Model of T-Type Fracture in Coal Fracturing and Analysis of Influence Factors of Fracture Morphology

Abstract

:1. Introduction

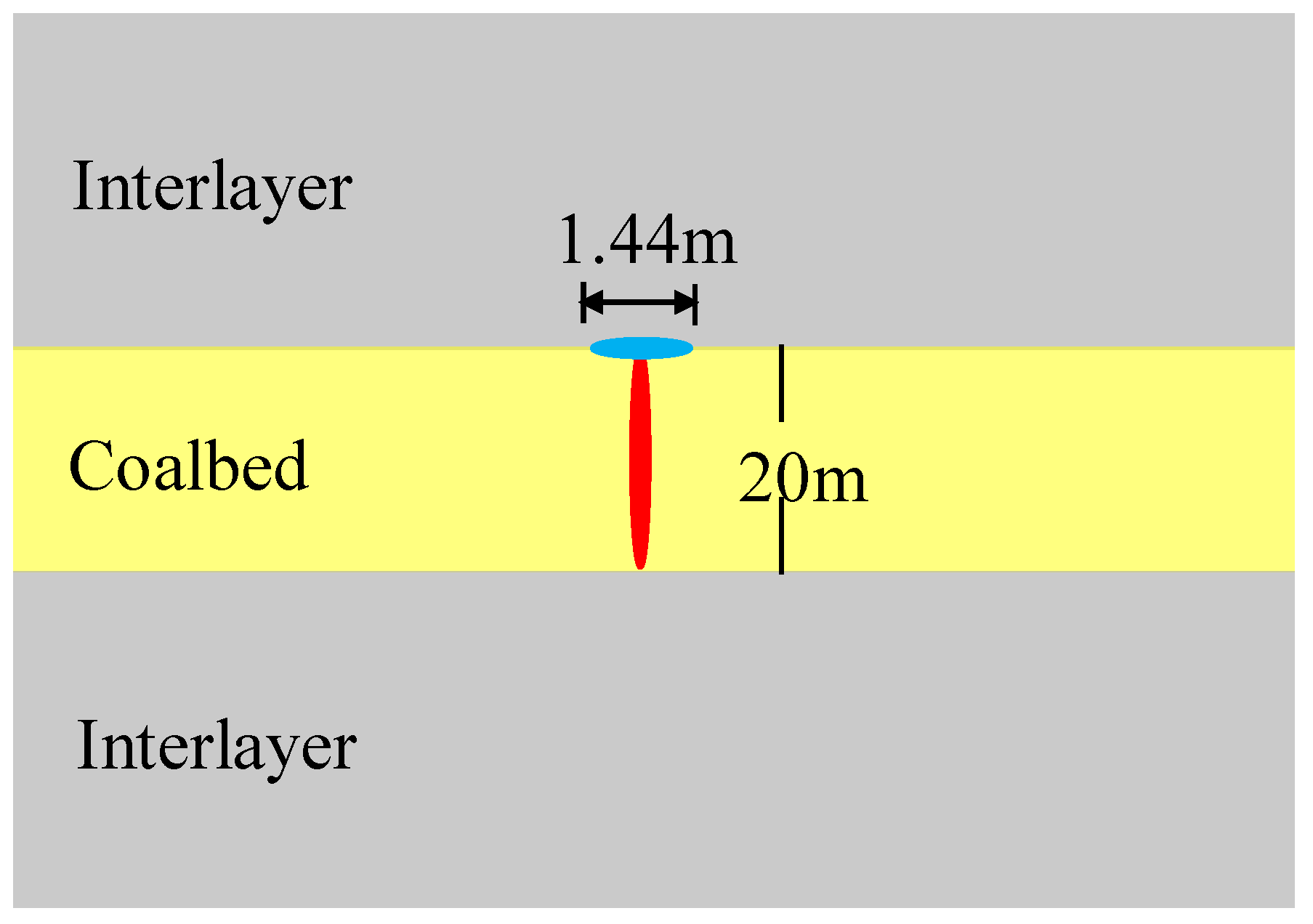

2. Derivation of the Model of T-Type Fracture

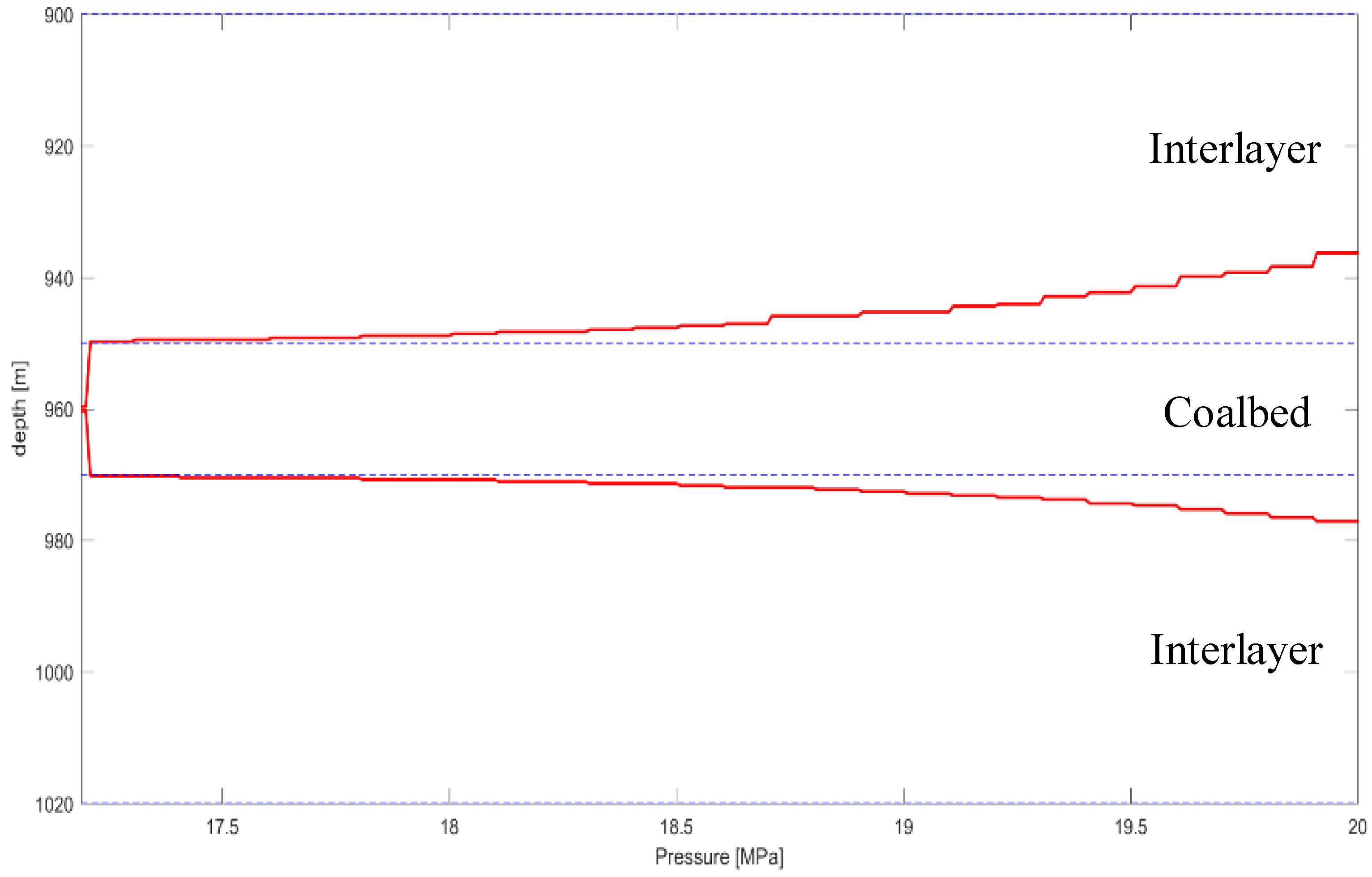

3. Model Validation

