Visualization Investigation of the Influence of Chamber Profile and Injection Parameters on Fuel Spray Spreading in a Double-Layer Diverging Combustion Chamber for a DI Diesel Engine

Abstract

:1. Introduction

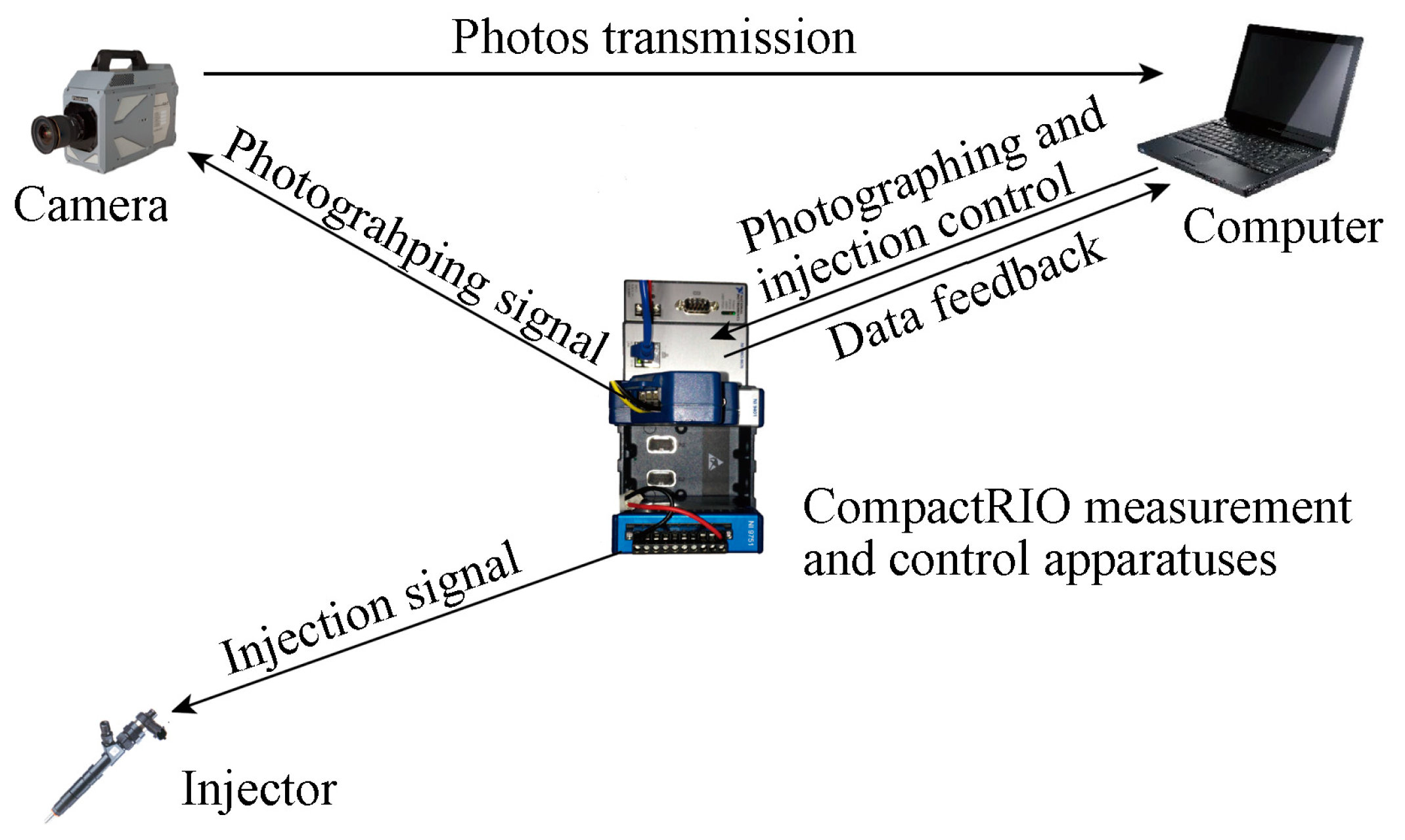

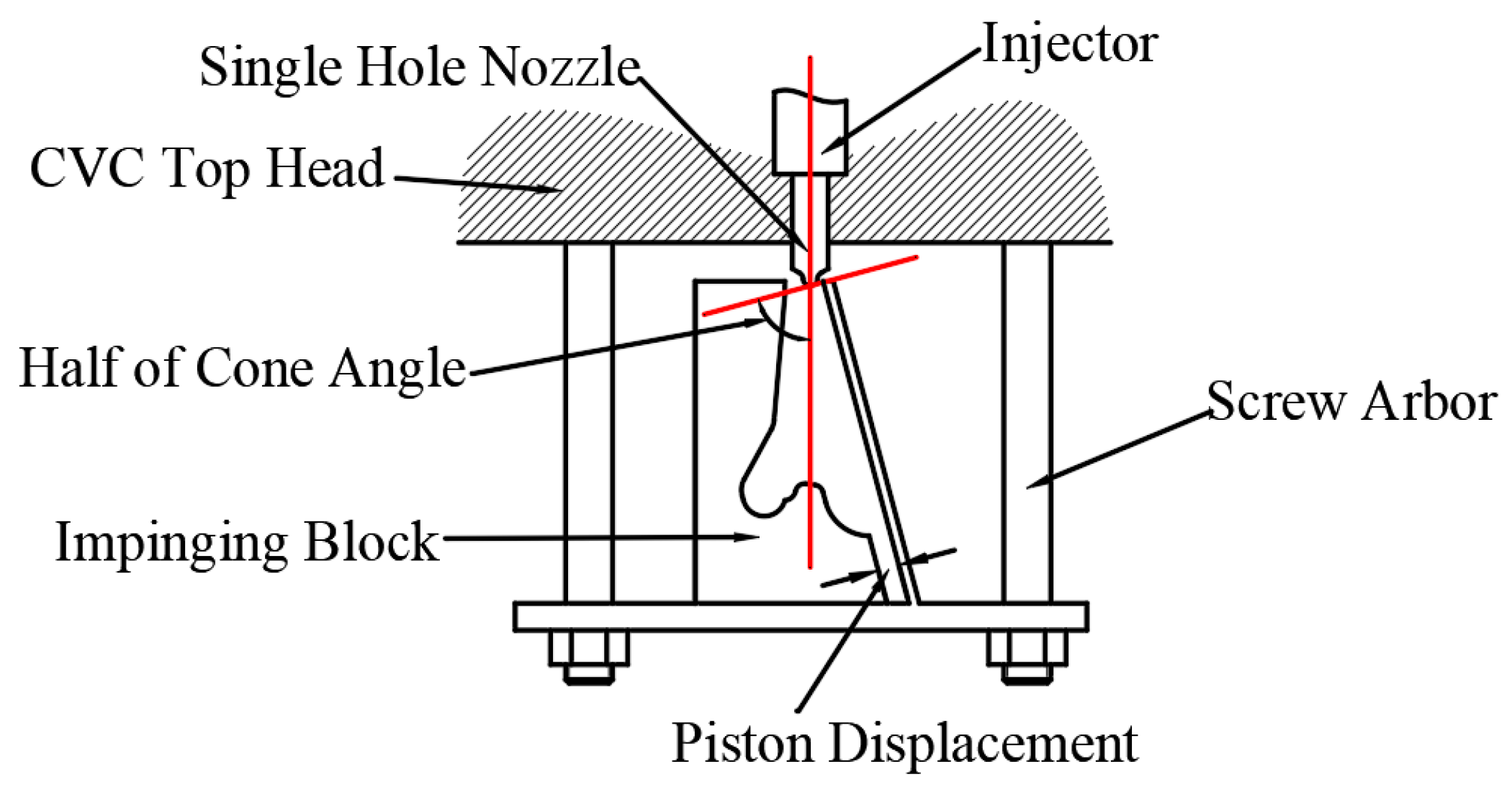

2. Experimental Setup and Method

3. Results and Discussion

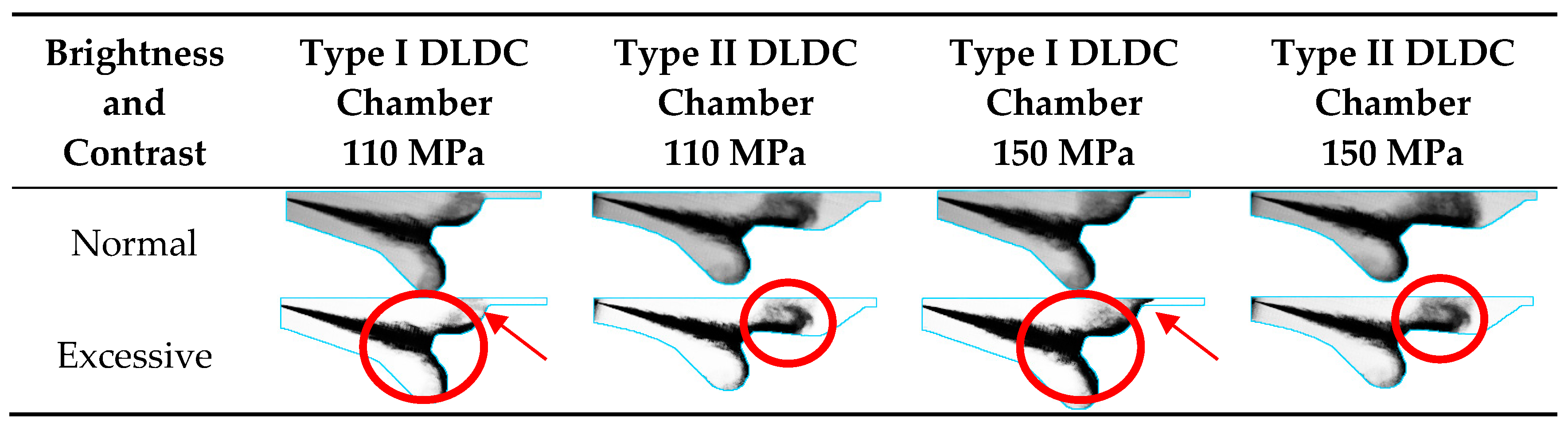

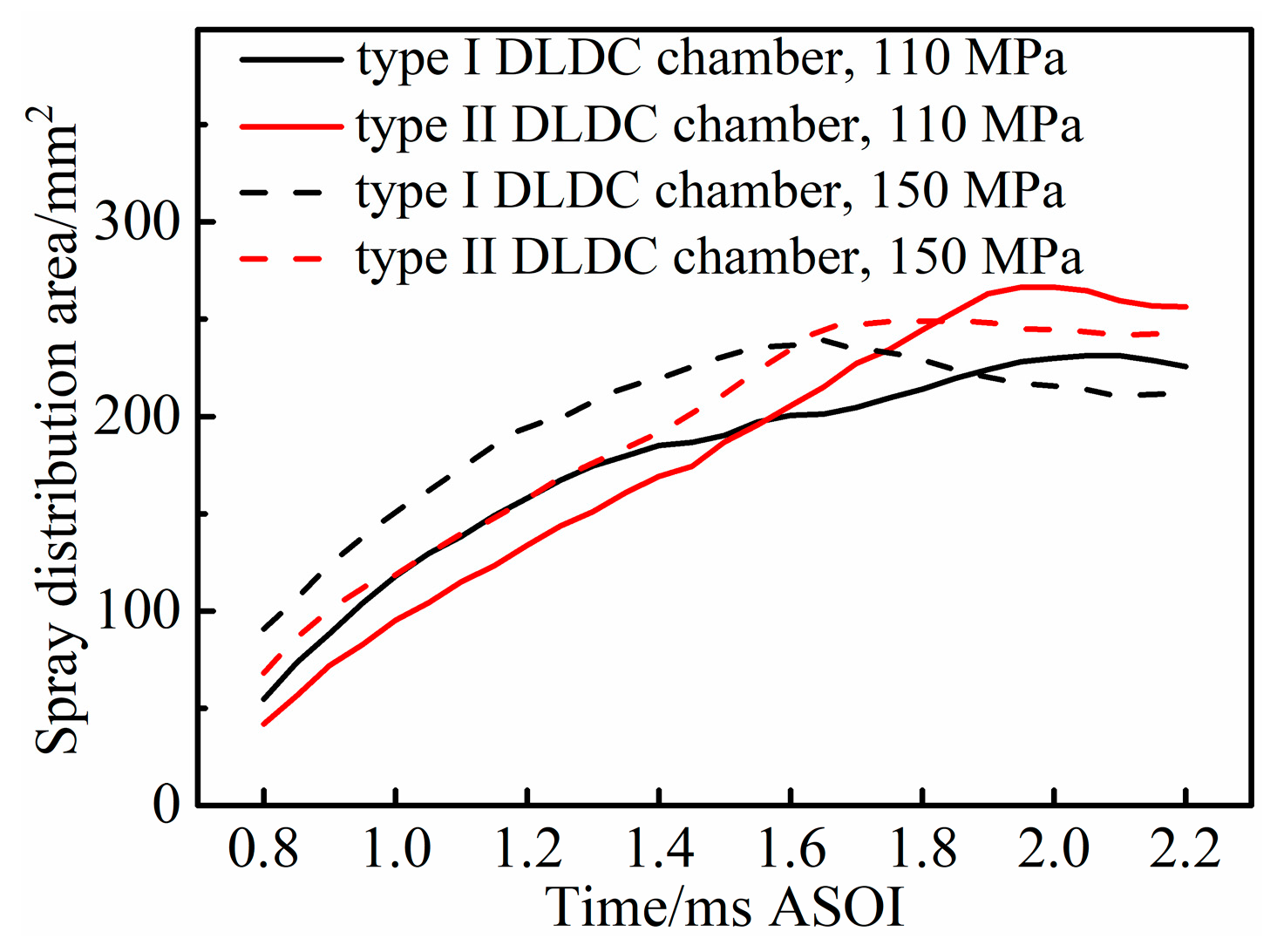

