Technical–Financial Feasibility Study of a Micro-Cogeneration System in the Buildings in Italy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methodology

2.2. Case Study

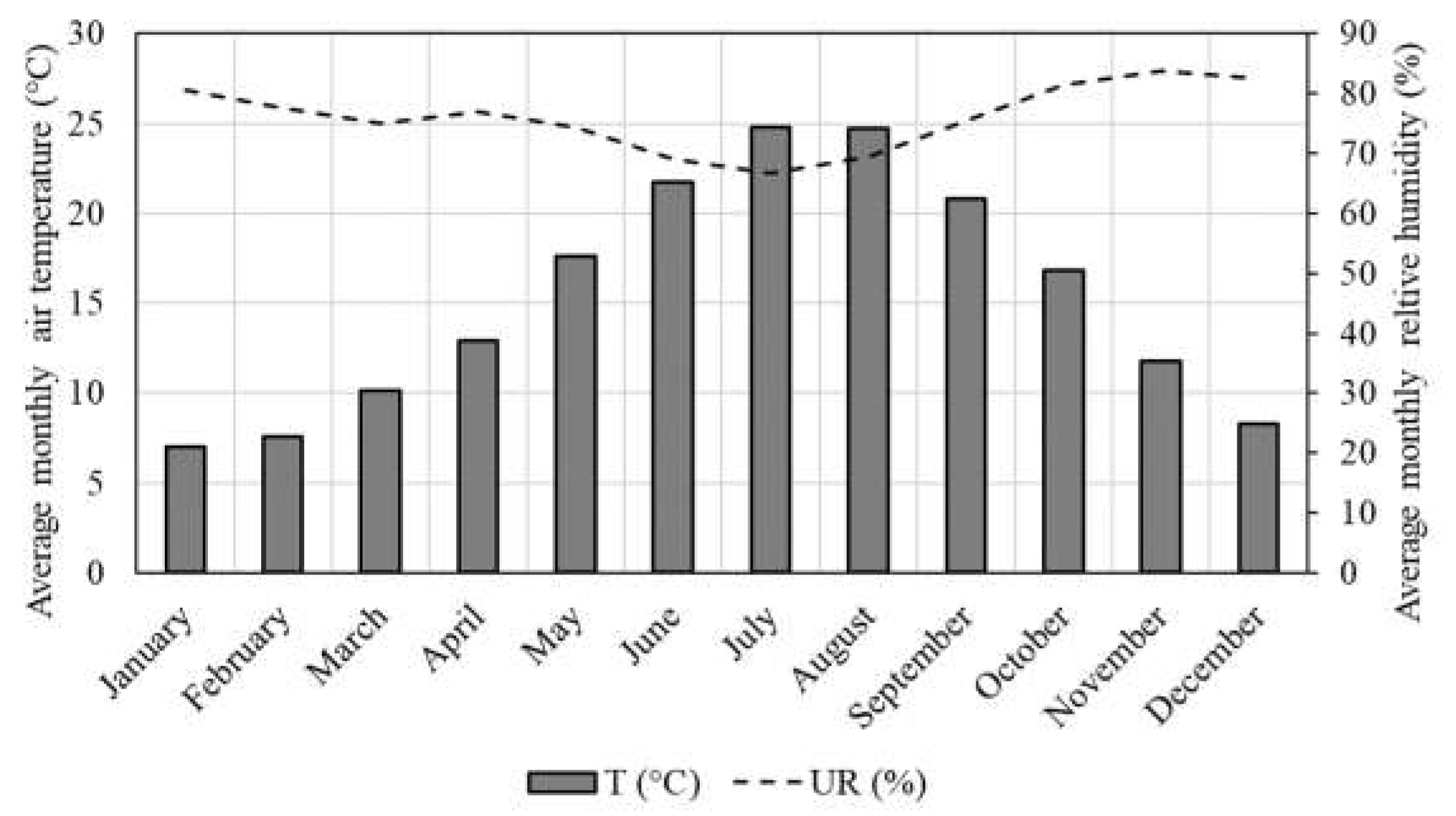

2.3. Boundary Conditions

2.4. Energy Plant Retrofit

3. Results

3.1. Model Calibration

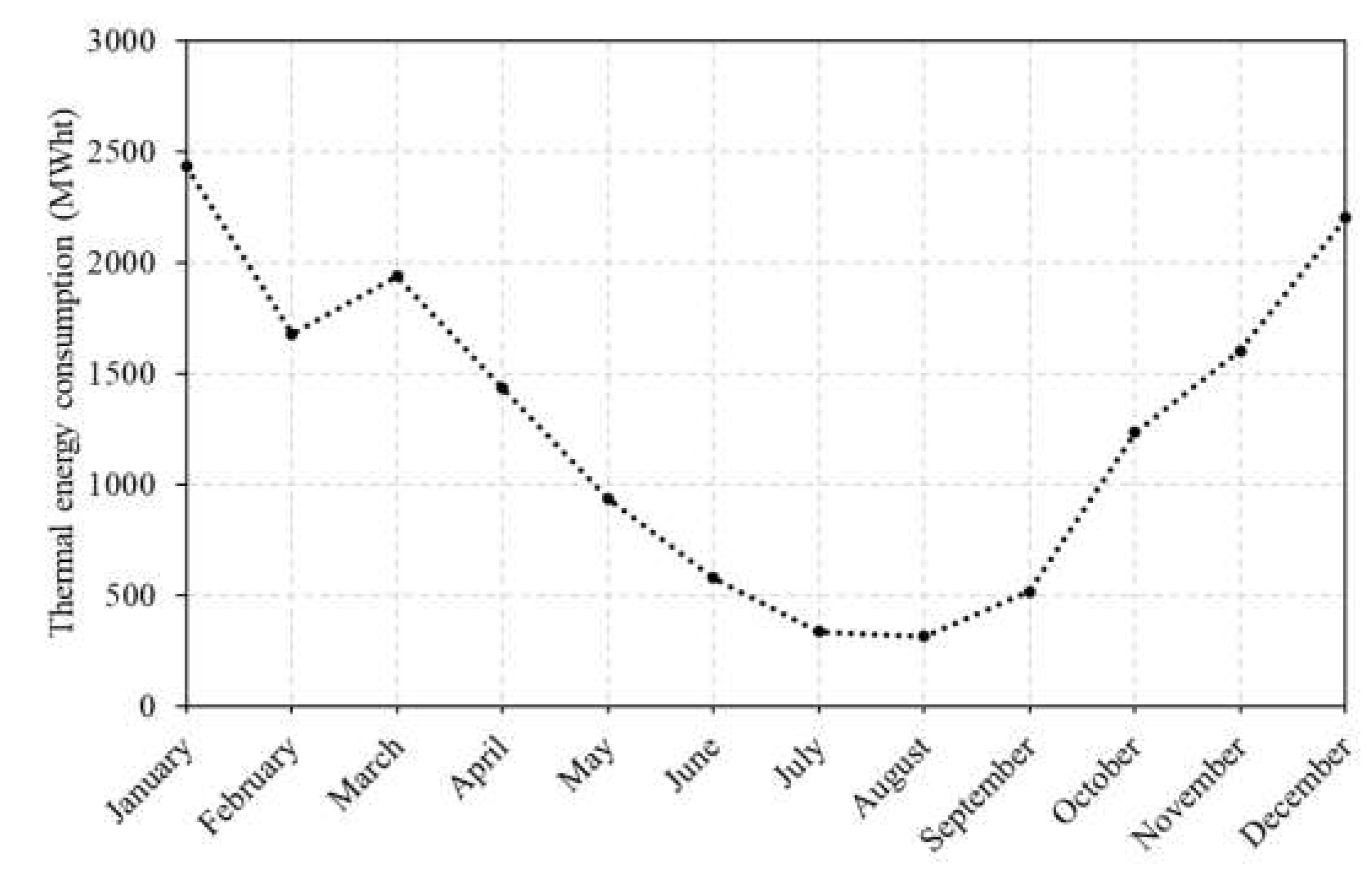

3.2. Analysis of the Actual Electrical and Thermal Consumption

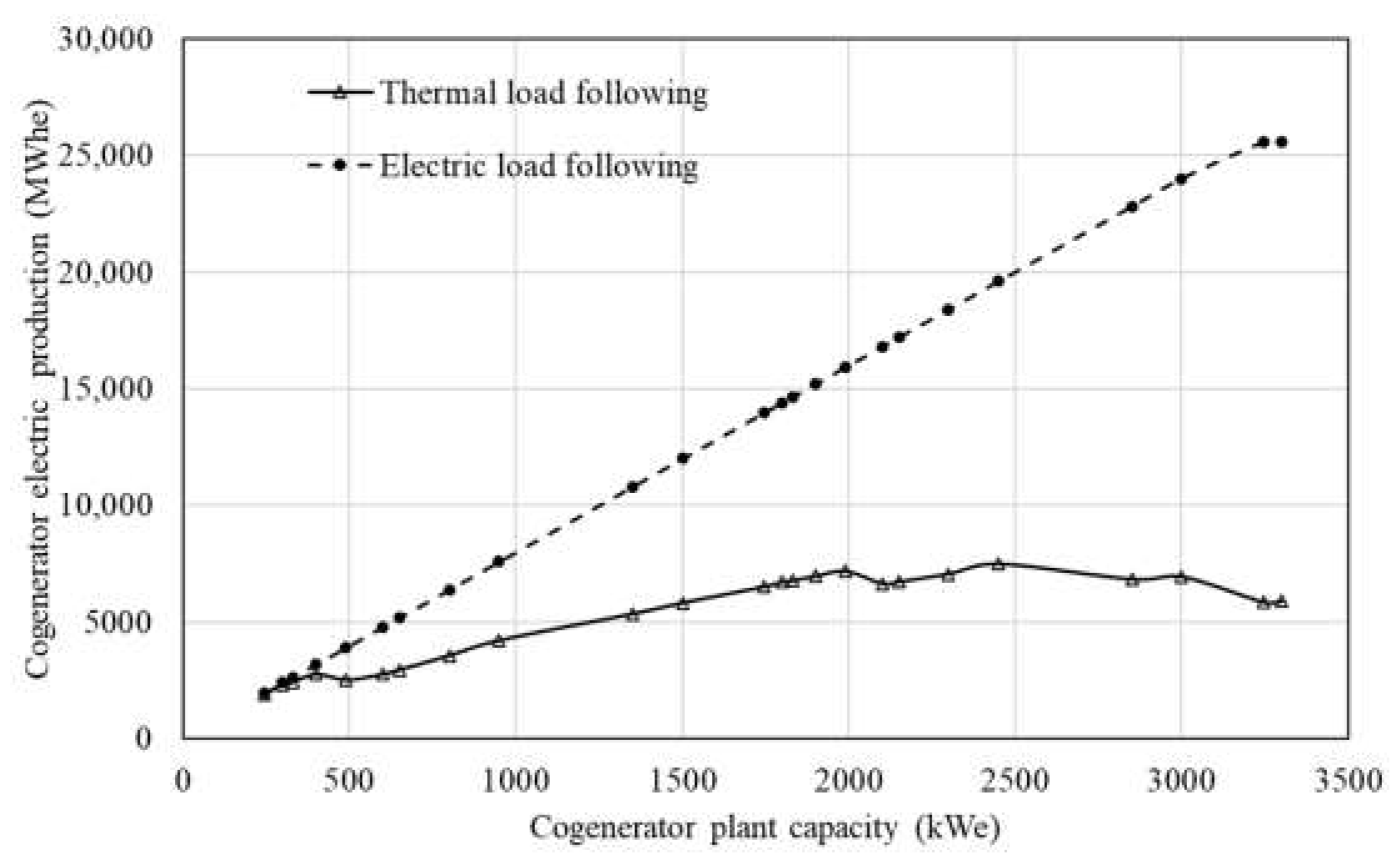

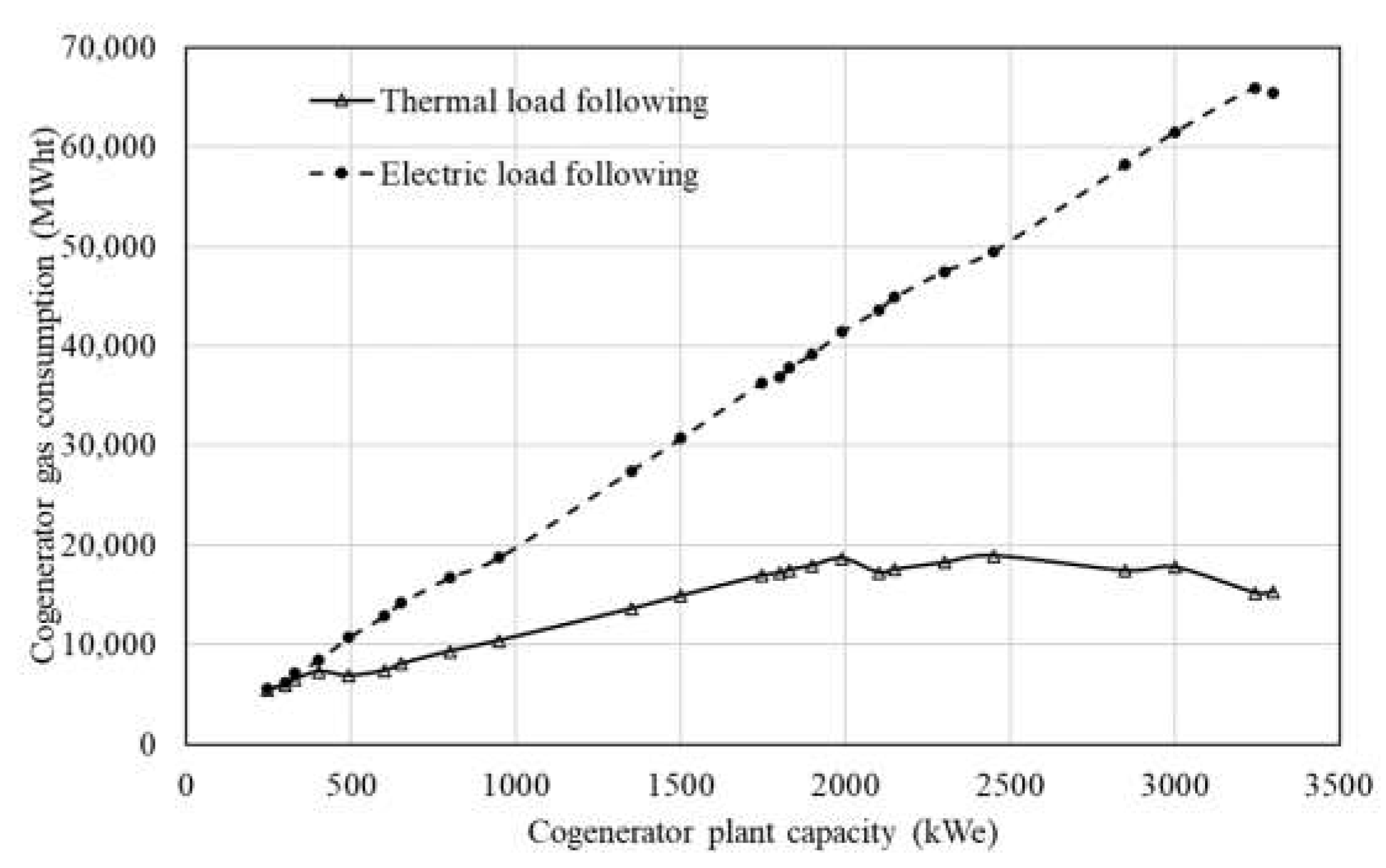

3.3. Analysis of the Cogenerator Performances

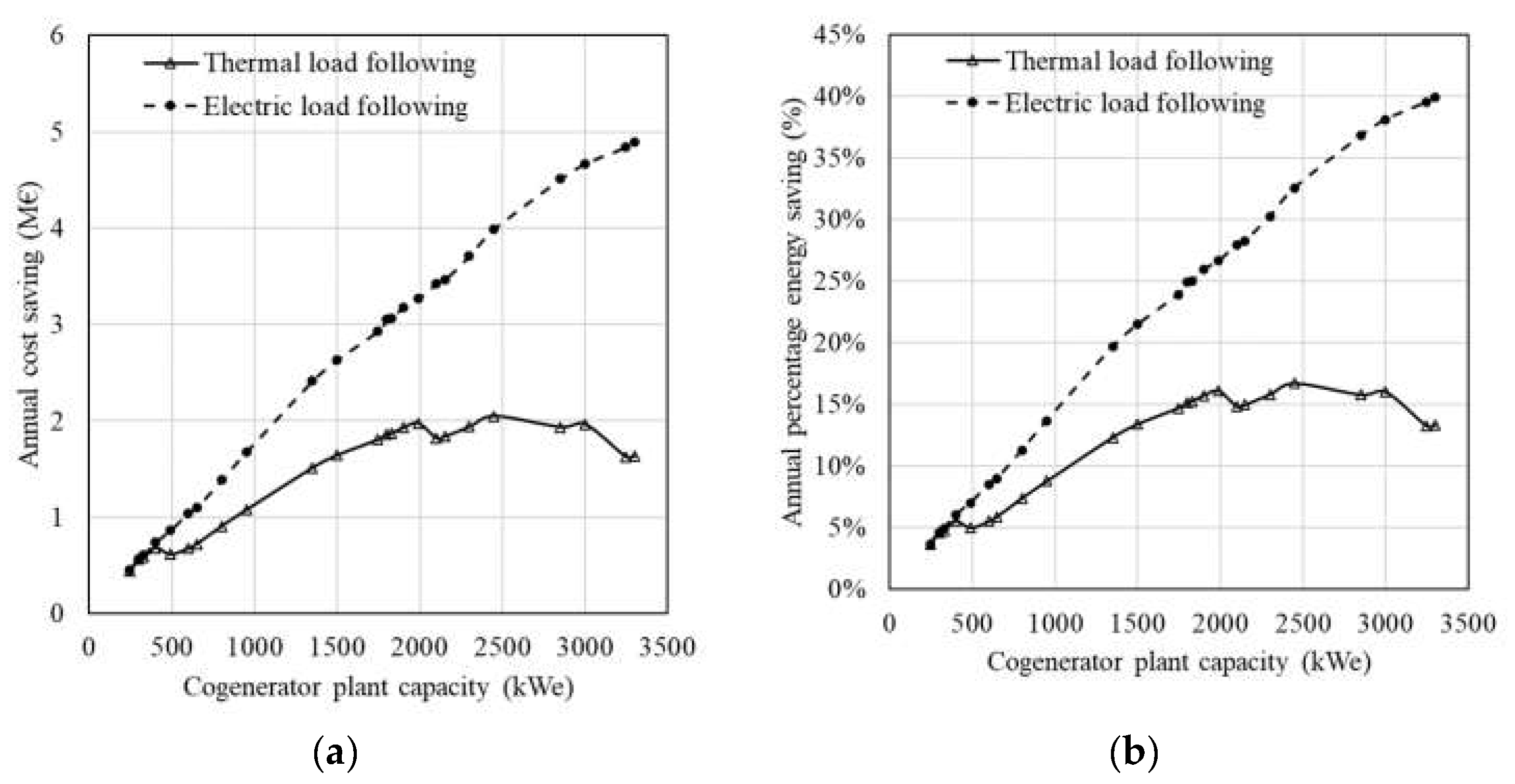

3.4. Analysis of the Cost, Energy, Toe and tCO2 Savings

