Prospects of Biodiesel Production from Macadamia Oil as an Alternative Fuel for Diesel Engines

Abstract

:1. Introduction

2. Materials and Method

2.1. Materials

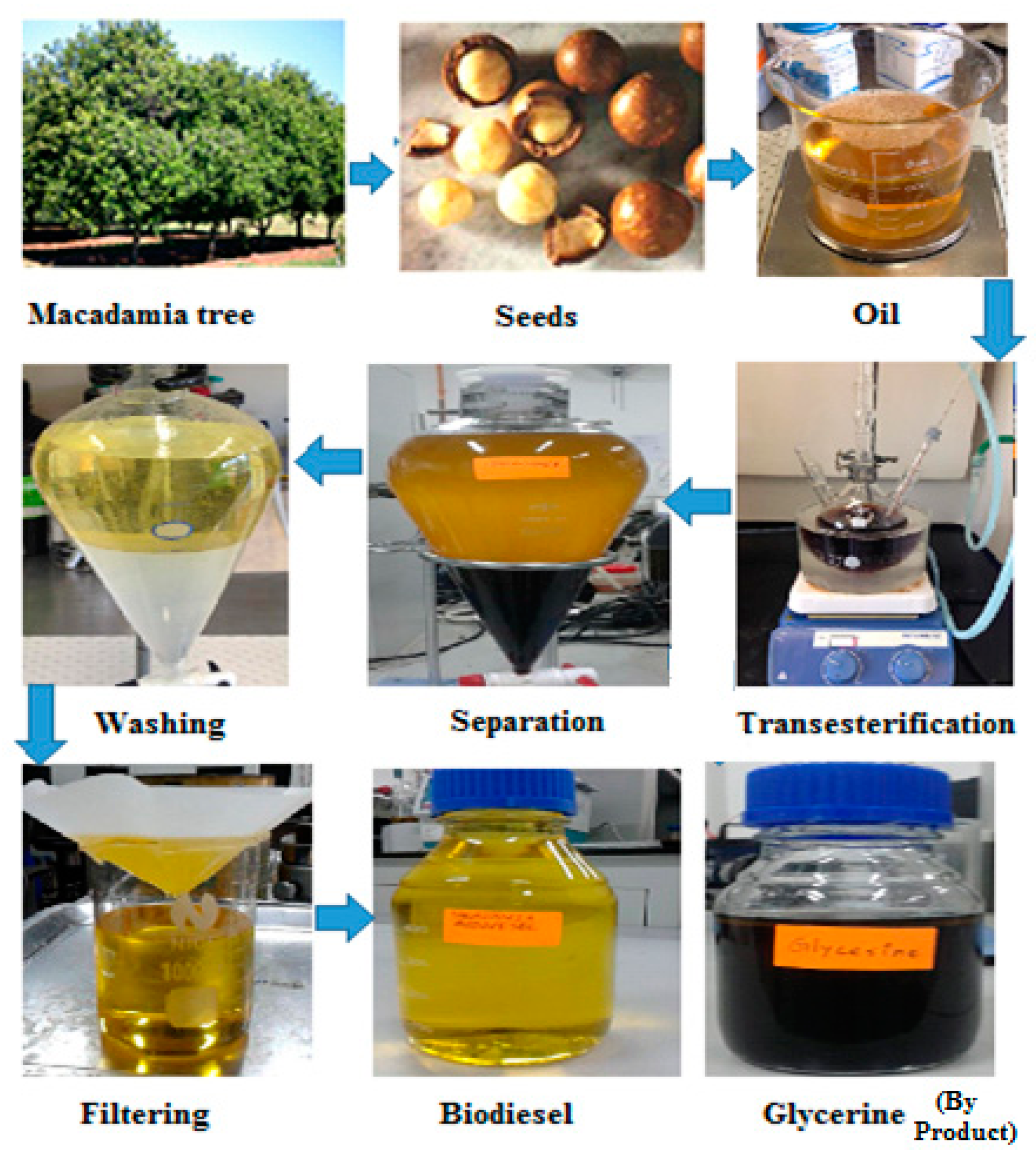

2.2. Biodiesel Fuel Production Procedure

2.3. Biodiesel–Diesel Blending

2.4. Characterization of Biodiesel Fuel

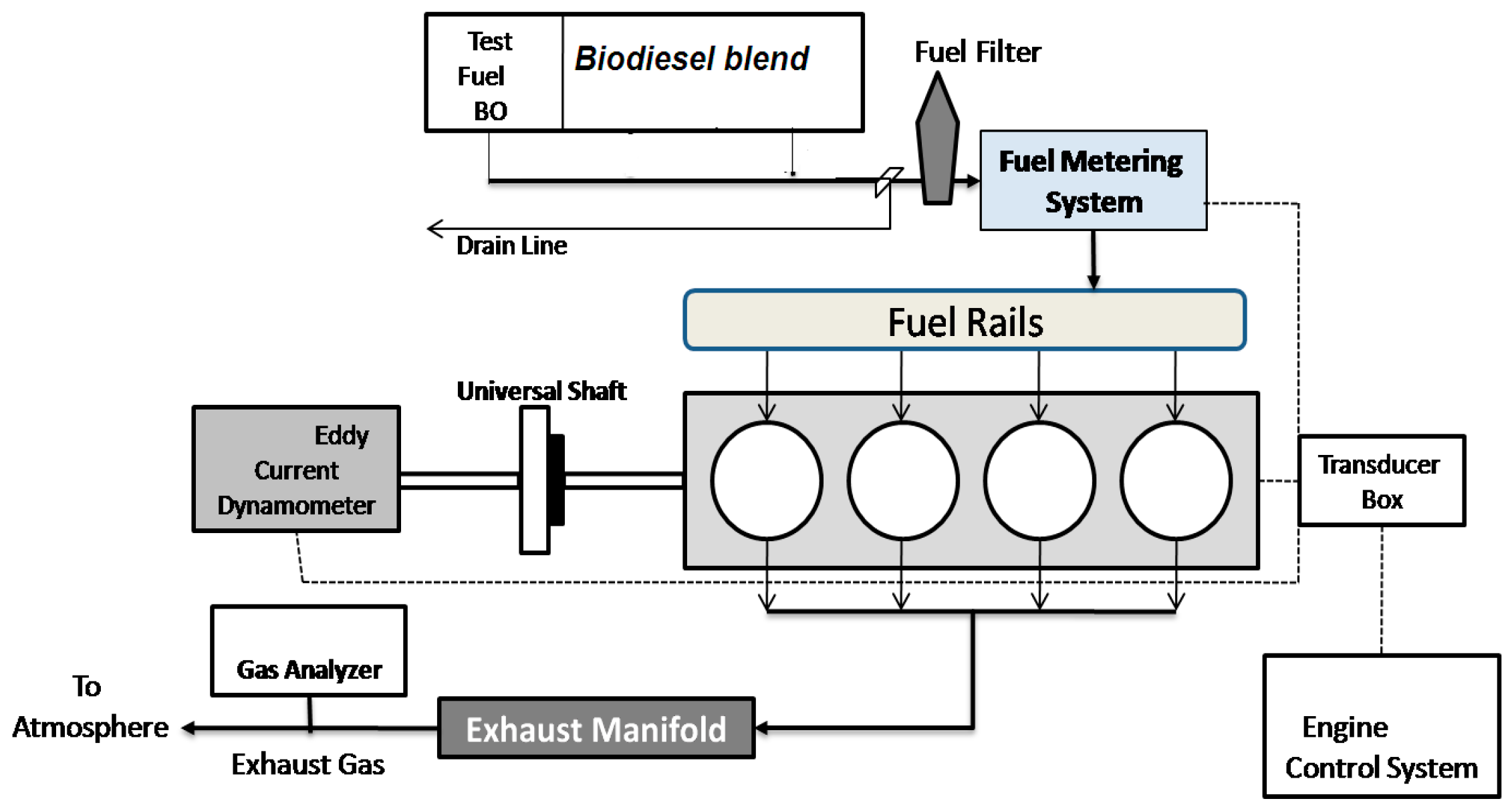

2.5. Engine Test

3. Results and Discussion

3.1. Crude Oil Properties

3.2. Characteristics of Macadamia Biodiesel Fuel

3.2.1. Fatty Acid Composition

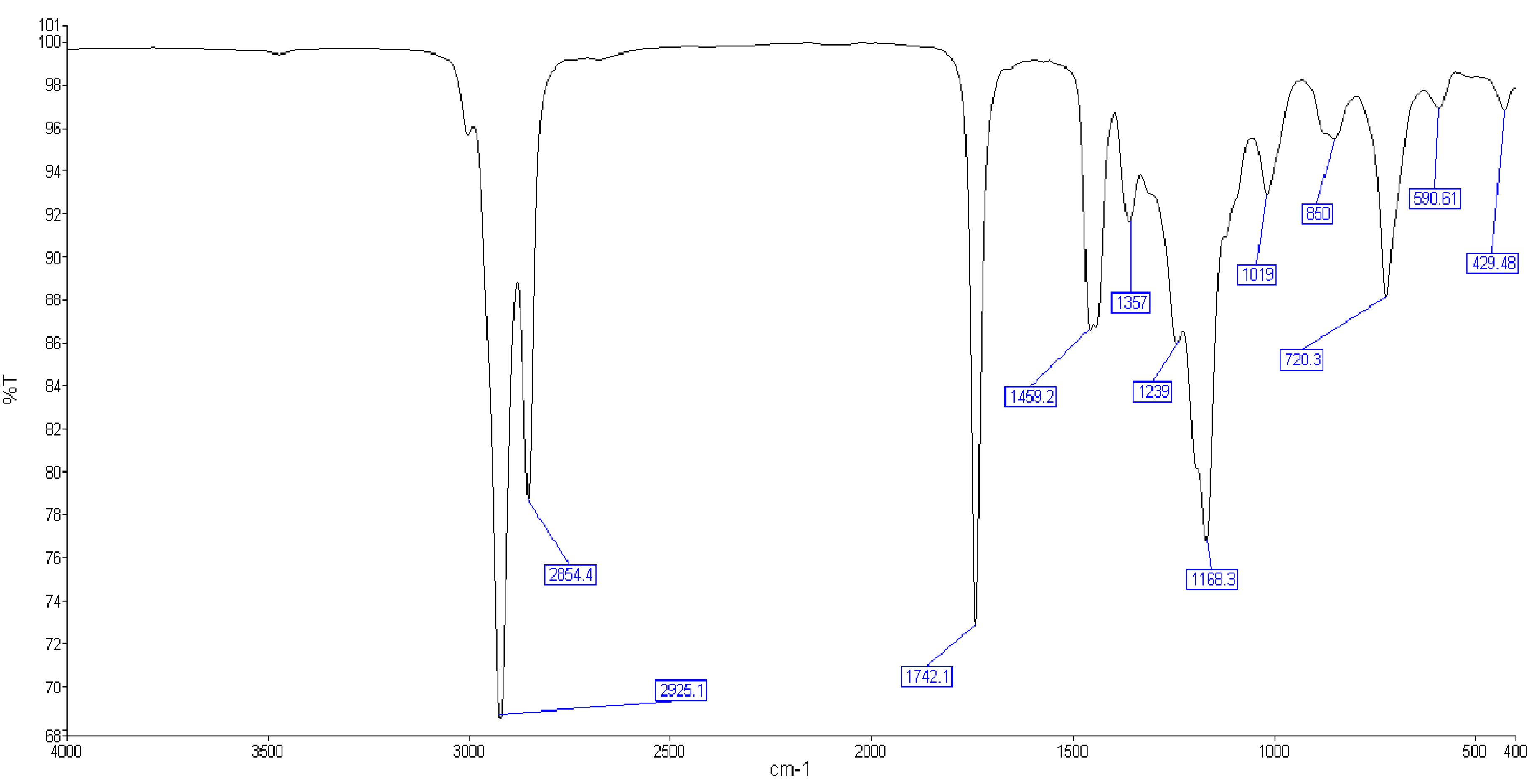

3.2.2. Fourier Transform Infrared Analysis

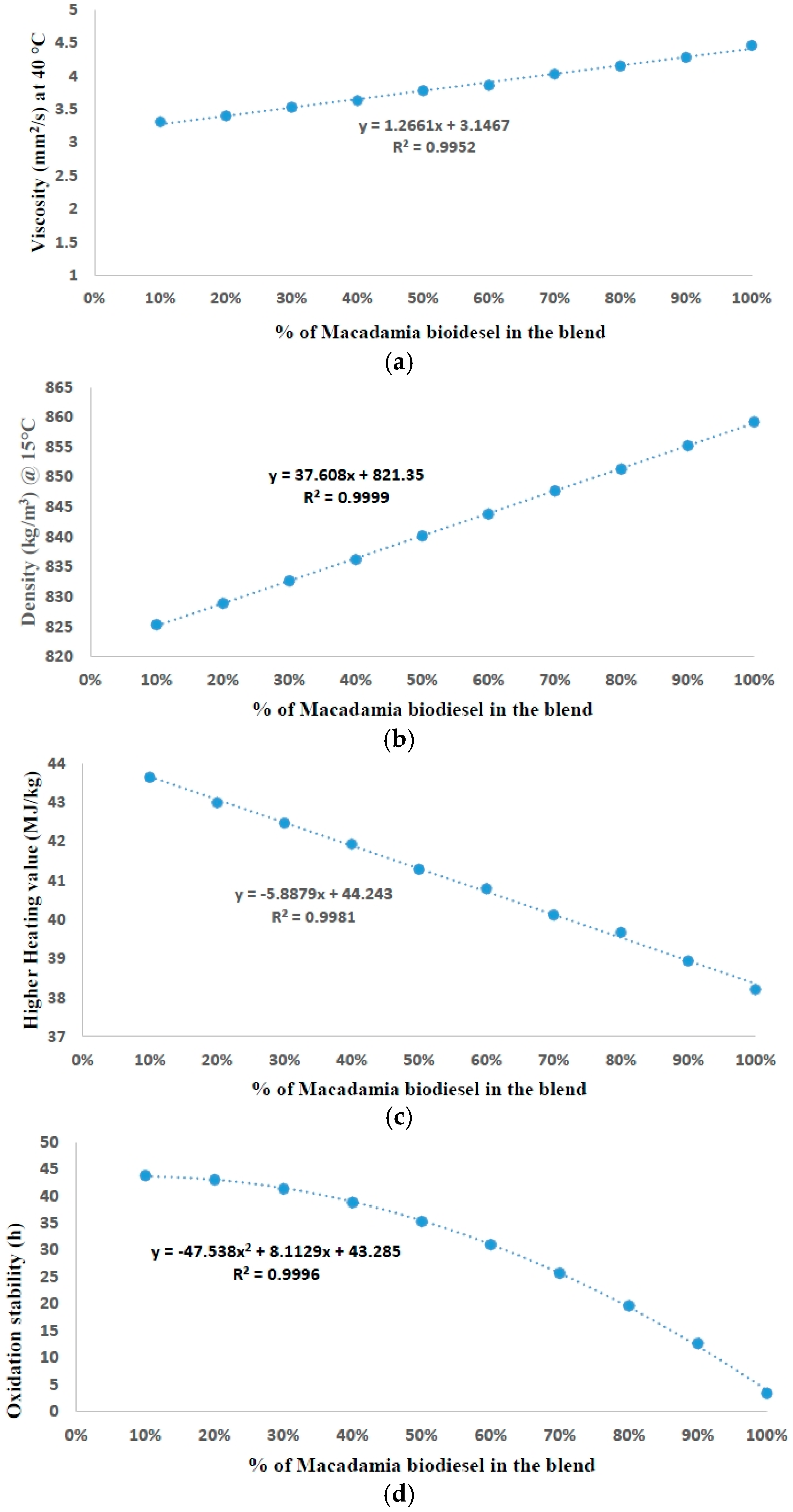

3.2.3. Properties of Biodiesel–Diesel Blending

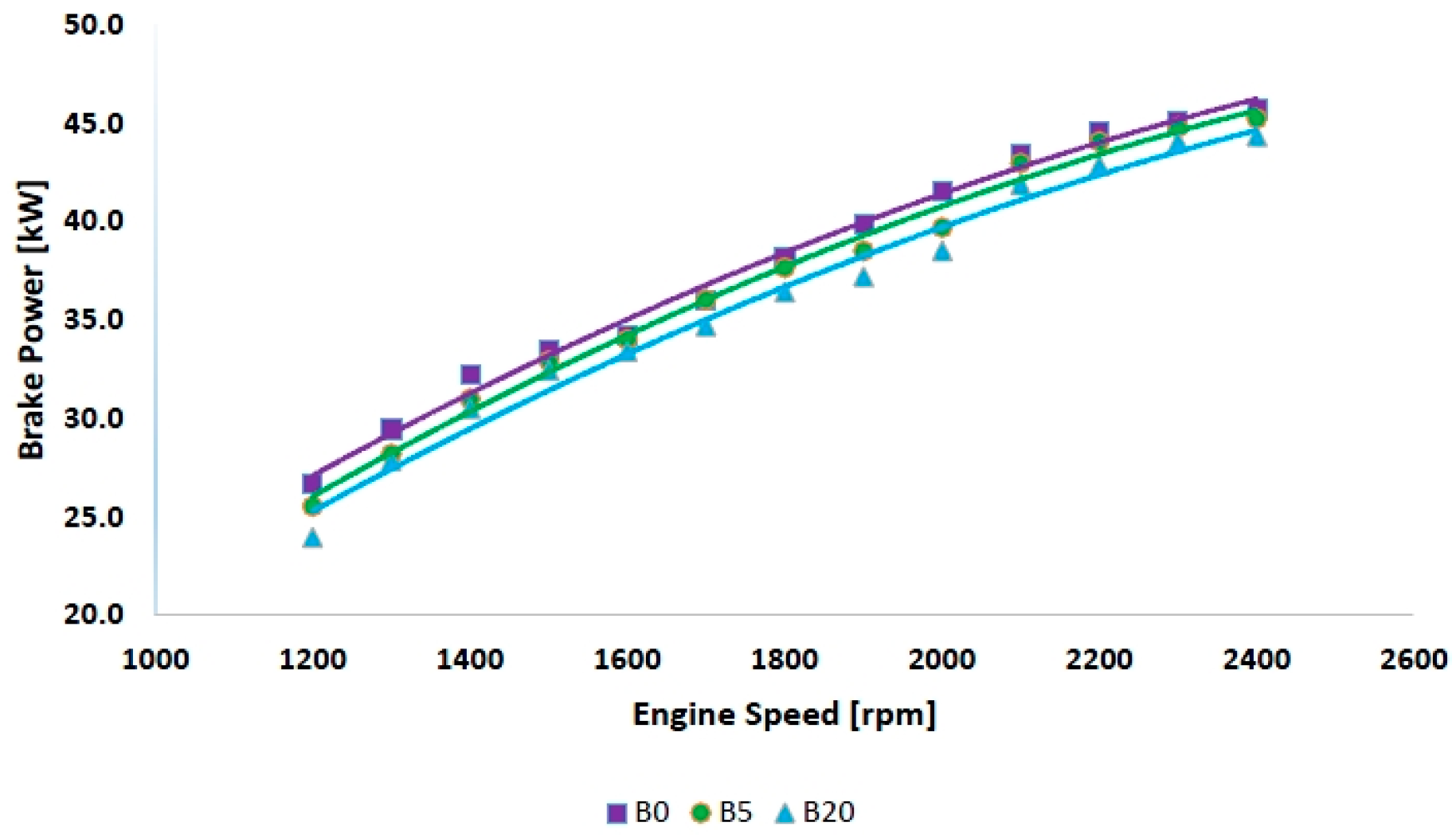

3.3. Brake Power

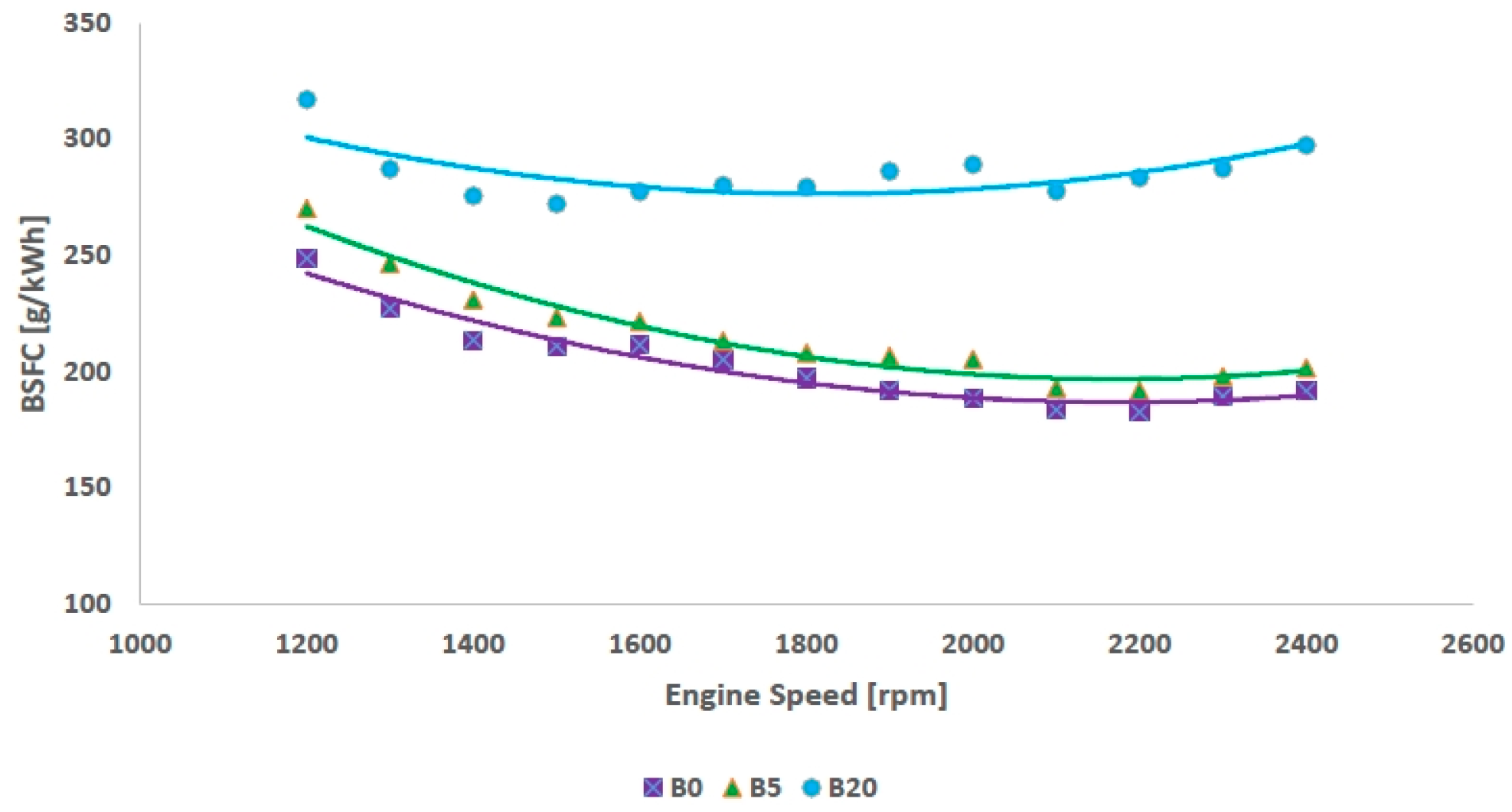

3.4. Brake Specific Fuel Consumption

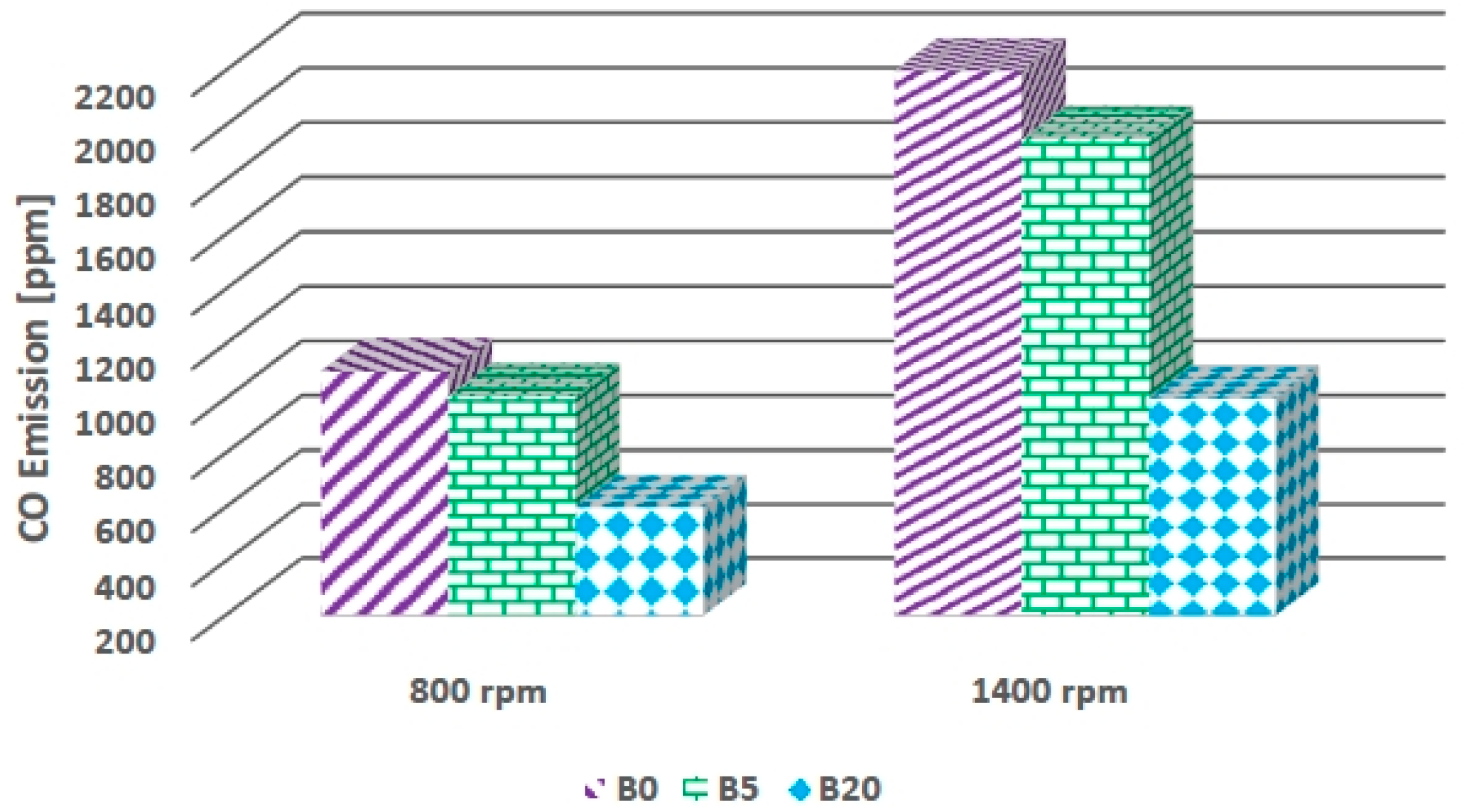

3.5. Carbon Monoxide Emission

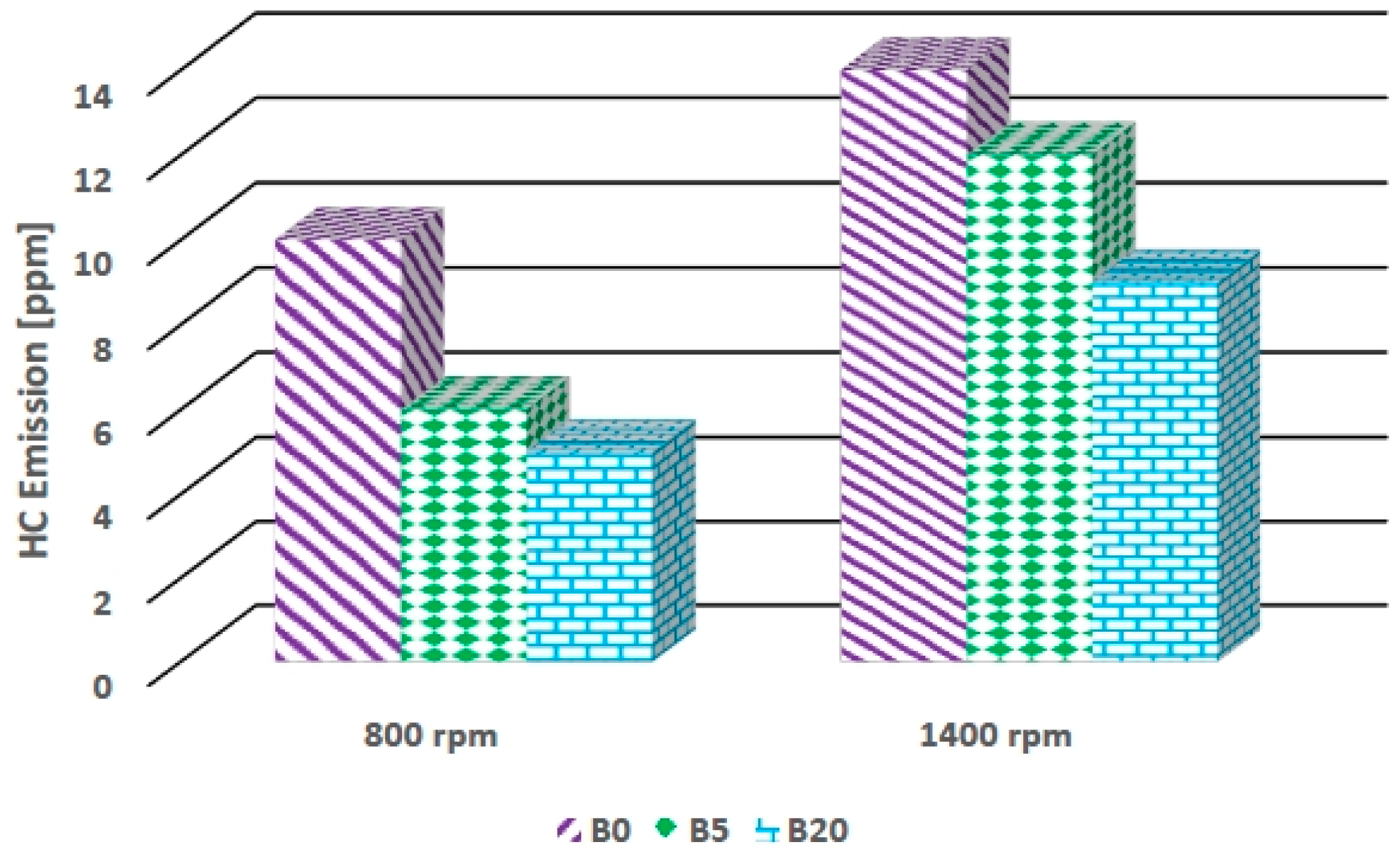