4. Analysis of Influence Factors of T-Type Fracture

4.1. Effect of Vertical Fracture Height on the Shape of T-Type Fracture

4.2. Influence of Coalbed Fracture Toughness on T-Type Fracture

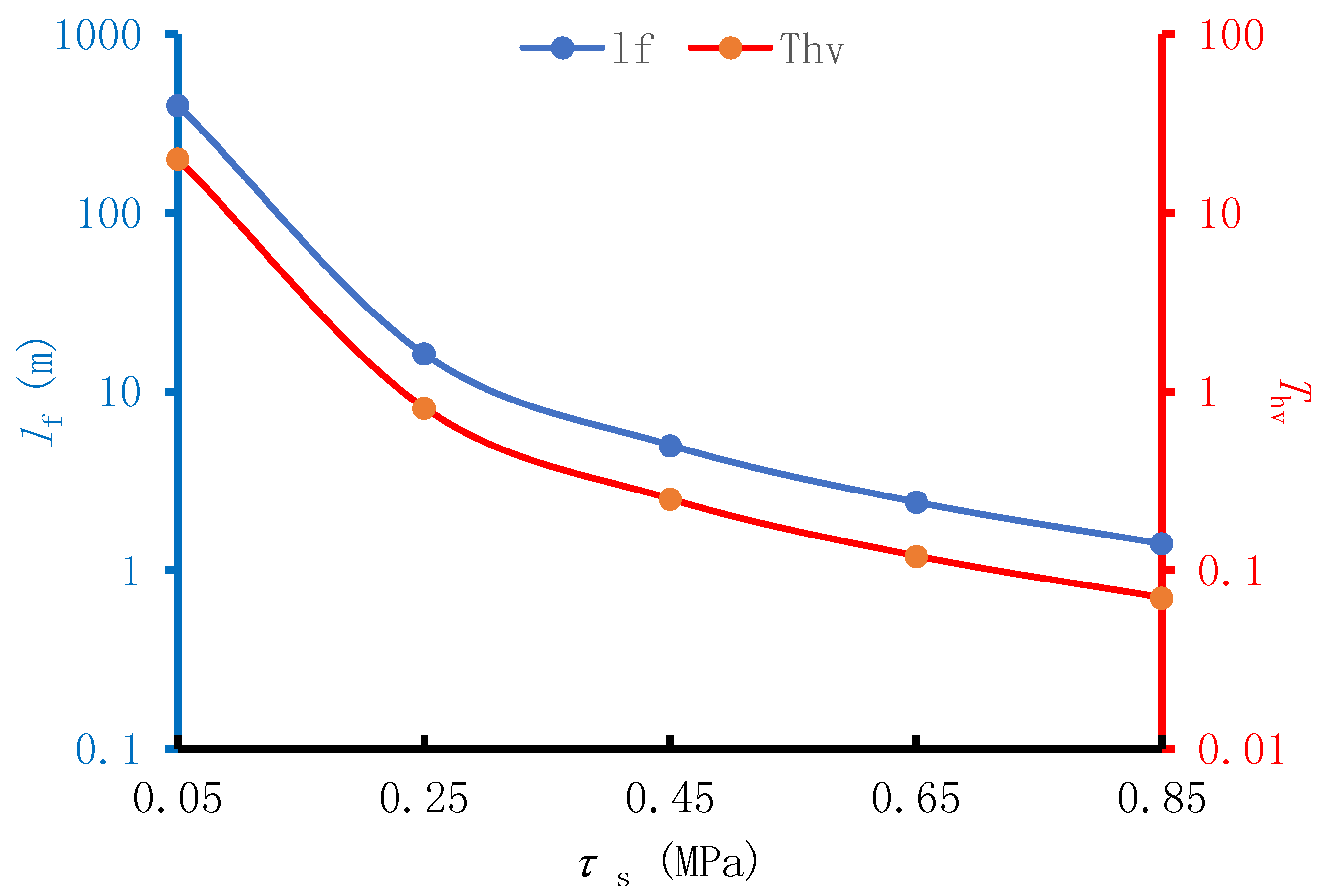

4.3. Influence of Bedding Shear Strength on the Morphology of T-Type Fracture

5. Discussion

5.1. Principal Insights

5.2. Model Limitations

6. Conclusions

- (1)

- T-type fractures in coal fracturing are mainly caused by vertical fractures extending to the bedding plane and causing horizontal fractures to form on the bedding plane after stretching or shear failure.