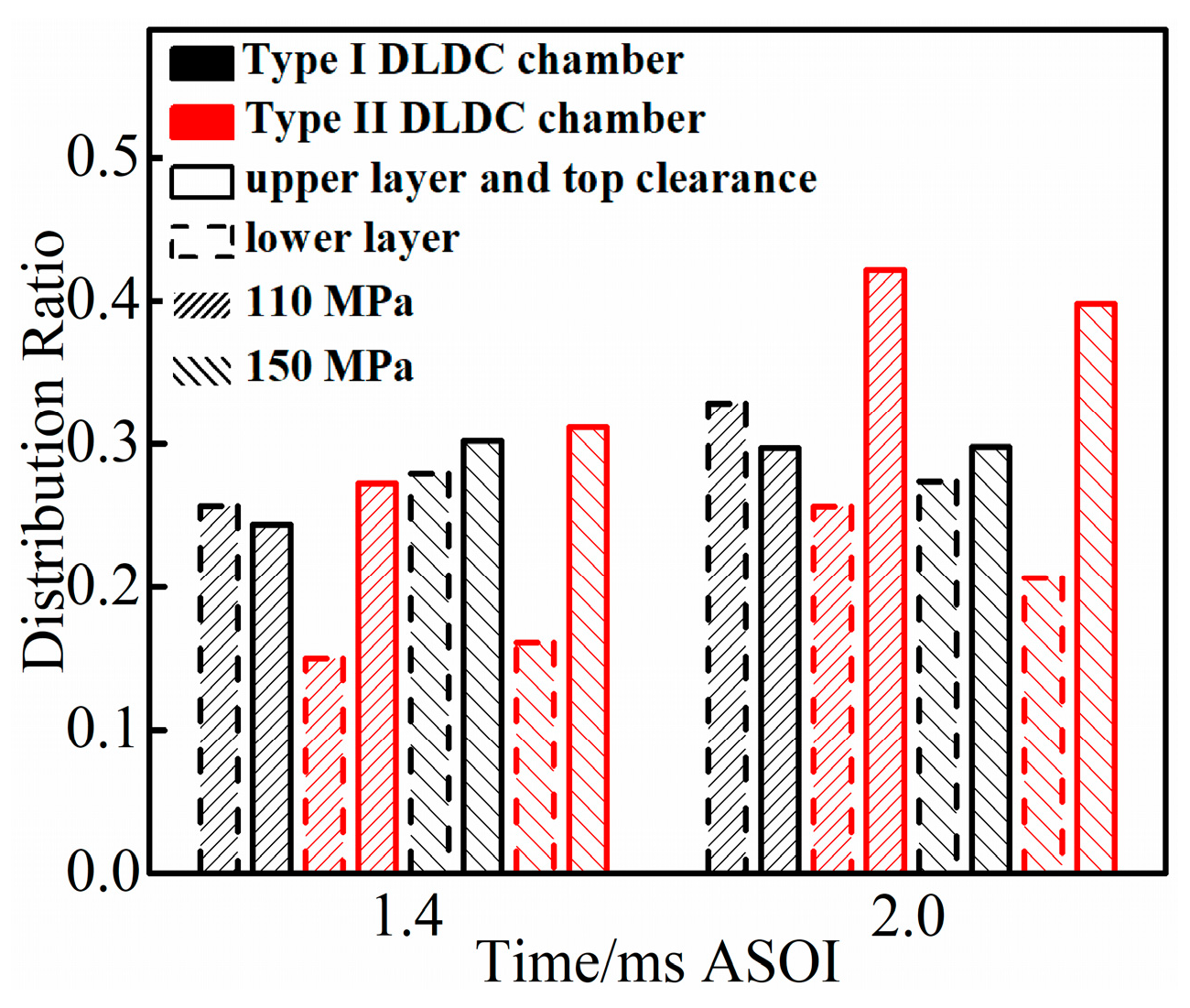

3.1. Influence of Injection Pressure and Chamber Profile

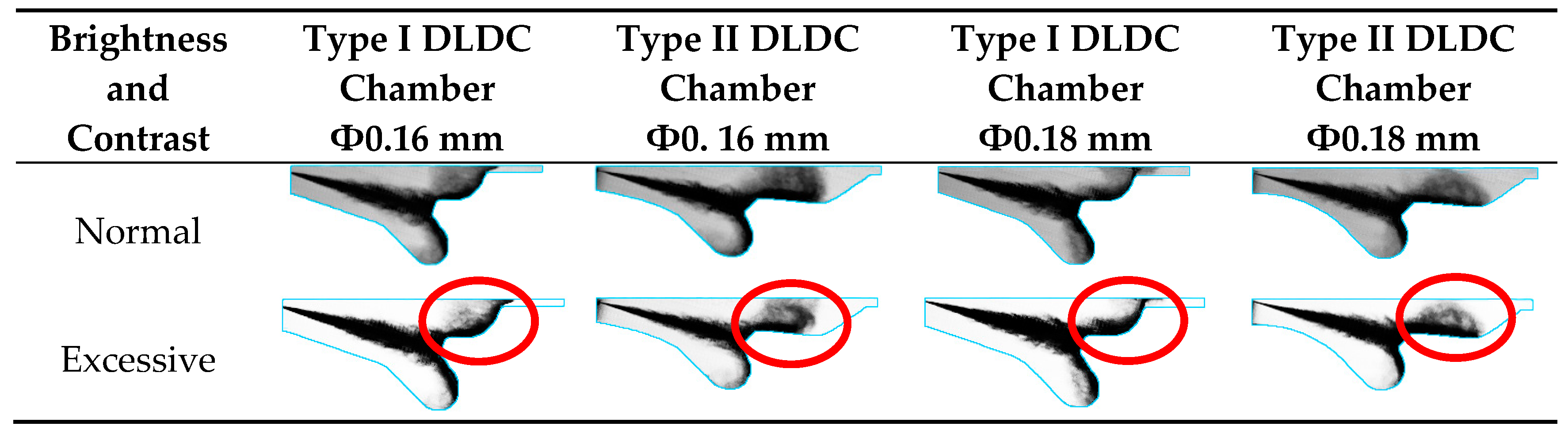

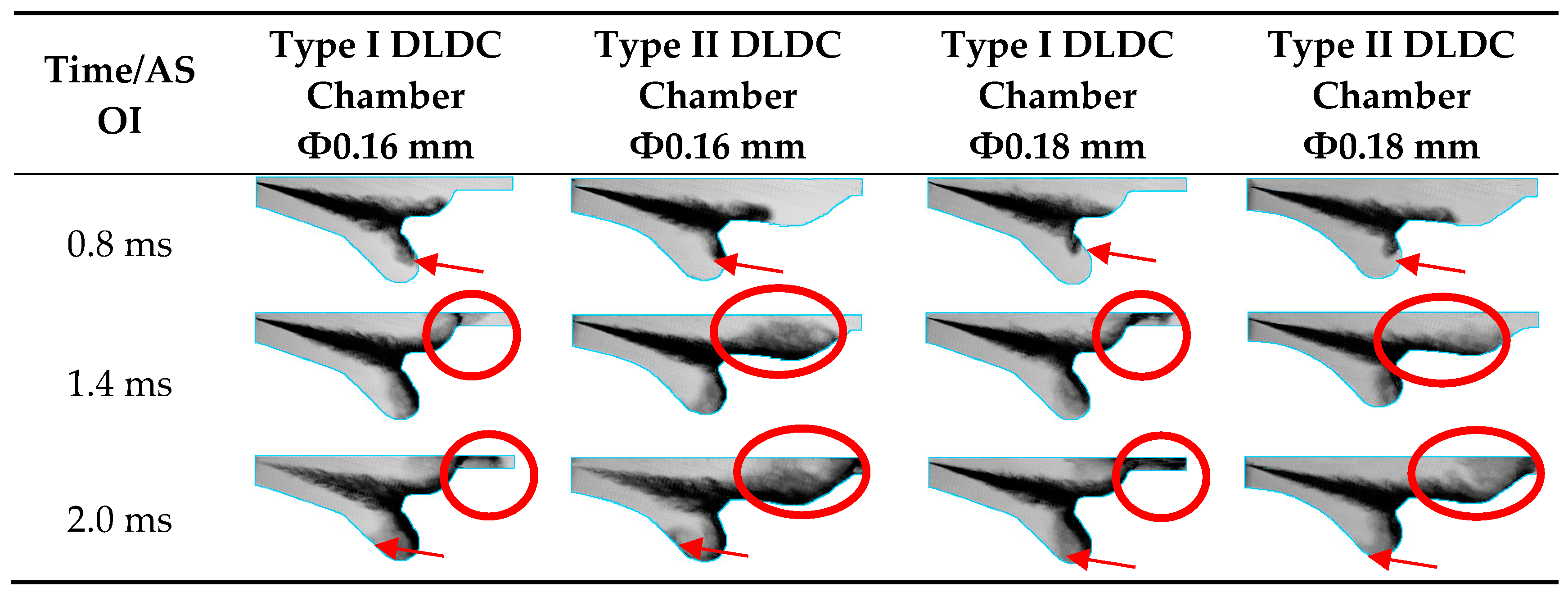

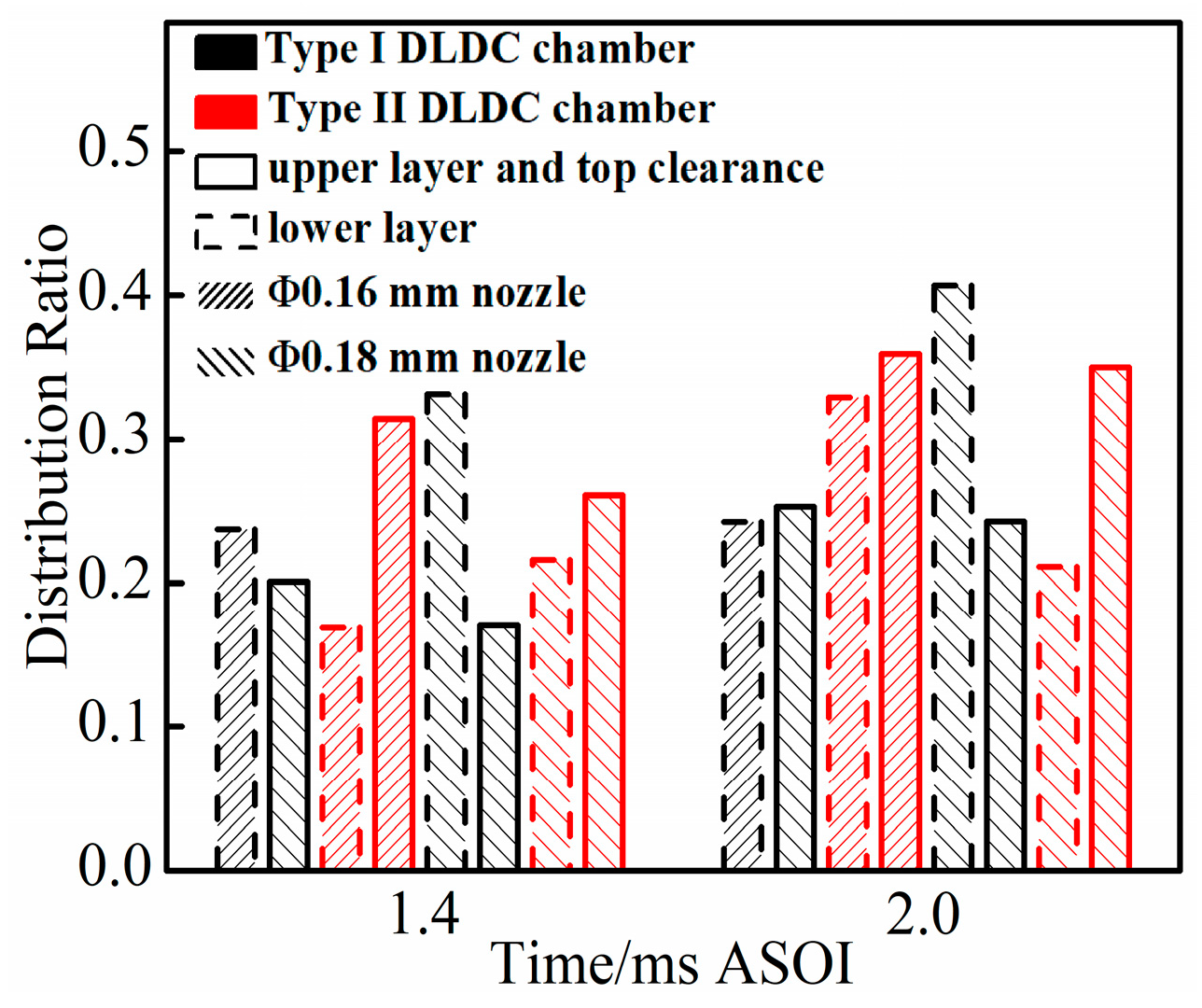

