1. Introduction

Environmental concern is now promoting the utilization of renewable and clean energy, which has largely developed electrical energy [

1,

2,

3,

4]. Power converters for electrical energy conversion have been widely used in the renewable energy applications such as motor control, electric vehicle, energy storage, high-power-factor rectifiers, and compensators for reactive and harmonic currents to the grid [

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15]. In these systems, at least two current sensors are employed to implement the closed-loop current control and overcurrent protection. To reduce cost and volume, as well as to increase reliability in hostile environment [

16], technical trends move towards driving power converts with fewer sensors or without sensors. Research to reconstruct three-phase currents using single current sensors, especially in motor drive systems, has been undertaken [

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34].

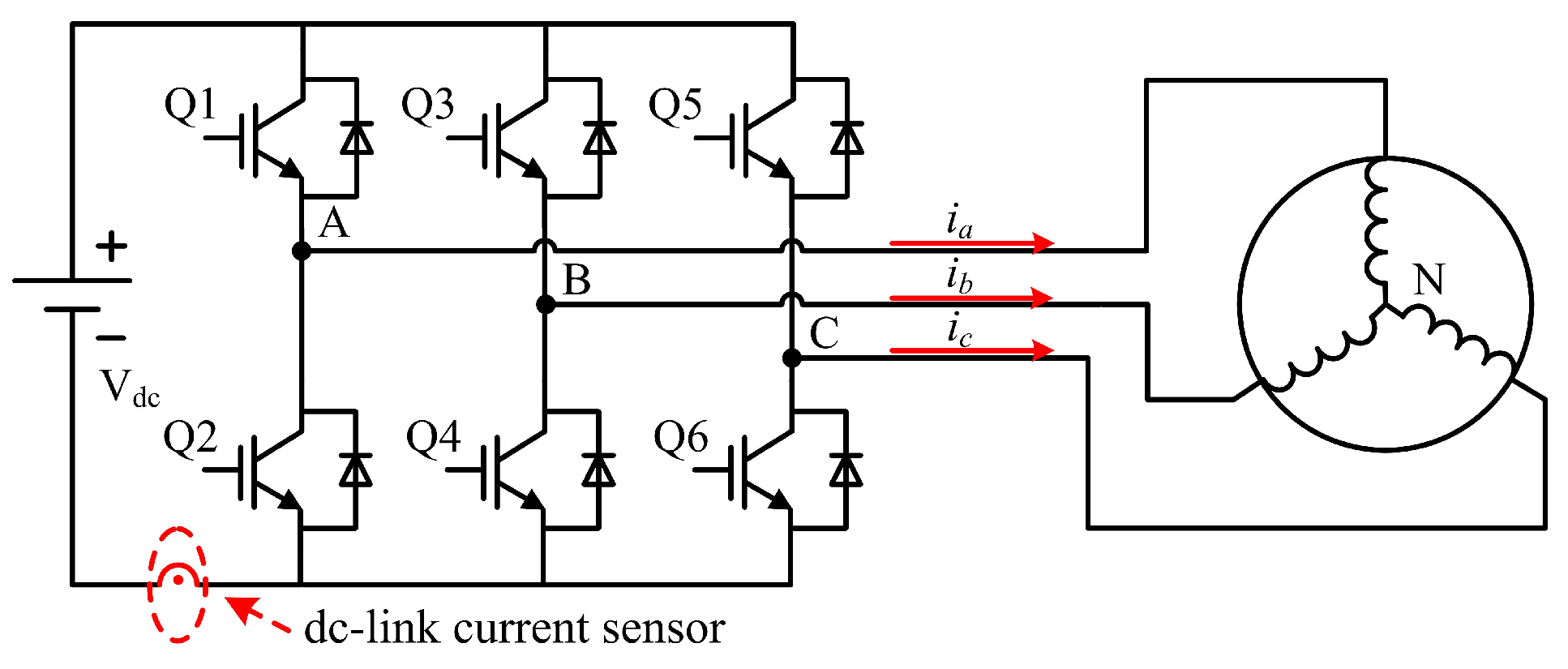

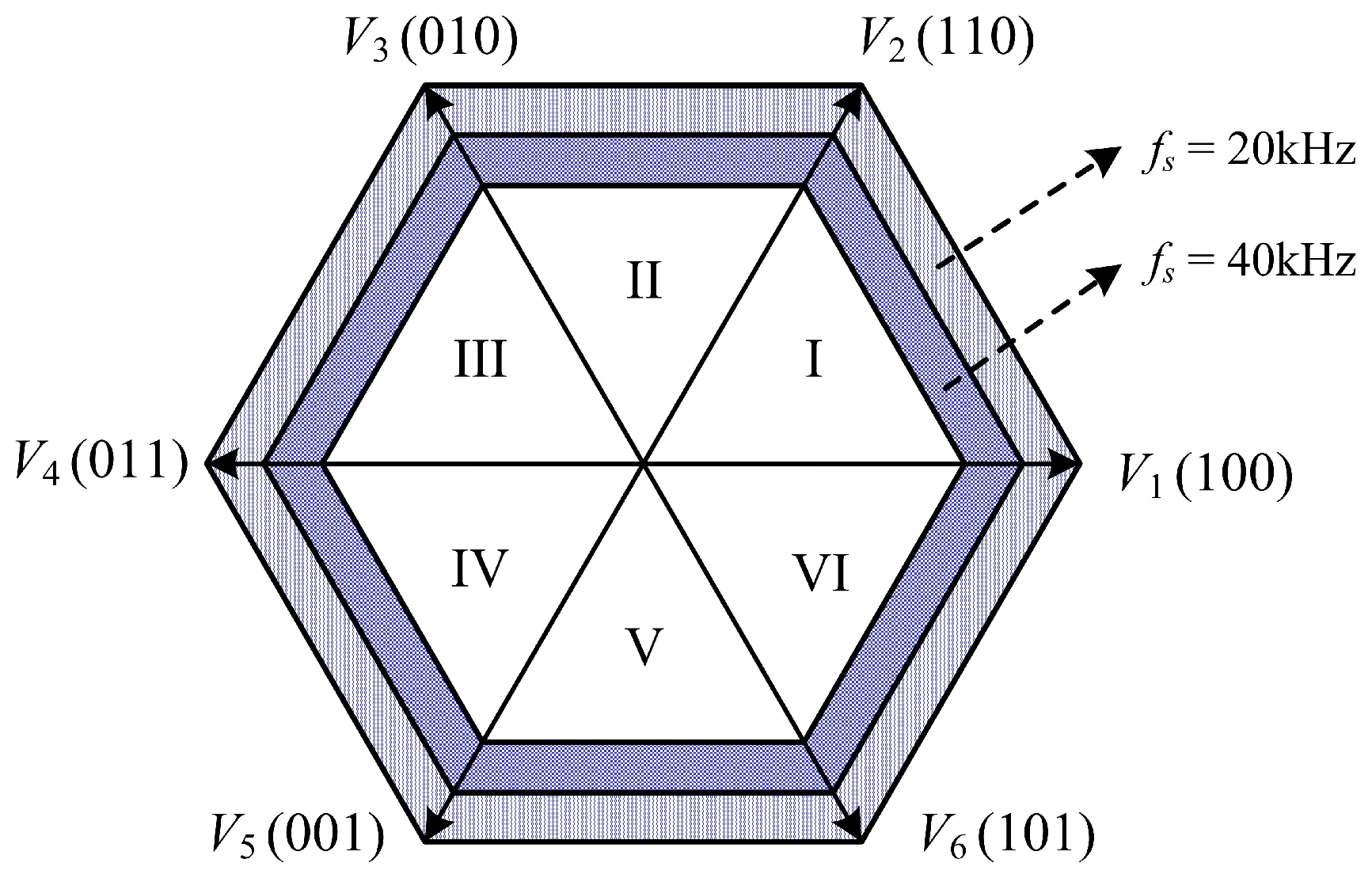

In recent years, PMSMs have been widely used owing to the merits such as high efficiency, high precision and high reliability. To reduce the volume and costs of the drive system, single current sensor techniques are used for PMSM drives. Among most of the single current sensor techniques, the single current sensor is used to sample the DC-link (direct current-link) current. As illustrated in

