1. Introduction

Within the past decade, decarbonizing the tailpipe emissions of passenger vehicles has become an area of significant focus for automotive manufacturers and suppliers, due to emergent government legislation mandating the development of carbon dioxide (CO

2) reducing technologies [

1]. There has also been increased consumer pressure, due to growing environmental awareness within society, for manufacturers to provide products that reduce the reliance on fossil fuels.

Vehicle electrification is a technology pathway being adopted by some original equipment manufacturers (OEMs) to either reduce or eliminate tailpipe emissions [

1,

2]. However electric vehicles (EV’s) that employ a rechargeable energy storage system (RESS) still have some significant barriers within the marketplace when compared to the incumbent internal combustion engine (ICE) vehicle technology [

3]. One of these barriers is ensuring that the RESS maintains customer satisfactory performance over a warranted life (such as 10 years or 100,000 miles of customer usage) [

3].

Traditionally vehicle OEMs perform a variety of life representative mechanical durability tests during the design and prototype stages of their development process to ensure in-market reliability [

4]. Not only do these tests ensure that new components are fit-for-purpose, they also allow for OEMs to obtain characterization data for simulations and computer aided engineering (CAE) activities [

4]. These testing activities ensure that the product meets the necessary requirements for vehicle homologation [

4]. Vibration durability is one of these tests. It is important to understand the degradation characteristics of a component or assembly when exposed to vibration loading representative of a vehicle life. Vibration can excite fatigue cracking or work hardening of materials [

5,

6,

7] resulting in component failure or reduced system performance. It is necessary to ensure that potentially costly vibration induced warranty failures are avoided through the optimization of component to assembly integration.

Within the fabrication of complete RESS, many OEMs are employing 18650 cylindrical cells [

8,

9,

10,

11]. This is due to a number of advantages over there pouch and prismatic counterparts. Firstly, 18650 cells are a cell form currently in use in a number of consumer electronic products and as a result are already manufactured in very large quantities resulting in a lower “unit cost per cell” through economies of scale [

11,

12,

13]. They also have the advantage of having built-in safety systems such as a current interrupt device (CID) that prevents the accumulation of excessive pressure within the cell, mitigating the risk of cell explosion [

11,

12,

13]. They also have and a positive temperature coefficient (PTC) resistor that prevents high current surge [

11,

12,

13].

A critical review of studies mechanically characterizing 18650 cylindrical cell is discussed within [

4]. It was concluded that whilst a significant body of research exists that defines the mechanical behavior of cylindrical format cells through static and dynamic test techniques (such as mechanical strain and bending [

14,

15,

16,

17], force displacement [

14,

15,

16,

17,

18], mechanical crush [

14,

18,

19], penetration [

16,

20], mechanical shock [

14,

21], impact resistance [

16,

22],

etc.) only a few studies exist that define the effects of degradation of cells through vibration excitation [

4,

21,

22,

23]. It was noted within [

4] that these contemporary cell vibration studies had conflicting results and that no correlation existed between investigations with regard to the susceptibility of battery cells to vibration. However, these previous studies have applied vibration profiles that have a vehicle homologation focus (such as Economic Commissions for Europe (ECE) R100 and United Nations (UN) 38.3 [

24,

25]) which are designed to validate a battery system to abusive vibration conditions [

3,

26]. Subsequently the results presented in these studies are unrepresentative of vibration loading that is experienced by a chassis mounted component during normal customer operation over a certified distance (e.g., 100,000 miles of EV operation) [

3,

4]. Research in [

4] noted that this area did not define the specific lithium-ion cell chemistry, nor did they define the electrical or mechanical characterization tests undertaken to determine cell degradation, thus making it difficult for engineers and researchers to identify specific vibration degradation phenomena relating to different cell attributes. Finally [

4] identified that the majority of previous vibration studies had not investigated the effect of cell state of charge (SOC) or in-pack orientation on the degradation witnessed as a function of vibration excitation.

