On the Flexible Operation of Supercritical Circulating Fluidized Bed: Burning Carbon Based Decentralized Active Disturbance Rejection Control

Abstract

:1. Introduction

- Higher requirement for operational flexibility. With increasing intermittent renewable energy integrated in the grid, thermal power plants are required to operate in a wider range [7]. Supercritical CFB boilers can regulate their load from 30% to 100%, which extends 20% more in the low load region compared with pulverized coal-fired boilers [8]. However, the considerable quantities of bed materials in furnace result in large inertia of the CFB boiler. In addition, dynamics of the boiler vary at different operation conditions, leading to strong nonlinearity. Both of these factors make it hard to design controllers of coordinated control system (CCS) to harmonize the boiler’s slow dynamics with the turbine’s fast dynamics so as to follow the command from grid promptly.

- Capability to reject disturbance in fuel. Since the CFB boiler works with a variety of fuels, the variability of fuel brings in disturbance for the unit operation. In addition, the amounts of fuel that enter the boiler sometimes fluctuate due to mechanical reasons. Consequently, it is necessary to design advanced controllers so as to suppress the influence of disturbance from fuel.

- Complex dynamics of the supercritical CFB unit. Besides the thermal inertia, strong nonlinearity, and time delay of supercritical CFB unit, multivariable coupling has a significant impact on the controller design [9]. The adjustments of manipulated variables would cause changes in all controlled variables. Furthermore, the unit would become more complicated when the bed temperature of the CFB boiler is taken into consideration [10].

- Burning carbon is integrated into the control framework to accelerate the load following;

- The disturbance rejection performance is improved via the design of decentralized ADRC controllers;

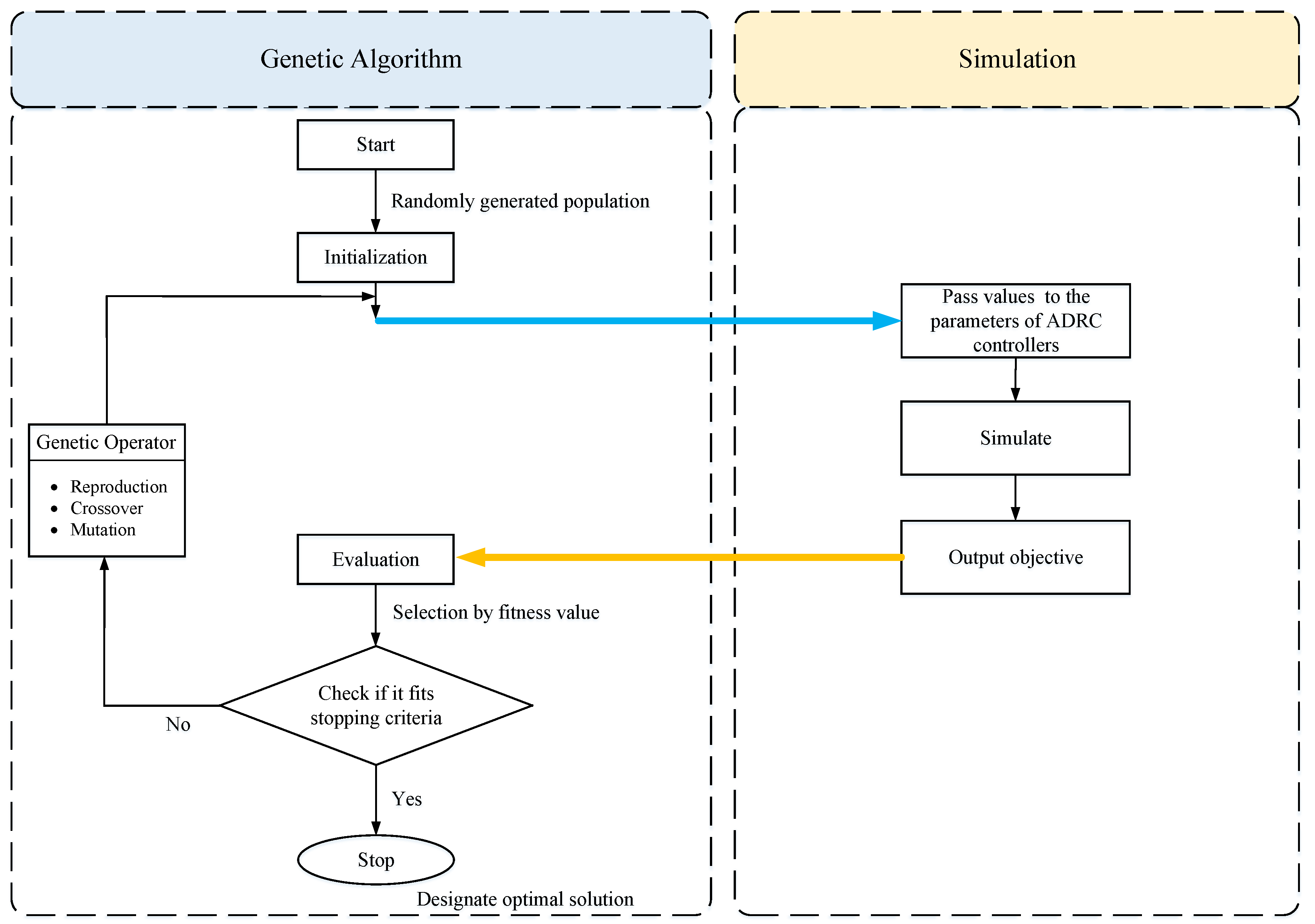

- Genetic algorithm (GA) is employed to tune the parameters of the ADRC controllers.