3.6. Hydrocarbon Emission

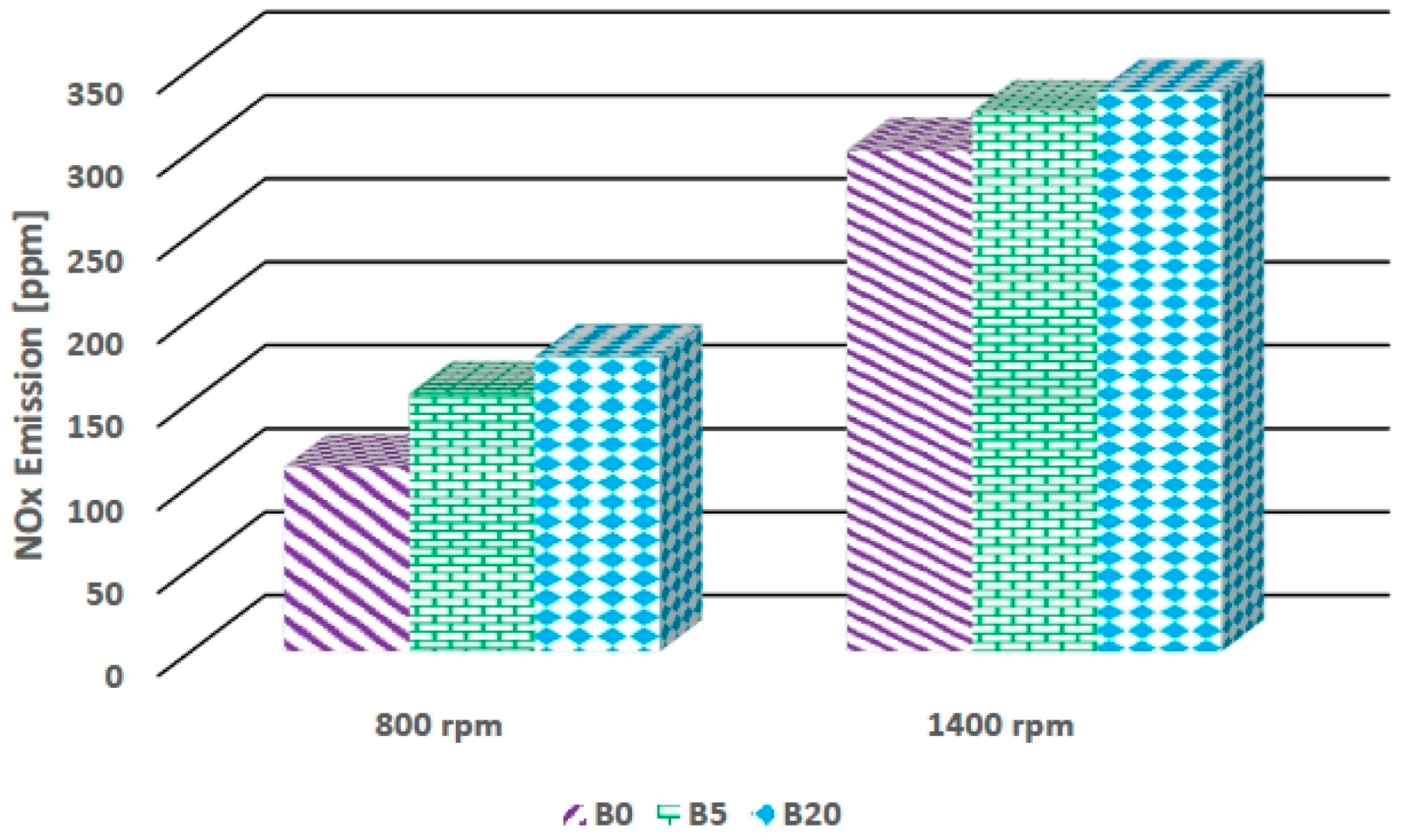

3.7. Nitrogen Oxides Emission

3.8. Particulate Matter Emission

4. Error Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Silitonga, A.S.; Masjuki, H.H.; Mahlia, T.M.I.; Ong, H.C.; Kusumo, F.; Aditiya, H.B.; Ghazali, N.N.N. Schleichera oleosa L oil as feedstock for biodiesel production. Fuel 2015, 156, 63–70. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.G.; Hyde, J.; Azad, A.K.; Mamat, R.; Bhuiya, M.M.K. Role of biofuel and their binary (diesel-biodiesel) and ternary (ethanol-biodiesel-diesel) blends on internal combustion engines emission reduction. Renew. Sustain. Energy Rev. 2016, 53, 265–278. [Google Scholar] [CrossRef]

- Imtenan, S.; Masjuki, H.H.; Varman, M.; Rizwanul Fattah, I.M. Evaluation of n-butanol as an oxygenated additive to improve combustion-emission-performance characteristics of a diesel engine fuelled with a diesel-calophyllum inophyllum biodiesel blend. RSC Adv. 2015, 5, 17160–17170. [Google Scholar] [CrossRef]

