Automatic Identification of Fractures Using a Density-Based Clustering Algorithm with Time-Spatial Constraints

Abstract

:1. Introduction

2. Theory

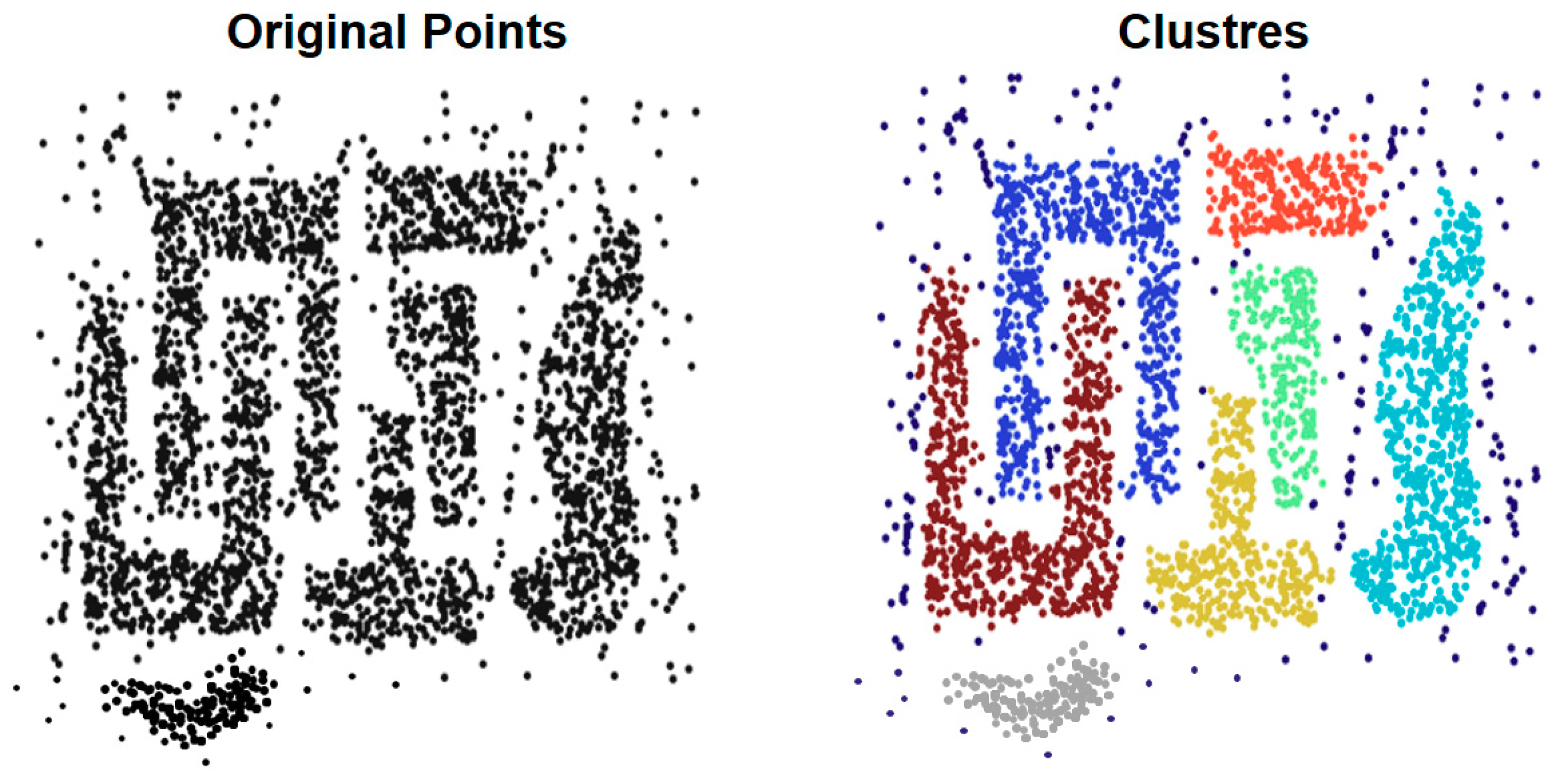

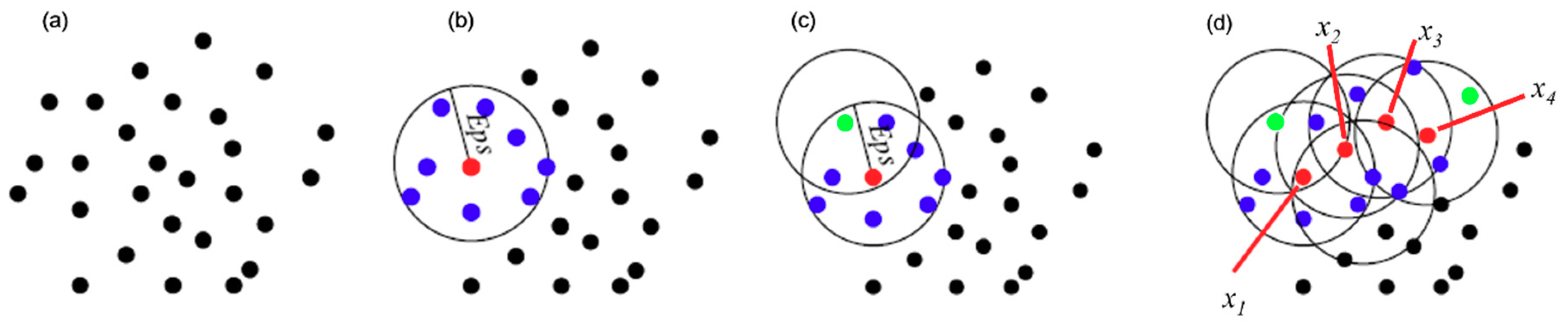

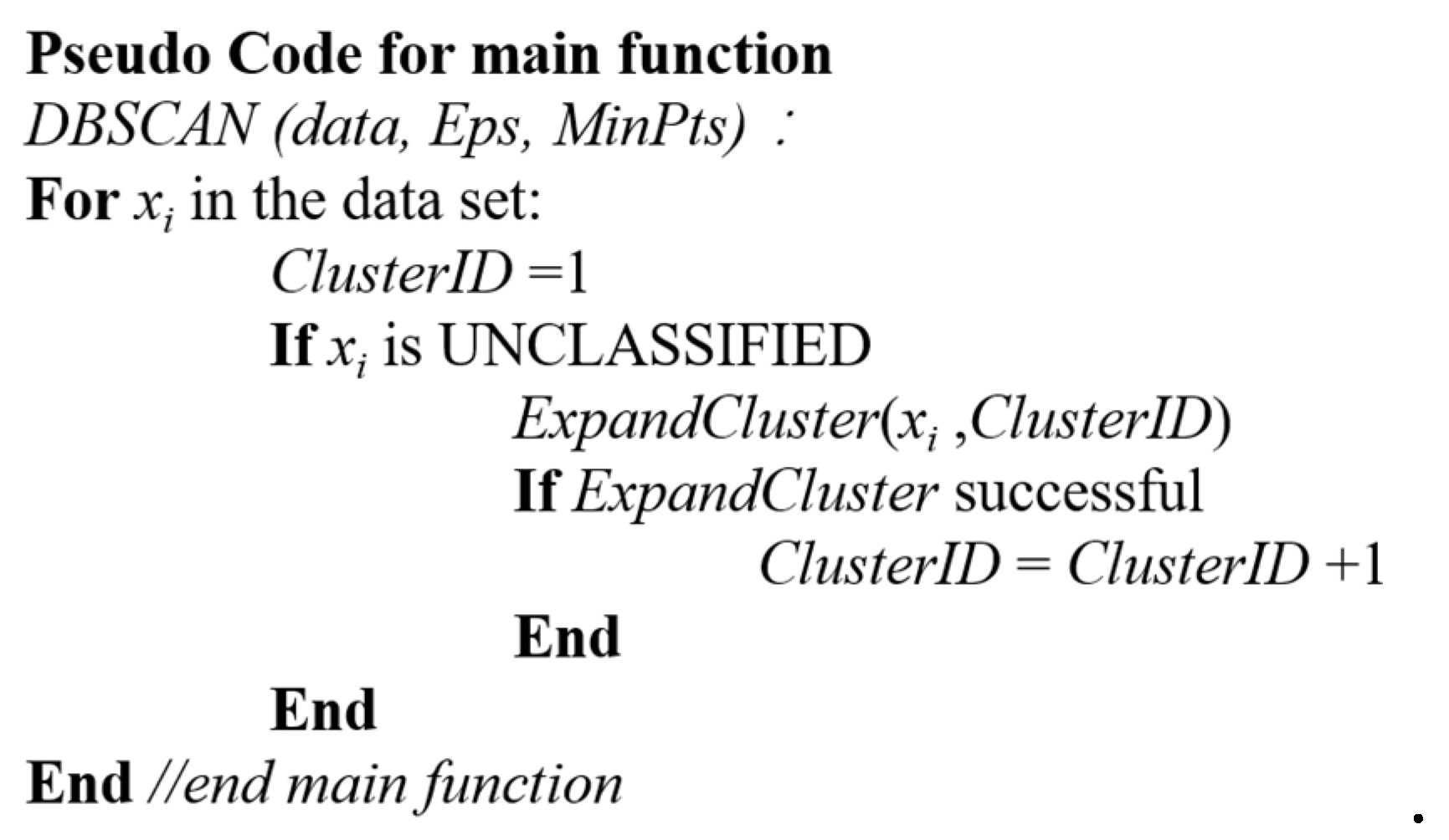

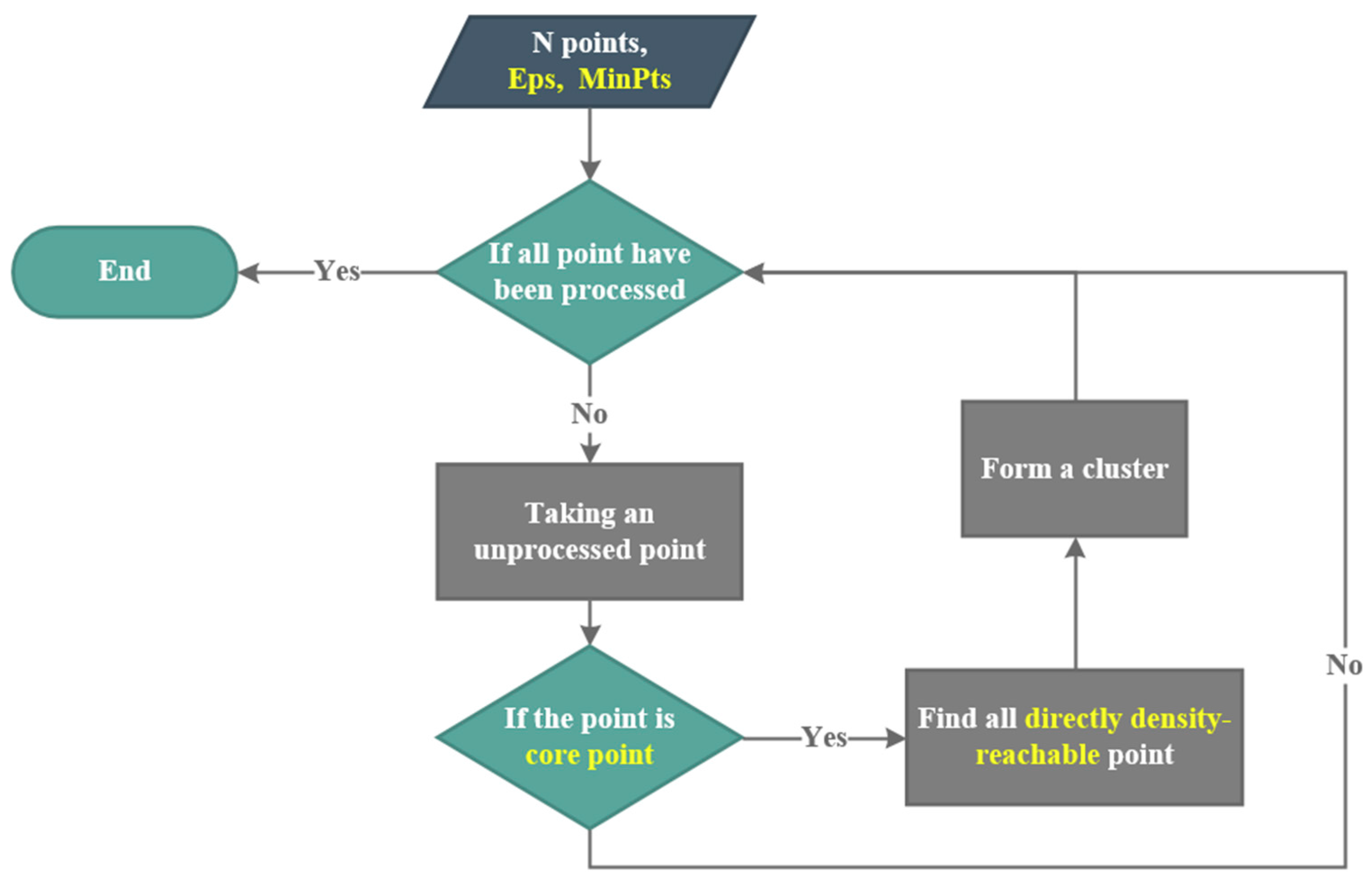

2.1. Density-Based Clustering Algorithm with Spatial Constraints: DBSCAN

- Inputting the data set and choosing an arbitrary data point x. Checking the Eps neighborhood of the data point x.

- If the point x is the core object and has not been divided by a certain class, then finding all density-reachable object from data point x. Finally, we can get a neighborhood include point x.

- If the point x is not the core object, then taking the point as the noise.

- Turn to the first step, repeating the algorithm until all the point in the data set has been handled.

