1. Introduction

Improved industrial energy efficiency is a cornerstone in climate change mitigation. Research results suggest that there is major untapped potential for improved industrial energy efficiency. A vast amount of research has empirically and theoretically studied the fact that a large number of improvement measures are not implemented, even though the measures are seemingly cost-effective. The major model used to explain this discrepancy is the barrier model, which states that different barriers to energy efficiency inhibit the adoption of cost-effective measures. Moreover, the measures outlined in research and policy action plans are almost exclusively technology-oriented. Reference [

1] questioned this technology paradigm, and stated that there is also a large untapped potential in the way technology is used in industry,

i.e., an energy management gap. In later empirical research [

2] found that for energy-intensive industries, this potential was in parity with the technology potential, while for less energy-intensive companies, the potential for technology solutions was viewed as larger. An even larger absolute potential in percent was stated by non-energy-intensive industry (13%), compared with energy-intensive industry (6%). Brunke

et al. [

3], in their study of the Swedish iron- and steel industry, stated that the potential for management was about 2.4% of the total energy use, while that for technology was stated to be 7.3%. Following [

1,

2,

3,

4] empirically investigated more than 900 energy efficiency measures undertaken by 100 Swedish energy-intensive industrial companies showing that a large number of the adopted measures were not, in fact, technology implementations. This research challenges the existing view that (best-available) technology is the sole means by which improved energy efficiency is achieved in industry, and accentuates a knowledge gap in the way improved energy efficiency in general is viewed.

One way to overcome the extended energy efficiency gap is to work strategically with energy issues in companies and develop an energy management system. Energy management has become more and more important and more frequently discussed as a tool to achieve improved energy efficiency in companies. Most research in the field of energy management is however grounded in engineering science, and theoretical models on how energy management in industry is carried out are scarce. One way to further develop and improve energy management, both theoretically and in practice, is to explore how a socio-technical perspective can contribute to this understanding. In this article we will further elaborate this potential of cross-pollinating these fields. The aim of this paper is to relate energy management to two theoretical models: situated action and transaction analysis.

2. Models, Policies, and Energy Management

According to [

5]: “Energy management can be defined as the procedures by which a company works strategically on energy, while an energy management system is a tool for implementing these procedures”.

Oftentimes, these two terms, energy management and energy management systems, are used interchangeably. The major reason for this is that the research conducted and models used are often based on a model, the plan-do-check-act cycle (PDCA) [

6], which views the operators based on the input-output model,

i.e., a signal goes into the operator in the form of information, and the signal is transformed by the operator into an action or activity which improves energy efficiency or reduces company energy use. This way of viewing energy management calls for a change.

One of the most cited market (failure) barriers to improved energy efficiency is information asymmetries and imperfections, and by reducing these asymmetries and imperfections by using energy information programs, a more perfect market is achieved, in terms of information. Oftentimes, the suggested and implemented actions for overcoming information asymmetries and imperfections are by the launch of energy information programs, the foremost of which are of energy assessment/energy audit programs. These programs are also based on the input-output model, by which the company is viewed as a utility-maximizing rational entity which, when information is provided, acts on this information and invests in new, more energy-efficiency technologies.

One of the most important policy activities to promote improved energy efficiency in energy-intensive industry is however by the use of Voluntary Agreements (VAs), Voluntary Agreement Programs (VAPs), or Long-Term Agreements (LTAs). The main idea, regardless of the name given to the policy, is a combination of energy assessment/energy auditing and energy management activities. To the authors’ knowledge, the oldest VAP that exists today is the Japanese Keidanren [

7]. Within the EU a large number of Member States (MS) have launched VAs aimed at their energy-intensive industrial sectors [

8].

The energy management system standard and ISO 50001 were both designed according to the plan-do-check-act cycle. The standard is similar to quality and environmental management system standards [

9], and is mostly implemented through energy policy programs, e.g., Voluntary Agreements among energy-intensive industries. Implementation of standardized energy management systems among industrial SMEs (Small- and Medium-Sized Enterprize) is limited [

10]. In attempts to improve energy efficiency through energy management, simplified management systems have been developed, e.g., in Sweden [

11] to promote energy management in industrial SMEs. Such initiatives have been inspired by the formal standard, but take a lighter approach than a standardized energy management system [

11]. The input-output model is also the major model used within EU energy policy action plan formulation.