In response to this gap within the academic literature, Hooper

et al. presents a study in which commercially available nickel manganese cobalt oxide (NMC) 2.2 Ah 18650 cylindrical cells were evaluated for electrical degradation when subject to vibration profiles representative of 100,000 miles of European and North American customer use [

4]. Within [

4] a third of the cells tested were evaluated using Society of Automotive Engineers (SAE) J2380 profiles [

27]. The SAE J2380 profiles were developed to underpin durability evaluations and replicate a 100,000 miles of vehicle use within the North American market. It is reported within [

4], that these NMC cells displayed a significant increase in ohmic resistance within the range of 25.82% to 38.09% post vibration testing. A reduction in the measured 1C energy capacity was observed in some samples, with 12.22% being the greatest reduction observed. The study in [

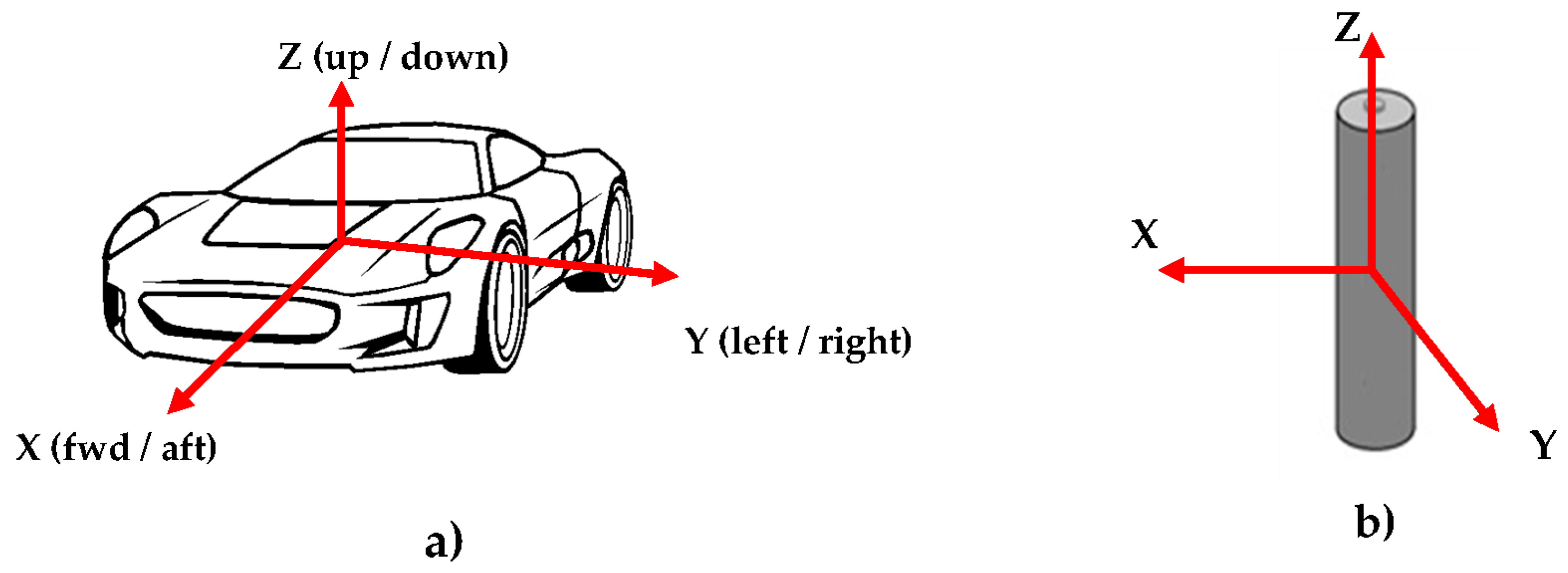

4] also investigated the impact of SOC and in-pack orientation on vibration induced degradation. It was identified that cells conditioned to 75% SOC and oriented in either of the cells horizontal planes (their

X and

Y axis) within the pack displayed a greater tendency for electrical degradation. However, it was acknowledged within [

4] that the study’s conclusions are restricted due to the limited sample size employed, since each test condition was evaluated through a single cell.