- Atabani, A.E.; Mofijur, M.; Masjuki, H.H.; Badruddin, I.A.; Kalam, M.A.; Chong, W.T. Effect of croton megalocarpus, calophyllum inophyllum, moringa oleifera, palm and coconut biodiesel-diesel blending on their physico-chemical properties. Ind. Crops Prod. 2014, 60, 130–137. [Google Scholar] [CrossRef]

- Ganjehkaviri, A.; Mohd Jaafar, M.N.; Hosseini, S.; Musthafa, A. Performance evaluation of palm oil-based biodiesel combustion in an oil burner. Energies 2016, 9. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Masjuki, H.H.; Kalam, M.A.; Abedin, M.J.; Sanjid, A.; Rahman, M.M. Assessing idling effects on a compression ignition engine fueled with jatropha and palm biodiesel blends. Renew. Energy 2014, 68, 644–650. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Chong, W.T. Characterization and production of ceiba pentandra biodiesel and its blends. Fuel 2013, 108, 855–858. [Google Scholar] [CrossRef]

- Mofijur, M.; Hazrat, M.A.; Rasul, M.G.; Mahmudul, H.M. Comparative evaluation of edible and non-edible oil methyl ester performance in a vehicular engine. Energy Procedia 2015, 75, 37–43. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E. Evaluation of biodiesel blending, engine performance and emissions characteristics of jatropha curcas methyl ester: Malaysian perspective. Energy 2013, 55, 879–887. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.M.R.; Mobarak, H.M. Comparative evaluation of performance and emission characteristics of moringa oleifera and palm oil based biodiesel in a diesel engine. Ind. Crops Prod. 2014, 53, 78–84. [Google Scholar] [CrossRef]

- Tüccar, G.; Aydın, K. Evaluation of methyl ester of microalgae oil as fuel in a diesel engine. Fuel 2013, 112, 203–207. [Google Scholar] [CrossRef]