3.2. Influence of Nozzle Hole Diameter and Chamber Profile

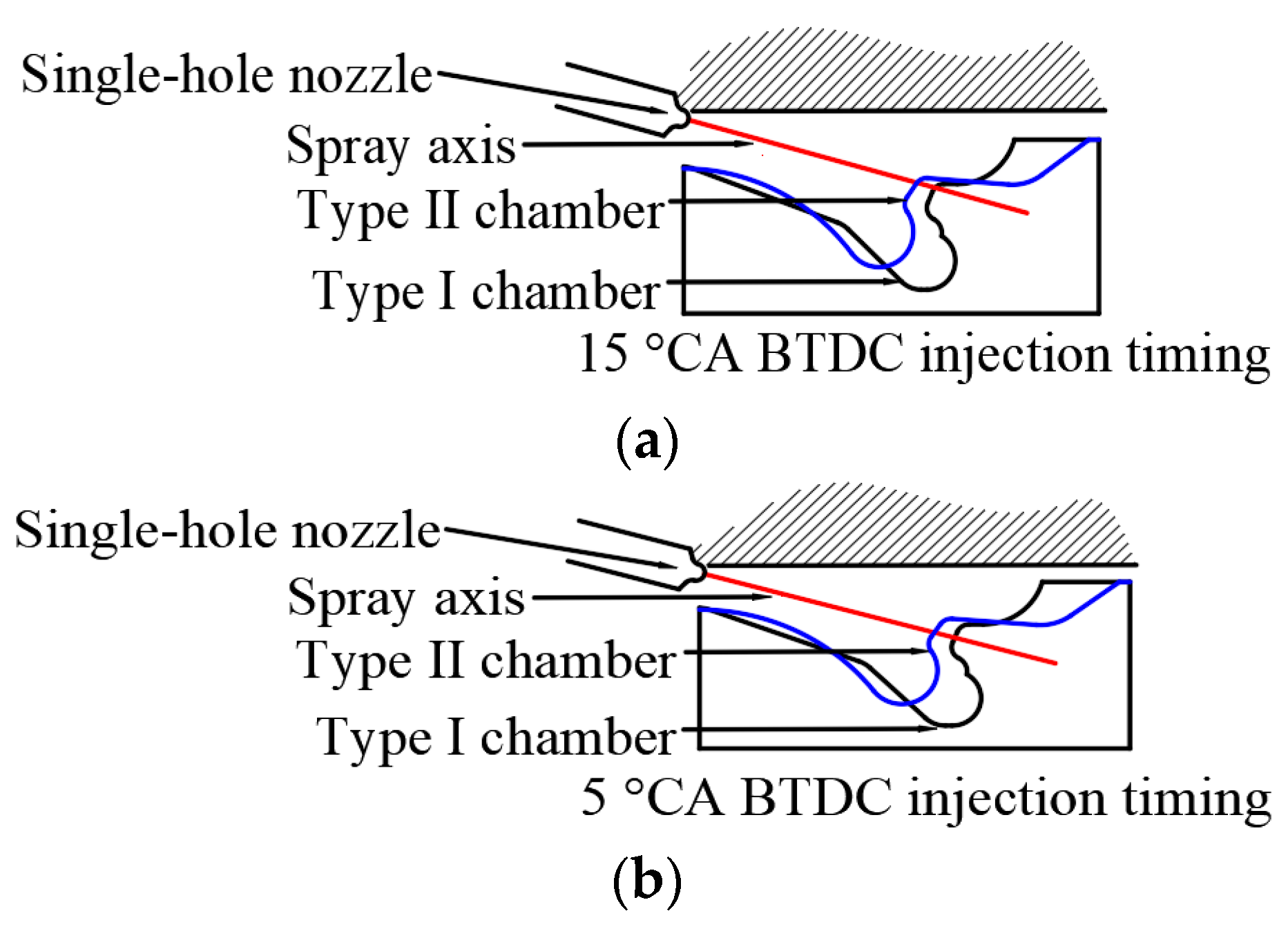

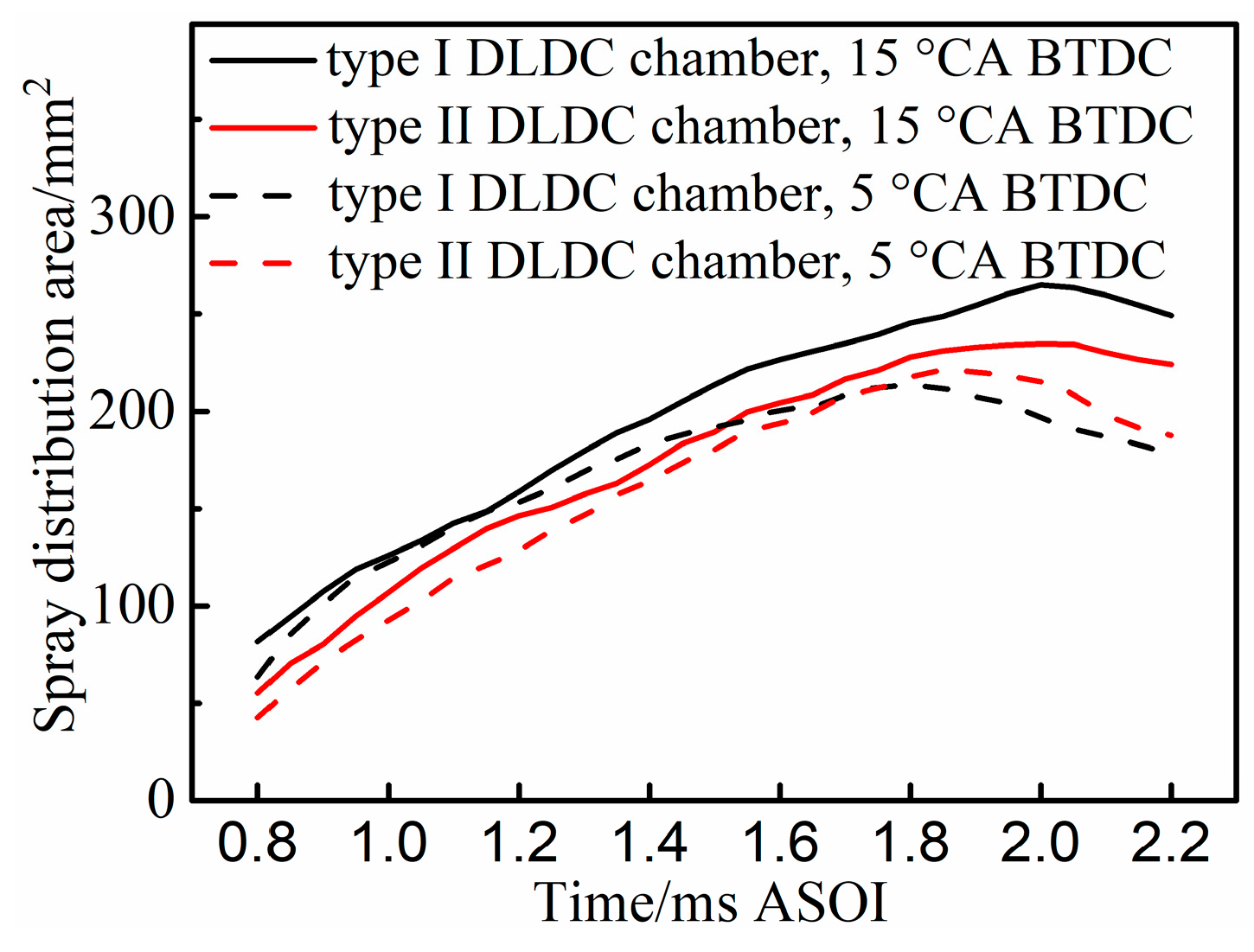

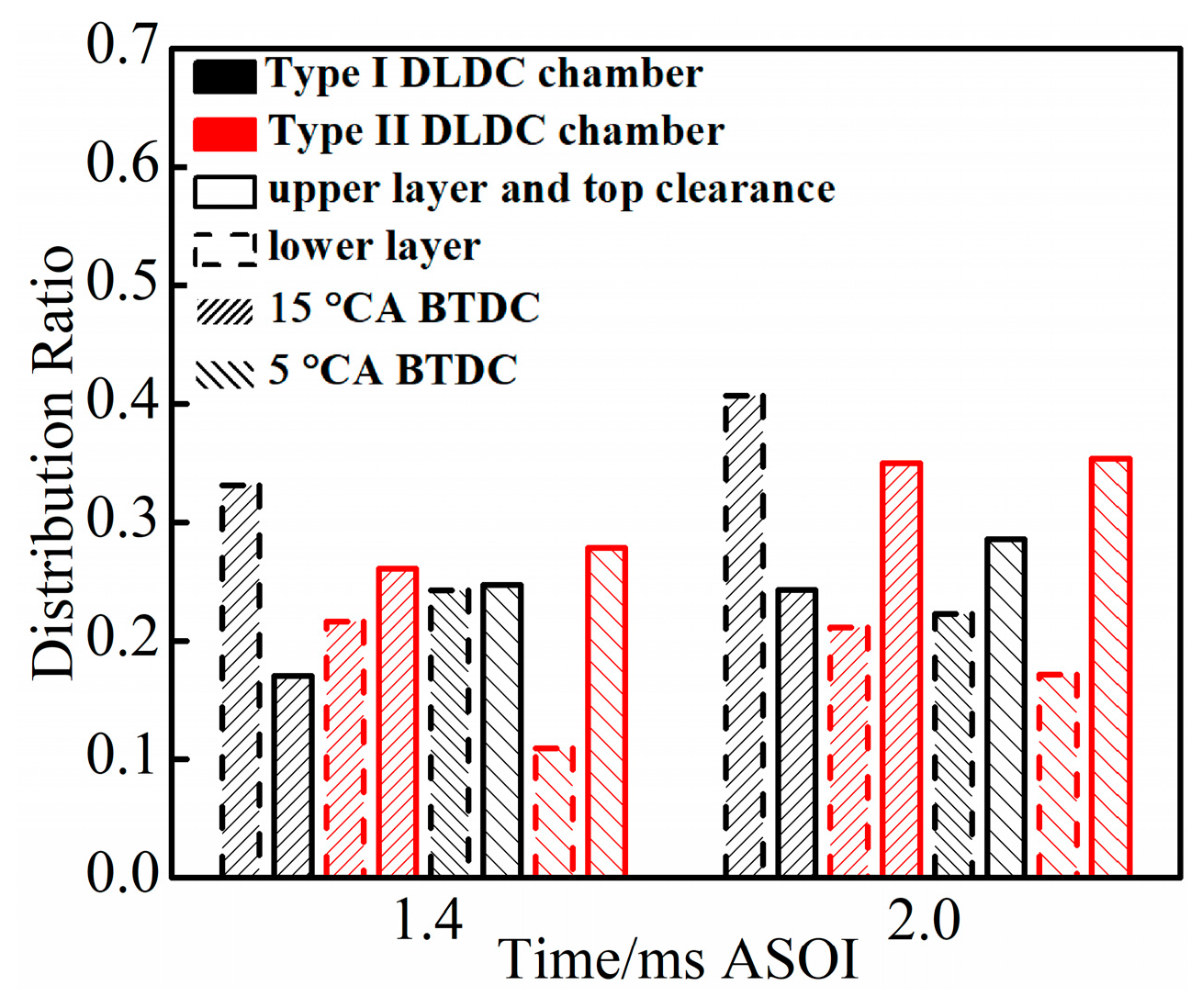

