Risk Assessment for Natural Gas Hydrate Carriers: A Hazard Identification (HAZID) Study

Abstract

:1. Introduction

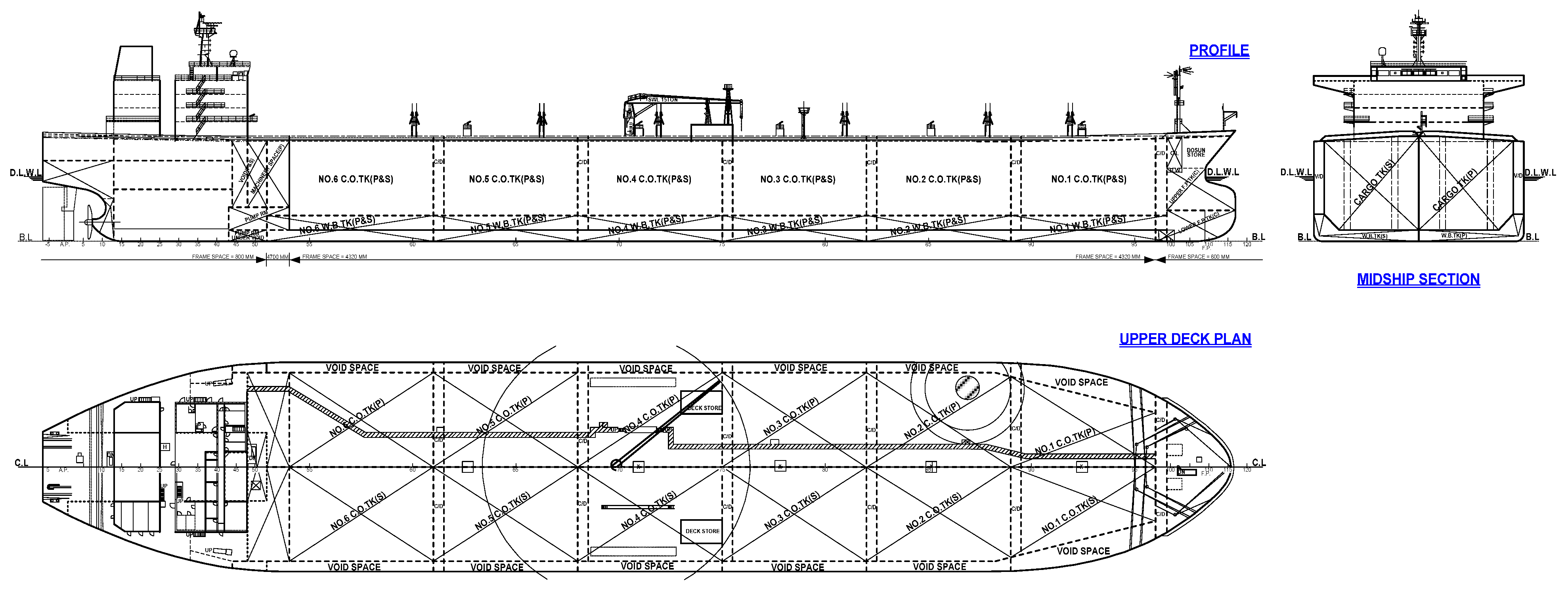

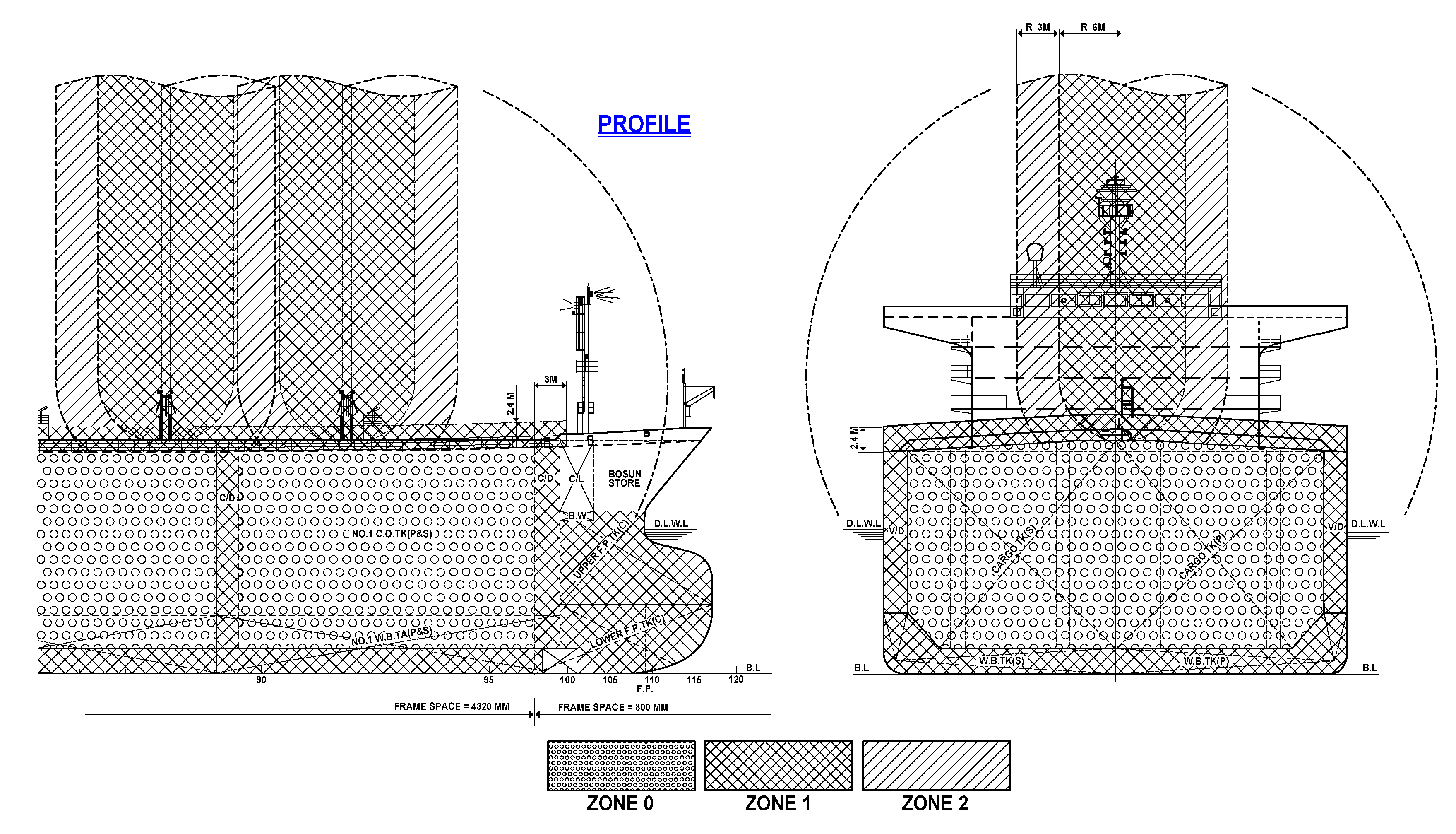

2. Conceptual Design of an NGH Pellet Carrier

- ▪

- Laboratory experiments and simulation models to investigate the production of natural gas hydrate from natural gas [6]; and,

- ▪

- The development of new technologies for the production and transport of natural gas hydrate pellets.

| LOA (Length Overall) | m | 249.9 |

| LBP (Length between perpendiculars) | m | 239.0 |

| Breadth | m | 44.0 |

| Depth | m | 21.0 |

| DWT (NGH) | ton | 80,305.6 |

| Tank volume (Natural gas) | ton | 10,440 |

| Specific Gravity of Hydrate | 0.9 | ton/m3 | |

| Maximum loading rate (including porosity) | 75 | % | |

| Weight ratio | Cargo NG | 0.13 | kg |

| Specific heat of hydrate | 2.0934 | kJ/kg∙°C | |

| Calories for dissociation of NGH | 415.31 | kJ/kg | |

| Specific heat of water | 4.187 | kJ/kg∙°C | |

| Specific heat of NG | 0.50 | kcal/kg∙°C | |

| No. | ID | Operation Mode | Sub-Operation Mode |

|---|---|---|---|

| 1 | EMER | Emergency operation mode | Emergency shutdown, Emergency depressurization, NGH jettisoning |

| 2 | STARTUP | Start-up operation mode | Inerting, Gassing-up, Cooling-down |

| 3 | SHTDN | Normal shutdown operation mode | NGH draining, Warming-up, Inerting, Aeration |

| 4 | LOAD | Loading operation mode | Drain system, Pipe drain system, Cooldown system, Loading system |

| 5 | NORMAL | Normal operation mode | Cargo hold and insulation, BOG handling system, Intact stability, Sloshing |

