Introduction

Bioethanol is a renewable transport fuel with the potential to go towards solving problems related to climate change, energy security and declining farm incomes (despite projected increases in the global human population, farm incomes relative to outside the agricultural sector have fallen in the Republic of Ireland, and are projected to fall further, especially in the livestock sector due to increasing supplies of raw food products from low cost producers outside of the EU [

10]). Bioethanol, as a renewable fuel can also go some way towards projected national Kyoto protocol greenhouse gas (GHG) emission limits of 13% above 1990 levels [

1], and also satisfy the EU biofuels directive 2003/30/EC which requires a 2% substitution by energy basis of mineral oil fuels with biofuels by 31

st December 2005 and a 5.75% substitution by 31

st December 2010 [

2]. Domestically, the Republic of Ireland has also set a target of 5.75% inclusion of biofuels by 2010 [

3].

Plant capacities and scale

Scale is an important issue with regard to ethanol production, as larger plants offer greater bargaining power and economies of scale. Research has shown that facilities with larger scales have considerably lower cost of construction per unit of output, which adds greatly to the potential viability of a facility, assuming required quantities of raw materials can be sourced cost efficiently [

4]. For example, in the world’s largest ethanol producing country, the US, the average annual capacity of commercial corn ethanol plants in 2007 was 189 million liters per year [

5]. A 2002 survey of 21 US ethanol plants recorded an ethanol output capacity range of between 34 and 340.65 million liters [

4]. Large scale facilities have much better bargaining power when it comes to purchasing raw materials and selling refined products. The plants mentioned above would require on average 485 ktonnes of corn and would require a comparable quantity of wheat if located in the Republic of Ireland. National annual production of wheat however is approximately 1 million tonnes. Therefore, a single ethanol plant using wheat would consume 49% of current wheat production. The Republic of Ireland is also a deficit producer of cereals, generally with a requirement to import grain and other feed additives to supply the demands of the combined feed, food and beverage industries. While some studies have endeavored to determine if Ireland can sustain an ethanol industry, they base their feedstock supply assumptions on national statistics and are therefore not suited to specific locations. Due to transport costs large-scale facilities source feedstock from limited catchment areas or else rely on large bulk shipments via rail or barge/ship. [

6,

7] As there is little scope for domestically sourced large bulk shipments the only strategies available are a local supply of feedstock or large shipments from non-domestic sources. The use of domestic feedstock is preferable to optimize national targets for greenhouse gas (GHG) abatement, job creation and energy security.

Land-use and agriculture in the Republic of Ireland

The Republic of Ireland is a deficit producer of cereal crops, which does not favor large scale bioethanol plants that require large areas of fertile land upon which to grow feedstock. Owing to ongoing developments in global, EU and national policies regarding land-use, agricultural support mechanisms and energy supply, almost all areas of Irish agriculture are in a period of rapid evolution [

8,

9,

10]. Of these developments, the major drivers of change include the radical amendments in EU agricultural policy brought about by the mid-term review and the EU biofuels directive 2003/30/EC. Global initiatives such as the recently stalled World Trade Organization (WTO) negotiations and the Kyoto protocol have in the past and will continue to impact the viability of different land-uses in Ireland. Notwithstanding these external drivers of biofuel demand and land-use change, probably the greatest single driver of a biofuels industry in Ireland at present is the state fiscal support in the form of excise relief for biofuels. The 2006 budget announced a five year biofuels excise relief package which aimed to place 163 million liters of biofuels on the Irish market, of which bioethanol was granted excise relief on an anticipated 85 million liters for the period 2008-2010 [

11].

Irish agriculture is primarily grass based, with 80% (3.52 Mha) of agricultural land comprising grass (pasture, silage, hay), 11% (0.484 Mha) rough grazing and around 9% (0.36 Mha) devoted to crop production. The main crops produced in Ireland during the last agricultural census were barley, wheat, potatoes, sugarbeet, and oats, which together supply the animal feed, milling, brewing, sugar and food industries [

12]. The Republic of Ireland can sustain some of the highest cereal yields in the world with averages of over 9 t/ha for wheat and 6.5 tonne/ha for barley regularly achieved [

13]. Bioethanol production is also seen as a means of replacing the former sugar industry which was recently phased out due to EU-wide rationalization of the sector in response to the changes to the EU sugar common market organization (CMO) [

14]. The land formerly under sugarbeet has the potential to be replaced by conventional cereal crops such as wheat or barley or re-cropped with sugarbeet to supply a bioethanol industry. Other possible sources of feedstock are biomass crops and agricultural by-products such as straw [

15,

16].

With both the demand for food and energy crops set to rise, careful planning of agricultural land resources is needed to ensure an efficient supply of raw materials to both the food and energy sectors without jeopardizing economic margins and environmental concerns [

17]. It has been previously estimated that 40-50 kha could be available for bioethanol feedstock production in the Republic of Ireland [

7]. However, bioethanol feedstock is in general sourced as locally as possible and national statistics can give a false impression of a countries true capacity to supply a bioethanol industry. Even when a country is divided into the Nomenclature of Territorial Units for Statistics (NUTS) level 3 regions it may not be small enough statistical units to accurately judge where exactly a good location for a bioethanol facility is. For example, in the Republic of Ireland there are eight NUTS-3 regions with an average area of 0.86 Mha. Therefore much smaller spatial units are needed to determine the suitability of particular locations.

The aim of this paper therefore is to accurately compare using a Geographical Information System (GIS) and a spreadsheet model nine most likely sites for locating a bioethanol plant based on the potential availability of the three feedstock wheat, sugarbeet and straw around their respective hinterlands and therefore determine if the Republic of Ireland can sustain a large scale bioethanol production facility using locally produced feedstocks.