However, the underlying logic for this, i.e., the models used to motivate both the spreading of information and the implementation of energy management practices, are only weakly linked with present theory building within the area of improved industrial energy efficiency. Almost exclusively, the scientific contributions in the field of energy management emanates from technical faculties. It is thus important to further explore the area of improved industrial energy efficiency in terms of the models used, and new models needed, not least from a socio-technical perspective.

3. Energy Management and the need to Delegate Leadership

One criticism of the input-output model and management systems is that they are based on a simplistic belief in rational actors choosing the best available technology. Improved industrial energy efficiency is multifaceted and an effect of that is the existence of an energy efficiency gap between the technical-economic potential for improved energy efficiency and what is actually implemented. If we acted as the theoretical rational woman or man, then this gap would not exist, but the gap obviously does exist according to numerous studies, and new tools and perspectives seem needed to approach these underlying problems.

First we need a multiple way to approach decision-making in industry, where management models need to be complemented by other decision models, apart from the “economic woman/man”. The classic “garbage can” model [

12] showed that decision-making in organizations does not necessarily need to be rational. How an industry understands a problem may be poor, due to the fact that people constantly enter and exit the organization, which makes learning processes complicated. The industry’s “garbage can” consists of a collection of choices searching for problems, issues and appropriate decisions to attach themselves to. The idea is that people in the organization dump problems and solutions into an imaginary garbage can and the outcome is a result of when a solution randomly finds an appropriate problem. At times action is also taken without a plan,

i.e., without any stated intention or goal for those actions. A plan or an energy strategy does not necessary change a practice or infrastructure but according to [

13] can likewise reproduce what already exists.

There are also different ways to manage organizations and lead change. In [

14] the authors describe two different paths to follow, namely method or result governance. The different methods are described by an illustrative example. If the goal is to go from A to B, this location can be reached in different ways. One is to run along a sandy beach, which will be a rather quick way. The tracks in the sand will however also be washed away rather quickly, so it will not be possible for someone to follow the same path. The result is that each person will need to find their own way to B. The first path will then be based on all individuals solving the challenge and the burden to move from A to B will be dependent on individual capacity and external conditions. This is a description of result governance [

5].

The second option is to construct a road. This will take a much longer time, and require more effort and organizational capacity. However, when the road is finished more people will travel easily from A to B and it will be possible to carry greater loads on the road [

14]. Improved modes of transport can be developed and more cargo carried compared to the first way described. This last option is also less dependent on individual capacity and external conditions. This second option is that of standardization and improvements, which can support others who want to repeat a behavior. The second approach is method governance [

5].

Result governance has the benefit that positive results can be achieved quite quickly, but then it is hard to uphold a continuum in behavior or measures. By this method members in the group need to achieve desired results on their own and solutions rely on individual approaches. Duplication of a solution is also hard to achieve, and structural capital does not accumulate in organizations. The organizational culture is not affected and if for example the leader changes job good results will not persist [

14].

Method governance (the road example) influences behavior by using a method leading to standardization. It is possible by this method to influence how a group works. It establishes the conditions for continuous improvements. Behavior modified in such a way often provide more economically efficient results and creates conditions that make it possible to maintain or improve the work [

14]. The drawback with this approach is of course if the method developed is not especially good or functional, as then the whole collective will follow the wrong path.

But in most cases it is also possible to improve methods, procedures and instructions. Unlike result governance, method governance creates structural capital and, with the right leadership, long-term improvement in group culture is possible [

14]. This also reduces the risk of becoming too dependent on one individual and her or his capacity.

In accordance with this we can conclude that it is important to work with structures and to establish methods and procedures, which also is the idea with energy management systems. For an organization to achieve ambitious energy efficiency goals, empowering individuals in an organization to work on improved energy efficiency is as important, regardless of whether one takes the perspective for example of implementing standards or a more top-down management perspective. The managers also need to adopt a transparent strategy for who can take responsibility for what.

Another way to look at this is by applying transactional analysis (TA), which has its origin in psychiatry [

15]. The adoption of an energy strategy is a way to structure energy work in a company. It is thus also a restriction of freedom to act for individuals and the organization. How this restriction is communicated is vital for how the energy management system will work in practice in an organization. Enforced measures are seldom looked upon with approval by employees, making how the measures are communicated vital. When taking a transactional analysis approach a communication strategy can be used that resembles peer-to-peer communication. The employees should be informed of changes or new procedures before adoption. They also should be given opportunities to provide their view on the changes. According to TA, this increases the chances that the organization will accept a new structure.