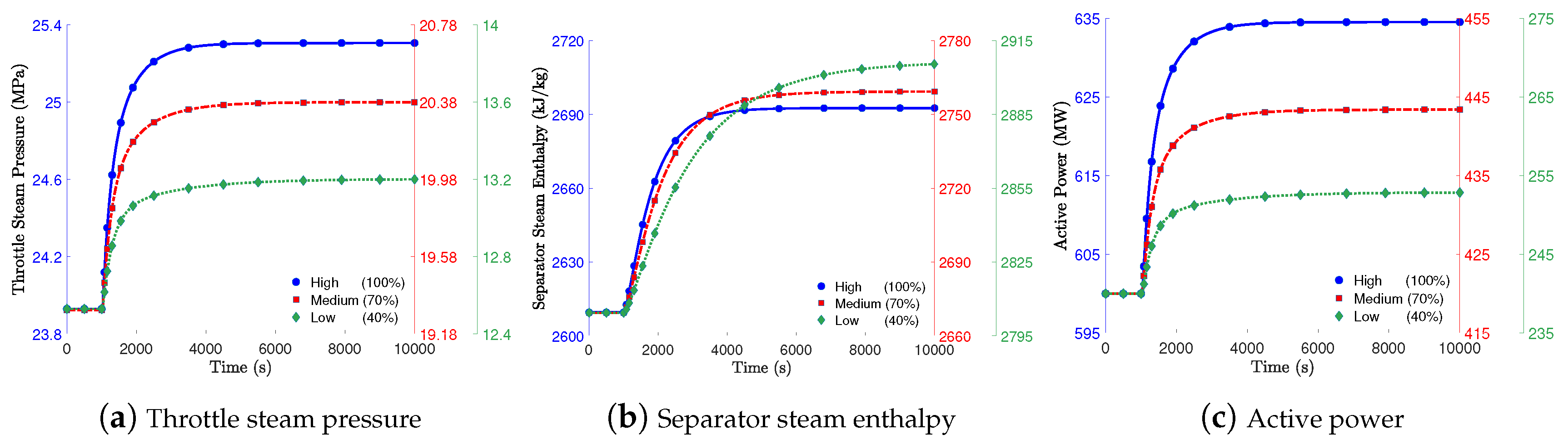

2. Performance Analysis of Supercritical Circulating Fluidized Bed Boiler-Turbine Unit Model

3. Burning Carbon Based Decentralized Active Disturbance