3.5. Analysis of the Finances

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dehwah, A.H.A.; Asif, M.; Rahman, M.T. Prospects of PV application in unregulated building rooftops in developing countries: A perspective from Saudi Arabia. Energy Build. 2018, 171, 76–87. [Google Scholar] [CrossRef]

- Congedo, P.M.; Baglivo, C.; D’Agostino, D.; Zacà, I. Cost-optimal design for nearly zero energy office buildings located in warm climates. Energy 2015, 91, 967–982. [Google Scholar] [CrossRef]

- D’Agostino, D.; Parker, D. A Framework for the cost-optimal design of nearly zero energy buildings (NZEBs) in representative climates across Europe. Energy 2018, 149, 814–829. [Google Scholar] [CrossRef]

- Rabani, M.; Bayera Madessa, H.; Mohseni, O.; Nord, N. Minimizing delivered energy and life cycle cost using graphical script: An Office building retrofitting case. Appl. Energy 2020, 268, 114929. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Marie-Reine Nishimwe, A.; Reiter, S. Towards nearly zero-energy residential neighbourhoods in the European Union: A case study. Renew. Sustain. Energy Rev. 2021, 135, 110198. [Google Scholar] [CrossRef]

- Mauri, L.; Vallati, A.; Ocłoń, P. Low impact energy saving strategies for individual heating systems in a modern residential building: A case study in Rome. J. Clean. Prod. 2019, 214, 791–802. [Google Scholar] [CrossRef]

- Mohammad Harmay, N.S.; Kim, D.; Choi, M. Urban heat island associated with land use/land cover and climate variations in Melbourne, Australia. Sustain. Cities Soc. 2021, 69, 102861. [Google Scholar] [CrossRef]

- Vallati, A.; Mauri, L.; Colucci, C. Impact of shortwave multiple reflections in an urban street canyon on building thermal energy demands. Energy Build. 2018, 174, 77–84. [Google Scholar] [CrossRef]

- Memon, R.A.; Leung, D.Y.C.; Liu, C.H. An investigation of urban heat island intensity (UHII) as an indicator of urban heating. Atmos. Res. 2009, 94, 491–500. [Google Scholar] [CrossRef]