Delegating responsibility is at the same time connected with a risk, a risk that a task for example will be managed in a way that is not beneficial from a system perspective. On the other hand change management and the need to handle risks are important parts of leadership. Improvements in energy efficiency also include a certain degree of risk. A production manager that needs to close down machines or replace equipment in the production line risks facing a period during which production decreases. One strategy to handle this is to create stable systems, e.g., a flexible machine that is easy to turn on and off. The person in charge of the energy management program needs to encourage risk taking and support managers of production, quality, maintenance,

etc. when taking investments that in the short run risk having adoption problems. An organization needs to accept a certain amount of risk. In industries with continuous production processes risk has proven to be a frequently mentioned barrier for energy efficiency. Batch production is less vulnerable, which is explained by the fact that a malfunction does not need to be as costly. In a continuous production process on the other hand equipment malfunction may cost several hundred thousand euros per hour [

16].

The CEO of an industrial organization is most likely not the person responsible for an energy management program, but delegating that authority is praxis. However, delegation of authority also entails risk, even if of a slightly different kind. Delegation of authority may indicate that the top manager is not interested in an issue. If a more junior co-worker takes responsibility, that person may also lack power to advocate certain major steps necessary for improved energy efficiency. It is crucial that the person in charge for the energy management program have a formal or informal leadership position. At least a strong connection to the board of directors is needed [

5].

There are good examples of successful leadership delegation. One example is when the CEO of a large multinational company decided to establish an in-house energy management program. An energy audit was conducted, which was followed by establishment of a group that met every month. The CEO delegated authority to the person in charge of the physical plant (e.g., HVAC, water and security system), but at the same time all managers were required to attend the meetings. The CEO also always attended the meetings. This work inspired another manager for the melting division to start working on energy efficiency. Quite soon several energy reduction measures were successfully implemented and in the end the savings equaled the sum of all undertaken measures suggested by the energy audit. This case is a successful example of an organizational change, where the CEO was able to empower individuals and mid-level managers to increase efficiency and even revenues [

5].

4. Industrial Energy Management in the Perspective of Situated Action

Yet another way to understand decision-making in organizations is to have a situated action perspective [

13]. When studying decision-making in this perspective, all activities are seen as situated and impossible to predict. In this perspective decisions on improved energy efficiency are made locally, in the practices where people meet, act and perform.

Imagine a meeting where the participants are supposed to decide on how to improve energy efficiency in the organization. From an energy management standard perspective the outcome will depend on existing policies, already decided goals and established procedures. From a situated action perspective the outcome of a meeting is a much more open issue. Rather than depending on a goal in a document or procedures in a standard it will be dependent on which actors participate in the meeting. The actors attending a meeting will most probably not have memorized all policies, standards and procedures that exist in the organization. They will base their input and contribution to the discussion on energy efficiency on their culturally embedded understanding of how to act, what choices are given in different contexts and what decisions seem to be suitable in different settings. In this way the outcome of an energy efficiency decision will be dependent on which actors participate on that occasion. If the meeting will be repeated but with totally new actors, then the discussions at the meeting will differ and thus also the outcome. Financial managers for example will discuss energy efficiency from their perspective which is different from say an HR manager or mechanical engineer.

The decisions made during a meeting are also a result of group dynamics and the participating actors’ mutual relationships. The participants in meetings take different roles, and the roles actors have in one group will differ from their roles in another group. Actors take different roles, and in this sense too roles are situated. How a discussion goes will then depend both on which actors participate and also the mutual relations in the group. For that reason it is not unusual or even strange that one actor can have one opinion at one meeting and then change opinion at another meeting with another constellation of actors. The actor can simply have taken different roles at the meetings or the discussions have taken different turns which make holding what seem like opposing opinions by an individual very logical. The opinion must simply be understood in the perspective of situated action.

Going back to improved energy efficiency as an example, one energy efficiency measure can be interpreted as beneficial and valid in one situation while in another situation the same measure can be dismissed as inappropriate [

17]. It depends on the situation, what problems and solutions become present in the discussion and what experience the involved actors have from energy efficiency in general and the measure in particular.

Actions are also something that we constantly do and are not necessarily intentional, reflected upon, or done to achieve a goal. According to Suchman, plans, for example, cannot be understood as instructions for targeted actions. Plans and strategies do not provide a solution for the problem, they simply relate it.