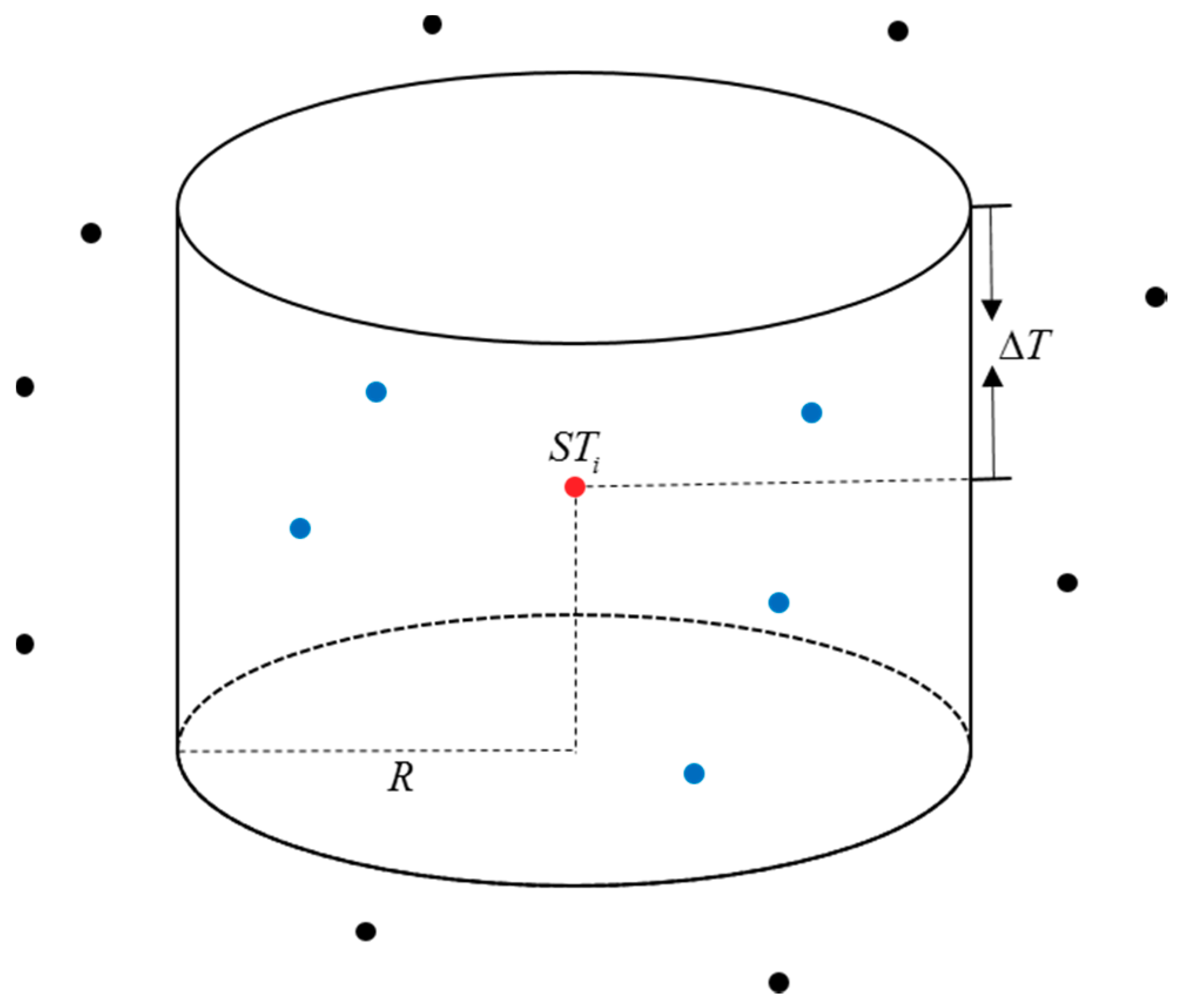

2.2. Density-Based 4D Clustering Algorithm: ST-DBSCAN

2.3. Automatic Fracture Plane Identification Implementation

- (1)

- Obtain high signal-to-noise ratio seismic data

- (2)

- Obtain high precision micro earthquake location results

- (3)

- Obtain the classification results using the clustering analysis algorithm we have proposed.

- (4)

- Use the least squares fitting method to obtain an accurate single fracture plane.