- (2)

- The increase of the vertical fracture height can increase the length of the horizontal fracture, but when the vertical fracture height increases to a certain value, the effect of increasing the horizontal fracture length by increasing the vertical fracture height is no longer obvious.

- (3)

- The fracture toughness has certain influence on the length of horizontal fracture, but there is a threshold. When the fracture toughness is less than the threshold, the length of horizontal fracture remains unchanged, otherwise, the length of horizontal fracture increases rapidly with the increase of fracture toughness.

- (4)

- When the shear strength of the interface between the coalbed and the interlayer is enhanced, the length of the horizontal part of T-type fracture is rapidly reduced. It shows that the greater the stratification strength is, the more stable it is and the less favorable it is to the formation of T-type fracture.

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| σH | maximum horizontal principal stress, MPa; |

| σh | minimum horizontal principal stress, MPa; |

| σv | vertical stress, MPa; |

| lf | length of horizontal fracture, m; |

| Pr | fracture propagation pressure, MPa; |

| C | the half height of the vertical fracture, m; |

| Pnet(x) | the net pressure of the fluid at any point in the fracture, MPa; |

| hi | the thickness of the i-th layer, I = 1, 2, …., n, m; |

| σI | the horizontal minimum principal stress of the i-th layer, I = 1, 2, …., n, MPa; |

| KICi | the fracture toughness of the i-th layer rock, I = 1, 2, …., n, MPa·m1/2; |

| TVD | the true vertical depth, m; |

| ρ | the fracturing fluid density, kg/m3; |

| m | the density gradient, kg/m2·s2; |

| dref | the vertical depth of perforation, m; |

| Pref | the fracturing fluid pumping pressure at the perforation location, MPa; |

| dmid | the vertical depth of the middle of the fracture, m; |

| Pmid | the fracturing fluid pressure in the middle of the fracture, MPa; |

| xd,I, xu,I | the bottom and top depth of the i-th layer respectively, m; |

| α | the angle between horizontal bedding and vertical stress, (°); |

| θ | the polar angle of any point in the polar coordinate system of the fracture tip deviating from the direction of the fracture extension line, (°); |

| β | the angle between the horizontal bedding polar coordinate system and vertical fracture rectangular coordinate system, (°); |

| σt | the tensile strength of the bedding plane, MPa; |

| τs | the cohesion of the bedding plane, MPa. |

References

- Song, D.; Liu, Z.; Wang, E.; Qiu, L.; Gao, Q.; Xu, Z. Evaluation of coal seam hydraulic fracturing using the direct current method. Int. J. Rock Mech. Min. Sci. 2015, 78, 230–239. [Google Scholar] [CrossRef]

- Li, Y.; Jia, D.; Wang, M.; Liu, J.; Fu, C.; Yang, X.; Ai, C. Hydraulic fracturing model featuring initiation beyond the wellbore wall for directional well in coal bed. J. Geophys. Eng. 2016, 13, 536–548. [Google Scholar] [CrossRef]

- Li, Y.; Jia, D.; Liu, J.; Fu, C.; Ai, C. The calculation method based on the equivalent continuum for the fracture initiation pressure of fracturing of coalbed methane well. J. Petrol. Sci. Eng. 2016, 146, 909–920. [Google Scholar] [CrossRef]

- Cheng, L.; Ge, Z.; Xia, B.; Li, Q.; Tang, J.; Cheng, Y.; Zuo, S. Research on Hydraulic Technology for Seam Permeability Enhancement in Underground Coal Mines in China. Energies 2018, 11, 427. [Google Scholar] [CrossRef]