At the same time there is existing knowledge that an energy management model is a formal process, with its tools and procedures, which will have impact on the everyday work. Even if it is impossible for plans or standards to predict actions they are still influential. Some ideas from the plan or standard will interest many actors and be included in the discussions at meetings and integrated in ongoing processes. Other ideas and standard will simply not attract interest from anyone and these will not be made present at meetings or highlighted during a process, and these ideas will not have any impact in practice.

Ideas and goals attractive to many actors will have a better chance of survival, because it will be possible for these to be present on many occasions and at many meetings. Specific ways to handle issues in support of these ideas will be developed into procedures and will eventually be understood as the “right” way to do things. Ideas, working procedures, relations and roles that many support and maintain over time will in this way become formalized in specific contexts. But all this will not come automatically, but happen in situated actions. If an idea at the same time is supported with great emphasis by a (strong) leader the chances for its implementation are high. It seems vital to integrate this perspective into the discussion of how to improve industrial energy management both in practice and in theory.

Also, to be able to capture how these formal energy management tools are translated and changed, how phenomena are formalized and energy efficiency measures are shaped it is important to follow how this is done and constantly negotiated in local practices. Improved energy efficiency from this perspective is something that is done in interaction between actors and artefacts and it is in this interaction that the scope of energy efficiency is defined and decided and its ingoing parts are crystallized. It is also in this interaction that different actors have their roles set, as experts, advisors or decision-makers, and where some issues or artefacts become “energy efficient” to its characters. To understand energy efficiency in industry we need to understand not only energy management systems and the industrial technical energy systems, but also equally importantly how improved energy efficiency is achieved in situated actions.

5. Discussion

This paper attempted to provide further theoretical insights into the area of industrial energy management. Even though the scope of the study has been industry, the theoretical implications are generalizable to others sectors such as the transport sector as well. We conclude that the current model for energy management systems, the input-output model, is insufficient for understanding in-house industrial energy management practices as it does not fully take current scientific understanding of people into account. By incorporating situated action and transaction analysis as models to improve understanding of in-house energy management, we hope to have improved the understanding a step further. Energy management and energy management systems are not the same. Energy management demands leadership skills sufficient to be sensitive to employees’ ideas and objections, but strong enough to dare to carry through ideas in the organization where people are hesitant.