| 6 | UNLOAD | Unloading operation mode | Re-gasification system pretreatment |

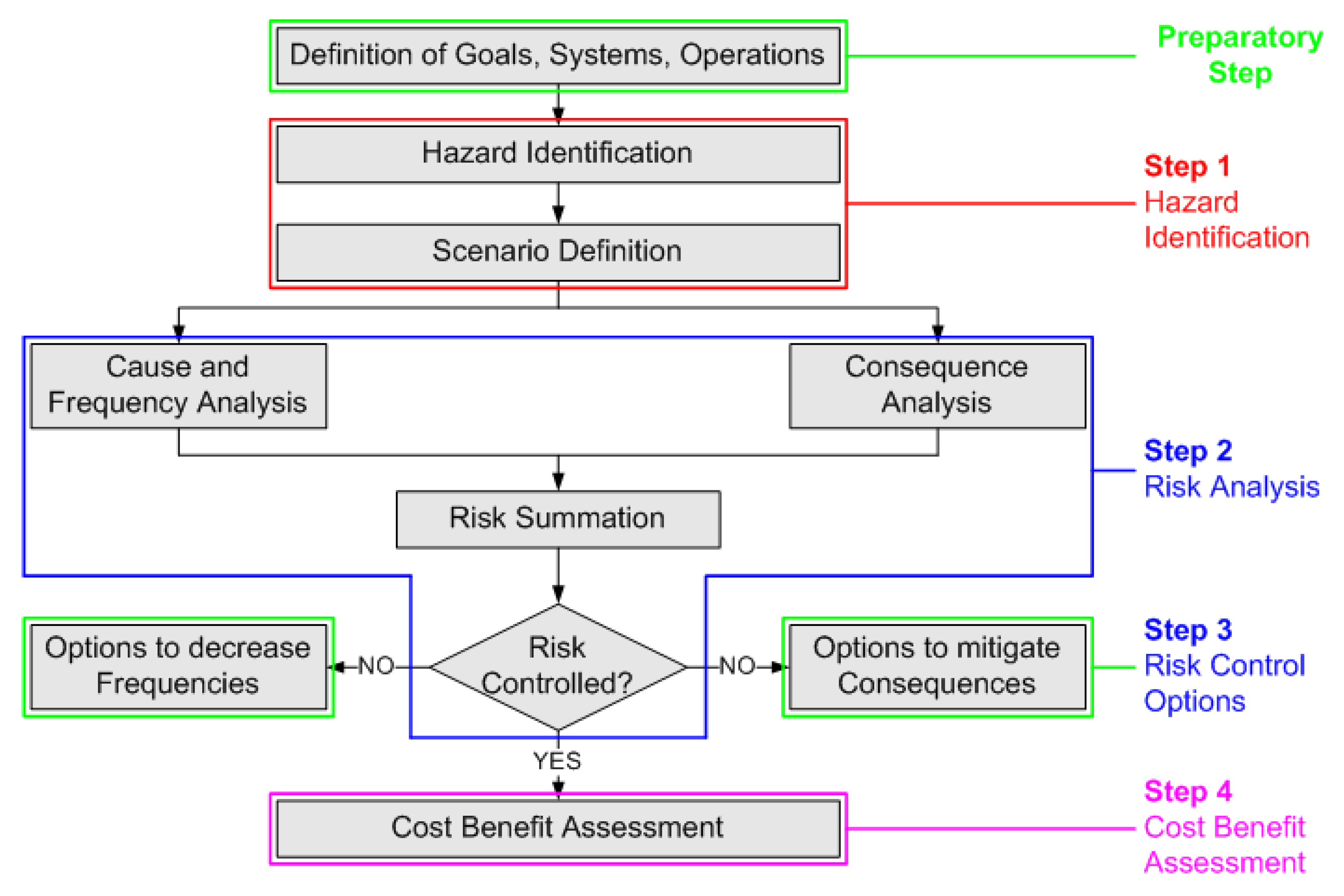

3. Risk Analysis

3.1. Hazard Identification

- ▪

- To obtain a list of hazards for subsequent evaluation using other risk assessment techniques. This is sometimes known as “failure case selection”.

- ▪

- To perform a qualitative evaluation of the significance of the hazards and the measures for reducing the risks from them. This is sometimes known as “hazard assessment”.

- ▪

- To identify the nature and scale of hazards that might present during the construction and operation phase of the NGH carrier

- ▪

- To identify the possible causes associated with the identified hazards

- ▪

- To identify the potential impact of hazards on humans, the environment and the vessel

- ▪

- To evaluate the adequacy of existing safeguards (hardware systems and/or procedures) associated with the identified hazards, and

- ▪

- To propose additional safety actions and recommendations for improving the safety of the NGH carrier.