Figure 1, the steady-state relationships between the three-phase currents and the DC-link current for various switching states are analysed in [

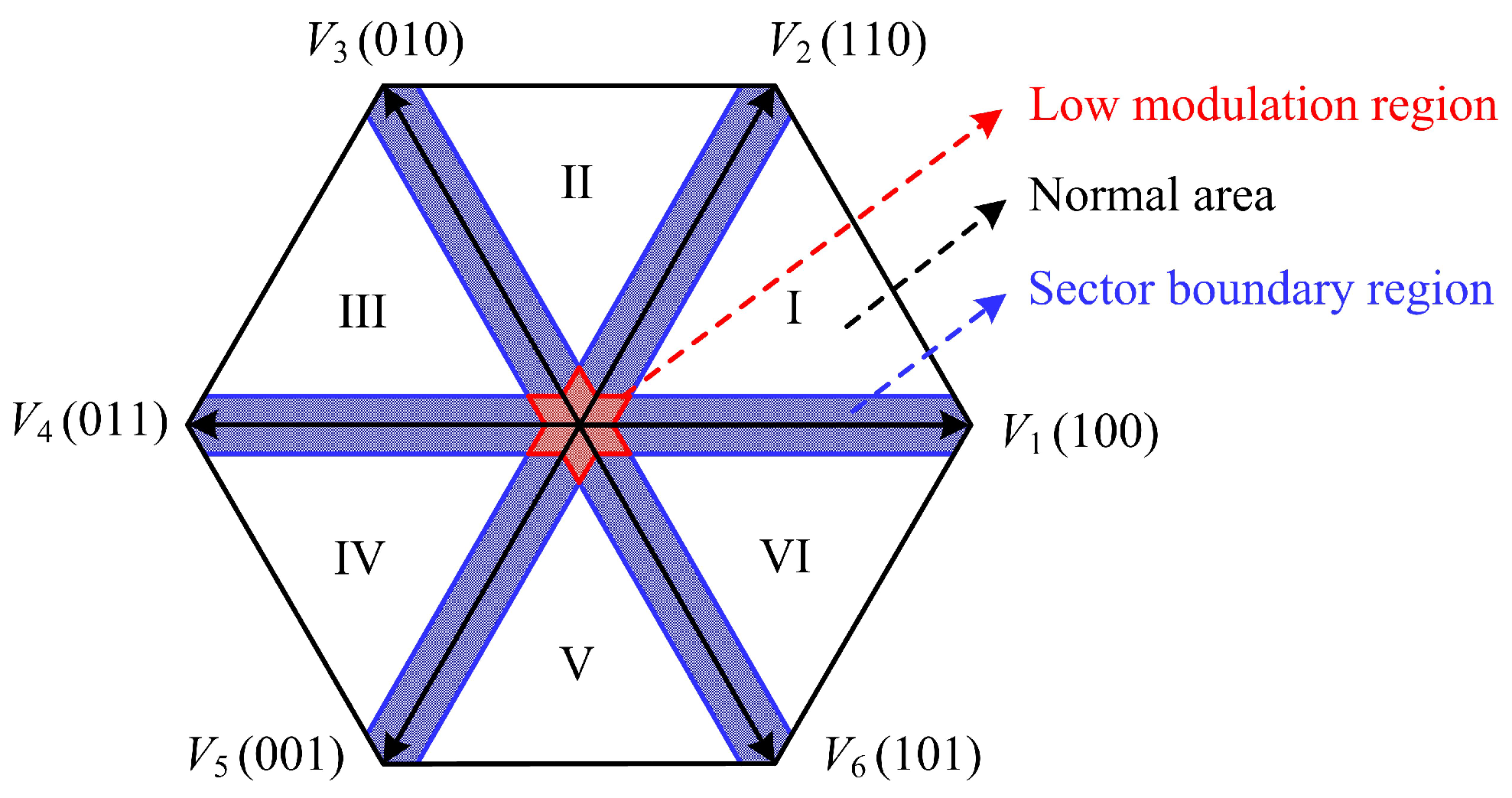

17]. However, dead zones are caused by using this method, and, in these dead zones, the steady-state conditions can not be satisfied. Ref. [

18] researches the dead zones, as shown in

Figure 2, and it can be seen that the dead zones are located in low modulation regions and space-vector sector boundary regions. A lot of compensation methods are proposed to deal with the current reconstruction dead zones, which are based on the measurement vector insertion method, modifying PWM modulation strategy, and the phase shifting method.

In [

19,

20], the modified PWM modulation strategies for reconstructing the three-phase currents using the single DC-link current are given. A new modulation strategy that can reduce the current distortion and enlarge the current reconstruction range for a three-phase inverter using only a DC-link sensor is also proposed in [

21]. It is a hybrid method that consists of the space vector modulation method and the PWM method without using zero voltage vectors. In [

22,

23], the three-phase currents are reconstructed by using the state observer algorithms. Moreover, in [

24,

25], a novel phase current reconstruction technology is used in the switched reluctance motor (SRM) drive and sensorless control. The single current sensor is also used to reconstruct the phase currents in direct matrix converters (DMC) [

26,

27]. There are nine power switches in the DMC, which increase the cost and volume compared with the three-phase pulse width modulation voltage source inverter.

Furthermore, in [

28], the measurement vector insertion method (MVIM) is used to reconstruct the three-phase currents using a single current sensor. The switching state phase shift method is proposed to reduce the dead zones in [

29]. An approach for predicting phase currents in vector-controlled inverters is reported in [

30]. Some other methods, like the over-modulation, tri-state PWM and Luenberger observers are all applied in the single current sensor techniques [

31,

32,

33]. In these methods, the single current sensor are installed on the DC-link and the PWM signals should be modified to enlarge the working regions.

After analyzing the existing single DC-link current sensor methods, the current reconstruction dead zones can be further optimised and the working region of power converters can be improved. Taking these factors into consideration, a method named zero voltage vector sampling method (ZVVSM) is proposed in [

34]. The single hall-effect current sensor is installed in a new position to sample the sum currents of two current flow paths.

Based on the ZVVSM, this paper proposes an extended single current sensor technique used in the three-phase PMSM drive due to the fact that the installation position of the single current sensor in [

34] is not a unique way to realize the phase current reconstruction. This paper extends this method by changing the installation position of the single current sensor and sampling the current during the zero voltage vectors. The structure of this paper is organized as follows. First, in

Section 2, the sampling analysis of the current paths between each two power switches are introduced. In addition, the six kinds of current sensor installation positions that can reconstruct the three-phase currents are listed. Then, the proposed phase current approach and dead zone analysis are introduced in

Section 3. The closed loop control system based on the proposed method and the experimental platform are established in

Section 4.

Section 5 presents the experimental results for further validation. Finally,

Section 6 gives the conclusions.

2. Sampling Analysis and Installation Position of the Single Current Sensor for Three-Phase Current Reconstruction

Figure 3 shows the schematic diagram of the conventional three-phase PMSM drive system using the PWM-VSI (Pulse Width Modulation-Voltage Source Inverter). In general, the PMSM is controlled by a PWM-VSI that includes six power switches and six freewheeling diodes. The power switches have eight combinations that form two zero voltage vectors and six active voltage vectors across its terminals. Usually, the eight generated switching states can be denoted as the voltage space vector

,

, as illustrated in

Figure 2.

Since the SVPWM algorithms are implemented by a combination of different voltage vectors, the currents between each two power switches change with the switching states. In

Figure 3, the current paths between each two power switches are labeled with circled numbers (①, ②, . . . , ⑦) for further analysis. First of all, the proposed phase current reconstruction method in this paper is available when the currents are sampled during the ZVVs. The sampling currents of the seven current paths during the two zero voltage vectors

(000) and

(111) are shown in

Table 1.

