Design and Experimental Analysis of an Exhaust Air Energy Recovery Wind Turbine Generator

Abstract

:1. Introduction

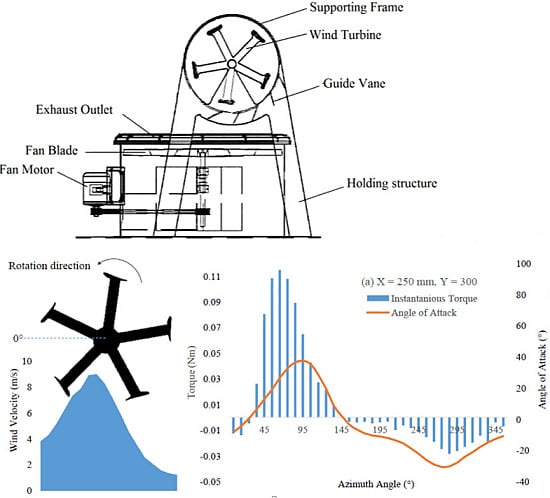

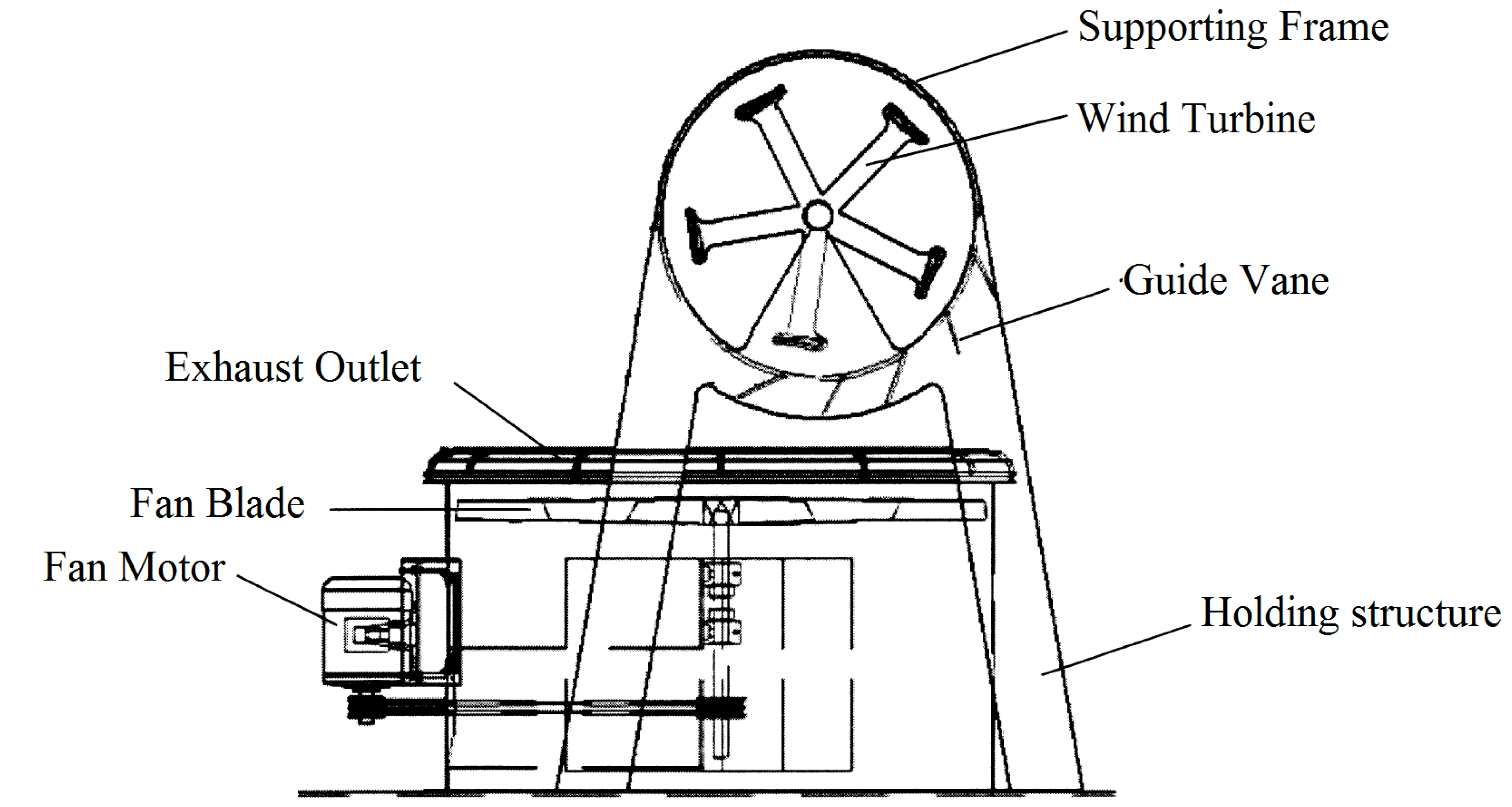

2. Design Description of the Novel Exhaust Air Energy Recovery Wind Turbine Generator

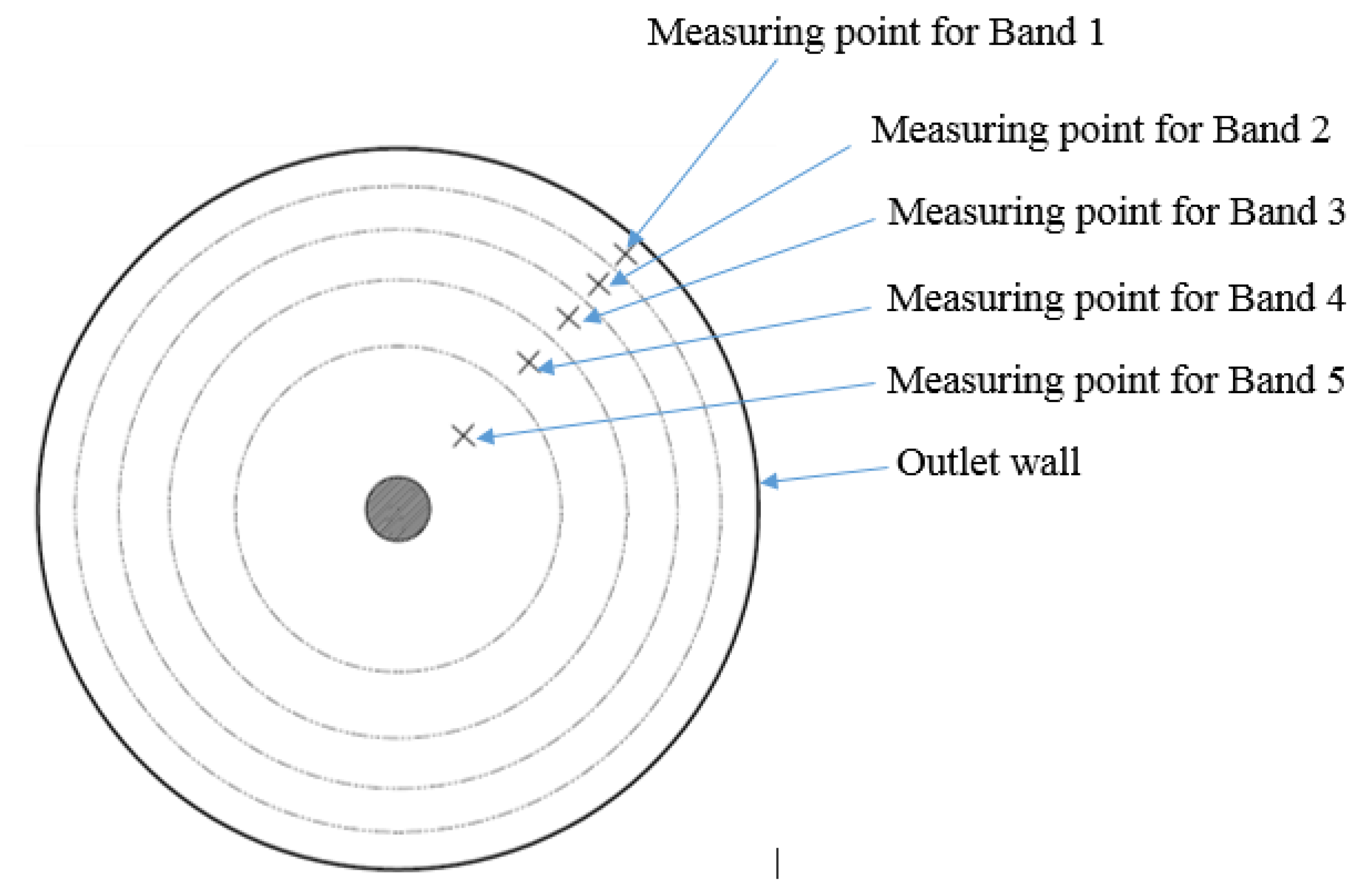

3. Methodology

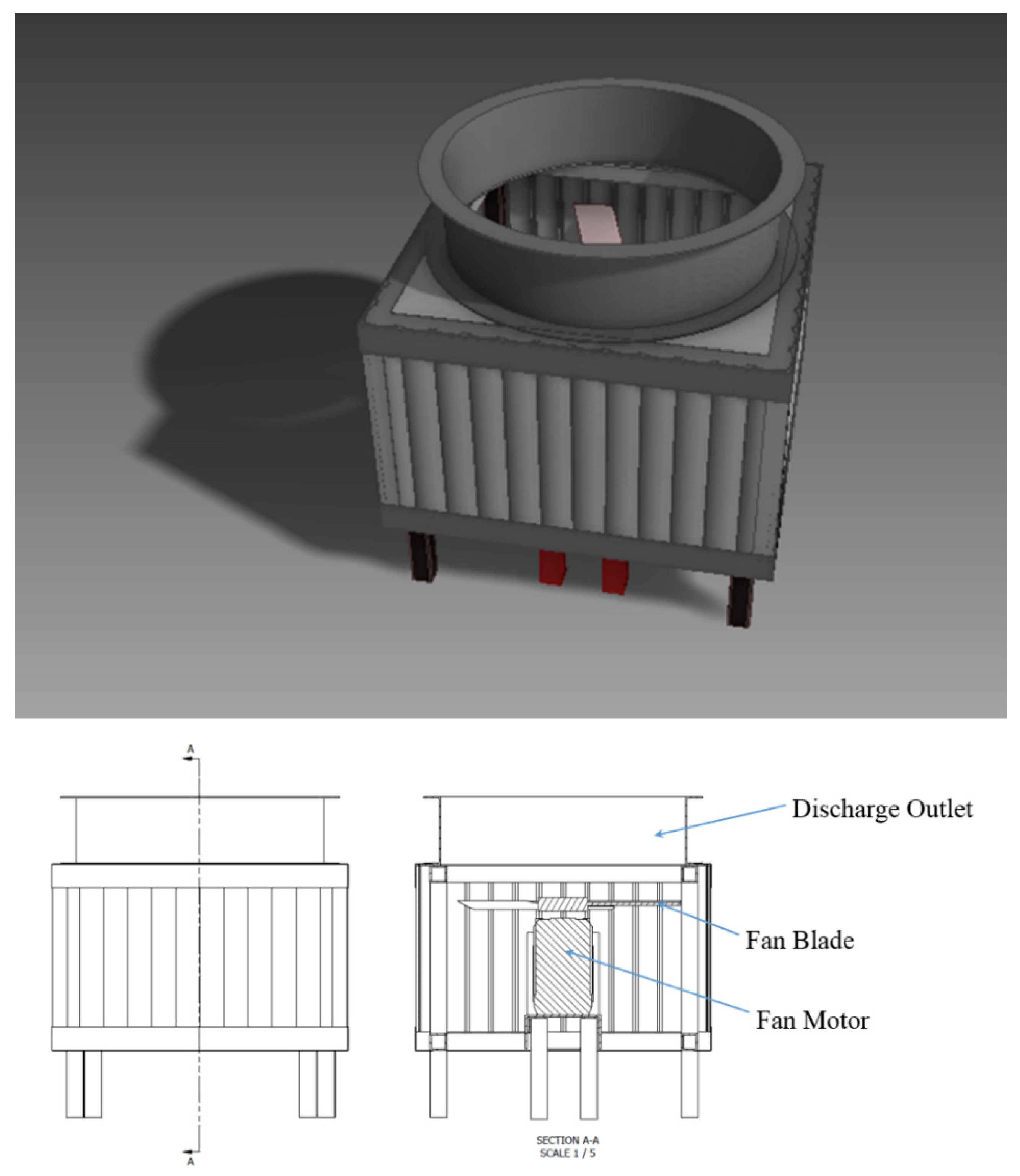

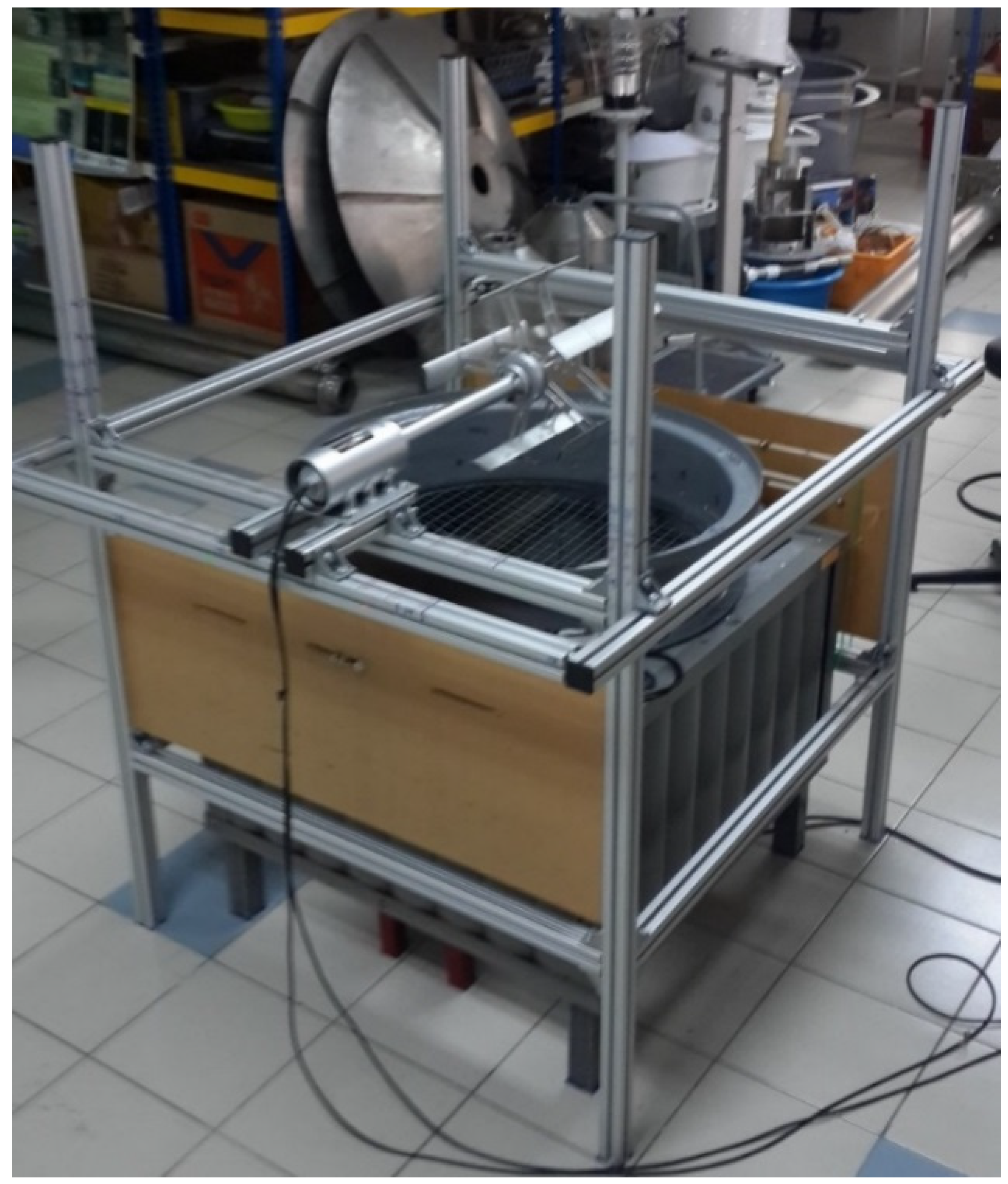

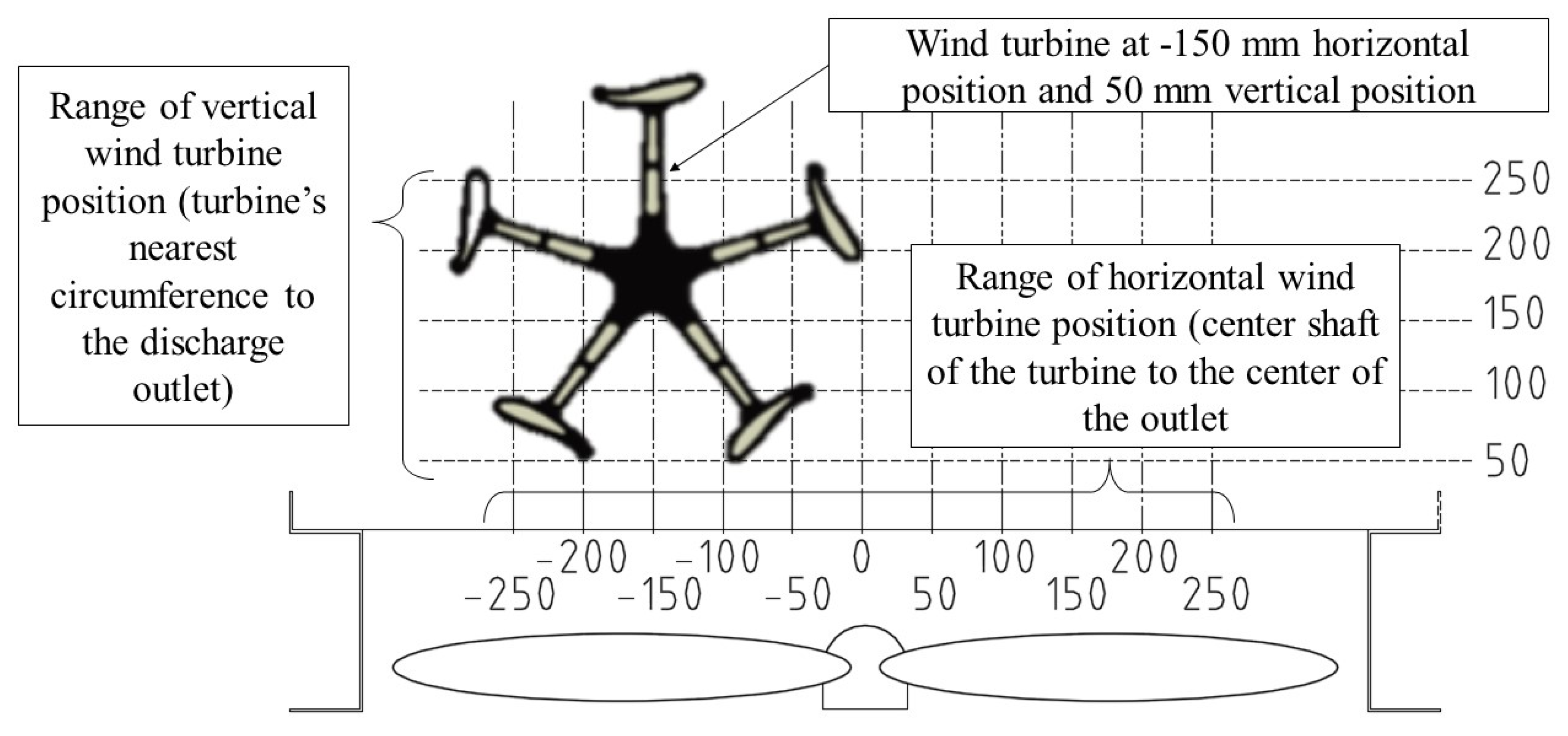

