Performance of LiCl Impregnated Mesoporous Material Coating over Corrugated Heat Exchangers in a Solid Sorption Chiller

Abstract

:1. Introduction

2. Experiments

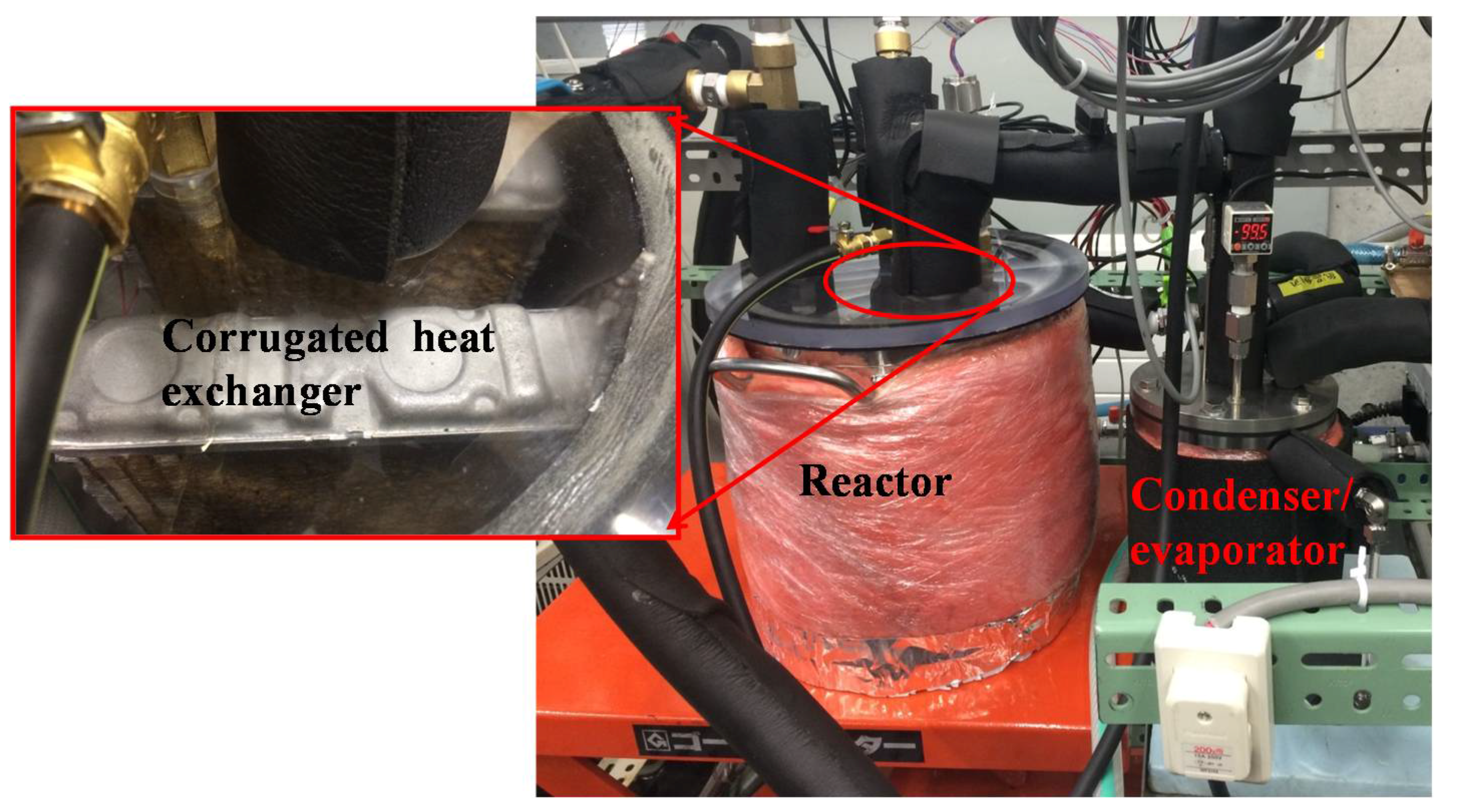

2.1. The Sorbent Coated Heat Exchanger

- The micropowders of WSS with peak particle diameter of 5 µm were dried at 120 °C for 24 h.

- The solution of LiCl was prepared first, and the corresponding amount of WSS was added to make the slurry of WSS and LiCl. The slurry was vacuumed to make sure the LiCl solution got into the pores of WSS.

- The corrugated aluminum heat exchanger was dip-coated with the slurry of WSS and LiCl without any binder, because the fine particles of WSS clay act as a kind of binder. There are no composite powder or LiCl drops after the coating procedure.

- The coated heat exchanger was left open to the air for 24 h for air drying, before being heated at 120 °C (the temperature was chosen according to the result obtained in Figure 9 in Liu et al. [22]) for 24 h to get its dry weight.