From

Table 1, it can be concluded that the currents of these seven paths vary with the switching states. Moreover, all of these currents will turn to zero during one of these two zero voltage vectors. If the hall-effect current sensor is adopted to sample the sum currents of some two of the seven currents, two phase currents can be obtained in a PWM period and the three-phase currents can be reconstructed. Nevertheless, not all the sum currents can be used to reconstruct the phase current, there are some principles. First, the two current paths sampled should not be on the upper or lower side of the three-phase PWM-VSI at the same time. For example, ① and ② should not be sampled together because the sum currents are always zero during

and the three-phase currents cannot be reconstructed. Similarly, ③ and ④ are both on the lower side of the PWM-VSI and the sum currents are always zero during

. The other principle is that the two sampling results during the zero voltage vectors should not be the same phase current. For example, if ① and ⑤ are sampled together, the two sampling results are both

and three-phase currents cannot be reconstructed. Taking these limitations into consideration, there are six combinations that can realize the three-phase current reconstruction, ① + ④, ② + ③, ① + ⑥, ① + ⑦, ② + ⑤, and ② + ⑥. In this paper, the single current sensor samples the sum currents of paths ② and ⑤ as examples and the proposed method is explained in the following section.

3. Proposed Phase Current Reconstruction Approach

Different from the previous methods, this paper proposes a phase current reconstruction method for a three-phase PMSM drive which uses the current paths between each two power switches and samples the sum currents. In addition, the proposed method is implemented by changing the installation position of the single current sensor and sampling its output during the two zero voltage vectors.

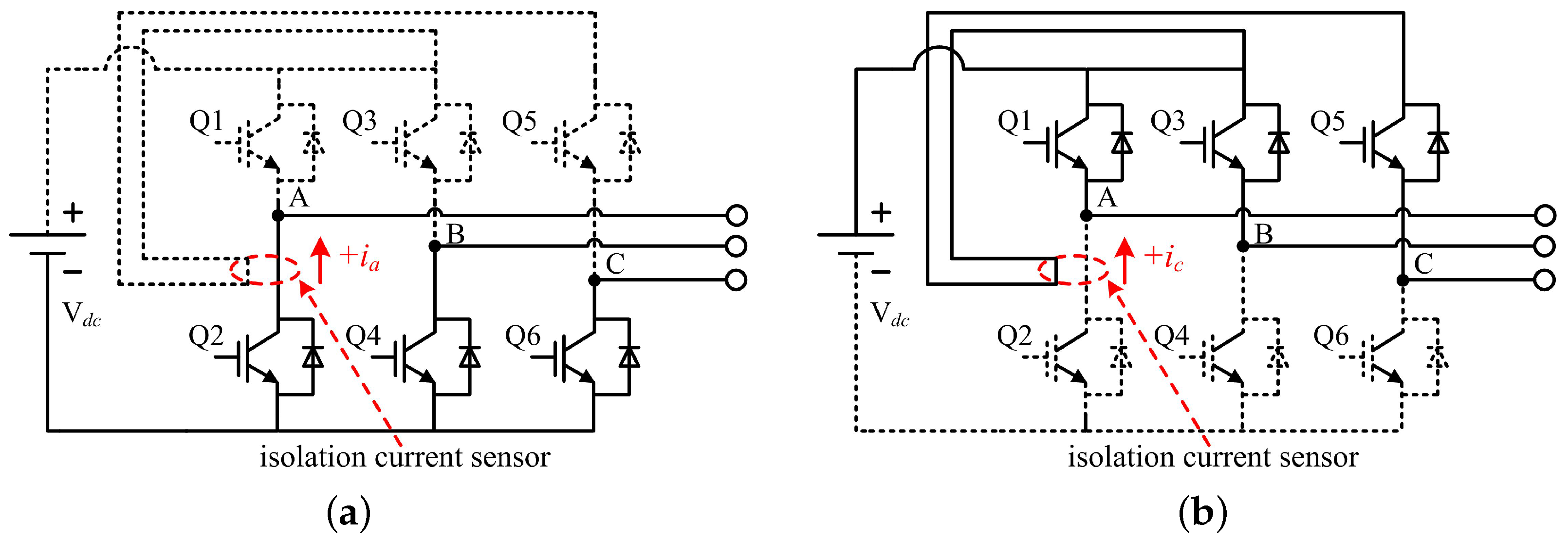

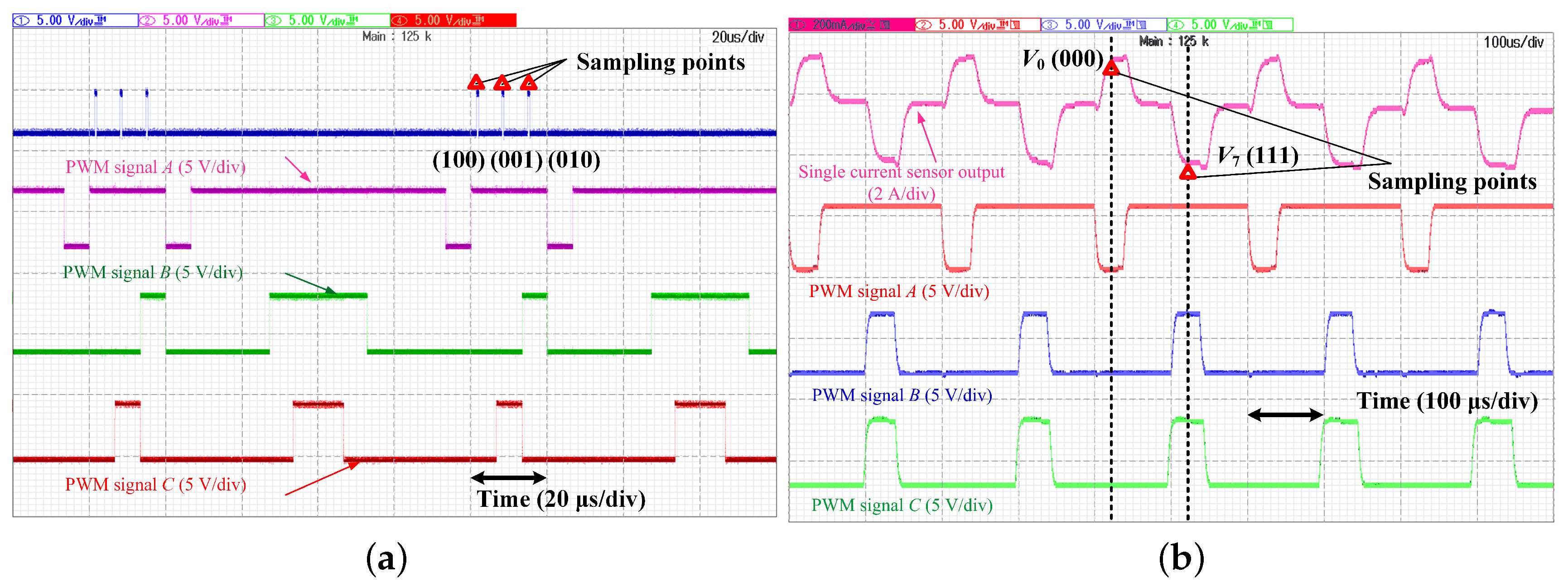

The circuit topology and the sampling points of the proposed method are shown in

Figure 4. In this paper, only the circuit topology that samples the sum currents of paths ② and ⑤ is analysed as an example. The isolated hall-effect current sensor is installed to detect the sum current flowing between two power switches. Moreover, as

Figure 4b illustrates, the current sensor output can be sampled at the zero voltage vectors.

3.1. Basic Working Principle of the Proposed Method

In this proposed method, the three-phase currents can be reconstructed by sampling the output of the single current sensor during the two zero voltage vectors. For further analysis, taking the voltage vector in the space vector hexagon, for example, in a PWM period, there are two zero voltage vectors (000) and (111). Moreover, the positive sign (+) represents the inflow of the three-phase currents and the negative sign (-) represents the outflow of the three-phase currents.