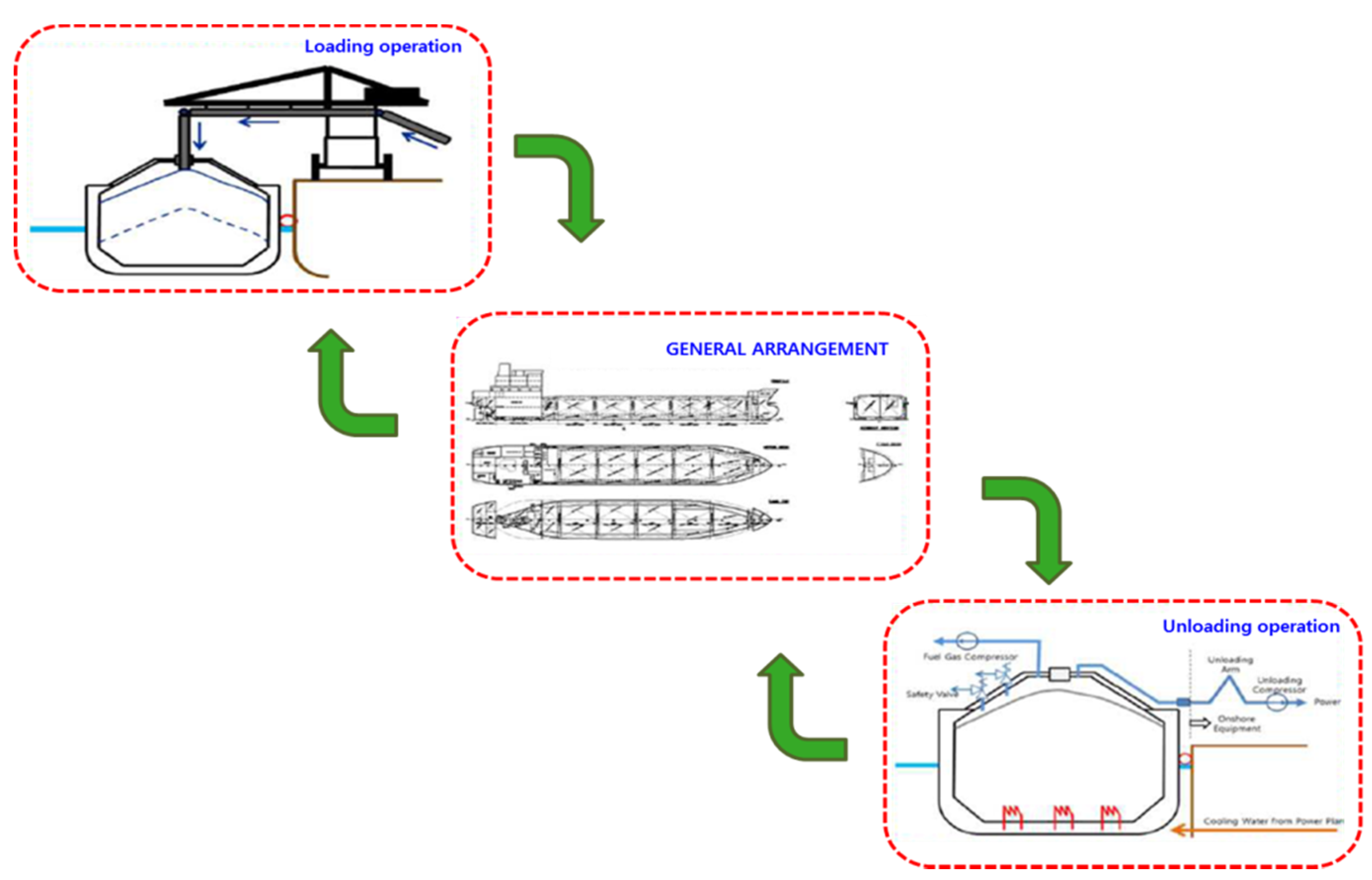

3.2. Work Scope

- ▪

- Loading operation system

- ▪

- General arrangement

- ▪

- Unloading operation system

3.3. HAZID Team

3.4. Risk Evaluation Criteria

3.4.1. Frequency Index (FI), Severity Index (SI) and Risk Index (RI)

| FI | Frequency | Description |

|---|---|---|

| 5 | Frequent | Likely to occur once per three months on one ship |

| 4 | Probable | Likely to occur once per six months on one ship |

| 3 | Occasional | Likely to occur once per one year on one ship |

| 2 | Remote | Likely to occur once per ten years on one ship |

| 1 | Improbable | Likely to occur once per thirty years on one ship |

| SI | Severity | Description | |||

|---|---|---|---|---|---|

| People | Assets | Environment | Reputation | ||

| 1 | Moderate | Slight injury | $ 91,000 | Slight effect | Slight impact |

| 2 | Serious | Minor injury | $ 910,000 | Minor effect | Minor impact |

| 3 | Major | Major injury | $ 9,100,000 | Localized effect | Considerable impact |

| 4 | Catastrophic | Single fatality | $ 23,000,000 | Major effect | National impact |

| 5 | Disastrous | Multiple fatalities | $ 46,000,000 | Massive effect | International impact |

3.4.2. Risk Matrix and Evaluation Criteria

- ▪

- Intolerable region: Risk index ≥ 10

- ▪

- ALARP region: 3 < Risk index < 10

- ▪

- Negligible region: Risk index ≤ 3

| FI | Frequency | Severity | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Moderate | Serious | Major | Catastrophic | Disastrous | ||

