Investigations of Ventilation Airflow Characteristics on a Longwall Face—A Computational Approach

Abstract

:1. Introduction

2. Review of CFD Modelling of Underground Ventilation Systems

3. Development of Longwall CFD Models

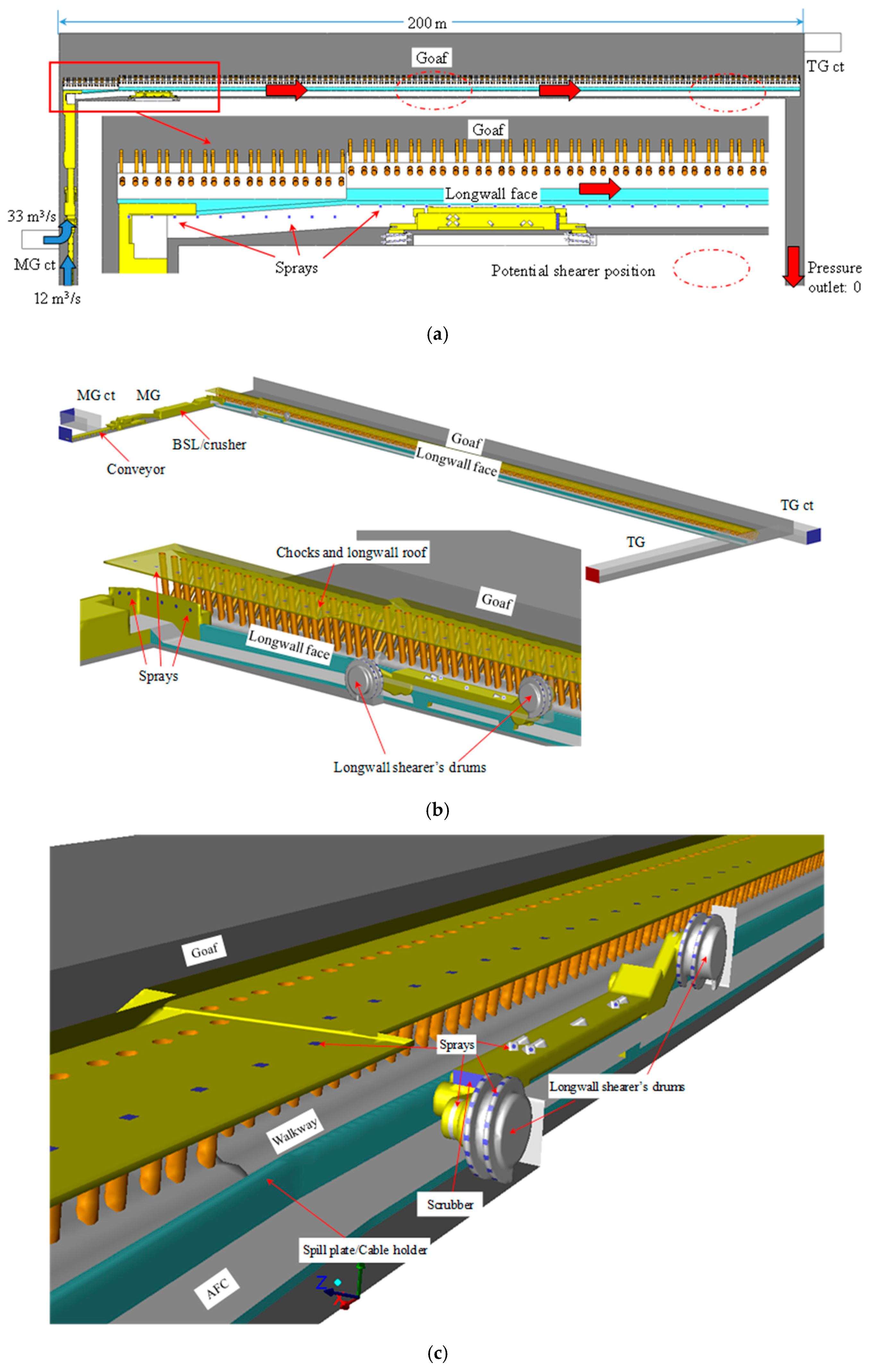

3.1. Overview of the Longwall Model

3.2. Model Mesh and Boundary Condition