- Chong, Z.; Li, X.; Chen, X.; Zhang, J.; Lu, J. Numerical Investigation into the Effect of Natural Fracture Density on Hydraulic Fracture Network Propagation. Energies 2017, 10, 914. [Google Scholar] [CrossRef]

- Li, Y.; Jia, D.; Rui, Z.; Peng, J.; Fu, C.; Zhang, J. Evaluation Method of Rock Brittleness Based on Statistical Constitutive Relations for Rock Damage. J. Petrol. Sci. Eng. 2017, 153, 123–132. [Google Scholar] [CrossRef]

- Tang, J.; Wu, K.; Zeng, B.; Huang, H.; Hu, X.; Guo, X.; Zuo, L. Investigate Effects of Weak Bedding Interfaces on Fracture Geometry in Unconventional Reservoirs. J. Petrol. Sci. Eng. 2018, 165, 992–1009. [Google Scholar] [CrossRef]

- Rui, Z.; Guo, T.; Feng, Q.; Qu, Z.; Qi, N.; Gong, F. Influence of Gravel on the Propagation Pattern of Hydraulic Fracture in the Glutenite Reservoir. J. Petrol. Sci. Eng. 2018, 165, 627–639. [Google Scholar] [CrossRef]

- Guo, J.; Luo, B.; Lu, C.; Lai, J.; Ren, J. Numerical Investigation of Hydraulic Fracture Propagation in A Layered Reservoir using the Cohesive Zone Method. Eng. Fract. Mech. 2017, 186, 195–207. [Google Scholar] [CrossRef]

- Rui, Z.; Cui, K.; Wang, X.; Lu, J.; Chen, G.; Ling, K.; Patil, S. A Quantitative Framework for Evaluating Unconventional Well Development. J. Petrol. Sci. Eng. 2018, 166, 900–905. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Z.; Yang, G. Experiments of fracturing and pressure curve analysis of T-shape fractures of coalbed. Spec. Oil Gas Reserv. 2013, 20, 123–126. [Google Scholar] [CrossRef]

- Wu, X.; Xi, C.; Wang, G. The mathematic model research of complicated fractures system in coalbed methane wells. Nat. Gas Ind. 2006, 26, 124–126. [Google Scholar]

- Li, Y.; Rui, Z.; Zhao, W.; Bo, Y.; Fu, C.; Chen, G.; Patil, S. Study on the mechanism of rupture and propagation of T-type fractures in coal fracturing. J. Nat. Gas Sci. Eng. 2018, 52, 379–389. [Google Scholar] [CrossRef]

- Jeffrey, R.G.; Zhang, X.; Thiercelin, M.J. Hydraulic fracture offsetting in naturally fractures reservoirs: Quantifying a long-recognized process. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, Woodlands, TX, USA, 19–21 January 2009. [Google Scholar]

- Zhang, G.; Chen, M. Complex fracture shapes in hydraulic fracturing with orientated perforations. Petrol. Explor. Dev. 2009, 36, 103–107. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, M. The relationship between the production rate and initiation location of new fractures in a refractured well. Petrol. Sci. Technol. 2010, 28, 655–666. [Google Scholar] [CrossRef]

- Zhou, J.; Jin, Y.; Chen, M. Experimental investigation of hydraulic fracturing in random naturally fractured blocks. Int. J. Rock Mech. Min. Sci. 2010, 47, 1193–1199. [Google Scholar] [CrossRef]

- Chuprakov, D.A.; Akulich, A.V.; Siebrits, E.; Thiercelin, M. Hydraulic-fracture propagation in a naturally fractured reservoir. SPE Prod. Oper. 2011, 26, 88–97. [Google Scholar] [CrossRef]

- Hou, B.; Chen, M.; Wang, Z.; Yuan, J.; Liu, M. Hydraulic fracture initiation theory for a horizontal well in a coal seam. Petrol. Sci. 2013, 10, 219–225. [Google Scholar] [CrossRef]

- Mohammad, A.; Sheik, S. Initiation of a secondary hydraulic fracture and its interaction with the primary fracture. Int. J. Rock Mech. Min. Sci. 2010, 47, 714–722. [Google Scholar] [CrossRef]