Rejection Control of a Supercritical CFB Unit

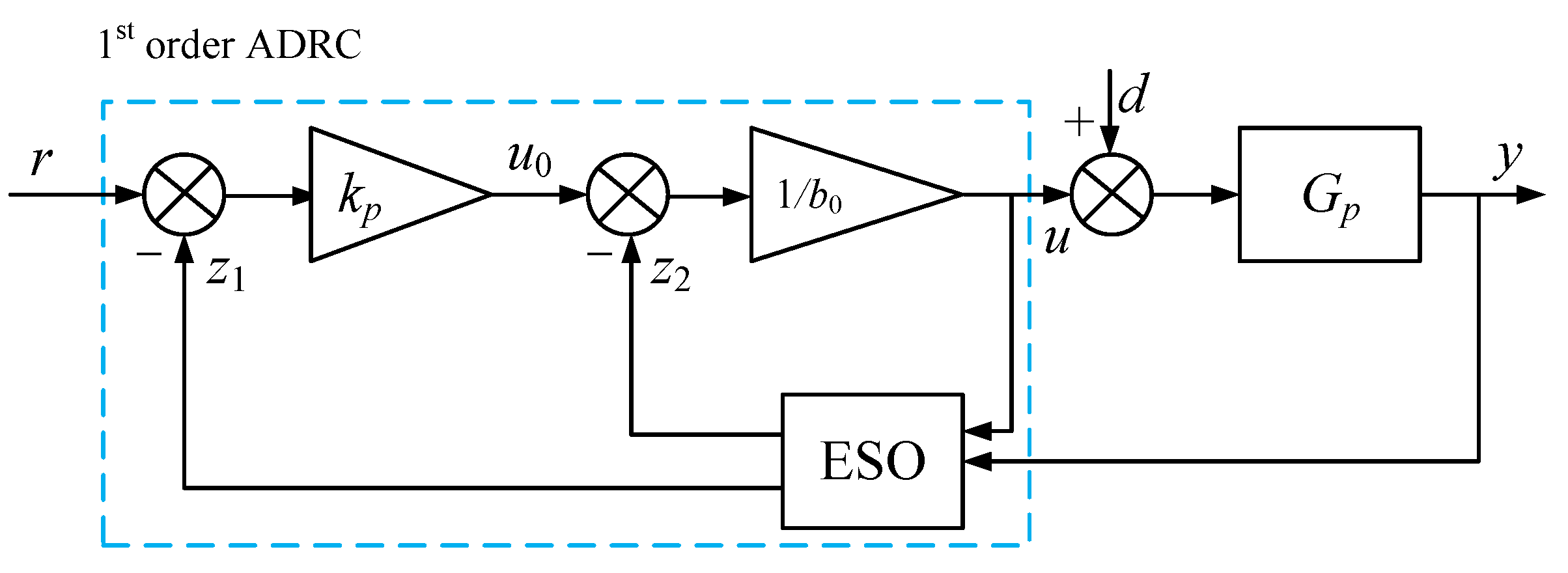

3.1. Linear Active Disturbance Rejection Control

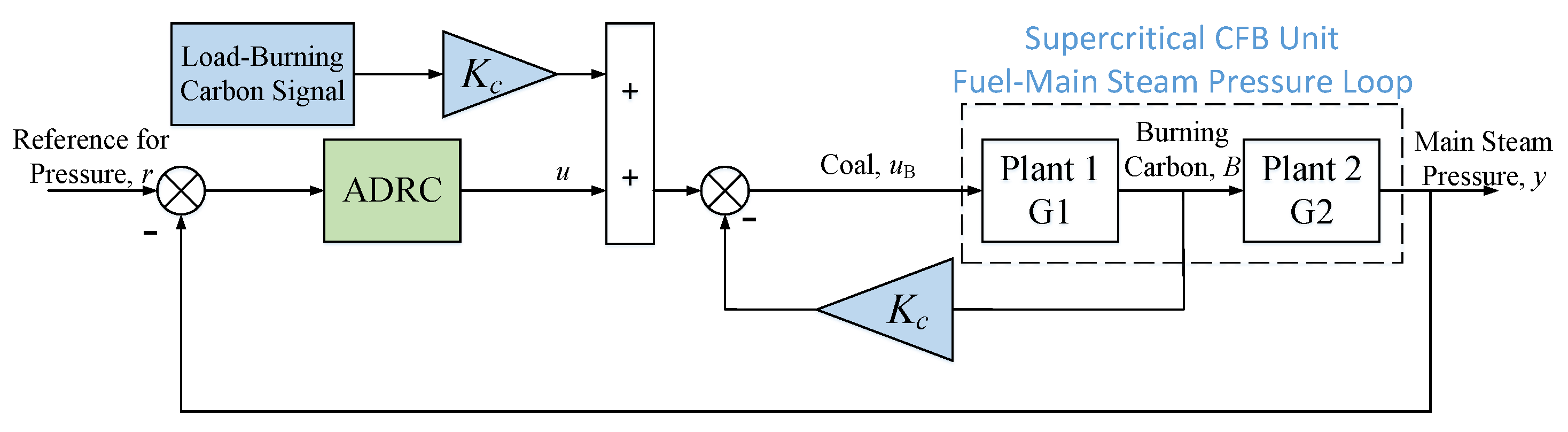