Methodology

There are two main parts to the method used in this study. Initially, data was processed using GIS software to build a database of useful land-use, soil, topographical, infrastructural and geographical data that could be used to best determine potential plant locations and determine the distribution of feedstock production potentials both nationally and locally. The principle source of data for this analysis was the 2000 agricultural census, conducted by the Central Statistics Office (CSO). The agricultural census is completed approximately every ten years (1980, 1991, 2000); the smallest area unit used for representing data by the CSO for this survey is the Electoral Division (ED). The Irish Republic constitutes some 3,300 ED’s, the average area of an ED is 2,400 ha, compared to 0.86 Mha for each of the eight regions used in normal NUTS level 3 analysis. The small area units are necessary for assessing the local land-use around a particular location. During the census, data are collected for most aspects of agricultural activity within each ED such as area of certain crops and livestock numbers [

18].

Site selection

The GIS was then used to isolate all the data around each of the nine locations at 10 Km radii intervals up to a maximum 100 Km. The nine locations were chosen based primarily on where they would most likely be successfully constructed, as opposed to selecting sites based on proximity to feedstock, although this was also taken into consideration. The reason for adopting this strategy was that in Ireland, areas of intensive crop production tend to also be comparatively more densely populated, compared to countries such as the US and Brazil where planning laws are also less stringent. The result is far less chance of actually building large scale refineries in these areas. For this reason, a potential bioethanol plant will more likely be forced to be constructed in areas already having an industrial use such as sea ports, inland rail depots and decommissioned sugar factories or near existing fuel refineries. Once the land-use data were isolated it was then outputted to a spreadsheet model. The spreadsheet model was used to calculate the feedstock requirements of an ethanol plant and compare it to what the surrounding hinterland could supply under various land-use strategies using the outputs from the GIS. In all, nine sites were compared. The nine locations were chosen based on criteria such as an historical link to the handling and processing of the chosen crops or on an association with suitable infrastructure that would allow for efficient importation and handling of suitable feedstock or products of an ethanol plant. For inland locations, that was deemed to be either rail depots with dry-bulk handling facilities or former sugar factories that still contain much of the sugar beet processing and handling infrastructure. For port locations, it was ports with existing dry-bulk and/or wet bulk handling and storage facilities and terminals capable of supporting ships of 2,000 tonnes or greater. Proximity to either fuel depots or oil refineries was another reason for site selection. The nine locations and their justification for selection are given in

Table 1. Their spatial locations are given in

Figure 1.

Table 1.

Potential bioethanol plant locations, currently available infrastructure and general information.

Table 1.

Potential bioethanol plant locations, currently available infrastructure and general information.

| Location | Current Infrastructure | General information |

|---|

| Carlow | Electricity, natural gas, road, rail | Site of former sugar factory |

| Mallow | Electricity, road, rail | Site of former sugar factory |

| New Ross | Electricity, road, rail, port | Dry bulk handling and storage facilities, inland. |

| Enniscorthy | Electricity, road, rail | Centre of intensive crop producing area |

| Portlaoise | Electricity, road, rail, natural gas | Central location, major inland rail port under development |

| Whitegate oil refinery | Electricity, road, rail, port, natural gas, refinery | Location of Ireland only oil refinery, wet bulk handling facilities |

| Foynes port | Electricity, natural gas, road, rail, port | Dry and wet bulk storage and handling facilities |

| Dublin port | Electricity, natural gas, road, rail, port | Irelands largest port with dry and wet bulk handling/storage facilities |

| Drogheda port | Electricity, natural gas, road, rail, port | Dry bulk handling and storage facilities |

Figure 1.

Locations of the final nine potential bioethanol plant locations modeled.

Figure 1.

Locations of the final nine potential bioethanol plant locations modeled.

Land-use changes and feedstock availability

It is important to retain the supply of annual crops used for ethanol plants within the current arable area, as this reduces any environmental concerns associated with direct land-use change. Recently in 2006, with the closure of the two remaining sugar factories that processed native sugarbeet to sugar a considerable bank of land which is potentially equal to 31 kha has become available due to reduced demand from that source. It cannot be expected however, that all this land is going to be available as some permanent decommissioning of handling, storage, sowing and harvesting infrastructure will have occurred with some changes in farm structures over the intervening period since 2006.

Recently introduced EU farm support policy now makes the former set-aside area that existed in 2000 during the census to become potentially available. Again, as set-aside land was generally less productive parts of individual farms not all this land could be expected to realistically be available for growing intensive crops like wheat and sugarbeet. With regard to the more mainstream land-uses for growing cereals such as the wheat and barley areas, their expected contraction may also make more land available for non-food/feed uses. The outputs of a study conducted by the Fapri Ireland partnership [

10] was used as a basis to determine the likely changes in these cropping areas that are expected to occur into the future. The study suggests a net reduction in land used for wheat and barley production from 2000, when the last agricultural census was conducted. The main premise behind Fapri’s expectation for a fall in land used for growing wheat and barley is a reduction in demand for animal feed as cattle numbers decrease, which in turn is a response to a loss of competitiveness with non-EU meat producing regions such as South America. The study conducted by the Fapri Ireland partnership modeled the potential effects of different outcomes of the on-going round of WTO negotiations. There were four scenarios tested by Fapri in the model: A baseline, low, medium and high scenarios which relate to expected levels of market openness into the EU. The modeled average change in land used for growing wheat and barley across all the scenarios suggests a 13% reduction compared to 2000, which equates to a national reduction of 23.7 kha (

Figure 2).

