This section is devoted to present and discuss the results and is divided into three parts. The first part presents the technical performance of the integrated BECCS systems to a hypothetical sugarcane mill. As previously mentioned, three levels of heat demand for solvent regeneration—related to the different stages of the technology—were evaluated. The second part focuses on the feasibility of carbon capture in a sugarcane mill. Finally, in the third part the effects of scale are analyzed.

3.1. Technical Performance

The simulated cogeneration system has a steam turbine with one controlled extraction at 2.5 bar and condensation of the remaining flow. Five cases were assessed: the reference case, i.e., the cogeneration plant without CCS; case 1—cogeneration plant with CCS only from CO2 of fermentation; case 2—cogeneration plant with CCS from both fermentation and combustion, and solvent regeneration requiring 4.4 GJ/t CO2; case 3—cogeneration plant with CCS (fermentation and combustion CO2) and 2.6 GJ/t CO2 as heat requirement; and case 4—cogeneration plant with CCS (fermentation and combustion CO2) and 1.6 GJ/t CO2 as heat requirement. For all cases, simulation includes harvest and off-harvest seasons.

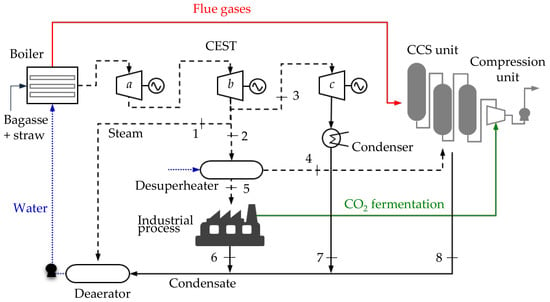

Figure 1 shows the process flow diagram that represents the operation in the harvest season (i.e., with steam extraction for industrial process), with CCS. In software’s basic configuration the steam turbine has three bodies. The steam flow to the deaerator (stream 1) corresponds to 2% of the steam raised and is extracted from the turbine body

b. The stream (2) feeds the industrial process (stream 5) and the heat exchanger for regenerating the solvent (stream 4), being its thermodynamic state adjusted (in a desuperheater) to the required temperature (137 °C). Streams (6), (7) and (8) refer to condensates, being assumed 90% recovery of streams (6) and (8), but both at 90 °C; pumps for setting the pressure of condensing flows before the deaerator are omitted in

Figure 1.

Performance results are presented in

Table 3. In the reference case—cogeneration without CO

2 capture, there is no steam extraction going to the CCS plant and, therefore, power output is maximum. In this case, net power output was estimated at 77 MW during harvest season and 64 MW in the off-season, result that corresponds to a surplus output of 144 kWh per tonne of sugarcane (174 kWh/t generated). Electricity generation, or sold, per tonne of sugarcane crushed is an indicator commonly used to express the efficiency of electricity production in a sugarcane mill, and the result above can be compared to the predicted current best figures in sugarcane sector (130–170 kWh/t of cane) [

9,

23].

Case 1 presents a special case in which capture of only CO2 from fermentation was considered. As the CO2 from fermentation is naturally a pure stream, and separation is not necessary, CO2 goes directly to the compression unit. Power requirement for compression was estimated at 2.4 MW (2% of the net power output) and capture corresponds to 0.13 Mt CO2/y, which means 10% of the total mill’s emissions.

Capturing CO2 from both fermentation and combustion imposes meaningful energy penalties. There is a constraint in Case 2—with 1998 kg of steam required per tonne of CO2—due to steam availability: during harvest season the system is unable to supply all required steam for both the industrial process and solvent regeneration, thus forcing the reduction of the capture rate. In all cases a minimum steam flow of 3 kg/s (stream (3)) was assumed to be expanded at c. Results of Case 2 indicate that it is possible to capture only 43% of the CO2 emitted by the combustion process. However, during the off-season, as no steam is required for the industrial process, 90% of the CO2 from combustion gases is captured (the maximum assumed). Thus, power required for compression during harvest season is due to all CO2 from fermentation and to the amount captured from flue gases, while during off-season all possible CO2 captured from flue gases (90%) is compressed. In summary, annual capture rate was estimated at 58%, capturing 0.79 Mt CO2 (0.13 from fermentation), which is a significant value for a BECCS system, taking into account what has been considered. However, in this case it is predicted a significant reduction in net power output: 48% of the total power during harvest season and 59% otherwise. The balance corresponds to the surplus of 40.7 MW and 28.3 MW, in the harvest and the off-season, respectively. Even though, results still correspond to meaningful surplus electricity regarding the current practices: 72 kWh/t of cane.