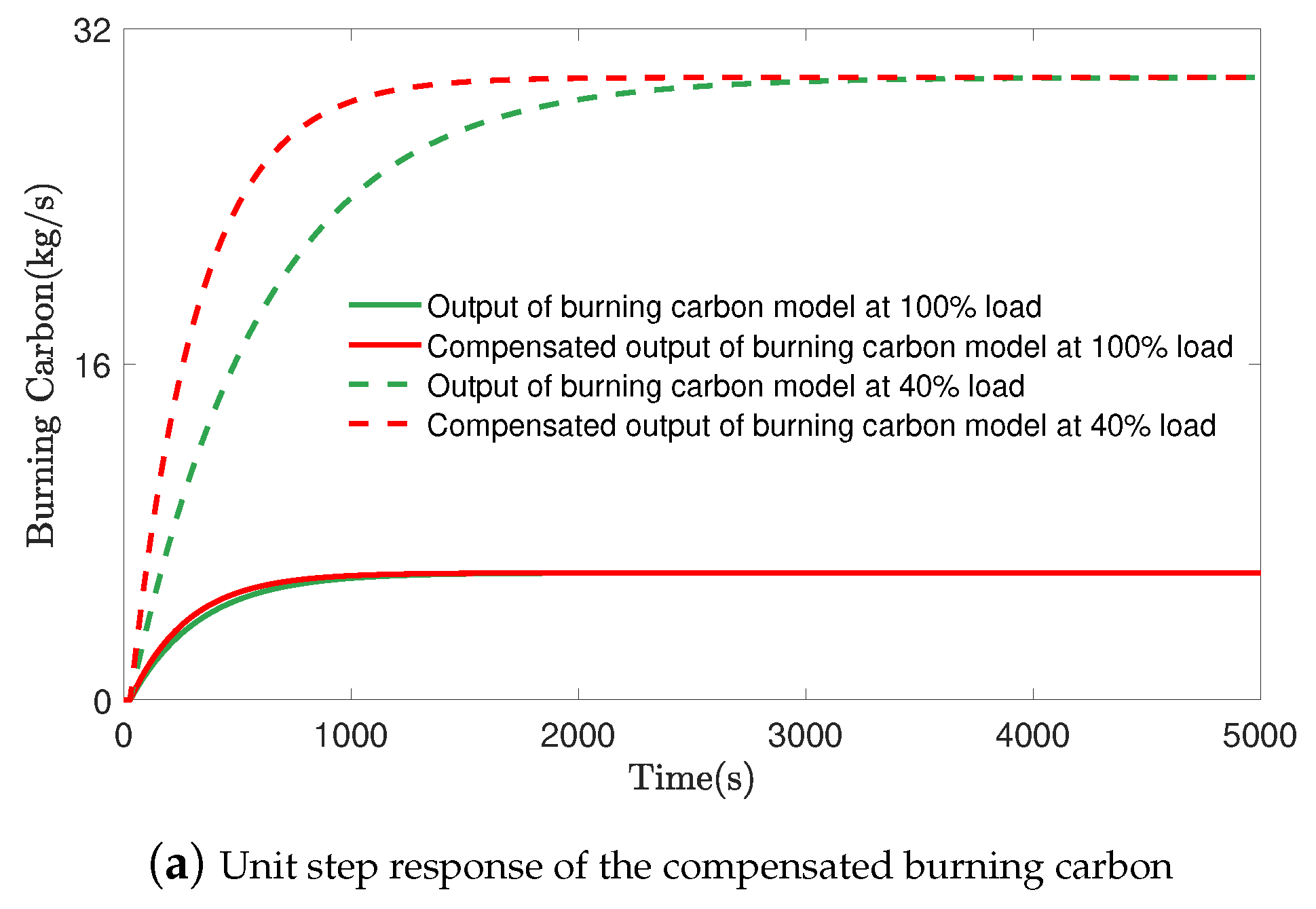

3.2. Burning Carbon Based Decentralized ADRC for Supercritical CFB Boiler-Turbine Unit

4. Tuning of ADRC Controllers

5. Simulations

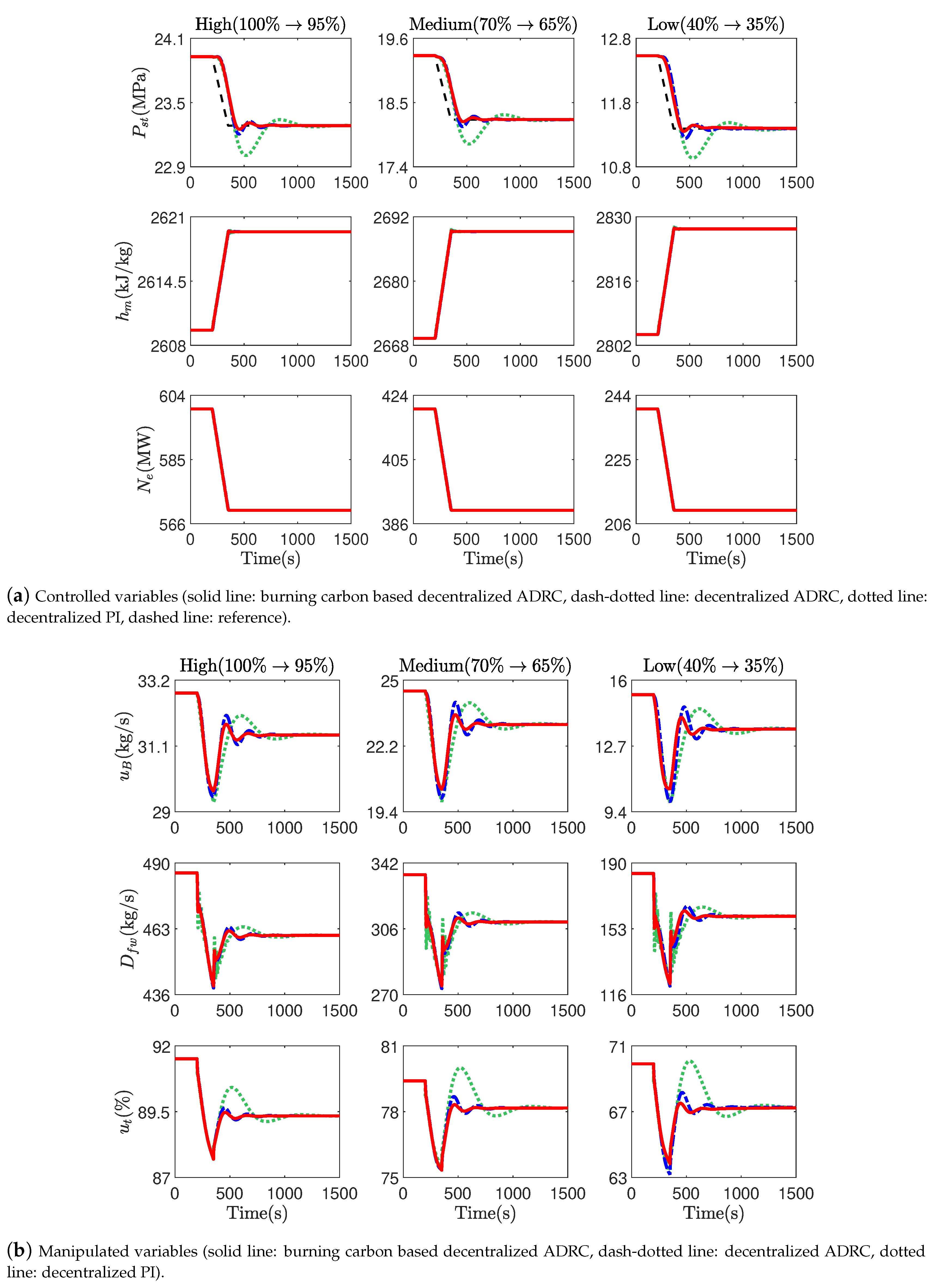