- Tang, S.; Zhu, B.; Yan, Z. Effect of crustal stress on hydraulic fracturing in coalbed methane wells. J. China Coal Soc. 2011, 36, 65–69. [Google Scholar] [CrossRef]

- Zhu, H.; Deng, J.; Jin, X.; Hu, L.; Luo, B. Hydraulic fracture initiation and propagation from wellbore with oriented perforation. Rock Mech. Rock Eng. 2015, 48, 585–601. [Google Scholar] [CrossRef]

- Liu, S.; Valkó, P.P. A rigorous hydraulic-fracture equilibrium-height model for multilayer formations. SPE Prod. Oper. 2017, 8, 1–21. [Google Scholar] [CrossRef]

- Zhi, L.; Changgui, J.; Chunhe, Y.; Yijin, Z.; Yintong, G.; Shuai, H. Propagation of hydraulic fissures and bedding planes in hydraulic fracturing of shale. Chin. J. Rock Mech. Eng. 2015, 34, 12–20. [Google Scholar] [CrossRef]

- Chuprakov, D.A.; Zhubayev, A.S. A variational approach to analyze a natural fault with hydraulic fracture based on the strain energy density criterion. Theor. Appl. Fract. Mech. 2010, 53, 221–232. [Google Scholar] [CrossRef]

| No. | Parameters | Symbol | Unit | Value |

|---|---|---|---|---|

| 1 | maximum horizontal principal stress | σH | MPa | 6 |

| 2 | minimum horizontal principal stress | σh | MPa | 4 |

| 3 | vertical stress | σv | MPa | 10 |

| 4 | length of vertical fracture | 2C | m | 0.25 |

| 5 | length of horizontal fracture | lf | m | 0.05–0.15 |

| 6 | fracture propagation pressure | Pr | MPa | 5.5 |

| 7 | fracturing fluid density | ρ | kg/m3 | 1050 |

| No. 1 | No. 2 | No. 3 | ||||||

|---|---|---|---|---|---|---|---|---|

| Symbol | Unit | Value | Symbol | Unit | Value | Symbol | Unit | Value |

| KIC | MPa·m1/2 | 0.94 | KIC | MPa·m1/2 | 0.94 | KIC | MPa·m1/2 | 0.94 |

| τ | MPa | 0.84 | τ | MPa | 0.59 | τs | MPa | 0.48 |

| lf | m | 0.05 | lf | m | 0.10 | lf | m | 0.15 |

| No. of Layer | Top Depth (m) | Thickness (m) | Minimum Horizontal Principal Stress (MPa) | Vertical Stress (MPa) | Fracture Toughness (MPa·m1/2) | Tensile Strength (MPa) | Shear Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 900 | 50 | 20.70 | 21.60 | 1.42 | 0.91 | 3.49 |

| 2 | 950 | 20 | 16.40 | 22.80 | 0.71 | 0.32 | 0.85 |

| 3 | 970 | 50 | 22.30 | 23.30 | 1.42 | 0.93 | 3.62 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Jia, D.; Li, W.; Zhang, K. Model of T-Type Fracture in Coal Fracturing and Analysis of Influence Factors of Fracture Morphology. Energies 2018, 11, 1196. https://doi.org/10.3390/en11051196

Li Y, Jia D, Li W, Zhang K. Model of T-Type Fracture in Coal Fracturing and Analysis of Influence Factors of Fracture Morphology. Energies. 2018; 11(5):1196. https://doi.org/10.3390/en11051196

Chicago/Turabian StyleLi, Yuwei, Dan Jia, Wei Li, and Kunpeng Zhang. 2018. "Model of T-Type Fracture in Coal Fracturing and Analysis of Influence Factors of Fracture Morphology" Energies 11, no. 5: 1196. https://doi.org/10.3390/en11051196

APA StyleLi, Y., Jia, D., Li, W., & Zhang, K. (2018). Model of T-Type Fracture in Coal Fracturing and Analysis of Influence Factors of Fracture Morphology. Energies, 11(5), 1196. https://doi.org/10.3390/en11051196