| 5 | Frequent | 5 | 10 | 15 | 20 | 25 |

| 4 | Probable | 4 | 8 | 12 | 16 | 20 |

| 3 | Occasional | 3 | 6 | 9 | 12 | 15 |

| 2 | Remote | 2 | 4 | 6 | 8 | 10 |

| 1 | Improbable | 1 | 2 | 3 | 4 | 5 |

4. Results and Discussion

4.1. Overview

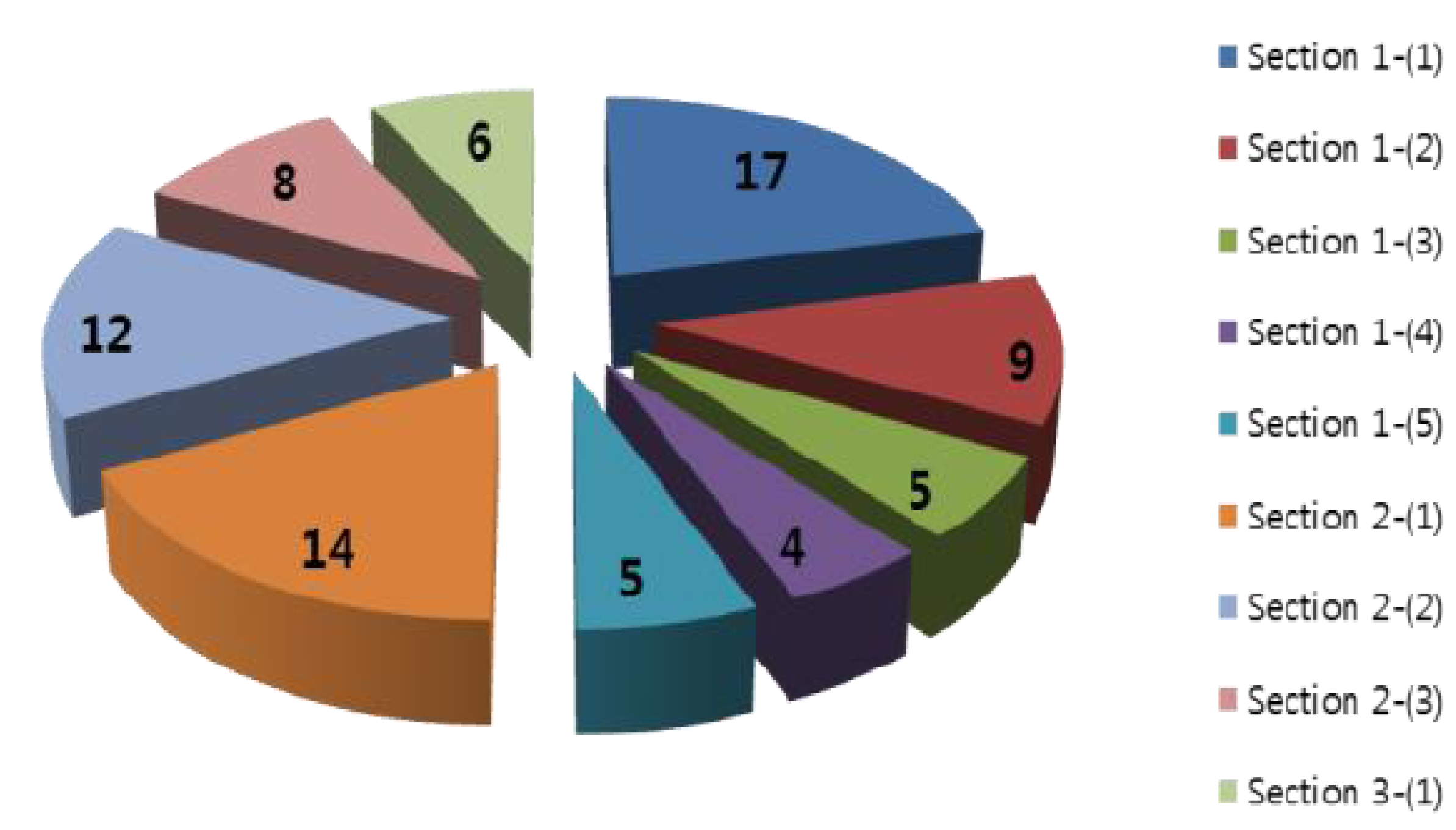

| Hazard Category | Sum | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Section 1-(1) | Section 1-(2) | Section 1-(3) | Section 1-(4) | Section 1-(5) | Section 2-(1) | Section 2-(2) | Section 2-(3) | Section 3-(1) | ||

| N.A. Hazards | 16 | 8 | 4 | 4 | 5 | 3 | 2 | 1 | 6 | 49 |

| Available Hazards | 1 | 2 | 1 | 0 | 0 | 11 | 10 | 7 | 0 | 31 |

- ▪

- Section 1-(1) Impact of natural and environmental hazard on the NGH carrier

- ▪

- Section 1-(2) Impact of the NGH carrier on the natural environment

- ▪

- Section 1-(3) Impact of the NGH carrier on the human environment

- ▪

- Section 1-(4) Effects on the NGH carrier of man-made hazards/constraints

- ▪

- Section 1-(5) Effects from infrastructures supporting the NGH carrier

- ▪

- Section 3-(1) Health hazards.

| Negligible Region | ALARP Region | Intolerable Region | ||||||

|---|---|---|---|---|---|---|---|---|

| Risk Index | N.A. | 2 | 3 | 4 | 5 | 6 | 10 | 12 |

| Number of Hazards | 36 | 2 | 12 | 18 | 1 | 8 | 2 | 1 |

| No. | Hazard Category | N.A. Hazards | Hazards with the Negligible Risk | Hazards with the ALARP Risk | Hazards with the Intolerable Risk | Sum |

|---|---|---|---|---|---|---|

| 1 | Section 1-(1) | 6 | 10 | 1 | 0 | 17 |

| 2 | Section 1-(2) | 7 | 1 | 1 | 0 | 9 |

| 3 | Section 1-(3) | 4 | 0 | 1 | 0 | 5 |

| 4 | Section 1-(4) | 4 | 0 | 0 | 0 | 4 |

| 5 | Section 1-(5) | 5 | 0 | 0 | 0 | 5 |

| 6 | Section 2-(1) | 1 | 2 | 10 | 1 | 14 |

| 7 | Section 2-(2) | 2 | 0 | 9 | 1 | 12 |

| 8 | Section 2-(3) | 1 | 0 | 6 | 1 | 8 |

| 9 | Section 3-(1) | 6 | 0 | 0 | 0 | 6 |

| Sum | 36 | 13 | 28 | 3 | 80 | |

4.2. Hazard Review

4.2.1. Hazards with Intolerable Risk

4.2.2. Hazards with ALARP Risk

4.2.3. Hazards with Negligible Risk

5. Conclusions

- ▪

- The majority of hazards to the NGH carrier fall in the acceptable risk region.

- ▪

- Critical hazards having an unacceptable risk level are just a few.

- ▪

- Hazards due to both the external factors associated with the environmental conditions and the internal factors associated with the process operation are the main concerns for the NGH carrier.

- ▪

- Regarding the external hazards associated with extremely harsh weather, relevant safety actions for risk reduction must be provided in the system design.

- ▪

- Regarding the internal hazards associated with the process operations, it is recommended that additional safety actions for risk reduction should be investigated on the basis of the ALARP principle.

- ▪

- Harmful effects of the NGH carrier on the natural environment and residential areas (third parties) are expected not to exist or to be of similar level as those of conventional vessels, including LNG carriers.

- ▪

- Security hazards, such as internal and external attacks, strikes and pirates, the NGH carrier are similar to those of existing LNG carriers and current practices being used are considered appropriate.

- ▪

- Health hazards to the crew onboard are insignificant.

