Development of Integrally Molded Bipolar Plates for All-Vanadium Redox Flow Batteries

Abstract

:1. Introduction

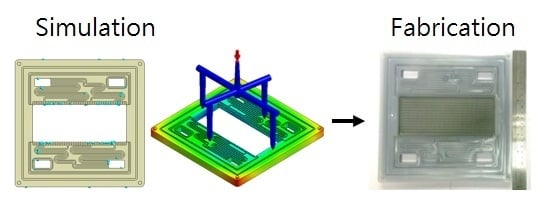

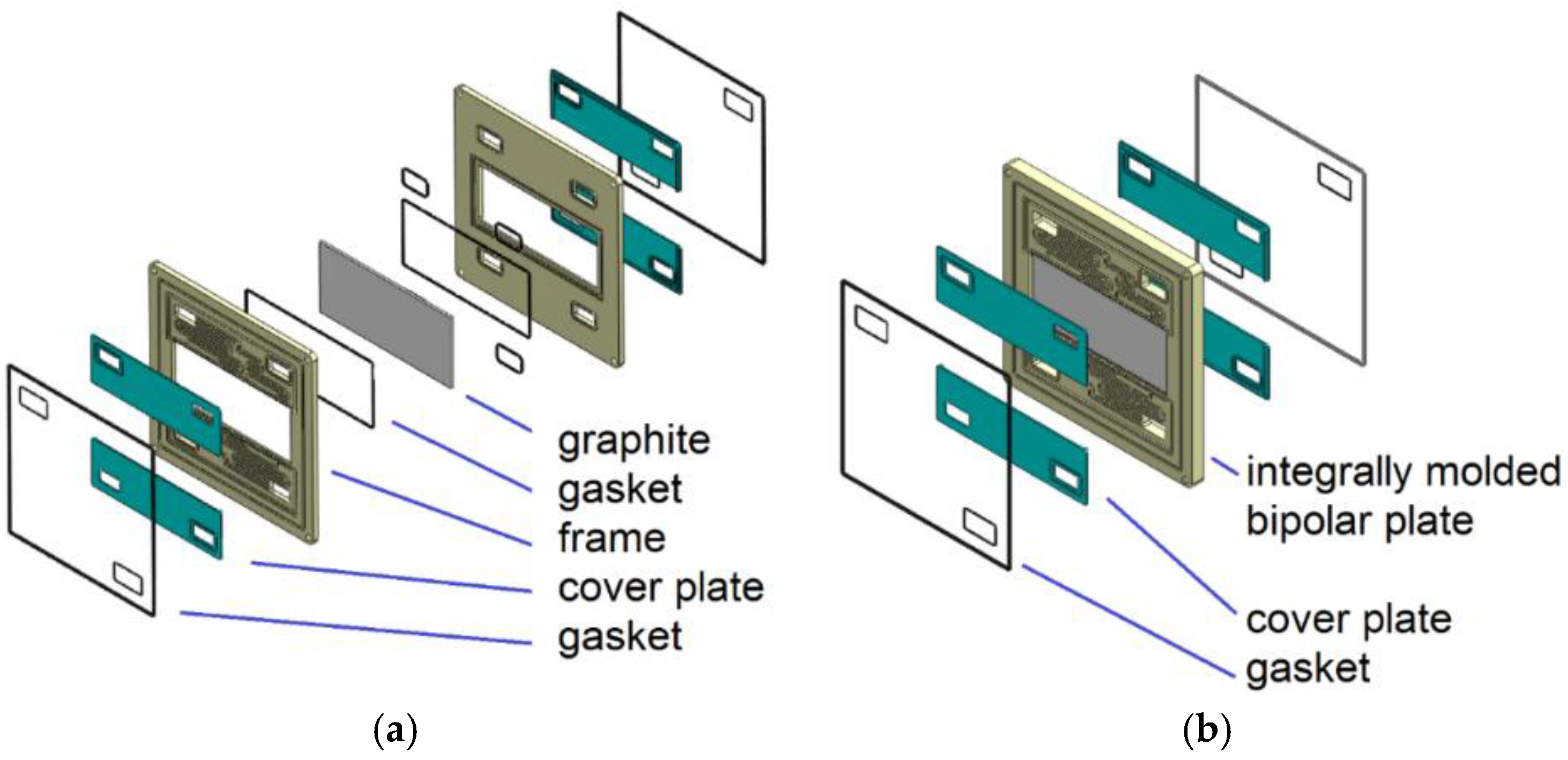

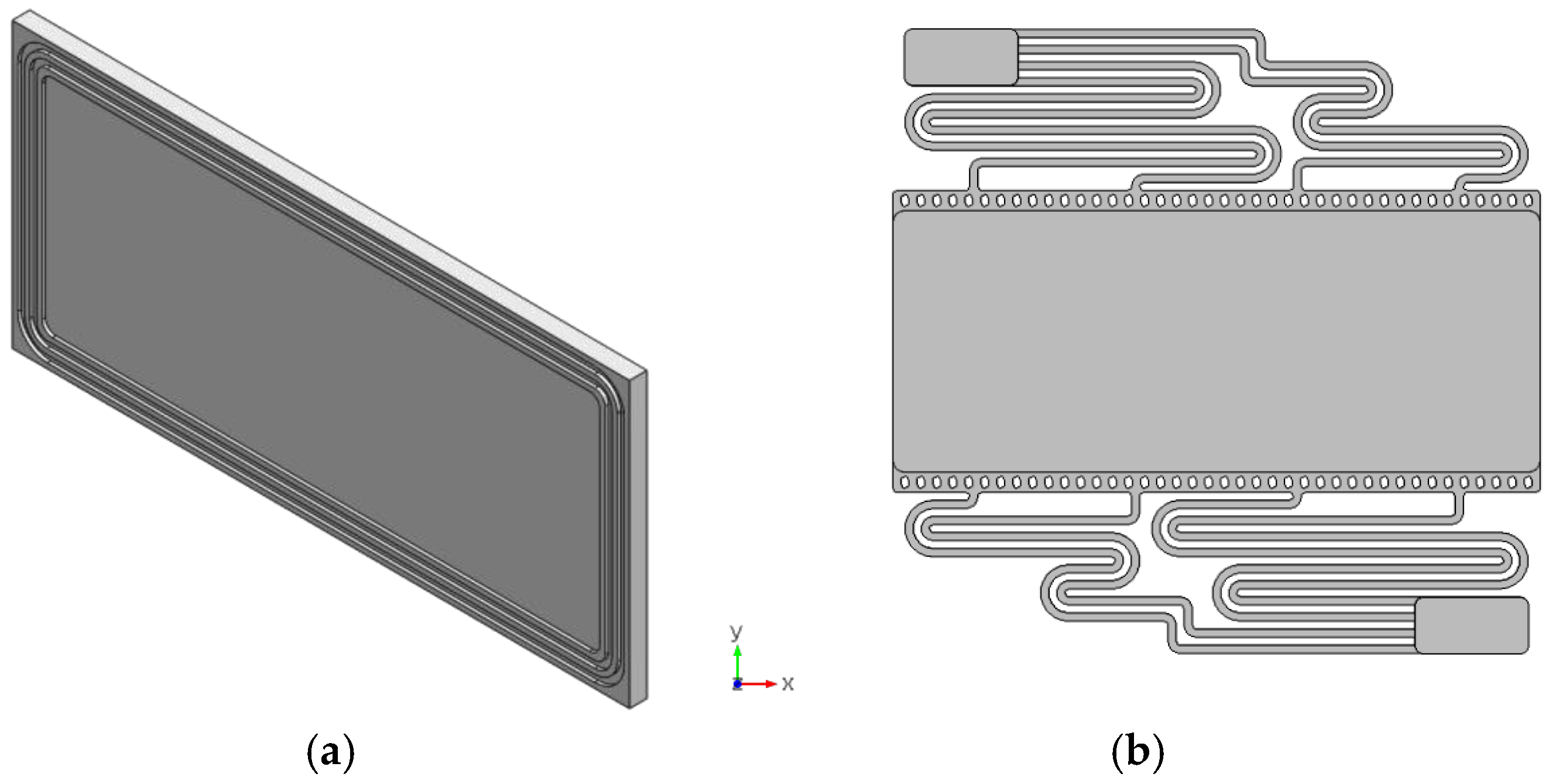

2. Mold Design and Analysis

2.1. Governing Equations

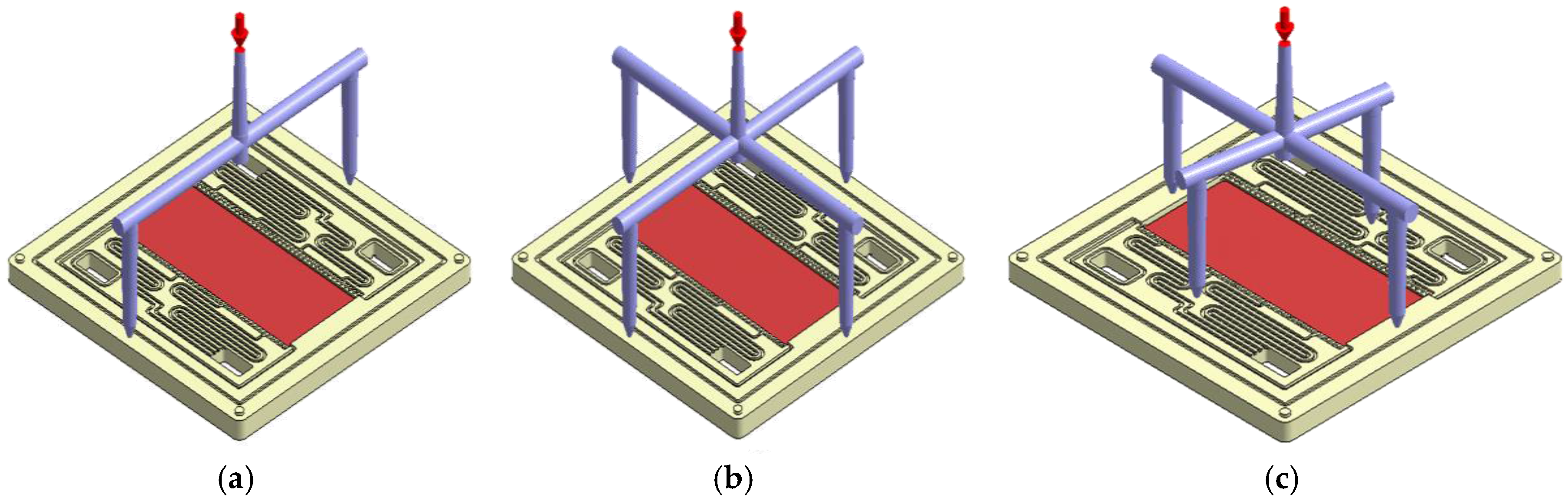