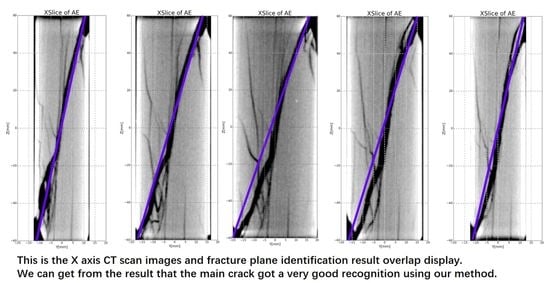

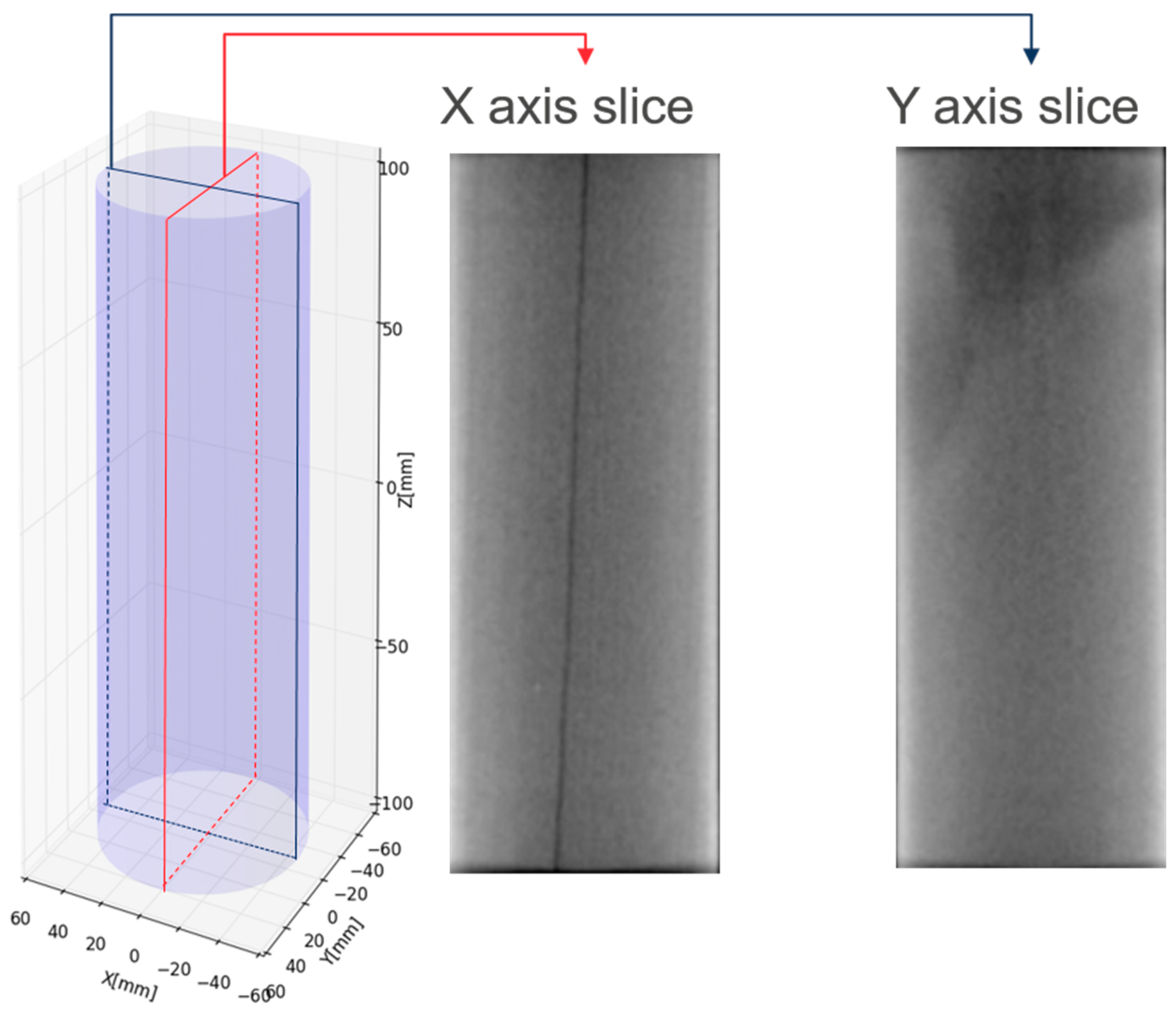

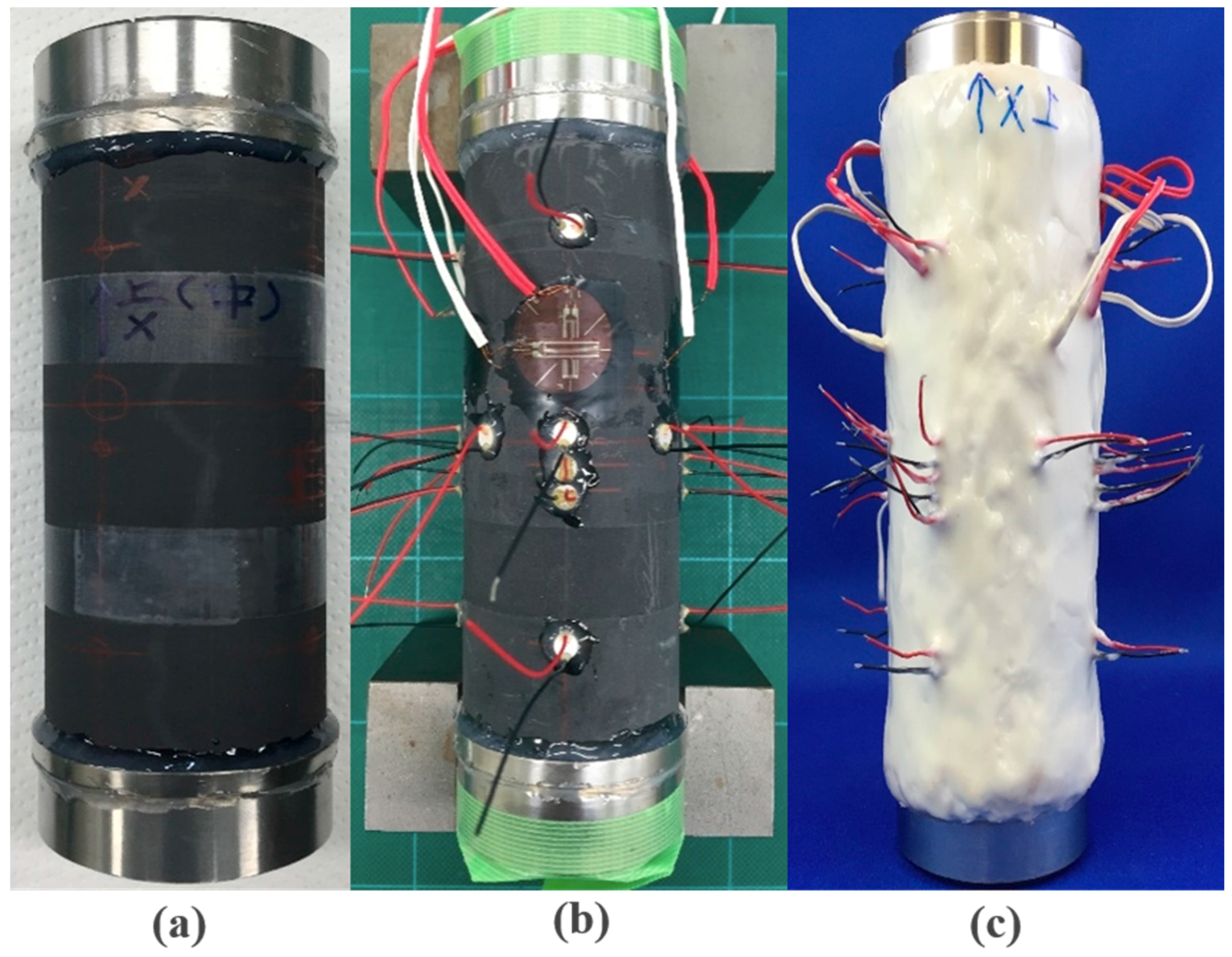

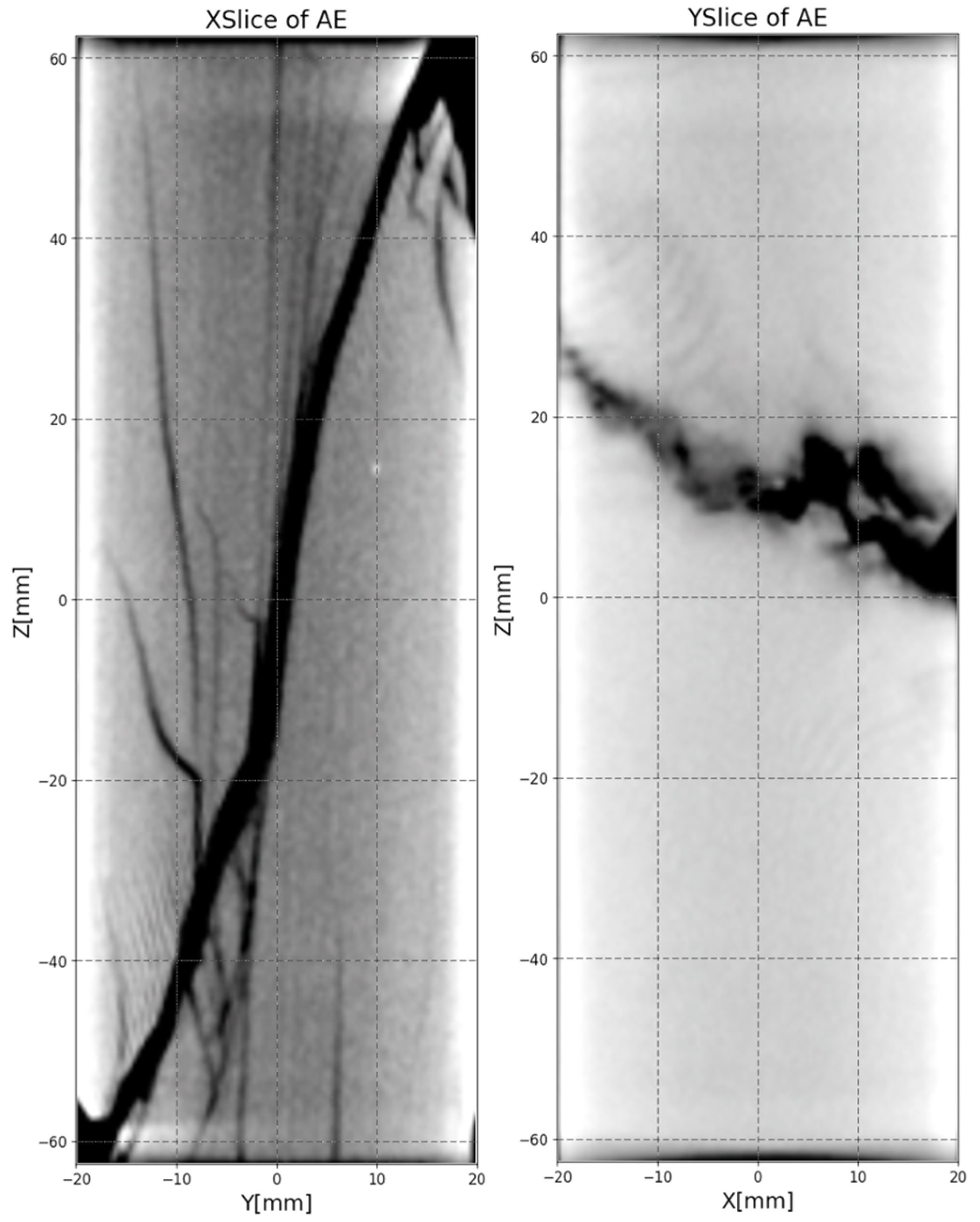

3. Acoustic Emission Verified Experiment

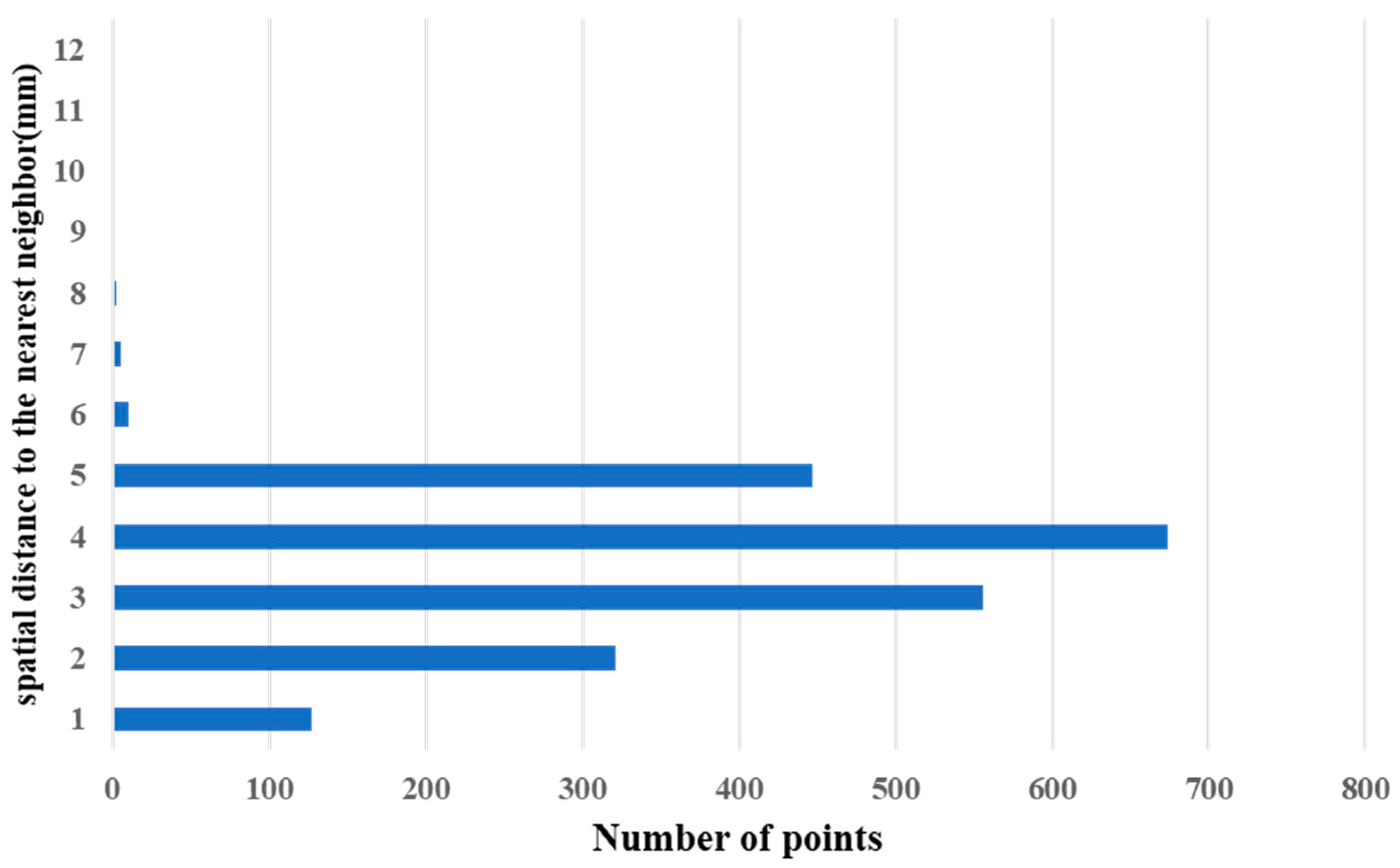

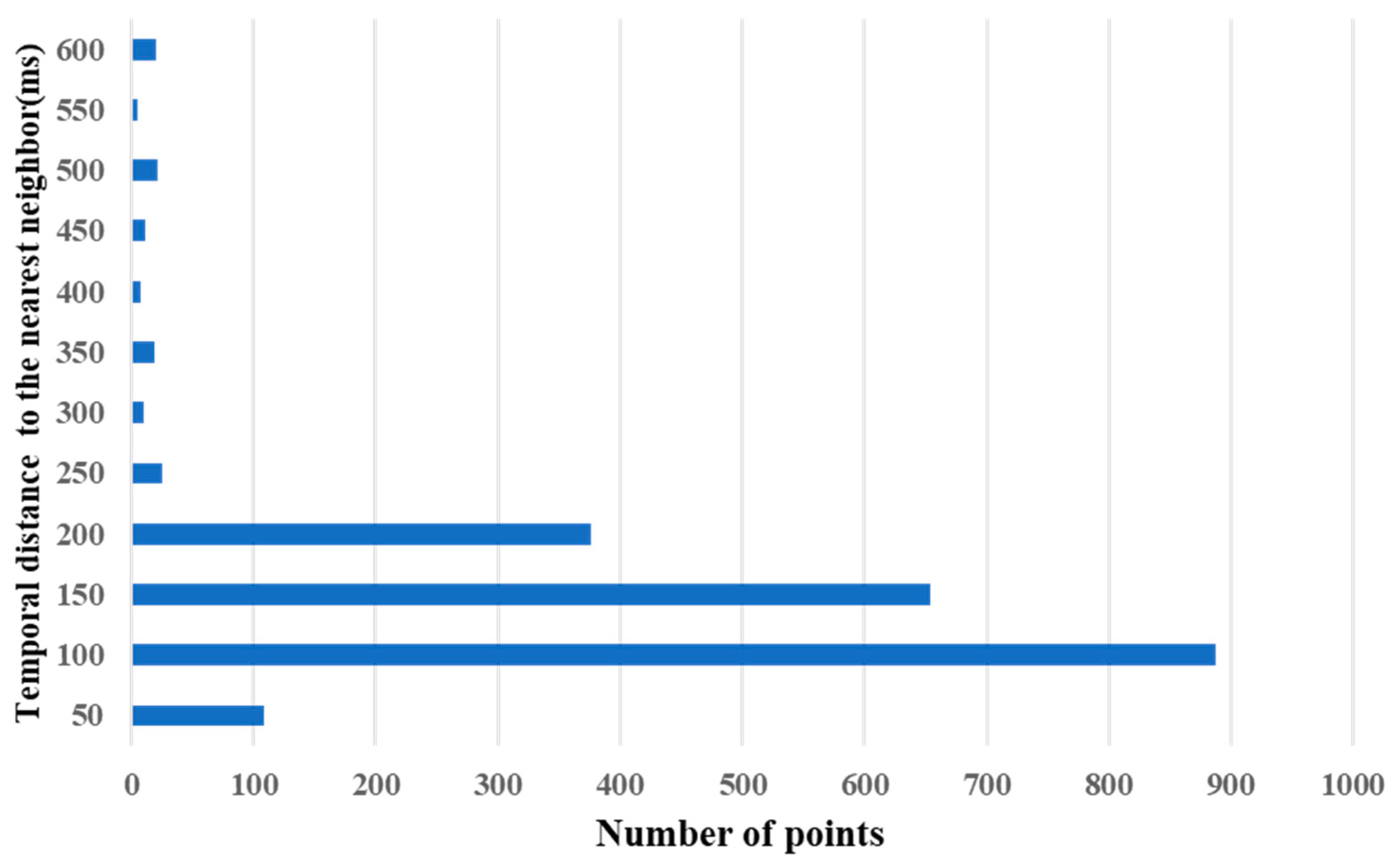

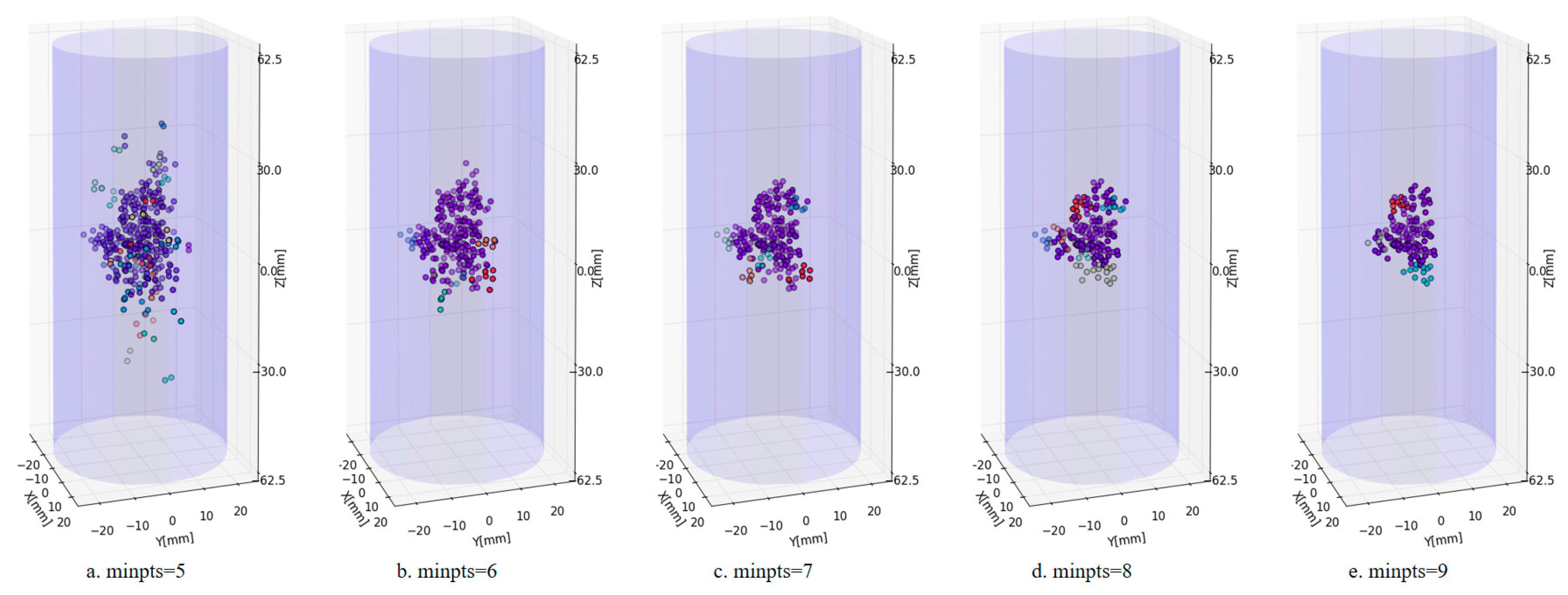

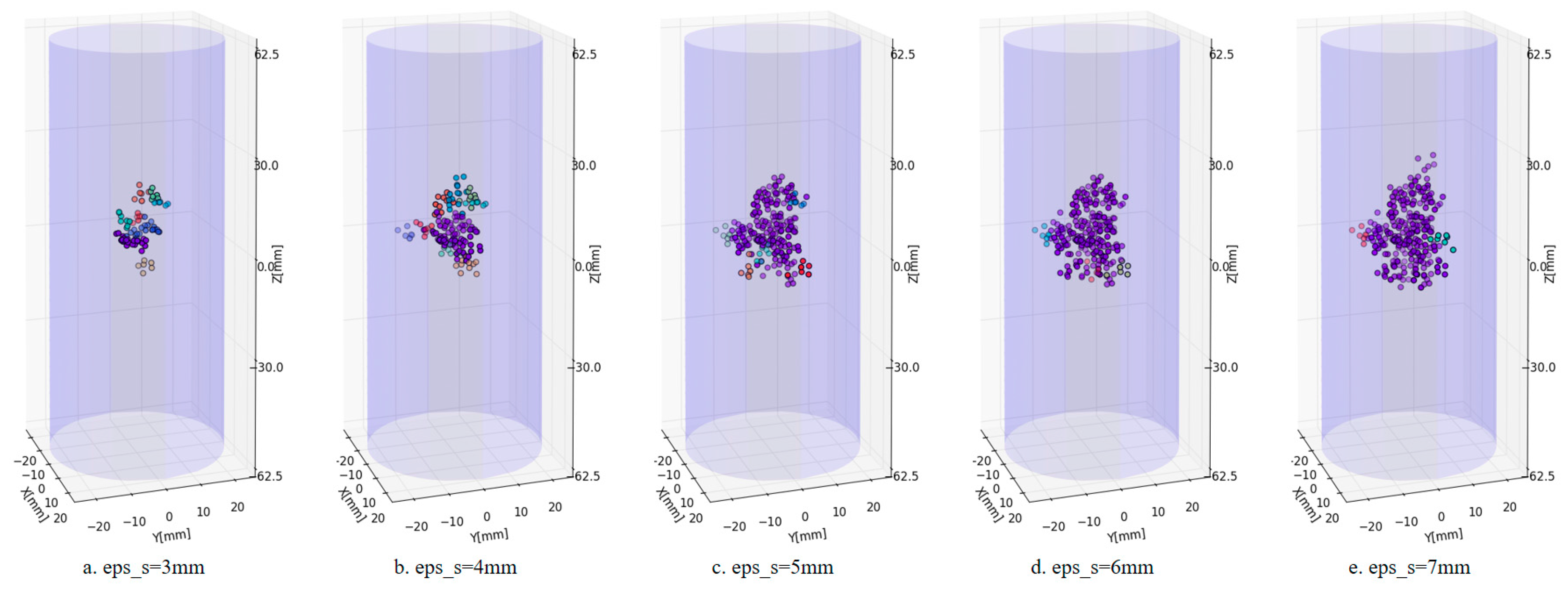

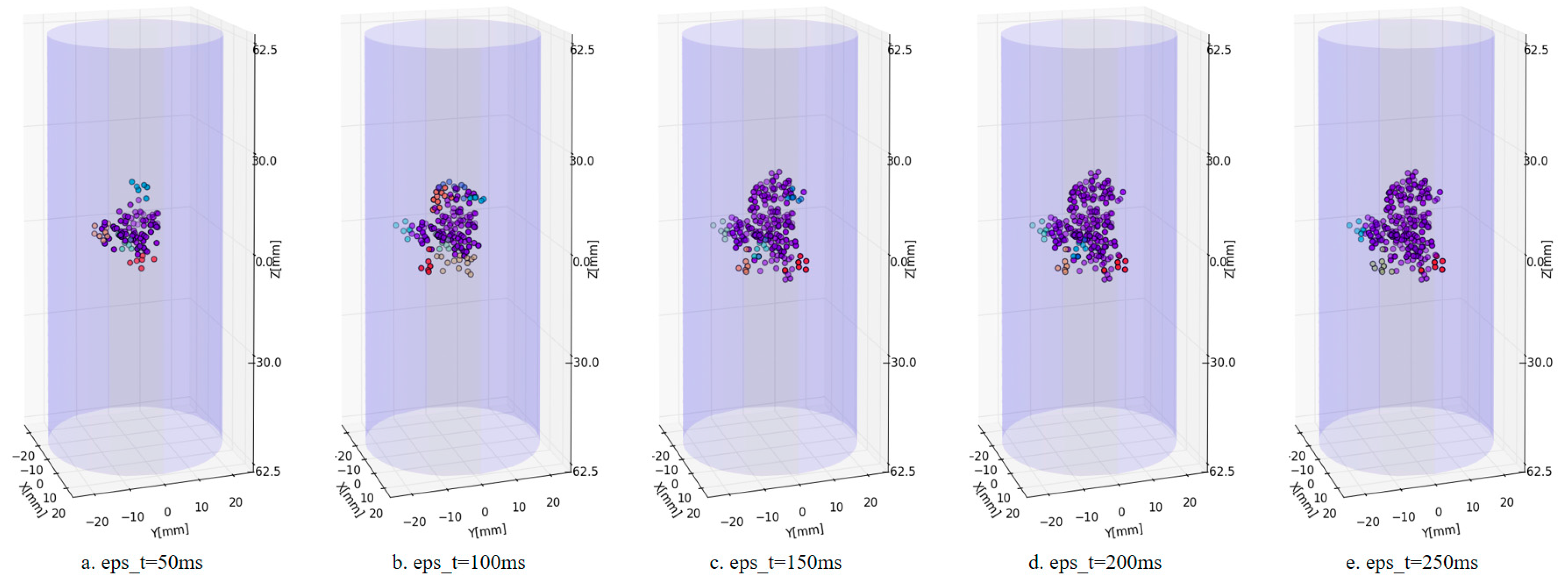

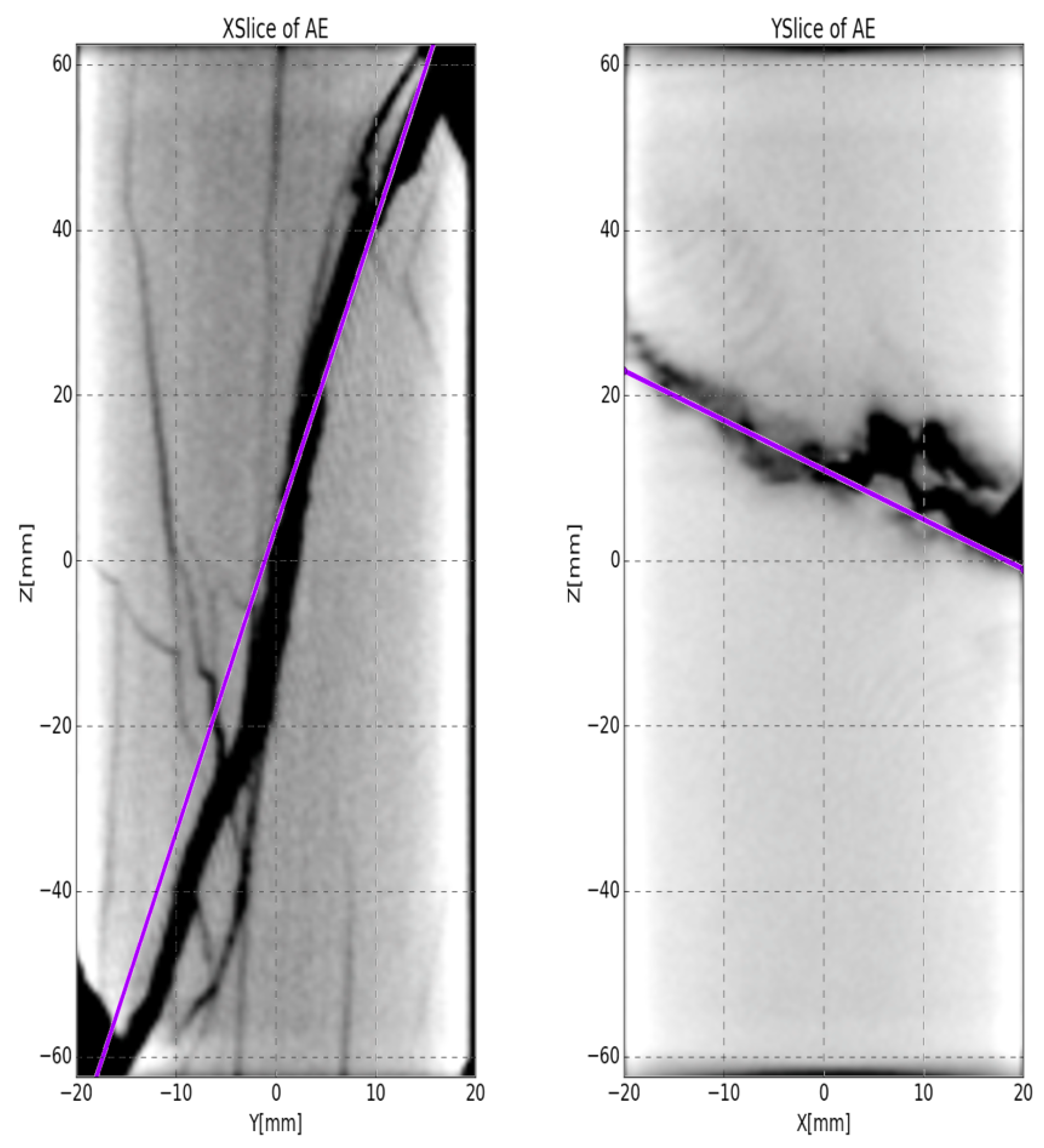

4. Parameter Detection and Sensitivity Analysis

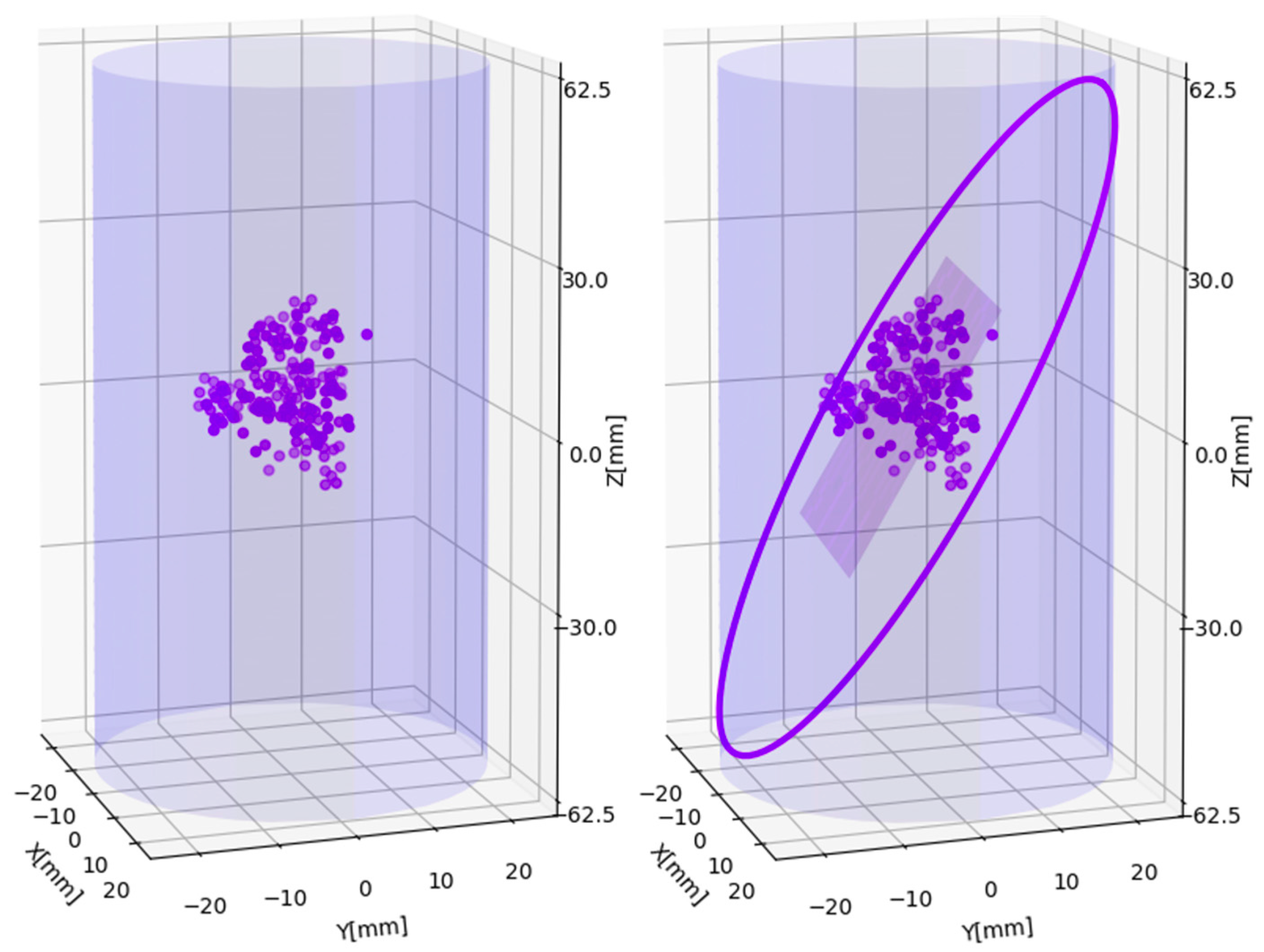

5. Results

6. Discussion and Conclusions

Acknowledgments

Author Contributions

References