3.3. Governing Equations and Turbulence Model Selection

4. Mesh Independent Study and Model Validation

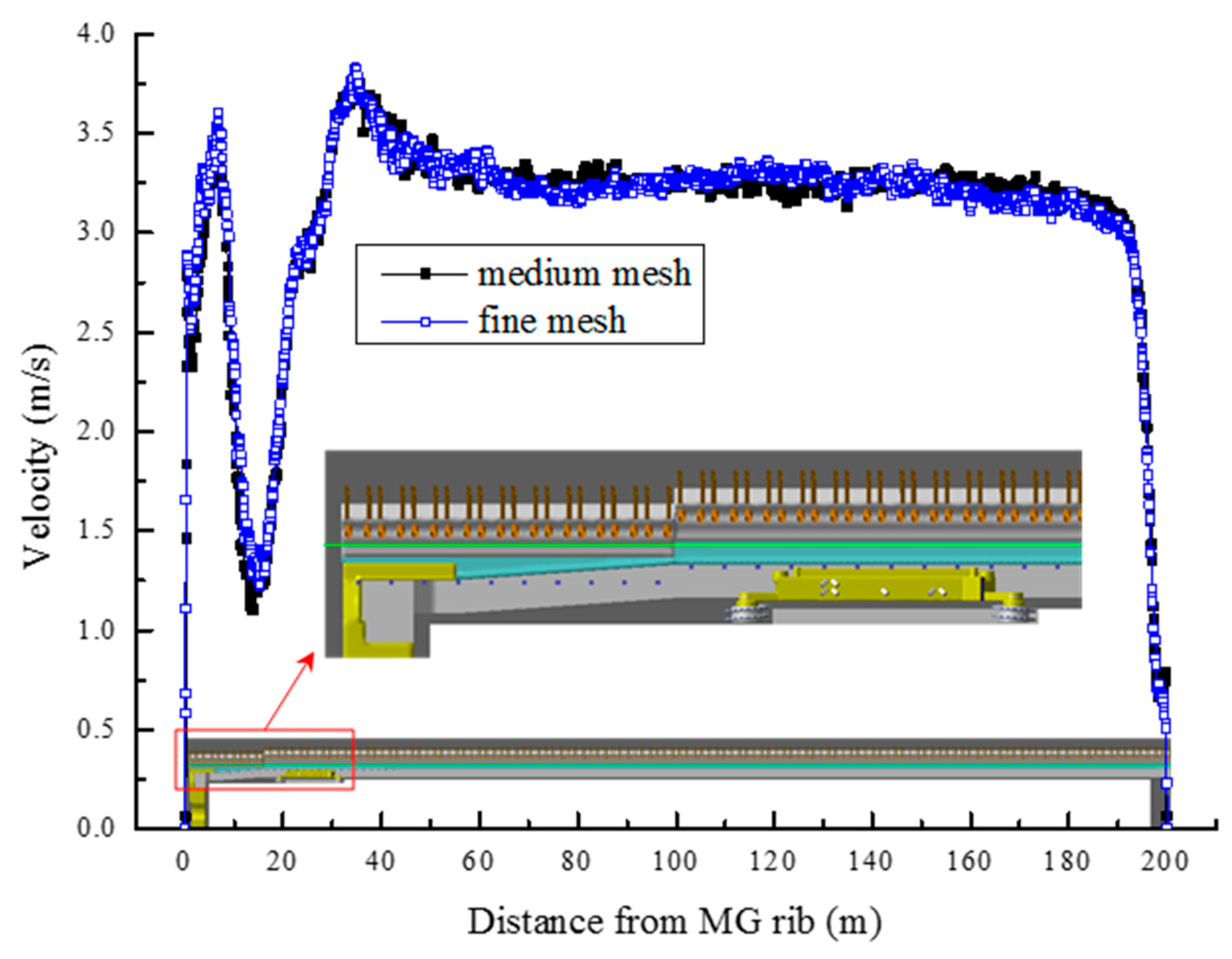

4.1. Mesh Independent Study

4.2. Model Validation

5. Base Model Results and Discussion

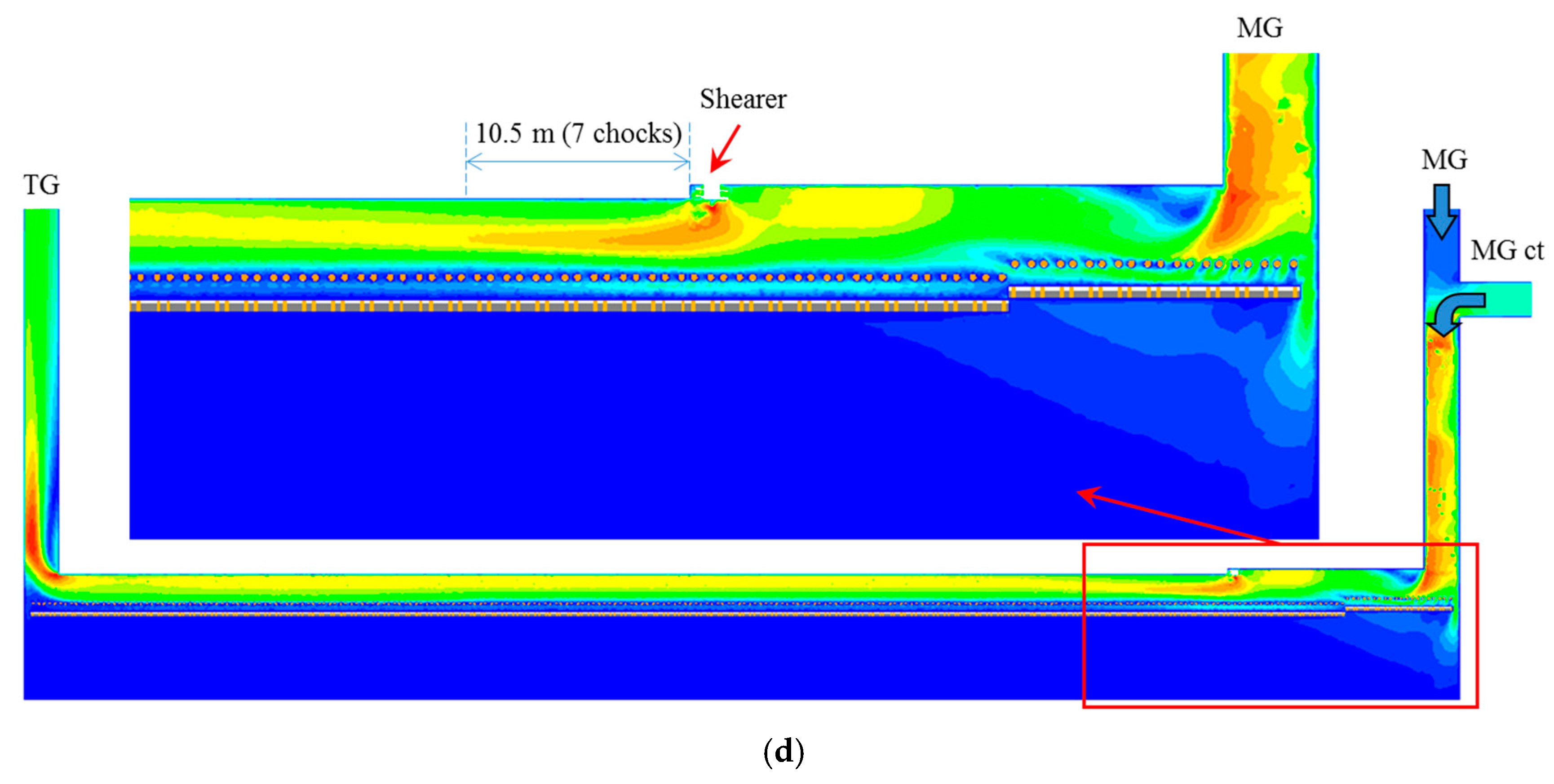

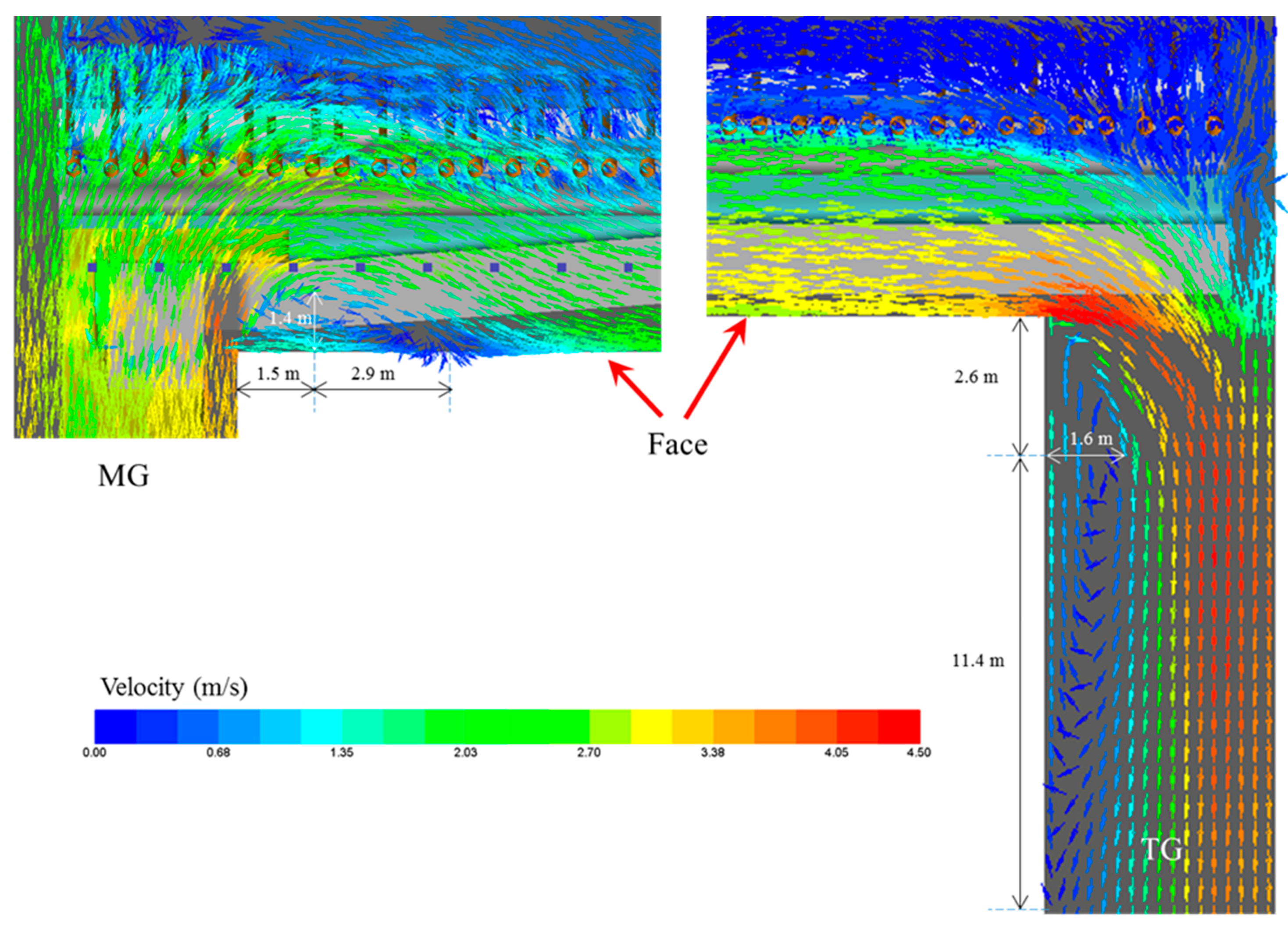