Figure 5a illustrates the current flow path when the output voltage vector is

(000). The load current of the power converter freewheels through the lower switches, and the current sensor is sampled as

where

is the sample result of the current sensor. Then,

Figure 5b shows the current flow path when the output voltage vector is

(111). Different from the above switching state, the current freewheels through the upper switches and the load. Then, the sample result of the current sensor is

Therefore, the phase currents

and

can be obtained if the single hall-effect current sensor is sampled during the two zero voltage vectors

(000) and

(111). Since the three-phase load are usually Y-connected and the phase currents meet the following Equation (

3), the phase current of phase B

can be also calculated. As a result, the three-phase currents can be reconstructed during a PWM period:

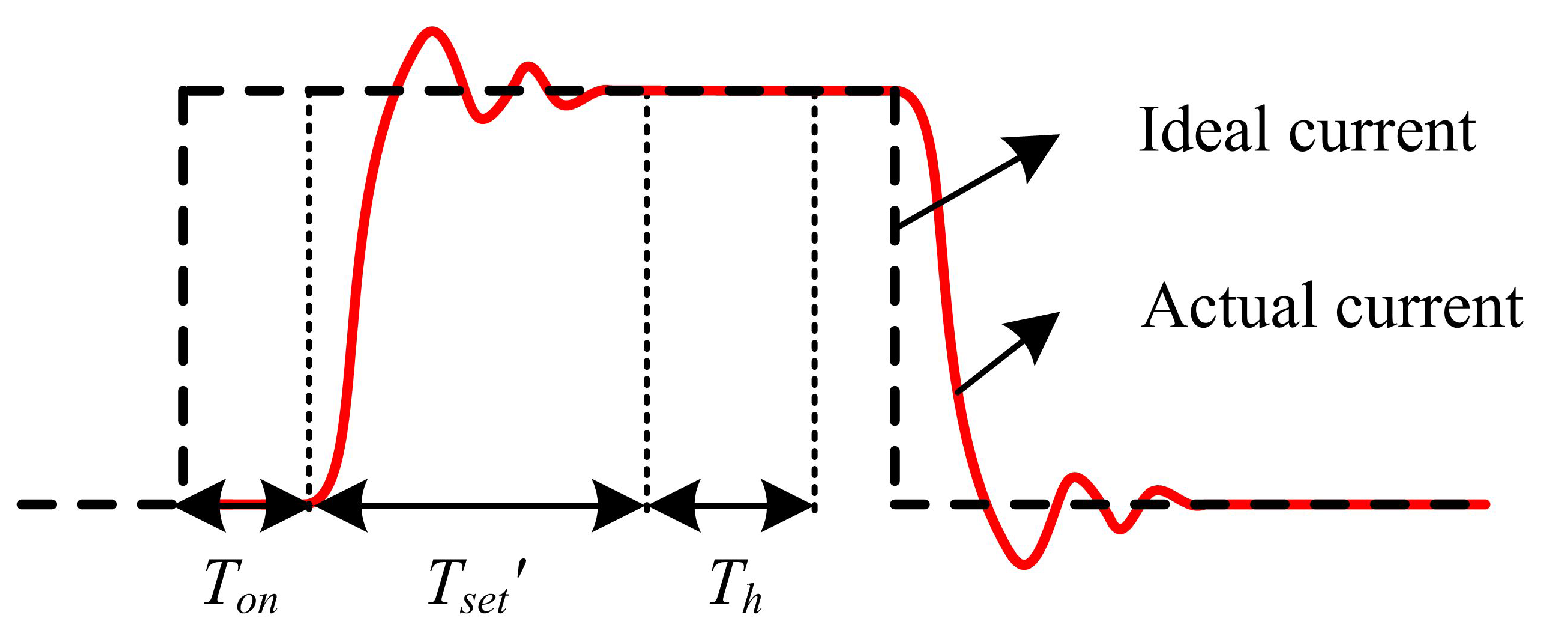

3.2. Minimum Sample Time

In the actual situation of current sampling, illustrated in

Figure 6, the current cannot follow the applied voltage immediately due to the motor inductance and there is some time delay, denoted as

, to reach the steady-state. Furthermore, the A/D converter in the digital signal processor (DSP) needs extra conversion time to hold the results after reaching the steady-state, denoted as

. In addition, the total switching device turn-on delay time and the dead zone time between the two switching devices in one bridge leg for protection should be considered as well, which are denoted as

and

, respectively. Furthermore, the dc link line is increased by using the novel method, and the stray inductance of the prolonged wire can influence the signal settling time. Hence, the signal settling time is changed from

to

after considering the increased dc link line. However, in the actual power circuits, this dc link line is not increased so much as

Figure 4a shows, and the effect of the proposed topology on the current sampling can be acceptable.

Based on these factors, a minimum duration of the voltage vectors is required for precise sampling. This minimum duration time, denoted as

, should meet the following inequality:

3.3. Dead Zone Analysis

Like other phase current reconstruction methods, there are also current reconstruction dead zones in the proposed method. The zero voltage vectors must be held long enough for reliable current sampling. Since the duration of zero voltage vectors will decrease with the amplitude of voltage vector increasing, the current cannot be sampled accurately when the amplitude of voltage vector is too large. As a result, the current reconstruction dead zone will be formed, which is illustrated in

Figure 7 and marked with the shaded area.

To further analyse the current reconstruction dead zones, a proportionality coefficient,

μ, is introduced. It is the ratio of active voltage vector duration to the PWM period, expressed as (

5):

In the conventional Space Vector PWM algorithm, the duration of zero voltage vector

is equally distributed to the switching states (000) and (111). Since there is a limitation of minimum sample time

for the two zero voltage vectors duration discussed above, the interval of zero voltage vector should meet the inequality

By substitution of the inequality into (

5), the maximum active voltage vector proportionality coefficient,

, can be calculated as (

7):

Then, the maximum voltage vectors output of the proposed phase current reconstruction method is

It can be seen that the proportionality coefficient,

, decreases with the PWM frequency

or the minimum sample time

increasing. In general, the minimum sample time

is a constant, so the maximum active voltage vector proportionality coefficient

, as well as the effective operation zones of the voltage vector, will decrease with the PWM frequency increasing. As shown in