- Islam, M.A.; Rahman, M.M.; Heimann, K.; Nabi, M.N.; Ristovski, Z.D.; Dowell, A.; Thomas, G.; Feng, B.; Von Alvensleben, N.; Brown, R.J. Combustion analysis of microalgae methyl ester in a common rail direct injection diesel engine. Fuel 2015, 143, 351–360. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M.P. Engine performance and emission analysis using oxidatively stabilized jatropha curcas biodiesel. Fuel 2013, 106, 152–156. [Google Scholar] [CrossRef]

- Islam, M.; Magnusson, M.; Brown, R.; Ayoko, G.; Nabi, M.; Heimann, K. Microalgal species selection for biodiesel production based on fuel properties derived from fatty acid profiles. Energies 2013, 6, 5676–5702. [Google Scholar] [CrossRef] [Green Version]

- Ali, O.; Mamat, R.; Najafi, G.; Yusaf, T.; Safieddin Ardebili, S.M. Optimization of biodiesel-diesel blended fuel properties and engine performance with ether additive using statistical analysis and response surface methods. Energies 2015, 8, 14136–14150. [Google Scholar] [CrossRef]

- Lim, S.; Teong, L.K. Recent trends, opportunities and challenges of biodiesel in malaysia: An overview. Renew. Sustain. Energy Rev. 2010, 14, 938–954. [Google Scholar] [CrossRef]

- Hassan, N.M.S.; Rasul, M.G.; Harch, C.A. Modelling and experimental investigation of engine performance and emissions fuelled with biodiesel produced from australian beauty leaf tree. Fuel 2015, 150, 625–635. [Google Scholar] [CrossRef]

- The bopple nut. Mount Bauple & District Historical Society Inc. Available online: http://www.Bauplemuseum.Com/bopple%20nut%20pub.Pdf (assessed on 30 December 2015).

- Macadamia%. Available online: https://www.anbg.gov.au/apni/ (assessed on 30 December 2015).

- Knothe, G. Biodiesel derived from a model oil enriched in palmitoleic acid, macadamia nut oil. Energy Fuels 2010, 24, 2098–2103. [Google Scholar] [CrossRef]

- Macadamias. Available online: http://nutindustry.Org.Au/anic/industry-snapshots/australian-macadamias.Asp (assessed on 21 March 2016).