- Thornton, M.; Eisner, L. Uncertainty in Surface Microseismic Monitoring. In Proceedings of the SEG San Antonio 2011 Annual Meeting, San Antonio, TX, USA, 18–23 September 2011; pp. 1524–1528. [Google Scholar]

- Busetti, S.; Jiao, W.; Reches, Z. Geomechanics of hydrolic fracturing microseismicity: Part 1. Shear, hybrid, and tensile events. Am. Assoc. Pet. Geol. Bull. 2014, 98, 2439–2457. [Google Scholar] [CrossRef]

- Wenlong, D.; Changchun, X.; Kai, J.; Chao, L.; Weite, Z.; Liming, W. The research progress of shale fractures. Adv. Earth Sci. 2011, 2, 3. [Google Scholar]

- Yu, Z.; Lai, F.; Xu, L.; Liu, L.; Yu, T.; Chen, J.; Zhu, Y. Study on fracture identification of shale reservoir based on electrical imaging logging. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 64, p. 12041. [Google Scholar]

- King, G.E. Thirty years of gas shale fracturing: What have we learned? In SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Eshiet, K.I.; Sheng, Y.; Ye, J. Microscopic modelling of the hydraulic fracturing process. Environ. Earth Sci. 2013, 68, 1169–1186. [Google Scholar] [CrossRef]

- Fayyad, U.; Piatetsky-Shapiro, G.; Smyth, P. From data mining to knowledge discovery in databases. AI Mag. 1996, 17, 37. [Google Scholar] [CrossRef]

- Alhanjouri, M.A.; Ahmed, R.D. New density-based clustering technique: GMDBSCAN-UR. Int. J. Adv. Res. Comput. Sci. 2012, 3, 1–9. [Google Scholar]

- Wang, M.; Wang, A.; Li, A. Mining spatial-temporal clusters from geo-databases. In Advanced Data Mining and Applications; Springer: New York, NY, USA, 2006; pp. 263–270. [Google Scholar]