3.1. Experimental Setup

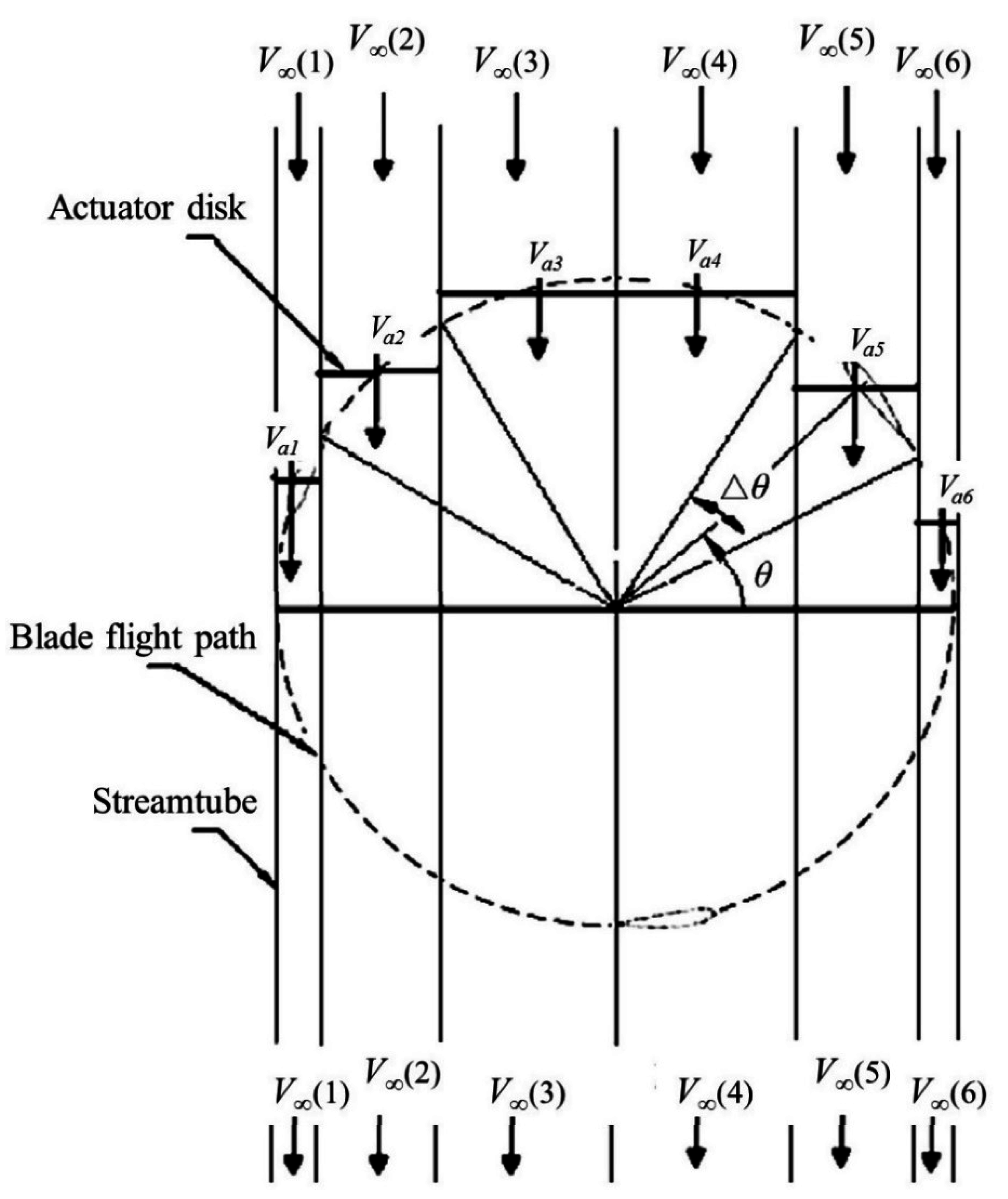

3.2. Double Multiple Stream Tube Theory

4. Results and Discussions

4.1. Velocity Profile

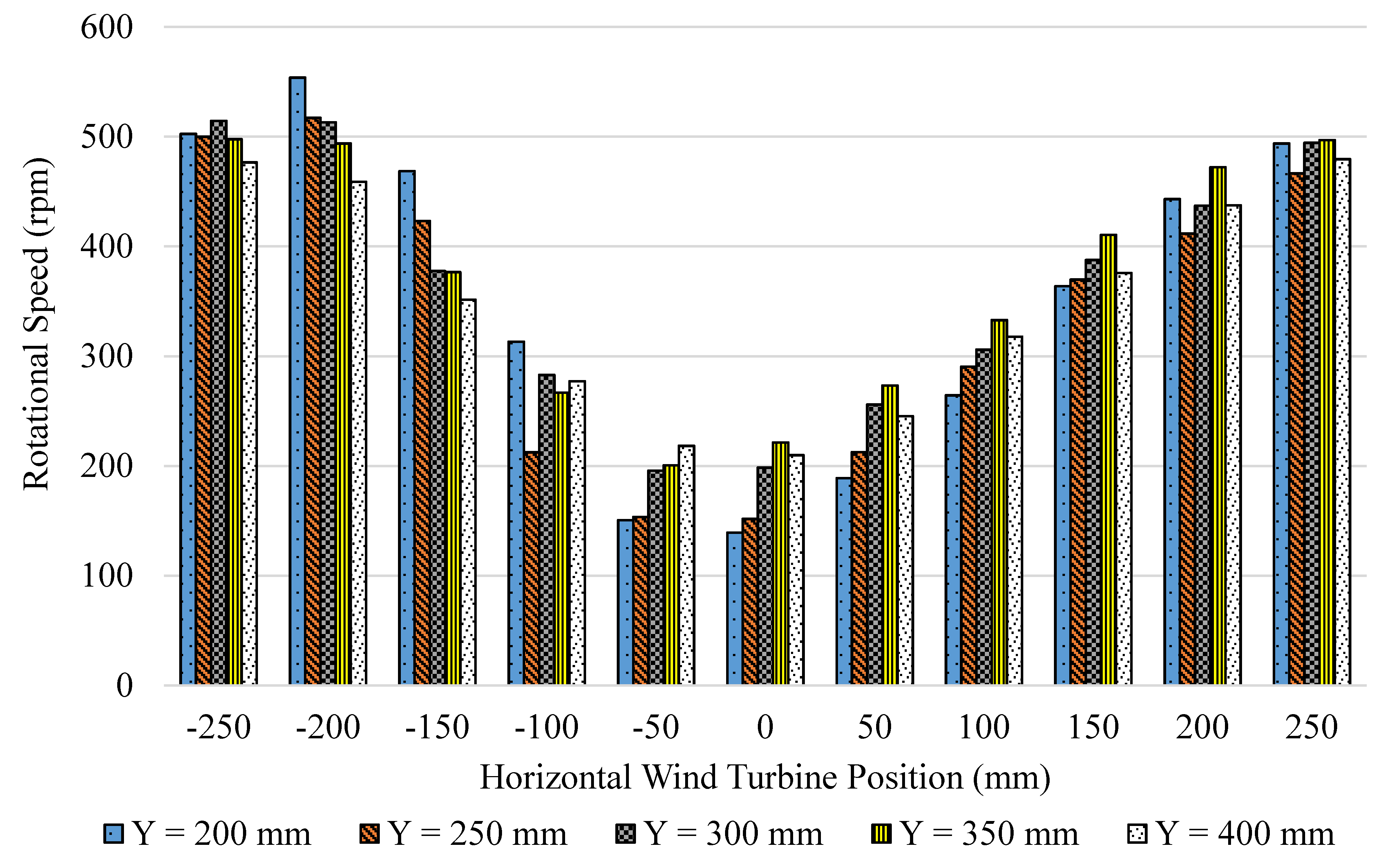

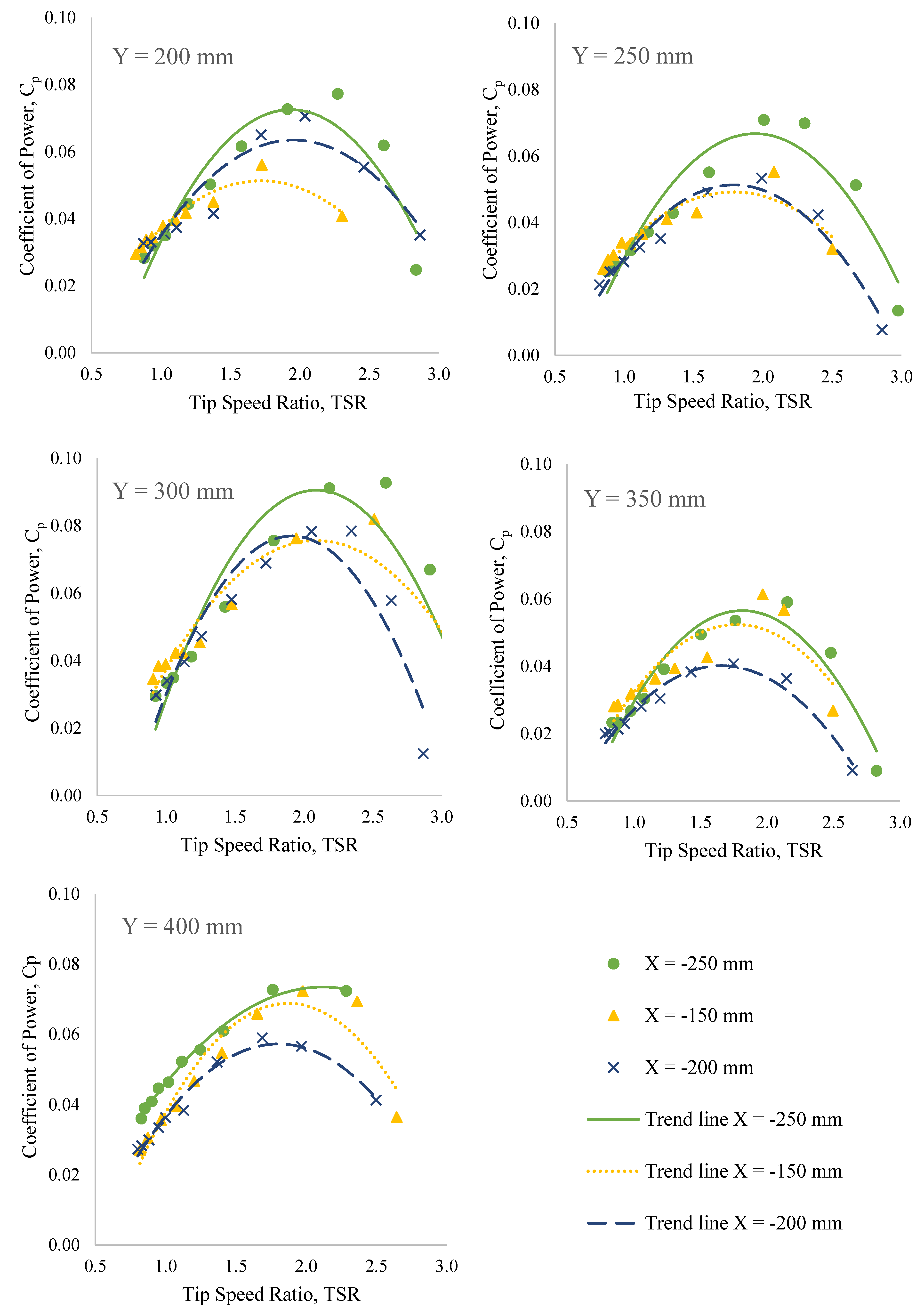

4.2. Wind Turbine Performance

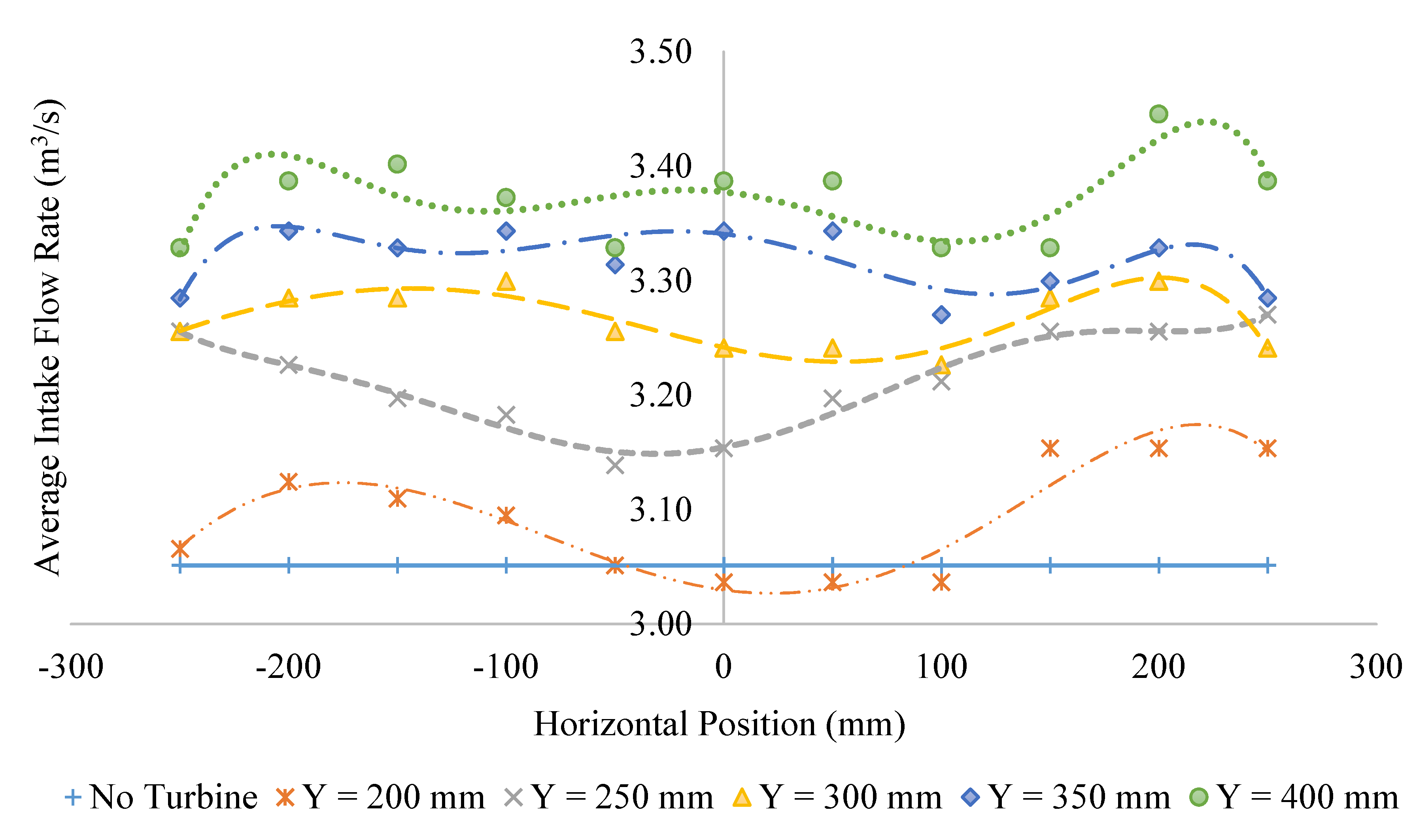

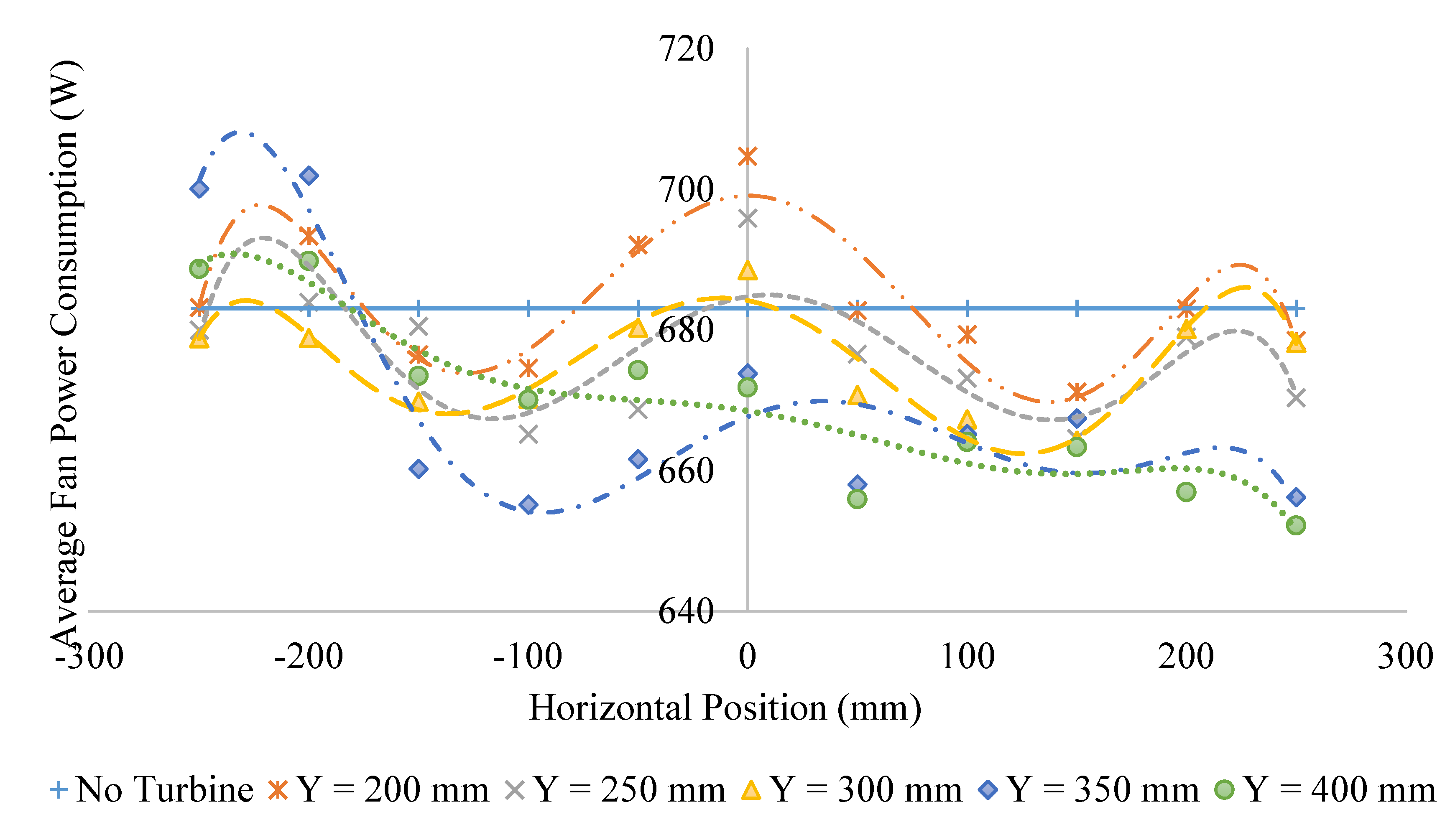

4.3. Cooling Tower Model Performance

4.4. Overall Performance Evaluation

| Configuration | Cooling Tower | Wind Turbine | ||||||