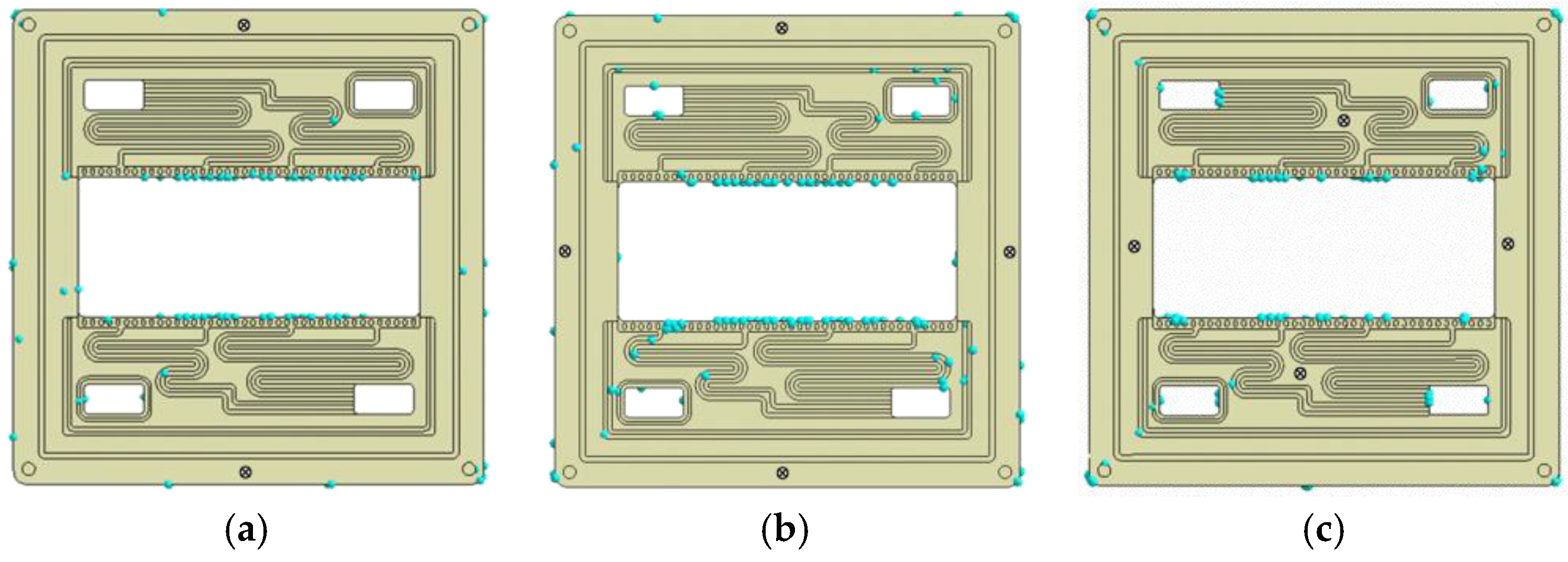

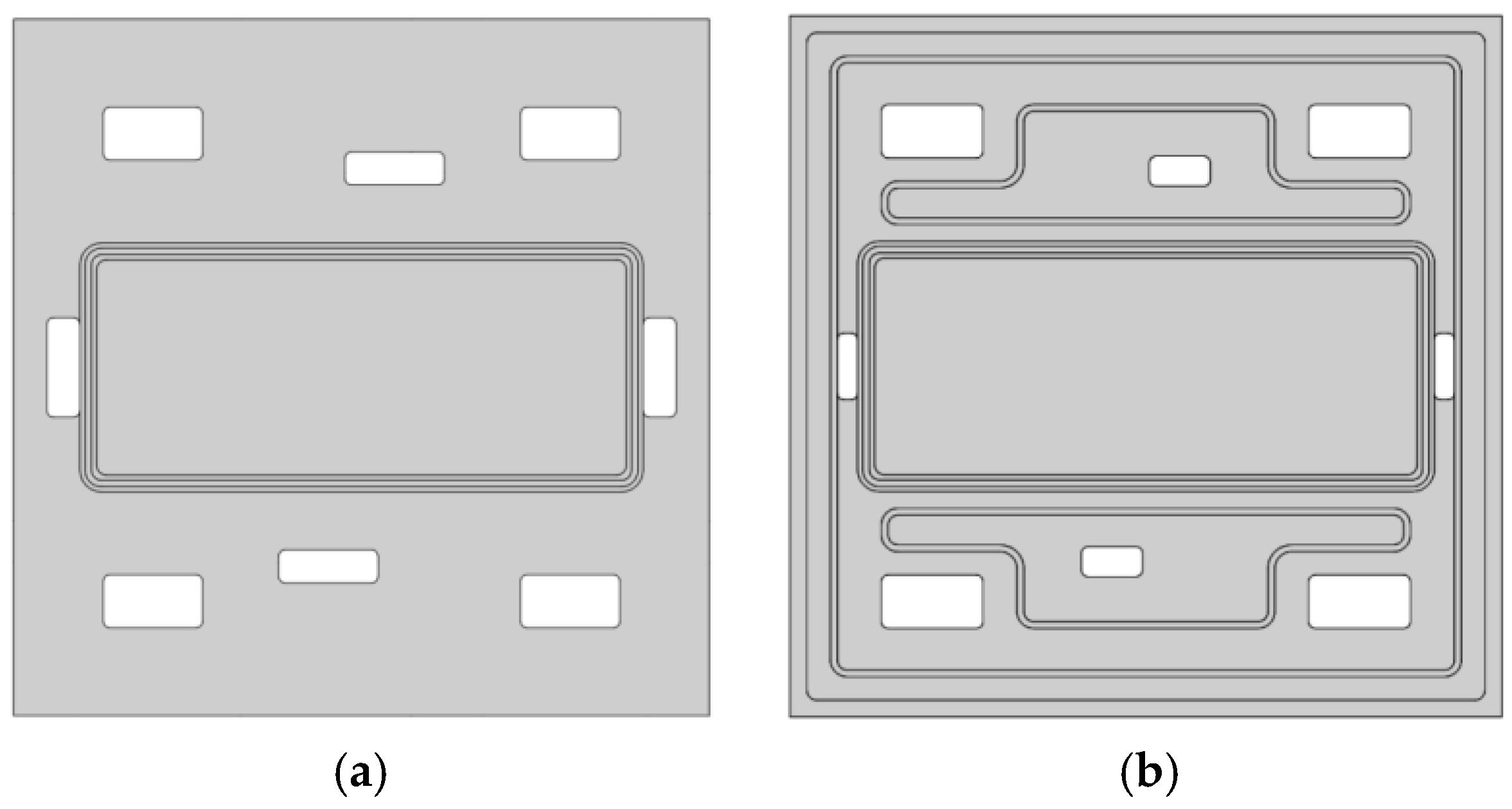

2.2. Position of Injection Gate

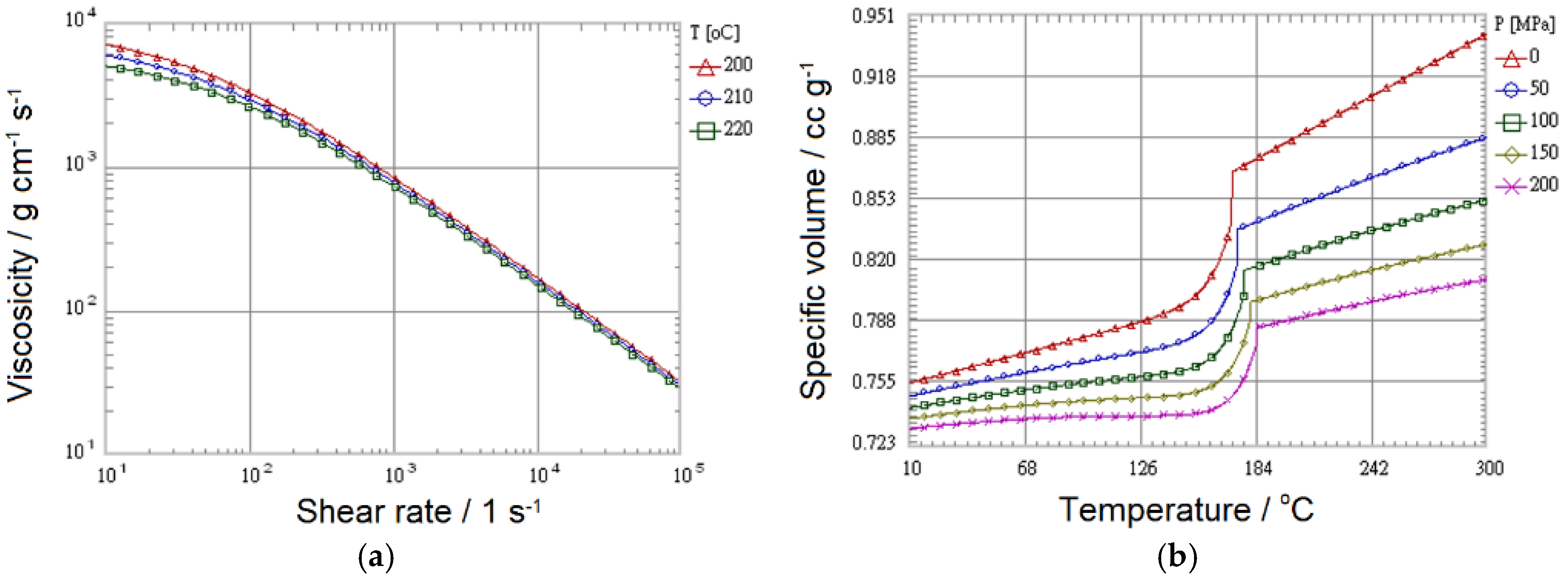

2.3. Injection Parameters