Figure 2.

(a) Historical and projected arable area in Ireland as estimated by [

10].

Figure 2.

(a) Historical and projected arable area in Ireland as estimated by [

10].

To determine the potential land available around each site the following assumptions were therefore made:

13% of the 2000 wheat and barley area is available for growing ethanol feedstock.

55% and 75% of the set-aside and former sugarbeet areas are available, respectively.

The maximum radius within which indigenously grown feedstock’s can be sourced is 100 Km from the plant.

The yields of wheat and sugarbeet are taken to be, 8.5 and 45 tonne/ha respectively.

The required sugarbeet area cannot exceed more than 25% of the cropping area in order to satisfy a 1 in 4 rotation.

The infield removable straw:grain ratio 0.55:1 and a maximum 50% of the catchment areas straw is supplied to the plant.

The ethanol plant will have an annual output of 200 million liters per annum.

The ethanol yield per tonne of feedstock is taken to be 252.4, 99.3 and 387.2 liters per tonne respectively for straw, sugarbeet and wheat (

Table 1).

Table 2.

Estimated ethanol yield from the modeled feedstock straw, sugarbeet and wheat.

Table 2.

Estimated ethanol yield from the modeled feedstock straw, sugarbeet and wheat.

| | Input | Output | Unit |

|---|

| | Wheat | 1000 | | kg |

| Starch content | 0.65 | 650.0 | kg |

| Starch to dextrin | 0.98 | 637.0 | kg |

| Dextrin to glucose | 0.99 | 630.6 | kg |

| Ethanol stoichiometric yield | 0.51 | 321.6 | kg |

| Glucose fermentation efficiency | 0.95 | 305.5 | kg |

| Total ethanol production | 387.2 | Liters/tonne |

| | Input | Output | Unit |

| | Sugarbeet | 1000 | | kg |

| Sugar content | 0.165 | 165 | kg |

| Sugar extraction efficiency | 0.96 | 158.4 | kg |

| Ethanol stoichiometric yield | 0.51 | 80.8 | kg |

| Glucose fermentation efficiency | 0.97 | 78.4 | kg |

| Total ethanol production | 99.3 | Liters/tonne |

| | Input | Output | Unit |

| Glucose | Straw | 1000 | | kg |

| Cellulose content | 0.38 | 380.0 | kg |

| Cellulose conversion and recovery efficiency | 0.76 | 288.8 | kg |

| Ethanol stoichiometric yield | 0.51 | 147.3 | kg |

| Glucose fermentation efficiency | 0.9 | 132.6 | kg |

| | 168.0 | Liters/tonne |

| Xylose | Straw | 1000 | | kg |

| Hemicellulose content | 0.29 | 290.0 | kg |

| Hemicellulose conversion and recovery efficiency | 0.9 | 261.0 | kg |

| Ethanol stoichiometric yield | 0.51 | 133.1 | kg |

| Xylose fermentation efficiency | 0.5 | 66.6 | kg |

| | 84.4 | Liters/tonne |

| Total ethanol production | 252.4 | Liters/tonne |

Once these assumptions and data inputs were known, they were inputted to the model, which then compared the land requirements of a large scale ethanol plant to the capacity of the hinterland to meet that demand.

Results

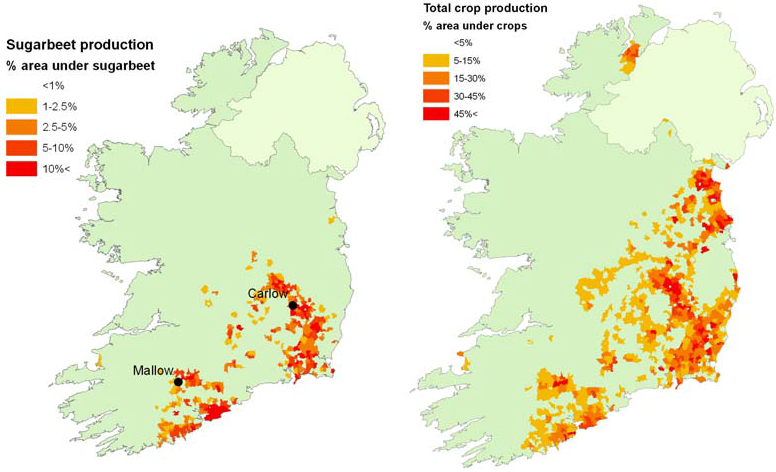

Outputs from the GIS show the distribution of crops grown in Ireland during the last census are highly concentrated to the south and east while sugarbeet production is concentrated both geographically to the south and also around the last two operating sugar factories in Mallow and Carlow (

Figure 3).

Figure 3.

(a) Distribution of sugarbeet production in the Republic of Ireland during the agricultural census and locations of the two former sugar factories in Carlow and Mallow (b) distribution of total crops in the Republic of Ireland during the agricultural census.

Figure 3.

(a) Distribution of sugarbeet production in the Republic of Ireland during the agricultural census and locations of the two former sugar factories in Carlow and Mallow (b) distribution of total crops in the Republic of Ireland during the agricultural census.