- Battista, G.; Evangelisti, L.; Guattari, C.; de Lieto Vollaro, E.; de Lieto Vollaro, R.; Asdrubali, F. Urban heat island mitigation strategies: Experimental and numerical analysis of a university campus in Rome (Italy). Sustainability 2020, 12, 7971. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Y.; Yu, S.; Jia, G.; Li, H.; Li, W. Urban heat island impacts on building energy consumption: A review of approaches and findings. Energy 2019, 174, 407–419. [Google Scholar] [CrossRef]

- Yang, X.; Peng, L.L.H.; Jiang, Z.; Chen, Y.; Yao, L.; He, Y.; Xu, T. Impact of urban heat island on energy demand in buildings: Local climate zones in Nanjing. Appl. Energy 2020, 260, 114279. [Google Scholar] [CrossRef]

- Kaloustian, N.; Aouad, D.; Battista, G.; Zinzi, M. Leftover spaces for the mitigation of urban overheating in Municipal Beirut. Climate 2018, 6, 68. [Google Scholar] [CrossRef] [Green Version]

- Larsen, M.A.D.; Petrović, S.; Radoszynski, A.M.; McKenna, R.; Balyk, O. Climate change impacts on trends and extremes in future heating and cooling demands over Europe. Energy Build. 2020, 226, 110397. [Google Scholar] [CrossRef]

- Abbassi, Y.; Ahmadikia, H.; Baniasadi, E. Prediction of pollution dispersion under urban heat island circulation for different atmospheric stratification. Build. Environ. 2020, 168, 106374. [Google Scholar] [CrossRef]

- Battista, G. Analysis of the air pollution sources in the city of Rome (Italy). Energy Procedia 2017, 126, 392–397. [Google Scholar] [CrossRef]

- Iaria, J.; Susca, T. Analytic hierarchy processes (AHP) evaluation of green roof- and green wall- based UHI mitigation strategies via ENVI-Met simulations. Urban Clim. 2022, 46, 101293. [Google Scholar] [CrossRef]

- Battista, G.; Pastore, E.M.; Mauri, L.; Basilicata, C. Green roof effects in a case study of Rome (Italy). Energy Procedia 2016, 101, 1058–1063. [Google Scholar] [CrossRef]

- Battista, G.; de Lieto Vollaro, E.; de Lieto Vollaro, R. How cool pavements and green roof affect building energy performances. Heat Transf. Eng. 2021, 43, 326–336. [Google Scholar] [CrossRef]

- Battista, G.; Pastore, E.M. Using cool pavements to mitigate urban temperatures in a case study of Rome (Italy). Energy Procedia 2017, 113, 98–103. [Google Scholar] [CrossRef]

- Diz-Mellado, E.; López-Cabeza, V.P.; Rivera-Gómez, C.; Roa-Fernández, J.; Galán-Marín, C. Improving school transition spaces microclimate to make them liveable in warm climates. Appl. Sci. 2020, 10, 7648. [Google Scholar] [CrossRef]

- Aboelata, A. Vegetation in different street orientations of aspect ratio (H/W 1:1) to mitigate UHI and reduce buildings’ energy in arid climate. Build. Environ. 2020, 172, 106712. [Google Scholar] [CrossRef]

- Theeuwes, N.E.; Solcerová, A.; Steeneveld, G.J. Modeling the influence of open water surfaces on the summertime temperature and thermal comfort in the city. J. Geophys. Res. Atmos. 2013, 118, 8881–8896. [Google Scholar] [CrossRef] [Green Version]

- Fahed, J.; Kinab, E.; Ginestet, S.; Adolphe, L. Impact of Urban heat island mitigation measures on microclimate and pedestrian comfort in a dense urban district of Lebanon. Sustain. Cities Soc. 2020, 61, 102375. [Google Scholar] [CrossRef]

- Battista, G.; de Lieto Vollaro, E.; Grignaffini, S.; Ocłoń, P.; Vallati, A. Experimental investigation about the adoption of high reflectance materials on the envelope cladding on a scaled street canyon. Energy 2021, 230, 120801. [Google Scholar] [CrossRef]

- Vollaro, A.D.L.; Galli, G.; Vallati, A.; Romagnoli, R. Analysis of Thermal field within an urban canyon with variable thermophysical characteristics of the building’s walls. J. Phys. Conf. Ser. 2015, 655, 012056. [Google Scholar] [CrossRef]

- Battista, G.; Mauri, L. Numerical study of buoyant flows in street canyon caused by ground and building heating. Energy Procedia 2016, 101, 1018–1025. [Google Scholar] [CrossRef]

- Cornaro, C.; Puggioni, V.A.; Strollo, R.M. Dynamic simulation and on-site measurements for energy retrofit of complex historic buildings: Villa mondragone case study. J. Build. Eng. 2016, 6, 17–28. [Google Scholar] [CrossRef]

- Rabani, M.; Bayera Madessa, H.; Nord, N. Achieving zero-energy building performance with thermal and visual comfort enhancement through optimization of fenestration, envelope, shading device, and energy supply system. Sustain. Energy Technol. Assess. 2021, 44, 101020. [Google Scholar] [CrossRef]

- Vallati, A.; Grignaffini, S.; Romagna, M.; Mauri, L. Effects of different building automation systems on the energy consumption for three thermal insulation values of the building envelope. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016. [Google Scholar] [CrossRef]

- Ali, U.; Shamsi, M.H.; Bohacek, M.; Hoare, C.; Purcell, K.; Mangina, E.; O’Donnell, J. A data-driven approach to optimize urban scale energy retrofit decisions for residential buildings. Appl. Energy 2020, 267, 114861. [Google Scholar] [CrossRef]

