Effect of Material Composition and Environmental Condition on Thermal Characteristics of Conductive Asphalt Concrete

Abstract

:1. Introduction

2. Materials and Experimental

2.1. Materials

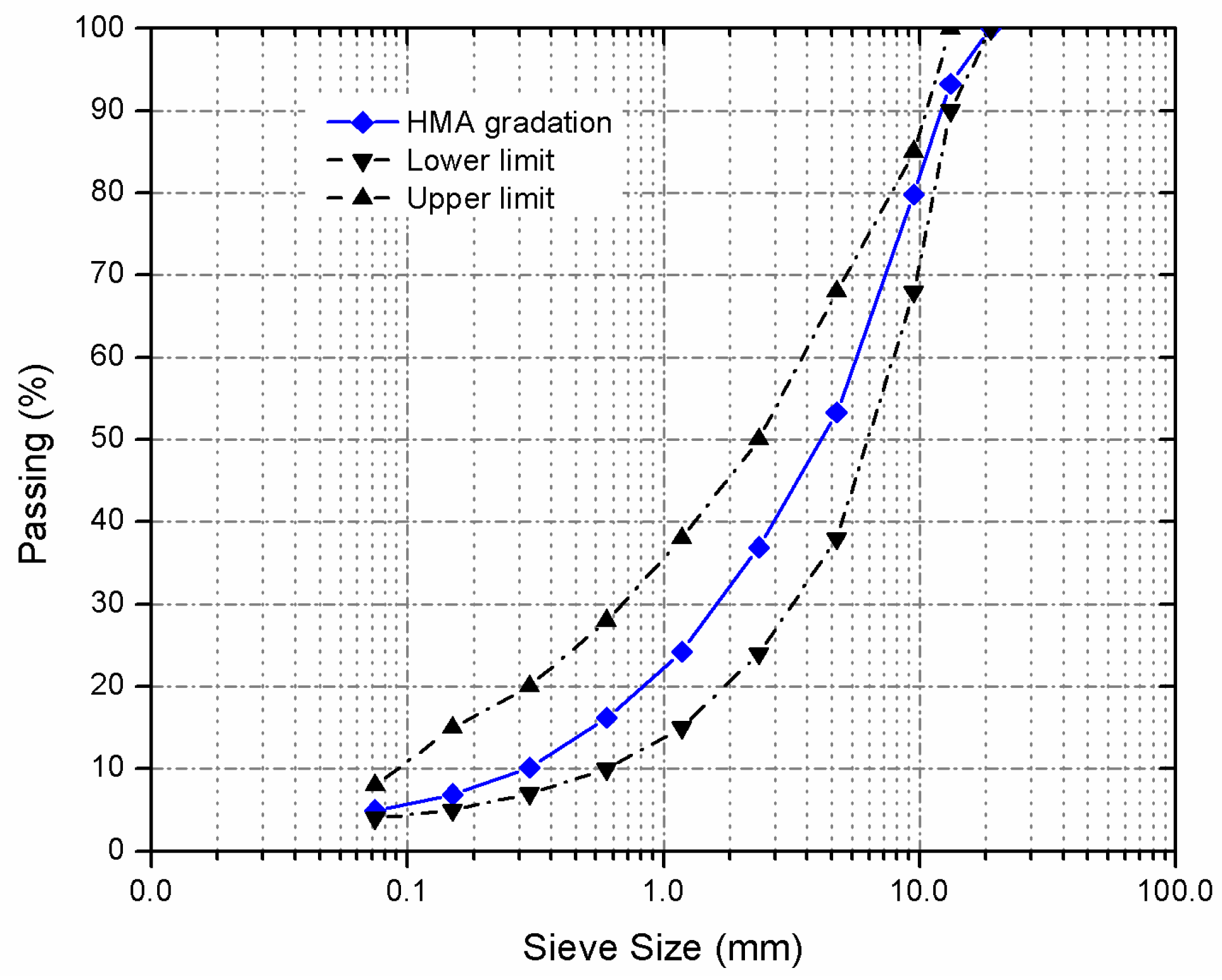

2.2. Preparation of Specimens

2.3. Thermal Characteristics Analysis

2.4. Standard Aging Procedure

2.5. Freezing–Thawing Procedure

3. Results and Discussion

3.1. Effect of Material Composition on Thermal Characteristics of Asphalt Concrete

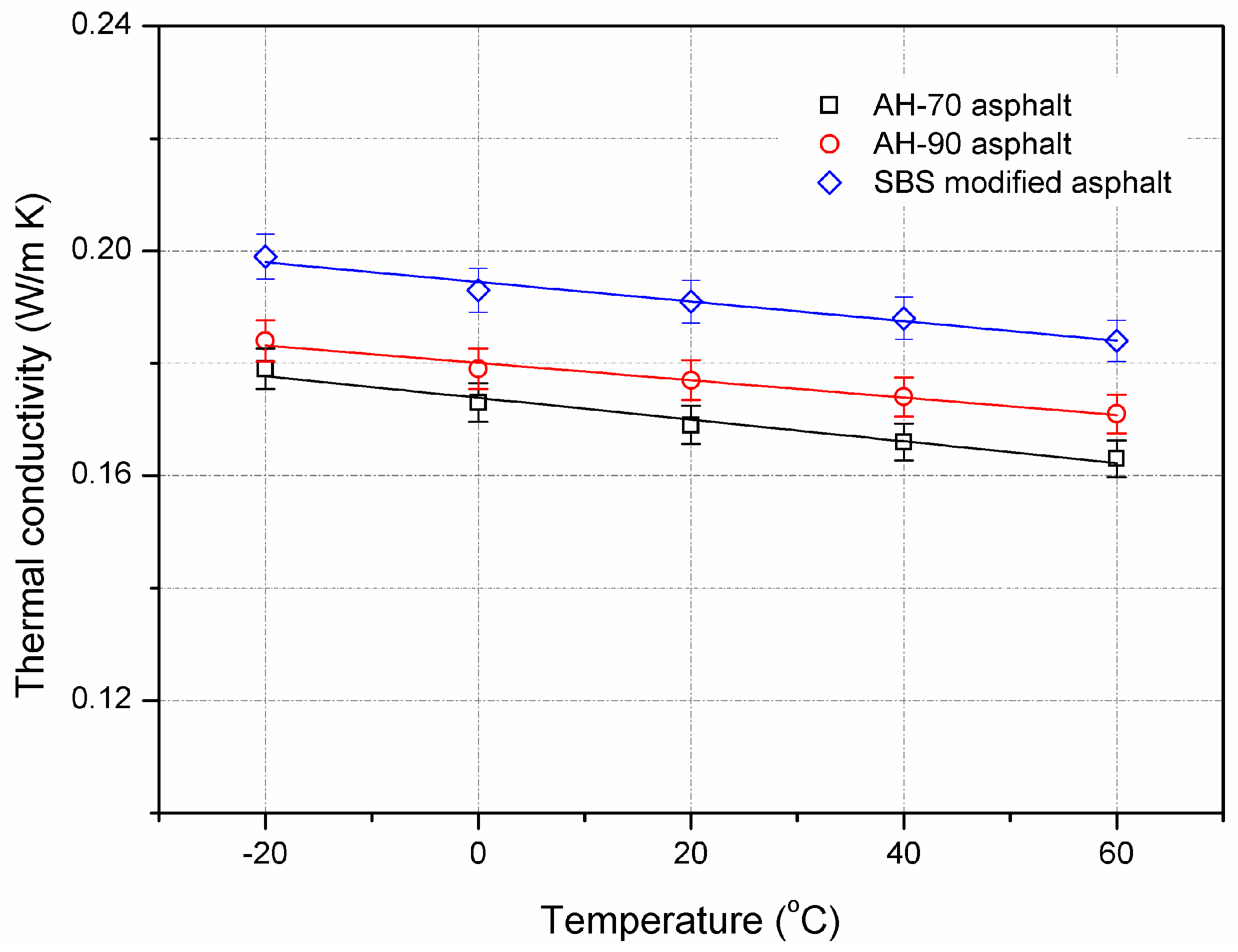