2.2. Experimental Setup

2.3. Experimental Procedure

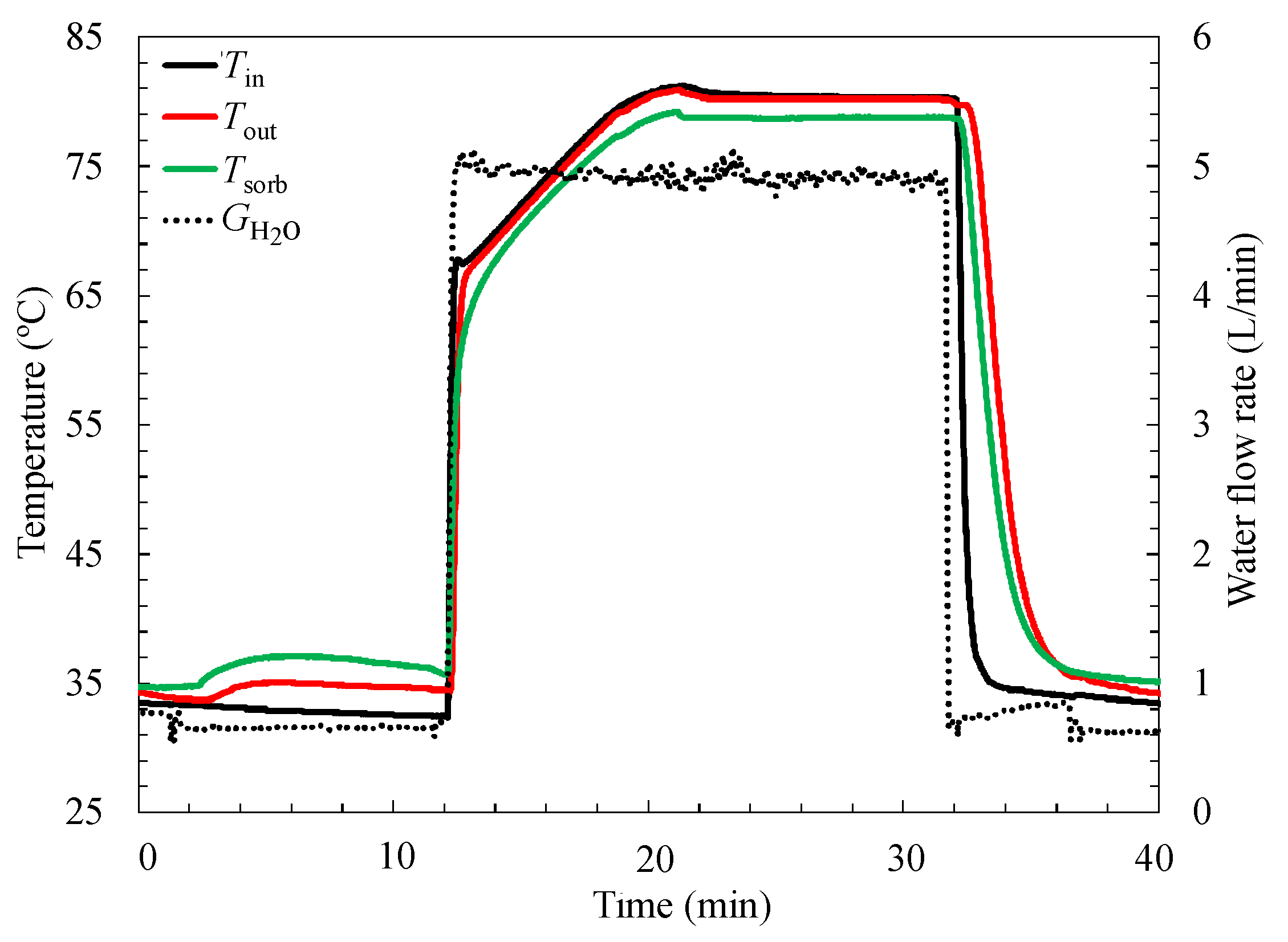

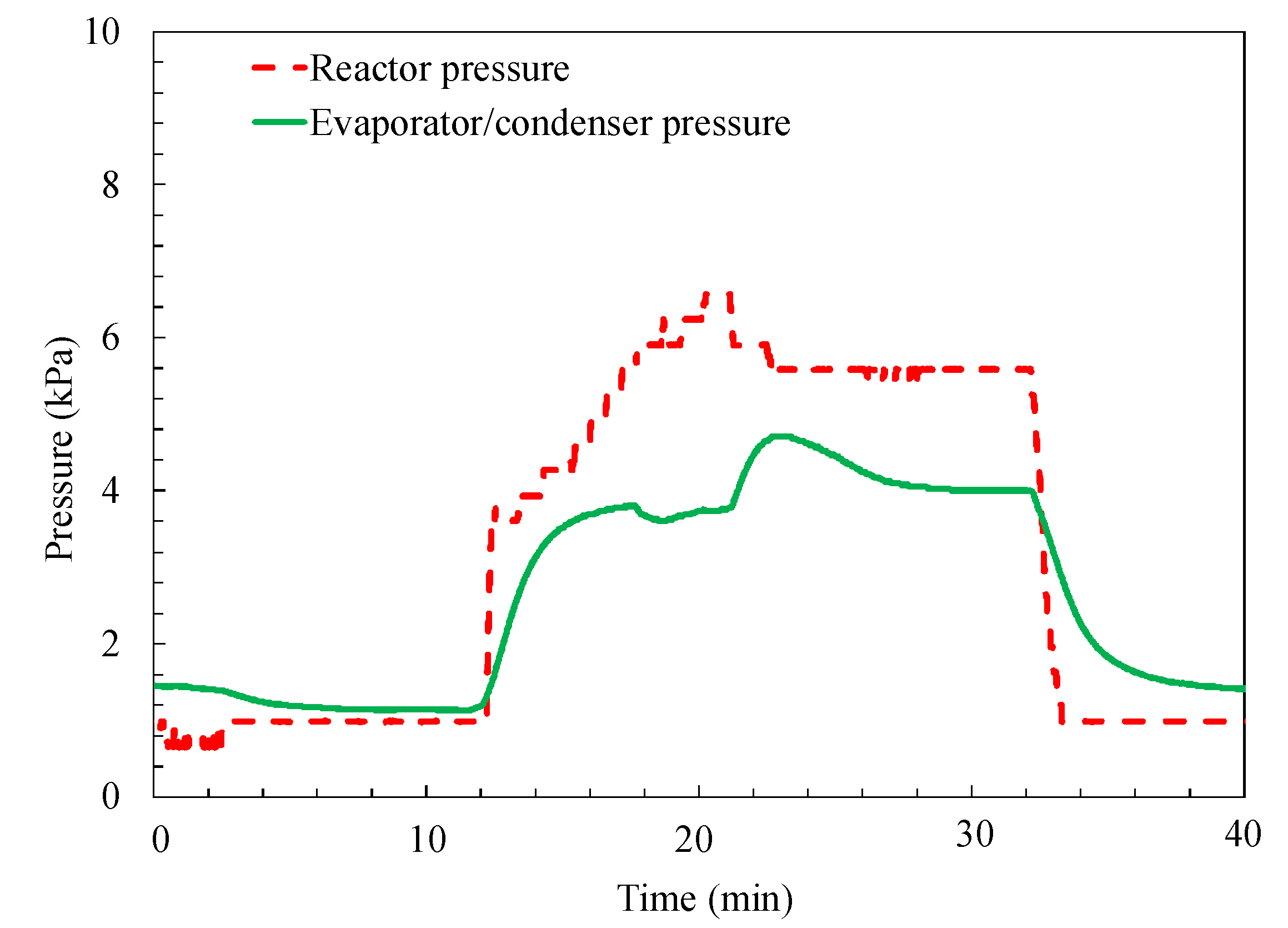

- The sorbent coated heat exchanger was cooled by the medium temperature thermostatic bath (Tin,sor = 30 °C), and the water inside the evaporator was controlled by a low temperature thermostatic bath at the same time (Tin,ev = 12 °C).

- When the pressure of the reactor decreased to the target pressure of the evaporator, the connecting valve between the evaporator and reactor was opened to start the heat release process. The connecting valve would be closed until the sorption time reached 10 min.

- The composite material was heated by the fluid from the high temperature circulating the thermostatic water bath. The water inside the condenser was controlled by the medium temperature thermostatic water bath at the same time (Tin,re = 80 °C, Tin,con = 30 °C).

- The valve connecting the reactor and condenser was opended to start the regeneration release process until the pressures of the two containers were the same. The condenser and reactor remained connected and the composite material was still heated until the desorption process was completed. The continued cycle began from step (1).