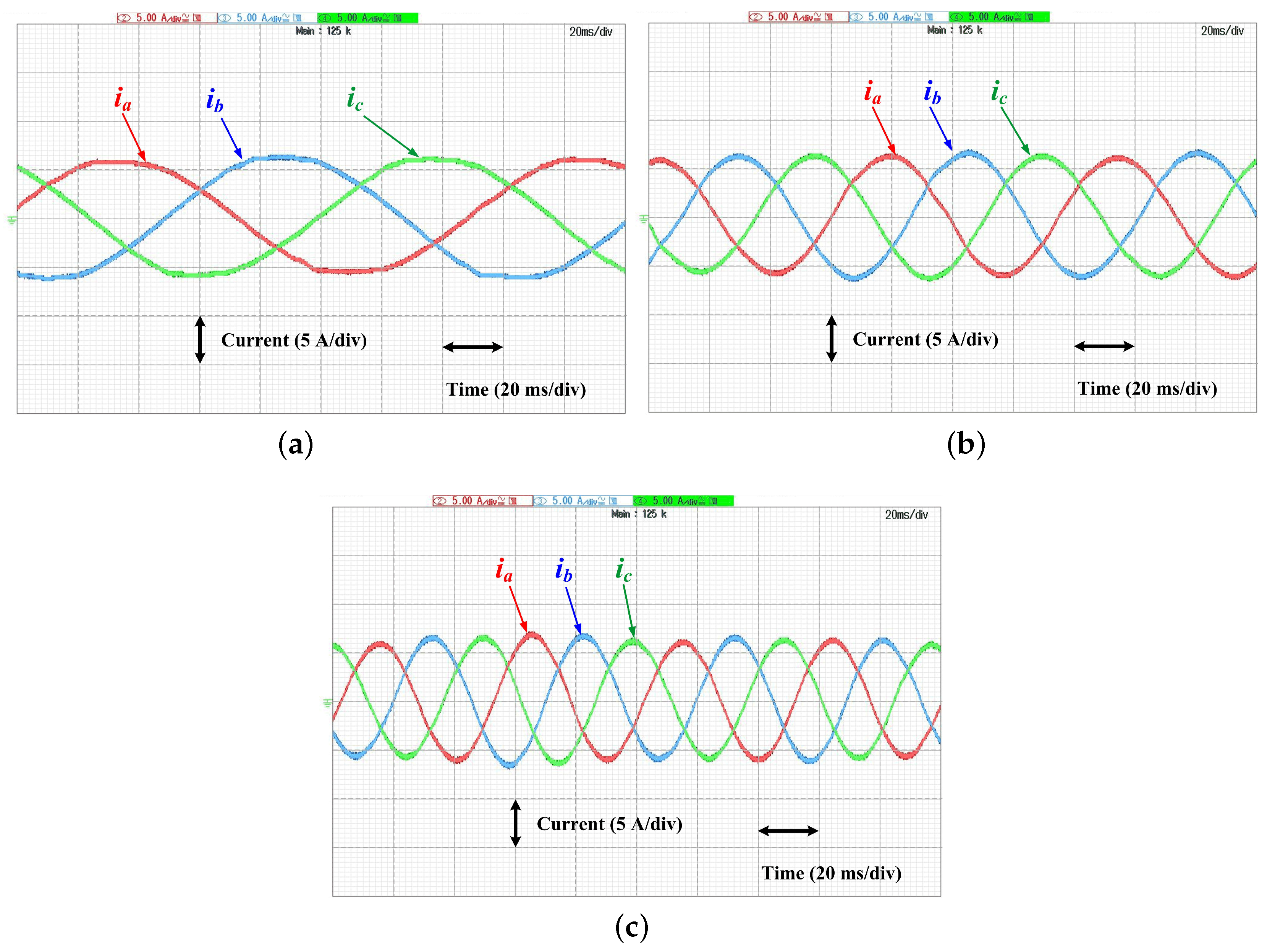

Figure 7, the effective operation zones shrink inward with the PWM frequency increasing. The shadow zones indicate the dead zones of the proposed phase current reconstruction approach at different frequencies. However, there is a limitation that the switching frequency or the ratio between the switching and modulation frequencies can not be too low. If the switching frequency of the SVPWM is too low, as 200 Hz, the three-phase currents and the single current sensor output will change too much in a PWM period. Consequently, if the phase currents would greatly change during half of the PWM period, the two samples will not represent the same state and the sampling errors will become large. Furthermore, low switching frequency will also cause the distortion of the phase currents, which can affect the drive performances of the system. Therefore, the switching frequency should be set at several kHz for the proposed phase current reconstruction method.

In addition, compared with the method using the single DC-link current sensor, the proposed method can drive the three-phase PMSM effectively in the low modulation region and sector boundary region. Hence, some complicated compensation algorithms used to narrow the dead zones are not needed.

4. Experimental Setup

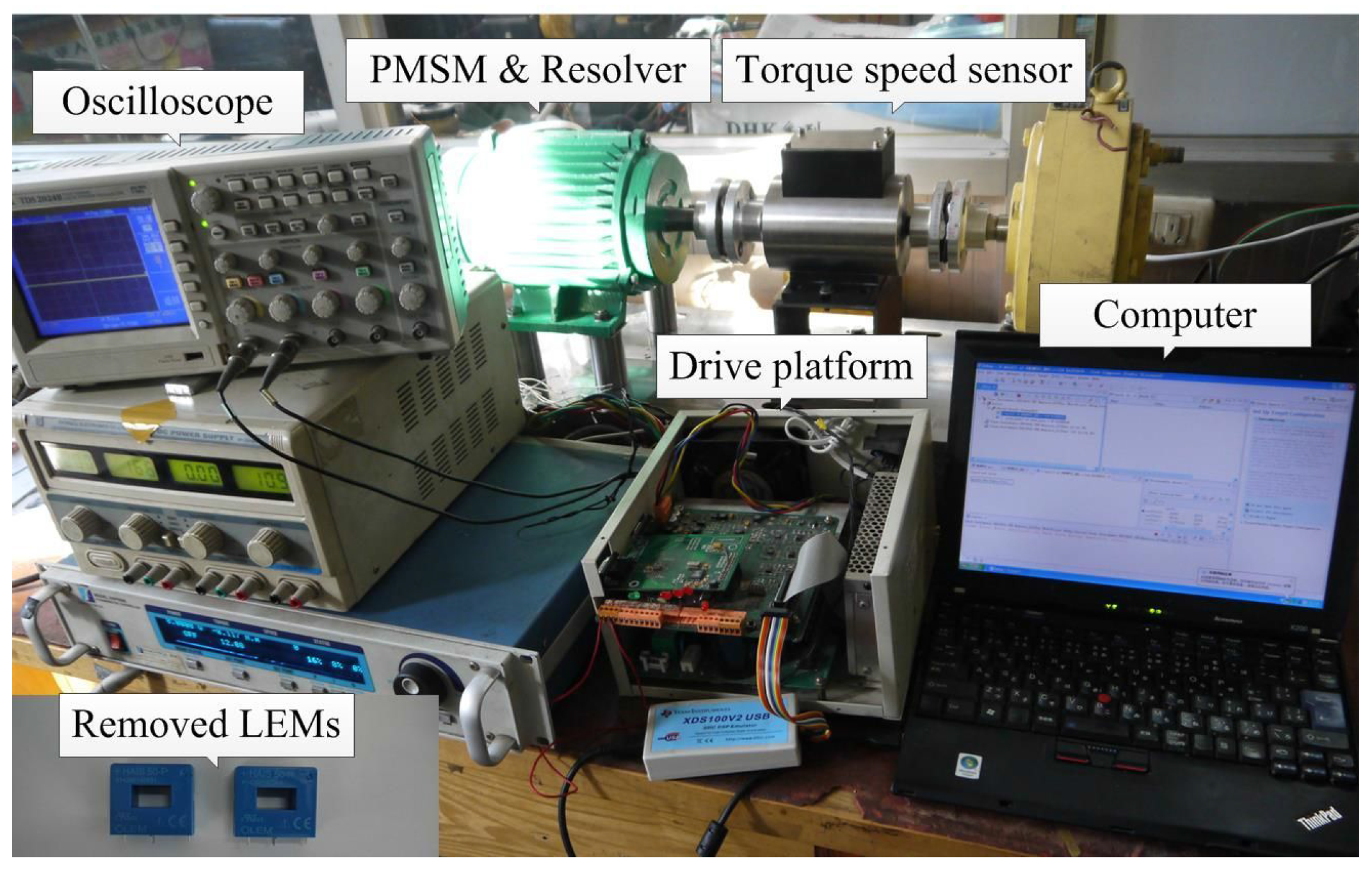

To verify the proposed phase current reconstruction method for motor drive, an experiment platform is established, whose scheme and photograph are shown in

Figure 8 and

Figure 9, respectively. In the experimental setup, a PMSM with a resolver is selected as the three-phase load. In addition, a PWM-VSI, a drive platform and a dc source are included. The PWM-VSI has a 3 kVA nominal power, a 5 kHz switching frequency of the IGBTs (Insulated Gate Bipolar Transistor) and an 80 V DC-link voltage. In the drive platform, a DSP (Digital Signal Processor) (TMS320F2812) (Texas Instruments Incorporated, Dallas, Texas, USA) is used as the control unit to generate the three-phase PWM signals, sampling signals and implement the proposed phase current reconstruction method. In the experiments, the minimum sample time