- Battista, G.; de Lieto Vollaro, E.; Ocłoń, P.; de Lieto Vollaro, R. Retrofit analysis of a historical building in an architectural constrained area: A case study in Rome, Italy. Appl. Sci. 2022, 12, 12305. [Google Scholar] [CrossRef]

- Martínez-Molina, A.; Tort-Ausina, I.; Cho, S.; Vivancos, J.L. Energy efficiency and thermal comfort in historic buildings: A review. Renew. Sustain. Energy Rev. 2016, 61, 70–85. [Google Scholar] [CrossRef]

- Bottero, M.; D’Alpaos, C.; Oppio, A. Ranking of adaptive reuse strategies for abandoned industrial heritage in vulnerable contexts: A multiple criteria decision aiding approach. Sustainability 2019, 11, 785. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Xu, J. Predicting and optimization of energy consumption using system dynamics-fuzzy multiple objective programming in world heritage areas. Energy 2013, 49, 19–31. [Google Scholar] [CrossRef]

- Langston, C.; Wong, F.K.W.; Hui, E.C.M.; Shen, L.Y. Strategic assessment of building adaptive reuse opportunities in Hong Kong. Build Environ. 2008, 43, 1709–1718. [Google Scholar] [CrossRef]

- Polo López, C.S.; Frontini, F. Energy efficiency and renewable solar energy integration in heritage historic buildings. Energy Procedia 2014, 48, 1493–1502. [Google Scholar] [CrossRef] [Green Version]

- De Berardinis, P.; Rotilio, M.; Marchionni, C.; Friedman, A. Improving the energy-efficiency of historic masonry buildings. A case study: A minor centre in the Abruzzo Region, Italy. Energy Build. 2014, 80, 415–423. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Masi, R.F.; De’Rossi, F.; Vanoli, G.P. Energy retrofit of an educational building in the ancient center of Benevento. Feasibility study of energy savings and respect of the historical value. Energy Build. 2015, 95, 172–183. [Google Scholar] [CrossRef]

- Alongi, A.; Scoccia, R.; Motta, M.; Mazzarella, L. Numerical investigation of the Castle of Zena energy needs and a feasibility study for the implementation of electric and gas driven heat pump. Energy Build. 2015, 95, 32–38. [Google Scholar] [CrossRef]

- Franco, G.; Magrini, A.; Cartesegna, M.; Guerrini, M. Towards a systematic approach for energy refurbishment of historical buildings. The case study of Albergo Dei Poveri in Genoa, Italy. Energy Build. 2015, 95, 153–159. [Google Scholar] [CrossRef]

- Ben, H.; Steemers, K. Energy retrofit and occupant behaviour in protected housing: A case study of the Brunswick Centre in London. Energy Build. 2014, 80, 120–130. [Google Scholar] [CrossRef]

- Ascione, F.; De Rossi, F.; Vanoli, G.P. Energy retrofit of historical buildings: Theoretical and experimental investigations for the modelling of reliable performance scenarios. Energy Build. 2011, 43, 1925–1936. [Google Scholar] [CrossRef]

- Kumbaroglu, G.; Madlener, R. Evaluation of economically optimal retrofit investment options for energy savings in buildings. Energy Build. 2012, 49, 327–334. [Google Scholar] [CrossRef]

- Amini Toosi, H.; Lavagna, M.; Leonforte, F.; Del Pero, C.; Aste, N. Life cycle sustainability assessment in building energy retrofitting; A review. Sustain. Cities Soc. 2020, 60, 102248. [Google Scholar] [CrossRef]

- Vogel, J.A.; Lundqvist, P.; Arias, J. Categorizing barriers to energy efficiency in buildings. Energy Procedia 2015, 75, 2839–2845. [Google Scholar] [CrossRef] [Green Version]

- Menassa, C.C. Evaluating sustainable retrofits in existing buildings under uncertainty. Energy Build. 2011, 43, 3576–3583. [Google Scholar] [CrossRef]

- Jenkins, G.P.; Kuo, C.-Y.; Harberger, A.C. Cost-Benefit Analysis for Investment Decisions, Chapter 8: The Economic Opportunity Cost of Capital. JDI Executive Programs. 2011. Available online: https://ideas.repec.org/p/qed/dpaper/201.html (accessed on 14 June 2023).

- Wyatt, P. Property Evaluation in an Economic Context; John Wiley & Sons: Hoboken, NJ, USA, 2007; p. 411. [Google Scholar]

- Remer, D.S.; Nieto, A.P. A compendium and comparison of 25 project evaluation techniques. Part 1: Net present value and rate of return methods. Int. J. Prod. Econ. 1995, 42, 79–96. [Google Scholar] [CrossRef]

- Gabrielli, L.; Ruggeri, A.G. Developing a model for energy retrofit in large building portfolios: Energy assessment, optimization and uncertainty. Energy Build. 2019, 202, 109356. [Google Scholar] [CrossRef]

- De Angelis, E.; Pansa, G.; Serra, E. Research of economic sustainability of different energy refurbishment strategies for an apartment block building. Energy Procedia 2014, 48, 1449–1458. [Google Scholar] [CrossRef] [Green Version]

- Copiello, S.; Gabrielli, L.; Bonifaci, P. Evaluation of energy retrofit in buildings under conditions of uncertainty: The prominence of the discount rate. Energy 2017, 137, 104–117. [Google Scholar] [CrossRef]

- Tadeu, S.; Rodrigues, C.; Tadeu, A.; Freire, F.; Simões, N. Energy retrofit of historic buildings: Environmental assessment of cost-optimal solutions. J. Build. Eng. 2015, 4, 167–176. [Google Scholar] [CrossRef]

