Experimental Study on Forced Convective Heat Transfer with Low Volume Fraction of CuO/Water Nanofluid

Abstract

:1. Introduction

| Author | Base fluid | Particle Material | Particle size | Volume fraction (%by Vol.) | Dimension | Flow Regime Re | Results and Remarks |

|---|---|---|---|---|---|---|---|

| Pak and Cho. [15] (1998) | Water TiO2 | γAl2O3 27 nm | 13 nm 1 - 3 | 1 - 3 | ID - 1.066 cm Length-480 cm S.S tube | Re = 104 - 105 (Turbulent flow) | Nu increased with increase in φ and Re |

| Eastman et al. [16] (1999) | Water | CuO | < 100 nm | 0.9 | - | (Turbulent flow conditions) | HTC increased by >15% compared with pure water. |

| Xuan and Li [17] (2003) | Water | Cu | < 100 nm | 0.3, 0.5, 0.8, 1, 1.2, 1.5, 2 | ID - 10 mm Length-800mm B Brass tube | Re = 10000 ~ 25000 (Turbulent flow) | Conv.HTC increases with increase in φ and flow velocity |

| Xuan and Li [18] (2004) | Water | Cu | 26 nm | 0.5,1,1.5,2 | Hydraulic Diameter = 1.29 mm | Re=200-2000 (Laminar flow) | Nu of nanofluid with φ=2% is 39% more than pure water. |

| Faulkner et al. [20] (2004) | Water | CNT | < 100nm | 1.1,2.2,4.4 | Hydraulic Diameter = 355µm | Re = 2-17 (Laminar flow) | HTC was found to be high at Higher concentrations. |

| Wen and Ding [19] (2004) | Water | γAl2O3 | 26-56nm | 0.6,1,1.6 | ID - 4.5 mm Length-970mm Copper tube | Re=500-2100 (Laminar flow) | For φ =1.6%, the HTC is 41% higher than the base fluid |

| Zhou [21] (2004) | Acetone | Cu | 80 -100 nm | 0.0-4.0 g/l | ID - 16 mm Length-200mm cCopper tube | - | Conv. HTC increases with addition of Cu nanoparticles. |

| Yang et al. [22] (2005) | Oil | Graphite | 20-40nm | 0.7- 1.0 | ID - 4.57mm Smooth tube | Re = 5 < 110 (Laminar flow) | HTC was 22% higher at 15% higher at 50oC&70oC for 2.5 wt% |

| Xuan and Li [23] (2005) | Water | Cu | 26 nm | 0.5,1,1.5,2 | ID - 10 mm Length-800mm Brass tube | Re=1000-4000 (Laminar&Turbulent flow) | Nu ratio varied from 1.06 to 1.39 when φ Increases from 0.5% to 2% 00.5% to 2% |

| Heris et al. [24] (2006) | Water | Al2O3 CuO | 20 nm 50-60nm | 0.2- 3.0 0.2- 3.0 | ID - 6 mm Copper tube | Re=650-2050 (Laminar flow) | HTC was high when φ increases for Al2O3, Nu is high |

| Esfahany et.al. [25] (2006) | Water | γAl2O3 | 20 nm | 0.2,0.5,1, 1.5,2,2.5 | ID - 6 mm Length - 1m CCopper tube | Re=700-2050 (Laminar flow) | HTC ratio increases with φ and 22% increase with Pe. |

| Ding et al. [26] (2006) | Water | MWCNT | 100nm | 0.1wt%-1.0 wt% | ID - 4.5 mm Length-970mm Copper tube | Re=800-1200 (Laminar flow) | 350% Enhancement was found for 0.5 wt% at Re=800. |

| Lai et al .[27] (2006) | Water | Al2O3 | 20 nm | 0 - 1% | ID - 1 mm S.S tube | Re < 270 | Nu enhancement of 8% for φ=1% Al2O3 Nanofluid at Re=270 |

| Jung et al. [28](2006) | Water | Al2O3 | 10 nm | 0.5 - 1.8% | Rectangular microchannel (50µm × 50µm) | 5 < Re < 300 | Conv.HTC increased by 32% for φ =1.8%. Nu increases with Re |

| Yulong. et al. [29] (2007) | Ethylene glycol | TiO2 CNT | - | - | - | - | Conv.HTC increases with φ and Re. |

| Williams et. al. [30] (2008) | Water | Al2O3 ZrO2 | 46 nm 60 nm | 0.9 - 3.6 0.2 - 0.9 | OD - 1.27 cm thick. =1.65mm SS.S tube | 9000< Re<63,000 (Turbulent flow) | Considerable heat transfer enhancement is observed |

| Chen et al. [31] (2008) | Water | Titanate Nanotube | 50 nm | 0.5, 1.0, 2.5 wt% | ID - 3.97 mm Length- 2 m Copper tube | Re=1100-2300 (Laminar flow) | Conv. HT enhancement was higher than that by thermal conductivity. Particle shape plays a major role |