is set as 5

s. Moreover, motor parameters are reported in

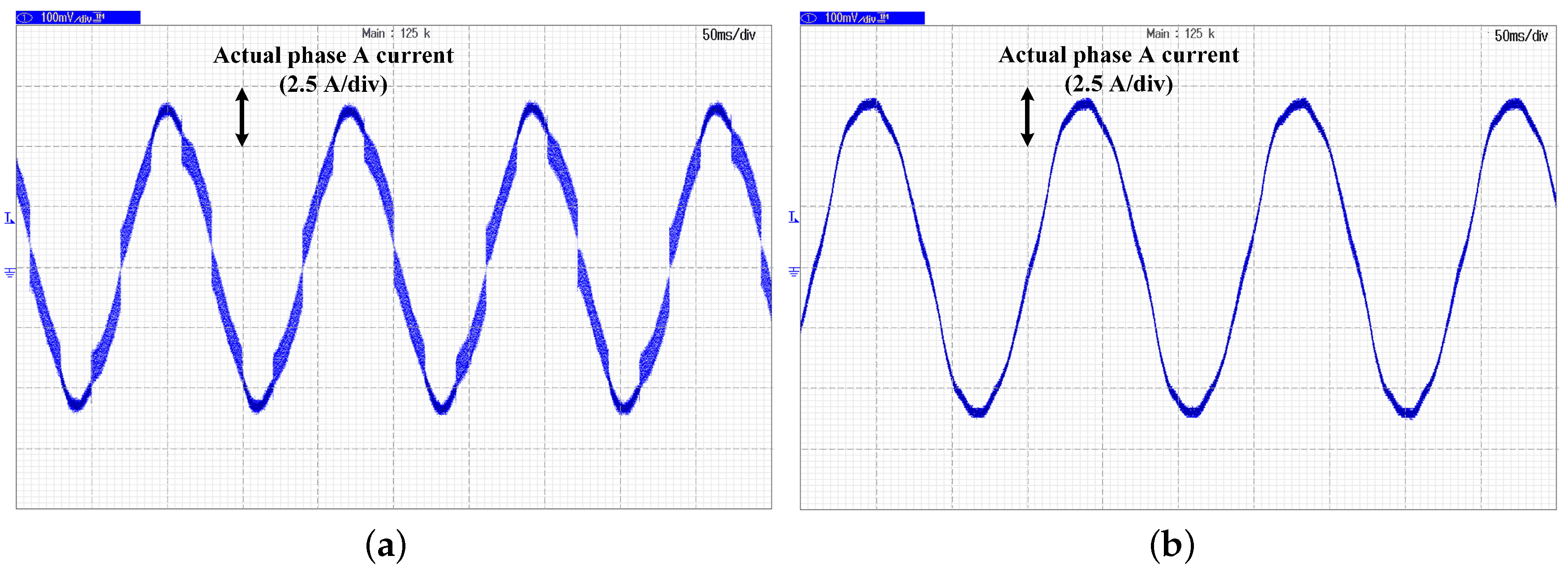

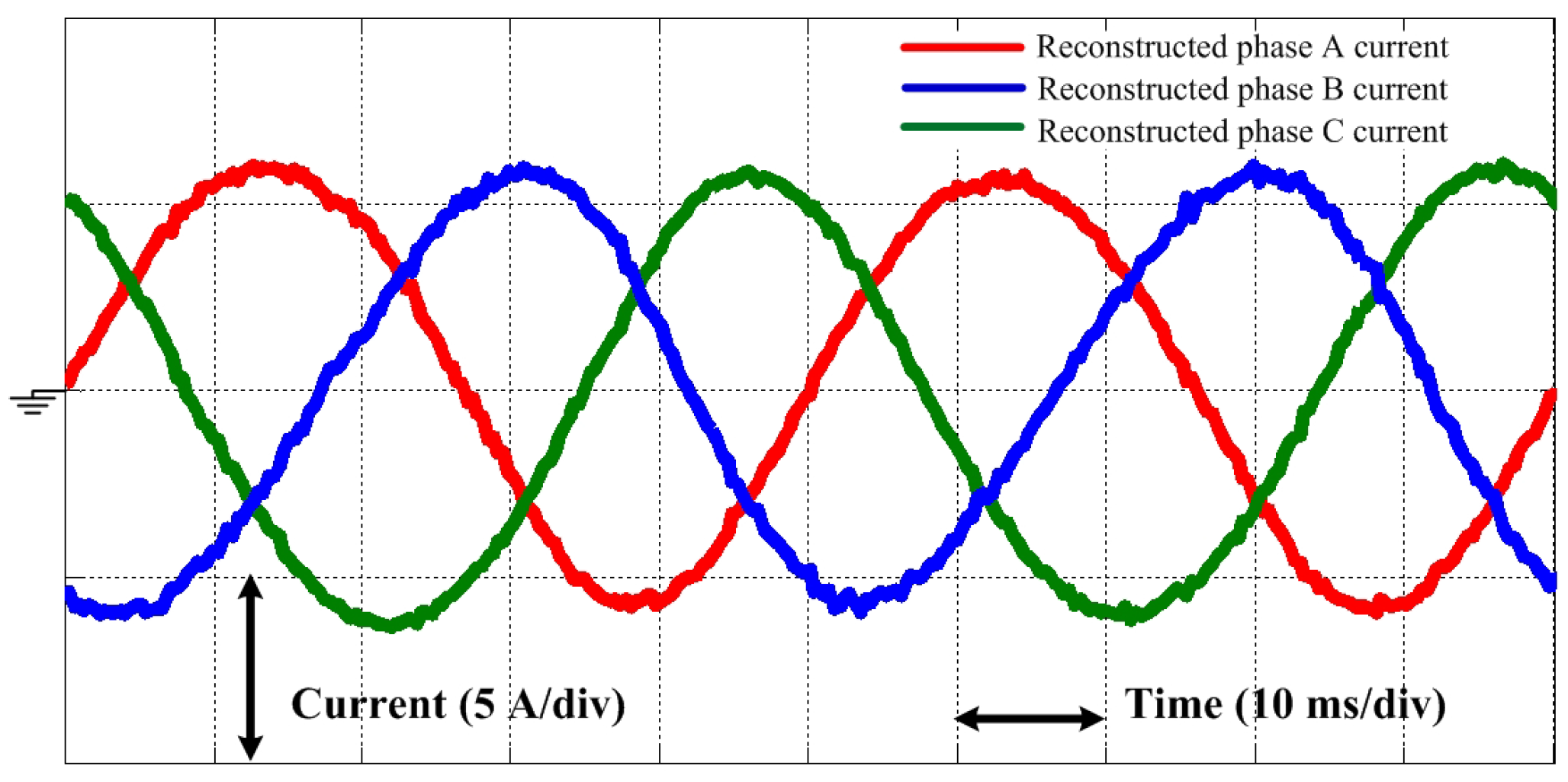

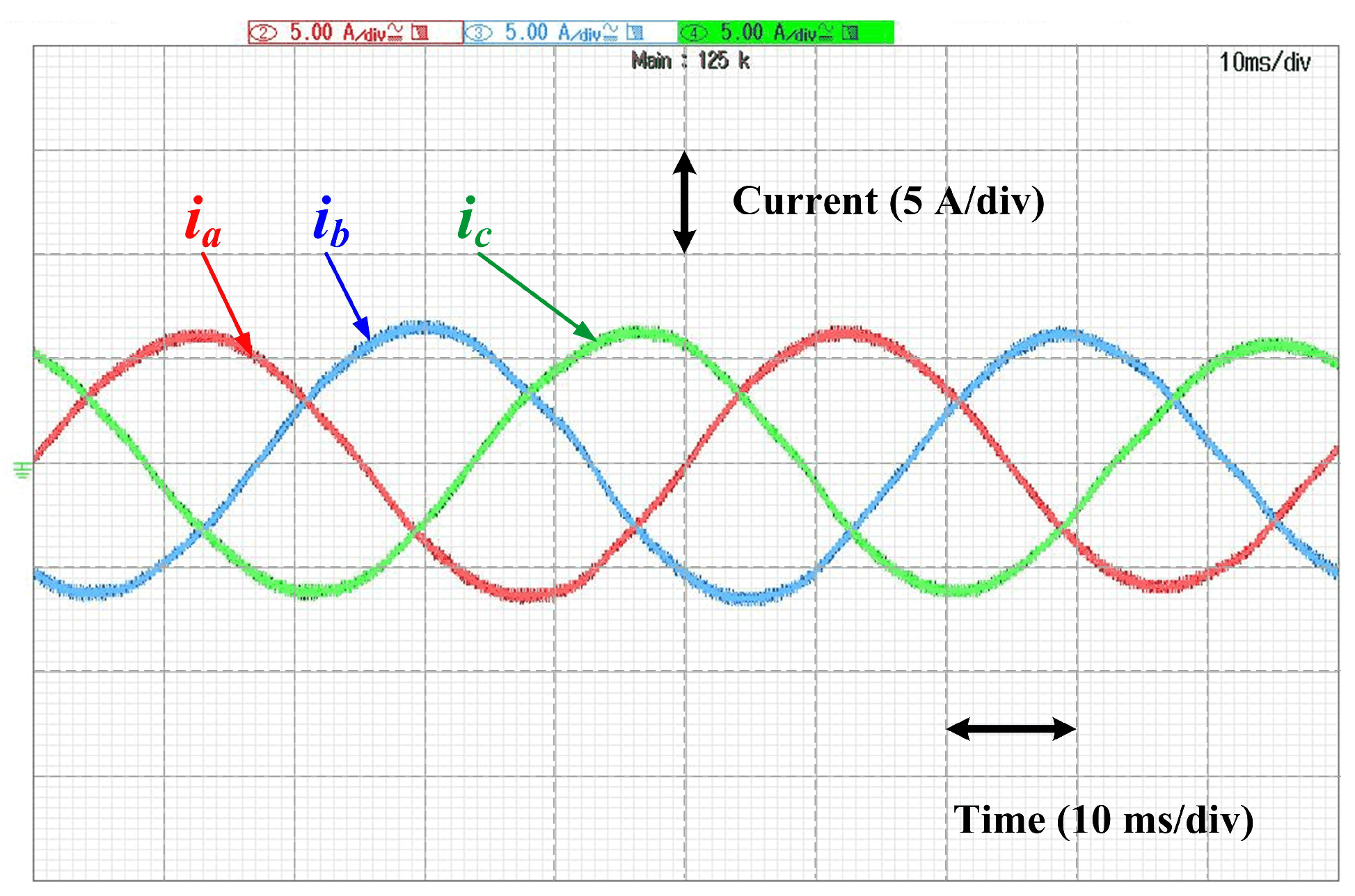

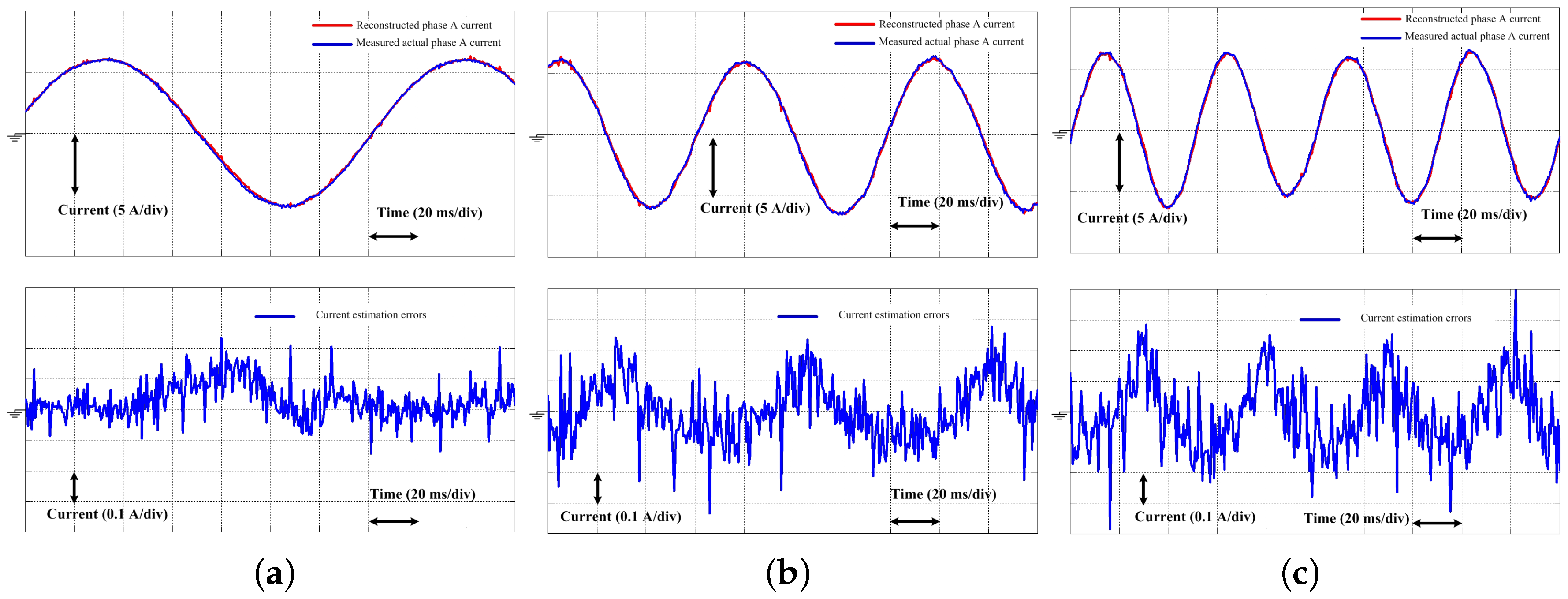

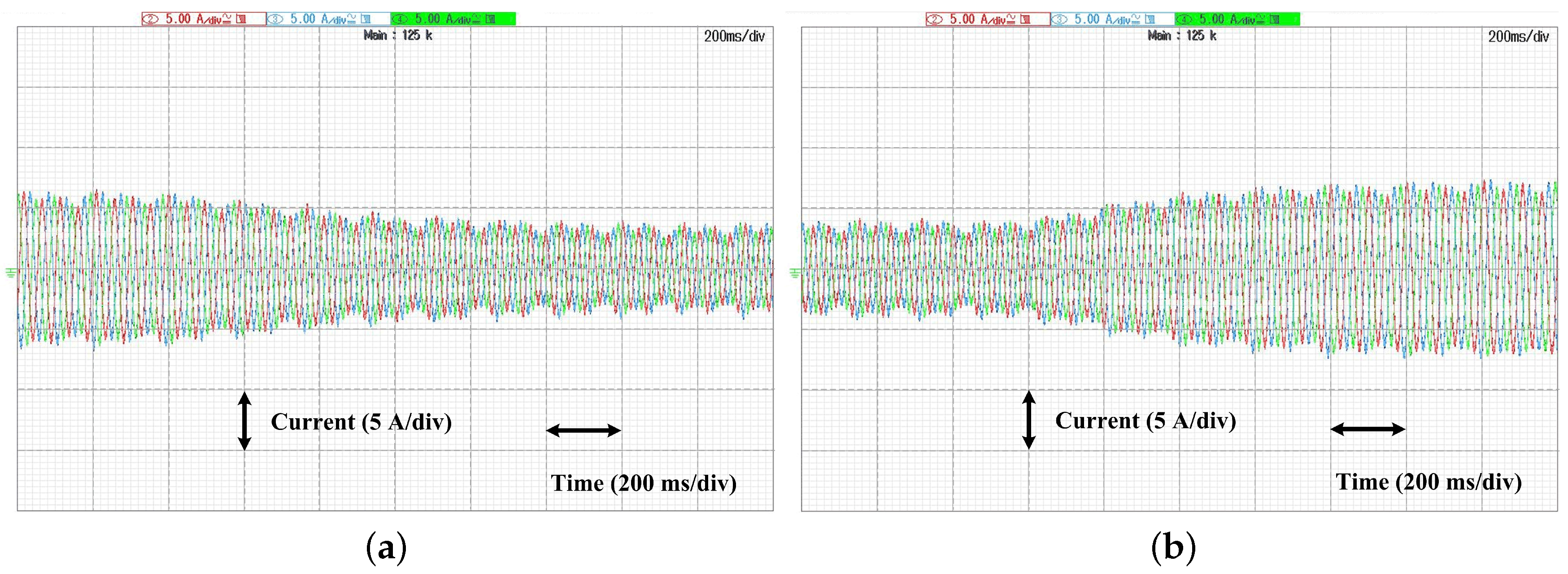

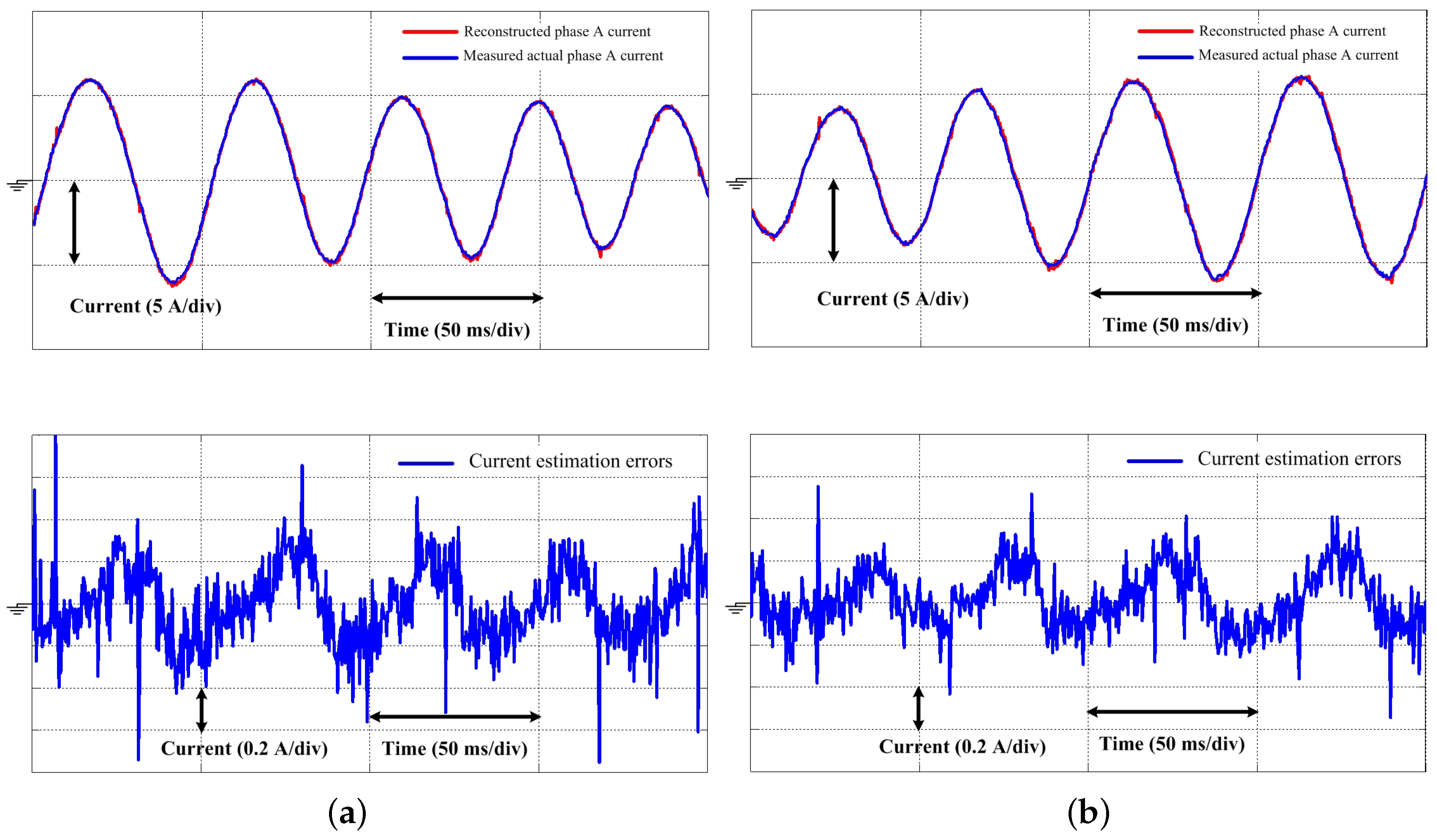

Table 2. Furthermore, in order to sample the current accurately, an isolated hall-effect current sensor (LEM HAIS-50P) (LEM Incorporated, Geneva, Switzerland)with a maximum sample rate 50 kHz is employed. In the drive platform, two current sensors are used. By changing the installation position of the DC-link current sensor to the proposed position in this paper, one current sensor is used to implement the proposed method. The other current sensor is the phase A current sensor and is used for comparison and calculating the estimation errors of the proposed phase current reconstruction method. To avoid the influence of high frequency noises in A/D on the sampling results and the reconstructed three-phase current, a small filter capacitor is connected in parallel to the output of the current sensor. Moreover, the signal processing circuit constructed by the amplifier is adopted to