|---|---|---|---|---|---|---|---|---|

| Y (mm) | X (mm) | Intake Flow Rate | Fan Motor Consumption | Free Running Rotational Speed (RPM) | Maximum Cp | TSR at Maximum Cp | ||

| Velocity (m/s) | % Difference | Input Power (W) | % Difference | |||||

| 200 | 150 | 5.40 | 3.3% | 671 | −1.7% | 364 | 0.036 | 1.88 |

| 200 | 5.40 | 3.3% | 683 | 0.0% | 443 | 0.050 | 1.85 | |

| 250 | 5.40 | 3.3% | 679 | −0.7% | 494 | 0.076 | 2.08 | |

| 250 | 150 | 5.60 | 6.7% | 665 | −2.7% | 370 | 0.074 | 2.08 |

| 200 | 5.58 | 6.7% | 679 | −0.6% | 412 | 0.087 | 2.04 | |

| 250 | 5.58 | 7.2% | 670 | −1.9% | 467 | 0.097 | 1.96 | |

| 300 | 150 | 5.55 | 7.7% | 664 | −2.8% | 388 | 0.086 | 2.15 |

| 200 | 5.65 | 8.1% | 680 | −0.4% | 437 | 0.096 | 1.98 | |

| 250 | 5.63 | 6.2% | 678 | −0.7% | 494 | 0.125 | 2.31 | |

| 350 | 150 | 5.63 | 8.1% | 667 | −2.3% | 410 | 0.075 | 1.88 |

| 200 | 5.70 | 9.1% | 656 | −3.8% | 472 | 0.075 | 1.99 | |