- Khan, T.Y.; Atabani, A.E.; Badruddin, I.A.; Ankalgi, R.F.; Khan, T.M.; Badarudin, A. Ceiba pentandra, nigella sativa and their blend as prospective feedstocks for biodiesel. Ind. Crops Prod. 2015, 65, 367–373. [Google Scholar] [CrossRef]

- Ali, O.M.; Mamat, R.; Abdullah, N.R.; Abdullah, A.A. Analysis of blended fuel properties and engine performance with palm biodiesel-diesel blended fuel. Renew. Energy 2016, 86, 59–67. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, Q.; Chang, F.; Pan, H.; Liu, X.-F.; Li, H.; Hu, D.-Y.; Yang, S. Production and fuel properties of biodiesel from firmiana platanifolia l.F. As a potential non-food oil source. Ind. Crops Prod. 2015, 76, 768–771. [Google Scholar] [CrossRef]

- Palash, S.M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.R.; Sanjid, A. Biodiesel production, characterization, diesel engine performance, and emission characteristics of methyl esters from aphanamixis polystachya oil of bangladesh. Energy Convers. Manag. 2015, 91, 149–157. [Google Scholar] [CrossRef]

- Mattarelli, E.; Rinaldini, C.; Savioli, T. Combustion analysis of a diesel engine running on different biodiesel blends. Energies 2015, 8, 3047–3057. [Google Scholar] [CrossRef]

- Tesfa, B.; Gu, F.; Mishra, R.; Ball, A. Emission characteristics of a ci engine running with a range of biodiesel feedstocks. Energies 2014, 7, 334–350. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, M.; Kim, H.; Choi, N. Effects of canola oil biodiesel fuel blends on combustion, performance, and emissions reduction in a common rail diesel engine. Energies 2014, 7, 8132–8149. [Google Scholar] [CrossRef]

- Islam, M.A.; Brown, R.J.; Brooks, P.R.; Jahirul, M.I.; Bockhorn, H.; Heimann, K. Investigation of the effects of the fatty acid profile on fuel properties using a multi-criteria decision analysis. Energy Convers. Manag. 2015, 98, 340–347. [Google Scholar] [CrossRef]

- Bari, S. Performance, combustion and emission tests of a metro-bus running on biodiesel-ulsd blended (b20) fuel. Appl. Energy 2014, 124, 35–43. [Google Scholar] [CrossRef]

- Ge, J.; Kim, M.; Yoon, S.; Choi, N. Effects of pilot injection timing and egr on combustion, performance and exhaust emissions in a common rail diesel engine fueled with a canola oil biodiesel-diesel blend. Energies 2015, 8, 7312–7325. [Google Scholar] [CrossRef]

- Atabani, A.E.; César, A.D.S. Calophyllum inophyllum l.—A prospective non-edible biodiesel feedstock. Study of biodiesel production, properties, fatty acid composition, blending and engine performance. Renew. Sustain. Energy Rev. 2014, 37, 644–655. [Google Scholar] [CrossRef]

- Wakil, M.A.; Kalam, M.A.; Masjuki, H.H.; Fattah, I.R.; Masum, B.M. Evaluation of rice bran, sesame and moringa oils as feasible sources of biodiesel and the effect of blending on their physicochemical properties. RSC Adv. 2014, 4, 56984–56991. [Google Scholar] [CrossRef]

- Altaie, M.A.H.; Janius, R.B.; Rashid, U.; Taufiq-Yap, Y.H.; Yunus, R.; Zakaria, R.; Adam, N.M. Performance and exhaust emission characteristics of direct-injection diesel engine fueled with enriched biodiesel. Energy Convers. Manag. 2015, 106, 365–372. [Google Scholar] [CrossRef]

- Xue, J.; Grift, T.E.; Hansen, A.C. Effect of biodiesel on engine performances and emissions. Renew. Sustain. Energy Rev. 2011, 15, 1098–1116. [Google Scholar] [CrossRef]

- Öztürk, E. Performance, emissions, combustion and injection characteristics of a diesel engine fuelled with canola oil–hazelnut soapstock biodiesel mixture. Fuel Process. Technol. 2015, 129, 183–191. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z. Experimental studies on the combustion characteristics and performance of a direct injection engine fueled with biodiesel/diesel blends. Energy Convers. Manag. 2010, 51, 2985–2992. [Google Scholar] [CrossRef]

- Pali, H.S.; Kumar, N.; Alhassan, Y. Performance and emission characteristics of an agricultural diesel engine fueled with blends of sal methyl esters and diesel. Energy Convers. Manag. 2015, 90, 146–153. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fueled with jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M.; Turkcan, A.; Sayin, C. Performance and combustion characteristics of a di diesel engine fueled with waste palm oil and canola oil methyl esters. Fuel 2009, 88, 629–636. [Google Scholar] [CrossRef]

- Özçelik, A.E.; Aydoğan, H.; Acaroğlu, M. Determining the performance, emission and combustion properties of camelina biodiesel blends. Energy Convers. Manag. 2015, 96, 47–57. [Google Scholar] [CrossRef]

- Meng, X.; Chen, G.; Wang, Y. Biodiesel production from waste cooking oil via alkali catalyst and its engine test. Fuel Process. Technol. 2008, 89, 851–857. [Google Scholar] [CrossRef]

- Qi, D.H.; Geng, L.M.; Chen, H.; Bian, Y.Z.; Liu, J.; Ren, X.C. Combustion and performance evaluation of a diesel engine fueled with biodiesel produced from soybean crude oil. Renew. Energy 2009, 34, 2706–2713. [Google Scholar] [CrossRef]

- Korres, D.M.; Karonis, D.; Lois, E.; Linck, M.B.; Gupta, A.K. Aviation fuel jp-5 and biodiesel on a diesel engine. Fuel 2008, 87, 70–78. [Google Scholar] [CrossRef]

| Property | Equipment | Standard Method | Accuracy |

|---|---|---|---|

| KV | NVB classic (Norma lab, Valliquerville, France) | ASTM D445 | ±0.01 mm2/s |

| D | DM40 LiquiPhysics™ density meter (Mettler Toledo, Columbia, MD, USA) | ASTM D127 | ±0.1 kg/m3 |

| FP | NPM 440 Pensky-martens FP tester (Norma lab) | ASTM D93 | ±0.1 °C |

| Cloud and Pour Point | NTE 450 Cloud and pour point tester (Norma lab) | ASTM D2500 | ±0.1 °C |

| Higher Heating Value | 6100EF Semi auto bomb calorimeter (Parr, Moline, IL, USA) | ASTM D240 | ±0.001 MJ/kg |

| Acid Number | Automation titration rondo 20 (Mettler Toledo) | ASTM D664 and EN 14111 | ±0.001 mg·KOH/g |

| OS, 110 °C | 873 Rancimat (Metrohm, Herisau, Switzerland) | EN 14112 | ±0.01 h |