5.1. Load Tracking

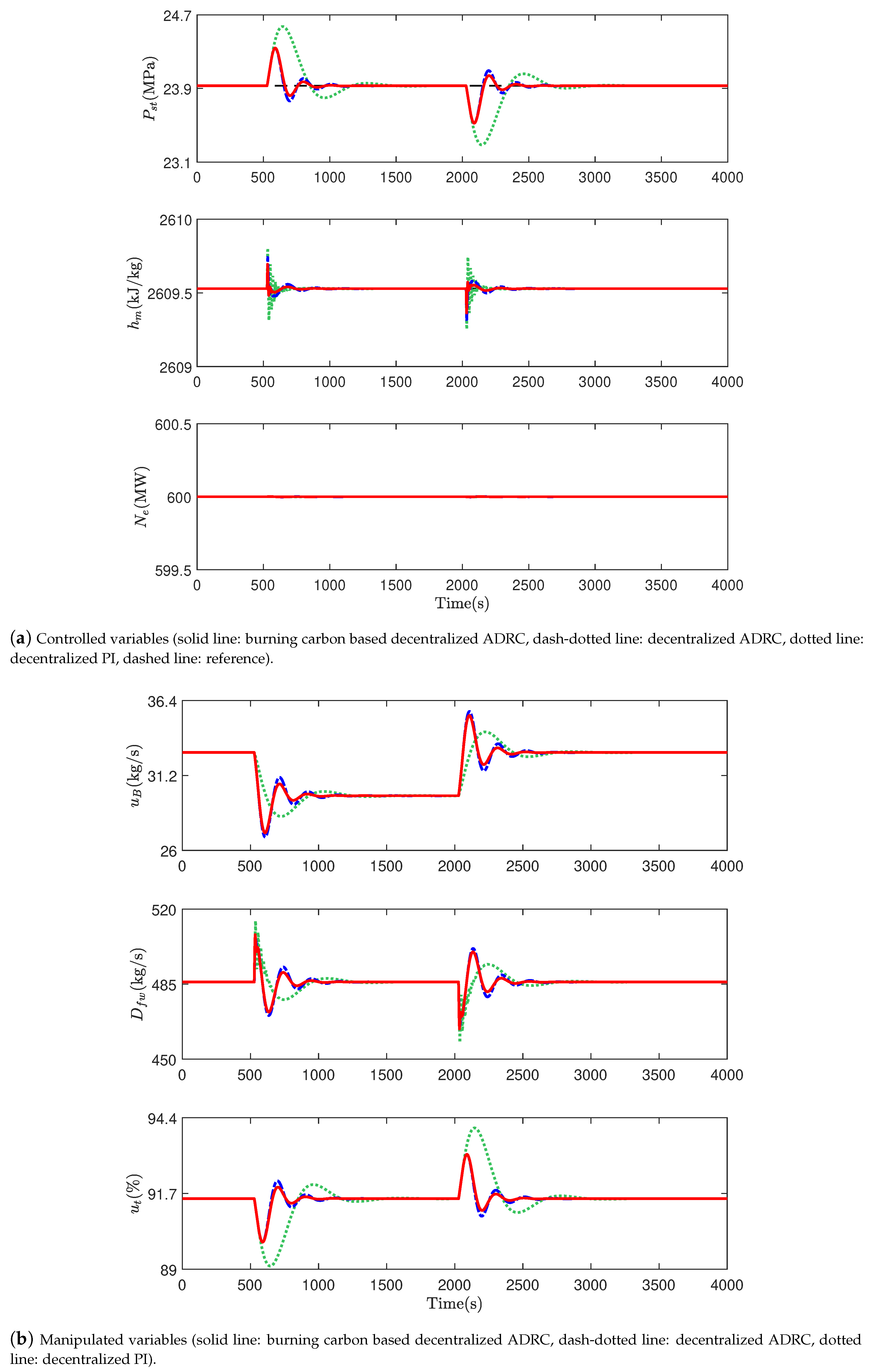

5.2. Disturbance Rejection

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ADRC | Active Disturbance Rejection Control |