This study represents a refinement and extension of the experiments discussed within [

4] and investigates if similar vibration induced electrical aging results can be excited within an 18650 format cell of a different lithium-ion chemistry. It is hypothesized within [

4,

28] that different chemistries of lithium-ion cells could display different mechanical ageing characteristic due to the different properties of the materials used within the anode and cathodes of the cells construction. The aim of study is to determine the susceptibility of Nickel Cobalt Aluminum Oxide (NCA) 18650 battery cells to vibration that is representative of 100,000 miles of North American customer usage. The results of this study are compared to those previously reported in [

4,

21] as one means of assessing the transferability of cell degradation mechanisms, as function of vibration, between different cell chemistries and cell manufacturers. This study also investigates if cell orientation with the EV battery assembly can affect the severity of the observed degradation.

Within the context of this research, cell aging is defined as a reduction in cell capacity and/or an increase in the cell’s impedance. Mechanical cell degradation is defined through measuring a change in the cell’s natural frequency (within the range: 5 to 3700 Hz).

This paper is structured as follows;

Section 2 provides a summary of the experimental procedure. Results are presented in

Section 3. Discussion, further work and conclusions are presented in

Section 4,

Section 5 and

Section 6, respectively.

4. Discussion

4.1. Experimental Results

The primary conclusion from this study is that both the electrical performance and the mechanical properties of the NCA Lithium-ion cells are relatively unaffected when exposed to vibration energy that is commensurate with a typical vehicle life. A similar change in electrical performance was observed within the control samples post testing. This indicates that the measured degradation was likely to have been influenced by other laboratory environmental conditions as opposed to being a function of the applied vibration. ANOVA analysis of the mean results confirmed (with a 95% confidence) that the effects of vibration did not change the cells ohmic resistance and capacity. For the mechanical characterization of the cells, two thirds of the cells showed no significant change with regard to the shift in the natural frequency of their first resonance. This correlates with the electrical characterization results, indicating that vibration has had a minimal impact on the performance of these cells. Changes in RCT followed an unusual trend however. Samples vibrated within the Z:Z orientation degraded at a similar rate to the control samples, whilst cells tested in the horizontal conditions did not degrade. A similar level of degradation was also observed within the control samples which were continually stored in the Z axis within the manufacturers shipping carton.

Reviewing the results of each cell from the multiple characterization activities, samples 1, 4 and 8 demonstrate a small degree of correlation between RDC, RO, energy capacity and a change in resonance. However, overall there is a limited correlation between electrical cell characterization and changes in the cell’s natural frequency.

4.2. Experimental Method

As discussed within

Section 3.6, there is some concern with regard to the effect on the amount of petro wax material employed between the accelerometer and the surface of the cell on the measured amplitude between SOT and EOT measurements. If the resonance search testing is to be repeated on future tests, it is recommended that the frequency sweep evaluations on the 18650 cells are conducted using light weight accelerometers that utilize a stud fastener and a machined cell surface-bonded collar. Despite a considerable amount of care being taken to ensure that the accelerometers were installed onto the same location of the cell at each frequency sweep measurement and levelled via an inclinometer, the use of petro wax is susceptible to user error. Ensuring the accelerometer is semi-permanently bonded to the radial surface of the cell; in a (perfectly true) vertical orientation can result in different quantities of petro wax being used for each accelerometer installation. The authors believe that this may introduce subtle changes in vibration transmissibility from the cell to the accelerometer. This hypothesis can be investigated further, as discussed in

Section 5, in a future study assessing the modal response of 18650 cells.

Whilst the data set was increased within this study when compared to that discussed in [

4], it is acknowledged that a larger data set is required to confirm the findings discussed within this paper and with [

4].