3. Results and Discussion

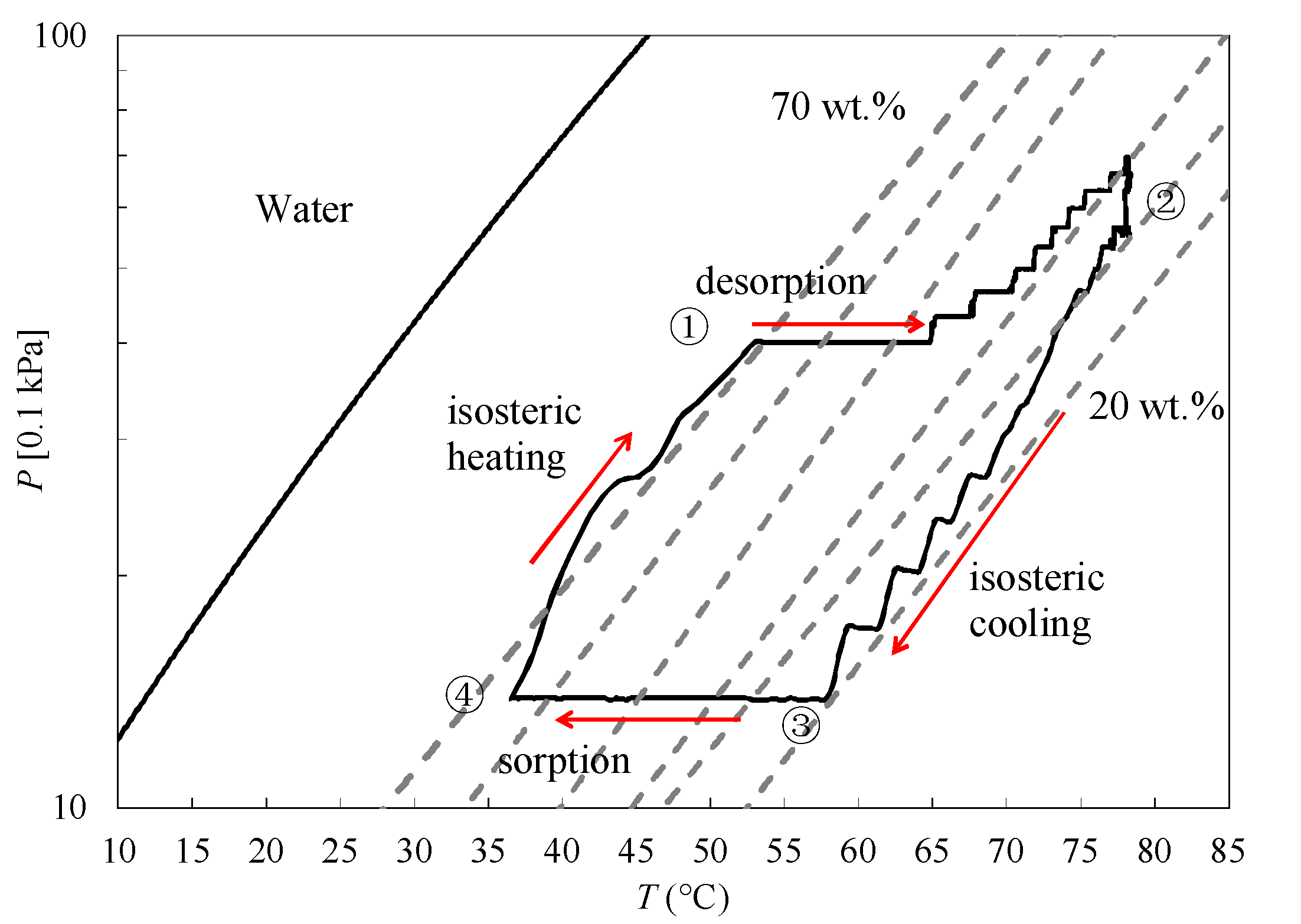

3.1. The Sorption Cycle on Clapeyron Diagram

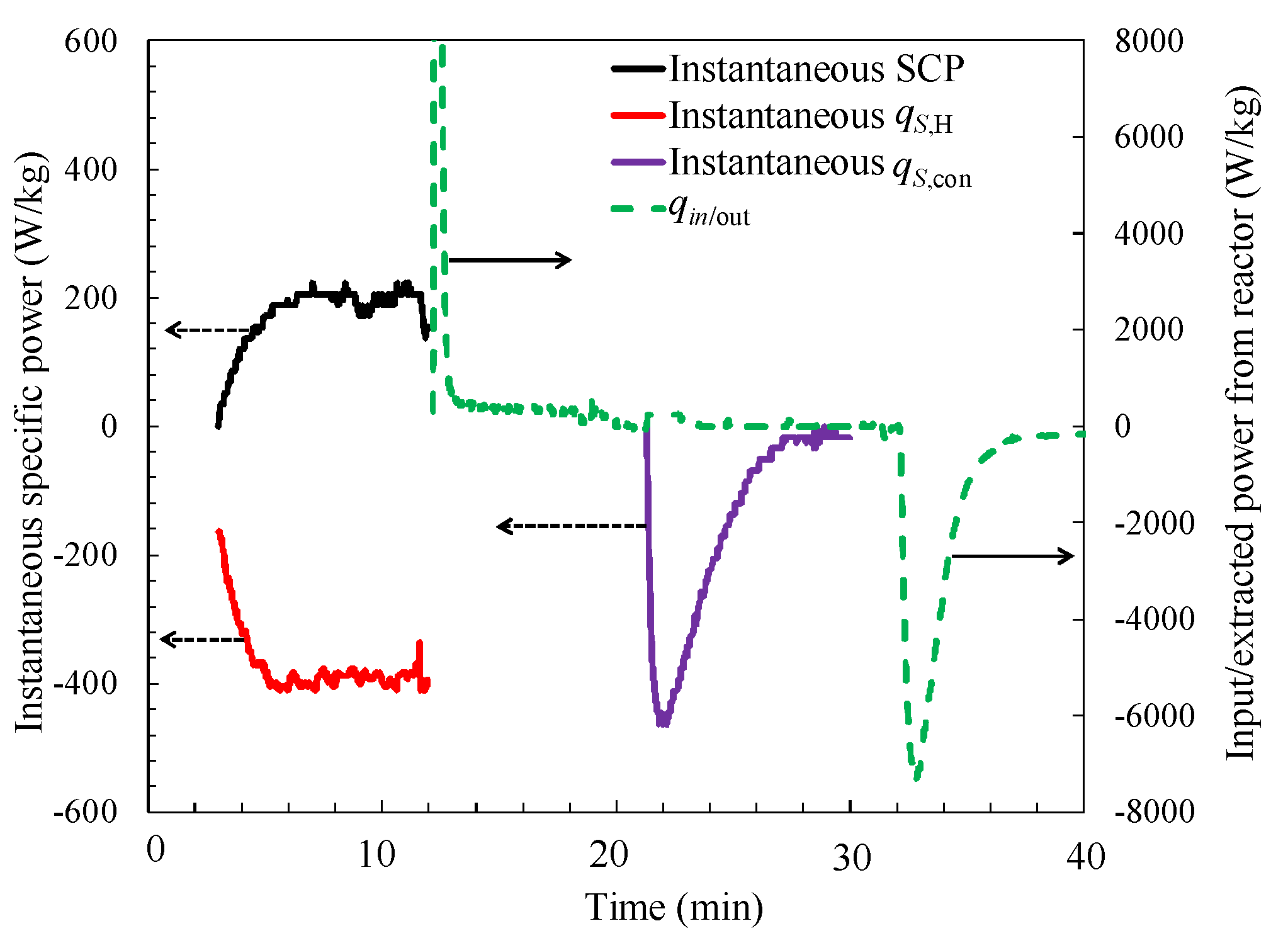

3.2. Performance of the Sorbent Coated Type Sorption Chiller

3.3. Performance Comparison

3.4. Further Improvements and Considerations

- -

- Lower the heat capacity of vessels of the reactor and condenser/evaporator, and increase the mass ratio of sorbent/metal.

- -

- Optimally design the corrugated heat exchanger in the reactor and heat exchanger in condenser/evaporator.

- -

- Optimize the coating thickness of the sorbent and the coating manufacture; fully packed bed type, thin coating on fins, moderate thickness of coating layer, and so on.

- -

- Install sorbent coated corrugated heat exchangers tightly into the evacuated reactor, while keeping proper gaps between each of the two heat exchangers, and in this case, a precise manifold should be made.

- -

- Set a coat of thermal insulation material over both the inside and outside surface of the reactor and condenser/evaporator vessels.

- -

- Add heat recovery process during the early several minutes after switching from the desorption to sorption process and from the sorption to desorption process.

- -

- Add vapor recovery process for the last several seconds before switching different processes.

4. Conclusions

- (1)

- The WSS + 40 wt. % LiCl was coated on two corrugated heat exchangers, and it can work well as the sorbent in the developed lab-scale sorption chiller under regeneration temperature of 80 °C and evaporation temperature of 12 °C.

- (2)

- In one sorption cooling cycle, the water uptake changes from 20 wt. % to 70 wt. %, which means that for per g dry WSS + 40 wt. % LiCl, 0.5 g water can ideally be sorbed and desorbed in one cycle.

- (3)

- The cycle time of the sorbent coated sorption chiller could be decreased compared with our previous packed bed sorption cooler under the same operating condition.

- (4)

- The experimental results showed a SCP of 86 W/kg, VSCP of 42 W/dm3, and specific sorption power of 170 W/kg with a total sorption and desorption time of 20 min. Based on the current operation condition (regeneration temperature of 80 °C, condensation temperature of 30 °C in the desorption process; sorption temperature of 30 °C and evaporation temperature of 12 °C in the sorption process), the obtained cooling COP is approximately 0.16.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| WSS | Wakkanai Siliceous Shale |