| CFB | Circulating Fluidized Bed |

| CCS | Coordinated Control System |

| DDE | Desired Dynamic Equation |

| DOB | Disturbance Observer |

| ESO | Extended State Observer |

| GA | Genetic Algorithm |

| IAE | Integrated Absolute Error |

| MIMO | Multi-Input-Multi-Output |

| PID | Proportional-Integral-Derivative |

References

- Yue, G.; Cai, R.; Lyu, J.; Zhang, H. From a CFB reactor to a CFB boiler—The review of R&D progress of CFB coal combustion technology in China. Powder Technol. 2017, 316, 18–28. [Google Scholar] [CrossRef]

- Nyashina, G.S.; Kurgankina, M.A.; Strizhak, P.A. Environmental, economic and energetic benefits of using coal and oil processing waste instead of coal to produce the same amount of energy. Energy Convers. Manag. 2018, 174, 175–187. [Google Scholar] [CrossRef]

- Kurgankina, M.A.; Nyashina, G.S.; Strizhak, P.A. Advantages of switching coal-burning power plants to coal-water slurries containing petrochemicals. Appl. Therm. Eng. 2019, 147, 998–1008. [Google Scholar] [CrossRef]

- Lyu, J.; Yang, H.; Ling, W.; Nie, L.; Yue, G.; Li, R.; Chen, Y.; Wang, S. Development of a supercritical and an ultra-supercritical circulating fluidized bed boiler. Front. Energy 2019, 13, 114–119. [Google Scholar] [CrossRef]

- Chang, S.; Zhuo, J.; Meng, S.; Qin, S.; Yao, Q. Clean Coal Technologies in China: Current Status and Future Perspectives. Engineering 2016, 2, 447–459. [Google Scholar] [CrossRef]

- Song, C.; Lyu, J.; Yang, H.; Wang, S.; Ling, W.; Yue, G. Research and Application of Supercritical and Ultra-supercritical Circulating Fluidized Bed Boiler Technology. Proc. CSEE 2018, 38, 338–347. [Google Scholar]

- Brouwer, A.S.; van den Broek, M.; Seebregts, A.; Faaij, A. Operational flexibility and economics of power plants in future low-carbon power systems. Appl. Energy 2015, 156, 107–128. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Zeng, D.; Tian, L.; Gao, M.; Wang, W.; Niu, Y.; Fang, F. Control Strategy for Operating Flexibility of Coal-fired Power Plants in Alternate Electrical Power Systems. Proc. CSEE 2015, 35, 5385–5394. [Google Scholar]

- Gao, M.; Hong, F.; Liu, J.; Chen, F. Investigation on the energy conversion and load control of supercritical circulating fluidized bed boiler units. J. Process Control 2018, 68, 14–22. [Google Scholar] [CrossRef]

- Lv, Y.; Hong, F.; Yang, T.; Fang, F.; Liu, J. A dynamic model for the bed temperature prediction of circulating fluidized bed boilers based on least squares support vector machine with real operational data. Energy 2017, 124, 284–294. [Google Scholar] [CrossRef]

- Majanne, Y.; Köykkä, P. Dynamic Model of a Circulating Fluidized Bed Boiler. IFAC Proc. Vol. 2009, 42, 255–260. [Google Scholar] [CrossRef]

- Gao, M.; Hong, F.; Yan, G.; Liu, J.; Chen, F. Mechanism modelling on the coordinated control system of a coal-fired subcritical circulating fluidized bed unit. Appl. Therm. Eng. 2019, 146, 548–555. [Google Scholar] [CrossRef]

- Wu, H.; Yang, C.; He, H.; Huang, S.; Chen, H. A hybrid simulation of a 600MW supercritical circulating fluidized bed boiler system. Appl. Therm. Eng. 2018, 143, 977–987. [Google Scholar] [CrossRef]

- Gao, M.; Hong, F.; Zhang, B.; Liu, J.; Yue, G.; Yang, A.; Chen, F. Study on Nonlinear Control Model of Supercritical (Ultra Supercritical) Circulating Fluidized Bed Unit. Proc. CSEE 2018, 38, 363–372. [Google Scholar]

- Hultgren, M.; Ikonen, E.; Kovács, J. Once-through Circulating Fluidized Bed Boiler Control Design with the Dynamic Relative Gain Array and Partial Relative Gain. Ind. Eng. Chem. Res. 2017, 56, 14290–14303. [Google Scholar] [CrossRef]

- Hao, Y.; Li, D.; Tan, W. Design of the PID controller for circulating fluidized bed boiler combustion system. In Proceedings of the 31st Chinese Control Conference, Hefei, China, 25–27 July 2012; pp. 4580–4585. [Google Scholar]