4.3. Comparison of Results to Those Recorded for the NMC Cell

Table 11 compares the measured post-test difference of all samples from this study with NMC samples conditioned to 75% SOC from [

4].

Reviewing the pulse power results from the NCA cells it is noticeable that the DC resistance measurement from the pulse power test has a far smaller spread than that observed within the 75% SOC samples from [

4]. A similar observation with regard to the value of R

o for the NMC and NCA cells is also noticeable.

The

RCT results from the two cell manufacturers show that the NCA cells do not illustrate the same level of degradation when oriented in any of the three test positons. In fact, the NMC cells from [

4] illustrate a reduction in

RCT post vibration testing. This trend is not witnessed within the NCA samples. However both the NCA reference cells and

Z:

Z oriented items shown similar changes in

RCT as the NMC cells.

Both studies highlighted that the OCV is unaffected irrespective of orientation, cell chemistry or manufacturer. The voltage difference recorded is within the tolerance of the error of the equipment. This supports the results presented in [

23,

38] that also noted that OCV is not adversely affected by vibration loading.

With regard to capacity, it is noticeable that the measured amount of capacity fade within the NCA cells is typically greater than that noted within the NMC items. However unlike the NMC cells, the NCA 18650’s have a smaller spread of results. The reference samples for the NCA cells also illustrate the same level of capacity fade indicating that this reduction is a function of laboratory climatic conditions, as opposed to vibration excitation. In terms of absolute change between SOT and EOT, the worst performing NMC sample (sample 16) has a comparable capacity fade to that of the typical NCA item.

With respect to the mechanical characterization results, it must be noted that with the NCA samples, the first resonance was less than 2 g

n (typically between 1.20 and 1.90 g

n) pre and post testing. In comparison to the NMC cells results presented in [

4], the NCA items display significantly less degradation in vibration response. Also no resonance at either pre or post testing was greater than twice the excitation force indicating that the NCA cells have both a greater damping coefficient and a stiffer construction than the NMC items. These characteristics may explain how the NCA cells have displayed less relative vibration aging than the NMC cells from the previous study.

With regard to visual condition, both types of 18650 cell showed no significant external degradation, other than marks from the clamp faces of the fixtures post testing.

Comparing the overall conclusions from [

4] for samples evaluated to SAE J2380 and comparing them to the NCA cells from this study, there is a correlation between the two different cell chemistries. Both types of 18650 cells typically show the least degradation when oriented in the

Z axis of the cell with respect to the

Z axis of the vehicle (

Z:

Z condition) when assessed to the SAE standard.

4.4. Implications for Vehicle Design

The results presented within this paper suggest that as part of the technology selection process, OEM’s should study how susceptible the proposed cell technology is to vibration. It is also recommended that this is conducted during the concept phase of a vehicle program. The susceptibility of the cell to different packaging orientations within the battery assembly should also be considered at this stage of the vehicle development process to ensure that the orientation that results in the least degradation is chosen for the battery assembly.

Whilst typically the cells evaluated within this study are unaffected by a representative 100,000 mile road vibration excitation, there were some specific aging behavior (such as an observed increase in DC resistance (derived from pulse power testing) in

Z:

X oriented samples) identified. Any aging behavior as a function of vibration would have to be characterized to ensure effective battery management system (BMS) development and to maximize useful service life. As discussed within

Section 4.3, there is evidence from both this study and that presented within [

4] that 18650 cells installed in there

Z orientation with respect to the

Z orientation of the vehicle within a battery assembly are less likely to degrade when subjected to vibration representative of 100,000 miles of North American durability.