2. Experimental Section

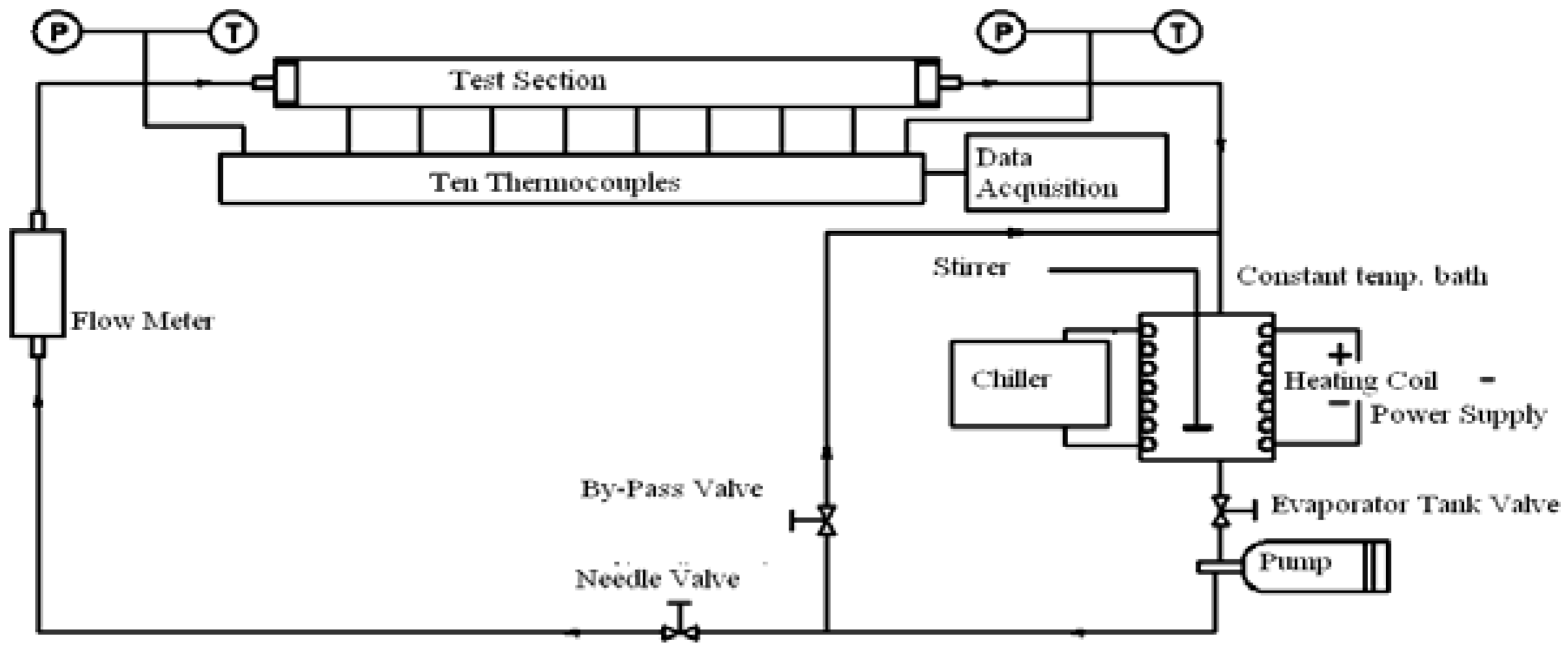

2.1. Experimental Apparatus

2.2. Cross sectional view of test section

2.3. Experimental procedure

| Parameters | Test Conditions |

|---|---|

| Base fluid | Water |

| Particle Material | CuO |

| Particle size | 40 nm |

| Volume fraction | 0.003% by vol. |

| Flow Regime | Laminar Re = 1,350 – 2,170 |

| Heat load | 300 – 400 watts |

| Inlet temperature | 10 – 17 0C |

2.4. Nanofluid preparation

2.4.1. Materials and dispersion of nano-particles in base fluid

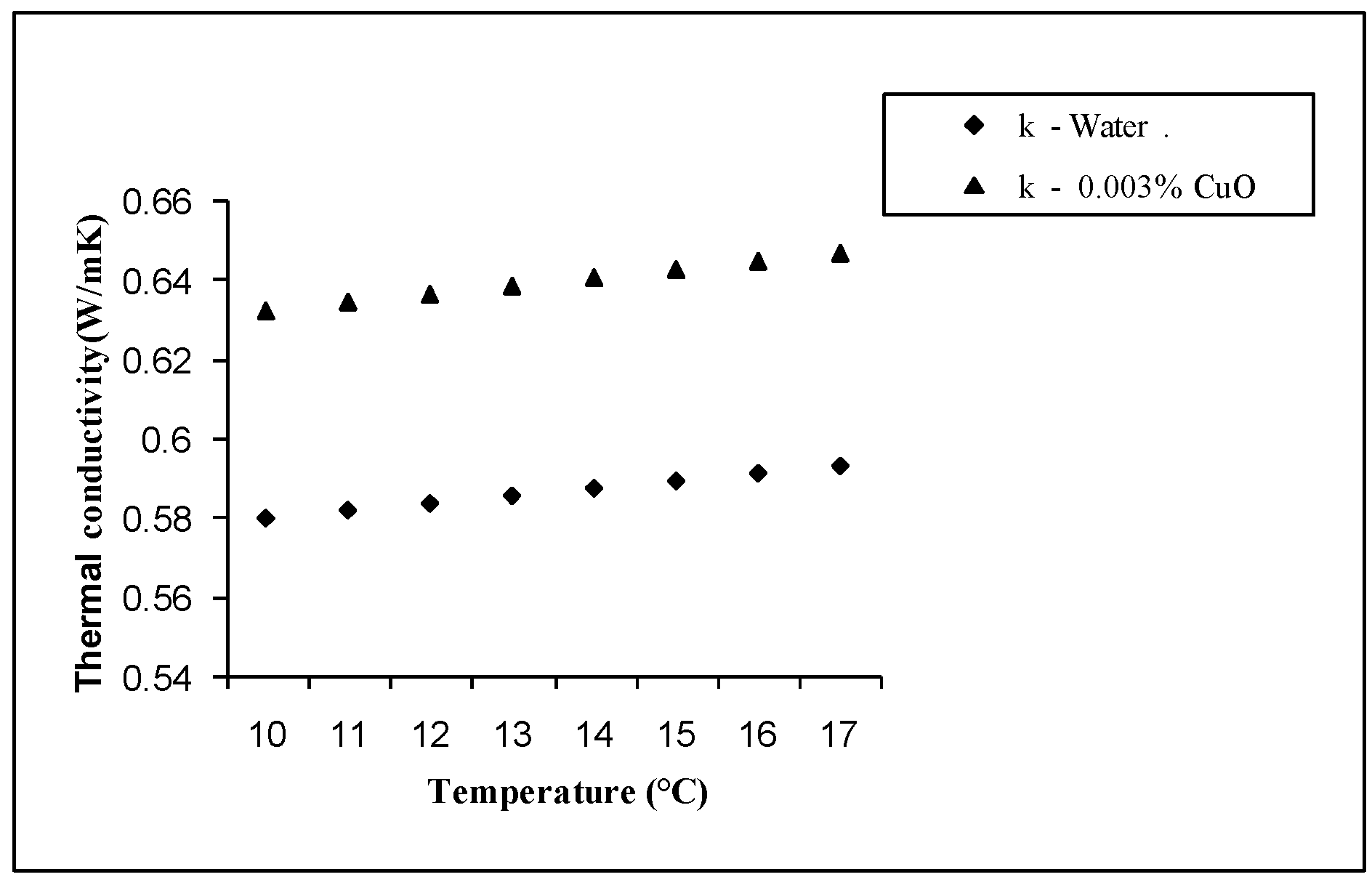

2.5. Nanofluid properties