- ▪

- Loss of cargo tank

- ▪

- Gas release into enclosed spaces

- ▪

- Fire and explosion

- ▪

- Collisions and impacts

- ▪

- Structural and/or foundation failures

- ▪

- Dropped objects

- ▪

- Stability failure

- ▪

- Loss of mooring or other position keeping means.

Acknowledgments

Author Contributions

Appendix 1

| Hazard Category | Guideword | Possible Cause |

|---|---|---|

| (1) Impact of natural and environmental hazards on the NGH Transport Vessel | 1. Climatic extremes | 101. High ambient temperature 102. Low ambient temperature 103. Snow/ice 104. Swell/waves 105. Typhoon/hurricane 106. Flooding 107. Wind 108. Dust 109. Fog |

| 2. Lightning | 110. Electrical strike | |

| 3. Seismic events | 111. Tsunami | |

| 4. Miscellaneous | ※ Might be explored/decided during HAZID workshop | |

| (2) Impact of the NGH Transport Vessel on the natural environment | 1. Continuous/frequent discharge to air | 201. Vents 202. Fugitive emissions |

| 2. Continuous/frequent discharge to water | 203. Target/legislative requirements 204. Drainage facilities | |

| 3. Emergency/upset discharge | 205. Vents 206. Drainage | |

| 4. Waste disposal options | 207. Pollution 208. Ignition source | |

| 5. Miscellaneous | ※ Might be explored/decided during HAZID workshop | |

| (3) Impact of the NGH Transport Vessel on the human environment | 1. Proximity to transport corridors | 301. Shipping lanes 302. Fishing grounds |

| 2. Proximity to centers of population | 303. Villages/towns | |

| 3. Adjacent land use | 304. Construction yard | |

| 4. Miscellaneous | ※ Might be explored/decided during HAZID workshop | |

| (4) Effects on the NGH Transport Vessel of man-made hazards/constraints | 1. Security hazards | 401. Internal and external security threats |

| 2. Social/political unrest | 402. Strikes 403. Pirate | |

| 3. Miscellaneous | ※ Might be explored/decided during HAZID workshop | |

| (5) Effects from infrastructures supporting the NGH Transport Vessel | 1. Normal communication links with the system | 501. Road links 502. Air links 503. Water links 504. Personnel transport to/from site |

| 2. Supply support to the system | 505. Chemicals/consumables/spares means of supply 506. Fuel supply to site | |

| 3. Mutual aid/emergency services | 507. Tugs 508. Firefighting boats in harbor | |

| 4. Miscellaneous | ※ Might be explored/decided during HAZID workshop |

| Hazard Category | Guideword | Possible Cause |

|---|---|---|

| (1) Loading operation | 1. Drain system | 601. Oil spill on the deck 602. The damage of the valve 603. Freezing the residual water 604. Pyrophoric substance |

| 2. Pipe drain system | 605. The pressure in the pipe 606. The failure of the drain | |

| 3. Cooldown system | 607. Freezing in the pipe 608. The damage of the pipe and the nozzle 609. The blockage of the vent line | |

| 4. Loading system | 610. The damage of the internals 611. The blockage of the NGH loading pipe 612. The generation of the BOG 613. The bias of the loading | |

| 5. Miscellaneous | ※ Might be explored/decided during HAZID workshop | |

| (2) Normal service | 1. Cargo hold and insulation | 701. The damage of the cargo hold 702. The leak of the loading 703. The explosion in the void 704. The generation of the dissociation gas 705. The flooding in the void |

| 2. BOG handling system | 706. Freezing the vent line 707. The damage of the safety relief valve 708. The damage of the safety relief valve of the buffer tank 709. The excess of the BOG removal capacity | |

| 3. Intact stability | 710. The loss of the stability | |

| 4. Sloshing | 711. Sloshing | |

| 5. Miscellaneous | ※ Might be explored/decided during HAZID workshop | |

| (3) Unloading operation | 1. Regasification system | 801. The damage of the circulating pump 802. The blockage of the water injection nozzle 803. The damage of the pipe 804. The excess of the gas production 805. The sudden stops while unloading |

| 2. Pretreatment | 806. The blockage of the nozzle 807. The damage of the drain valve | |

| 3. Miscellaneous | ※ Might be explored/decided during HAZID workshop |

| Hazard Category | Guideword | Possible Cause |

|---|---|---|

| (1) Health hazards | 1. Disease hazards | 901. Endemic disease 902. Malarial mosquitoes |

| 2. Carcinogenic | 903. Chemicals in use | |

| 3. Toxic | 904. Toxic chemicals in use 905. Chemicals giving toxic combustion products at high temperature | |

| 4. Miscellaneous | ※ Might be explored/decided during HAZID workshop |

Appendix 2

| No. | Hazard ID | Hazard Category | Cause | Consequence | Op. Mode | RI | Remark |

|---|---|---|---|---|---|---|---|

| 1 | 804 | Section 2-(3) | The excess of the gas production | * The damage of the cargo hold. | UNLOAD | 12.0 | Intolerable risk |

| 2 | 605 | Section 2-(1) | The pressure in the pipe | * The explosion. | LOAD | 10.0 | Intolerable risk |

| 3 | 706 | Section 2-(2) | Freezing the vent line | * The damage of the cargo hold by the pressure rise. | NORMAL | 10.0 | Intolerable risk |