3. Results and Discussion

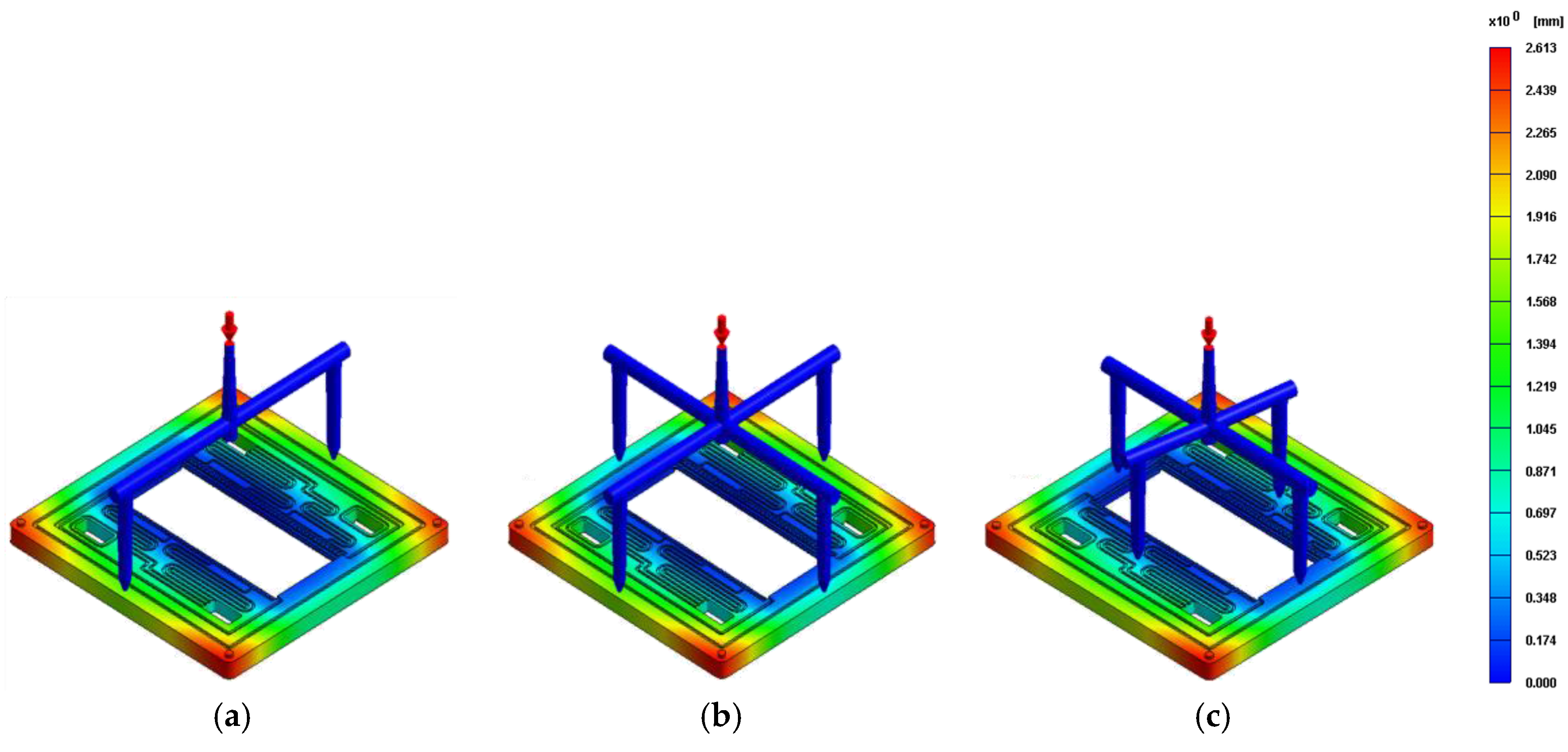

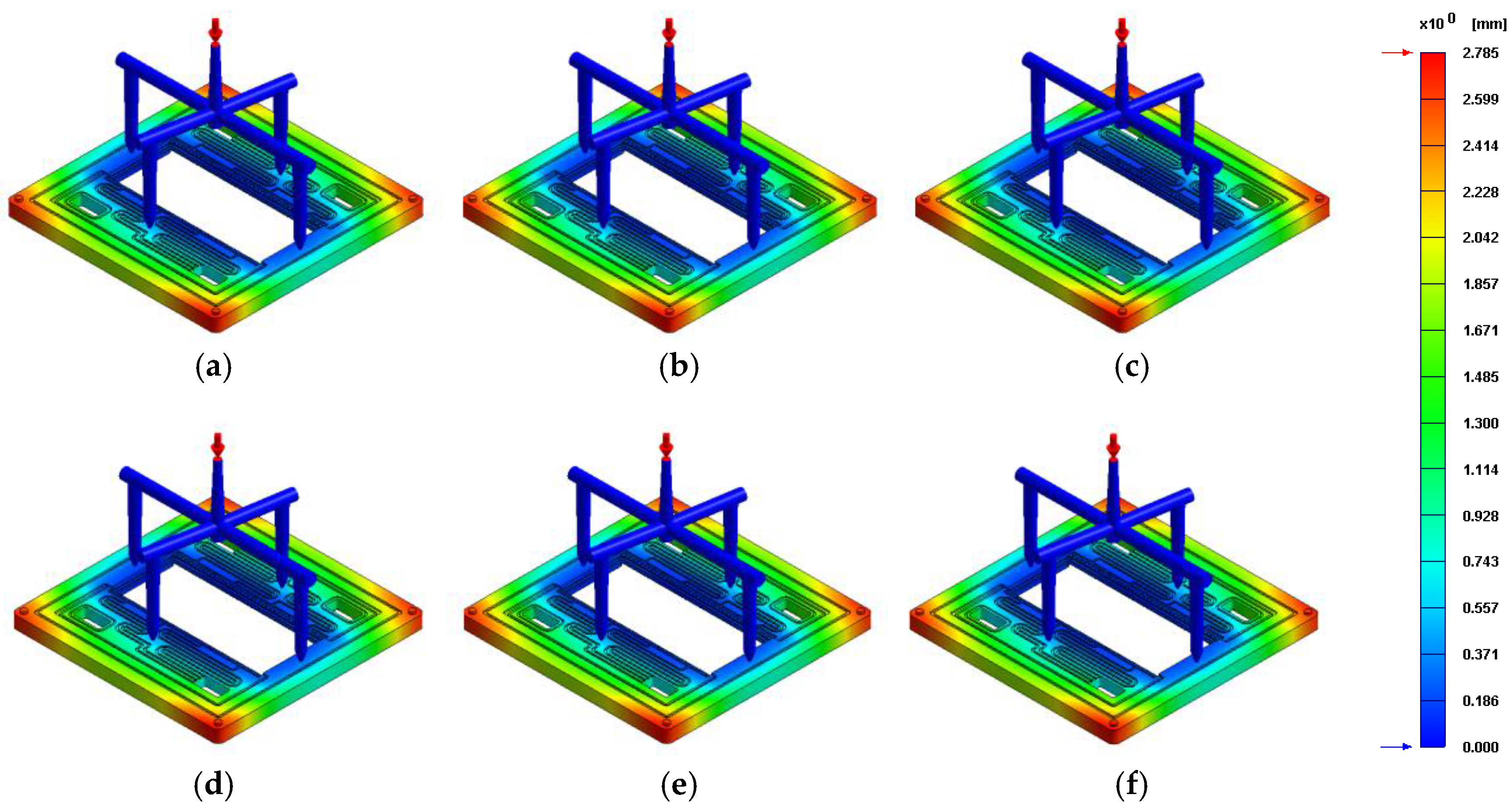

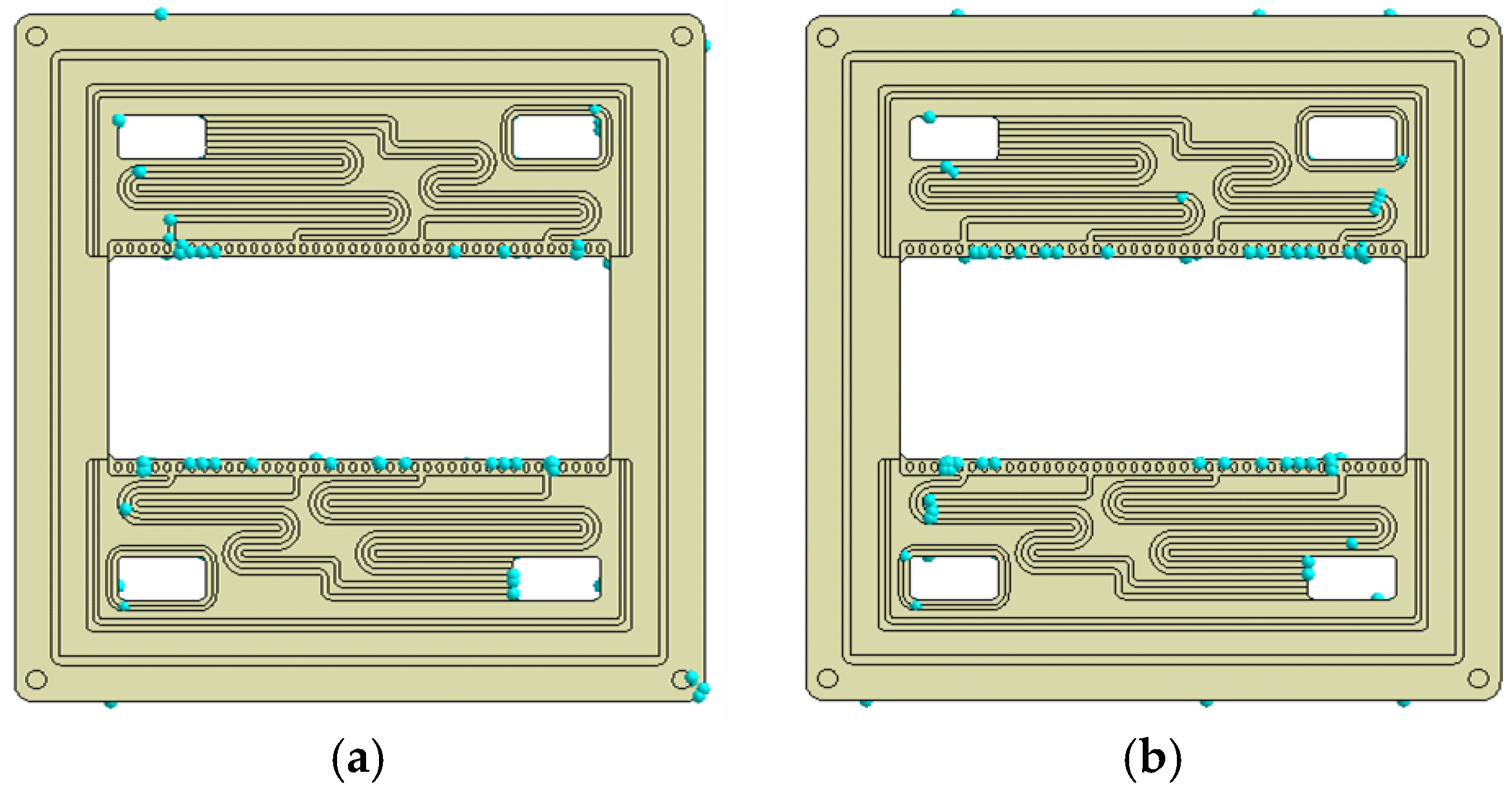