5.1. General Airflow Patterns

5.2. Flow Separation along Longwall Face

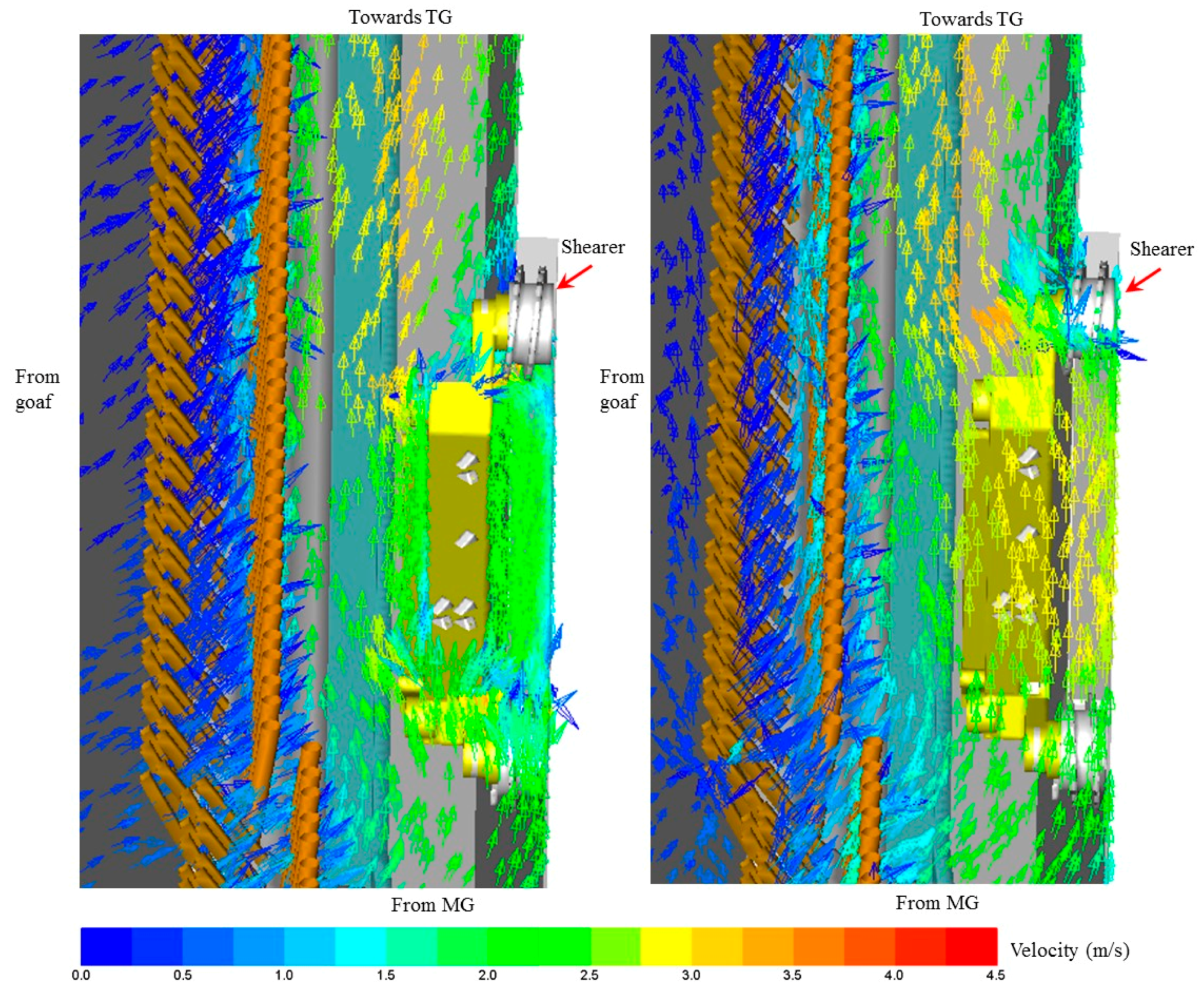

5.3. Airflow Patterns around the Shearer

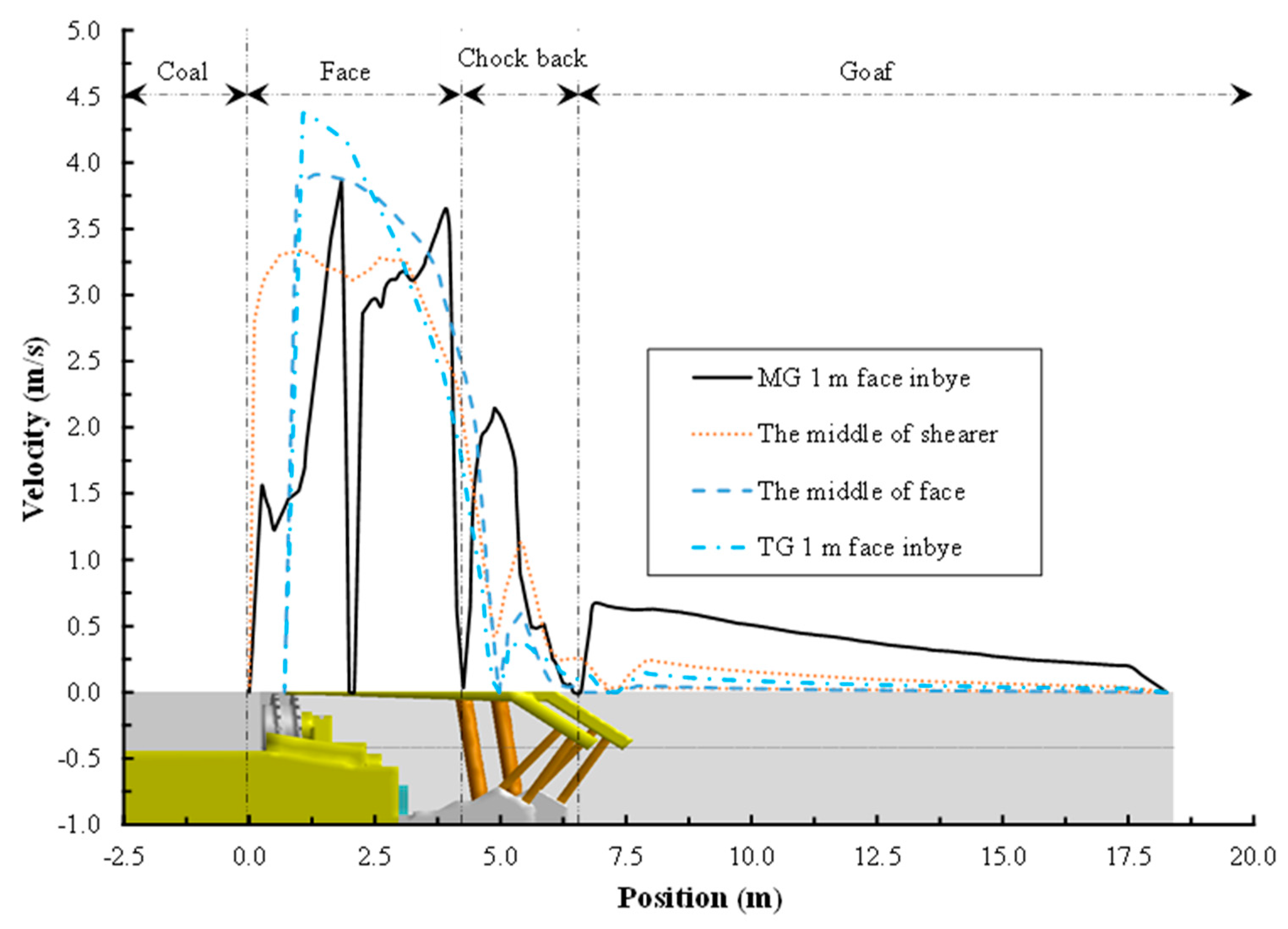

5.4. Velocity Distribution cross the Face

6. Parametric Studies

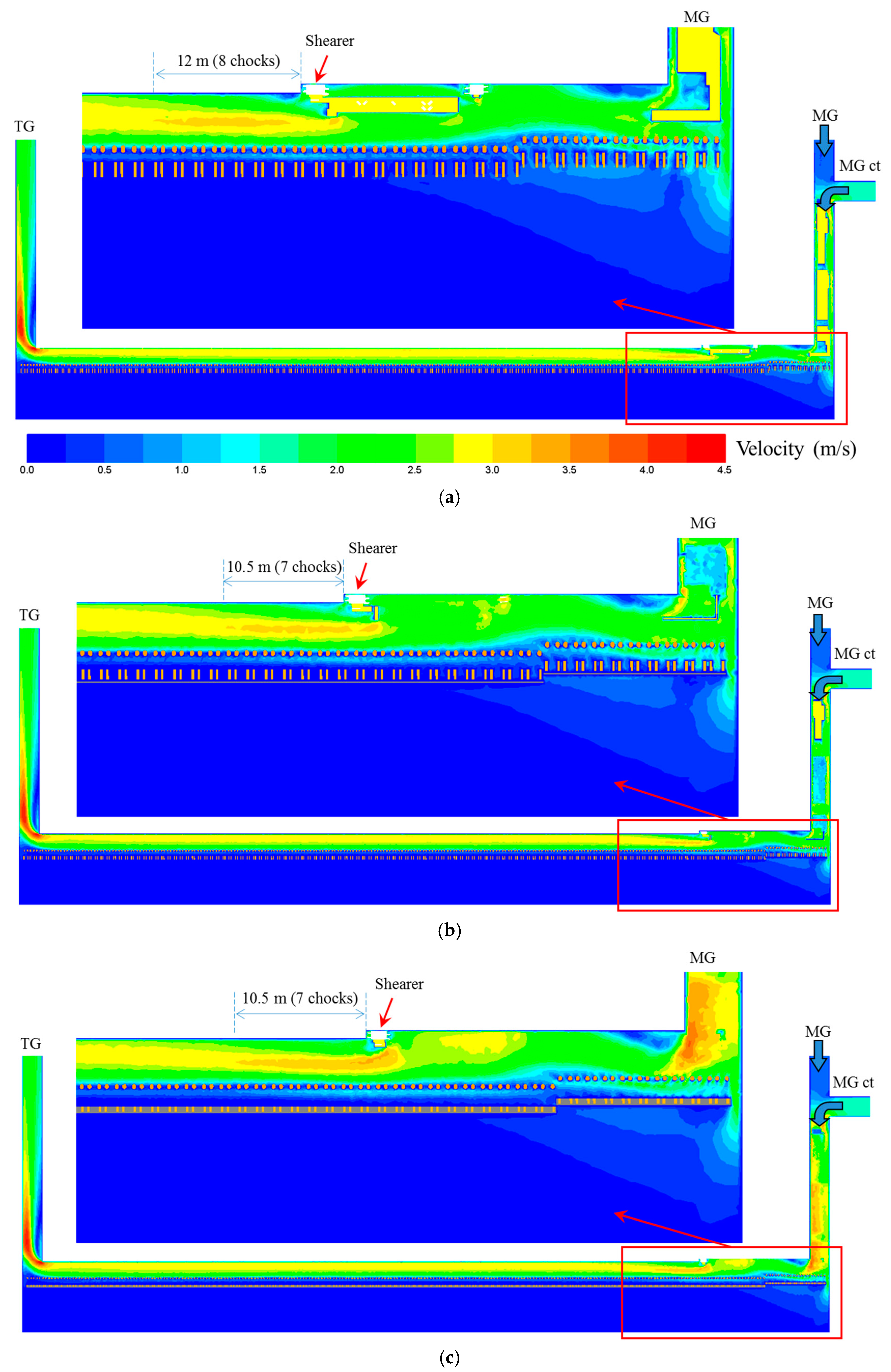

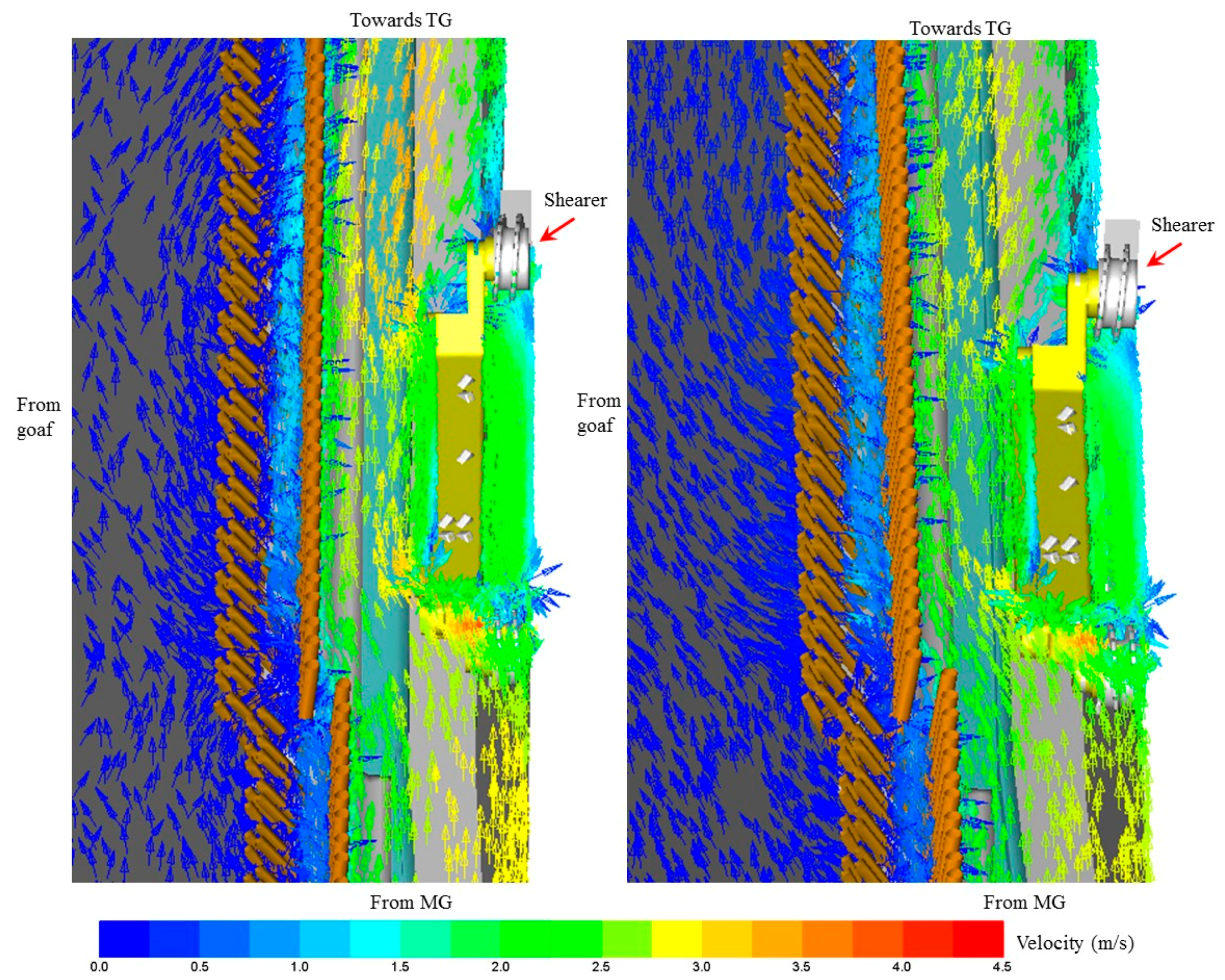