| Serial No. | Model | Kubota V3300 |

|---|---|---|

| 1 | Type | Vertical, 4 cycle liquid cooled diesel |

| 2 | No. of cylinder | 4 |

| 3 | Total displacement (L) | 3.318 |

| 4 | Bore × Stroke (mm) | 98 × 110 |

| 5 | Combustion system | E-TVCS |

| 6 | Intake system | Natural aspired |

| 7 | Output: Gross intermittent (kW/rpm); Net intermittent (Rated power output) (kW/rpm); Net continuous (kW/rpm) | 54.5/2600; 50.7/2600; 44.1/2600 |

| 8 | Rated Torque (N-m/rpm) | 230/1400 |

| 9 | Compression ratio | 22.6 |

| 10 | No load high idling speed (rpm) | 2800 |

| 11 | No load low idling speed (rpm) | 700–750 |

| 12 | Direction of rotation | Counter clockwise (viewed from flywheel side) |

| 13 | Governing | Centrifugal fly weight high speed governor |

| 14 | Fuel | Diesel fuel No-2-D (ASTM D975) |

| 15 | Starter capacity (V-kW) | 12–2.5 |

| 16 | Alternator capacity (V-A) | 12–60 |

| Serial No. | Properties | Macadamia Oil |

|---|---|---|

| 1 | Dynamic Viscosity (mPa.s) | 35.23 |

| 2 | KV (mm2/s) at 40 °C | 39.22 |

| 3 | D (kg/m3) at 15 °C | 898.60 |

| 4 | Higher Heating Value (MJ/kg) | 38.20 |

| 5 | Acid Value (mg·KOH/g) | 4 |

| 6 | FP (°C) | 167.5 |

| 7 | Pour Point (°C) | 8 |

| 8 | Cold Filter Plugging Point (°C) | 9 |

| Properties | Unit | M. Integrifolia Biodiesel | Diesel | ASTM D6751 [32] |

|---|---|---|---|---|

| KV at 40 °C | mm2/s | 4.46 | 3.23 | 1.9-6 |

| D at 15 °C | kg/m3 | 859.2 | 827.2 | - |

| Higher Heating Value | MJ/kg | 39.90 | 45.30 | - |

| OS | h | 3.35 | - | 3 min |

| Acid Value | mg·KOH/g | 0.07 | - | 0.05 max |

| FP | °C | 178.5 | 68.5 | 130 min |

| Pour Point | °C | 0 | 0 | - |

| Cloud Point | °C | 8 | 8 | report |

| CFPP | °C | 8 | 5 | - |

| Cetane Number | - | 56 | 48 | 47 min |

| Iodine Number | - | 77.85 | - | - |

| Saponification Value | - | 199 | - | - |

| Fatty Acids | Molecular Weight | Structure | Formula | M. Integrifolia Biodiesel (wt%) |

|---|---|---|---|---|

| Lauric | 200 | 12:0 | C12H24O2 | 0.1 |

| Myristic acid | 228 | 14:0 | C14H28O2 | 0.6 |

| Palmitic | 256 | 16:0 | C16H32O2 | 7.9 |

| Palmitoleic | 254 | 16.1 | C16H30O2 | 16.2 |

| Stearic | 284 | 18:0 | C18H36O2 | 3.2 |

| Oleic | 282 | 18:1 | C18H34O2 | 61.3 |

| Linoleic | 280 | 18:2 | C18H32O2 | 2.1 |

| Linolenic | 278 | 18:3 | C18H30O2 | 0.1 |

| Arachidic | 312 | 20:0 | C20H40O2 | 2.7 |

| Eicosenoic | 310 | 20:1 | C20H38O2 | 2.6 |

| Behenic | 340 | 22:0 | C22H44O2 | 0.9 |

| Erucic | 338 | 22:1 | C22H42O2 | 0.3 |

| Lignoceric | 368 | 24:0 | C24H48O2 | 0.4 |

| Total saturated fatty acid | 15.80 | |||

| Total monounsaturated fatty acid (MUFA) | 80.40 | |||

| Total polyunsaturated fatty acid (PUFA) | 2.20 | |||

| Others | 1.6 | |||

| DU | 84.50 | |||

| LCSF | 7.24 | |||

| Biodiesel–Diesel Blending | Viscosity (mm2/s) at 40 °C | D (kg/m3) at 15 °C | Higher Heating Value (MJ/kg) | OS (h) |

|---|---|---|---|---|

| M. Integrifolia 10% | 3.31 | 825.30 | 43.64 | 43.8 |

| M. Integrifolia 20% | 3.40 | 828.90 | 42.99 | 43.0 |

| M. Integrifolia 30% | 3.53 | 832.63 | 42.47 | 41.3 |

| M. Integrifolia 40% | 3.63 | 836.20 | 41.93 | 38.8 |

| M. Integrifolia 50% | 3.78 | 840.15 | 41.29 | 35.3 |

| M. Integrifolia 60% | 3.86 | 843.80 | 40.79 | 31.0 |

| M. Integrifolia 70% | 4.03 | 847.67 | 40.12 | 25.7 |

| M. Integrifolia 80% | 4.15 | 851.30 | 39.67 | 19.6 |

| M. Integrifolia 90% | 4.28 | 855.19 | 38.94 | 12.6 |

| Measurements | Accuracy | Relative Uncertainty | Average Reading for Diesel |

|---|---|---|---|

| BP | ±0.07 kW | (±0.07/37.7) = 0.002 | 37.7 |

| BSFC | ±5 g/kWh | (±5/203) = 0.024 | 203 |

| CO | ±10 ppm | (±10/1650) = 0.006 | 1650 |

| HC | ±1 ppm | (±1/12) = 0.083 | 12 |

| NOx | ±1 ppm | (±1/206) = 0.005 | 206 |

| PM | ±0.1 mg/m3 | (±0.1/397) = 0.0003 | 397 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.M.; Rasul, M.; Hassan, N.M.S.; Hyde, J. Prospects of Biodiesel Production from Macadamia Oil as an Alternative Fuel for Diesel Engines. Energies 2016, 9, 403. https://doi.org/10.3390/en9060403

Rahman MM, Rasul M, Hassan NMS, Hyde J. Prospects of Biodiesel Production from Macadamia Oil as an Alternative Fuel for Diesel Engines. Energies. 2016; 9(6):403. https://doi.org/10.3390/en9060403

Chicago/Turabian StyleRahman, Md Mofijur, Mohammad Rasul, Nur Md Sayeed Hassan, and Justin Hyde. 2016. "Prospects of Biodiesel Production from Macadamia Oil as an Alternative Fuel for Diesel Engines" Energies 9, no. 6: 403. https://doi.org/10.3390/en9060403

APA StyleRahman, M. M., Rasul, M., Hassan, N. M. S., & Hyde, J. (2016). Prospects of Biodiesel Production from Macadamia Oil as an Alternative Fuel for Diesel Engines. Energies, 9(6), 403. https://doi.org/10.3390/en9060403