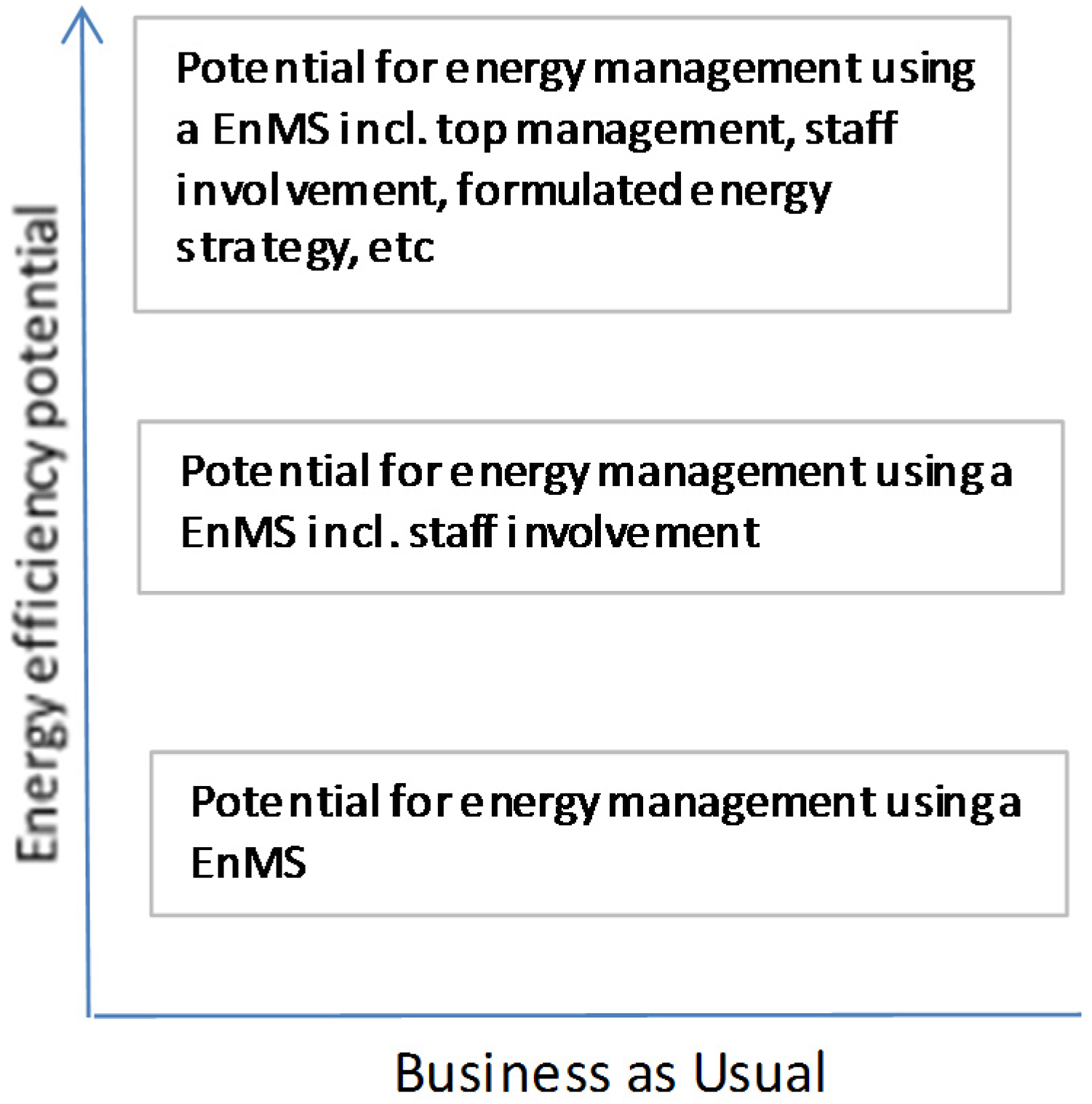

By the incorporation of situated action and transaction analysis to the currently used input-output model, an enhanced understanding about the complexity of energy management is gained. In

Figure 1, one example of such a revised model is given.

Figure 1.

The energy efficiency potentials for various energy management approaches.

Figure 1.

The energy efficiency potentials for various energy management approaches.

As illustrated in

Figure 1, and which has also been elaborated upon by [

1,

3,

5], it is clearly seen that solely implementing an energy management system,

i.e., a tool for improved energy efficiency, will not deploy the extended energy efficiency potential,

i.e., the energy efficiency potential outside of technology implementation. Rather, successful energy management means setting a clear strategy, having top management support, involving staff,

etc.We do not think it is possible to find a single energy management solution suitable for any industrial company, but rather the idea is to find a reflexive model that can be adjusted from time to time. An idea for such a reflexive model will contain structural elements from energy management models with consideration for decisions being situated and impossible to predict.

Our findings have serious implications for energy and climate change mitigation policy design. As stated in the introductory part of the paper, recent findings indicate a vast (often neglected) potential for energy management practices, which is one of the underlying major motivations for this type of policy. However, so far little attention has been paid to theoretical understanding of the growing number of industrial energy and climate change mitigation policies that are now being developed in different parts of the world. Our findings reveal that policies that have implementation of an energy management system as its main component, despite its vast potential, need to be sensitive to the persons implementing the management system.

For individual companies, our findings are key to understanding why some companies, despite having management systems in place, fail to deliver high energy efficiency improvement figures, while others do. In order to realize the vast potential for improved energy efficiency through energy management, the leaders of an organization implementing an energy management system need to be sensitive to the workers facing and carrying out the measures.

There is pressure from policy makers, the markets and internal processes behind the need for energy efficiency measures. This pressure is captured by the management level and if the demands are in line with the management culture, the process can continue and measures to change behavior and activities will be initiated. This might in turn affect how energy-related practices are performed and whether this will lead to the expected results, for example, reduced energy use. If so, then a positive spiral has been created. It is also possible that the measures and ideas cannot come through existing cultures and get access to different situated actions. In such cases more interaction will be needed with both employees and managers at the company and an awareness of the importance of energy efficiency needs to be embedded in the culture.

This process can take more or less time, depending on whether the pressure for change is in line with the values of the existing organization and how easy it is to change activities and behavior, whether or not behavioral change leads to consistent change in practices, and, finally, whether or not the results are as expected or whether the process will have to start again.