3.3. Influence of Nozzle Hole Diameter and Injection Timing (Piston Position)

4. Conclusions

- (1)

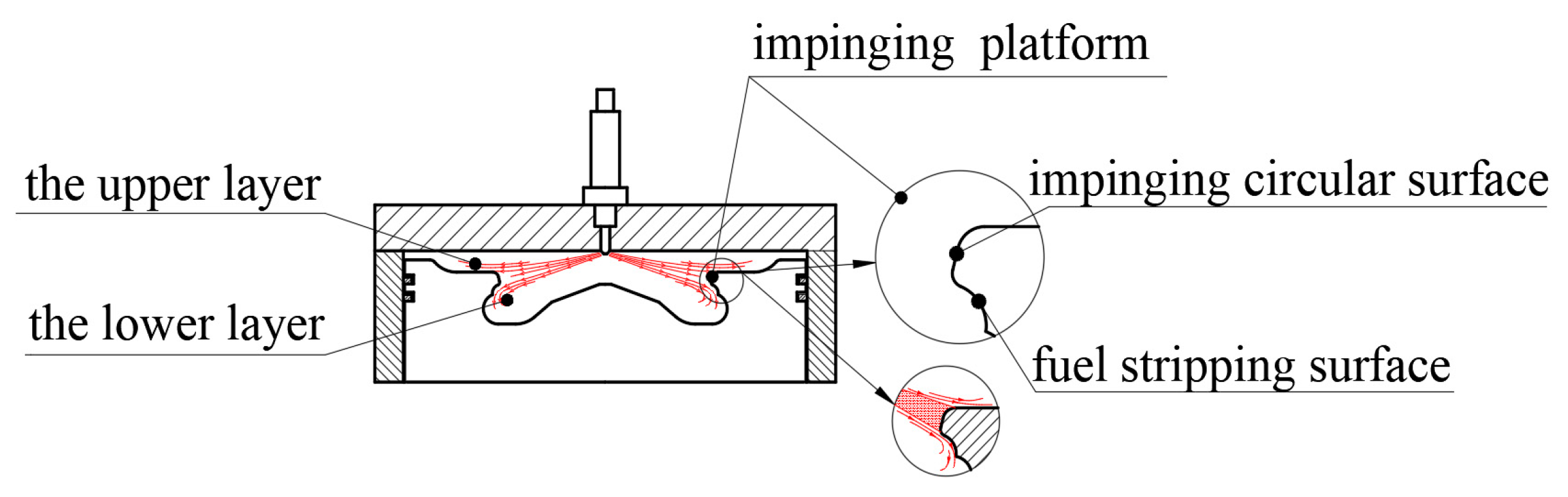

- Both DLDC chambers can split the fuel spray into two layers under different injection conditions by their impinging platforms and utilize the peripheral top clearances well. The impinging circular surface and the fuel stripping surface can strip the fuel spray away from the piston cavity wall;

- (2)