- Ester, M.; Kriegel, H.-P.; Sander, J.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the Second International Conference on Knowledge Discovery and Data Mining, Portland, OR, USA, 2–4 August, 1996. [Google Scholar]

- Birant, D.; Kut, A. ST-DBSCAN: An algorithm for clustering spatial–temporal data. Data Knowl. Eng. 2007, 60, 208–221. [Google Scholar] [CrossRef]

- Tango, T. Space-Time Scan Statistics. In Statistical Methods for Disease Clustering; Springer: New York, NY, USA, 2010; pp. 211–233. [Google Scholar]

- Li, X.Y.; Lei, X.L.; Li, Q.; Cui, Y.X. Characteristics of acoustic emission during deformation and failure of typical reservoir rocks under triaxial compression: An example of Sinian dolomite and shale in the Sichuan Basin. Chin. J. Geophys. Chin. Ed. 2015, 58, 982–992. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, Q.; Wang, Y.; Zhai, H.; Chang, X. Automatic Identification of Fractures Using a Density-Based Clustering Algorithm with Time-Spatial Constraints. Energies 2018, 11, 563. https://doi.org/10.3390/en11030563

Xue Q, Wang Y, Zhai H, Chang X. Automatic Identification of Fractures Using a Density-Based Clustering Algorithm with Time-Spatial Constraints. Energies. 2018; 11(3):563. https://doi.org/10.3390/en11030563

Chicago/Turabian StyleXue, Qingfeng, Yibo Wang, Hongyu Zhai, and Xu Chang. 2018. "Automatic Identification of Fractures Using a Density-Based Clustering Algorithm with Time-Spatial Constraints" Energies 11, no. 3: 563. https://doi.org/10.3390/en11030563