In Case 3 the heat requirement for solvent regeneration is 2.6 GJ/t CO

2, and this demand is related to a technology that is expected to be feasible by 2020 [

7]. Current technologies are yet further from this parameter (3.2–3.6 GJ/t CO

2) [

4,

24]. With lower steam requirement per tonne of CO

2 captured (1180 kg), capture from combustion would be higher, but the maximum cannot yet be reached: 73% during harvest season. As consequence, total annual capture would be 1.09 Mt CO

2 (capture rate of 79%). The impacts on power would correspond to 68% of the total generation during the harvest season and to 37% during the off-season. Due to the higher power consumption during harvest, final surplus electricity decreases to 59 kWh/t of cane.

Finally, in Case 4, with heat requirement equivalent to 726 kg of steam per tonne of CO2, it would be possible to supply all steam required both for the industrial process and the CCS unit, resulting in maximum capture efficiency. In this case the annual capture would be 1.26 Mt CO2, corresponding to a capture rate of 91% (due to fermentation). The net production of energy during the harvest was further reduced (73% of the power output), but the impact during off-season was reduced to 35% of power output. The indicator of surplus electricity per tonne of sugarcane was estimated at 57 kWh.

3.2. Economic Performance

In order to compare the results presented in this paper with some presented in the literature, the economic assessment was done with all costs estimated for 2014, in Euro. In all cases the investments were supposed to correspond to a single flow in year 0 of the cash flow.

In the reference case, in which the aim is to maximize surplus electricity, the MSP was estimated taking into account all taxes and charges usually incident to this type of enterprise in Brazil.

Table 4 presents the main costs and the calculated MSP for the reference case.

The MSP resulted at 48 €/MWh, a value that could be compared with the reference price set in auctions for new enterprises in 2014 (New Energy Auctions), 62 €/MWh, for biomass power units [

25]. The difference is explained by the discount rate usually assumed by investors in bioelectricity (higher than the one assumed here) and by the competition in the electricity sector, which vary depending on the investments in other energy sources and the expectation of investing in new hydro power plants.

Results for the Cases 1–4 are also presented in

Table 4. The estimated CO

2 credit price, based on the amount of CO

2 captured, would cover all costs (the minimum rate of attractiveness would be 10% per year) and also the loss of revenue due to less electricity sold. In this sense, the results presented in

Table 4 correspond to the minimum selling price of capturing CO

2.

In Case 1, a small amount of CO

2 is captured with no meaningful energy penalty. The CO

2 minimum credit price was estimated at 21 €/t CO

2, a relative low cost for CCS, being the best opportunity in case of sugarcane mills. The estimated CO

2 price for Case 1 is basically the same presented in [

9] (27.2 US

$/t CO

2 in 2014, when the average exchange rate was 1.33 Euro/US

$).

It can be seen from

Table 4 that, in Cases 2 to 4, the capital costs due to the CCS units represent from 72% to 79% of the total investment, and from 88% to 92% of the total annual O&M costs. It is clear from these figures that carbon capture would be the main driver of investments in Cases 2 to 4, far exceeding the costs of surplus electricity production.

A comparison with the results presented by [

4,

18] is shown in

Table 5. References consider CCS plants based on MEA technology, and both publications were used as reference for estimating costs and performance parameters. However, in both cases the estimates were done for CCS natural gas combined cycle (NGCC) power plants. MEA technology considered in [

4] had a heat specific requirement equal to 3.66 GJ/t CO

2, that would be intermediate between Cases 2 and 3 in this paper, while [

18] considers heat requirement similar to Case 4. As in both references the discount rate is relatively low (7–7.5%), new results related with this study—for a discount rate of 8% per year—were included in

Table 5. The minimum price to be paid per tonne of CO

2 captured is relatively similar comparing the results of this study (for lower discount rate) to those presented by [

18], but the cases are very different for a straight comparison.