3.1. Effect of Gate Position on Formability

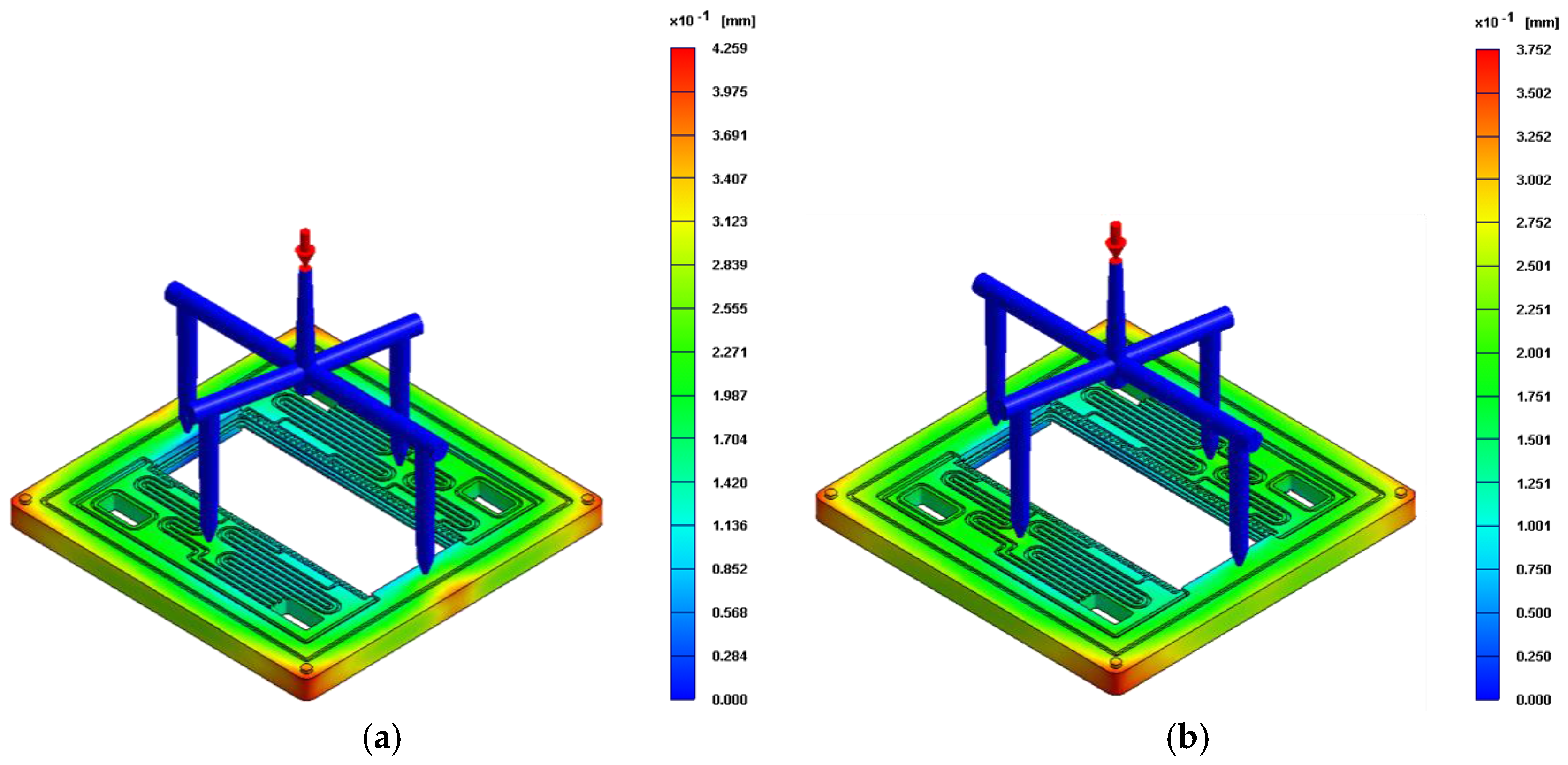

3.2. Effect of Injection Parameters on Formability

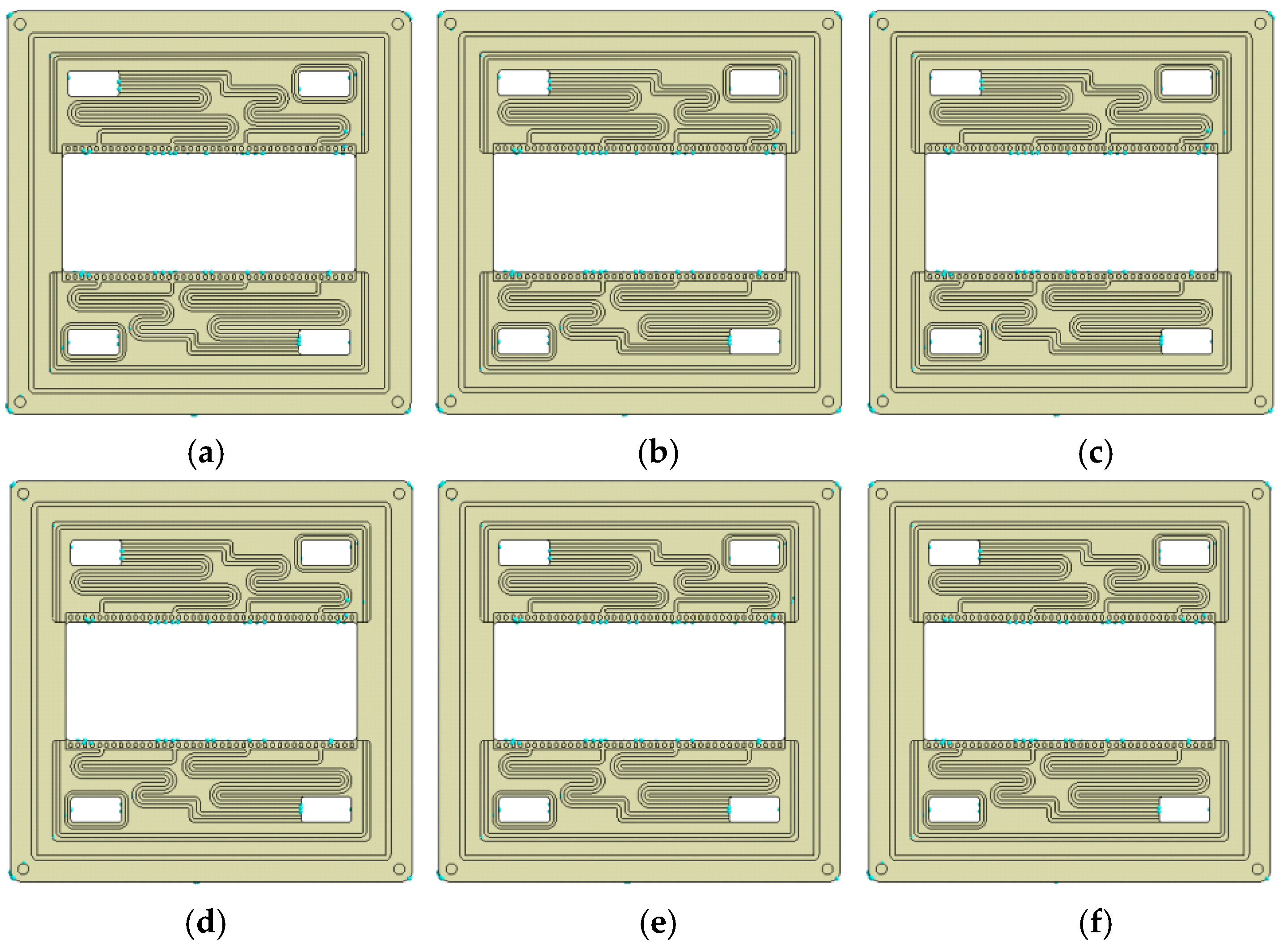