3.1.1. Asphalt Binder

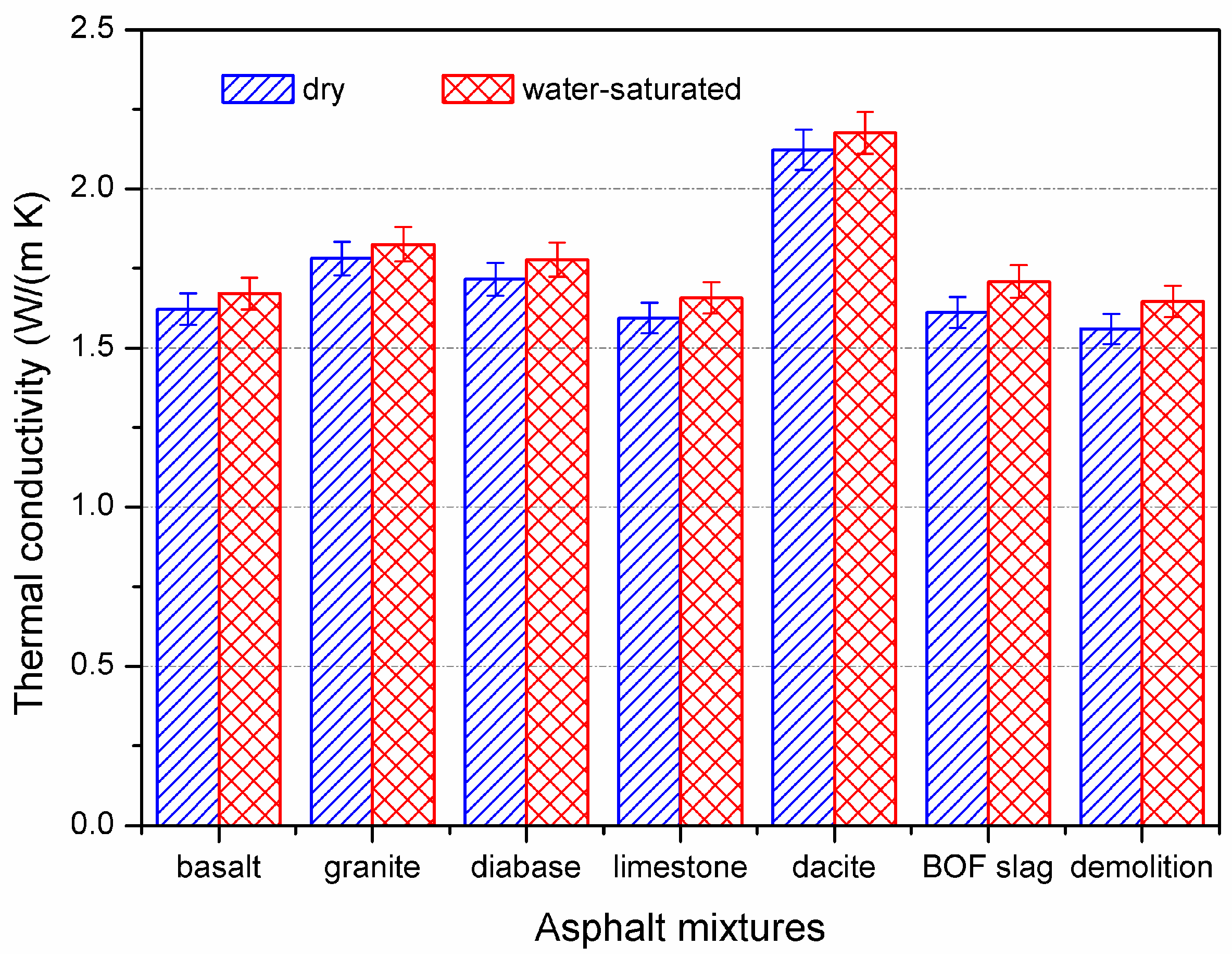

3.1.2. Aggregate

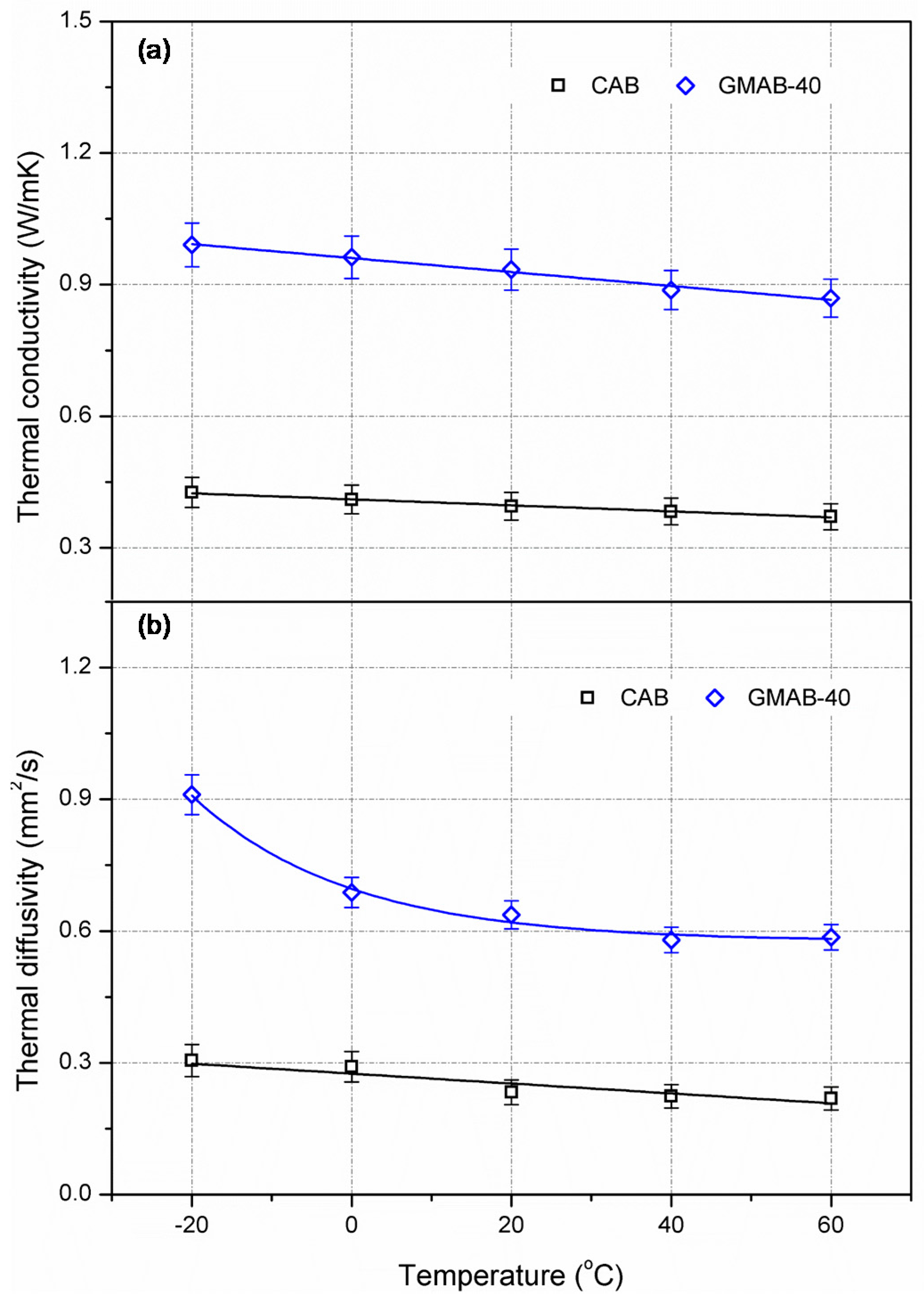

3.1.3. Filler

3.2. Effect of Environmental Condition on Thermal Characteristics of Conductive Asphalt Concrete

3.2.1. Temperature

Asphalt Binder

Aggregate and Filler

3.2.2. Water

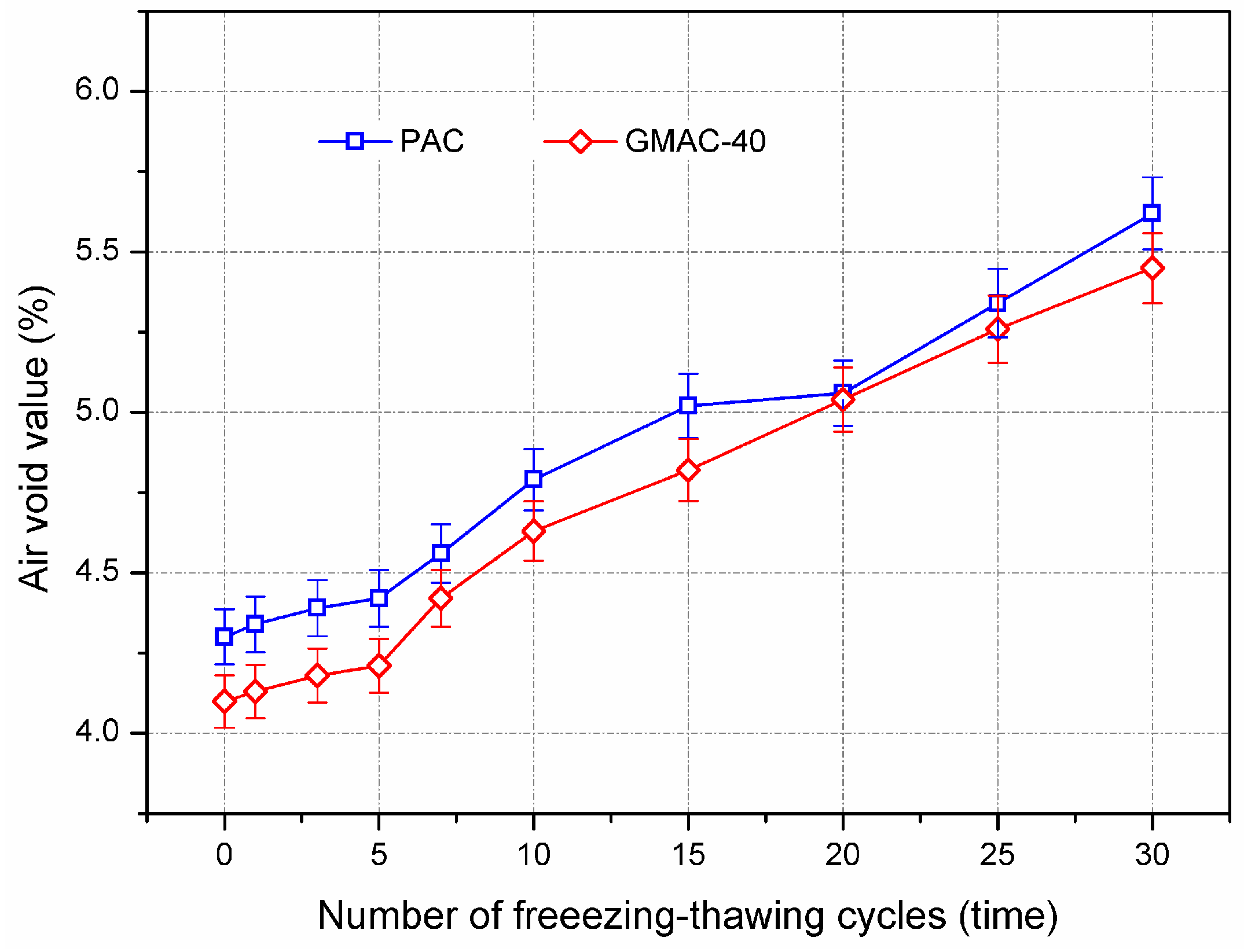

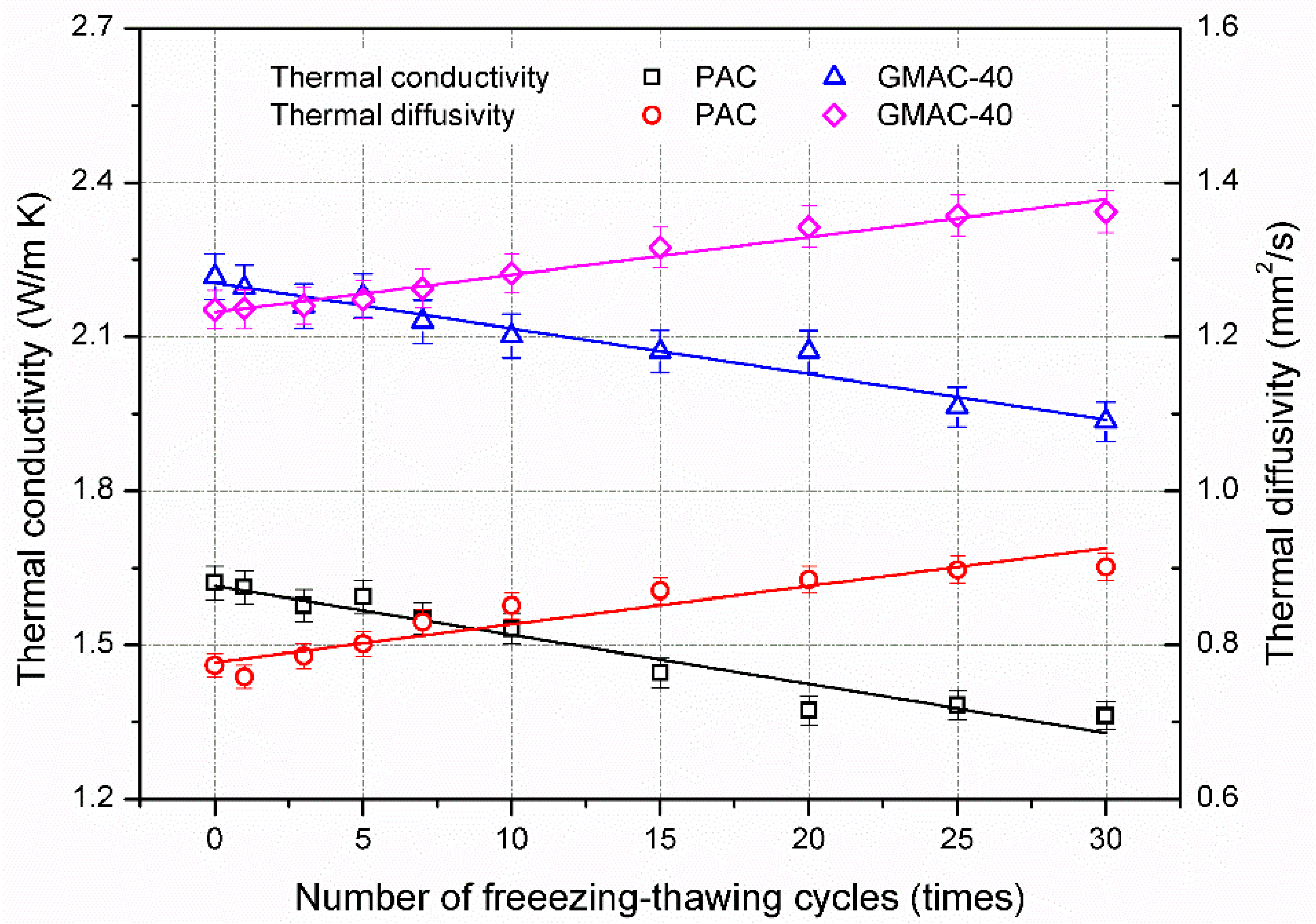

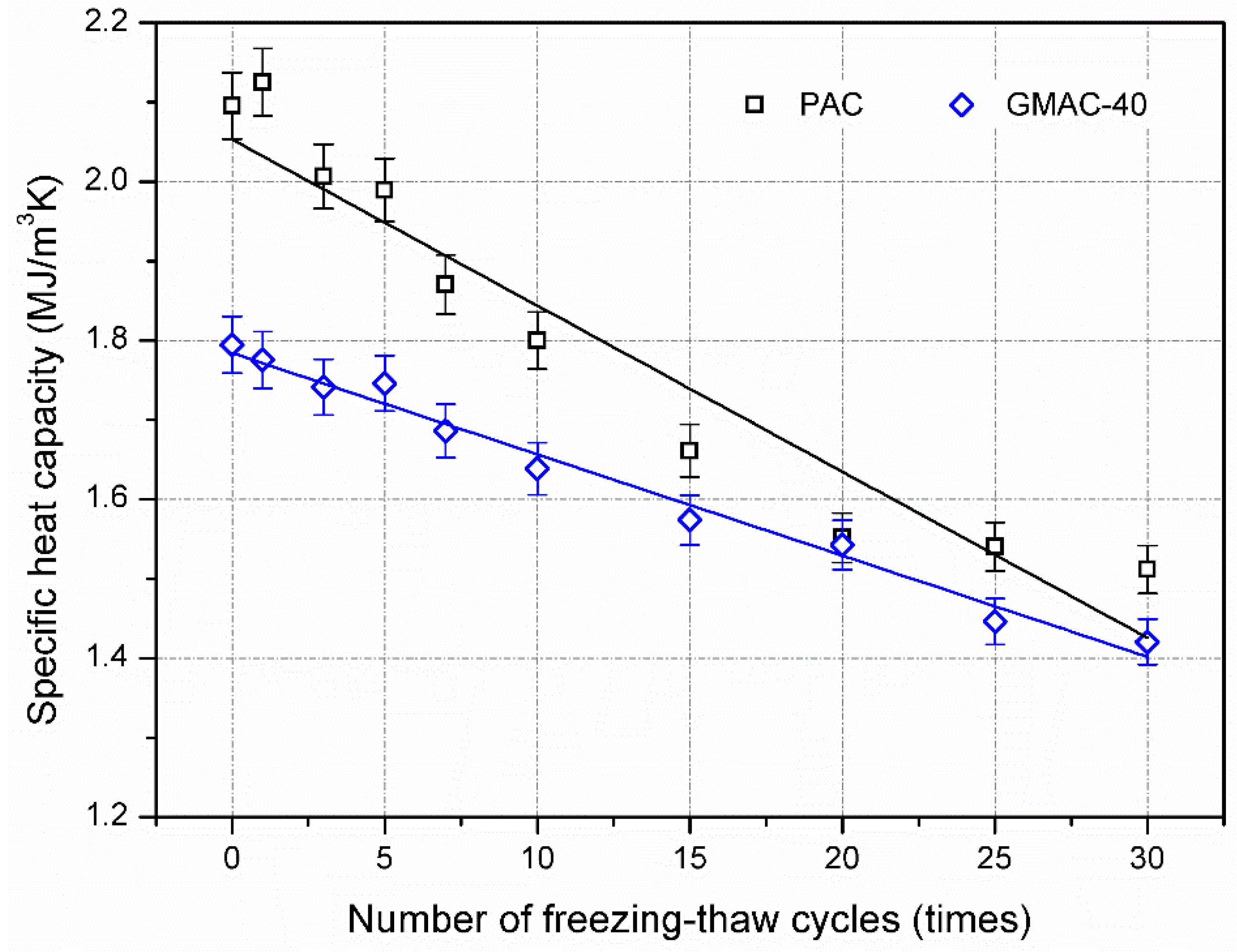

3.2.3. Freezing–Thawing Cycles

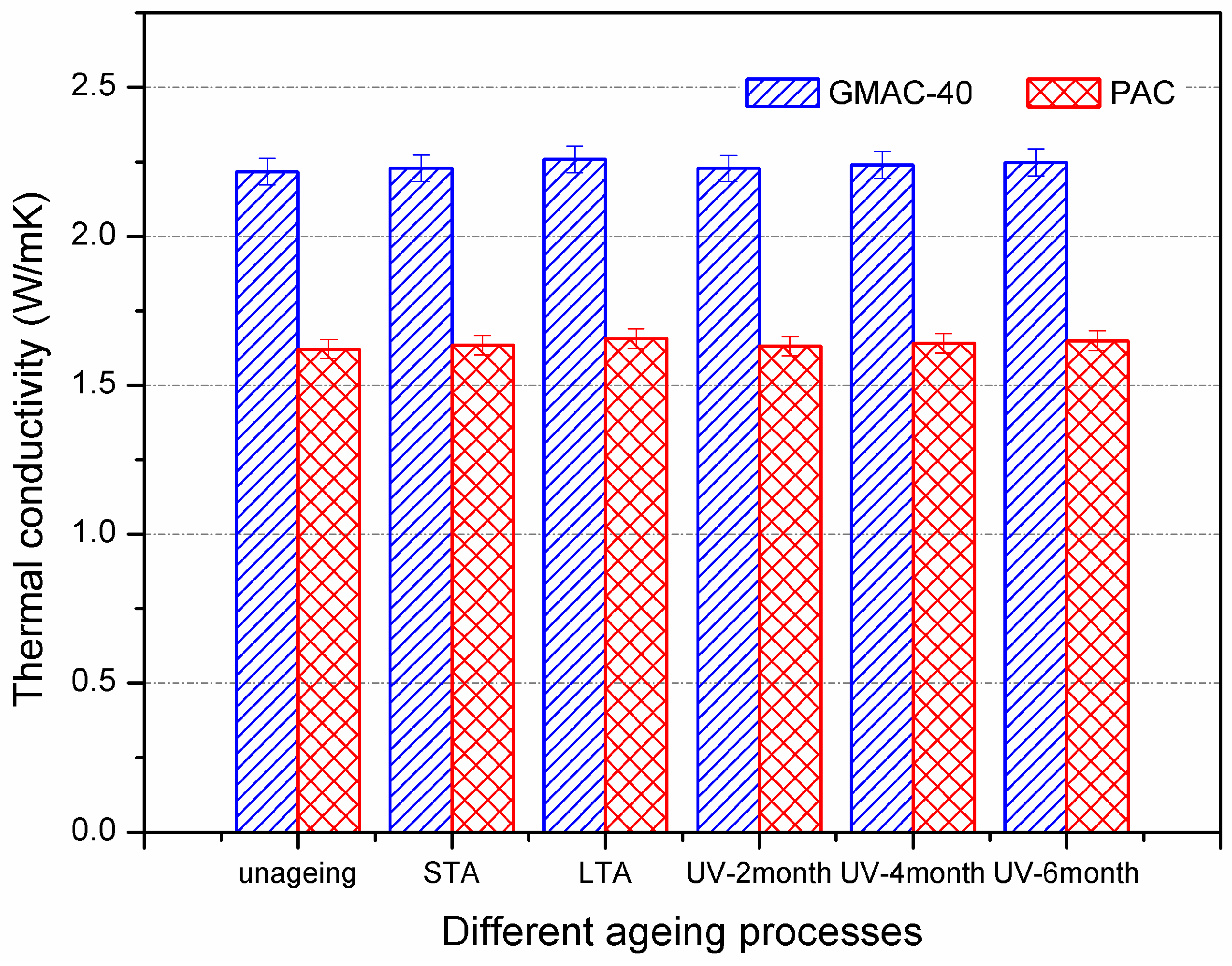

3.2.4. Aging