- Menhas, M.I.; Wang, L.; Hui, P.; Fei, M. CFBB PID Controller Tuning with Probability based Binary Particle Swarm Optimization Algorithm. In Proceedings of the International Conference on Intelligent Computing for Sustainable Energy and Environment; Springer: Berlin/Heidelberg, Germany, 2010; pp. 44–51. [Google Scholar]

- Xue, Y.; Li, D.; Zhang, Y.; Gao, Q.; Wang, J.; Sun, Z. Decentralized nonlinear control of 300MWe circulating fluidized boiler power unit. In Proceedings of the 2012 UKACC International Conference on Control, Cardiff, UK, 3–5 September 2012; pp. 1019–1024. [Google Scholar] [CrossRef]

- Sun, L.; Li, D.; Lee, K.Y. Enhanced decentralized PI control for fluidized bed combustor via advanced disturbance observer. Control Eng. Pract. 2015, 42, 128–139. [Google Scholar] [CrossRef]

- Zhuo, X.; Lou, C.; Zhou, H.; Zhuo, J.; Fu, P. Hierarchical Takagi-Sugeno fuzzy hyperbolic tangent static model control for a circulating fluidized bed boiler thermal power unit. Energy 2018, 162, 910–917. [Google Scholar] [CrossRef]

- Sun, H.; Sun, P. Study on fuzzy control of circulating fluidized bed temperature. In Proceedings of the 3rd International Conference on Control Science and Systems Engineering, Beijing, China, 17–19 August 2017; pp. 154–157. [Google Scholar] [CrossRef]

- Wang, L.; Yang, R.; Pardalos, P.M.; Qian, L.; Fei, M. An adaptive fuzzy controller based on harmony search and its application to power plant control. Int. J. Electr. Power Energy Syst. 2013, 53, 272–278. [Google Scholar] [CrossRef]

- Sethi, B.K.; Vinayak, J.R.; Sivakumaran, N. Internal model controller for CFBC boiler using neural networks. In Proceedings of the 2018 Indian Control Conference, Kanpur, India, 4–6 January 2018; pp. 276–281. [Google Scholar] [CrossRef]

- Hu, M.; Ling, H.; Liu, D. The application of LM-BP Neural Network in the Circulating Fluidized Bed Unit. In Proceedings of the 4th International Conference on Mechatronics, Materials, Chemistry and Computer Engineering 2015; Liang, Z., Li, X., Eds.; ACSR-Advances in Comptuer Science Research; Atlantis Press: Paris, France, 2015; Volume 39, pp. 2017–2020. [Google Scholar]

- Xue, W.; Bai, W.; Yang, S.; Song, K.; Huang, Y.; Xie, H. ADRC With Adaptive Extended State Observer and its Application to Air–Fuel Ratio Control in Gasoline Engines. IEEE Trans. Ind. Electron. 2015, 62, 5847–5857. [Google Scholar] [CrossRef]

- Sun, L.; Shen, J.; Hua, Q.; Lee, K.Y. Data-driven oxygen excess ratio control for proton exchange membrane fuel cell. Applied Energy 2018, 231, 866–875. [Google Scholar] [CrossRef]

- Han, J.; Wang, H.; Jiao, G.; Cui, L.; Wang, Y. Research on Active Disturbance Rejection Control Technology of Electromechanical Actuators. Electronics 2018, 7, 174. [Google Scholar] [CrossRef]

- Roman, R.C.; Radac, M.B.; Tureac, C.; Precup, R.E. Data-Driven Active Disturbance Rejection Control of Pendulum Cart Systems. In Proceedings of the 2018 IEEE Conference on Control Technology and Applications, Copenhagen, Denmark, 21–24 August 2018; pp. 933–938. [Google Scholar] [CrossRef]

- Wang, G.; Xu, Q. Sliding Mode Control with Disturbance Rejection for Piezoelectric Nanopositioning Control. In Proceedings of the 2018 Annual American Control Conference, Milwaukee, WI, USA, 27–29 June 2018; pp. 6144–6149. [Google Scholar] [CrossRef]

- Ma, S.; Sun, M.; Chen, Z. Interactive ADRC design for flight attitude control. In Proceedings of the 6th Data Driven Control and Learning Systems, Chongqing, China, 26–27 May 2017; pp. 611–616. [Google Scholar] [CrossRef]

- Feng, H.; Guo, B.Z. Active disturbance rejection control: Old and new results. Annu. Rev. Control 2017, 44, 238–248. [Google Scholar] [CrossRef]

- Huang, Y.; Xue, W. Active disturbance rejection control: Methodology and theoretical analysis. ISA Trans. 2014, 53, 963–976. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; He, T.; Li, D.; Xue, Y.; Sun, L.; Sun, L. Superheated steam temperature control based on modified active disturbance rejection control. Control Eng. Pract. 2019, 83, 83–97. [Google Scholar] [CrossRef]