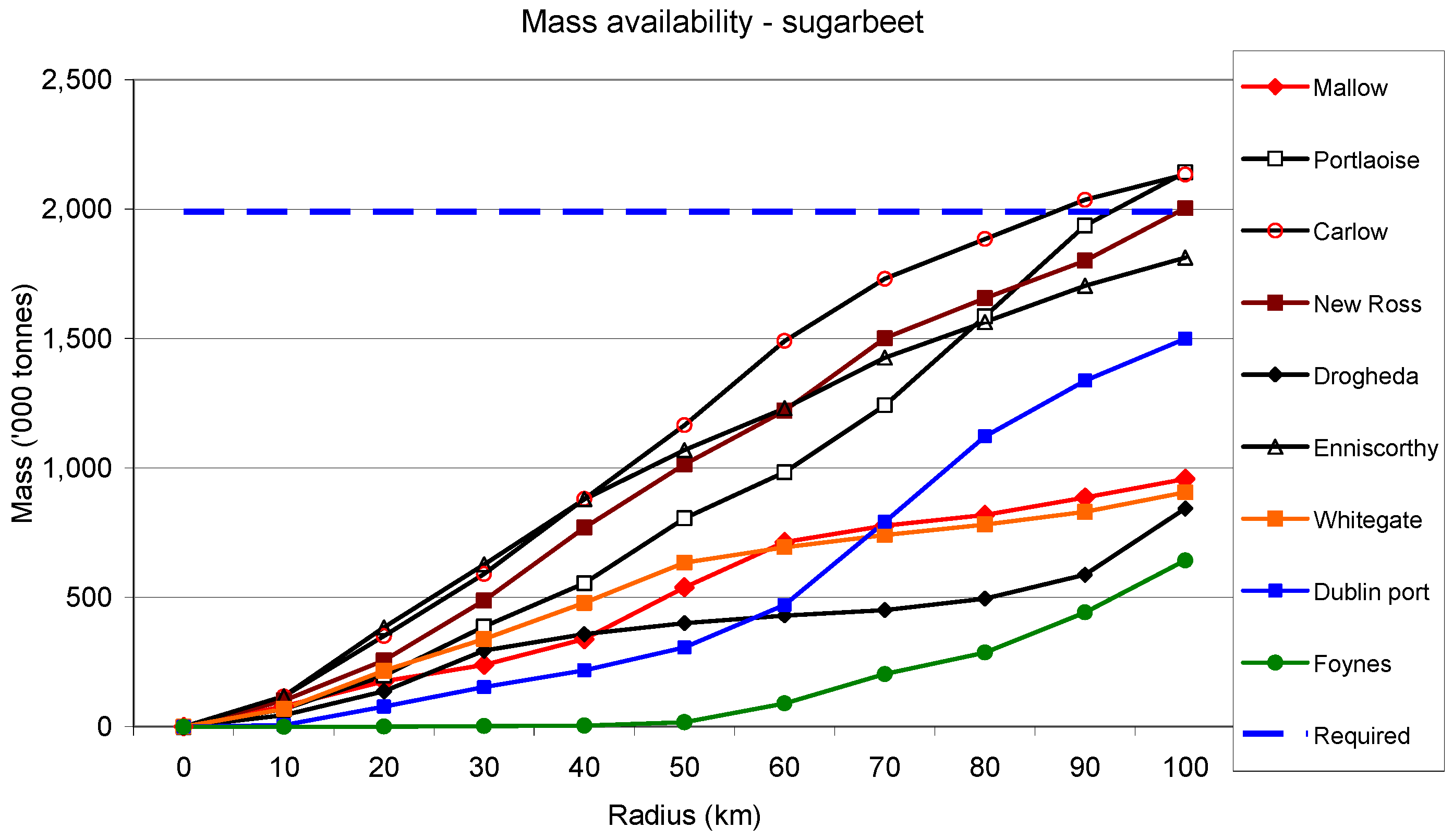

Figure 4.

Modeled availability of sugarbeet around each location.

Figure 4.

Modeled availability of sugarbeet around each location.

When the locations were modeled for the potential of their respective hinterlands to supply the required area of land to meet the needs of an ethanol plant based on sugarbeet as a feedstock it was found, that under the assumptions in this study, three of the nine locations could meet their feedstock demands within 100 km. These included the locations at New Ross, Carlow and Portlaoise, with Carlow and Portlaoise meeting their needs within 90 km (

Figure 4).

