 LDPM parameters might be a very demanding and challenging task with a high number of variations. Hence, using the suggested methodology, the calibration process can be started with a number of known parameters to improve the effectiveness of the calibration procedure.

Further research is needed to enable upscaling the full set of LDPM parameters, including the remaining ten parameters that are related to the friction and compression behavior. Generally speaking, the full set of parameters requires hydrostatic and confined compression simulations of the lower scales to obtain the six compression parameters, and combined compression and shear loading simulations of the lower scales to obtain the friction parameters. In addition, a complete calibration procedure should include an experimental study on the lower scale. These procedures should include a hydration test and uniaxial tensile tests for the cement paste and mortar scales.

The result of this research is a powerful methodology that, after further development, will have broad industrial applications. Potential users of the methodology are producers of cement-based materials and structural designers.