| 4 | 602 | Section 2-(1) | The damage of the valve | * The rupture of the pipe because of the pressure rise. * The leak of the gas. | LOAD | 6.0 | ALARP risk |

| 5 | 603 | Section 2-(1) | Freezing the residual water | * The rupture of the pipe at cooldown and normal operation. * The interruption of operation in regasification system. * The interruption of operation in cooldown system and pretreatment system. | LOAD | 6.0 | ALARP risk |

| 6 | 604 | Section 2-(1) | Pyrophoric substance | * The explosion by the pyrophoric substance. * The damage of the cargo hold by the failure of the pressure control in the pipe. | LOAD | 6.0 | ALARP risk |

| 7 | 610 | Section 2-(1) | The damage of the internals | * The damage of the insulation for the cargo hold. * The damage of the insulation. * The damage of the regasification. | LOAD | 6.0 | ALARP risk |

| 8 | 702 | Section 2-(2) | The leak of the loading | * The explosion in the void. | NORMAL | 6.0 | ALARP risk |

| 9 | 801 | Section 2-(3) | The damage of the circulating pump | * To shut regasification system down. | UNLOAD | 6.0 | ALARP risk |

| 10 | 802 | Section 2-(3) | The blockage of the water injection nozzle | * The regasification system is out of control. | UNLOAD | 6.0 | ALARP risk |

| 11 | 803 | Section 2-(3) | The damage of the pipe | * The delay of the regasification system. * The fire explosion. | UNLOAD | 6.0 | ALARP risk |

| 12 | 601 | Section 2-(1) | Oil spill on the deck | * The drain system is out of control. * The negligent accident. | LOAD | 5.0 | ALARP risk |

| 13 | 103 | Section 1-(1) | Snow/ice | * Blockage of BOG vent line due to icing. * Bad operation of external valves due to icing. | All | 4.0 | ALARP risk |

| 14 | 206 | Section 1-(2) | Drainage | * Explosion risk due to NGH jettisoning into the sea. * Marine pollution due to NGH jettisoning into the sea. | EMER | 4.0 | ALARP risk |

| 15 | 301 | Section 1-(3) | Shipping lanes | * Fracture on hull structure due to collision. * Fracture on piping, equipments and supporting structure due to collision. | All | 4.0 | ALARP risk |

| 16 | 607 | Section 2-(1) | Freezing in the pipe | * The leak of the gas. * The explosion. * The rupture of the pipe. | LOAD | 4.0 | ALARP risk |

| 17 | 609 | Section 2-(1) | The blockage of the vent line | * The damage of the cargo hold. | LOAD | 4.0 | ALARP risk |

| 18 | 611 | Section 2-(1) | The blockage of the NGH loading pipe | * The blockage of the NGH loading pipe. | LOAD | 4.0 | ALARP risk |

| 19 | 612 | Section 2-(1) | The excess of the generation of the BOG | * Environmental pollution. * The damage of the cargo hold by the pressure. * The damage of the cargo. | LOAD | 4.0 | ALARP risk |

| 20 | 613 | Section 2-(1) | The bias of the loading | * Heeling. | LOAD | 4.0 | ALARP risk |

| 21 | 703 | Section 2-(2) | The explosion in the void | * The damage of the insulation on the side. * The excess of the generation of the BOG. | NORMAL | 4.0 | ALARP risk |

| 22 | 704 | Section 2-(2) | The generation of the dissociation gas | * The damage of the cargo. * The damage of the cargo hold by the pressure rise. | NORMAL | 4.0 | ALARP risk |

| 23 | 707 | Section 2-(2) | The damage of the safety relief valve | * The damage of the cargo hold by the pressure rise. | NORMAL | 4.0 | ALARP risk |

| 24 | 708 | Section 2-(2) | The damage of the safety relief valve of the buffer tank | * The damage of the buffer tank. | NORMAL | 4.0 | ALARP risk |

| 25 | 709 | Section 2-(2) | The excess of the BOG removal capacity | * Environmental pollution. | NORMAL | 4.0 | ALARP risk |

| 26 | 710 | Section 2-(2) | The loss of the stability | * Stopping navigation. | NORMAL | 4.0 | ALARP risk |

| 27 | 711 | Section 2-(2) | Sloshing | * The damage of the cargo hold. | NORMAL | 4.0 | ALARP risk |

| 28 | 805 | Section 2-(3) | The sudden stops while unloading | * The leak of the gas while the regasification operation. | UNLOAD | 4.0 | ALARP risk |

| 29 | 806 | Section 2-(3) | The blockage of the nozzle | * To stop the operation. | UNLOAD | 4.0 | ALARP risk |

| 30 | 807 | Section 2-(3) | The damage of the drain valve | * The delay of the operation. | UNLOAD | 4.0 | ALARP risk |

Appendix 3

| SAFETY ACTION REGISTER | No. (1) of (8) | |||

|---|---|---|---|---|

| PROJECT | Development of NGH carrier | |||

| TASK | HAZID Study on the NGH Transport Vessel | |||

| DOCUMENT | HAZID Report | |||

| TARGET SYSTEM | The NGH Transport Vessel | |||

| Hazard ID | Op. Mode | Risk Index | Risk Level | Remark |

| 804 | UNLOAD | 12.0 | Intolerable | Section 2-(3) |

| [√] Course of Action (Compulsory) : [ ] Recommendation (Advisory) : 1. System analysis should be performed, the parameters should be carefully defined. 2. The measures to block the hydrothermal supply should be prepared. 3. The dual-line should be managed. | ||||

| Response: | ||||

| Close out: | ||||

Conflicts of Interest

References

- Kanda, H. Economic study on natural gas transportation with natural gas hydrate (NGH) pellets. In Proceedings of the 23rd World Gas Conference, Amsterdam, The Netherlands, 5–9 June 2006.