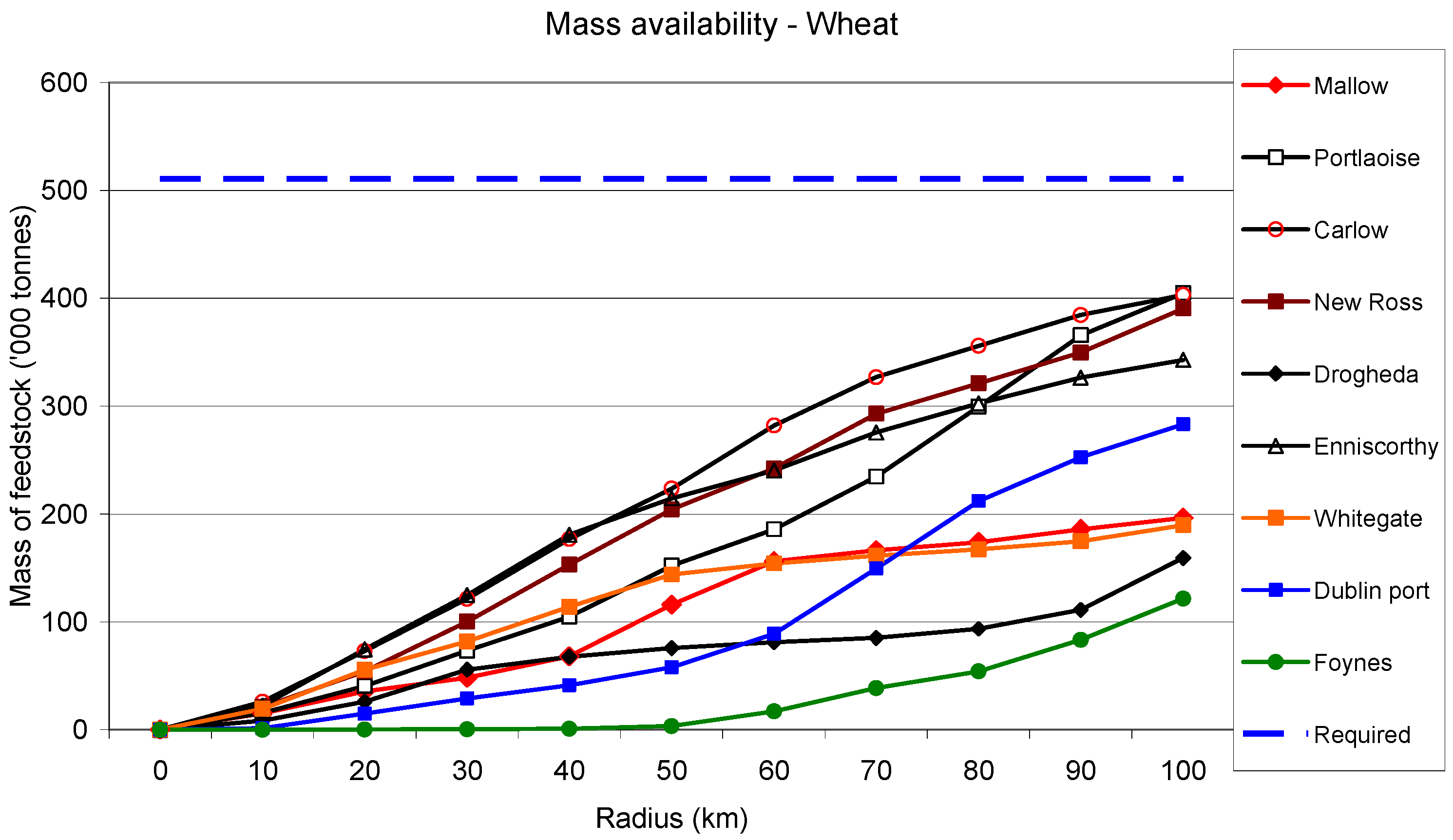

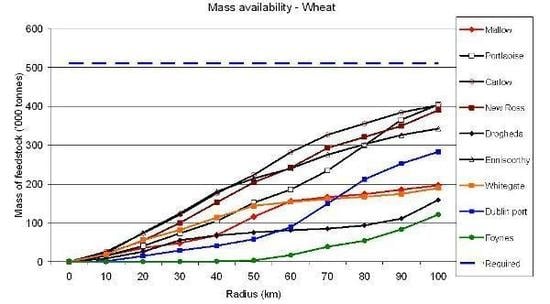

In the case of wheat as a potential feedstock none the locations could all meet their feedstock demands within 100 km. The closest locations to meeting their demands were Portlaoise and Carlow, each meeting 79% of their expected demands (