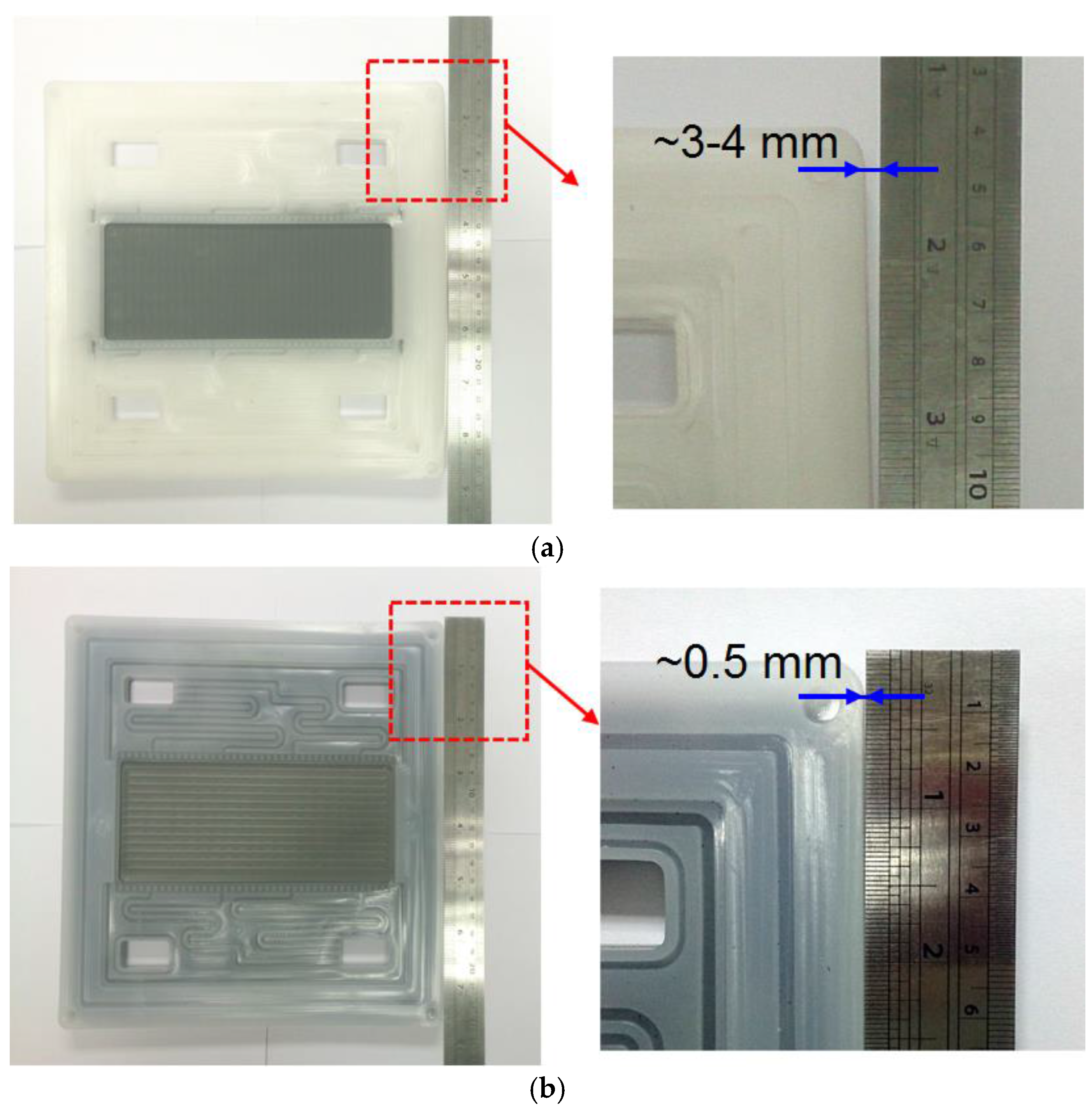

3.3. Improved Design of Bipolar Plates

4. Conclusions

- Gate position significantly affects air traps. Gates located at the central part of a flow field reduce the number of air traps.

- Maximum volume shrinkage occurs at the corners of a BP owing to the relatively thicker injected material.