The more expensive electricity generation is, the higher the credit for capturing CO

2 would be. The results of this study are relative close to those presented by [

18] because here the case is related to a cogeneration unit that mostly uses residual biomass as fuel, despite the fact that the benefits of scaling effects on electricity generation do not exist. The results presented by [

5] are impacted by a higher cost of fuel. Another important aspect is that for the case reported in this paper, the minimum price to be paid for capturing CO

2 is impacted by the stream of CO

2 from fermentation (that varies from 16% of the total in Case 2, to 10% in Case 4) and that has a relatively small cost. Following the same procedure described in this paper, but not considering the capture of CO

2 from fermentation, the credit price would grow from 59 €/t CO

2 to 70 €/t CO

2 (for discount rate 10%). It is also worth mentioning that the amount of CO

2 captured per year is not much smaller (57% to 83%) than in power units that would burn natural gas, despite the much smaller installed electricity capacity (12% to 18%). Comparing biomass and natural gas, the higher carbon content per unit of energy and the much lower efficiency of electricity generation explain the huge penalties of CO

2 capture on electricity generation. Another useful comparison is with the carbon price needed for making a technology competitive. In the case of switching from NGCC to a coal power plant with CCS, considering 8% as the annual capital costs for the investments, [

26] presents 85 €/t CO

2 as the break-even price. Thus, in a general sense it can be concluded that the CO

2 capture costs presented in this paper are in line with the estimates presented in the literature, but a main difference is that the BECCS system considered here is able to contribute with negative GHG emissions.

Cases 2 to 4 correspond to different stages of development of MEA based technology. Case 2 corresponds to the current commercial stage, while Case 3 represents the technology that could be available in short term. Moving from current to future technologies would impact carbon capture, with an increase of 38% on annual output as long as Case 3 is compared to Case 2; as previously mentioned, capturing in Case 2 is negatively impacted by the higher steam demand for recovering amine. On the other hand, moving from Case 2 to Case 3 significantly impact surplus electricity, with a decrease of almost 13% in the total electricity that could be sold along the year. The impact on the minimum price to be paid per tonne of CO2 captured is less pronounced, with a reduction of 6% comparing Cases 3 and 2. The change from Case 3 to Case 4 is less pronounced (an increase of 16% in annual capture, a reduction of 2.8% in surplus electricity, and a 4.8% reduction in carbon costs).

The fact that the minimum price to be paid per tonne of CO2 captured is almost equal in all three cases indicates that, from an economic point of view, it is not necessary to wait for advanced MEA technologies in order to go for pilot BECCS projects. Therefore, it is necessary to consider technologies that would impact less on surplus electricity. However, a very important find is that CO2 capture from fermentation has a lower cost and a small impact on the energy balance, and should be prioritized for pilot BECCS units in Brazil.

3.3. Scaling Effects

For the considered BECCS system scaling effects are analyzed in this section. Case 3, with heat requirement for solvent regeneration equivalent to 2.6 GJ/t CO

2, was chosen to be scaled into a smaller industry (2 Mt/y) and a larger mill (8 Mt/y). The same performance parameters previously presented were considered, and costs were estimated according to the assumptions mentioned before (for 10% discount rate).

Table 6 presents total plant costs and the main economic results. Scale effects are clear both on the MSP of surplus electricity and on the minimum price to be paid for capturing CO

2.

Taking as reference the price presented by [

4] in the case of capture in a large combined cycle power plant (80.7 €/t CO

2), and assuming that people would be able to pay this value in the future, full carbon capture (both from fermentation and combustion) would be feasible in Brazilian sugarcane mills, but it is clear that the feasibility would be enhanced with the mill capacity. As regard with the results presented by [

18], comparatively the feasibility would exist for larger mills. Considering that mills with capacity equivalent to 2 Mt/y are currently the average in Brazil, in many existing mills it would be feasible to capture CO

2. On the other hand, considering that new mills tend to be larger, in the future it would be reasonable to consider mill’s location also taking into account the aim of storing CO

2 at lower costs.

Allocating all capital costs to the annual surplus electricity, the indicator varies from 1874 to 1099 €/MWh, depending on the mill size (see

Table 6). This figure for the reference case [

4] is only 134 €/MWh. Alternatively, allocating total capital costs to the annual amount of CO

2 captured, this indicator varies from 237 to 405 €/t CO

2 captured per year (

Table 6), while this figure is 483 €/t in the case presented by [

4]. It seems clear that investors should have a completely different rationale in each case: while in case of a natural gas combined power plant CO

2 capture would be a complement that should be fairly paid, in the case of carbon capture in a sugarcane mill surplus electricity produced in a cogeneration unit should no longer be the priority. In this case, the priority should be capturing CO

2, with the advantage that this enterprise would contribute with negative emissions. Indeed, whether the benefits of negative emissions would be recognized, a larger payment per tonne of CO

2 would be possible, and surplus electricity could be more competitive with other generation options.