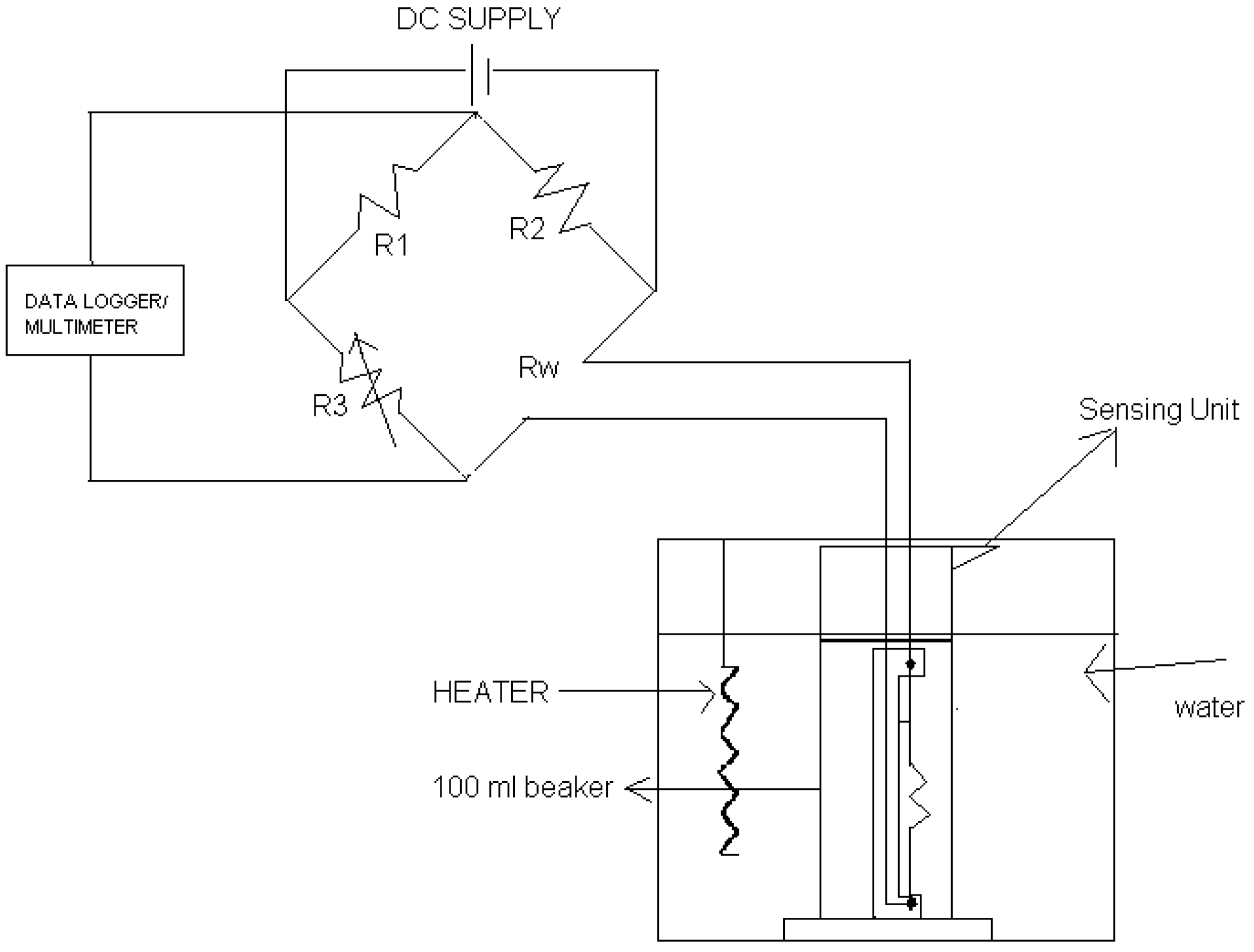

2.6. Transient Hot Wire Method

2.6.1. Experimental setup

2.7. Reliability and accuracy of the experimental system

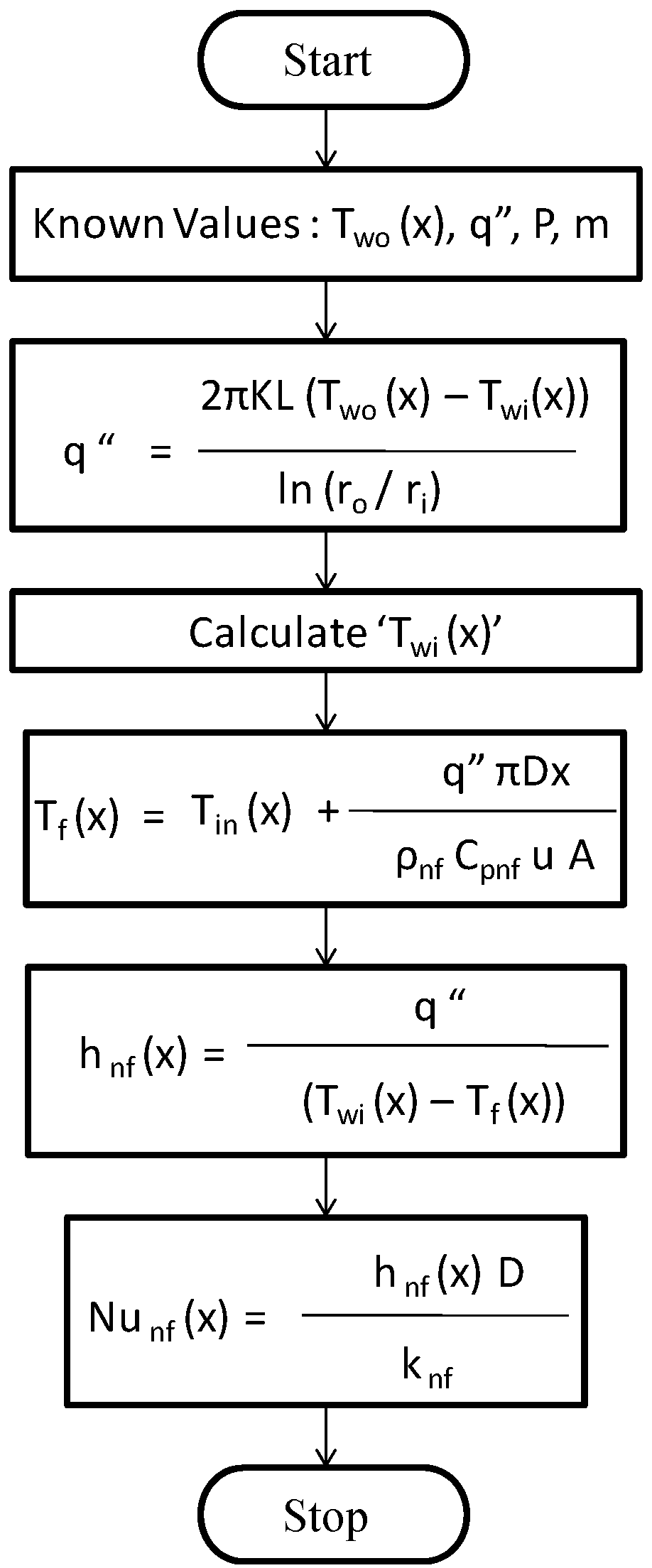

3. Mathematical Modeling

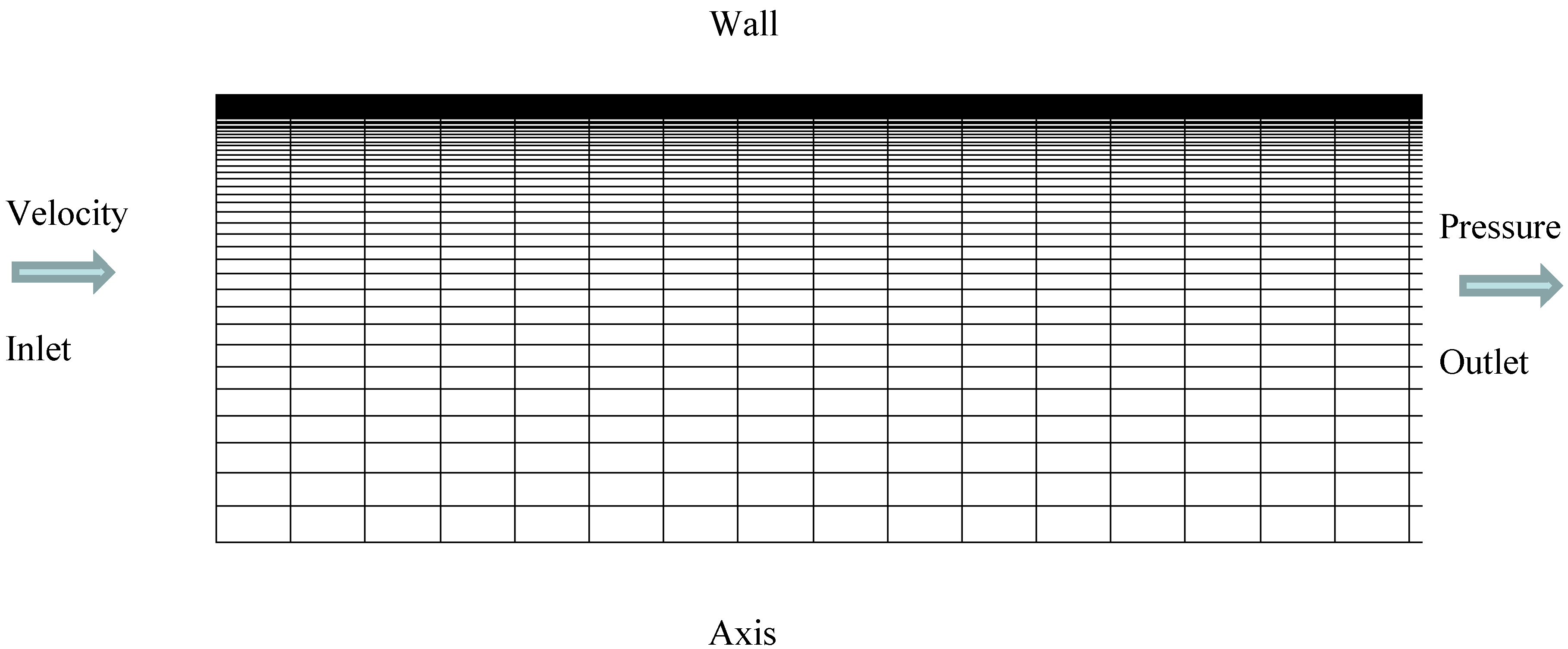

3.1. Geometrical Configurations

3.2. Assumptions

3.3. Boundary Conditions:

4. Numerical Methods

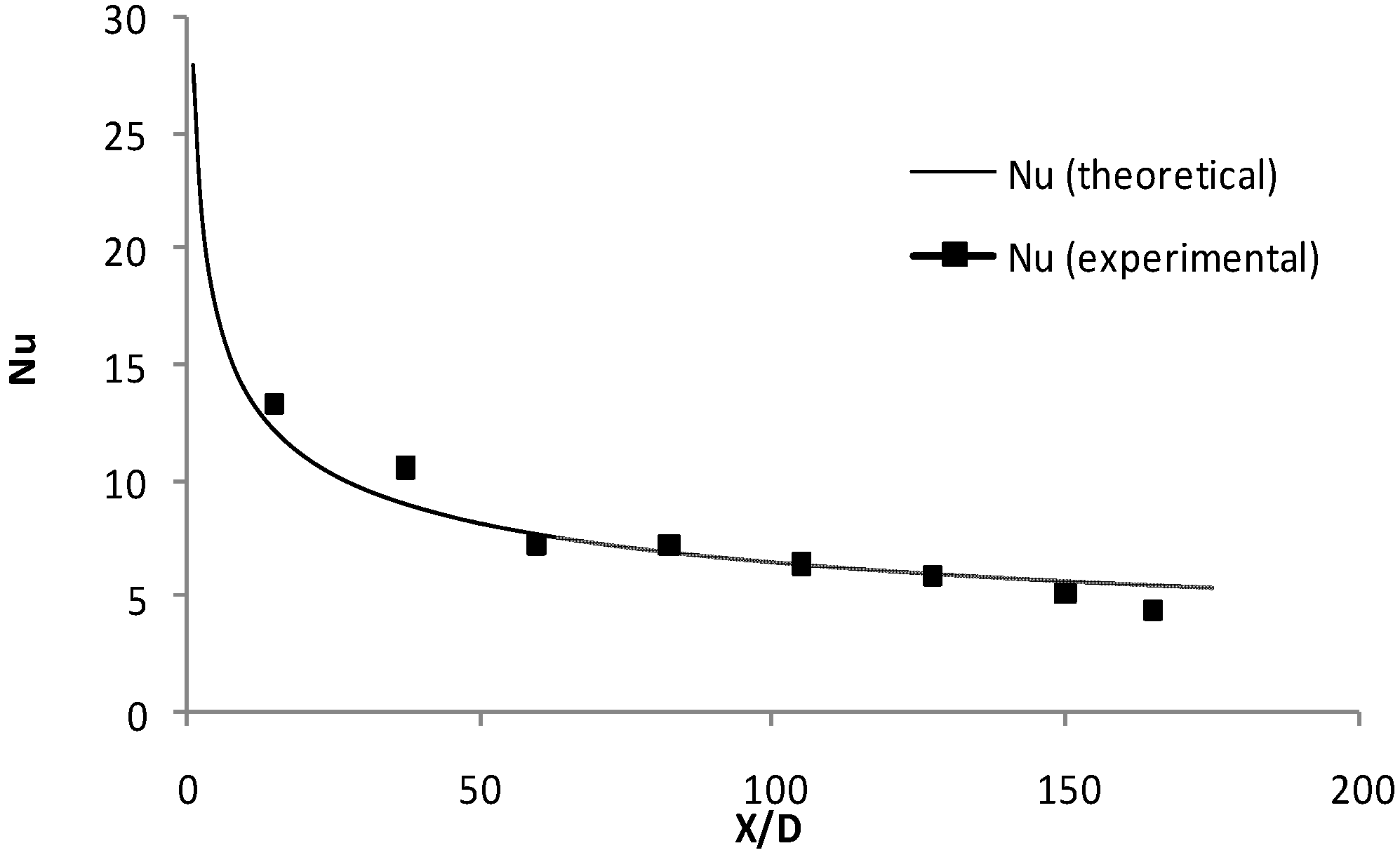

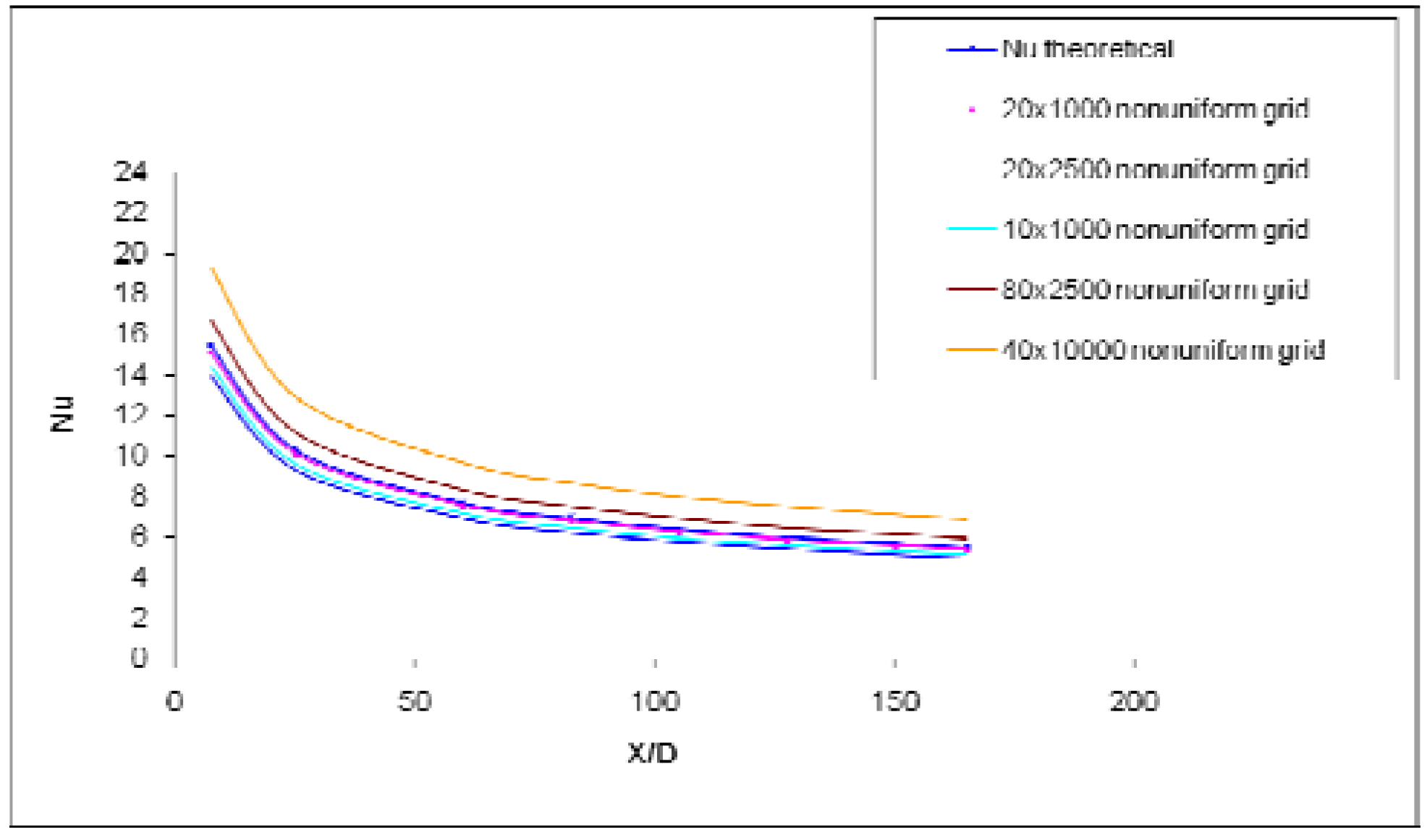

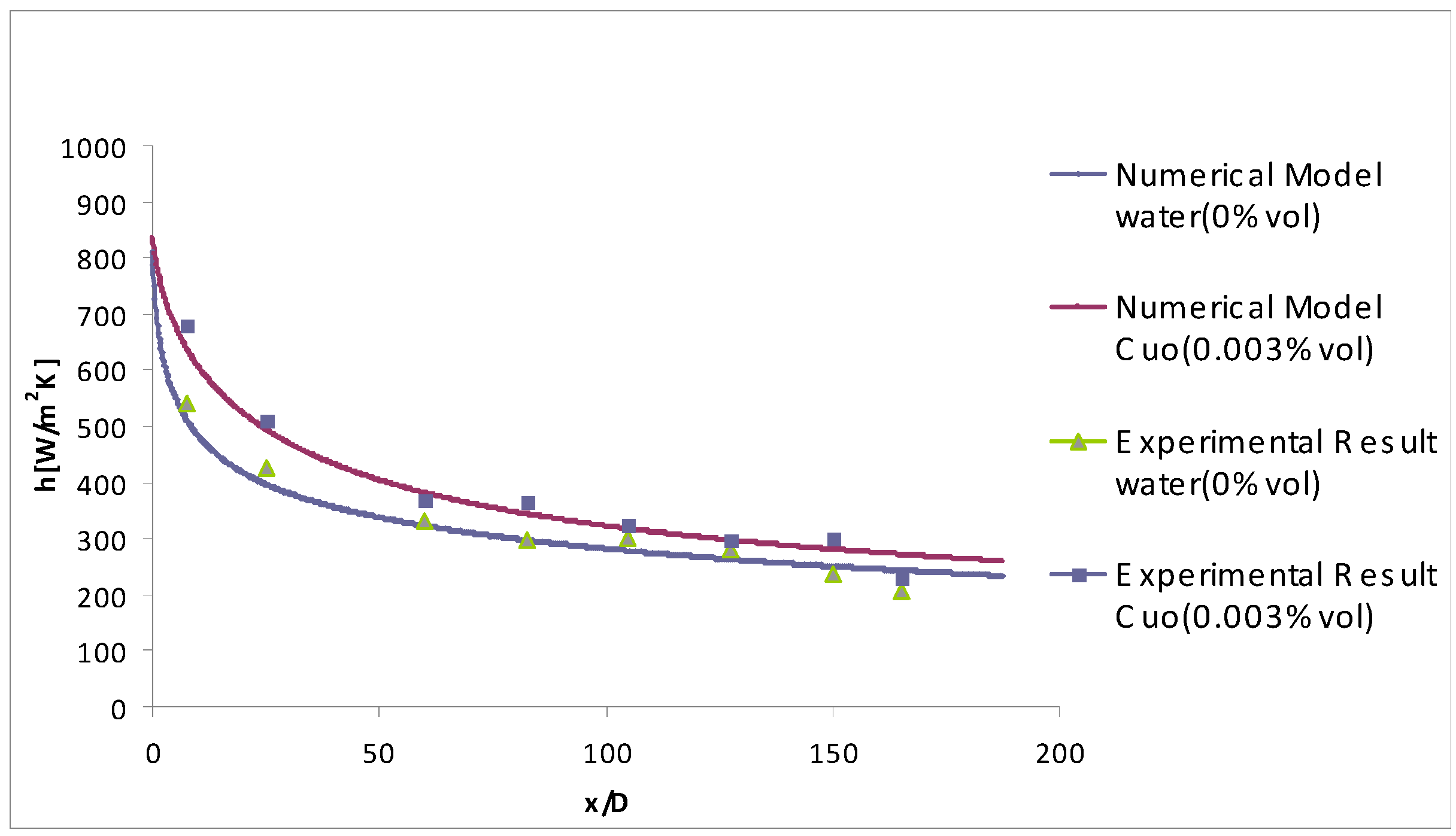

4.1. Grid Optimization and Code Validation

5. Experimental Results and Discussion