further improve the reconstruction phase current waveform quality. Finally, in the software of the whole drive system, when the current sampling interrupt occurs, the current signals will be cyclical sampled four times by the A/D module of DSP. Then, the four times of sampling results will be averaged, which can further improve the accuracy of the results.

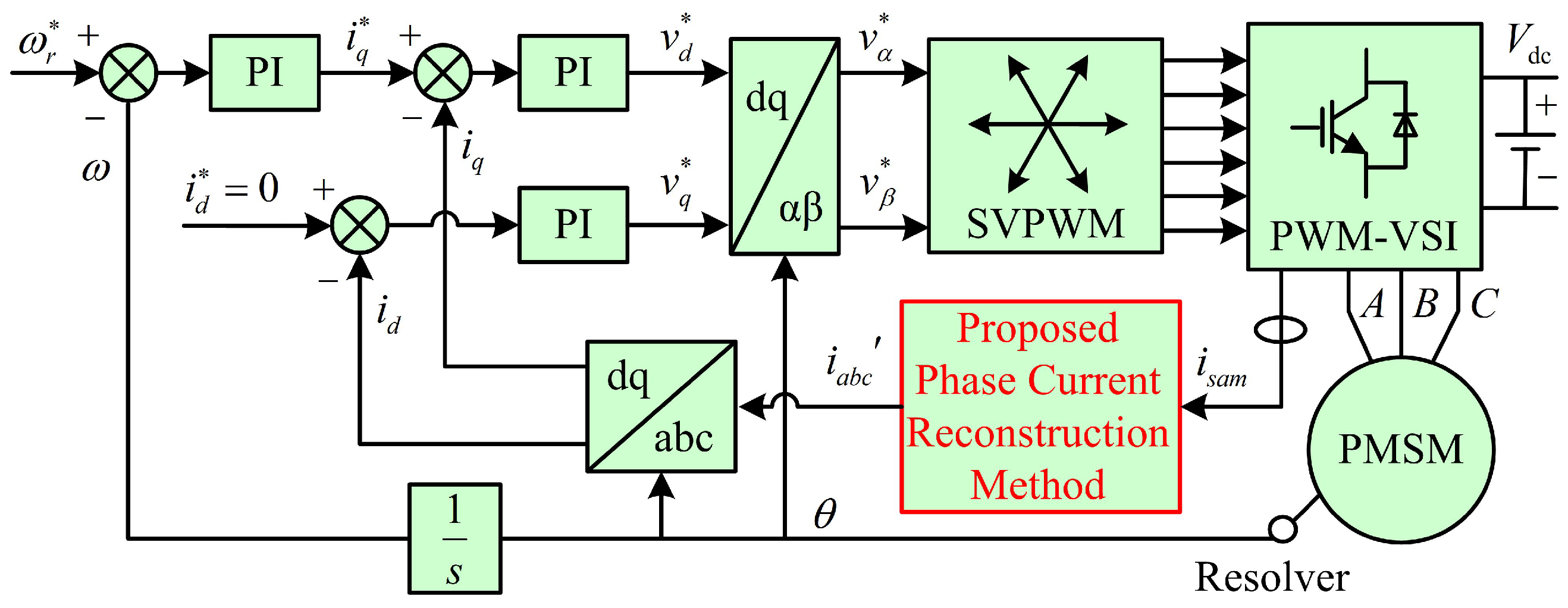

Figure 10 shows the PMSM control strategy based on the proposed phase current reconstruction method. In the control strategy, the PMSM is controlled by a speed and current double closed loop. The outputs of single current sensor are sampled based on the proposed method and the three-phase currents are reconstructed. Then, the reconstructed three-phase currents are transformed to the d–q (direct axis-quadrature axis) synchronous rotating frame,

and

, which are the feedback current signals of the current loops. Other algorithms in this control strategy are identical to the conventional double close loop PMSM control strategy.

6. Conclusions

In this paper, a novel extended single current sensing technique is proposed for the three-phase PMSM drive, which can reconstruct the three-phase currents without modifying the PWM signal. Since the currents between each two power switches change with the switching states, by arranging the single current sensor at six novel positions and sampling their sum currents in two zero voltage vectors, the phase current can be reconstructed. In this method, the modulation mode of Space Vector PWM is not changed, and there are no dead zones in the sector boundary region and low modulation region. Therefore, lots of complicated compensation algorithms are avoided. Compared with previous single current sensor methods, the proposed method is easy to realize and other modification methods are not needed. Furthermore, it can reduce the cost and volume of the motor drive system. Although this proposed method increases the DC-link line, the influence is small and the phase current reconstruction results are still acceptable. The effectiveness of the proposed phase current reconstruction method for motor drive is validated by the different experiments. The proposed phase current reconstruction method is a suitable control strategy for low-cost and small-size three-phase PMSM drive systems, which can be used in electric energy conversion application.