4. Conclusions

- From the material composition of view, thermal properties of asphalt concrete are strongly dependent on the thermal properties of mineral aggregate. The effect of asphalt types is not significant due to its low proportion. Conductive filler and mineral aggregate with high thermal conductivity are recommended to prepare asphalt concrete for asphalt solar collector.

- Environmental conditions, including temperature, water, freezing–thawing, and aging can affect the thermal characteristics of asphalt concrete. Among all the factors, the freezing–thawing effect is the most significant, due to volume expansion and bonding degradation of asphalt concrete.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook, 6th ed.; ICE Publishing: London, UK, 2015. [Google Scholar]

- Mrawira, D.M.; Luca, J. Thermal properties and transient temperature response of full-depth asphalt pavements. Transp. Res. Rec. J. Transp. Res. Board 2002, 1809, 160–171. [Google Scholar] [CrossRef]

- Xu, Q.W.; Solaimanian, M. Modeling temperature distribution and thermal property of asphalt concrete for laboratory testing applications. Constr. Build. Mater. 2010, 24, 487–497. [Google Scholar] [CrossRef]

- Han, R.B.; Jin, X.; Glover, C.J. Modeling pavement temperature for use in binder oxidation models and pavement performance prediction. J. Mater. Civ. Eng. 2011, 23, 351–359. [Google Scholar] [CrossRef]

- Minhoto, M.; Pais, J.; Pereira, P.; Picado-Santos, L. Predicting asphalt pavement temperature with a three-dimensional finite element method. Transp. Res. Rec. J. Transp. Res. Board 2005, 1919, 96–110. [Google Scholar] [CrossRef]

- Hall, M.R.; Dehdezi, P.K.; Dawson, A.R.; Grenfell, J.; Isola, R. Influence of the thermophysical properties of pavement materials on the evolution of temperature depth profiles in different climatic regions. J. Mater. Civ. Eng. 2012, 24, 32–47. [Google Scholar] [CrossRef]

- Chen, M.; Wu, S.; Zhang, Y.; Wang, H. Effects of conductive fillers on temperature distribution of asphalt pavements. Phys. Scr. 2010, 139, 1–5. [Google Scholar]