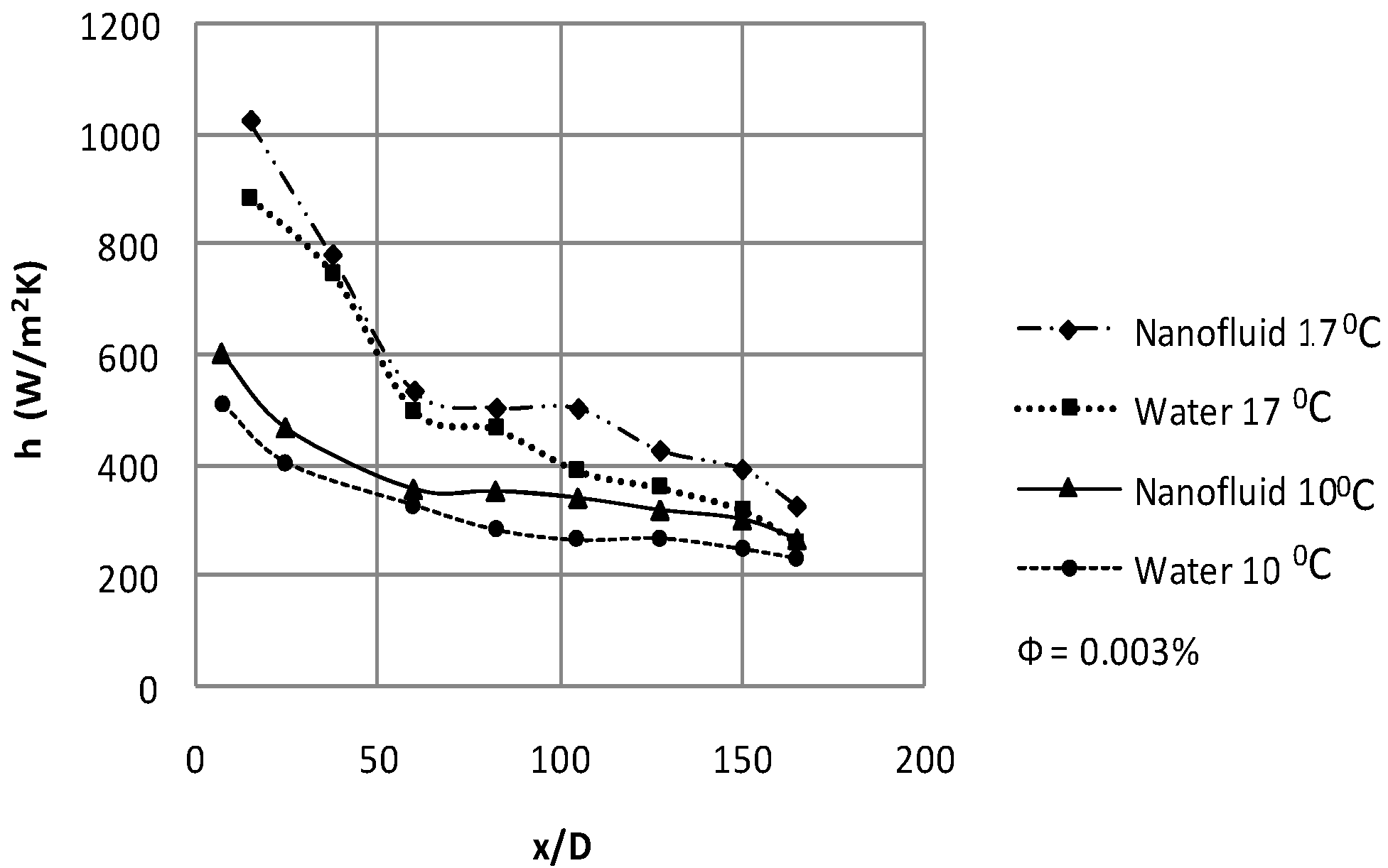

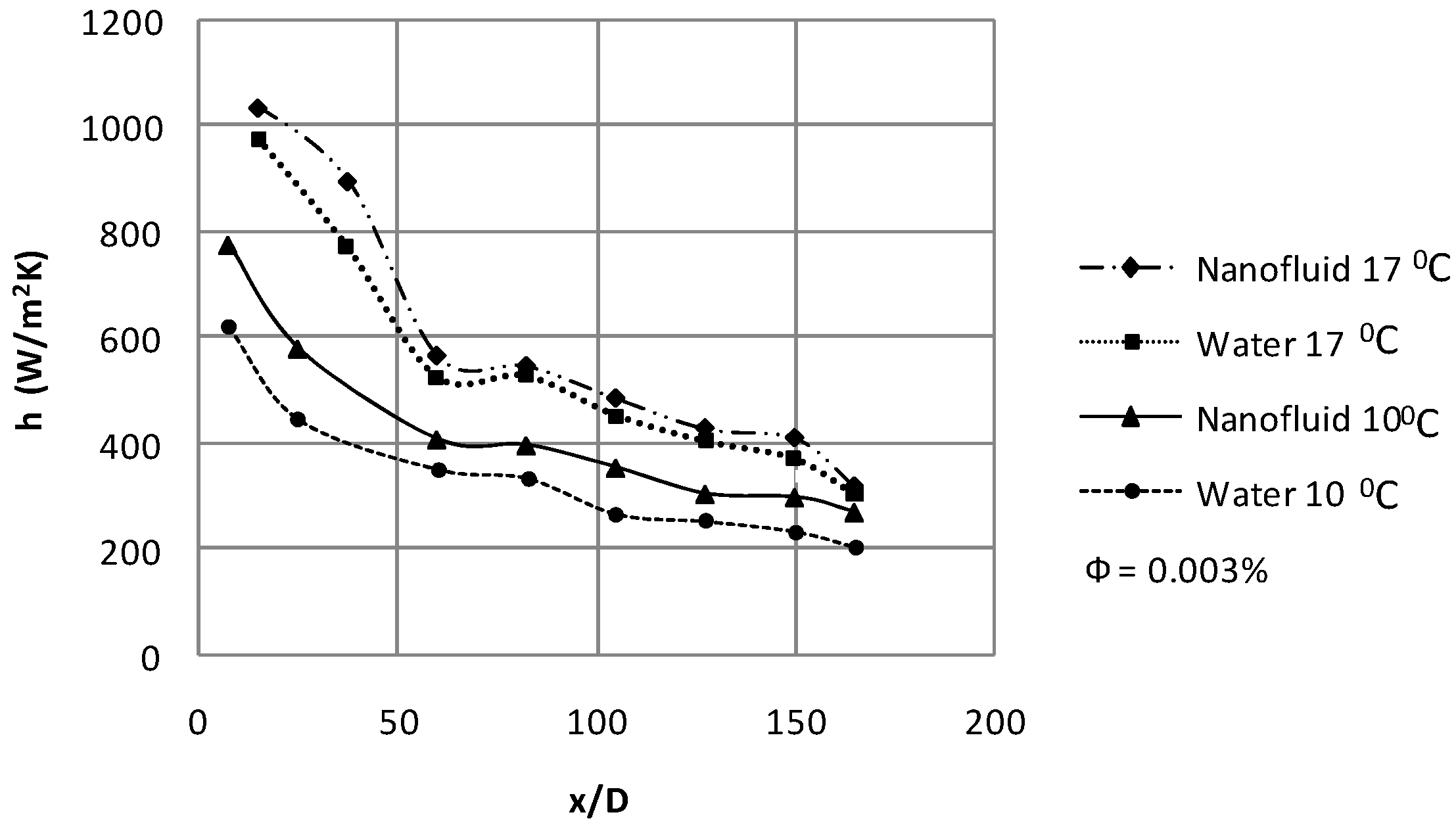

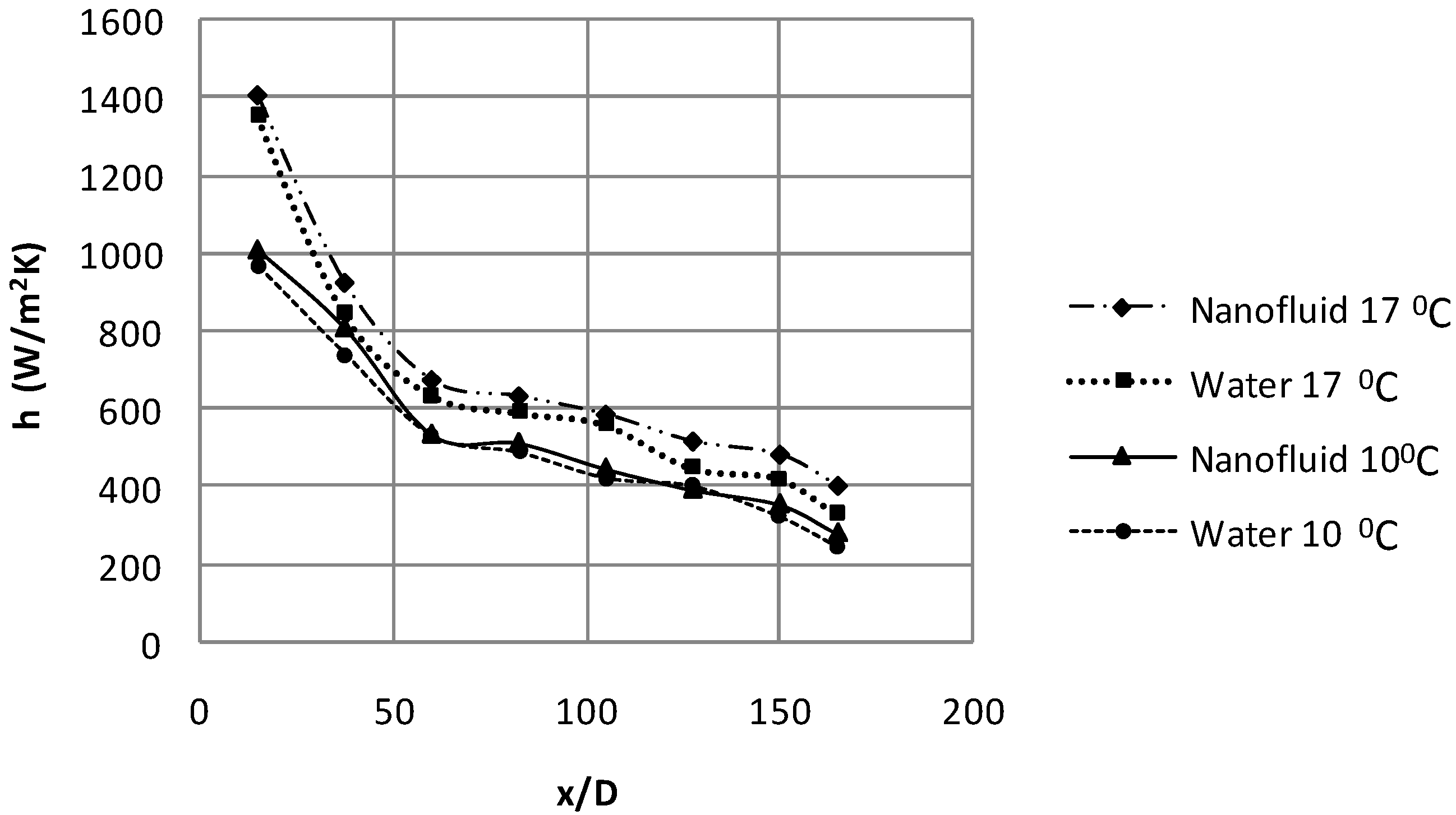

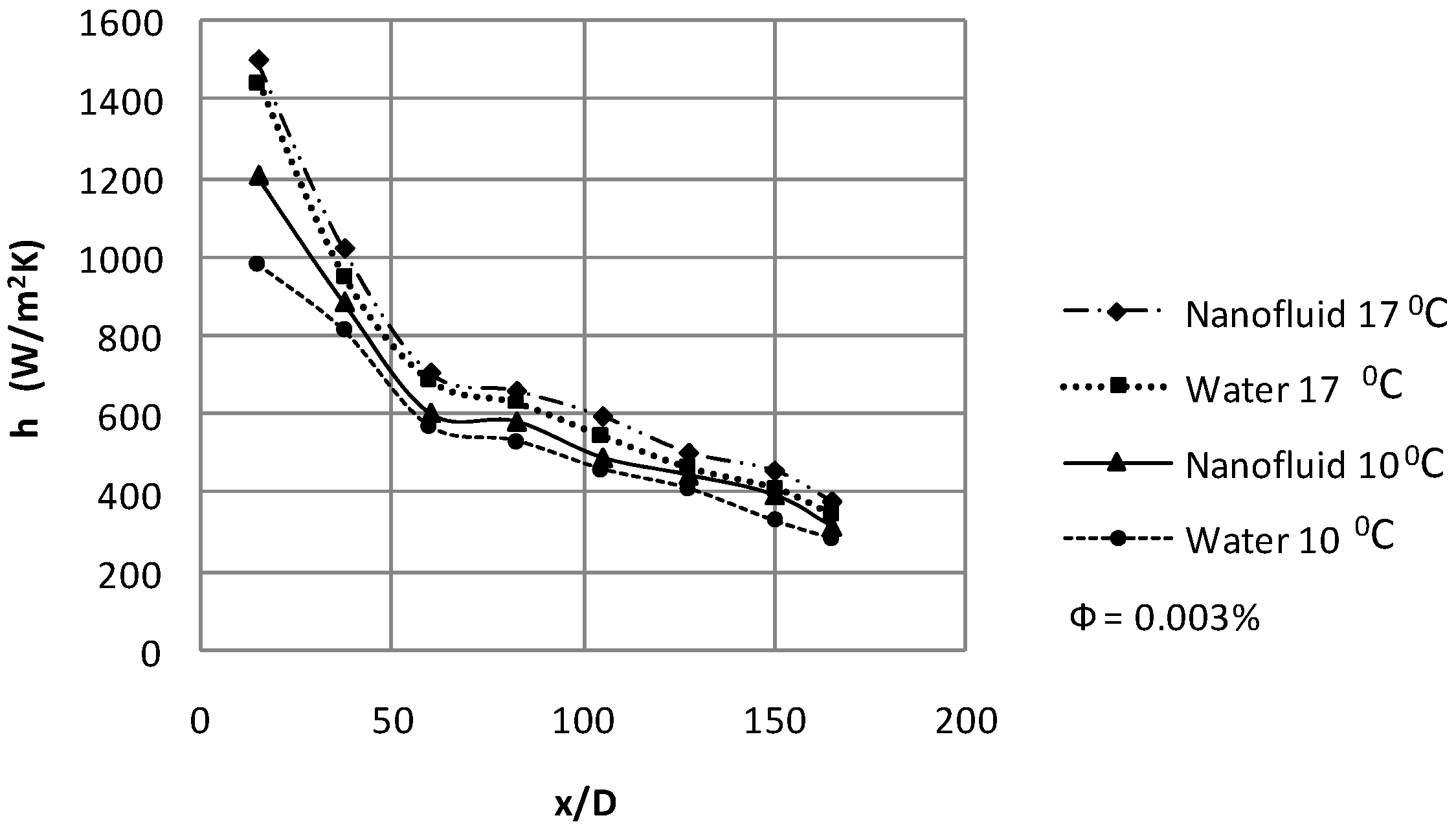

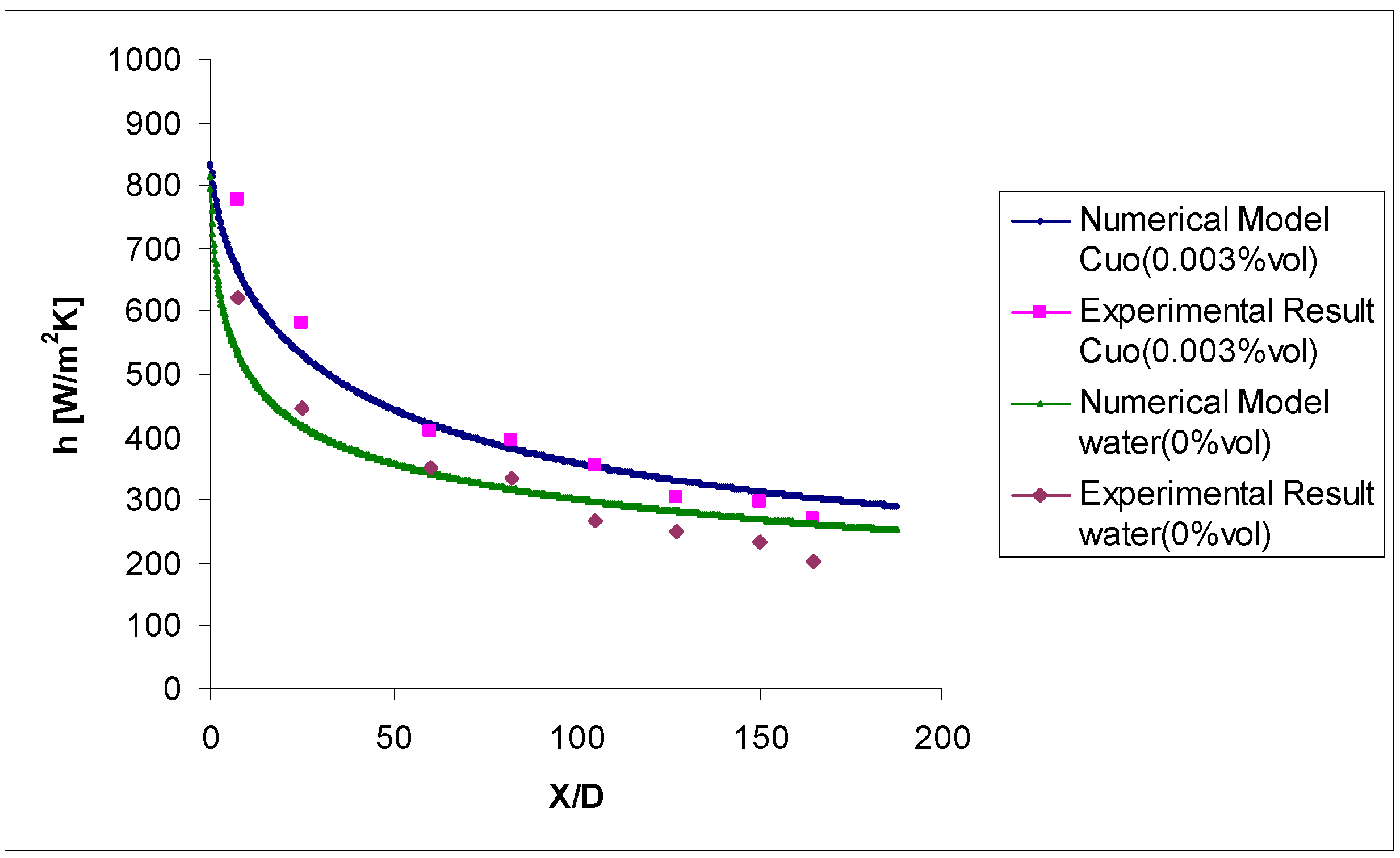

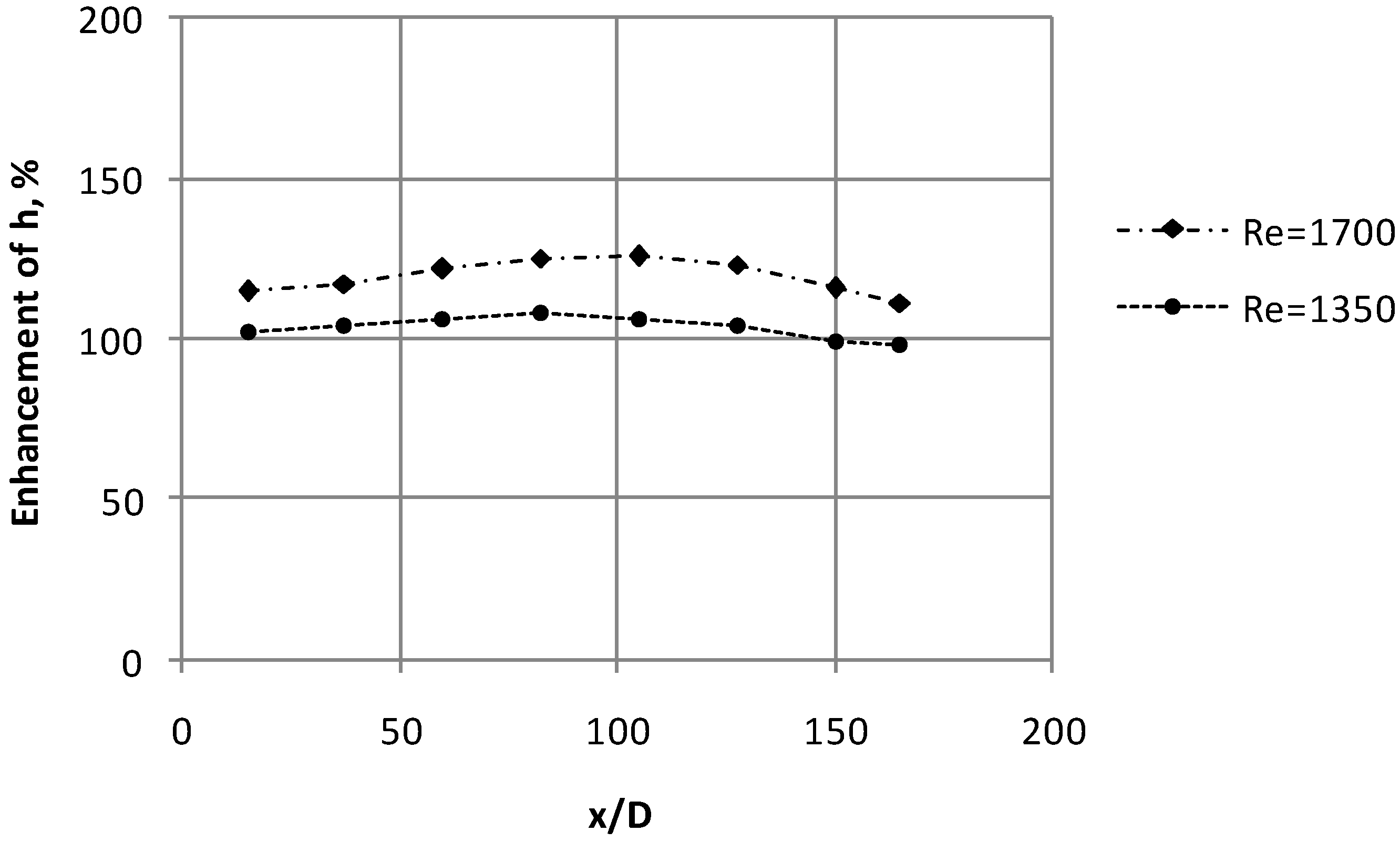

5.1 Axial profiles of convective heat transfer coefficient

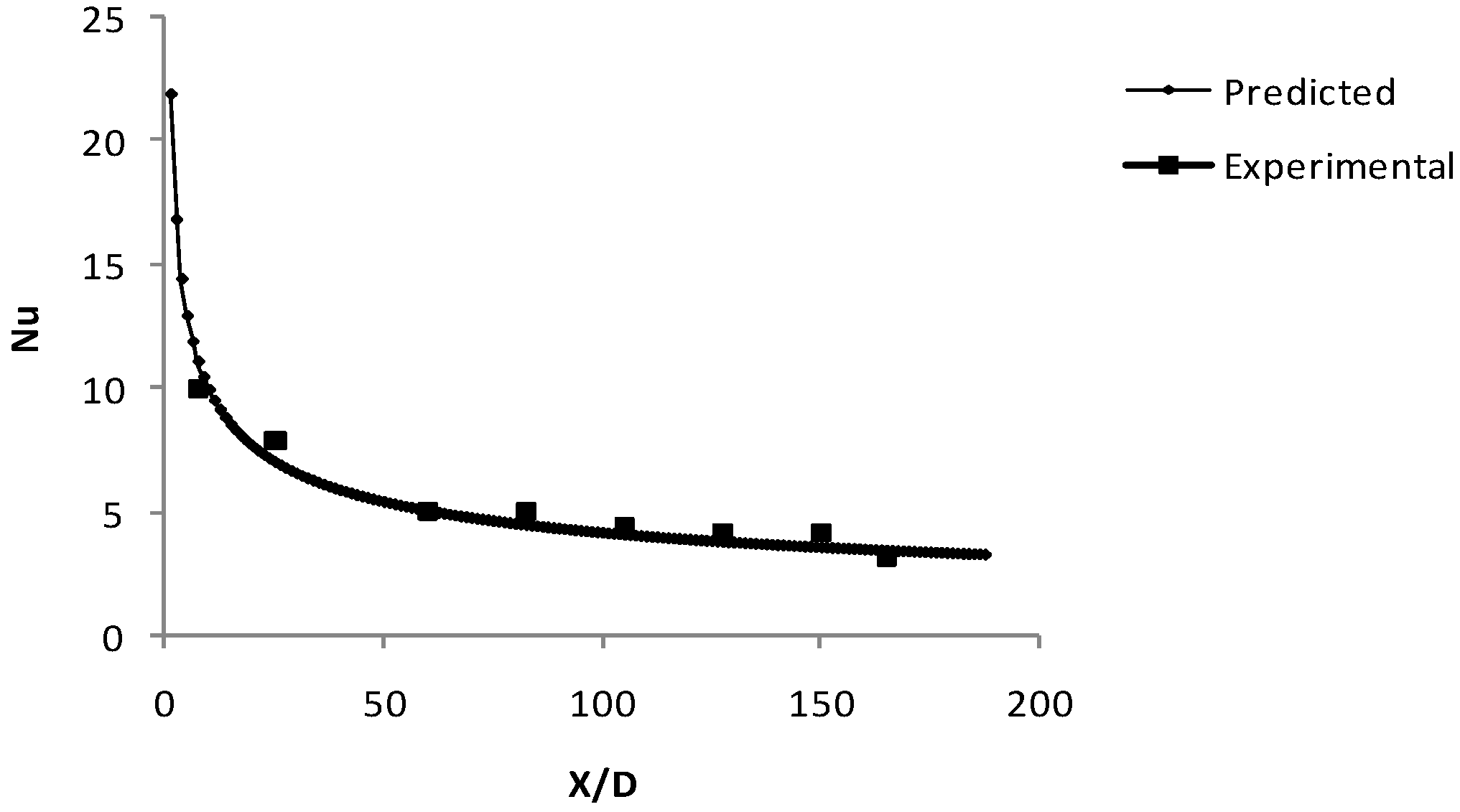

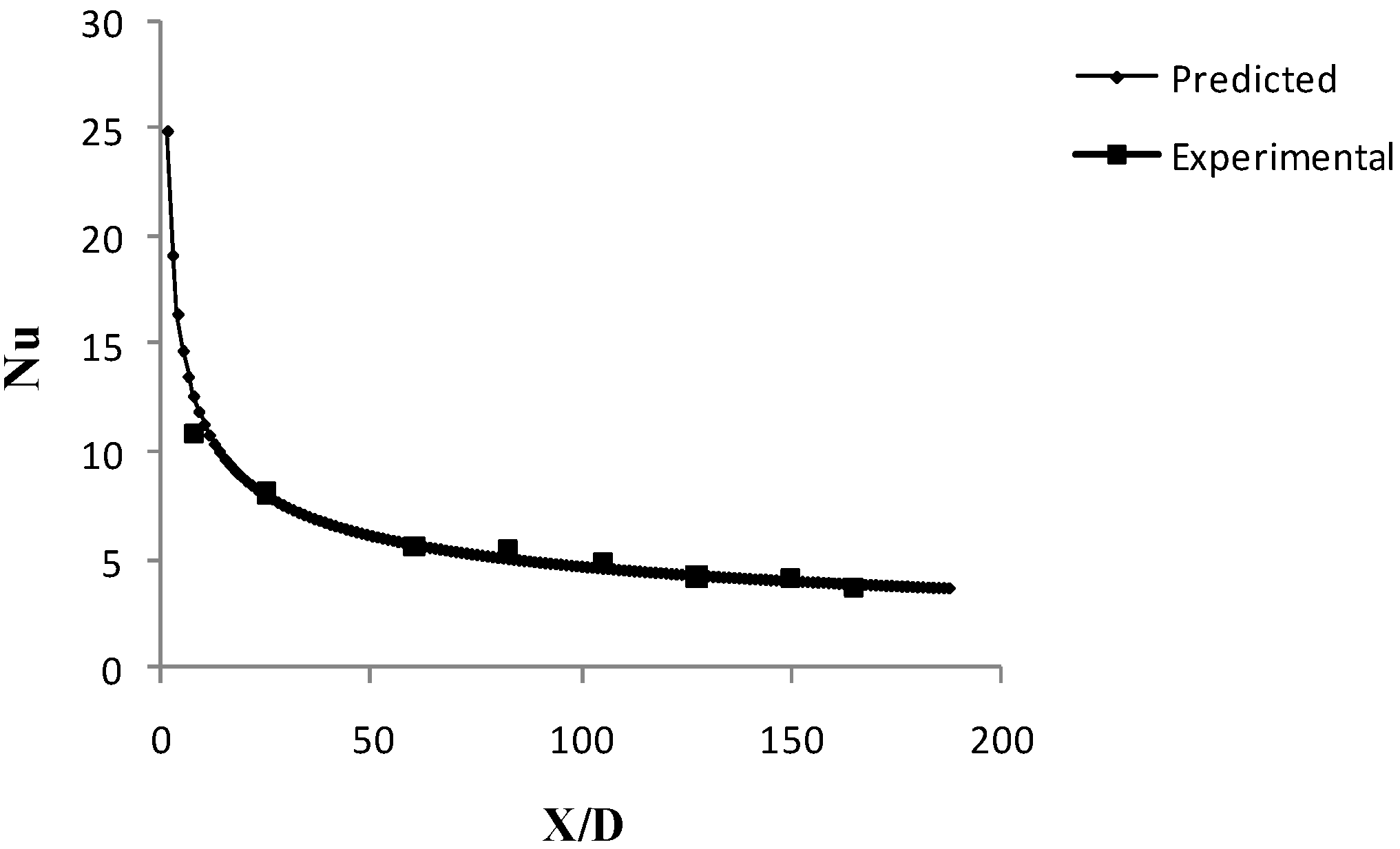

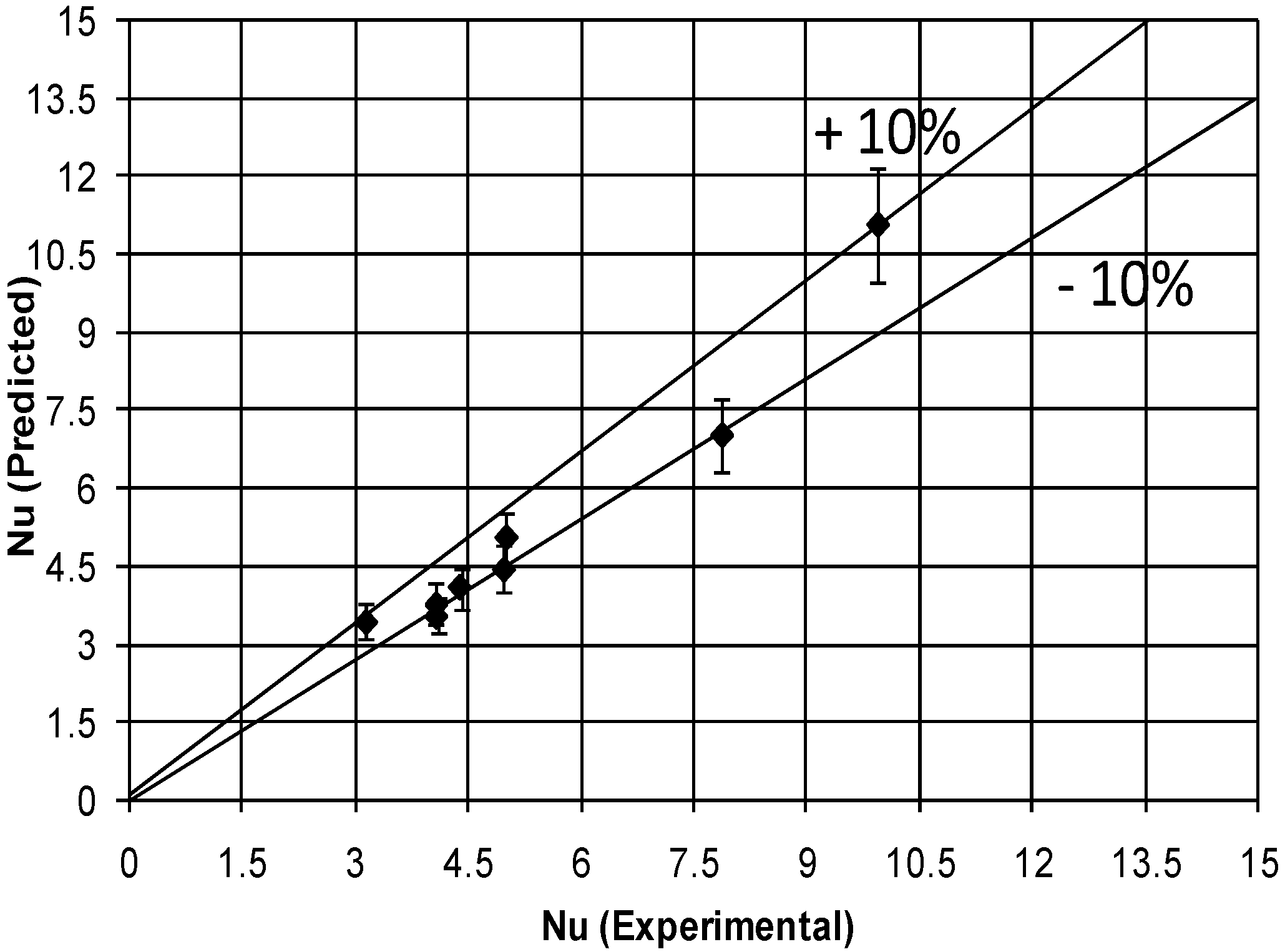

6. Correlations for Nusselt Number (Nu)

6.1. Methodology

7. Discussion on the possible mechanisms for enhancement

7.1. Effect of low volume fraction of CuO nanofluid on the convective heat transfer