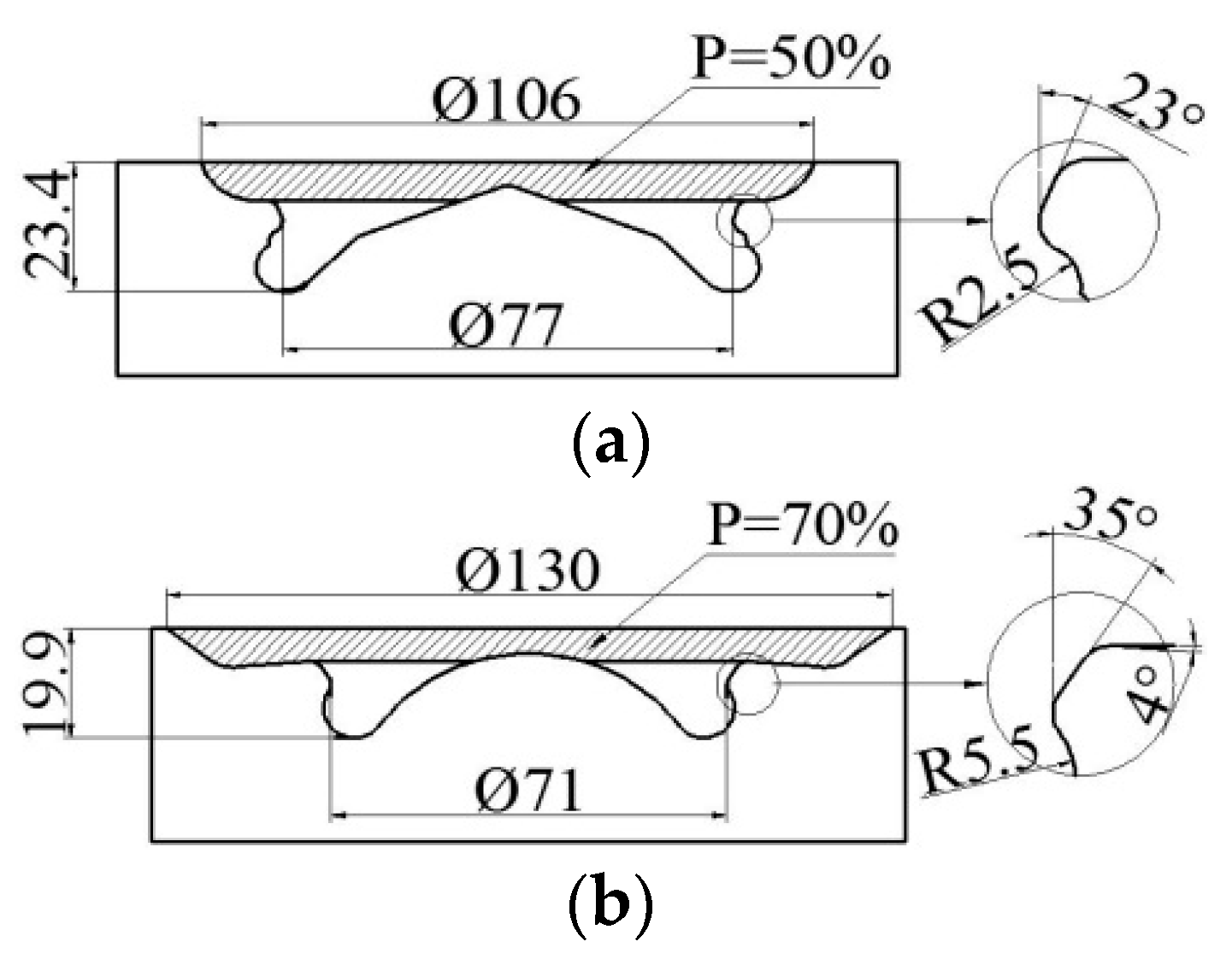

- The DLDC chamber with a 50% upper layer volume can obtain a larger fuel spray distribution region at the beginning of injection. The DLDC chamber with a 70% upper layer volume can obtain a larger fuel spray distribution region with better top clearance utilization, but it needs a longer distribution time;

- (3)

- Injection parameters show significant effects on the fuel spray spreading in the two DLDC chambers. Increasing the injection pressure provides a larger fuel spray distribution area and encourages the rich fuel spray distribution after the start of injection, while a lower injection pressure provides a larger fuel spray distribution at the later stage of injection. A smaller hole diameter nozzle leads to a larger and more homogeneous fuel spray distribution in the DLDC chamber. The nozzle hole diameter shows a more obvious influence on the fuel spray distribution in the DLDC chamber with a 70% upper layer volume. Advancing the injection timing shows a positive influence on obtaining a larger fuel spray distribution in the DLDC chamber; however, the larger top clearance is not fully utilized.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| DLDC chamber | Double-layer diverging combustion chamber |

| BSFC | Brake specific fuel consumption |

| DSCS chamber | Double swirl combustion system chamber |

| CVC | Constant volume chamber |

| Ф | Nozzle hole diameter |

| P | Percentage of the upper layer volume to the chamber bowl volume |

| °CA | Crank angle |

| BTDC | Before top dead center |

| ASOI | After the start of injection |

References

- Taylor, A.M.K.P. Science review of internal combustion engines. Energy Policy 2008, 36, 4657–4667. [Google Scholar] [CrossRef]

- Berggren, C.; Magnusson, T. Reducing automotive emissions—The potentials of combustion engine technologies and the power of policy. Energy Policy 2012, 41, 636–643. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Peng, Y.; Ma, C.; Shen, B. Can environmental innovation facilitate carbon emissions reduction? Evidence from China. Energy Policy 2017, 100, 18–28. [Google Scholar] [CrossRef]

- Su, W.; Zhao, K.; Wang, J. An investigation of effects of injection parameters and chamber wall confinement on spray characteristics in constant volume bomb. Chin. Intern. Combust. Engine Eng. 1992, 13, 1–5. [Google Scholar]

- Katsura, N.; Saito, M.; Senda, J.; Fujimoto, H. Characteristics of a Diesel Spray Impinging on a Flat Wall; Technical Report; SAE International Congress and Exposition: Detroit, MI, USA, February 1989. [Google Scholar]

- Montajir, R.M.; Tsunemoto, H.; Ishitani, H.; Minami, T. Fuel Spray Behavior in a Small DI Diesel Engine: Effect of Combustion Chamber Geometry; Technical Report; SAE 2000 World Congress: Detroit, MI, USA, March 2000. [Google Scholar]

- Montajir, R.M.; Tsunemoto, H.; Ishitani, H.; Minami, T. Effect of Reverse Squish on Fuel Spray Behavior in a Small DI Diesel Engine under High Pressure Injection and High Charging Condition; Technical Report; International Fuels & Lubricants Meeting & Exposition: Baltimore, MD, USA, October 2000. [Google Scholar]

- Gao, G.; Yuan, Z.; Zhou, A.; Liu, S.; Wei, Y. Effects of fuel temperature on injection process and combustion of dimethyl ether engine. J. Energy Resour. Technol. 2013, 135. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.J.; Gimeno, J.; Bracho, G. The effect of temperature and pressure on thermodynamic properties of diesel and biodiesel fuels. Fuel 2013, 90, 1172–1180. [Google Scholar] [CrossRef]

- Soriano, J.A.; Mata, C.; Armas, O.; Ávila, C. A zero-dimensional model to simulate injection rate from first generation common rail diesel injectors under thermodynamic diagnosis. Energy 2018, 158, 845–858. [Google Scholar] [CrossRef]

- Mobassheri, R. Influence of narrow fuel spray angle and split injection strategies on combustion efficiency and engine performance in a common rail direct injection diesel engine. Int. J. Spray Combust. Dyn. 2017, 9, 71–81. [Google Scholar] [CrossRef]

- Lee, B.H.; Song, J.H.; Chang, Y.J.; Jeon, C.H. Effect of the number of fuel injector holes on characteristics of combustion and emissions in a diesel engine. Int. J. Automot. Technol. 2010, 11, 783–791. [Google Scholar] [CrossRef]

- Miles, P.C.; Megerle, M.; Sick, V.; Richards, K.; Nagel, Z.; Reitz, R.D. The Evolution of Flow Structures and Turbulence in a Fired HSDI Diesel Engine; Technical Report; Spring Fuels & Lubricants Meeting & Exhibition SAE International Fall Fuels & Lubricants Meeting & Exhibition: San Antonio, TX, USA, September 2001. [Google Scholar]

- Diwakar, R.; Singh, S. Importance of Spray-Bowl Interaction in a DI Diesel Engine Operating under PCCI Combustion Mode; Technical Report; SAE World Congress & Exhibition: Detroit, MI, USA, April 2009. [Google Scholar]

- Park, S.W.; Reitz, R.D. Optimization of fuel/air mixture formation for stoichiometric diesel combustion using a 2-spray-angle group-hole nozzle. Fuel 2009, 88, 843–852. [Google Scholar] [CrossRef]

- Ikegami, M.; Masatoshi, H.; Tamane, K.; Fukuda, M. Influence of top clearance on combustion in direct-injection diesel engine. JSAE Rev. 1990, 11, 10–15. [Google Scholar]

- Aronsson, U.; Andersson, Ö.; Egnell, R.; Miles, P.C.; Ekoto, I.W. Influence of Spray-Target and Squish Height on Sources of CO and UHC in a HSDI Diesel Engine during PPCI Low-Temperature Combustion; Technical Report; SAE 2009 Powertrains Fuels and Lubricants Meeting: San Antonio, TX, USA, November 2009. [Google Scholar]

- Yoo, D.; Kim, D.; Jung, W.; Kim, N.; Lee, D. Optimization of Diesel Combustion System for Reducing PM to Meet Tier4 Final Emission Regulation without Diesel Particulate Filter; Technical Report; SAE/KSAE 2013 International Powertrains, Fuels & Lubricants Meeting: Seoul, Korea, October 2013. [Google Scholar]

- Kogo, T.; Hamamura, Y.; Nakatani, K.; Toda, T.; Kawaguchi, A.; Shoji, A. High Efficiency Diesel Engine with Low Heat Loss Combustion Concept—Toyota’s Inline 4-Cylinder 2.8-Liter ESTEC 1GD-FTV Engine; Technical Report; SAE 2016 World Congress and Exhibition: Detroit, MI, USA, 2016. [Google Scholar]