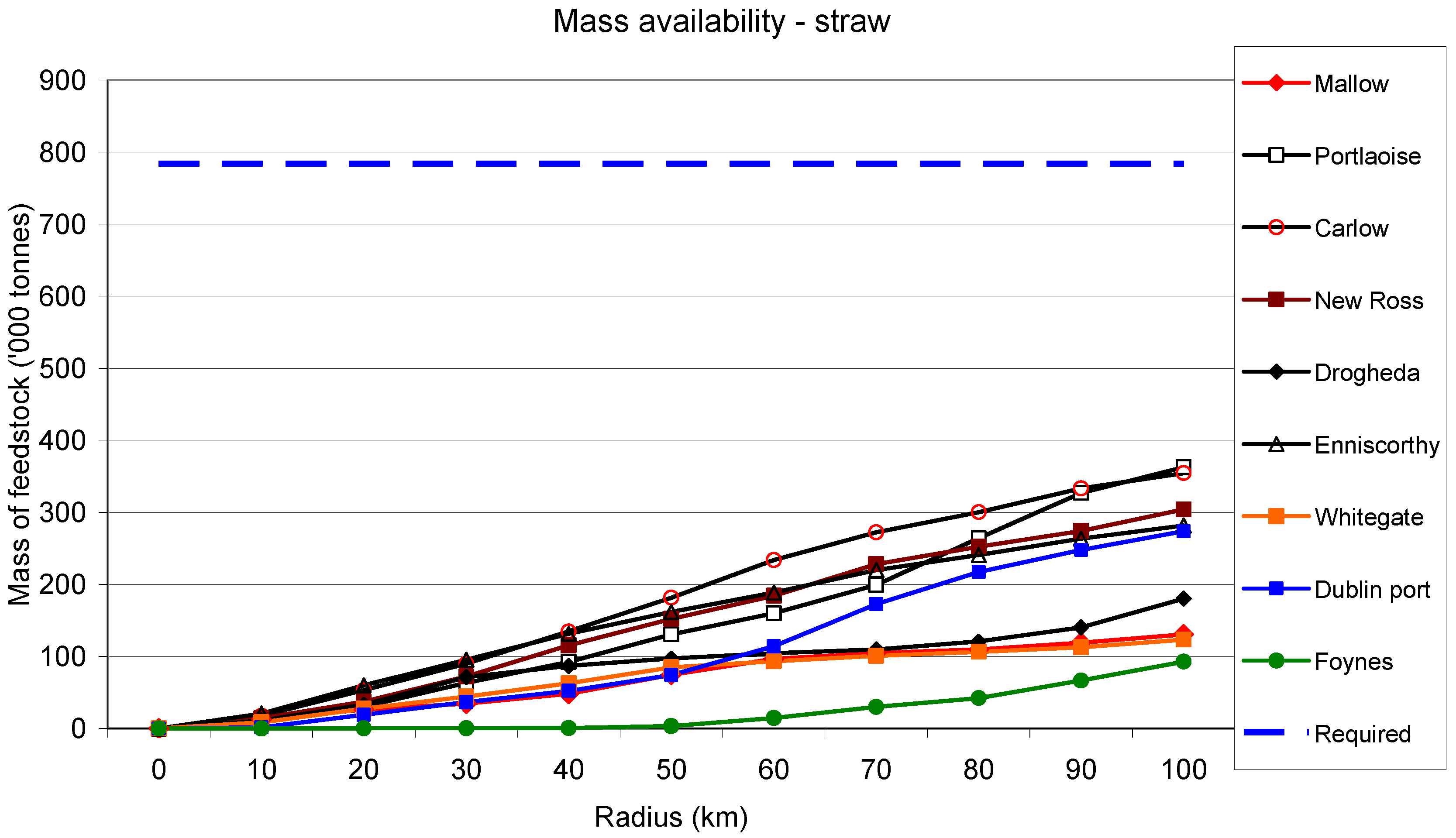

Figure 5). Straw alone as a feedstock could not meet the needs of a large scale ethanol plant within 100 km at any of the locations, with none of the locations being able to supply more than 46% of the ethanol plants needs (

Figure 6).

Figure 5.

modeled availability of wheat around each location.

Figure 5.

modeled availability of wheat around each location.

Figure 6.

Modeled availability of straw around each location.

Figure 6.

Modeled availability of straw around each location.

Discussion

The results look initially very promising for sugarbeet, with three of the modeled locations supplying sufficient quantities of feedstock within 100 km. A single, large scale facility would require 25% more sugarbeet than the two former sugarbeet factories consumed together. This would pose a considerable logistical problem. Assuming a 150 day harvest campaign, the sugarbeet would have to be supplied at a rate of over 13,000 tonnes per day, which would require a minimum of 533 deliveries per day. Also, as sugarbeet cannot be imported, the ethanol producer would have to rely solely on domestic feedstock. Sugarbeet has a low yield of ethanol per tonne due to a very high moisture content, which will likely reduce the maximum transport distance threshold to below the 100 km modeled here which would force a reduction in plant scale and an increase in capital expenditure relative to output, therefore jeopardizing profitability .

Wheat, on the other hand, may initially look like a less promising alternative to sugarbeet for meeting the demands of a large scale facility, it is however a more dense source of fermentable carbohydrates than sugarbeet, which would reduce the physical mass of material that would need to be transported and would therefore reduce the negative impacts of haulage such as noise and air pollution. Also, due to its more favorable storage characteristics, it can also have much longer intake period that can potentially last the entire year. This is a strategy employed by most existing commercial ethanol plants using corn, with on-sight storage capacity generally not greater that 3-4 weeks of plant demand. This helps to reduce initial capital investment and also reduces company overheads. Assuming a year round delivery of wheat, 1,500 tonnes of wheat would need to be delivered daily requiring 62 deliveries per day. This equates to 12% of the deliveries required for a similarly scaled ethanol plant using sugarbeet.