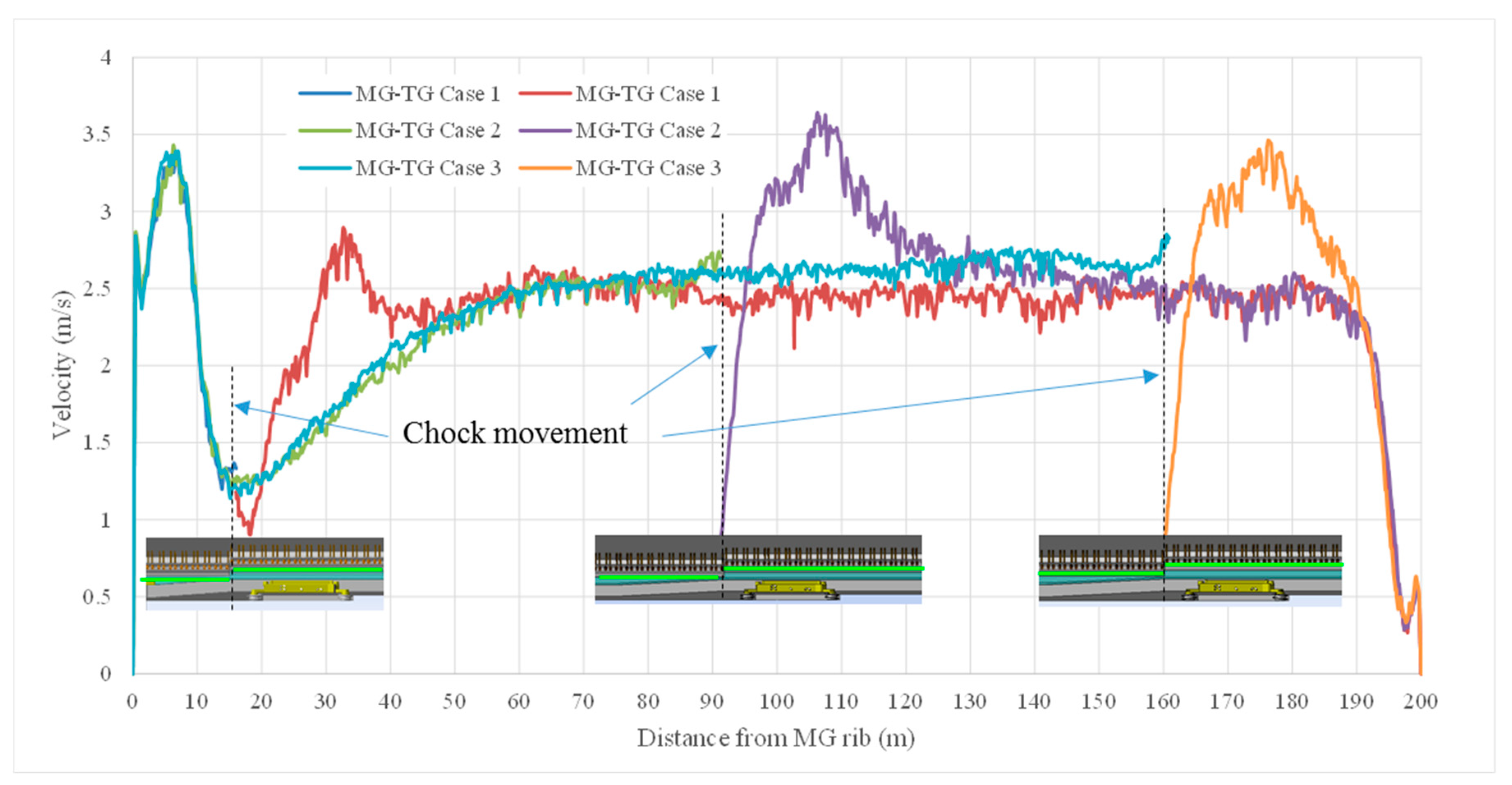

6.1. Impact of Shearer Position

6.2. Impact of Cutting Sequence

7. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Brodny, J.; Tutak, M.; Michalak, M. The Use of the TGŚP Module as a Database to Identify Breaks in the Work of Mining Machinery; Springer International Publishing: Cham, Switzerland, 2017; pp. 441–452. [Google Scholar]

- Brodny, J.; Tutak, M. Analysis of Methane Hazard Conditions in Mine Headings. Teh. Vjesn. 2018, 25, 271–276. [Google Scholar]

- Branny, M. Computer simulation of flow of air and methane mixture in the longwall-return crossing zone. Arch. Min. Sci. 2006, 51, 133–145. [Google Scholar]