| 250 | 5.65 | 7.7% | 656 | −3.9% | 497 | 0.103 | 1.90 | |

| 400 | 150 | 5.80 | 9.1% | 663 | −2.9% | 376 | 0.075 | 2.05 |

| 200 | 5.90 | 12.9% | 657 | −3.8% | 437 | 0.077 | 2.03 | |

| 250 | 5.70 | 11.0% | 652 | −4.5% | 479 | 0.106 | 1.88 | |

| No Wind Turbine | 5.23 | - | 683 | - | - | - | - | |

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, D.C.; Gong, X.; Raju Huidrom, E.; Vashakmadze, J.Z.; Zhao, T. Understanding the Plunge in Oil Prices: Sources and Implications; The World Bank: Washington, DC, USA, 2015. [Google Scholar]

- Organization of the Petroleum Exporting Countries (OPEC). OPEC Monthly Oil Market Report; OPEC: Vienna, Austria, 2014. [Google Scholar]

- Prambudia, Y.; Nakano, M. Integrated simulation model for energy security evaluation. Energies 2012, 5, 5086–5110. [Google Scholar] [CrossRef]

- Mirchi, A.; Hadian, S.; Madani, K.; Rouhani, O.M.; Rouhani, A.M. World energy balance outlook and opec production capacity: Implications for global oil security. Energies 2012, 5, 2626–2651. [Google Scholar] [CrossRef]

- Chauhan, S.; Singh, R. Design of domestic helix vertical axis wind turbine to extract energy from exhaust fans. Innov. Syst. Des. Eng. 2014, 5, 23–28. [Google Scholar]

- Ahmad, S.; Ab Kadir, M.Z.A.; Shafie, S. Current perspective of the renewable energy development in Malaysia. Renew. Sustain. Energy Rev. 2011, 15, 897–904. [Google Scholar] [CrossRef]