- Zhang, Y.; Xue, Y.; Li, D.; Wu, H.; Lee, K.Y. Active Disturbance Rejection Control for Bed-inventory Balancing of CFB Boilers with Pant-leg Structure. IFAC-PapersOnLine 2015, 48, 66–71. [Google Scholar] [CrossRef]

- He, T.; Wu, Z.; Shi, R.; Li, D.; Sun, L.; Wang, L.; Zheng, S. Maximum Sensitivity-Constrained Data-Driven Active Disturbance Rejection Control with Application to Airflow Control in Power Plant. Energies 2019, 12, 231. [Google Scholar] [CrossRef]

- Pan, F.; Liu, Q.; Sun, L.; Li, D.; Tan, W. A novel design of active disturbance rejection controller and its application in the Circulating Fluidized Bed Boiler combustion system. In Proceedings of the 2015 American Control Conference, Chicago, IL, USA, 1–3 July 2015; pp. 3950–3955. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, D.; Xue, Y. Active disturbance rejection control for Circulating Fluidized Bed Boiler. In Proceedings of the 12th International Conference on Control, Automation and Systems, JeJu Island, Korea, 17–21 October 2012; pp. 1413–1418. [Google Scholar]

- Wu, H.; Xue, Y.; Guo, Z.; Wang, Z.; Li, Z. Dynamic Simulation Model of Combustion System of CFB Boilers. In Proceedings of the 23rd International Conference on Fluidized Bed Conversion; KIChE: Seoul, Korea, 2018; pp. 1–7. [Google Scholar]

- Gao, Z. Scaling and bandwidth-parameterization based controller tuning. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; Volume 6, pp. 4989–4996. [Google Scholar] [CrossRef]

- Madoński, R.; Herman, P. Survey on methods of increasing the efficiency of extended state disturbance observers. ISA Trans. 2015, 56, 18–27. [Google Scholar] [CrossRef]

- Xue, W.; Huang, Y.; Gao, Z. On ADRC for non-minimum phase systems: canonical form selection and stability conditions. Control Theory Technol. 2016, 14, 199–208. [Google Scholar] [CrossRef]

- Tan, W.; Fu, C. Linear Active Disturbance-Rejection Control: Analysis and Tuning via IMC. IEEE Trans. Ind. Electron. 2016, 63, 2350–2359. [Google Scholar] [CrossRef]

- Whitley, D.; Sutton, A.M. Genetic algorithms—A survey of models and methods. In Handbook of Natural Computing; Springer: Berlin/Heidelberg, Germany, 2012; Volume 2–4, pp. 637–671. [Google Scholar] [CrossRef]

| (MPa) | (kJ/kg) | (MW) | (kg/s) | (kg/s) | (%) | |

|---|---|---|---|---|---|---|

| High (100%) | 23.93 | 2609.53 | 600 | 32.79 | 485.98 | 91.51 |

| Medium (70%) | 19.30 | 2669.29 | 420 | 24.54 | 335.60 | 79.40 |

| Low (40%) | 12.53 | 2804.35 | 240 | 15.28 | 184.10 | 69.91 |

| Decentralized PI | Decentralized ADRC | Burning Carbon Based Decentralized ADRC | |||||||

|---|---|---|---|---|---|---|---|---|---|

| High | Medium | Low | High | Medium | Low | High | Medium | Low | |

| Overshoot (%) | 1.20 | 2.30 | 4.02 | 0.23 | 0.55 | 1.14 | 0.28 | 0.84 | 0.62 |

| Settling time (s) | 793.4 | 798.8 | 829.0 | 487.4 | 492.6 | 508.7 | 397.1 | 397.1 | 405.3 |

| Decentralized PI | Decentralized ADRC | Burning Carbon Based Decentralized ADRC | |||||||

|---|---|---|---|---|---|---|---|---|---|

| High | Medium | Low | High | Medium | Low | High | Medium | Low | |

| Overshoot (%) | 1.16 | 2.15 | 3.62 | 0.20 | 0.49 | 0.98 | 0.25 | 0.80 | 0.50 |

| Settling time (s) | 789.3 | 794.7 | 823.8 | 484.1 | 488.7 | 504.6 | 398.9 | 396.0 | 404.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Xue, Y.; Li, D.; Wu, Z.; He, T. On the Flexible Operation of Supercritical Circulating Fluidized Bed: Burning Carbon Based Decentralized Active Disturbance Rejection Control. Energies 2019, 12, 1132. https://doi.org/10.3390/en12061132

Zhang F, Xue Y, Li D, Wu Z, He T. On the Flexible Operation of Supercritical Circulating Fluidized Bed: Burning Carbon Based Decentralized Active Disturbance Rejection Control. Energies. 2019; 12(6):1132. https://doi.org/10.3390/en12061132

Chicago/Turabian StyleZhang, Fan, Yali Xue, Donghai Li, Zhenlong Wu, and Ting He. 2019. "On the Flexible Operation of Supercritical Circulating Fluidized Bed: Burning Carbon Based Decentralized Active Disturbance Rejection Control" Energies 12, no. 6: 1132. https://doi.org/10.3390/en12061132