- Crosse, J. Going Clean-off Highway; Ricardo plc: West Sussex, UK, 2010. [Google Scholar]

- Deraad, S.; Fulton, B.; Gryglak, A.; Hallgren, B.; Hudson, A.; Ives, D.; Morgan, P.; Styron, J.; Waszczenko, E.; Cattermole, I. The New Ford 6.7L V-8 Turbocharged Diesel Engine; Technical Report; SAE 2010 World Congress & Exhibition: Detroit, MI, USA, 2016. [Google Scholar]

- Eder, T.; Luckert, P.; Kemmner, M.; Sass, H. OM654—Launch of a new engine family by Mercedes–Benz. MTZ Worldw. 2016, 77, 60–67. [Google Scholar] [CrossRef]

- Nakai, E. Development of MAZDA diesel engine SKYACTIV-D1.5. In Proceedings of the 2015 SAE/JSAE P, F & L, International Meeting, Kyoto, Japan, 1–4 September 2015. [Google Scholar]

- Kidoguchim, Y.; Sanda, M.; Miwa, K. Experimental and theoretical optimization of combustion chamber and fuel distribution for the low emission direct injection diesel engine. J. Eng. Gas Turbines Power 2003, 125, 351–357. [Google Scholar] [CrossRef]

- Horibe, N.; Takahashi, K.; Kee, S.; Ishiyama, T.; Shioji, M. The Effects of Injection Conditions and Combustion Chamber Geometry on Performance and Emissions of DI-PCCI Operation in a Diesel Engine; Technical Report; JSAE/SAE International Fuels & Lubricants Meeting: Kyoto, Japan, July 2007. [Google Scholar]

- Wei, R.; Li, X.; Zhang, G. A study of mixing and burning for a new DSCS in diesel engine. Trans. CSICE 1998, 16, 446–452. [Google Scholar]

- Pei, Y.; Su, W.; Lin, T. The BUMP combustion chamber presented based on the concept of lean diffusion combustion in a D.I. diesel engine with common rail fuel injector. Trans. CSICE 2002, 20, 381–386. [Google Scholar]

- Long, W.; Fu, Y.; Tian, J.; He, S.; Chen, L.; Qi, K. Researches of Double-Layer Diverging Combustion System (DLDCS) in a DI Diesel Engine; Technical Report; JSAE/SAE 2015 International Powertrains, Fuels & Lubricants Meeting: Kyoto, Japan, September 2015. [Google Scholar]

- Zhao, M. Experimental Study on Spray and Combustion Characteristics of V-Type Intersection Hole Nozzle and in Double-Layer Diverging Combustion System. Master’s Thesis, Dalian University of Technology, Dalian, China, June 2015. [Google Scholar]

- Miles, P.C.; Andersson, Ö. A review of design considerations for light-duty diesel combustion system. Int. J. Engine Res. 2016, 17, 6–15. [Google Scholar] [CrossRef]

- Fu, Y.; Long, W.; Tian, H.; Dong, D.; Tian, J. Visualization research of double-layer diverging combustion system in CA4DK diesel engine. In Proceedings of the 9th Conference of CSICE, Shanghai, China, 17–19 October 2016. [Google Scholar]

- Panigrahi, P.K.; Muralidhar, K. Shadowgraph technique. In Schlieren and Shadowgraph Methods in Heat and Mass Transfer; Kulacki, F., Ed.; Springer: New York, NY, USA, 2012. [Google Scholar]

- Pastor, J.V.; García, J.M.; Pastor, J.M.; Zapata, L.D. Evaporating Diesel Spray Visualization Using a Double-Pass Shadowgraphy/Schlieren Imaging; Technical Report; 8th International Conference on Engines for Automobiles: Naples, Italy, September 2007. [Google Scholar]

- Klein-Douwel, R.J.H.; Frijeters, P.J.M.; Somers, L.M.T.; de Boer, W.A.; Baert, R.S.G. Macroscopic diesel fuel spray shadowgraphy using high speed digital imaging in a high pressure cell. Fuel 2007, 86, 1994–2007. [Google Scholar] [CrossRef]

- State Administration for Market Regulation, Standardization Administration of the People’s Republic of China. In General Diesel Fuels (GB 252-2015); China Standard Press: Beijing, China, 2015.

| Apparatus | Type |

|---|---|

| Constant volume chamber (CVC) | Maximum pressure 10 MPa Maximum temperature 1000 K |

| Solenoid-valve fuel injector | Liaoyang Xinfeng NCI3.1052 |

| Fuel pressure generator | HIP USA |

| High-speed camera | FASTCAM SA-Z by Photron Co. |

| Lens | NIKON AF-S VR 70-300mm f/4.5-5.6G IF-ED |

| Illuminator | SIGMA LS-LHA |

| Synchronous control system | NI Compact RIO/NI 9075, NI 9751, NI 9401 |

| Crank Angle/°CA | 0 | 5 | 10 | 15 |

| Displacement/mm | 0 | 0.36 | 1.45 | 3.26 |

| Parameter | Parameter Value | |

|---|---|---|

| Fuel type | Chinese Standard #0 diesel [35], density 860 kg/m3, kinetic viscosity 40 Pa·s @ 20 °C, low calorific value, 42.5 MJ/kg | |

| Single-hole nozzle diameter | Φ0.16 mm, Φ0.18 mm | |

| Piston position/ambient pressure | 5 °CA BTDC/3.4 MPa, 15 °CA BTDC/2.7 MPa | |

| Injection pressure | 110 MPa, 150 MPa | |

| Injection pulse | Φ0.16 mm | medium load: 1.13 ms/110 MPa, 0.79 ms/150 MPa; full load: 0.95 ms/150 MPa |

| Φ0.18 mm | medium load: 1 ms/150 MPa; full load: 1.19 ms/150 MPa | |

| Operation | Parameter Value | |||

|---|---|---|---|---|

| Load Level | Nozzle Diameter | Injection Pressure | Injection Timing | |

| Mode A | Medium load | Φ0.16 mm | 110 MPa, 150 MPa | 5 °CA BTDC |

| Mode B | Medium load | Φ0.16 mm, Φ0.18 mm | 150 MPa | 5 °CA BTDC |

| Mode C | Full load | Φ0.16 mm, Φ0.18 mm | 150 MPa | 15 °CA BTDC |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Y.; Feng, L.; Tian, H.; Long, W.; Dong, D.; Leng, X. Visualization Investigation of the Influence of Chamber Profile and Injection Parameters on Fuel Spray Spreading in a Double-Layer Diverging Combustion Chamber for a DI Diesel Engine. Energies 2018, 11, 2343. https://doi.org/10.3390/en11092343

Fu Y, Feng L, Tian H, Long W, Dong D, Leng X. Visualization Investigation of the Influence of Chamber Profile and Injection Parameters on Fuel Spray Spreading in a Double-Layer Diverging Combustion Chamber for a DI Diesel Engine. Energies. 2018; 11(9):2343. https://doi.org/10.3390/en11092343

Chicago/Turabian StyleFu, Yao, Liyan Feng, Hua Tian, Wuqiang Long, Dongsheng Dong, and Xianyin Leng. 2018. "Visualization Investigation of the Influence of Chamber Profile and Injection Parameters on Fuel Spray Spreading in a Double-Layer Diverging Combustion Chamber for a DI Diesel Engine" Energies 11, no. 9: 2343. https://doi.org/10.3390/en11092343