- Yavuzturk, C.; Ksaibati, K.; Chiasson, A.D. Assessment of temperature fluctuations in asphalt pavement due to thermal environmental conditions using a two dimensional, transient finite-difference approach. J. Mater. Civ. Eng. 2005, 17, 465–475. [Google Scholar] [CrossRef]

- Hermansson, A. Mathematical model for paved surface summer and winter temperature: Comparison of calculated and measured temperatures. Cold Reg. Sci. Technol. 2004, 40, 1–17. [Google Scholar] [CrossRef]

- Gui, J.; Phelan, P.; Kaloush, K.; Golden, J. Impact of Pavement Thermophysical Properties on Surface Temperatures. J. Mater. Civ. Eng. 2007, 19, 683–690. [Google Scholar] [CrossRef]

- Stempihar, J.J.; Pourshams-Manzouri, T.; Kaloush, K.E.; Rodezno, M.C. Porous Asphalt Pavement Temperature Effects for Urban Heat Island Analysis. Transp. Res. Rec. J. Transp. Res. Board 2012, 2293, 123–130. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.P.; Xiao, Y.; Liu, G. A review on hydronic asphalt pavement for energy harvesting and snow melting. Renew. Sustain. Energy Rev. 2015, 48, 624–634. [Google Scholar] [CrossRef]

- Van Bijsterveld, W.; Houben, L.J.; Scarpas, A.; Molenaar, A.A. Using pavement as solar collector: Effect on pavement temperature and structural response. Transp. Res. Rec. J. Transp. Res. Board 2001, 1778, 140–148. [Google Scholar] [CrossRef]

- Hamada, Y.; Nakamura, M.; Kubota, H. Field measurements and analyses for a hybrid system for snow storage/melting and air conditioning by using renewable energy. Appl. Energy 2007, 84, 117–134. [Google Scholar] [CrossRef]

- Chen, M.Y.; Wu, S.; Wang, H.; Zhang, J.Z. Study of ice and snow melting process on conductive asphalt solar collector. Solar Energy Mater. Sol. Cells 2011, 95, 3241–3250. [Google Scholar] [CrossRef]

- Mallick, R.B.; Chen, B.; Bhowmick, S. Harvesting heat energy from asphalt pavements: Development of and comparison between numerical models and experiment. Int. J. Sustain. Eng. 2012, 5, 159–169. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, X.; Zhang, X.; Chen, G.; Zuo, J.; Pullen, S. Effectiveness of pavement-solar energy system—An experimental study. Appl. Energy 2015, 138, 1–10. [Google Scholar] [CrossRef]

- Guldentops, G.; Nejad, A.; Vuye, C.; van den bergh, W.; Rabhar, N. Performance of a pavement solar energy collector: Model development and validation. Appl. Energy 2016, 163, 180–189. [Google Scholar] [CrossRef]

- Bobes-Jesus, V.; Pascual-Muñoz, P.; Castro-Fresno, D.; Rodriguez-Hernandez, J. Asphalt solar collectors: A literature review. Appl. Energy 2013, 102, 962–970. [Google Scholar] [CrossRef]

- Pan, P.; Wu, S.P.; Xiao, F.P.; Pang, L.; Xiao, Y. Conductive asphalt concrete: A review on structure design, performance, and practical applications. J. Intell. Mater. Syst. Struct. 2015, 26, 755–769. [Google Scholar] [CrossRef]

- Wu, S.; Li, B.; Wang, H.; Jian, Q. Numerical simulation of temperature distribution in conductive asphalt solar collector due to pavement material parameters. Mater. Sci. Forum 2008, 575–578, 1314–1319. [Google Scholar] [CrossRef]

- Liu, X.M.; Wang, C.; Deng, Y.D.; Gao, F.J. Computation of fractal dimension on conductive path of conductive asphalt concrete. Constr. Build. Mater. 2016, 115, 699–704. [Google Scholar] [CrossRef]

- Cong, P.L.; Xu, P.J.; Chen, S.F. Effects of carbon black on the anti aging, rheological and conductive properties of SBS/asphalt/carbon black composites. Constr. Build. Mater. 2014, 52, 306–313. [Google Scholar] [CrossRef]

- Mallick, R.B.; Chen, B.L.; Bhowmick, S.; Hulen, M. Capturing solar energy from asphalt pavements. In Proceedings of the International Society for Asphalt Pavements International Symposium on Asphalt Pavements and Environment, Zurich, Switzerland, 18–20 August 2008.

- Pan, P.; Wu, S.P.; Xiao, Y.; Wang, P.; Liu, X. Influence of graphite on the thermal characteristics and anti-ageing properties of asphalt binder. Constr. Build. Mater. 2014, 68, 220–226. [Google Scholar] [CrossRef]

- Wu, S.P.; Chen, M.Y.; Zhang, J.Z. Laboratory investigation into thermal response of asphalt pavements as solar collector by application of small-scale slabs. Appl. Therm. Eng. 2011, 31, 1582–1587. [Google Scholar]

- Wu, S.P.; Pan, P.; Chen, M.Y.; Zhang, Y. Analysis of characteristics of electrically conductive asphalt concrete prepared by multiplex conductive materials. J. Mater. Civ. Eng. 2013, 25, 871–879. [Google Scholar] [CrossRef]

- Côté, J.; Grosjean, V.; Konrad, J. Thermal conductivity of bitumen concrete. Can. J. Civ. Eng. 2013, 40, 172–180. [Google Scholar] [CrossRef]

- Wu, S.P.; Mo, L.T.; Shui, Z.H.; Chen, Z. Investigation of the conductivity of asphalt concrete containing conductive fillers. Carbon 2005, 43, 1358–1363. [Google Scholar] [CrossRef]