- Nogami, T.; Oya, N.; Ishida, H.; Matsumoto, H. Development of natural gas ocean transportation chain by means of natural gas hydrate (NGH). In Proceedings of 6th International Conference on Gas Hydrates, Vancouver, BC, Canada, 6–10 July 2008.

- Gudmundsson, J.S.; Borrehaug, A. Frozen hydrate for transport of natural gas. In Proceedings of the 2nd International Conference on Natural Gas Hydrates, Toulouse, France, 2–6 June 1996; pp. 415–422.

- Nakata, T.; Hirai, K.; Takaoki, T. Study of natural gas hydrate (NGH) carriers. In Proceedings of 6th International Conference on Gas Hydrates, Vancouver, BC, Canada, 6–10 July 2008.

- Ota, S.; Uetani, H.; Kawano, H. Use of methane hydrate pellets for transportation of natural gas—III—Safety Measures and conceptual design of natural gas hydrate pellet carrier. In Proceedings of the 4th International Conference on Gas Hydrates, Yokohama, Japan, 19–23 May 2002.

- Lee, Y.H.; Koh, B.H.; Kim, H.S.; Song, M.H. Compressive strength properties of natural gas hydrate pellet by continuous extrusion from a twin-roll system. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Stern, L.A.; Circone, S.; Kirby, S.H. Anomalous preservation of pure methane hydrate at 1 atm. J. Phys. Chem. B 2001, 105, 1756–1762. [Google Scholar] [CrossRef]

- Takeya, S.; Ebinuma, T.; Uchida, T.; Nagao, J.; Narita, H. Self-preservation effect and dissociation rates of CH4 hydrate. J. Cryst. 2002, 237–239, 379–382. [Google Scholar] [CrossRef]

- Circone, S.; Stern, L.A.; Kirby, S.H.; Durham, W.B.; Chakoumakos, B.C.; Rawn, C.J.; Rondinone, A.J.; Ishii, Y. CO4 hydrate: Synthesis, composition, structure, dissociation behavior, and a comparison to structure I CH4 hydrate. J. Phys. Chem. B 2003, 107, 5529–5539. [Google Scholar] [CrossRef]

- Shirota, H.; Hikida, K.; Nakajima, Y.; Ota, S.; Iwasaki, T. Self-preservation property of hydrate pellets in bulk in ship cargo holds during sea-borne transport of natural gas. In Proceedings of the 5th International Conference on Gas Hydrates, Trondheim, Norway, 13–16 June 2005.

- Takaoki, T.; Hirai, K.; Kamei, M.; Kanda, H. Study of natural gas hydrate (NGH) carriers. In Proceedings of the 5th International Conference on Gas Hydrate, Trondheim, Norway, 13–16 June 2005; pp. 1258–1256.

- IMO. MSC 83/INF.3. FSA—Liquefied Natural Gas (LNG) Carriers Details of the Formal Safety Assessment; IMO: London, UK, 2007. [Google Scholar]

- IMO. MEPC 58/INF.2. FSA—Crude Oil Tankers; IMO: London, UK, 2008. [Google Scholar]

- Kaehler, N.; Hamann, R. Safety and risk analysis of a natural gas hydrate pellet carrier. In Proceedings of the Twenty-second (2012) International Offshore and Polar Engineering Conference, Rhodes, Greece, 17–22 June 2012; pp. 35–40.

- IMO. BLG14. Draft interim Guidelines for the Construction and Equipment of Ships Carrying Natural Gas Hydrate Pellets (NGHP) in Bulk; IMO: London, UK, 2010. [Google Scholar]

- Braband, J. Improving the risk priority number concept. J. Syst. Saf. 2003, 32, 21–23. [Google Scholar]

- Rehder, G.; Eckl, R.; Elfgen, M.; Falenty, A.; Hamann, R.; Kaehler, N.; Kuhs, W.F.; Osterkamp, H.; Windmeier, C. Methane hydrate pellet transport using the self-preservation effect: A techno-economic analysis. Energies 2012, 5, 2499–2523. [Google Scholar] [CrossRef]

- IMO. MSC 83/INF.2. Formal Safety Assessment—Consolidated Text of the Guidelines for Formal Safety Assessment (FSA) for Use in the IMO sRule-Making Process (MSC/Circ.1023-MEPC/Circ.329); IMO: London, UK, 2007. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Kang, H.; Kim, Y. Risk Assessment for Natural Gas Hydrate Carriers: A Hazard Identification (HAZID) Study. Energies 2015, 8, 3142-3164. https://doi.org/10.3390/en8043142

Kim K, Kang H, Kim Y. Risk Assessment for Natural Gas Hydrate Carriers: A Hazard Identification (HAZID) Study. Energies. 2015; 8(4):3142-3164. https://doi.org/10.3390/en8043142

Chicago/Turabian StyleKim, Kipyoung, Hokeun Kang, and Youtaek Kim. 2015. "Risk Assessment for Natural Gas Hydrate Carriers: A Hazard Identification (HAZID) Study" Energies 8, no. 4: 3142-3164. https://doi.org/10.3390/en8043142