7.2. Effect of inlet temperature on the convective heat transfer

7.3. Effect of heat flux on the convective heat transfer

7.4. Effect of Reynolds number on the convective heat transfer

5. Conclusions

- ■

- The presence of nanoparticles increases the convective heat transfer coefficient by 8% than that of the original base fluid under the same Reynolds number; and the increase is significant even though the concentration is less. At a given concentration the enhancement of heat transfer coefficient increases in the entrance region and decreases with the axial distance.

- ■

- The thermo-physical properties of nanofluids and chaotic movement of ultrafine particles are considered to be the important factors for an increase in heat transfer rate.

- ■

- Considerable fluctuations in the wall temperature readings at high heat fluxes indicate flow oscillations because of the random motion (Brownian motion) of the particles that cause changes in the instantaneous values of local nanofluid temperature and heat transfer rate.

- ■

- The energy exchange of the nanoparticle-fluid contacts increases as the temperature increases. This rise in temperature influences the particle collisions in the nanofluid resulting in an enhancement of thermal conductivity and in turn brings about higher heat transfer coefficient. More study will determine the extent of such temperature-dependant behavior. Such a type of studies could provide new findings which will be used for determining the importance of particle motion in controlling thermal transport behavior.

- ■

- Based on the experimental data a correlation for convective heat transfer coefficient of nanofluids, based on transport property and D/x for an 8 mm tube has been evolved.