- Kneifel, J. Life-cycle carbon and cost analysis of energy efficiency measures in new commercial buildings. Energy Build. 2010, 42, 333–340. [Google Scholar] [CrossRef]

- Fregonara, E.; Lo Verso, V.R.M.; Lisa, M.; Callegari, G. Retrofit scenarios and economic sustainability. A case-study in the Italian context. Energy Procedia 2017, 111, 245–255. [Google Scholar] [CrossRef] [Green Version]

- Sharif, S.A.; Hammad, A. Simulation-based multi-objective optimization of institutional building renovation considering energy consumption, life-cycle cost and life-cycle assessment. J. Build. Eng. 2019, 21, 429–445. [Google Scholar] [CrossRef]

- Sartori, D.; Gelsomina, C.; Genco, M.; Pancotti, C.; Sirtori, E.; Vignetti, S.; Del Bo, C. Guide to Cost-Benefit Analysis of Investment Projects; European Union: Luxembourg, 2014. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, T.; Ye, S.; Liu, Y. Cost-benefit analysis for energy efficiency retrofit of existing buildings: A case study in China. J. Clean. Prod. 2018, 177, 493–506. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Kaklauskas, A.; Raslanas, S. Evaluation of investments into housing renovation. Int. J. Strateg. Prop. Manag. 2004, 8, 177–190. [Google Scholar] [CrossRef] [Green Version]

- Friedman, C.; Becker, N.; Erell, E. Energy retrofit of residential building envelopes in Israel: A cost-benefit analysis. Energy 2014, 77, 183–193. [Google Scholar] [CrossRef]

- Zhao, S.; Feng, W.; Zhang, S.; Hou, J.; Zhou, N.; Levine, M. Energy savings and cost-benefit analysis of the new commercial building standard in China. Procedia Eng. 2015, 121, 317–324. [Google Scholar] [CrossRef]

- Gabay, H.; Meir, I.A.; Schwartz, M.; Werzberger, E. Cost-benefit analysis of green buildings: An Israeli office buildings case study. Energy Build. 2014, 76, 558–564. [Google Scholar] [CrossRef]

- Memon, A.G.; Memon, R.A. Parametric based economic analysis of a trigeneration system proposed for residential buildings. Sustain. Cities Soc. 2017, 34, 144–158. [Google Scholar] [CrossRef]

- Jradi, M.; Riffat, S. Tri-generation systems: Energy policies, prime movers, cooling technologies, configurations and operation strategies. Renew. Sustain. Energy Rev. 2014, 32, 396–415. [Google Scholar] [CrossRef]

- Kerr, T. Combined Heat and Power: Evaluating the Benefits of Greater Global Investment; International Energy Agency: Washington, DC, USA, 2008. [Google Scholar]

- Relazione Annuale sulla Cogenerazione in Italia. Available online: https://www.mimit.gov.it/images/stories/documenti/IT_-_Relazione_annuale_CAR_2020.pdf (accessed on 14 June 2023).

- Il Presente e Il Futuro della Cogenerazione in Italia. Available online: https://industriale.viessmann.it/blog/presente-e-futuro-cogenerazione-italia (accessed on 4 December 2022).

- RETScreen. Available online: https://www.nrcan.gc.ca/maps-tools-and-publications/tools/modelling-tools/retscreen/7465 (accessed on 19 June 2022).

- Lee, K.H.; Lee, D.W.; Baek, N.C.; Kwon, H.M.; Lee, C.J. Preliminary determination of optimal size for renewable energy resources in buildings using RETScreen. Energy 2012, 47, 83–96. [Google Scholar] [CrossRef]

- ARERA—Aggiornamento del Fattore di Conversione dei KWh in Tonnellate Equivalenti di Petrolio Connesso al Meccanismo dei Titoli di Efficienza Energetica. Available online: https://www.arera.it/it/docs/08/003-08een.htm (accessed on 14 June 2023).

- Gazzetta Ufficiale. Available online: https://www.gazzettaufficiale.it/atto/serie_generale/caricaDettaglioAtto/originario?atto.dataPubblicazioneGazzetta=2014-04-07&atto.codiceRedazionale=14G00069&elenco30giorni=false (accessed on 14 June 2023).

- Indicatori Di Efficienza e Decarbonizzazione Del Sistema Energetico Nazionale e Del Settore Elettrico—Italiano. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/indicatori-di-efficienza-e-decarbonizzazione-del-sistema-energetico-nazionale-e-del-settore-elettrico (accessed on 14 June 2023).

- Kenneth, K.H. Jelen’s Cost and Optimization Engineering; McGraw-Hill: New York, NY, USA, 1991; Volume 386. [Google Scholar]