- Felka, D.; Brodny, J. Application of Neural-Fuzzy System in Prediction of Methane Hazard. In International Conference on Intelligent Systems in Production Engineering and Maintenance; Springer: Berlin, Germany, 2017; pp. 151–160. [Google Scholar]

- Mine Safety and Health Administration. Report of Investigation: Fatal Underground Mine Explosion April 5, 2010; Upper Big Branch Mine-South, Performance Coal Company, Montcoal, Raleigh County, West Virginia: Naoma, WV, USA, 2011. [Google Scholar]

- Brodny, J. Determination of the zone endangered by methane explosion in goaf with caving of operating longwalls. In Proceedings of the 16th International Multidisciplinary Scientific GeoConference, Albena, Bulgaria, 30 June–6 July 2016; Volume 2, pp. 299–306. [Google Scholar]

- Royal Commission on the Pike River Coal Mine. Tragedy Report to the Governor General; Royal Commission on the Pike River Coal Mine: Wellington, New Zealand, 2012. [Google Scholar]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- McPherson, M.J. Subsurface Ventilation Engineering, 2nd ed.; Mine Ventilation Services, Inc.: Fresno, CA, USA, 2009. [Google Scholar]

- Belle, B. Real-time air velocity monitoring in mines—A quintessential design parameter for managing major mine health and safety hazards. In 13th Coal Operators’ Conference; Aziz, N., Ed.; University of Wollongong: Wollongong, Australia, 2013; pp. 184–198. [Google Scholar]

- Hartman, H.L.; Mutmansky, J.M.; Ramani, R.V.; Wang, Y.J. Mine Ventilation and Air Conditioning; Wiley: Hoboken, NJ, USA, 1997. [Google Scholar]

- Xu, G.; Huang, J.; Nie, B.; Chalmers, D.; Yang, Z. Calibration of Mine Ventilation Network Models Using the Non-Linear Optimization Algorithm. Energies 2018, 11, 31. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J. Analysis of Influence of Goaf Sealing from Tailgate on the Methane Concentration at the Outlet from the Longwall. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042025. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. Computational Study of Thermal Management in Underground Coal Mines: Effect of Operating Ventilation Parameters; Technical Report: Report No. M3TC TN-10-05; National University of Singapore: Singapore, 2012. [Google Scholar]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. CFD simulation of methane dispersion and innovative methane management in underground mining faces. Appl. Math. Model. 2014, 38, 3467–3484. [Google Scholar] [CrossRef]

- Gao, J.; Liu, J.; Zhang, X. Simulation Study on the Influence of Permeability on Gas Migration in Gob. China Saf. Sci. J. 2010, 20, 9–14. [Google Scholar]

- Heerden, J.; Sullivan, P. The application of CFD for evaluation of dust suppression and auxiliary ventilation systems used with continuous miners. In Proceedings of the 6th US Mine Ventilation Symposium, Salt Lake City, UT, USA, 21–23 June 1993; pp. 293–297. [Google Scholar]

- Srinivasa, R.B. Design and Development of a Multi-Scrubber Dust Control System for Longwall Faces: Experimental and Modelling Studies. Ph.D. Thesis, University of Wollongong, Wollongong, Australia, 1993. [Google Scholar]

- Edwards, J.S.; Ren, T.; Jozefowicz, R. Using Computational Fluid Dynamics (CFD) to solve mine safety and health problems. In Proceedings of the APCOM XXV 1995 Conference, Brisbane, Australia, 9–14 July 1995. [Google Scholar]

- Oberholzer, D.R.J.W.; Meyer, C.F. The evaluation of heading ventilation systems through the use of computer simulations. In Proceedings of the 7th US Mine Ventilation Symposium, Lexington, KY, USA, 5–7 June 1995. [Google Scholar]

- Oberholzer, D.R.J.W.; Meyer, C.F. Computer modelling in the solution of continuous miner heading ventilation problems. In Proceedings of the APCOM XXV 1995 Conference, Brisbane, Australia, 9–14 July 1995. [Google Scholar]

- Moloney, K.W. An Analysis of Airflow Patterns in Auxiliary Ventilated Drivages. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 1997. [Google Scholar]

- Moloney, K.W.; Lowndes, I.S.; Hargrave, G.K. Analysis of flow patterns in drivages with auxiliary ventilation. Trans. Inst. Min. Metall. Sect. A Min. Technol. 1999, 108, A17–A26. [Google Scholar]

- Moloney, K.W.; Lowndes, I.S. Comparison of measured underground air velocities and air flows simulated by computational fluid dynamics. Trans. Inst. Min. Metall. Sect. A Min. Technol. 1999, 108, A105–A114. [Google Scholar]

- Wala, M.A.; Yingling, J.C.; Zhang, J. Evaluation of the face ventilation systems for extended cuts with remotely operated mining machines using three-dimensional numerical simulations. In Proceedings of the SME Annual Meeting, Orlando, FL, USA, 9–11 March 1998. [Google Scholar]

- Wala, M.A.; Huang, P.G.; Brown, J.T. New approaches to mine-face ventilation. Min. Eng. 2003, 55, 25–30. [Google Scholar]

- Wala, M.A.; Vytla, S.; Taylor, C.D.; Huang, P.G. Mine face ventilation: A comparison of CFD results against benchmark experiments for the CFD code validation. Min. Eng. 2007, 59, 49–55. [Google Scholar]

- Balusu, R.; Tuffs, N.; Peace, R.; Xue, S. Longwall goaf gas drainage and control strategies for highly gassy mines. In Proceedings of the 8th Iternational Mine Ventilation Congress, Brisbane, Australia, 6–8 July 2005. [Google Scholar]

- Parra, M.T.; Villafruela, J.M.; Castro, F.; Mendez, C. Numerical and experimental analysis of different ventilation systems in deep mines. Build. Environ. 2006, 41, 87–93. [Google Scholar] [CrossRef]

- Hargreaves, D.M.; Lowndes, I.S. The computational modeling of the ventilation flows within a rapid development drivage. Tunn. Undergr. Space Technol. 2007, 22, 150–160. [Google Scholar] [CrossRef]

- Ren, T.; Balusu, R. Dust Control Technology Development for Longwall Faces—Shearer Scrubber Development; Australian Coal Association Research Program, Brisbane: Queensland, Australia, 2007; p. 58. [Google Scholar]

- Ren, T.; Balusu, R. Innovative CFD modelling to improve dust control in longwalls. In 8th Underground Coal Operators’ Conference; Aziz, N., Ed.; University of Wollongong: Wollongong, Australia, 2008; pp. 137–142. [Google Scholar]

- Ren, T.; Balusu, R. The use of CFD modelling as a tool for solving mining health and safety problems. In 10th Underground Coal Operators’ Conference; Aziz, N., Kininmonth, B., Nemcik, J., Eds.; University of Wollongong: Wollongong, Australia, 2010; pp. 339–349. [Google Scholar]

- Aminosadati, S.M.; Hooman, K. Numerical simulation of ventilation air flow in underground mine workings. In Proceedings of the 12th North American Mine Ventilation Symposium, Sparks, NV, USA, 9–11 June 2008; pp. 253–259. [Google Scholar]

- Toraño, J.; Torno, S.; Menendez, M.; Gent, M.; Velasco, J. Models of methane behaviour in auxiliary ventilation of underground coal mining. Int. J. Coal Geol. 2009, 80, 35–43. [Google Scholar] [CrossRef]