Acknowledgements

Nomenclature

| A | cross sectional area, m2 |

| Cp | specific heat, J/kg K |

| d | tube diameter, m |

| h | heat transfer coefficient, W/m2 K |

| k | thermal conductivity, W/m K |

| m | mass flow rate, kg/s |

| Nu | Nusselt number, |

| Pr | Prandtl number, |

| q" | heat flux, W/m2 |

| Re | Reynolds number |

| T | temperature, oC |

Greek Symbols:

| β | thermal dispersion coefficient, N/m2 K |

| φ | volume fraction |

| ρ | density, kg/m3 |

| µ | dynamic viscosity, kg/m s |

Subscripts:

| f | bulk fluid |

| nf | nanofluid |

| w | tube wall |

| x | axial distance |

| bf | base fluid |

| i | inner wall |

| o | outer wall |

References and Notes

- Hwang, Y.J.; Ahn, Y.C.; Shin, H.S.; Lee, C.G.; Kim, G.T.; Park, H.S.; Lee, J.K. Investigation on characteristics of thermal conductivity enhancement of nanofluids. Curr. Appl. Phys. 2006, 6, 1068–1071. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R. F. W. High Performance Heat Sinking for VLSI. IEEE Elec. Dev. Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Liu, M.-S.; Lin, M.C.-C.; Huang, I-T.; Wang, C.-C. Enhancement of thermal conductivity with carbon nanotube for nanofluids. Int. Commun. Heat Mass Transfer 2005, 32, 1202–1210. [Google Scholar] [CrossRef]

- Lee, S.; Choi, S.; Lee, S.; Eastman, J. Measuring thermal conductivity of fluids containing oxide nanoparticles. J. Heat Transfer 1999, 121, 280–289. [Google Scholar] [CrossRef]

- Masuda, H.; Ebata, A.; Teramae, K.; Hishinuma, N. Alteration of thermal conductivity and viscosity of liquid by dispersion of ultra-fine particles. Netsu Bussei (Japan) 1993, 4, 227–233. [Google Scholar] [CrossRef]

- Eastman, J.; Choi, S.; Li, S.; Yu, W.; Thompson, L. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl. Phys. Lett. 2001, 78, 718–720. [Google Scholar] [CrossRef]

- Xie, H.; Wang, T.; Xi, J.; Liu, Y.; Ai, F.; Wu, Q. Thermal conductivity enhancement of suspensions containing nanosized alumina particles. J. Appl. Phys. 2002, 91, 4568–4572. [Google Scholar] [CrossRef]

- Das, S.; Putra, N.; Thiesen, P.; Roetzel, W. Temperature dependence of thermal conductivity enhancement for nanofluids. J. Heat Transfer 2003, 125, 567–574. [Google Scholar] [CrossRef]

- Patel, H.; Das, S.; Sundararajan, T.; Sreekumaran, A.; George, B.; Pradeep, T. Thermal conductivities of naked and monolayer protected metal nanoparticle based nanofluids: Manifestation of anomalous enhancement and chemical effects. Appl. Phys. Lett. 2003, 83, 2931–2933. [Google Scholar] [CrossRef]

- Choi, S.; Zhang, Z.; Yu, W.; Lockwood, F.; Grulke, E. Anomalously thermal conductivity enhancement of in nanotube suspensions. Appl. Phys. Lett. 2001, 79, 2252–2254. [Google Scholar] [CrossRef]

- Xie, H.; Lee, H.; Youn, W.; Choi, M. Nanofluids containing multiwalled carbon nanotubes and their enhanced thermal conductivities. J. Appl. Phys. 2003, 94, 4967–4971. [Google Scholar] [CrossRef]

- Choi, S.U.S. Enhancing thermal conductivity of fluids with nanoparticles, Developments and applications of non-Newtonian flows. ASME FED 231/MD 1995, 66, 99–103. [Google Scholar]

- Ahuja, A.S. Augmentation of heat transport in Laminar flow of polystyrene suspensions. I. Experiments and Results. J. Appl. Phys. 1975, 46, 408–3416. [Google Scholar]

- Ahuja, A.S. Thermal design of heat exchanger employing Laminar flow of particle suspensions. Int. J. Heat Mass Transfer 1982, 25, 725–728. [Google Scholar] [CrossRef]

- Pak, B.C.; Young, C.I. Hydrodynamic and heat transfer study of dispersed fluids with sub-micron metallic oxide particles. Exp. Heat Transfer 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Eastman, J.A.; Choi, S.U.S.; Li, S.; Soyez, G.; Thompson, L.J.; DiMelfi, R.J. Novel thermal properties of nanostructure materials. Mater. Sci. Forum 1999, 312, 629–34. [Google Scholar] [CrossRef]

- Xuan, Y.M.; Li, Q. Investigation on convective heat transfer and flow features of nanofluids. J. Heat Transfer 2003, 125, 151–155. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Flow and Heat Transfer Performances of Nanofluids inside Small Hydraulic Diameter Flat Tube. J. Eng. Thermophys. 2004, 25, 305–307. [Google Scholar]

- Wen, D.S.; Ding, Y.L. Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions. Int. J. Heat Mass Transfer 2004, 47, 5181–5188. [Google Scholar] [CrossRef]

- Faulkner, D.; Rector, D.R.; Davison, J.J.; Shekarriz, R. Enhanced Heat Transfer through the Use of Nanofluids in Forced Convection. Proc. ASME Heat Transfer Div. 2004, 219–224. [Google Scholar]

- Zhou, D.W. Heat transfer enhancement of copper nanofluid with acoustic cavitation. Int. J. Heat Mass Transfer 2004, 47, 3109–3117. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.G.; Grulke, E.A.; Anderson, W.B.; Wu, G.F. Heat transfer properties of nanoparticles-in-fluid dispersions (nanofluids) in laminar flow. Int. J. Heat Mass Transfer 2005, 48, 1107–1116. [Google Scholar] [CrossRef]

- Li, Q.; Xuan, Y.; Jiang, J.; Xu, J.W. Experimental Investigation on Flow and Convective Heat Transfer Feature of a Nanofluid for Aerospace Thermal Management. J. Astronautics 2005, 26, 391–394. [Google Scholar]

- Zeinali Heris, S.; Etemad, S.G.; Nasr Esfahany, M. Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int. Commun. Heat Mass Transfer 2006, 33, 529–535. [Google Scholar] [CrossRef]

- Zeinali Heris, S.; Nasr Esfahany, M.; Etemad, S.G. Experimental investigation of convective heat transfer of Al2O3/water nanofluid in circular tube. Int. J. Heat Fluid Flow 2007, 28, 203–210. [Google Scholar] [CrossRef]

- Ding, Y.; Alias, G.; Wen, D.; Williams, Richard A. Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids). Int. J. Heat Mass Transfer 2006, 49, 240–250. [Google Scholar] [CrossRef]

- Lai, W.Y.; Duculescu, B.; Phelan, P.E.; Prasher, R.S. Convective heat transfer with nanofluids in a single 1.02-mm tube. In Proc. ASME Int. Mech. Eng. Congress and Exposition (IMECE 2006), Chicago, IL, USA, 2006.

- Jung, J.-Y.; Oh, H.S.; Kwak, H.Y. Forced convective heat transfer of nanofluids in microchannels. In Proc. ASME Int. Mech. Eng. Congress and Exposition (IMECE 2006), Chicago, IL, USA; 2006. [Google Scholar] [CrossRef]

- Ding, Y.L.; Chen, H.S.; He, Y.R.; Alexei, L.; Mahboubeh, Y.; Lidija, Š.; Butenko Yuriy, V. Forced convective heat transfer of nanofluids. Adv. Powder Technology. 2007, 18, 813–824. [Google Scholar] [CrossRef]

- Wesley, W.; Buongiorno, J.; Hu, L.-W. Experimental Investigation of Turbulent Convective Heat Transfer and Pressure Loss of Alumina/Water and Zirconia/Water Nanoparticle Colloids(Nanofluids) in Horizontal Tubes. J. Heat Transfer. 2008, 130, 1–6. [Google Scholar]

- Chen, H.S.; Yang, W.; He, Y.R.; Ding, Y.L.; Zhang, L.L.; Tan, C.Q.; Lapkin, A.A.; Bavykin, D.V. Heat transfer and flow behaviour of aqueous suspensions of titanate nanotubes (nanofluids). Powder Technol. 2008, 183, 63–72. [Google Scholar] [CrossRef]

- Maiga Sidi, E.; Palm, S.J.; Tam, N.C.; Gilles, R.; Nicolas, G. Heat transfer enhancements by using nanofluids in forced convection flows. Int. J. Heat Fluid Flow 2005, 26, 530–546. [Google Scholar] [CrossRef]

- Anoop, K.B.; Patel, H.E.; Sundararajan, T.; Das, S.K. Numerical study of convective laminar heat transfer in nanofluids. Int. Heat Transfer Conf. 2006. (http://dx.doi.org/)10.1615/IHTC13.p8.110. [Google Scholar] [CrossRef]

- Xuan., Y.; Roetzel, W. Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass transfer. 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- Drew, D.A.; Passman, S.L. Theory of Multicomponent Fluids; Springer: Berlin, 1999. [Google Scholar]

- Kodhandaraman, C.P.; Subramanyan, S. Heat Mass Transfer Data Book; New Age Int. (P) Ltd: New Delhi, 1989; Reprint 2007. [Google Scholar]

- Eastman, J.A.; Phillpot, S.R.; Choi, S.U.S.; Keblinski, P. Thermal Transport in Nanofluids. Annu. Rev. Mater. Res. 2004, 34, 219–246. [Google Scholar] [CrossRef]

- Buongiorno, J. Convective Transport in Nanofluids. J. Heat Transfer. 2006, 128, 240–250. [Google Scholar] [CrossRef]

- Wang, B.X.; Zhou, L.P.; Peng, X.F.; Zhang, X.X. Enhancing the effective thermal conductivity of liquid withdilute suspensions of nano particles. In 15th Symposium on Thermophysical Properties; Boulder, CO, USA, June 2003. [Google Scholar]

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Asirvatham, L.G.; Vishal, N.; Gangatharan, S.K.; Lal, D.M. Experimental Study on Forced Convective Heat Transfer with Low Volume Fraction of CuO/Water Nanofluid. Energies 2009, 2, 97-119. https://doi.org/10.3390/en20100097

Asirvatham LG, Vishal N, Gangatharan SK, Lal DM. Experimental Study on Forced Convective Heat Transfer with Low Volume Fraction of CuO/Water Nanofluid. Energies. 2009; 2(1):97-119. https://doi.org/10.3390/en20100097

Chicago/Turabian StyleAsirvatham, Lazarus Godson, Nandigana Vishal, Senthil Kumar Gangatharan, and Dhasan Mohan Lal. 2009. "Experimental Study on Forced Convective Heat Transfer with Low Volume Fraction of CuO/Water Nanofluid" Energies 2, no. 1: 97-119. https://doi.org/10.3390/en20100097