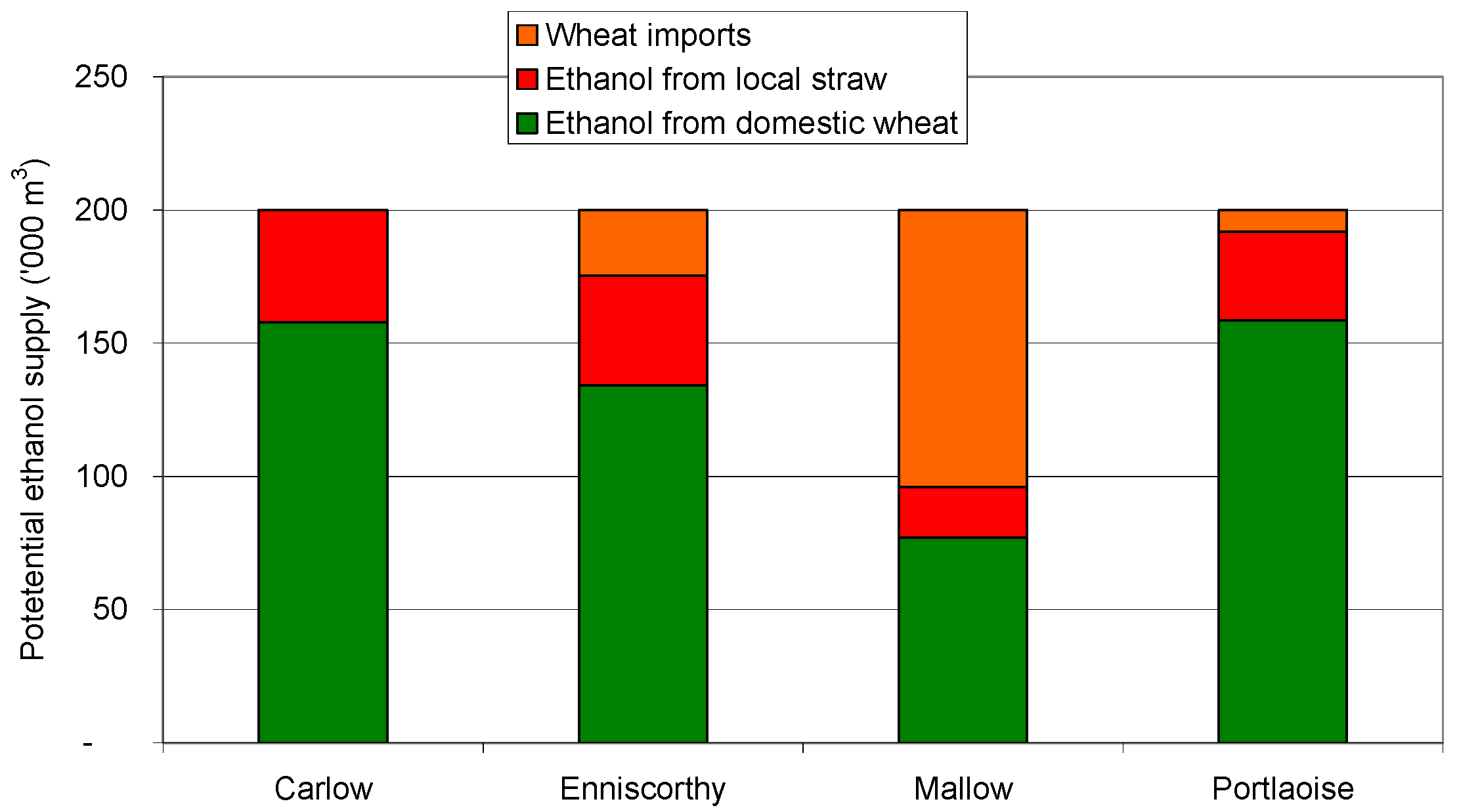

Figure 7.

Modeled production of ethanol from the potential feedstock of domestic wheat and straw and required imports for inland locations.

Figure 7.

Modeled production of ethanol from the potential feedstock of domestic wheat and straw and required imports for inland locations.

If a process of using straw as a feedstock is eventually commercialized it would likely be developed in conjunction with, as opposed to a substitute for, ethanol from wheat. Combining these feedstock resources, results in the location at the former Carlow sugar factory meeting all its feedstock needs from the immediate hinterland (

Figure 7). The Mallow, Portlaoise and Enniscorthy locations would however still require 104, 25 and 8 ktonnes of imported wheat respectively to meet their required output, even when straw and wheat resources are combined.