| WSS + 40 wt. % LiCl | WSS impregnated with 40 wt. % LiCl |

| Nomenclature | |

| COP | Coefficient of performance (-) |

| CP | Specific heat capacity (kJ/(kg∙K)) |

| G | Flow rate of the fluid (m3/s) |

| m | Weight of sorbent (g) |

| P | Pressure (Pa) |

| qS | Specific power (W/kg-sample) |

| SCP | Specific cooling power (W/kg) |

| T | Temperature (°C) |

| V | Volume (m3) |

| VSCP | Volumetric specific cooling power (W/dm3) |

| Greek symbols | |

| ∆τ | Time interval (s) |

| ρ | Density (kg/m3) |

| τ | Time (s) |

| ω | Water sorption amount (g/g) |

| Subscripts | |

| C | Cooling |

| con | Condensation |

| cycle | Cycle |

| dry | Dry state |

| ev | Evaporation |

| H | Heating |

| H2O | Water or water vapor |

| hex | Heat exchanger |

| in | Inlet |

| out | Outlet |

| re | Regeneration |

| sor | Sorption |

| sorb | Sorbent |

| 0 | Start of cycle |

| 1 | End of isosteric heating |

| 2 | End of desorption phase |

| 3 | End of isosteric cooling |

| 4 | End of cycle |

References

- Oliveira, R.G.; Wang, R.Z. A consolidated calcium chloride-expanded graphite compound for use in sorption refrigeration systems. Carbon 2007, 45, 390–396. [Google Scholar] [CrossRef]

- Jiang, L.; Gao, J.; Wang, L.; Wang, R.; Lu, Y.; Roskilly, A.P. Investigation on performance of multi-salt composite sorbents for multilevel sorption thermal energy storage. Appl. Energy 2017, 190, 1029–1038. [Google Scholar] [CrossRef]

- Daou, K.; Wang, R.Z.; Xia, Z.Z. Development of a new synthesized adsorbent for refrigeration and air conditioning applications. Appl. Therm. Eng. 2006, 26, 56–65. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, R.Z.; Xia, Z.; Gong, L. Experimental investigation adsorption chillers using micro-porous silica gel-water and compound adsorbent-methanol. Energy Convers. Manag. 2013, 65, 430–437. [Google Scholar] [CrossRef]

- Tokarev, M.M.; Gordeeva, L.G.; Grekova, A.D.; Aristov, Y.I. Adsorption cycle “heat from cold” for upgrading the ambient heat: The testing a lab-scale prototype with the composite sorbent CaClBr/silica. Appl. Energy 2018, 211, 136–145. [Google Scholar] [CrossRef]

- Aristov, Y.I. New family of solid sorbents for adsorptive cooling: Material scientist approach. J. Eng. Thermophys. 2007, 16, 63–72. [Google Scholar] [CrossRef]

- Okunev, B.N.; Aristov, Y.I. Making adsorptive chillers faster by a proper choice of adsorption isobar shape: Comparison of optimal and real adsorbents. Energy 2014, 76, 400–405. [Google Scholar] [CrossRef]

- Sapienza, A.; Velte, A.; Girnik, I.; Frazzica, A.; Füldner, G.; Schnabel, L.; Aristov, Y. “Water—Silica Siogel” working pair for adsorption chillers: Adsorption equilibrium and dynamics. Renew. Energy 2017, 110, 40–46. [Google Scholar] [CrossRef]

- Wittstadt, U.; Fuldner, G.; Andersen, O.; Herrmann, R.; Schmidt, F. A new adsorbent composite material based on metal fiber technology and its application in adsorption heat exchangers. Energies 2015, 8, 8431–8446. [Google Scholar] [CrossRef]

- Gordeeva, L.; Frazzica, A.; Sapienza, A.; Aristov, Y.; Freni, A. Adsorption cooling utilizing the “LiBr/silica–Ethanol” working pair: Dynamic optimization of the adsorber/heat exchanger unit. Energy 2014, 75, 390–399. [Google Scholar] [CrossRef]

- Vasta, S.; Freni, A.; Sapienza, A.; Costa, F.; Restuccia, G. Development and lab-test of a mobile adsorption air-conditioner. Int. J. Refrig. 2012, 35, 701–708. [Google Scholar] [CrossRef]

- Freni, A.; Russo, F.; Vasta, S.; Tokarev, M.; Aristov, Y.I.; Restuccia, G. An advanced solid sorption chiller using SWS-1L. Appl. Therm. Eng. 2007, 27, 2200–2204. [Google Scholar] [CrossRef]

- Gordeeva, L.G.; Freni, A.; Aristov, Y.I.; Restuccia, G. Composite sorbent of methanol “lithium chloride in mesoporous silica gel” for adsorption cooling machines: Performance and stability evaluation. Ind. Eng. Chem. Fund. 2009, 48, 6197–6202. [Google Scholar] [CrossRef]

- Saha, B.B.; Chakraborty, A.; Koyama, S.; Aristov, Y.I. A new generation cooling device employing CaCl2-in-silica gel–water system. Int. J. Heat Mass Transf. 2009, 52, 516–524. [Google Scholar] [CrossRef]