| Parameter | Value |

|---|---|

| Conversion factor TOE-electricity (toe/MWh) [71] | 0.187 |

| Conversion factor TOE-natural gas (toe/MWh) [72] | 0.086 |

| Conversion factor tCO2-electricity (tCO2/MWh) [73] | 0.483 |

| Conversion factor tCO2-natural gas (tCO2/MWh) [73] | 0.202 |

| Parameter | Value |

|---|---|

| Seasonal efficiency of existing boiler system (%) | 93.7 |

| Thermal load (W/m2) | 75.27 |

| Hot water demand (%) | 21.5 |

| Annual availability of the cogeneration system (h) | 8000 |

| Minimum operating power of the cogenerator (%) | 60 |

| Useful life of the cogenerator plant (years) | 20 |

| Discount rate referred to the 1 December 2022 (%) | 3.04 |

| Plant Capacity | NPV | nNPV | IRR | PI | PBT |

|---|---|---|---|---|---|

| 245 | €5,566,976.31 | €22,722.35 | 143% | 20.17 | 1 |

| 300 | €7,154,401.55 | €23,848.01 | 162% | 22.96 | 1 |

| 330 | €7,376,916.47 | €21,076.90 | 158% | 22.35 | 1 |

| 400 | €8,705,759.20 | €21,764.40 | 165% | 23.51 | 1 |

| 490 | €7,507,681.27 | €15,321.80 | 128% | 17.95 | 1 |

| 600 | €8,260,047.20 | €13,766.75 | 125% | 17.49 | 1 |

| 650 | €8,842,052.39 | €13,603.16 | 127% | 17.84 | 1 |

| 800 | €11,311,468.74 | €14,139.34 | 143% | 20.15 | 1 |

| 950 | €13,584,974.03 | €14,299.97 | 154% | 21.83 | 1 |

| 1350 | €19,493,752.00 | €14,439.82 | 178% | 25.37 | 1 |

| 1500 | €21,247,350.49 | €14,164.90 | 182% | 25.96 | 1 |

| 1745 | €22,569,546.41 | €12,933.84 | 146% | 20.62 | 1 |

| 1800 | €23,259,027.79 | €12,921.68 | 146% | 20.58 | 1 |

| 1830 | €23,371,687.32 | €12,771.41 | 144% | 20.35 | 1 |

| 1900 | €24,061,363.64 | €12,663.88 | 143% | 20.24 | 1 |

| 1990 | €24,542,433.23 | €12,332.88 | 141% | 19.84 | 1 |

| 2100 | €22,014,212.60 | €10,482.96 | 122% | 17.05 | 1 |

| 2150 | €22,215,128.59 | €10,332.62 | 121% | 16.90 | 1 |

| 2300 | €23,482,913.53 | €10,209.96 | 122% | 17.02 | 1 |

| 2450 | €24,874,818.16 | €10,152.99 | 123% | 17.26 | 1 |

| 2850 | €22,637,673.38 | €7943.04 | 103% | 14.26 | 2 |

| 3000 | €22,859,717.60 | €7619.91 | 101% | 13.96 | 2 |

| 3245 | €16,815,002.93 | €5181.82 | 66% | 8.79 | 2 |

| 3300 | €16,806,605.07 | €5047.03 | 65% | 8.62 | 2 |

| Plant Capacity | NPV | nNPV | IRR | PI | PBT |

|---|---|---|---|---|---|

| 245 | €5,622,120.40 | €22,947.43 | 144% | 20.37 | 1 |

| 300 | €7,271,290.50 | €24,237.64 | 164% | 23.33 | 1 |

| 330 | €7,755,099.59 | €22,157.43 | 165% | 23.50 | 1 |

| 400 | €9,521,708.27 | €23,804.27 | 180% | 25.71 | 1 |

| 490 | €11,190,561.73 | €22,837.88 | 187% | 26.75 | 1 |

| 600 | €13,638,818.32 | €22,731.36 | 202% | 28.87 | 1 |

| 650 | €14,436,134.03 | €22,209.44 | 203% | 29.13 | 1 |

| 800 | €18,379,397.78 | €22,974.25 | 228% | 32.74 | 1 |

| 950 | €22,469,412.78 | €23,652.01 | 250% | 36.10 | 1 |

| 1350 | €32,828,788.13 | €24,317.62 | 295% | 42.72 | 1 |

| 1500 | €35,883,170.92 | €23,922.11 | 302% | 43.84 | 1 |

| 1745 | €39,265,264.43 | €22,501.58 | 249% | 35.87 | 1 |

| 1800 | €40,886,064.65 | €22,714.48 | 251% | 36.17 | 1 |

| 1830 | €41,055,220.56 | €22,434.55 | 248% | 35.74 | 1 |

| 1900 | €42,539,676.68 | €22,389.30 | 248% | 35.78 | 1 |

| 1990 | €43,698,785.56 | €21,959.19 | 245% | 35.33 | 1 |

| 2100 | €45,764,754.19 | €21,792.74 | 246% | 35.45 | 1 |

| 2150 | €46,306,026.38 | €21,537.69 | 244% | 35.24 | 1 |

| 2300 | €49,722,535.89 | €21,618.49 | 250% | 36.03 | 1 |

| 2450 | €53,661,901.44 | €21,902.82 | 258% | 37.24 | 1 |

| 2850 | €60,761,329.20 | €21,319.76 | 265% | 38.29 | 1 |

| 3000 | €62,953,078.18 | €20,984.36 | 266% | 38.45 | 1 |

| 3245 | €64,438,082.38 | €19,857.65 | 234% | 33.68 | 1 |

| 3300 | €65,056,159.47 | €19,536.38 | 232% | 33.38 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Battista, G.; Vollaro, E.d.L.; Vallati, A.; Vollaro, R.d.L. Technical–Financial Feasibility Study of a Micro-Cogeneration System in the Buildings in Italy. Energies 2023, 16, 5512. https://doi.org/10.3390/en16145512

Battista G, Vollaro EdL, Vallati A, Vollaro RdL. Technical–Financial Feasibility Study of a Micro-Cogeneration System in the Buildings in Italy. Energies. 2023; 16(14):5512. https://doi.org/10.3390/en16145512

Chicago/Turabian StyleBattista, Gabriele, Emanuele de Lieto Vollaro, Andrea Vallati, and Roberto de Lieto Vollaro. 2023. "Technical–Financial Feasibility Study of a Micro-Cogeneration System in the Buildings in Italy" Energies 16, no. 14: 5512. https://doi.org/10.3390/en16145512