- Zheng, Y.; Tien, J.C. Simulation of longwall face methane distribution. In Proceedings of the SME Annual Meeting, Colorado, FL, USA, 22–25 February 2009. [Google Scholar]

- Krog, R.B.; Schatzel, S.J.; Garcia, F.; Marshall, J.K. Predicting methane emissions from wider longwall panels by analysis of emission contributors. In Proceedings of the 11th U.S./North American Mine Ventilation Symposium, Pennsylvania, PA, USA, 5–7 June 2006. [Google Scholar]

- Ndenguma, D.D. Computational Fluid Dynamics Model for Controlling Dust and Methane in Underground Coalmines. Master‘s Thesis, University of Pretoria, South Africa, 2010. [Google Scholar]

- Ren, T.; Wang, Z.; Plush, B.; Cooper, G.; Cook, A.; Karekal, S.; Yarlagadda, S. Improved Dust Control on Longwalls Using a New Water Mist Venturi System; Australian Coal Association Research Program, Brisbane: Queensland, Australia, 2012; p. 89. [Google Scholar]

- Ren, T.; Wang, Z.; Cooper, G. CFD modelling of ventilation and dust flow behaviour above an underground bin and the design of an innovative dust mitigation system. Tunn. Undergr. Space Technol. 2014, 41, 241–254. [Google Scholar] [CrossRef]

- Torno, S.; Toraño, J.; Ulecia, M.; Allende, C. Conventional and numerical models of blasting gas behaviour in auxiliary ventilation of mining headings. Tunn. Undergr. Space Technol. 2013, 34, 73–81. [Google Scholar] [CrossRef]

- Xu, G.; Luxbacher, K.D.; Ragab, S.; Schafrik, S. Development of a remote analysis method for underground ventilation systems using tracer gas and CFD in a simplified laboratory apparatus. Tunn. Undergr. Space Technol. 2013, 33, 1–11. [Google Scholar] [CrossRef]

- Xu, G.; Jong, E.C.; Luxbacher, K.D.; Ragab, S.A.; Karmis, M.E. Remote characterization of ventilation systems using tracer gas and CFD in an underground mine. Saf. Sci. 2015, 74, 140–149. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Birgersson, E.; Ly, H.C.; Mujumdar, A.S. Some approaches to improve ventilation system in underground coal mines environment—A computational fluid dynamic study. Tunn. Undergr. Space Technol. 2013, 34, 82–95. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. Simulation of a novel intermittent ventilation system for underground mines. Tunn. Undergr. Space Technol. 2014, 42, 206–215. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Wong, W.Y.; Mujumdar, A.S. Prediction and innovative control strategies for oxygen and hazardous gases from diesel emission in underground mines. Sci. Total Environ. 2014, 481, 317–334. [Google Scholar] [CrossRef] [PubMed]

- Hurtado, J.P.; Acuña, E.I. CFD analysis of 58 Adit main fans parallel installation for the 2015–2019 underground developments of the new level mine project. Appl. Therm. Eng. 2015, 90, 1109–1118. [Google Scholar] [CrossRef]

- Gilmore, R.; Brune, J.; Marts, J.; Saki, S.; Bogin, G.; Grubb, J. Gob Ventilation Modeling on HPC Platforms using GPGPU/CPU Combinations. In Application of Computers and Operations Research in the Mineral Industry (APCOM 2015): Proceedings of the 37th International Symposium; Society for Mining Metallurgy: Fairbanks, AK, USA, 2015; pp. 904–910. [Google Scholar]

- Guo, H.; Todhunter, C.; Qu, Q.; Qin, Z. Longwall horizontal gas drainage through goaf pressure control. Int. J. Coal Geol. 2015, 150–151, 276–286. [Google Scholar] [CrossRef]

- Qin, Z.; Yuan, L.; Guo, H.; Qu, Q. Investigation of longwall goaf gas flows and borehole drainage performance by CFD simulation. Int. J. Coal Geol. 2015, 150–151, 51–63. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Xu, P.; Sasmito, A.P. A novel concept of enhanced gas recovery strategy from ventilation air methane in underground coal mines—A computational investigation. J. Nat. Gas Sci. Eng. 2016, 35, 661–672. [Google Scholar] [CrossRef]

- Fang, Y.; Fan, J.; Kenneally, B.; Mooney, M. Air flow behavior and gas dispersion in the recirculation ventilation system of a twin-tunnel construction. Tunn. Undergr. Space Technol. 2016, 58, 30–39. [Google Scholar] [CrossRef]

- Cheng, J.; Li, S.; Zhang, F.; Zhao, C.; Yang, S.; Ghosh, A. CFD modelling of ventilation optimization for improving mine safety in longwall working faces. J. Loss Prev. Process Ind. 2016, 40, 285–297. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Aminossadati, S.M.; Wu, C. Numerical simulation of air ventilation in super-large underground developments. Tunn. Undergr. Space Technol. 2016, 52, 38–43. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, D.; Hu, C.; Wu, C.; Han, J. Numerical simulation of ventilation and dust suppression system for open-type TBM tunneling work area. Tunn. Undergr. Space Technol. 2016, 56, 70–78. [Google Scholar] [CrossRef]

- Xu, G.; Luxbacher, K.D.; Ragab, S.; Xu, J.; Ding, X. Computational fluid dynamics applied to mining engineering: A review. Int. J. Min. Reclam. Environ. 2017, 31, 251–275. [Google Scholar] [CrossRef]

- Gou, Y.; Shi, X.; Zhou, J.; Qiu, X.; Chen, X. Characterization and Effects of the Shock Losses in a Parallel Fan Station in the Underground Mine. Energies 2017, 10, 785. [Google Scholar] [Green Version]

- Zhou, G.; Zhang, Q.; Bai, R.; Fan, T.; Wang, G. The diffusion behavior law of respirable dust at fully mechanized caving face in coal mine: CFD numerical simulation and engineering application. Process Saf. Environ. Prot. 2017, 106, 117–128. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, G.; Qian, X.; Yuan, M.; Sun, Y.; Wang, D. Diffuse pollution characteristics of respirable dust in fully-mechanized mining face under various velocities based on CFD investigation. J. Clean. Prod. 2018, 184, 239–250. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, W.; Sun, B.; Ma, Y. Effects of radial air flow quantity and location of an air curtain generator on dust pollution control at fully mechanized working face. Adv. Powder Technol. 2017, 28, 1780–1791. [Google Scholar] [CrossRef]

- Wang, H.; Nie, W.; Cheng, W.; Liu, Q.; Jin, H. Effects of air volume ratio parameters on air curtain dust suppression in a rock tunnel’s fully-mechanized working face. Adv. Powder Technol. 2018, 29, 230–244. [Google Scholar] [CrossRef]

- Yu, H.; Cheng, W.; Wang, H.; Peng, H.; Xie, Y. Formation mechanisms of a dust-removal air curtain in a fully-mechanized excavation face and an analysis of its dust-removal performances based on CFD and DEM. Adv. Powder Technol. 2017, 28, 2830–2847. [Google Scholar] [CrossRef]

- Geng, F.; Luo, G.; Zhou, F.; Zhao, P.; Ma, L.; Chai, H.; Zhang, T. Numerical investigation of dust dispersion in a coal roadway with hybrid ventilation system. Powder Technol. 2017, 313, 260–271. [Google Scholar] [CrossRef]