- Solomon, S.; Qin, D.; Manning, M.; Chen, Z.; Marquis, M.; Averyt, K.B.; Tignor, M.; Miller, H.L. Climate Change 2007: The Physical Science Basis; International Governmental Panel on Climate Change: New York, NY, USA, 2007. [Google Scholar]

- Ohya, Y.; Karasudani, T. A shrouded wind turbine generating high output power with wind-lens technology. Energies 2010, 3, 634–649. [Google Scholar] [CrossRef]

- Kalantar, M.; Mousavi G., S.M. Dynamic behavior of a stand-alone hybrid power generation system of wind turbine, microturbine, solar array and battery storage. Appl. Energy 2010, 87, 3051–3064. [Google Scholar] [CrossRef]

- Schaeffer, R.; Szklo, A.S.; Pereira de Lucena, A.F.; Moreira Cesar Borba, B.S.; Pupo Nogueira, L.P.; Fleming, F.P.; Troccoli, A.; Harrison, M.; Boulahya, M.S. Energy sector vulnerability to climate change: A review. Energy 2012, 38, 1–12. [Google Scholar] [CrossRef]

- Chong, W.T.; Pan, K.C.; Poh, S.C.; Fazlizan, A.; Oon, C.S.; Badarudin, A.; Nik-Ghazali, N. Performance investigation of a power augmented vertical axis wind turbine for urban high-rise application. Renew. Energy 2013, 51, 388–397. [Google Scholar] [CrossRef]

- Sharpe, T.; Proven, G. Crossflex: Concept and early development of a true building integrated wind turbine. Energy Build. 2010, 42, 2365–2375. [Google Scholar] [CrossRef]

- Wang, W.-X.; Matsubara, T.; Hu, J.; Odahara, S.; Nagai, T.; Karasutani, T.; Ohya, Y. Experimental investigation into the influence of the flanged diffuser on the dynamic behavior of CFRP blade of a shrouded wind turbine. Renew. Energy 2015, 78, 386–397. [Google Scholar] [CrossRef]

- Müller, G.; Jentsch, M.F.; Stoddart, E. Vertical axis resistance type wind turbines for use in buildings. Renew. Energy 2009, 34, 1407–1412. [Google Scholar] [CrossRef]

- Shan, Z.; Qin, S.; Liu, Q.; Liu, F. Key manufacturing technology & equipment for energy saving and emissions reduction in mechanical equipment industry. Int. J. Precis. Eng. Manuf. 2012, 13, 1095–1100. [Google Scholar]

- Chong, W.T.; Kong, Y.Y.; Fazlizan, A. Wind and Exhaust Air Energy Recovery System. WO2013073930 A1, 16 November 2012. [Google Scholar]

- Chong, W.T.; Hew, W.P.; Yip, S.Y.; Fazlizan, A.; Poh, S.C.; Tan, C.J.; Ong, H.C. The experimental study on the wind turbine’s guide-vanes and diffuser of an exhaust air energy recovery system integrated with the cooling tower. Energy Convers. Manag. 2014, 87, 145–155. [Google Scholar] [CrossRef]

- Jeong, H.M.; Chung, H.S.; Bae, K.Y.; Kim, S.H.; Shin, Y.S. Water cooling characteristics in an enclosed vacuum tank by water driven ejector. J. Mech. Sci. Technol. 2005, 19, 164–172. [Google Scholar] [CrossRef]

- Hensley, J.C. Cooling Tower Fundamental, 2nd ed.; SPX Cooling Technologies Inc.: Overland Park, KS, USA, 2009. [Google Scholar]

- Herrman, D.D. Field Tests of Fan Performance on Induced Draft Cooling Towers; Cooling Tower Institute: Houston, TX, USA, 1962. [Google Scholar]

- Paraschivoiu, I. Double-Multiple Streamtube Model for Darrieus in Turbines; Lewis Research Center Wind Turbine Dynamics: Hampton, NH, USA, 1981; pp. 19–25. [Google Scholar]

- Beri, H.; Yao, Y. Double Multiple Streamtube Model and Numerical Analysis of Vertical Axis Wind Turbine. Energy Power Eng. 2011, 3, 262–270. [Google Scholar] [CrossRef]

- AID Airfoil Investigation Database. Available online: http://www.airfoildb.com/foils/481 (accessed on 27 April 2015).

- Montgomerie, B. Methods for Root Effects, Tip Effects and Extending the Angle of Attack Range to ±180, with Application to Aerodynamics for Blades on Wind Turbines and Propellers; Swedish Defense Research Agency: Stockholm, Sweden, 2004. [Google Scholar]

- Kim, D.; Gharib, M. Efficiency improvement of straight-bladed vertical-axis wind turbines with an upstream deflector. J. Wind Eng. Ind. Aerodyn. 2013, 115, 48–52. [Google Scholar] [CrossRef]

- Chen, S.Q.; Wang, H.Q.; Cheng, J.L. Experimental investigation on the energy-saving diffuser of a main fan. J. Coal Sci. Eng. China 2012, 18, 108–112. [Google Scholar] [CrossRef]

- Chong, W.T.; Fazlizan, A.; Poh, S.C.; Pan, K.C.; Hew, W.P.; Hsiao, F.B. The design, simulation and testing of an urban vertical axis wind turbine with the omni-direction-guide-vane. Appl. Energy 2013, 112, 601–609. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fazlizan, A.; Chong, W.T.; Yip, S.Y.; Hew, W.P.; Poh, S.C. Design and Experimental Analysis of an Exhaust Air Energy Recovery Wind Turbine Generator. Energies 2015, 8, 6566-6584. https://doi.org/10.3390/en8076566

Fazlizan A, Chong WT, Yip SY, Hew WP, Poh SC. Design and Experimental Analysis of an Exhaust Air Energy Recovery Wind Turbine Generator. Energies. 2015; 8(7):6566-6584. https://doi.org/10.3390/en8076566

Chicago/Turabian StyleFazlizan, Ahmad, Wen Tong Chong, Sook Yee Yip, Wooi Ping Hew, and Sin Chew Poh. 2015. "Design and Experimental Analysis of an Exhaust Air Energy Recovery Wind Turbine Generator" Energies 8, no. 7: 6566-6584. https://doi.org/10.3390/en8076566