- Wang, L.W.; Wang, R.Z.; Oliveira, R.G. A review on adsorption working pairs for refrigeration. Renew. Sustain. Energy Rev. 2009, 13, 518–534. [Google Scholar] [CrossRef]

- Aristov, Y.I. Challenging offers of material science for adsorption heat transformation: A review. Appl. Therm. Eng. 2013, 50, 1610–1618. [Google Scholar] [CrossRef]

- Aristov, Y.I. Novel Materials for Adsorptive Heat Pumping and Storage: Screening and Nanotailoring of Sorption Properties. J. Chem. Eng. Jpn. 2007, 40, 1242–1251. [Google Scholar] [CrossRef] [Green Version]

- Restuccia, G.; Freni, A.; Vasta, S.; Aristov, Y.I. Selective water sorbent for solid sorption chiller: Experimental results and modelling. Int. J. Refrig. 2004, 27, 284–293. [Google Scholar] [CrossRef]

- Freni, A.; Sapienza, A.; Glaznev, I.S.; Aristov, Y.I. Experimental testing of a lab-scale adsorption chiller using a novel selective water sorbent “silica modified by calcium nitrate”. Int. J. Refrig. 2012, 35, 518–524. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Sapienza, A.; Ovoshchnikov, D.S.; Freni, A.; Restuccia, G. Reallocation of adsorption and desorption times for optimisation of cooling cycles. Int. J. Refrig. 2012, 35, 525–531. [Google Scholar] [CrossRef]

- Kurokawa, A.; Togawa, J.; Nabeshima, Y.; Nagano, K. The evaluation of the moisture sorption mechanism of chloride-impregnated Wakkanai Siliceous Shale. Kagaku Kogaku Ronbun 2011, 37, 394–399. [Google Scholar] [CrossRef]

- Liu, H.; Nagano, K.; Togawa, J. A composite material made of mesoporous siliceous shale impregnated with lithium chloride for an open sorption thermal energy storage system. Sol. Energy 2015, 111, 186–200. [Google Scholar] [CrossRef]

- Wen, T.; Lu, L.; Dong, C.; Luo, Y. Investigation on the regeneration performance of liquid desiccant by adding surfactant PVP-K30. Int. J. Heat Mass Transf. 2018, 123, 445–454. [Google Scholar] [CrossRef]

- Wen, T.; Lu, L.; Dong, C. Enhancing the dehumidification performance of LiCl solution with surfactant PVP-K30. Energy Build. 2018, 171, 183–195. [Google Scholar] [CrossRef]

- Jiang, R.; Qin, F.G.F.; Yang, X.; Huang, S.; Chen, B. Performance analysis of a liquid absorption dehumidifier driven by jacket-cooling water of a diesel engine in a CCHP system. Energy Build. 2018, 163, 70–78. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Pavlovic, S.; Stefanovic, V. Thermodynamic investigation of LiCl-H2O working pair in a double effect absorption chiller driven by parabolic trough collectors. Therm. Sci. Eng. Prog. 2017, 3, 75–87. [Google Scholar] [CrossRef]

- Pandya, B.; Kumar, V.; Patel, J.; Matawala, V.K. Optimum Heat Source Temperature and Performance Comparison of LiCl–H2O and LiBr–H2O Type Solar Cooling System. J. Energy Resour. Technol. 2018, 140, 051204. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. Exergetic and energetic comparison of LiCl-H2O and LiBr-H2O working pairs in a solar absorption cooling system. Energy Convers. Manag. 2016, 123, 453–461. [Google Scholar] [CrossRef]

- Liu, H.; Nagano, K.; Morita, A.; Togawa, J.; Nakamura, M. Experimental testing of a small sorption air cooler using composite material made from natural siliceous shale and chloride. Appl. Therm. Eng. 2015, 82, 68–81. [Google Scholar] [CrossRef]

- Freni, A.; Bonaccorsi, L.; Calabrese, L.; Caprì, A.; Frazzica, A.; Sapienza, A. SAPO-34 coated adsorbent heat exchanger for adsorption chillers. Appl. Therm. Eng. 2015, 82, 1–7. [Google Scholar] [CrossRef]

- Girnik, I.S.; Grekova, A.D.; Gordeeva, L.G.; Aristov, Y.I. Dynamic optimization of adsorptive chillers: Compact layer vs. bed of loose grains. Appl. Therm. Eng. 2017, 125, 823–829. [Google Scholar] [CrossRef]

- Nakabayashi, S.; Nagano, K.; Nakamura, M.; Togawa, J.; Kurokawa, A. Improvement of water adsorption ability of natural mesoporous material by impregnating with chloride salts for development of a new desiccant filter. Adsorption 2011, 17, 675–686. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Tokarev, M.M.; Restuccia, G.; Cacciola, G. Selective water sorbents for multiple applications, 2. CaCl2 confined in micropores of silica gel: Sorption properties. React. Kinet. Catal. Lett. 1996, 59, 335–342. [Google Scholar] [CrossRef]