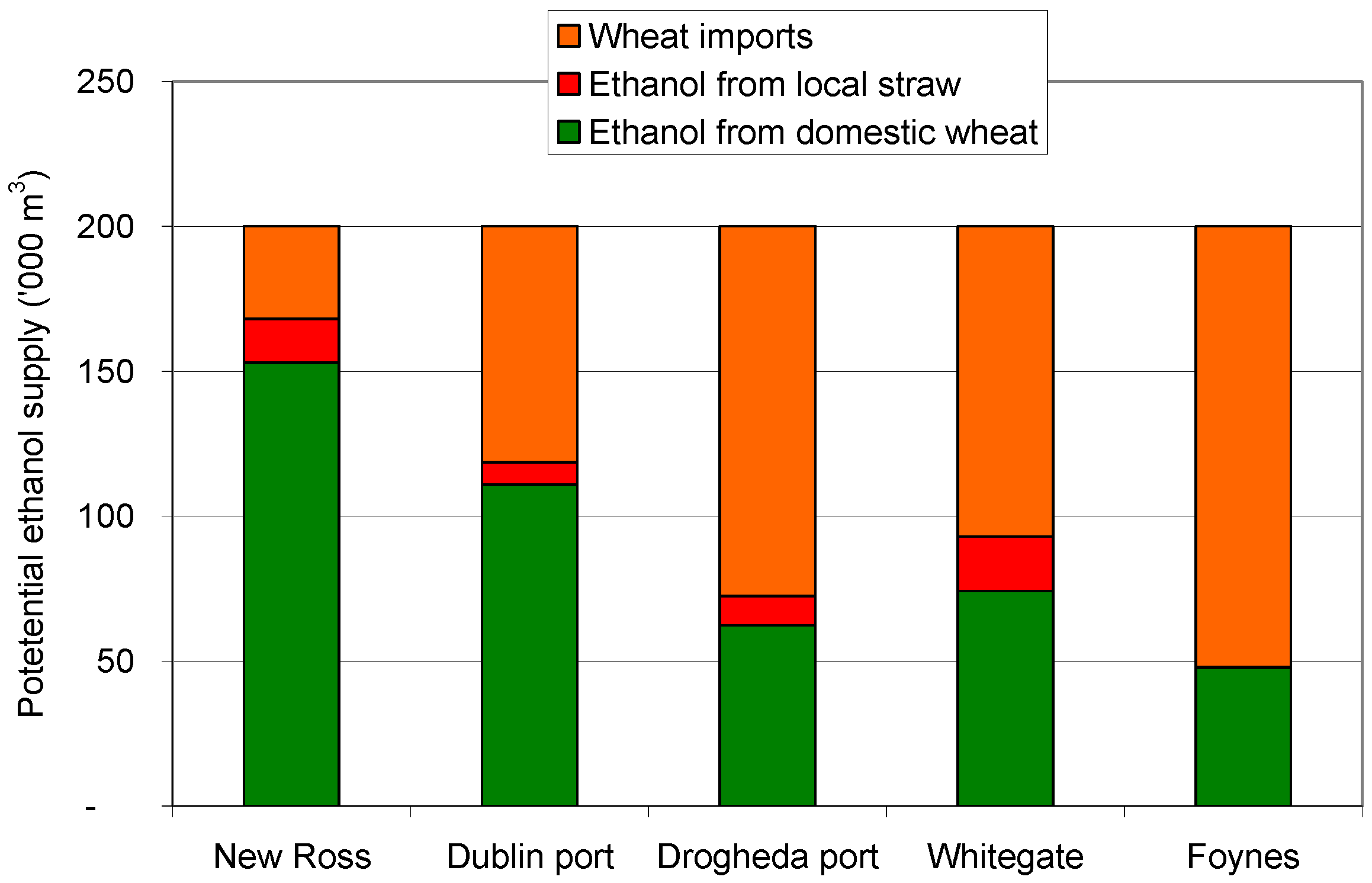

Taking the potential supply around each of the ports, New Ross port can potentially supply the greatest amount of feedstock from domestic wheat and straw requiring only 14% or 28 million liters to be produced from imported wheat (

Figure 8). The Dublin, Drogheda, Foynes and Whitegate options offer far less scope to use local feedstock. This leaves a site at or near New Ross port as the only location that meets the dual requirements of suitable scale and supply of domestically grown feedstock.

Figure 8.

Modeled production of ethanol from the potential feedstock of domestic wheat and straw and required imports for port locations

Figure 8.

Modeled production of ethanol from the potential feedstock of domestic wheat and straw and required imports for port locations

The three most efficient locations based on the assumptions used in this study are Portlaoise, Carlow and New Ross. However, as all three of these locations are within 100 km of each other, it would not be likely that Ireland could sustain more than one large scale bioethanol plant based on the feedstock considered here without significant levels of feedstock imports. Constructing one of the modeled plants would supply 200 million liters of ethanol per year, this equates to 7% of national petrol demand on a volume basis and this in turn would at least meet the 5.75% target for 2010 for petrol substitutes and would meet 3% of total transport fuel (petrol + diesel) use.

Economic and Environmental considerations

Given the intense and ongoing arguments made by both proponents and detractors of bioethanol as a potential transport fuel, at least some reference to economic and environmental considerations, which are the core of theses arguments, should be made. The two feedstock, wheat and sugarbeet, resemble the two mainstream feedstock currently used to produce the bulk of bioethanol traded globally. Wheat is a starch based feedstock, similar to corn used in the US, requiring a number of simple process steps to convert the grains starch portion to fermentable sugars. Examples in Europe of plants that can use wheat as a feedstock would include the Abengoa operated facilities in Teixiero, Babilafuente and Valle de Escombreras in Spain [

19]. On the other hand, sugarbeet is a sugar based feedstock, similar to sugarcane used in Brazil, requiring only to be cleaned and comminuted before the sugar is diffused into a solution ready for fermentation and distillation. Examples of plants that can use this feedstock would be the British Sugar owned plant in Wissington, UK [

20] and the Nordzucker AG operated facility in Klein Wanzleben, Germany [

21]. For both wheat and sugarbeet, proven and commercialized large-scale technology is readily available. Straw on the other hand is a product whose fermentable sugars are derived from its cellulose and hemicellulose components which must undergo intensive chemical, biochemical or thermochemical processes to liberate the fermentable sugars before fermentation and distillation can occur. The technologies suggested to conduct these processes are not as yet commercialized on a large scale [

22].

It would be fair to say that the bioethanol produced from these feedstocks will require financial subsidies to compete economically with fossil fuels such as petrol. It would also be acceptable to suggest that the bioethanol produced from these feedstocks will reduce net GHG emissions and energy imports to the country compared to their fossil fuel counter parts. What is in dispute, however, is how long the need for financial subsidies will last and amount to which bioethanol from these resources can reduce GHG emissions and energy import dependence. These questions need to be accurately answered before Ireland should decide to support such fuels. However, results from previous Life Cycle Analysis (LCA) for similar feedstock (corn and sugarcane) have wide-ranging assumptions and results and cannot be expected to be used as useful references to judge ethanol from the feedstock considered in this study [

23]. Therefore, a LCA using data specific to Ireland’s unique crop production capabilities and infrastructure availabilities is required.

The data needed for a LCA is far reaching; requiring inputs from the initial feedstock production phase through to final utilization, the assumptions used also impact final results. What this paper does, is help to make more accurate assumptions that can be used in future LCA. For example, it can now be assumed that ethanol plants in Ireland will not have bioethanol production capacities larger than 200 ML per year using only indigenous wheat or sugarbeet and that further proliferation of bioethanol beyond this quantity will require either a greater number of smaller plants or alternatively the importation of feedstocks, both of these scenarios will impact greatly the inputs and outputs of a LCA having implications for both transport and land-use change that relate to emissions and energy consumption. With regard to straw as a potential feedstock, future economic and environmental analysis can now assume that this feedstock will not be suited to a large scale facility and may only be used as either a supplement to larger plants using other more abundant feedstock or alternatively in much smaller, more numerous decentralized plants. As previously stated in this paper’s methodology section, the assumptions used in this paper use only previously cropped land to source the feedstock, therefore eliminating land-use change related emissions. This is an important input to future LCA, if further proliferation beyond the 200ML capacity plant modeled here were used then land-use changes will have to be considered as part of the LCA.

This paper does not suggest to answer these important questions regarding economic, energetic and GHG life-cycle impacts, but does answer many of the questions that such analysis need to ask while conducting such analysis, such as where the plants will be built, where will the feedstock come from, what capacities will the plants have and how far will the feedstock and products need to be transported. This paper can be adjudged to be a first step towards an accurate LCA of bioethanol production in Ireland.