5. Further Work

One of the limitations of the experimental methodology employed within this study (and that within [

4]) is that the change in electrical and mechanical performance was only assessed at SOT and EOT. As a result, no information with respect to the degradation rate over 100,000 miles of customer usage was determined. It is recommended that in future studies that the cells should be characterized at intermediate points during the test program, such as at 10,000 miles intervals. Not only would this facilitate further investigations into both the absolute value of degradation, but would also allow researchers to define the expected in-service rate of capacity and power fade over a defined vehicle mileage. To perform this activity via SAE J2380 vibration profiles, if a linear vibration profile is assumed, the test duration for each axis profile would have to be divided by 10 to achieve 10,000 mile test intervals. Another limitation is that whilst three cells of each orientation were evaluated, a greater sample size is necessary to increase confidence of the findings disclosed from this study. Therefore a further set of repeat tests should be conducted to increase the size of the data set.

The electromechanical condition and assembly of the cells after EOT characterization and those from [

4] should be assessed using novel cell imaging and autopsy methods, as discussed within [

21]. This is firstly to quantify the changes that occur within the material composition and structure of the cell post vibration and also to determine why the cells from this study displayed significantly less degradation than the cell technology evaluated within [

4,

21].

The research reported here and within [

4] has highlighted that cells of the same type (18650 cylindrical cells) can have significantly different performance with regard to vibration durability. The data within this study and that defined in [

4,

21] indicates that OEM’s should conduct vibration durability testing as part of their cell selection activities. These results also demonstrate that the experimental programme should be broadened to include using cells from a wider cross-section of manufacturers and chemistries. This will further highlight the transferability of these results to other cell technologies.

Whilst there is evidence within this paper to suggest that NCA chemistry cells are more resilient to vibration than NMC, it would be undesirable to make this conclusion as this study does not consider the variability of different manufacturing and assembly processes employed by the two different cell suppliers (such as the binder, the film thickness etc.), which could impact the cell vibration performance. Therefore the authors propose a future study in which cells of the same chemistry are selected from different manufacturers and are assessed when subjected to the same vibration durability conditions. However it must be noted that it will be challenging within this proposed study to make any definitive conclusions, since cell manufacturers rarely fully disclose their manufacturing processes. Therefore it is also recommended that a further experiment is conducted using cells that have been specially manufactured by a specialist cell fabricator so that data on cells with a known construction provenance can be obtained.

Finally, different methods of mechanical accelerometer mounting should be investigated (such as the method outlined in

Section 4). This is so the risk of user error in the natural frequency measurement of cells during the swept sine wave evaluations is reduced. The authors recommend that the potential error associated with the use of petro wax mounting, particularly when bonding accelerometers to the radial cell surface should be quantified through a measurement repeatability study.

6. Conclusions

Typically, both the electrical performance and the mechanical properties of the NCA 18650 Lithium-ion cells evaluated within this study were relatively unaffected when evaluated in accordance with SAE J2380 to vibration that is representative of 100,000 miles EV durability. No external damage or electrolyte leakage was observed in any of the test cells post vibration testing. No significant change in R

O, or cell capacity was observed as a result of vibration at the 95% confidence level. OCV was not affected by vibration within this testing. Cell degradation as a function of vibration was observed within the pulse power DC resistance of the cells oriented in the

Z:

X axis. However no significant change in the pulse power DC resistance was noted at the 95% confidence level in either the

Z:

Y and

Z:

Z oriented samples. Samples tested in the horizontal orientations of

Z:

X or

Z:

Y did not illustrate an increase in charge transfer resistance, which was observed to increase within both the

Z:

Z and control samples. A similar reduction in energy capacity, increase in R

O and increase in R

DC was witnessed within the reference samples. These results indicate that the change in these electrical attributes is a function of other environmental conditions and the casualty between cell ageing and vibration cannot be fully quantified. When comparing the orientation results from this study to the previous assessment on 18650 type cells defined in [

4,

21] no significant correlation in performance was observed. At this stage, the underlying causality between the application of vibration energy and cell orientation is not fully understood. Defining these relationships is the focus of on-going research, using novel cell imaging and autopsy methods, to quantify changes in material composition and structure. Expanding the experimental programme to also include cells of different form-factor and chemistries will identify if the experimental results presented here are transferable to other cell technologies.