- Monnin, C.; Dubois, M.; Papaiconomou, N.; Simonin, J.-P. Thermodynamics of the LiCl + H2O System. J. Chem. Eng. Data 2002, 47, 1331–1336. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Tokarev, M.M.; Cacciola, G.; Restuccia, G. Selective water sorbents for multiple applications, 1. CaCl2 confined in mesopores of silica gel: Sorption properties. React. Kinet. Catal. Lett. 1996, 59, 325–333. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Marco, G.D.; Tokarev, M.M.; Parmon, V.N. Selective water sorbents for multiple applications, 3. CaCl2 solution confined in micro- and mesoporous silica gels: Pore size effect on the “solidification-melting” diagram. React. Kinet. Catal. Lett. 1997, 61, 147–154. [Google Scholar] [CrossRef]

- Kamali, A.R.; Fray, D.J.; Schwandt, C. Thermokinetic characteristics of lithium chloride. J. Therm. Anal. Calorim. 2010, 104, 619–626. [Google Scholar] [CrossRef]

- Fiorentino, M.; Starace, G. The design of countercurrent evaporative condensers with the hybrid method. Appl. Therm. Eng. 2018, 130, 889–898. [Google Scholar] [CrossRef]

- Starace, G.; Fiorentino, M.; Meleleo, B.; Risolo, C. The hybrid method applied to the plate-finned tube evaporator geometry. Int. J. Refrig. 2018, 88, 67–77. [Google Scholar] [CrossRef]

- Ernest, D. Measurement Systems: Application and Design, 4th ed.; McGraw-Hill: New York, NY, USA, 1990. [Google Scholar]

| Compound | Concentration (wt. %) |

|---|---|

| SiO2 | 87.09 |

| Al2O3 | 8.09 |

| Fe2O3 | 3.39 |

| K2O | 0.78 |

| TiO2 | 0.41 |

| CaO | 0.21 |

| V2O5 | 0.03 |

| Parameters | Value |

|---|---|

| Total metal mass of one heat exchanger (kg) | 0.454 |

| Total volume of one heat exchanger (m3) | 0.5625 × 10−3 |

| Heat transfer area of one heat exchanger (m2) | 6.375 × 10−2 |

| Total mass of the coated material on a heat exchanger (kg) | 0.143 |

| Coating density (kg/m3) | 254.2 |

| Number of coated heat exchangers inside reactor (–) | 2 |

| Total mass of the lithium chloride (LiCl) (kg) | 0.1144 |

| Component | Type | Properties |

|---|---|---|

| Sorbent temperature | T | −200 < T < 350 °C, ±0.5 °C |

| Water temperature | Pt100 | Screw-in sensor, −40 < T < 150 °C, ±0.15% |

| Pressure sensor | Digital pressure indicator | −100 kPa < p < 100 kPa, ±1.0% full scale |

| Flow meter | Electromagnetic flow sensor | G < 5 L/min., −25 °C < T < 80 °C, ±0.6% full scale |

| Data logger | Digital measuring station | Sample rate every 125 ms, ±0.05% |

| WSS + 40 wt. % LiCl Coated Heat Exchanger | WSS + 40 wt. % LiCl Packed Bed [29] | SWS-1L Coated Heat Exchanger [12] | |

|---|---|---|---|

| Salt content x (%) | 40 wt. % LiCl | 40 wt. % LiCl | 33.7 wt. % CaCl2 |

| SCP (W/kg) | 86 | 50–60 | 150–200 |

| Cycle time tcycle (min.) | 20 | 120 | 10–20 |

| Cooling COP | 0.16 | 0.2–0.3 | 0.15–0.3 |

| Sorption/evaporation temperature Tcon (°C) | 30/12 | 30/12 | (15–20)/(7–12) |

| Regeneration/condensation temperature Tre (°C) | 80/30 | (80–90)/30 | (95–100)/35 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Nagano, K.; Togawa, J. Performance of LiCl Impregnated Mesoporous Material Coating over Corrugated Heat Exchangers in a Solid Sorption Chiller. Energies 2018, 11, 1565. https://doi.org/10.3390/en11061565

Liu H, Nagano K, Togawa J. Performance of LiCl Impregnated Mesoporous Material Coating over Corrugated Heat Exchangers in a Solid Sorption Chiller. Energies. 2018; 11(6):1565. https://doi.org/10.3390/en11061565

Chicago/Turabian StyleLiu, Hongzhi, Katsunori Nagano, and Junya Togawa. 2018. "Performance of LiCl Impregnated Mesoporous Material Coating over Corrugated Heat Exchangers in a Solid Sorption Chiller" Energies 11, no. 6: 1565. https://doi.org/10.3390/en11061565