- Geng, F.; Luo, G.; Wang, Y.; Peng, Z.; Hu, S.; Zhang, T.; Chai, H. Dust dispersion in a coal roadway driven by a hybrid ventilation system: A numerical study. Process Saf. Environ. Prot. 2018, 113, 388–400. [Google Scholar] [CrossRef]

- Shi, G.; Liu, M.; Guo, Z.; Hu, F.; Wang, D. Unsteady simulation for optimal arrangement of dedusting airduct in coal mine heading face. J. Loss Prev. Process Ind. 2017, 46, 45–53. [Google Scholar] [CrossRef]

- Ren, T.; Edwards, J.S.; Jozefowicz, R.R. CFD modelling of methane flow around longwall coal faces. In Proceedings of the 6th International Mine Ventilation Congress, Pittsburgh, PA, USA, 17–22 May 1997. [Google Scholar]

- Ren, T.X.; Edwards, J.S. Three-dimensional computational fluid dynamics modelling of methane flow through permeable strata around a longwall face. Trans. Inst. Min. Metall. Sec. A Min. Ind. 2000, 109, 41–48. [Google Scholar] [CrossRef]

- Ren, T.; Wang, Z.; Liang, Y.; Zhang, J. Numerical investigation of CO2 fringe behaviour on a longwall face and its control. Int. J. Coal Geol. 2018, 186, 80–96. [Google Scholar] [CrossRef]

- ANSYS. ANSYS Fluent Theory Guide; ANSYS: Canonsburg, PA, USA, 2010. [Google Scholar]

- Wang, Z.; Ren, T.; Cheng, Y. Numerical investigations of methane flow characteristics on a longwall face Part I: Methane emission and base model results. J. Nat. Gas Sci. Eng. 2017, 43, 242–253. [Google Scholar] [CrossRef]

| Country | Date | Coal Mine | Fatalities |

|---|---|---|---|

| China | 14 February 2005 | Sunjiawan, Haizhou shaft, Fuxin | 214 |

| USA | 2 June 2006 | Sago, West Virginia | 12 |

| Poland | 21 November 2006 | KWK Halemba, Ruda Śląska | 19 |

| Kazakhstan | 20 September 2006 | Lenina, Karaganda | 43 |

| Russia | 19 March 2007 | Ulyanovskaya, Kemerovo | 108 |

| Ukraine | 19 November 2007 | Zasyadko, Donetzk | 80 |

| Poland | 18 September 2009 | KWK Wujek (Śląsk), Ruda Śląska | 20 |

| USA | 5 April 2010 | Upper Big Branch, West Virginia | 29 |

| Russia | 8 May 2010 | Raspadskaya, Kemerovo Oblast | 66 |

| Turkey | 17 May 2010 | Karadon, Zonguldak | 30 |

| New Zealand | 19 November 2010 | Pike River Mine | 29 |

| Turkey | 13 May 2014 | Soma, Turkey | 301 |

| Ukraine | 4 March 2015 | Zasyadko, Donetzk | 33 |

| China | 30 October 2016 | Jinshangou, Chongqing | 33 |

| Item | Unit/m | Item | Unit/m |

|---|---|---|---|

| Face length | 200 | MG/TG width | 5 |

| Face height | 3.5 | MG/TG height | 3.5 |

| Goaf depth | 10 | MG/TG length | 50 |

| Model Reference Name | Scenario |

|---|---|

| MG-TG Case 1 | Shearer is cutting towards TG and is located on MG side |

| MG-TG Case 2 | Shearer is cutting towards TG and is located at face middle |

| MG-TG Case 3 | Shearer is cutting towards TG and is located on TG side |

| TG-MG Case 1 | Shearer is cutting towards MG and is located on MG side |

| TG-MG Case 2 | Shearer is cutting towards MG and is located at face middle |

| TG-MG Case 3 | Shearer is cutting towards MG and is located on TG side |

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 m from MG | - | - | - | - | - | - | - | - | - | - |

| Measured (m/s) | 1.8 | 3.5 | 2.9 | 3.0 | 2.2 | 3.3 | 2.2 | 2.8 | 2.3 | 1.7 |

| Modelled (m/s) | 1.71 | 3.68 | 2.79 | 3.06 | 2.41 | 3.33 | 2.43 | 2.71 | 2.13 | 1.78 |

| Error (%) | −5.00 | 5.14 | −3.79 | 2.00 | 9.55 | 0.91 | 10.45 | −3.21 | −7.39 | 4.71 |

| 2 m before MG drum | - | - | - | - | - | - | - | - | - | - |

| Measured (m/s) | 2.5 | 3.0 | 1.9 | 2.0 | 2.2 | 1.6 | 1.2 | 2.6 | 1.5 | 1.0 |

| Modelled (m/s) | 2.61 | 2.95 | 2.05 | 2.17 | 2.36 | 1.55 | 1.25 | 2.53 | 1.38 | 0.95 |

| Error (%) | 4.40 | −1.67 | 7.89 | 8.50 | 7.27 | −3.13 | 4.17 | −2.69 | −8.00 | −5.00 |

| Shearer middle | - | - | - | - | - | - | - | - | - | |

| Measured (m/s) | 3.0 | - | 2.5 | 2.6 | 2.3 | 1.2 | 2.0 | 2.9 | 1.8 | 1.0 |

| Modelled (m/s) | 3.23 | - | 2.67 | 2.78 | 2.46 | 1.31 | 2.12 | 2.87 | 1.69 | 0.91 |

| Error (%) | 7.67 | - | 6.80 | 6.92 | 6.96 | 9.17 | 6.00 | −1.03 | −6.11 | −9.00 |

| 2 m behind TG drum | - | - | - | - | - | - | - | - | - | - |

| Measured (m/s) | 2.5 | 2.6 | 3.6 | 3.2 | 2.8 | 2.2 | 2.5 | 3.2 | 0.8 | 0.2 |

| Modelled (m/s) | 2.53 | 2.71 | 3.83 | 3.39 | 2.92 | 2.06 | 2.41 | 3.08 | 0.75 | 0.26 |

| Error (%) | 1.20 | 4.23 | 6.39 | 5.94 | 4.29 | −6.36 | −3.60 | −3.75 | −6.25 | 30.00 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Ren, T.; Ma, L.; Zhang, J. Investigations of Ventilation Airflow Characteristics on a Longwall Face—A Computational Approach. Energies 2018, 11, 1564. https://doi.org/10.3390/en11061564

Wang Z, Ren T, Ma L, Zhang J. Investigations of Ventilation Airflow Characteristics on a Longwall Face—A Computational Approach. Energies. 2018; 11(6):1564. https://doi.org/10.3390/en11061564

Chicago/Turabian StyleWang, Zhongwei, Ting Ren, Liqiang Ma, and Jian Zhang. 2018. "Investigations of Ventilation Airflow Characteristics on a Longwall Face—A Computational Approach" Energies 11, no. 6: 1564. https://doi.org/10.3390/en11061564

APA StyleWang, Z., Ren, T., Ma, L., & Zhang, J. (2018). Investigations of Ventilation Airflow Characteristics on a Longwall Face—A Computational Approach. Energies, 11(6), 1564. https://doi.org/10.3390/en11061564