- Gustafsson, S.E. Transient plane source techniques for thermal conductivity and thermal diffusivity measurements of solid materials. Rev. Sci. Instrum. 1991, 62, 797–804. [Google Scholar] [CrossRef]

- Tang, N.; Wu, S.P.; Chen, M.Y.; Pan, P.; Sun, C.J. Effect mechanism of mixing on improving conductivity of asphalt solar collector. Int. J. Heat Mass Transf. 2014, 75, 650–655. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; dos Santos, S.; Bueno, M.; Kuentzel, S.; Hugener, M.; Partl, M.N. Influence of short and long term aging on chemical, microstructural and macro-mechanical properties of recycled asphalt mixtures. Constr. Build. Mater. 2014, 51, 414–423. [Google Scholar] [CrossRef]

- Wu, S.P.; Xue, Y.J.; Ye, Q.S.; Chen, Y.C. Utilization of steel slag as aggregate for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Li, B. Properties Investigation of Thermal Conductive Asphalt Mixture. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2008. [Google Scholar]

- Maqsood, A.; Gul, I.H.; Anis-ur-Rehman, M. Thermal transport properties of granites in the temperature range 253–333 K. J. Phys. D Appl. Phys. 2004, 27, 1405–1409. [Google Scholar] [CrossRef]

- Cai, B.H.; Dong, D.P.; Qu, J.X. Measurement of thermal conductivity for home-made graphite sheet at low temperature. Cryogenics 2008, 1, 29–32. (In Chinese) [Google Scholar]

| Indexes | Standard | AH-70 | AH-90 | SBS |

|---|---|---|---|---|

| Softening point (°C) | ASTM D36 | 47.2 | 46.3 | 53.6 |

| Penetration (dmm) | ASTM D5 | 73 | 87 | 48.1 |

| Viscosity (Pa·s) | ASTM D4402 | 0.59 | 0.32 | 1.28 |

| Indexes | Standard | Basalt | Granite | Diabase | Limestone | Dacite | BOF Slag | Demolition Waste |

|---|---|---|---|---|---|---|---|---|

| Bulk S.G. | ASTM C127 | 2.842 | 2.691 | 2.953 | 2.716 | 2.709 | 3.197 | 2.591 |

| Apparent S.G. | ASTM C127 | 2.887 | 2.723 | 2.970 | 2.754 | 2.740 | 3.396 | 2.623 |

| Water absorption (%) | ASTM C127 | 0.4 | 0.6 | 0.3 | 0.8 | 0.4 | 2.5 | 6.9 |

| Los Angeles abrasion (%) | ASTM C131 | 16.8 | 21.6 | 16.6 | 22.1 | 12.1 | 13.1 | 33.6 |

| Volume expansion (%) | BS EN1744-1 | N/A | N/A | N/A | N/A | N/A | 1.3 | N/A |

| Free lime content (%) | BS EN1744-1 | N/A | N/A | N/A | N/A | N/A | 2.3 | N/A |

| Asphalt | Thermal Conductivity (W/m·K) | Thermal Diffusivity (mm2/s) | Specific Heat (MJ/m3·K) |

|---|---|---|---|

| AH-70 | 0.169 | 0.123 | 1.374 |

| AH-90 | 0.177 | 0.128 | 1.383 |

| SBS | 0.191 | 0.124 | 1.540 |

| Asphalt | Thermal Conductivity (W/m·K) | Thermal Diffusivity (mm2/s) | Specific Heat (MJ/m3·K) |

|---|---|---|---|

| AH-70 | 1.548 | 0.744 | 2.081 |

| AH-90 | 1.597 | 0.759 | 2.105 |

| SBS | 1.622 | 0.748 | 2.166 |

| Asphalt | Thermal Conductivity (W/m·K) | Standard Deviation (W/m·K) | Thermal Diffusivity (mm2/s) | Standard Deviation (mm2/s) | Specific Heat (MJ/m3·K) | Standard Deviation (MJ/m3·K) |

|---|---|---|---|---|---|---|

| Basalt | 1.621 | 0.0465 | 0.774 | 0.0215 | 2.096 | 0.0719 |

| Granite | 1.781 | 0.0396 | 1.017 | 0.0334 | 1.751 | 0.0935 |

| Diabase | 1.717 | 0.0544 | 0.810 | 0.0362 | 2.120 | 0.0824 |

| Limestone | 1.594 | 0.0366 | 0.710 | 0.0342 | 2.246 | 0.0892 |

| Dacite | 2.123 | 0.0526 | 0.949 | 0.0298 | 2.238 | 0.0686 |

| BOF slag | 1.612 | 0.0567 | 0.812 | 0.0362 | 1.985 | 0.0757 |

| Demolition | 1.560 | 0.0588 | 0.871 | 0.0374 | 1.791 | 0.0682 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, P.; Wu, S.; Hu, X.; Liu, G.; Li, B. Effect of Material Composition and Environmental Condition on Thermal Characteristics of Conductive Asphalt Concrete. Materials 2017, 10, 218. https://doi.org/10.3390/ma10030218

Pan P, Wu S, Hu X, Liu G, Li B. Effect of Material Composition and Environmental Condition on Thermal Characteristics of Conductive Asphalt Concrete. Materials. 2017; 10(3):218. https://doi.org/10.3390/ma10030218

Chicago/Turabian StylePan, Pan, Shaopeng Wu, Xiaodi Hu, Gang Liu, and Bo Li. 2017. "Effect of Material Composition and Environmental Condition on Thermal Characteristics of Conductive Asphalt Concrete" Materials 10, no. 3: 218. https://doi.org/10.3390/ma10030218