- Volume shrinkage can be reduced using a large graphite plate with the maximum shrinkage of approximately 0.4 mm at the corners.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rychcik, M.; Skyllas-Kazacos, M. Characteristics of a new all-vanadium redox flow battery. J. Power Sources 1988, 22, 59–67. [Google Scholar] [CrossRef]

- Skyllas-Kazacos, M.; Kazacos, G.; Poon, G.; Verseema, H. Recent advances with UNSW vanadium-based redox flow batteries. Int. J. Energy Res. 2010, 34, 182–189. [Google Scholar] [CrossRef]

- Sun, B.; Skyllas-Kazacos, M. Modification of graphite electrode materials for vanadium redox flow battery application—I. Thermal treatment. Electrochim. Acta 1992, 37, 1253–1260. [Google Scholar] [CrossRef]

- Sun, B.; Skyllas-Kazacos, M. Chemical modification of graphite electrode materials for vanadium redox flow battery application—Part II. Acid treatments. Electrochim. Acta 1992, 37, 2459–2465. [Google Scholar] [CrossRef]

- Haddadi-Asl, V.; Kazacos, M.; Skyllas-Kazacos, M. Carbon–polymer composite electrodes for redox cells. J. Appl. Polym. Sci. 1995, 57, 1455–1463. [Google Scholar] [CrossRef]

- Hagg, C.M.; Skyllas-Kazacos, M. Novel bipolar electrodes for battery applications. J. Appl. Electrochem. 2002, 32, 1063–1069. [Google Scholar] [CrossRef]

- Kuan, H.-C.; Ma, C.-C.M.; Chen, K.H.; Chen, S.-M. Preparation, electrical, mechanical and thermal properties of composite bipolar plate for a fuel cell. J. Power Sources 2004, 134, 7–17. [Google Scholar] [CrossRef]

- Antunes, R.A.; de Oliveira, M.C.L.; Ett, G.; Ett, V. Carbon materials in composite bipolar plates for polymer electrolyte membrane fuel cells: A review of the main challenges to improve electrical performance. J. Power Sources 2011, 196, 2945–2961. [Google Scholar] [CrossRef]

- Dweiri, R.; Sahari, J. Electrical properties of carbon-based polypropylene composites for bipolar plates in polymer electrolyte membrane fuel cell (PEMFC). J. Power Sources 2007, 171, 424–432. [Google Scholar] [CrossRef]

- Kim, K.H.; Kim, B.G.; Lee, D.G. Development of carbon composite bipolar plate (BP) for vanadium redox flow battery ( VRFB ). Compos. Struct. 2014, 109, 253–259. [Google Scholar] [CrossRef]

- Lim, J.W.; Lee, D.G. Carbon fiber / polyethylene bipolar plate-carbon felt electrode assembly for vanadium redox flow batteries ( VRFB ). Compos. Struct. 2015, 134, 483–492. [Google Scholar] [CrossRef]

- Choe, J.H.; Lim, J.W.; Kim, M.K.; Kim, J.H.; Lee, D.G. Durability of graphite coated carbon composite bipolar plates for vanadium redox flow batteries. Compos. Struct. 2015, 134, 106–113. [Google Scholar] [CrossRef]

- Caglar, B.; Fischer, P.; Kauranen, P.; Karttunen, M.; Elsner, P. Development of carbon nanotube and graphite filled polyphenylene sulfide based bipolar plates for all-vanadium redox flow batteries. J. Power Sources 2014, 256, 88–95. [Google Scholar] [CrossRef]

- Lee, N.J.; Lee, S.W.; Kim, K.J.; Kim, J.H.; Park, M.S.; Jeong, G.; Kim, Y.J.; Byun, D. Development of carbon composite bipolar plates for vanadium redox flow batteries. Bull. Korean Chem. Soc. 2012, 33, 3589–3592. [Google Scholar] [CrossRef]

- Park, M.; Jung, Y.-J.; Ryu, J.; Cho, J. Material selection and optimization for highly stable composite bipolar plates in vanadium redox flow batteries. J. Mater. Chem. A 2014, 2, 15808–15815. [Google Scholar] [CrossRef]

- Soohyun, N.; Dongyoung, L.; Ilbeom, C.; Dai Gil, L. Smart cure cycle for reducing the thermal residual stress of a co-cured E-glass/carbon/epoxy composite structure for a vanadium redox flow battery. Compos. Struct. 2015, 120, 107–116. [Google Scholar] [CrossRef]

- Nakaishi, H.; Kanno, T.; Ogino, S.; Ito, T.; Shigematsu, T.; Tokuda, N. Cell Frame for Redox-Flow Cell and redox-Flow Cell. U.S. Patent 20040202915, 14 October 2004. [Google Scholar]

- Nakaishi, H.; Kanno, T.; Ogino, S.; Ito, T.; Shigematsu, T.; Tokuda, N. Cell Frame for Redox-Flow Battery and Redox-Flow Battery. U.S. Patent 20080081247, 3 April 2008. [Google Scholar]

- Dos Santos, A.R.; Chromik, A.; Kerres, J.; Düerkop, D.; Widdecke, H.; Hickmann, T.; Turek, T.; Kunz, U. Development of improved bipolar plates for vanadium redox-flow batteries with functionality integration. In Proceedings of the 2014 International Flow Battery Forum, Hamberg, Germany, 1–2 July 2014.

| Injection Parameters | P1 | P2 | P3 | P4 | P5 | P6 |

|---|---|---|---|---|---|---|

| Polymer temperature (°C) | 210 | 210 | 210 | 210 | 200 | 220 |

| Molding temperature (°C) | 60 | 60 | 60 | 60 | 60 | 60 |

| Injection pressure (MPa) | 140 | 100 | 180 | 220 | 140 | 140 |

| Maintaining pressure (MPa) | 140 | 100 | 180 | 220 | 140 | 140 |

| Ambient temperature (°C) | 25 | 25 | 25 | 25 | 25 | 25 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, C.-H.; Chou, H.-W.; Hsu, N.-Y.; Chen, Y.-S. Development of Integrally Molded Bipolar Plates for All-Vanadium Redox Flow Batteries. Energies 2016, 9, 350. https://doi.org/10.3390/en9050350

Chang C-H, Chou H-W, Hsu N-Y, Chen Y-S. Development of Integrally Molded Bipolar Plates for All-Vanadium Redox Flow Batteries. Energies. 2016; 9(5):350. https://doi.org/10.3390/en9050350

Chicago/Turabian StyleChang, Chih-Hsun, Han-Wen Chou, Ning-Yih Hsu, and Yong-Song Chen. 2016. "Development of Integrally Molded Bipolar Plates for All-Vanadium Redox Flow Batteries" Energies 9, no. 5: 350. https://doi.org/10.3390/en9050350